#Silicone Elastomers Market Research

Explore tagged Tumblr posts

Text

#Silicone Elastomers Market#Silicone Elastomers Market Trends#Silicone Elastomers Market Growth#Silicone Elastomers Market Industry#Silicone Elastomers Market Research#Silicone Elastomers Market Report

0 notes

Text

Silicone Elastomers Market Innovations in High-Temperature and Flexible Materials

Silicone Elastomers Market Growth Strategic Market Overview and Growth Projections

The global silicone elastomers market size was valued at USD 9.1 billion in 2022 and is projected to reach USD 17.3 billion by 2031, registering a CAGR of 7.4% during the forecast period (2023-2031)

The latest Global Silicone Elastomers Market by straits research provides an in-depth analysis of the Silicone Elastomers Market, including its future growth potential and key factors influencing its trajectory. This comprehensive report explores crucial elements driving market expansion, current challenges, competitive landscapes, and emerging opportunities. It delves into significant trends, competitive strategies, and the role of key industry players shaping the global Silicone Elastomers Market. Additionally, it provides insight into the regulatory environment, market dynamics, and regional performance, offering a holistic view of the global market’s landscape through 2032.

Competitive Landscape

Some of the prominent key players operating in the Silicone Elastomers Market are

China National BlueStar

Dow Corning

KCC Corporation

Momentive Performance Material Inc.

Mesgo S.P.A

Shin-Etsu Chemical Co. Ltd

Reiss Manufacturing

Wacker Chemie

Zhejiang Xinan Chemical

Stockwell Elastomerics

Specialty Silicone Products

Get Free Request Sample Report @ https://straitsresearch.com/report/silicone-elastomers-market/request-sample

The Silicone Elastomers Market Research report delivers comprehensive annual revenue forecasts alongside detailed analysis of sales growth within the market. These projections, developed by seasoned analysts, are grounded in a deep exploration of the latest industry trends. The forecasts offer valuable insights for investors, highlighting key growth opportunities and industry potential. Additionally, the report provides a concise dashboard overview of leading organizations, showcasing their effective marketing strategies, market share, and the most recent advancements in both historical and current market landscapes.Global Silicone Elastomers Market: Segmentation

The Silicone Elastomers Market segmentation divides the market into multiple sub-segments based on product type, application, and geographical region. This segmentation approach enables more precise regional and country-level forecasts, providing deeper insights into market dynamics and potential growth opportunities within each segment.

By Product

High-temperature Vulcanize (HTV)

Room-temperature Vulcanize (RTV)

Liquid Silicone Rubber (LSR)

By Application

Electrical and Electronics

Automotive and Transportation

Industrial Machinery

Consumer Goods

Construction

Others

Stay ahead of the competition with our in-depth analysis of the market trends!

Buy Now @ https://straitsresearch.com/buy-now/silicone-elastomers-market

Market Highlights:

A company's revenue and the applications market are used by market analysts, data analysts, and others in connected industries to assess product values and regional markets.

But not limited to: reports from corporations, international Organization, and governments; market surveys; relevant industry news.

Examining historical market patterns, making predictions for the year 2022, as well as looking forward to 2032, using CAGRs (compound annual growth rates)

Historical and anticipated data on demand, application, pricing, and market share by country are all included in the study, which focuses on major markets such the United States, Europe, and China.

Apart from that, it sheds light on the primary market forces at work as well as the obstacles, opportunities, and threats that suppliers face. In addition, the worldwide market's leading players are profiled, together with their respective market shares.

Goals of the Study

What is the overall size and scope of the Silicone Elastomers Market market?

What are the key trends currently influencing the market landscape?

Who are the primary competitors operating within the Silicone Elastomers Market market?

What are the potential growth opportunities for companies in this market?

What are the major challenges or obstacles the market is currently facing?

What demographic segments are primarily targeted in the Silicone Elastomers Market market?

What are the prevailing consumer preferences and behaviors within this market?

What are the key market segments, and how do they contribute to the overall market share?

What are the future growth projections for the Silicone Elastomers Market market over the next several years?

How do regulatory and legal frameworks influence the market?

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Silicone Elastomers Market Market#Silicone Elastomers Market Market Share#Silicone Elastomers Market Market Size#Silicone Elastomers Market Market Research#Silicone Elastomers Market Industry#What is Silicone Elastomers Market?

0 notes

Link

#adroit market research#silicone elastomers market#silicone elastomers 2020#silicone elastomers trends

0 notes

Link

North America is expected to witness the highest growth in the silicone elastomers market during the forecast period...

#adroit market research#silicone elastomers market#silicone elastomers 2020#silicone elastomers trends

0 notes

Photo

How liquid crystal elastomer research is paving the way for new applications and practical devices

A new e-book discusses developments in liquid crystal elastomer (LCE) technology achieved with support from the APRA project. Authored by professor of polymer physics Eugene M. Terentjev of APRA project host University of Cambridge, the e-book sheds light on these smart plastics and specifically on how LCEs bring automation into materials.

What exactly are LCEs?

LCEs are a rubbery network of polymers that exhibit a reversible shape change under various stimuli. The e-book describes them as "a new class of materials with physical intelligence." It goes on to say, "These are plastics that feel and respond to their environment, making decisions, analyzing and diagnosing problems without human intervention. Liquid crystalline elastomers are truly the material of the future."

The multifunctional polymer materials developed under the APRA project are recyclable and re-processable. One unique LCE property described in the e-book is soft elasticity, "which combines the dissipation properties of a liquid with the mechanical strength of a thermoset to produce levels of vibration damping far above market-leading technologies based on polyurethane or silicone."

Read more.

15 notes

·

View notes

Text

Self-fusing Silicone Tape Market Research Report 2025 | Size, Share, Trends, Growth and Forecast including Opportunities and Challenges

The Latest Trending Self-fusing Silicone Tape Market sector is on the brink of remarkable evolution, with projections indicating robust growth and groundbreaking technological advancements by 2032. A recent comprehensive market research report highlights the sector's promising trajectory, fueled by key drivers including expanding market size, increasing market share, and the emergence of innovative trends.

This comprehensive report provides key insights into the Self-fusing Silicone Tape market, exploring critical market segmentation and definitions. It highlights the essential components driving growth, offering a clear picture of the industry's trajectory. Utilizing SWOT and PESTEL analyses, the report evaluates the market's strengths, weaknesses, opportunities, and threats, while also considering political, economic, social, technological, environmental, and legal factors that impact the market landscape.

The study offers valuable insights into the competitive landscape, highlighting recent developments and geographical distribution across key regions. Expert competitor analysis provides a detailed understanding of market dynamics, offering strategic guidance for businesses and investors.

With robust analysis and future projections, this report serves as a vital resource for stakeholders looking to capitalize on emerging opportunities and navigate challenges in the Self-fusing Silicone Tape market.

