#PIR panels

Explore tagged Tumblr posts

Text

Understanding PIR Panels | For Your Home

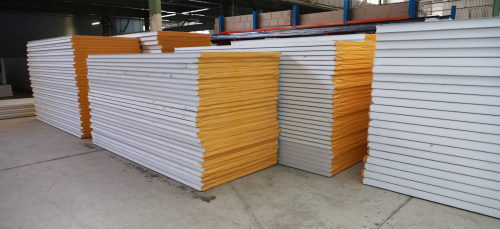

Sandwich panels are unique thermal components that are primarily used for walls and roofs; these are made of two thin metal sheets and one thick core material. These core materials play an important role in the properties of the panels; types include PIR/PUR, EPS, Rockwool, Glass, Wool, Hollow glass magnesium, among others. Let us try and decode the ones that are most commonly known and used, i.e. PIR panels, EPS wall panels, rock wool and glass wool.

PIR Panels

PIR sandwich panels are regarded to be the best when it comes to insulation material and can be used under varied joint applications depending on how or where you want to use them. Their general characteristics include optimal fire resistance, insulation, extensive strength, waterproofing propensity, and easy installation features.

EPS Wall Panels

EPS sandwich panels are well known for their lightweight design, easy installation, and especially for their competitive pricing range. These can be found in concealed and overlap joint ways depending on whether or not you want the screws to be visible upon installation or not.

Others:

Rockwool panels:

These panels are known for their optimal fireproof material, along with the propensity of exhibiting soundproof performance. They also display immense strength, insulation, waterproofing and are made out of pure material.

Glass Wool panels:

Panels with this core material are lightweight, fire-resistant and soundproof as well. However, this is not the ideal option for those with regard to the environment since they are not made of eco-friendly materials.

Which Is The Right Fit For You?

In order to decide which of the panels are the right choice for your insulation requirements, based on their core materials, let us understand key features and the application of each of these. This will help make decision making easier.

EPS wall panels are lightweight budget solutions and are ideally used to make temporary buildings, steel sheds, container houses, mobile homes, or partition walls.

PIR panels are the ideal thermal material partnered with high tensile strength; these are most frequently used in the curation of cold areas, cold storage projects, and buildings that require increased insulation propensity. Food preserve areas, meat storage units, and other refrigeration projects fall under the purview of these panels.

When it comes to rock wool and glass wool, these are most commonly optimised at commercial or civil structures that require high fire resistance and noise proofing features.

Reasons To Use Sandwich Panels:

uction process also doesn't demand any wet processes or fixed and controlled approximate humidity levels.

If one were to compare these to single skin panels or traditional walls or roofs, the time of construction optimised by these panels is negligible. Further, there is no waiting time between construction for the structure shell to lose any excess moisture.

The pointers, as mentioned above, throw light on the various types of insulated sandwich panels along with their respective characteristics and features; consider these and make the optimal choice to meet your construction requirements suitably.

0 notes

Text

The Best PIR Sandwich Panel Supplier UAE by APT Metal

The best leading of premium-quality PIR Sandwich Panel supplier UAE, known as APT Metal for delivering superior insulation and structural solutions to a wide range of industries. Whether you’re building cold storage units, warehouses, or industrial facilities, our PIR sandwich panels are engineered to meet your unique needs. Here’s why APT Metal is the go-to choice for PIR panels:

1. Exceptional Thermal Efficiency

Our PIR sandwich panels are designed to provide top-tier thermal insulation, ensuring energy efficiency and reduced operational costs. These panels are ideal for maintaining controlled environments such as cold rooms, food storage facilities, and clean rooms.

2. Advanced Fire Resistance

Safety is a priority at APT Metal. Our PIR panels are crafted with superior fire-resistant properties, minimizing fire hazards and providing reliable protection for your buildings and equipment.

3. Lightweight Yet Durable

Their PIR sandwich panels strike the perfect balance between weight and strength. Their lightweight nature simplifies transportation and installation, while their robust construction ensures durability and longevity.

4. Customizable for Your Needs

Every project is unique, and so are our solutions. We offer PIR sandwich panels in various thicknesses, lengths, and finishes, tailoring them to meet the exact specifications of your construction requirements.

5. Wide Range of Applications

APT Metal’s PIR sandwich panels are versatile and suitable for:

Roof and wall systems

Industrial and commercial buildings

Cold storage and refrigeration units

Modular clean rooms and laboratories

6. Resilience Against Harsh Conditions

Engineered to withstand the challenging UAE climate, our panels are highly resistant to heat, humidity, and corrosion, ensuring long-lasting performance in extreme environments.

7. Sustainable Construction Solutions

APT Metal is committed to environmentally responsible practices. Our PIR panels are energy-efficient and eco-friendly, supporting sustainable construction initiatives and reducing carbon footprints.

8. Competitive Pricing Without Compromise

We offer high-quality PIR sandwich panels at competitive prices, ensuring cost-effective solutions for projects of any scale without sacrificing performance or durability.

9. Reliable and On-Time Delivery

With a well-organized supply chain and logistics system, they ensure that your orders are delivered promptly, keeping your project timelines intact.

10. Dedicated Customer Support

Our experienced team is here to assist you at every stage, from consultation and product selection to installation guidance, ensuring a seamless experience.

Trust APT Metal as your reliable partner for PIR Sandwich Panel supplier UAE. Contact us today to learn more about our durable and efficient solutions, and let us help bring your project to life with unmatched quality and expertise.

For more information

Visit us : https://aptmetals.com/

Mail us : [email protected]

Contact us : 00971-50-9884721

0 notes

Text

#PUF Panels#Polyurethane Foam Panels#PUF Sandwich Panels#Thermal Insulation#Fire Retardant PUF Panels#Durable PUF Panels#PUR/PIR Panels#Cold Storage Solutions#Modern Building Materials

1 note

·

View note

Text

PBPL is a leading PIR PUF Panel Manufacturer in Greater Noida, providing high-quality and durable PUF Panels for various applications at affordable prices. PBPL is renowned for its cutting-edge technology, high-quality products, and unparalleled customer service.

0 notes

Text

Fire Resistant PIR Insulation in UAE: Protecting Your Property

Fire Resistant PIR Insulation in UAE offers a reliable and effective solution to safeguard your property with utmost confidence. Designed to withstand high temperatures and prevent the spread of fire, this advanced insulation material provides an added layer of protection. Visit us now.

#pir insulation uae#polyisocyanurate insulation#fire resistant pir insulation#pir insulation panels#pir roof insulation

0 notes

Link

0 notes

Text

High-Quality Rockwool Panels for Superior Insulation

Lucky Deep offers premium rockwool panels manufacturers in India, designed to provide excellent insulation and structural support. These panels are crafted with a combination of materials like PCGI, PPGI, SS, and GI for optimal performance. The thickness ranges from 35 mm to 100 mm, with insulation options including PUF, PIR, and Rockwool with densities of 40±2 kg/m³, 48±2 kg/m³, and 96-144 kg/m³ respectively. The panels are coated with powder and pre-coating to ensure durability, with a sealant of food-grade silicon to prevent gaps larger than 4 mm. Available in custom dimensions and colors, these panels meet the highest quality standards for insulation and structural applications.

0 notes

Text

0 notes

Text

0 notes

Text

Công ty TNHH Cách Nhiệt Hòa Phú chuyên cung cấp các sản phẩm cách âm, cách nhiệt và chống cháy, bao gồm các dòng sản phẩm như: Mút cách nhiệt, Panel Rockwool, Panel EPS, Panel PIR, Panel PU, Tôn PU, Panel vân gỗ, Bông khoáng Rockwool, Xốp XPS, Gạch mát, Panel Inox, Trần tôn xốp, Túi khí cách nhiệt, Phụ kiện nhôm và nhiều sản phẩm khác.

Với phương châm mang đến cho khách hàng các giải pháp tối ưu về cách âm, cách nhiệt và chống cháy, công ty Hòa Phú tự hào là nhà cung cấp uy tín trong và ngoài nư���c. Sản phẩm của chúng tôi không chỉ đảm bảo chất lượng cao mà còn giúp tiết kiệm chi phí và mang lại tính thẩm mỹ vượt trội. Các sản phẩm của Hòa Phú có những đặc tính ưu việt như: khả năng cách âm, cách nhiệt và chống nóng tốt, cùng mức giá hợp lý.