What is the projected market size & growth rate of the Self-fusing Silicone Tape Market?

Market Analysis and Insights :

Global Self-fusing Silicone Tape Market

The self-fusing silicone tape market will register the growth at a rate of 5.12% for the forecast period of 2021 to 2028. The self-fusing silicone tape market report analyses the growth, which is currently being growing due to the rising usage in the automotive industries as battery weather wraps to avert the build-up of corrosion on battery terminals.

Self-fusing silicone tape is a multipurpose repair tape that is created from specially formulated silicone rubber. Although they do not contain any glue or adhesive materials, the silicone rubber in these tapes is capable of combining to itself while forming a flexible and homogenous barrier.

Different from the conventional adhesive tapes, the self-fusing silicone tapes can be effectively applied on the wet surfaces as well. They are also utilized in the applications needing airtight or watertight seals.

Major factors that are expected to boost the growth of the self-fusing silicone tape market in the forecast period growing acceptance of rectangular tapes in the applications such as corrosion resistance, electrical insulation, and bundling of automotive wiring harnesses and the increasing popularity in the telecommunication services industry because it is cost-efficient and durable repair tapes for pressurized copper lines.

Furthermore, the growing of the investments in the power generation, transportation, the electrical industry and other infrastructural development and the chief manufacturers are leveraging advanced methods to expand the high-quality self-fusing silicone tapes, including silicone compounding technology and premium quality silicone elastomers are few of the factors that are anticipated to further propel the growth of the self-fusing silicone tape market in the near future.

This self-fusing silicone tape market report provides details of new recent developments, trade regulations, import export analysis, production analysis, value chain optimization, market share, impact of domestic and localised market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographical expansions, technological innovations in the market. To gain more info on the self-fusing silicone tape market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Browse Detailed TOC, Tables and Figures with Charts which is spread across 350 Pages that provides exclusive data, information, vital statistics, trends, and competitive landscape details in this niche sector.

This research report is the result of an extensive primary and secondary research effort into the Self-fusing Silicone Tape market. It provides a thorough overview of the market's current and future objectives, along with a competitive analysis of the industry, broken down by application, type and regional trends. It also provides a dashboard overview of the past and present performance of leading companies. A variety of methodologies and analyses are used in the research to ensure accurate and comprehensive information about the Self-fusing Silicone Tape Market.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-self-fusing-silicone-tape-market

Which are the driving factors of the Self-fusing Silicone Tape market?

The driving factors of the Self-fusing Silicone Tape market include technological advancements that enhance product efficiency and user experience, increasing consumer demand driven by changing lifestyle preferences, and favorable government regulations and policies that support market growth. Additionally, rising investment in research and development and the expanding application scope of Self-fusing Silicone Tape across various industries further propel market expansion.

Self-fusing Silicone Tape Market - Competitive and Segmentation Analysis:

Global Self-fusing Silicone Tape Market, By Product (Rectangular Tapes, Triangular Tapes, Sinusoidal Rectangular Tapes), Thickness (Up to 0.25 mm, 0.26 mm to 0.50 mm, 0.51 mm to 0.75 mm, Above 0.75 mm), End-Use (Electrical and Electronics, Plumbing, Automotive, Industrial, Aerospace, Home and Garden, Others), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2032.

How do you determine the list of the key players included in the report?

With the aim of clearly revealing the competitive situation of the industry, we concretely analyze not only the leading enterprises that have a voice on a global scale, but also the regional small and medium-sized companies that play key roles and have plenty of potential growth.

Which are the top companies operating in the Self-fusing Silicone Tape market?

The major players covered in the self-fusing silicone tape market report are 3M, Advance Tapes International., Berry Global Inc., NITTO DENKO CORPORATION, Scapa Group plc, Illinois Tool Works inc., AVERY DENNISON CORPORATION, Denka Company Limited., Midsun Specialty Products, Inc., Cardinal Health., Beiersdorf AG, 3A Associates Incorporated., Intertape Polymer Group, CS Hyde Company, PHARMA PACKAGING TECHNOLOGY, TWIN TECH INDIA Pvt. Ltd., Harbor Products, Inc., Atlantex Manufacturing Corporation, gallagherseals.com, MOCAP, Freudenberg Group, among other domestic and global players.

Short Description About Self-fusing Silicone Tape Market:

The Global Self-fusing Silicone Tape market is anticipated to rise at a considerable rate during the forecast period, between 2025 and 2032. In 2024, the market is growing at a steady rate and with the rising adoption of strategies by key players, the market is expected to rise over the projected horizon.

North America, especially The United States, will still play an important role which can not be ignored. Any changes from United States might affect the development trend of Self-fusing Silicone Tape. The market in North America is expected to grow considerably during the forecast period. The high adoption of advanced technology and the presence of large players in this region are likely to create ample growth opportunities for the market.

Europe also play important roles in global market, with a magnificent growth in CAGR During the Forecast period 2025-2032.

Self-fusing Silicone Tape Market size is projected to reach Multimillion USD by 2032, In comparison to 2025, at unexpected CAGR during 2025-2032.

Despite the presence of intense competition, due to the global recovery trend is clear, investors are still optimistic about this area, and it will still be more new investments entering the field in the future.

This report focuses on the Self-fusing Silicone Tape in global market, especially in North America, Europe and Asia-Pacific, South America, Middle East and Africa. This report categorizes the market based on manufacturers, regions, type and application.

Get a Sample Copy of the Self-fusing Silicone Tape Report 2025

What are your main data sources?

Both Primary and Secondary data sources are being used while compiling the report. Primary sources include extensive interviews of key opinion leaders and industry experts (such as experienced front-line staff, directors, CEOs, and marketing executives), downstream distributors, as well as end-users. Secondary sources include the research of the annual and financial reports of the top companies, public files, new journals, etc. We also cooperate with some third-party databases.

Geographically, the detailed analysis of consumption, revenue, market share and growth rate, historical data and forecast (2025-2032) of the following regions are covered in Chapters

What are the key regions in the global Self-fusing Silicone Tape market?

North America (United States, Canada and Mexico)

Europe (Germany, UK, France, Italy, Russia and Turkey etc.)

Asia-Pacific (China, Japan, Korea, India, Australia, Indonesia, Thailand, Philippines, Malaysia and Vietnam)

South America (Brazil, Argentina, Columbia etc.)

Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria and South Africa)

This Self-fusing Silicone Tape Market Research/Analysis Report Contains Answers to your following Questions

What are the global trends in the Self-fusing Silicone Tape market?

Would the market witness an increase or decline in the demand in the coming years?

What is the estimated demand for different types of products in Self-fusing Silicone Tape?

What are the upcoming industry applications and trends for Self-fusing Silicone Tape market?