Giới thiệu về Mút cách nhiệt PE-OPP

Mút cách nhiệt PE-OPP là một vật liệu hiệu quả trong việc cách âm và cách nhiệt, được chế tạo từ một hoặc nhiều lớp mút xốp PE Foam, kết hợp với lớp màng OPP đã qua xử lý chống oxy hóa.

Cấu trúc này mang lại nhiều lợi ích khi sử dụng trong công trình, nổi bật là khả năng cách nhiệt vượt trội và khả năng chống cháy lan hiệu quả. Bên cạnh đó, sản phẩm cũng có khả năng chống thấm và chống dột rất tốt.

Mút cách nhiệt PE-OPP được sản xuất từ polyolefin, với cấu trúc ô kín rất nhỏ, giúp mang lại hiệu quả cách âm cực kỳ tốt nhờ các liên kết vật lý ngang. Thêm vào đó, lớp xi mạ nhôm nguyên chất giúp tăng cường tính năng của sản phẩm.

Đặc biệt, sản phẩm có tỷ trọng nhẹ, không gây tải trọng lớn lên tường, trần hay sàn nhà. Điều này giúp việc thi công trở nên nhanh chóng và tiết kiệm chi phí, đồng thời giúp đẩy nhanh tiến độ thi công cho công trình.

Lợi ích của Mút Cách Nhiệt PE-OPP

Giảm từ 60% đến 80% sự chênh lệch nhiệt độ giữa môi trường bên ngoài và mái tole.

Giúp tiết kiệm chi phí điện năng cho các thiết bị chiếu sáng và hệ thống điều hòa.

An toàn, không gây độc hại và không bị ảnh hưởng bởi hóa chất hay độ ẩm.

Dễ dàng thi công và lắp đặt, với độ bền lâu dài.

Ứng Dụng Của Mút Cách Nhiệt PE-OPP Mút cách nhiệt PE-OPP là giải pháp hiệu quả để chống ồn và cách nhiệt cho nhiều công trình công cộng và công nghiệp.

Dùng để dán lên tôn, giúp giảm nhiệt và cách âm cho mái nhà, văn phòng, nhà xưởng, kho bãi trong các khu công nghiệp, chuồng trại chăn nuôi.

Cách âm và cách nhiệt cho hệ thống điều hòa của bệnh viện, siêu thị, trung tâm thương mại.

Chống ẩm cho các công trình có sàn gỗ cao cấp, như khách sạn và các tòa nhà cao tầng.

Cung cấp khả năng chống ẩm cho sàn gỗ trong các khách sạn và nhà ở.

Chống nóng và chống ẩm cho các nhà xưởng, kho bãi, văn phòng trong các khu công nghiệp và khu chế xuất.

Dùng làm bảo ôn và cách nhiệt cho các hệ thống điều hòa không khí và phòng lạnh.

Chống ồn và cách âm cho các hệ trần, vách tại nhà ga, sân bay, trường học, siêu thị, bệnh viện, phòng họp, hội trường, nhà hát, phòng thu âm, sàn nhảy, bar, karaoke.

QUY CÁCH MÚT CÁCH NHIỆT PE-OPP:

THÔNG SỐ KỸ THUẬT MÚT CÁCH NHIỆT PE-OPP:

Lý Do Lựa Chọn Sản Phẩm Từ Hòa Phú

Khi đến với Hòa Phú, quý khách sẽ được trải nghiệm dịch vụ lắp đặt và bảo trì với mức giá hợp lý nhất. Chúng tôi cam kết mang đến cho khách hàng sản phẩm chất lượng cao, với độ bền vượt trội, khả năng chịu nhiệt, nắng, mưa cực tốt.

Trên thị trường hiện nay, có rất nhiều đơn vị cung cấp Mút cách nhiệt PE-OPP, điều này khiến khách hàng khó khăn trong việc tìm kiếm nơi cung cấp sản phẩm uy tín và chất lượng. Tuy nhiên, khi lựa chọn công ty Cách Nhiệt Hòa Phú, bạn có thể hoàn toàn yên tâm vì chúng tôi là đối tác đáng tin cậy.

Với nhiều năm hoạt động trong ngành, Hòa Phú đã xây dựng được uy tín vững chắc trong lòng khách hàng. Chúng tôi luôn đặt sự hài lòng của khách hàng lên hàng đầu và cam kết cung cấp dịch vụ tốt nhất. Chính vì vậy, lượng khách hàng tin tưởng và lựa chọn chúng tôi ngày càng đông. Bạn cũng đã sẵn sàng để trải nghiệm sự chuyên nghiệp trong công việc của chúng tôi chưa?

Công ty Cách Nhiệt Hòa Phú cung cấp đầy đủ các loại Mút cách nhiệt PE-OPP với chất lượng đảm bảo và mức giá cạnh tranh. Chúng tôi sẽ mang đến cho bạn nhiều sự lựa chọn phù hợp cho công trình của mình. Hãy liên hệ với chúng tôi để nhận tư vấn chi tiết và báo giá chính xác về sản phẩm.

MỌI CHI TIẾT XIN LIÊN HỆ:

CÔNG TY TNHH CÁCH NHIỆT HÒA PHÚ

Trụ sở chính: 223/11 Tân Thới Hiệp, Quận 12, Tp. Hồ Chí Minh

VP GD: 109B XTT01 – Ấp 5, Xuân Thới Thượng, Hóc Môn, Tp. Hồ Chí Minh

Mã số thuế: 0317209829 – Ngày thành lập: 21/03/2022

Email: [email protected] – Website: cachnhiethoaphu.com

Fanpage: https://www.facebook.com/cachnhiet

Youtube: https://www.youtube.com/@cachnhiethoaphu743

HOTLINE: 0978.671.331 (Mr. Yên) – 0973.877.090 – 0858.94.55.99 (Mr. Thi) – 0971.77.44.51 (Mr. Sỹ)

1 note

·

View note

Text

0 notes

Text

What Are The Lucrative Leverages Of Employing Pir And Eps Insulated Wall Sandwich Panels?

Commercial applications often employ Pir panels and Eps wall panels as a form of insulated wall sandwich panels to eliminate the ultimate energy consumption. Most individuals prefer this kind of insulated wall sandwich panel not just merely for its energy efficiency but owing to its aesthetic appeal and shimmer as well.

Insulated wall sandwich panels are not restricted and constrained to commercial applications. Homeowners can enjoy the advantages of this energy-efficient customised solution too. Employing insulated wall sandwich panels can very well lower your utility bills. Still, at the same time, they also possess something more to offer and deliver:

This blog post specifies the topmost five lucrative and enticing leverages of insulated wall sandwich panels:

Design Flexibility:

Pir panels and Eps wall panels are exceptionally lauded for the design flexibility that they deliver to the end-users. These wall sandwich panels are available in varied colours and finishes embedded with custom modular widths. With the assistance of such an extensive spectrum of designs, you would identify one that suits and complements the theme or style of your home.

Higher Return value:

Among the advantages and benefits of these Pir panels and Eps wall panels is that they deliver better and improvised insulation than allied insulation solutions. These panels deliver a higher return value even in thinner assemblies. Other allied insulation materials, such as fibreglass, need twice as much thickness to accomplish insulation of insulated wall sandwich panels.

Easy and effortless installation:

Pir panels and Eps wall panels are easy and simpler to install than other insulation methods and mechanisms. The dimensions of the panels can be customised as per your needs and requirements, delivering alternatives for vertical or horizontal installation.

Longevity:

The manufactured Pir panels and Eps wall panels are rigid but at the same time robust and durable. These insulated wall sandwich panels are resistant to weather as well as abuse, so they can last for years and decades without requiring a replacement or a substitute. Insulated wall sandwich panels are the ultimate idealistic choice and preferred alternative for homes situated in areas that experience and witness severe weather conditions such as storms, hail and heavy winds. Moreover, Pir panels and Eps wall panels deliver superior fire resistance. These panels are composed of non-combustible steel, preventing the spread of fire to your house. Fire-resistant insulated wall sandwich panels are a mandatory requirement if you are situated in an area that becomes prone and vulnerable to wildfires.