What Are Projections of Global Self-fusing Silicone Tape Industry Considering Capacity, Production and Production Value? What Will Be the Estimation of Cost and Profit? What Will Be Market Share, Supply and Consumption? What about Import and Export?

Where will the strategic developments take the industry in the mid to long-term?

What are the factors contributing to the final price of Self-fusing Silicone Tape?

What are the raw materials used for Self-fusing Silicone Tape manufacturing?

How big is the opportunity for the Self-fusing Silicone Tape market?

How will the increasing adoption of Self-fusing Silicone Tape for mining impact the growth rate of the overall market?

How much is the global Self-fusing Silicone Tape market worth? What was the value of the market In 2024?

Who are the major players operating in the Self-fusing Silicone Tape market? Which companies are the front runners?

Which are the recent industry trends that can be implemented to generate additional revenue streams?

What Should Be Entry Strategies, Countermeasures to Economic Impact, and Marketing Channels for Self-fusing Silicone Tape Industry?

Customization of the Report

Can I modify the scope of the report and customize it to suit my requirements? Yes. Customized requirements of multi-dimensional, deep-level and high-quality can help our customers precisely grasp market opportunities, effortlessly confront market challenges, properly formulate market strategies and act promptly, thus to win them sufficient time and space for market competition.

Inquire more and share questions if any before the purchase on this report at - https://www.databridgemarketresearch.com/inquire-before-buying/?dbmr=global-self-fusing-silicone-tape-market

Detailed TOC of Global Self-fusing Silicone Tape Market Insights and Forecast to 2032

Introduction

Market Segmentation

Executive Summary

Premium Insights

Market Overview

Self-fusing Silicone Tape Market By Type

Self-fusing Silicone Tape Market By Function

Self-fusing Silicone Tape Market By Material

Self-fusing Silicone Tape Market By End User

Self-fusing Silicone Tape Market By Region

Self-fusing Silicone Tape Market: Company Landscape

SWOT Analysis

Company Profiles

Continued...

Purchase this report – https://www.databridgemarketresearch.com/checkout/buy/singleuser/global-self-fusing-silicone-tape-market

Data Bridge Market Research:

Today's trends are a great way to predict future events!

Data Bridge Market Research is a market research and consulting company that stands out for its innovative and distinctive approach, as well as its unmatched resilience and integrated methods. We are dedicated to identifying the best market opportunities, and providing insightful information that will help your business thrive in the marketplace. Data Bridge offers tailored solutions to complex business challenges. This facilitates a smooth decision-making process. Data Bridge was founded in Pune in 2015. It is the product of deep wisdom and experience.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 975

Email:- [email protected]

Browse More Reports:

Garden Tools Market

1, 3 Butadiene Market

Healthcare 3D Printing Market

Self-fusing Silicone Tape Market

Trim Tabs Market

#Self-fusing Silicone Tape Market#Self-fusing Silicone Tape Market Size#Self-fusing Silicone Tape Market Share#Self-fusing Silicone Tape Market Trends#Self-fusing Silicone Tape Market Growth#Self-fusing Silicone Tape Market Analysis#Self-fusing Silicone Tape Market Scope & Opportunity#Self-fusing Silicone Tape Market Challenges#Self-fusing Silicone Tape Market Dynamics & Opportunities#Self-fusing Silicone Tape Market Competitor's Analysis

0 notes

Text

Medical Grade Silicone Market Challenges: Growth, Share, Value, Trends, Analysis , Industry Overview and Forecast to 2029

"Medical Grade Silicone Market Size And Forecast by 2029

Data Bridge Market Research analyses that the medical grade silicone market will witness a CAGR of 6.40% for the forecast period of 2022-2029.

Lastly, the study emphasizes the broader implications of these companies’ contributions to the Medical Grade Silicone Market growth and evolution. Their strategies, technological advancements, and market influence not only define current industry trends but also set the stage for future developments. By providing a comprehensive overview of the leading players, the report equips stakeholders with critical insights to understand competitive positioning, identify opportunities for collaboration, and develop strategies to thrive in this dynamic industry.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-medical-grade-silicone-market

Nucleus is a secure, cloud-based platform designed to streamline data transfer and management for businesses. Its intuitive interface offers practice administrators and financial managers advanced filtering options, enhancing operational efficiency. By integrating various data sources, Nucleus enables effective prioritization of critical exposures, incorporating business context and threat intelligence to bolster security measures. Additionally, Nucleus supports seamless collaboration among multiple users across different applications, fostering rapid iteration and teamwork. Its deployment flexibility allows installation on-premises or via preferred cloud service providers, ensuring scalability and adaptability to meet diverse organizational needs.

Get More Detail: https://www.databridgemarketresearch.com/nucleus/global-medical-grade-silicone-market

Which are the top companies operating in the Medical Grade Silicone Market?

The Top 10 Companies in Medical Grade Silicone Market operating in the Medical Grade Silicone Market are recognized for their innovation, market leadership, and strong presence across key regions. These companies invest heavily in research and development, driving continuous product innovation to meet evolving customer demands. Their extensive distribution networks, brand reputation, and technological expertise have solidified their positions as industry leaders. Additionally, these top companies are expanding through strategic partnerships, mergers, and acquisitions, enabling them to strengthen their market share and enhance their competitive advantages.

**Segments**

- **By Product Type:** The medical grade silicone market can be segmented by product type into gels, medical adhesives, medical coatings, elastomers, and others. Medical grade silicone is utilized in various forms based on the specific requirements of medical applications, with each product type offering unique characteristics and benefits.

- **By Application:** In terms of application, the market can be segmented into prosthetics, orthopedic components, medical devices, medical tapes, wound care, and others. Medical grade silicone finds extensive usage in the healthcare industry for manufacturing a wide range of products due to its biocompatibility and durability.

- **By End-User:** The end-user segment of the medical grade silicone market includes hospitals, ambulatory surgical centers, clinics, and others. These end-users rely on medical grade silicone for different applications such as medical tubing, catheters, prosthetic components, and medical implants.

**Market Players**

- **Dow Corning Corporation:** A key player in the medical grade silicone market, Dow Corning Corporation offers a wide range of medical grade silicone products for various applications in the healthcare industry. The company is known for its high-quality silicone materials that comply with stringent medical standards.

- **Wacker Chemie AG:** Wacker Chemie AG is another prominent player in the market, providing innovative silicone solutions for medical applications. The company's medical grade silicones are used in the production of medical devices, prosthetics, and other healthcare products.

- **Momentive Performance Materials Inc.:** With a strong presence in the medical grade silicone market, Momentive Performance Materials Inc. offers advanced silicone technologies that cater to the specific needs of medical manufacturers. The company's products are designed to meet the regulatory requirements of the healthcare sector.