Cost-Efficiency:

Finally, insulated wall sandwich panels are more cost-effective than other insulation alternatives and avenues. The longevity and energy efficiency delivered by insulated wall sandwich panels eliminates your maintenance expenditure as well as utility bills. Ultimately, this insulated wall panel solution delivers you significant cost savings in a longer time frame, maximising your Return on Investment. You must invest only in high-end premium quality insulated material wall sandwich panels to assure and guarantee the performance of your structural premises. You are required to execute with a prestigious insulated wall sandwich panels contractor to ensure that you are procuring your money's worth.

Conclusion:

The team of professional builders deliver high-end premium quality performing insulated wall sandwich panels in Pir Panels and Eps wall panels. These equipped systems enable your outdoor living area to be more comfortable. This professional manifestation specialises in room enclosures consisting of patios, glass rooms, and carports, allowing you to achieve and accomplish the indoor-outdoor lifestyle you wish for in the ultimate quest of home décor lifestyle.

0 notes

Text

PIR Sandwich Panel Supplier UAE – APT Metal

APT Metal is a trusted name in the UAE for providing high-quality PIR sandwich panels, catering to the needs of various industries, including construction, cold storage, and warehouses. Our panels are designed to deliver superior insulation, structural strength, and cost-effectiveness. Here’s why APT Metal is the ideal choice for PIR Sandwich Panel supplier UAE:

1. Superior Thermal Insulation

PIR sandwich panels from APT Metal offer excellent thermal insulation, making them ideal for temperature-sensitive applications such as cold storage facilities and food processing units. Their advanced insulation properties help maintain consistent indoor temperatures, reducing energy costs significantly.

2. Fire-Resistant Material

One of the standout features of PIR panels is their fire-resistant properties. APT Metal’s PIR sandwich panels are designed to withstand high temperatures, minimizing fire risks and ensuring safety for your buildings and occupants.

3. Lightweight and High Strength

Our PIR sandwich panels are lightweight yet incredibly strong, making them easy to transport and install. Despite their low weight, they provide exceptional structural integrity, ensuring long-lasting performance.

4. Customizable Sizes and Designs

They offers a range of customizable options for PIR sandwich panels. Whether you need specific lengths, thicknesses, or surface finishes, we tailor our panels to meet the unique requirements of your project.

5. Versatile Applications

Our PIR sandwich panels are suitable for a wide range of applications, including:

Roof and wall cladding

Cold storage construction

Clean rooms and laboratories

Warehouses and industrial facilities

6. Weather and Corrosion Resistance

Designed to withstand the UAE’s extreme weather conditions, APT Metal’s PIR sandwich panels are resistant to humidity, UV radiation, and corrosion, ensuring durability and long-term performance.

7. Eco-Friendly Solutions

APT Metal prioritizes sustainability. Our PIR sandwich panels are energy-efficient and environmentally friendly, contributing to greener construction practices and lower carbon footprints.

8. Competitive Pricing and Timely Delivery

We offer cost-effective solutions without compromising on quality. Additionally, our streamlined supply chain ensures that your panels are delivered on time, keeping your projects on schedule.

9. Expert Support and Consultation

Our team of experienced professionals is dedicated to providing exceptional customer service. From initial consultation to installation guidance, they supports you every step of the way.

10. Trusted Quality and Performance

APT Metal’s PIR sandwich panels are manufactured to meet international standards, ensuring unmatched quality and reliability.

Choose APT Metal as your trusted PIR sandwich panel supplier UAE for innovative, durable, and cost-effective solutions. Contact us today to discuss your project requirements and discover how our products can enhance your construction endeavors.

For more information

Visit us : https://aptmetals.com/

Mail us : [email protected]

Contact us : 00971-50-9884721

0 notes

Text

Advanced Cleanroom Panels for Critical Applications

Kingspan Jindal Pvt. Ltd. offers modular panel clean room systems tailored to your unique needs. Our panels, available in PUR, PIR, and Honeycomb cores, provide exceptional cleanliness, easy installation, and long-lasting durability. Perfect for pharmaceutical and semiconductor industries.

0 notes

Text

0 notes

Text

Flat Sandwich Panels

Find high-quality Flat Sandwich Panels at SAAS METAL. Ideal for construction and insulation, our panels are designed for durability and energy efficiency, providing superior thermal insulation and structural integrity. Visit: https://saasmetal.com/pir-flat-roof-wall-sandwich-panels/

0 notes