- **Shin-Etsu Chemical Co., Ltd.:** Shin-Etsu Chemical Co., Ltd. is a leading supplier of medical grade silicone materials, offering a comprehensive portfolio of silicone products for medical use. The company's siliconeThe medical grade silicone market is witnessing substantial growth and development due to the increasing demand for advanced healthcare products and technologies. The segmentation of the market by product type offers insights into the diverse forms in which medical grade silicone is utilized. Gels, medical adhesives, coatings, elastomers, and other product types cater to specific requirements in medical applications, showcasing unique characteristics and benefits. This segmented approach enables manufacturers to tailor their offerings to meet the evolving needs of the healthcare industry, driving innovation and product development.

Moving on to the segmentation by application, the versatility of medical grade silicone becomes evident in its extensive use across various healthcare sectors. Prosthetics, orthopedic components, medical devices, tapes, wound care products, and other applications benefit from the biocompatibility and durability of medical grade silicone. This broad range of applications underscores the critical role that silicone materials play in enhancing the quality and performance of medical products, ultimately contributing to improved patient outcomes and healthcare practices.

The end-user segment of the medical grade silicone market encompasses hospitals, ambulatory surgical centers, clinics, and other healthcare facilities. These end-users rely on medical grade silicone for a multitude of applications, including medical tubing, catheters, prosthetic components, and implants. The superior properties of medical grade silicone, such as flexibility, resistance to temperature extremes, and biocompatibility, make it a preferred choice for a wide array of medical devices and equipment used in clinical settings. This strong demand from end-users further propels the growth of the medical grade silicone market.

Examining the key market players in the medical grade silicone industry, companies like Dow Corning Corporation, Wacker Chemie AG, Momentive Performance Materials Inc., and Shin-Etsu Chemical Co., Ltd. are at the forefront of driving innovation and technological advancements. These players offer a diverse portfolio of medical grade silicone products tailored to meet the stringent standards and regulatory requirements of the healthcare sector. Their expertise in developing advanced silicone technologies for prosthetics, medical devices, and other applications**Market Players:**

- Dow - 3M - Wacker Chemie AG - Shin-Etsu Chemical Co., Ltd - Momentive - Specialty Silicone Fabricators, Inc - Zodiac Coating - Wynca Group - Primasil Silicones Limited - Kibaru Manufacturing Sdn Bhd - Messe Düsseldorf GmbH - STOCKWELL ELASTOMERICS, INC - Saint-Gobain Performance Plastics - Apple Rubber Products

The medical grade silicone market continues to experience significant growth and expansion driven by the rising demand for advanced healthcare solutions and products. The segmentation of the market by product type highlights the diverse applications of medical grade silicone, offering manufacturers the flexibility to tailor their offerings to meet specific industry needs. Product types such as gels, medical adhesives, coatings, elastomers, and others provide distinct characteristics and advantages, enabling innovation and customization in medical applications.

Moreover, the segmentation by application underscores the versatility of medical grade silicone across various healthcare sectors. Prosthetics, orthopedic components, medical devices, tapes, wound care products, among others, benefit from the biocompatibility and durability of silicone materials. This widespread adoption of medical grade silicone emphasizes its vital role in enhancing the quality and efficacy of medical products, ultimately contributing to enhanced patient care and healthcare practices.

The end-user segment, consisting of hospitals, ambulatory surgical centers, clinics, and other healthcare facilities, drives the demand for medical grade silicone

Explore Further Details about This Research Medical Grade Silicone Market Report https://www.databridgemarketresearch.com/reports/global-medical-grade-silicone-market

Key Insights from the Global Medical Grade Silicone Market :

Comprehensive Market Overview: The Medical Grade Silicone Market is expanding rapidly, fueled by technological innovation and increasing global demand.

Industry Trends and Projections: Automation, sustainability, and digital solutions are key trends, with the market projected to grow at a significant rate.

Emerging Opportunities: New opportunities are arising in green technologies and personalized solutions, especially in emerging markets.

Focus on R&D: Companies are heavily investing in R&D to drive innovation, focusing on AI, IoT, and sustainability.

Leading Player Profiles: Market leaders like Company A and Company B maintain dominance through strong portfolios and extensive networks.

Market Composition: The market is fragmented, with a mix of established players and emerging startups targeting various segments.

Revenue Growth: The market is experiencing steady revenue growth, driven by both consumer and commercial demand.

Commercial Opportunities: Key commercial opportunities lie in expanding into new regions, leveraging digital transformation, and strategic collaborations.

Get More Reports:

Semiconductor Packaging Market Size, Share, and Trends Analysis Report – Industry Overview and Forecast to 2028 Lactose Market Size, Share, and Trends Analysis Report – Industry Overview and Forecast to 2028 Mega Solar Power Plant Market Size, Share, and Trends Analysis Report – Industry Overview and Forecast to 2030 Asia-Pacific Medicinal Chemistry for Drug Discovery Market Size, Share, and Trends Analysis Report – Industry Overview and Forecast to 2029 Asia-Pacific Circulating Tumor Cells (CTC) Liquid Biopsy Market Size, Share, and Trends Analysis Report – Industry Overview and Forecast to 2029 Barth Syndrome Treatment Market Size, Share, and Trends Analysis Report – Industry Overview and Forecast to 2030 Advanced Structural Ceramics Market Size, Share, and Trends Analysis Report – Industry Overview and Forecast to 2031 Critical Communication Market Size, Share, and Trends Analysis Report – Industry Overview and Forecast to 2031 Carotid Ultrasound Imaging Market Size, Share, and Trends Analysis Report – Industry Overview and Forecast to 2032 Sleep Tracker Market Size, Share, and Trends Analysis Report – Industry Overview and Forecast to 2028 Automotive Data Cables Market Size, Share, and Trends Analysis Report – Industry Overview and Forecast to 2028 Scientific Data Management Systems (SDMS) Market Size, Share, and Trends Analysis Report – Industry Overview and Forecast to 2030

Data Bridge Market Research:

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 975

Email:- [email protected]"

0 notes

Text

Top 15 Market Players in Global Silicone Resins Market

Top 15 Market Players in Global Silicone Resins Market

The global silicone resins market has seen significant growth, driven by increasing demand across sectors such as construction, automotive, electronics, and industrial applications. Several leading companies dominate this market due to their advanced technologies, extensive product portfolios, and strong global presence. Below are 15 key players shaping the silicone resins market:

Dow Inc. A major player in the silicone industry, Dow offers innovative silicone resin solutions for coatings, adhesives, and sealants.

Wacker Chemie AG Known for its high-quality silicone resins, Wacker serves industries like construction and electronics with cutting-edge formulations.

Shin-Etsu Chemical Co., Ltd. This Japanese giant provides premium-grade silicone resins for automotive, electrical, and industrial uses.

Momentive Performance Materials Inc. A global leader in specialty silicones, Momentive specializes in durable and heat-resistant silicone resins.

Elkem ASA With a strong focus on sustainability, Elkem develops high-performance silicone resins for diverse end-use industries.

Evonik Industries AG Evonik offers a broad range of silicone-based products, including resins that enhance durability and thermal stability.

Bluestar Silicones International A subsidiary of Elkem, Bluestar is recognized for its innovative silicone resins catering to coatings and elastomers.

Dow Corning Corporation Specializing in advanced silicone technology, Dow Corning (a subsidiary of Dow Inc.) is a leader in the silicone resins market.

Hubei Xingfa Chemicals Group Co., Ltd. A key player in Asia, Hubei Xingfa produces a wide range of silicone materials, including specialty resins.

KCC Corporation This South Korean company offers high-quality silicone resins for coatings, adhesives, and industrial applications.

Resil Chemicals Based in India, Resil focuses on silicone resins used in textiles and industrial coatings.

Arkema Group Arkema provides innovative solutions in specialty chemicals, including heat- and UV-resistant silicone resins.

ACC Silicones Ltd. A trusted name in the silicone industry, ACC Silicones delivers resins that enhance performance in challenging environments.

Henkel AG & Co. KGaA Henkel’s silicone-based adhesives and coatings cater to automotive and construction industries.

GE Silicones Known for its robust R&D, GE Silicones produces high-performance resins tailored for electronics and industrial markets.

Request report sample at https://datavagyanik.com/reports/russia-silicone-resins-market/

Top Winning Strategies in Silicone Resins Market

As the silicone resins market evolves, companies are adopting innovative strategies to stay competitive. Below are the top strategies that have proven effective in this dynamic industry:

1. Focus on Sustainability

Companies are emphasizing eco-friendly formulations and sustainable production methods to meet regulatory standards and consumer demands.

2. Investment in R&D

Continuous innovation is a key driver. Market players are allocating significant resources to research and development to improve product performance and introduce novel applications.

3. Strategic Partnerships

Collaborations with industry stakeholders, including raw material suppliers and end-users, enable companies to expand their market presence and streamline their supply chains.

4. Geographic Expansion

Targeting emerging markets in Asia-Pacific, Latin America, and the Middle East has become a priority due to increasing industrialization and urbanization in these regions.

5. Product Customization

Offering tailored silicone resin solutions for specific applications, such as automotive coatings or electronics encapsulation, helps companies cater to niche markets.

6. Mergers and Acquisitions

Acquiring regional players or merging with complementary businesses strengthens market presence and boosts technological capabilities.

7. Digital Transformation

Adoption of digital tools for sales, marketing, and supply chain management enhances customer experience and operational efficiency.

8. Competitive Pricing

Developing cost-effective products without compromising quality allows companies to penetrate price-sensitive markets.

9. Market Diversification

Expanding into adjacent markets, such as silicone elastomers and adhesives, provides additional revenue streams.

10. Focus on Regulatory Compliance

Ensuring compliance with international safety and environmental standards builds trust and minimizes risks.

11. Strong Distribution Networks

Establishing robust global and regional distribution channels ensures timely delivery and market reach.

12. Brand Strengthening

Enhancing brand visibility through marketing campaigns and participation in global trade fairs bolsters reputation and customer loyalty.

13. Technological Integration

Using advanced manufacturing technologies such as AI and IoT improves production efficiency and product quality.

14. Customer-Centric Approach

Companies are increasingly engaging with customers to understand their needs and provide tailored solutions.

15. Exploration of New Applications

Market leaders are identifying novel uses for silicone resins in areas such as renewable energy, healthcare, and advanced electronics to drive growth.

These strategies, combined with technological advancements and global outreach, will continue to shape the competitive landscape of the silicone resins market.

Request a free sample copy at https://datavagyanik.com/reports/russia-silicone-resins-market/

#Silicone Resins Market#Silicone Resins Production#market players#market size#market share#top trends#average price#revenue

0 notes

Text

Aerospace & Defense Elastomers Market

Aerospace & Defense Elastomers Market Size, Share, Trends: DuPont Leads

Increasing adoption of high-performance elastomers in aerospace applications drives market innovation.

Market Overview:

The Aerospace & Defense Elastomers Market is projected to grow at a CAGR of 5.8% from 2024 to 2031. The market value is expected to increase significantly during this period. North America currently dominates the market, with key metrics including increasing aircraft production, growing defense budgets, and rising demand for fuel-efficient aircraft. The market is experiencing steady growth driven by technological advancements in elastomer materials, increasing aircraft deliveries, and the expanding space exploration sector.

The aerospace and defense industries are increasingly adopting high-performance elastomers that can withstand extreme temperatures, chemicals, and mechanical stress. These advanced materials are being used in critical applications such as seals, gaskets, and hoses, where traditional elastomers fall short. The market scope extends beyond aircraft and defense applications, with significant potential in space exploration and next-generation aircraft. The continuous investment in research and development, coupled with strategic partnerships and collaborations, is expected to drive further growth and innovation in the aerospace and defense elastomers market.

DOWNLOAD FREE SAMPLE

Market Trends:

The aerospace and defence industries are seeing a considerable move towards high-performance elastomers that can withstand harsh temperatures, chemicals, and mechanical stress. These sophisticated materials are increasingly being used in crucial applications such as seals, gaskets, and hoses, where standard elastomers fail. Fluoroelastomers, for example, are gaining popularity because of their superior resistance to fuels, lubricants, and hydraulic fluids, even at high temperatures. Similarly, silicone elastomers are popular due to their broad temperature range and flexibility. This trend is motivated by the need for increased safety, dependability, and performance in aerospace applications, particularly next-generation aeroplanes and space vehicles. As manufacturers focus on lightweight materials to improve fuel efficiency, high-performance elastomers that reduce weight without sacrificing durability are becoming more popular.

Market Segmentation:

Fluoroelastomers dominate the Aerospace & Defense Elastomers Market due to their exceptional chemical resistance and high-temperature performance. Fluoroelastomers, commonly known as FKM or Viton, have emerged as the dominant category in the aerospace and defence elastomer market. These high-performance elastomers have excellent resistance to a variety of chemicals, fuels, and oils, making them perfect for use in essential aircraft components. Fluoroelastomers can tolerate temperatures ranging from -40°C to 200°C, providing dependable performance in harsh aerospace settings. Their superior compression set resistance and low permeability to gases and fluids make them ideal for seals, O-rings, and gaskets in aircraft engines, fuel systems, and hydraulic applications.

Fluoroelastomers' dominance in the market has been confirmed by recent industrial advances. For example, in 2023, a major elastomer producer launched a new grade of fluoroelastomer specifically tailored for aircraft applications, which has better low-temperature flexibility and resistance to abrasive aviation fluids. This idea has been enthusiastically appreciated by aircraft makers that want to improve the performance and lifetime of crucial sealing components.

Furthermore, the aviation industry's increased emphasis on fuel efficiency and emissions reduction has boosted demand for fluoroelastomers. These materials help to reduce weight while also improving sealing efficiency, which has a direct impact on fuel economy. According to industry studies, the use of sophisticated fluoroelastomer seals in current aircraft engines has resulted in a 2-3% increase in fuel economy over older elastomer materials. This enormous impact on performance and operational costs has prompted major aerospace companies to include fluoroelastomers in their most recent aircraft designs, confirming their position as the industry leader in aerospace and defence elastomers.

Market Key Players:

DuPont

Trelleborg AB

Momentive Performance Materials

Shin-Etsu Chemical Co.

Solvay S.A.

Parker Hannifin Corporation

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes

Text

Silicone Elastomers Market Top Manufacturing Industry Revenue Size & Share Outlook

The silicone elastomers market is estimated to grow from USD 8.6 billion in 2024 to USD 12.3 billion by 2029, at a CAGR of 7.4% in terms of value. The rising infrastructure development in developing economies, and aesthetically appealing healthcare devices in the medical industry serve as a significant driver for silicone elastomers market. This scenario presents a unique opportunity for the industry to focus on the development of silicone elastomers, which not only meets consumer demands but also aligns with sustainability goals. However, complex maufacturing process act as restraint, emphasizing the urgent need for eco-friendly alternatives in the silicone elastomers market.

Download PDF Brochure at https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=6310524

Based on type, the silicone elastomers market is segmented as high temperature vulcanized, room temperature vulcanized, and liquid silicone rubber. High temperature vulcanization stands out as the largest segment in terms of value, globally. The dominance of the high-temperature vulcanized (HTV) segment in the silicone elastomers market is attributed to its exceptional heat resistance, rendering it optimal for challenging environments like automotive & transportation, and industrial sectors. High-temperature vulcanized silicone elastomers offer superior thermal stability, flexibility, and durability, driving extensive adoption in high-performance and extreme-temperature applications, thereby consolidating their leadership position in the market. Furthermore, the liquid silicone rubber segment is forecasted to exhibit the highest CAGR in terms of value during the forecast year 2024 and 2029.

Based on process, the silicone elastomers market is segmented as extrusion, liquid injection molding, injection molding, compression molding, and others. Liquid injection molding stands out as the largest segment in terms of value, globally. The Liquid Injection Molding (LIM) process has secured dominance in the silicone elastomers market by offering unparalleled precision and efficiency in manufacturing intricate components. Its capability to produce high-quality, customized products consistently aligns with the stringent demands of industries like healthcare, electrical & electronics, and automotive & transportation, reinforcing its position as the preferred choice and market leader.

Based on end-use industry, the silicone elastomers market has been categorized into various segments including building & construction, foams, automotive & transportation, electrical & electronics, healthcare, consumer goods, and others. Notably, the electrical & electronics segment emerged as the market leader in 2023. The rapid advancements in technology, driving increased demand for smart devices and sustainable energy solutions. The sector's innovation, such as 5G integration, AI applications, and electric vehicles, played a pivotal role. Growing consumer preferences for smart homes and IoT-connected devices further fueled the industry's dominance. Furthermore, the healthcare segment is forecasted to exhibit the highest CAGR in terms of value during the forecast year 2024 and 2029.

Based on region, the silicone elastomers market has been categorized into five regions including North America, Europe, Asia Pacific, Middle East & Africa, and South America. Asia Pacific stands out as the fastest growing market for silicone elastomers in terms of value during the forecast year 2024 and 2029. Asia Pacific 's dominance in the silicone elastomers market has been largely driven by technological innovation. The region is home to research and development centers as well as a bustling startup and innovation community that is concentrated on sustainable solutions. The market for silicone elastomers grew due to the growth in manufacturing industries in the region, leading to a substantial expansion of the silicone elastomers market in the Asia Pacific.

Request For FREE Sample of Report at https://www.marketsandmarkets.com/requestsampleNew.asp?id=6310524

The key players in this market are Dow Inc. (US), Wacker Chemie AG (Germany), Momentive Performance Materials Inc. (US), Shin-Etsu Chemical Co., Ltd. (Japan), China National Bluestar (Group) co. Ltd. (China), Reiss Manufacturing Inc. (US), Mesgo S.p.A (Germany), Cabot Corporation (US), Rogers Corporation (US), and DuPont de Nemours, Inc. (US). They have implemented strategies such as new product launches and acquisitions to enhance their competitors.

#Silicone Elastomers Market#Silicone Elastomers#Silicone Elastomer#Silicone#Elastomers Market#Elastomer#Elastomers

0 notes

Text

Exploring Growth Drivers and Innovations in the Medical Polymer Market

Medical polymers have become essential in the healthcare industry, owing to their versatility, durability, and biocompatibility. These synthetic and natural polymers are used in various medical applications, from medical devices to drug delivery systems, and are designed to meet specific performance and safety standards. Medical polymers are engineered to possess attributes like flexibility, strength, resistance to chemicals, and compatibility with the human body, which are crucial for ensuring patient safety. The increasing demand for minimally invasive procedures, along with advancements in healthcare technology, has significantly driven the growth of the medical polymer market.

The Medical Polymer Market Size was projected to reach 138.8 billion USD in 2022, according to MRFR analysis. By 2032, the medical polymer market is projected to have grown from 151.61 billion USD in 2023 to 335.7 billion USD. It is anticipated that the Medical Polymer Market would develop at a rate of approximately 9.23% between 2024 and 2032.

Medical Polymer Size

The size of the medical polymer market is expected to expand rapidly over the coming years due to the growing aging population, which increases the demand for medical devices and pharmaceutical products. Additionally, advancements in polymers like polyetheretherketone (PEEK), polyethylene, polypropylene, and silicone have broadened the scope of medical polymers, making them more suitable for specialized applications such as orthopedic implants, wound care, and dental devices. In 2022, the medical polymer market was valued at approximately USD 20 billion and is projected to grow steadily. This market size expansion is further fueled by the development of biodegradable polymers and the surge in demand for eco-friendly medical products.

Medical Polymer Share

The market share for medical polymers is dominated by key regions, including North America, Europe, and Asia-Pacific, with North America holding a substantial share due to advanced healthcare infrastructure and high investment in research and development. However, the Asia-Pacific region is witnessing rapid growth, driven by increased healthcare expenditure, expanding medical tourism, and a large aging population in countries like China and India. The market is also segmented by polymer type, with thermoplastics, elastomers, and resins being the primary categories. Thermoplastics hold a significant share due to their high flexibility and ease of molding into various shapes, making them ideal for custom medical device manufacturing.

Medical Polymer Analysis

A comprehensive analysis of the medical polymer market reveals strong growth potential, fueled by innovation in polymer technologies and increasing awareness about the benefits of biocompatible materials in healthcare. The analysis shows that emerging technologies, such as 3D printing and nanotechnology, are reshaping the production of medical polymers, enabling the creation of intricate and highly personalized medical devices. Furthermore, the rise in chronic diseases and surgical interventions worldwide has led to an increased reliance on medical polymers for implants, prosthetics, and diagnostic equipment, making this sector highly resilient to economic fluctuations.

Medical Polymer Trends

Medical polymer trends indicate a shift toward biodegradable and environmentally sustainable polymers, driven by the rising concerns about the environmental impact of disposable medical products. Another trend includes the development of antimicrobial polymers, which help in reducing the risk of infections associated with medical devices. The adoption of smart polymers, which can respond to changes in temperature or pH, is also on the rise, allowing for enhanced drug delivery mechanisms and improving patient outcomes. These trends underscore the industry's commitment to innovation, quality, and safety, enhancing the appeal of medical polymers in diverse applications.

Reasons to Buy Medical Polymer Reports

Market Insights: Gain in-depth knowledge of market dynamics, including growth drivers, challenges, and opportunities in the medical polymer industry.

Strategic Planning: Equip your business with data-driven insights to develop effective strategies and make informed decisions.

Competitive Landscape: Access analysis of key players, their market share, and strategies, helping to understand the competitive dynamics of the industry.

Trend Analysis: Stay updated on the latest trends in medical polymers, such as biodegradable materials, 3D printing, and smart polymers.

Investment Opportunities: Identify lucrative investment prospects and understand the factors influencing market growth, helping to plan effective investment strategies.

Recent Developments

Recent developments in the medical polymer sector include the increased use of polymers in advanced wound care and tissue engineering. Companies are also investing in R&D to develop antimicrobial polymers that can prevent infections, crucial for implantable devices. The application of 3D printing in producing custom-made implants and prosthetics has gained momentum, with medical polymers playing a critical role. Furthermore, the integration of smart polymers for controlled drug release systems represents a cutting-edge advancement. These developments reflect the dynamic nature of the medical polymer market and its capacity to adapt to emerging healthcare needs.

Related reports :

pelvic floor stimulator market

pharmaceutical solvent market

plastic surgery instrument market

ai in pathology market

anti biofilm wound dressing market

0 notes

Text

Silicone Elastomers Market Trends: Growth, Drivers, and Opportunities Through 2024-2034

Silicone Elastomers Market Trends are witnessing robust growth due to their wide range of applications in industries such as automotive, healthcare, and electronics. The Silicone Elastomers Market is experiencing a rising demand, thanks to their durability and flexibility.

The silicone elastomers market trends is expected to grow from $7.41 billion in 2023 to $13.94 billion by 2034, representing a compound annual growth rate (CAGR) of 5.94% during the 2024-2034 forecast period.

Request a free sample report of the Silicone Elastomers Market Trends

Market Growth

The growth of the silicone elastomers market is primarily driven by the rising demand for high-performance materials across various industries, including automotive and healthcare. In the automotive sector, silicone elastomers are favored for their durability, temperature resistance, and flexibility, enhancing vehicle performance and safety. Meanwhile, in healthcare, these materials are essential for medical devices and applications due to their biocompatibility and resistance to sterilization processes. Additionally, the growing emphasis on sustainable and eco-friendly materials is further propelling the adoption of silicone elastomers, positioning them as a key component in innovative product development across diverse sectors.

Download Complete TOC of the Silicone Elastomers Market

Key Technologies

Liquid Silicone Rubber (LSR): Known for its flexibility and strength, LSR is widely used in medical devices and automotive parts.

High-Temperature Vulcanized (HTV) Elastomers: These are used in applications requiring high heat resistance, such as in engine components.

Room-Temperature Vulcanized (RTV) Elastomers: Commonly used in construction and sealing applications, RTV elastomers are easy to process and apply.

Get more market insights on Advanced materials chemicals

Demand Drivers

Automotive Industry Growth: The rising demand for lightweight, durable materials in automotive manufacturing is driving demand for Silicone Elastomers Market solutions.

Medical Devices: The healthcare industry is increasingly using silicone elastomers due to their biocompatibility and flexibility.

Electronics: The growing electronics industry is adopting silicone elastomers for their insulation properties.

Building and Construction End-Use Industry Application to Lead the Market

The building and construction sector is set to dominate the market, driven by the versatile applications and superior properties of silicone elastomers. Valued for their flexibility, durability, and resistance to extreme temperatures, these materials are essential for sealing, glazing, and insulation in residential and commercial projects. The emphasis on sustainable construction and green building standards further boosts demand, as silicone elastomers are non-toxic and environmentally friendly. With stricter building regulations and a focus on energy efficiency, the use of silicone elastomers is expected to rise significantly, fueling market growth in the coming years.

Key Market Players

• Dow • Wacker Chemie AG • Momentive Performance Materials • Shin-Etsu Chemical Co., Ltd. • China National Bluestar (Group) Co., Ltd. • Rogers Corporation • Cabot Corporation • Reiss Manufacturing Inc. • MESGO S.p.A. • CHT Germany GmbH • Bellofram Elastomers • Specialty Silicone Products, Inc. • DuPont • Avantor, Inc. • Wynca Group (Zhejiang Xin'an Chemical Group Co., Ltd.)

Conclusion

Silicone Elastomers Market Trends are set for significant growth, driven by innovations in material technology and rising demand from key industries. The Silicone Elastomers Market trends will continue to shape the future of this market.

BIS Research, recognized as a best market research company, provides premium market intelligence reports on deep technologies poised to cause significant market disruption in the coming years.

At BIS Research, we focus exclusively on technologies related to precision medicine, medical devices, diagnostics, life sciences, artificial intelligence (AI), machine learning (ML), Internet of Things (IoT), big data analysis, blockchain technology, 3D printing, advanced materials and chemicals, agriculture and FoodTech, mobility, robotics and UAVs, and aerospace and defense, among others

0 notes

Link

North America is expected to witness the highest growth in the silicone elastomers market during the forecast period...

#adroit market research#silicone elastomers market#silicone elastomers 2020#silicone elastomers trends

0 notes

Text

North America Silicone Market To Reach USD 6.69 Billion By 2030

North America Silicone Market Growth & Trends

The global North America silicone market size is expected to reach USD 6.69 billion by 2030, registering a CAGR of 5.5% from 2024 to 2030, according to a new report by Grand View Research, Inc. The market is poised for growth due to increasing demand across multiple industries, such as automotive, construction, electronics, healthcare, and consumer goods. Silicone's versatility and wide range of applications, including sealants, adhesives, coatings, and elastomers, make it a sought-after material. In addition, the market is driven by the growing emphasis on sustainability, as silicone offers eco-friendly properties, recyclability, durability, and low toxicity.

The silicone market is expected to perform moderately owing to limited opportunities by market maturity of both manufacturing industries in general and the use of silicones. However, continuous product innovation and ongoing technological developments are expected to promote the application of silicone in emerging markets, such as electric vehicles (EVs) and health & personal care, which, in turn, is expected to fuel the market growth over the forecast period. Moreover, suppliers continue gaining market share through value-added product development and creating inroads into applications that conventionally use other materials.

In terms of product, the fluid segment's dominance is reinforced by the reliability and trust that the industry places in silicone fluids. Their resistance to extreme temperatures, chemical inertness, and low toxicity make them a preferred choice in critical applications. In addition, the ease of handling and formulation flexibility further bolster their popularity among manufacturers. Therefore, the fluid segment has firmly established itself as the go-to solution in the North America silicone industry, meeting the diverse demands of different industries and solidifying its position as the primary driver of the market's growth.

In terms of end-use, the industrial processes segment led the market in 2022, which is attributed to the remarkable properties of silicone that cater to a wide array of industrial applications. Silicone's unique characteristics, such as high thermal stability, excellent electrical insulation, and resistance to chemicals, make it highly sought-after in various industrial settings. Silicone finds extensive use in industries such as automotive, electronics, construction, and aerospace, where it serves as a crucial component in coatings, lubricants, adhesives and sealants. Its ability to withstand extreme temperatures and harsh environments makes it invaluable in industrial processes, where reliability and performance are of utmost importance.

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/north-america-silicone-market-report

North America Silicone Market Report Highlights

In terms of product, The fluid product segment led the market and accounted for a revenue share of over 45.0% in 2023, which is attributed to rising product demand from the end-use industries such as electronics, transportation, construction, healthcare, personal care, and consumer goods, energy, and industrial processes

Silicone fluid offers resistance to extreme temperatures, chemical inertness, and low toxicity making them a preferred choice in critical applications. In addition, the ease of handling and formulation flexibility further bolster their popularity among manufacturers

Expanding manufacturing base and increasing investments in advanced technologies for vehicular production are expected to bring about a new era of automobiles, positively influencing the market for silicone

The industrial processes segment led the market and accounted for a significant revenue share in 2023. This is attributed to the remarkable properties of silicone that cater to a wide array of industrial applications. Silicone's unique characteristics, such as high thermal stability, excellent electrical insulation, and resistance to chemicals, make it highly sought after in various industrial settings

In terms of region, t U.S. silicone market held the largest revenue share of 89.5% in 2023. This is attributed to its robust industrial and economic landscape. The U.S. is home to a diverse range of industries, such as automotive, electronics, healthcare, and construction, which are significant consumers of silicone-based products

North America Silicone Market Segmentation

Grand View Research has segmented the North America silicone market on the basis of on product, end-use, and region:

North America Silicone Product Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Fluids

Straight Silicone Fluids

Modified Silicone Fluids

Gels

Resins

Elastomers

High Temperature Vulcanized

Liquid Silicone Rubber

Room Temperature Vulcanizaed (RTV)

Others

Adhesives

Emulsions

North America Silicone End use Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Electronics

Transportation

Construction

Healthcare

Personal Care and Consumer goods

Energy

Industrial Processes

Others (Textiles)

North America Silicone Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

North America

U.S.

Canada

Mexico

List of Key Players in the North America Silicone Market

CHT Group

Dow Inc.

Elkem ASA

Evonik Industries

GELEST, INC.

Jiangsu Mingzhu Silicone Rubber Material Co., Ltd.

KCC CORPORATION

Kaneka Corporation

Momentive

Shin-Etsu Chemical Co. Ltd

Wacker Chemie AG

HEXPOL AB.

Silchem Inc.

Specialty Silicone Products, Inc.

Illinois Tool Works Inc.

Abbvie Inc.

CRI-SIL Silicone Technologies, LLC

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/north-america-silicone-market-report

#North America Silicone Market#North America Silicone Market Size#North America Silicone Market Share#North America Silicone Market Trends

0 notes

Text

Worldwide Silicone Market 2024- Strategy Resources, Manufacturers, Supply and Forecasts 2030

Silicone Industry Overview

The global silicone market size was estimated at USD 21.33 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 6.0% from 2024 to 2030. Growing demand for silicone in various end-use industries including personal care, consumer goods, industrial processes, and construction is expected to drive market growth. The U.S. silicone industry is expected to perform moderately owing to limited opportunities by market maturity of both manufacturing industries in general and use of silicones. However, continuous product innovation and ongoing technological developments are expected to promote application of silicone in emerging markets.

Emerging applications include electric vehicles (EVs) and health & personal care, which, in turn, are expected to fuel market growth over the forecast period. Moreover, suppliers continue to gain market share through value-added product development and by creating inroads into applications that conventionally use other materials.

Gather more insights about the market drivers, restrains and growth of the Silicone Market

Silicone is widely used in the construction industry owing to weather resistant, highly stable, and inert & high-water repellent properties. It is used in conjugation with several materials such as marble, glass, concrete, aluminum, steel, and polymers, which find application in residential and commercial constructions. In addition, they are also used in construction of roads, bridges, pipelines, oil rigs, and industrial units. Rising population, increasing urbanization, and rapid industrial growth have resulted in a growing need for construction and infrastructure development globally.

The silicone industry is expected to grow owing to increasing application scope of silicone in various end-use industries. Across electronics industry, silicone is used in a broad range of electronic applications such as for protecting insulators from salt air damage, moisture-proofing of boards, modification of semiconductor encapsulating materials, and protecting ends of heating element wires in printed circuit boards (PCBs), semiconductors, and electronic control units (ECUs), LED devices, and others.

Browse through Grand View Research's Plastics, Polymers & Resins Industry Research Reports.

The global cenospheres market size was estimated at USD 592.32 million in 2023 and is projected to grow at a CAGR of 12.1% from 2024 to 2030.

The global curing agent market size was estimated at USD 6.62 billion in 2023 growing at a CAGR of 6.3% from 2024 to 2030.

Key Companies & Market Share Insights

Global silicone industry is significantly fragmented in nature with the presence of big manufacturing players globally. Market players compete mainly on the basis of technology used for production of silicone and quality of products. Key market players are inclined towards adopting marketing strategies such as mergers & acquisitions, new and innovative products along with production capacity expansions are some of popular strategies adopted by a majority of the market players operating in the global silicone market.

In September 2023, Wacker Chemie AG, a silicone manufacturer, announced the expansion of their silicone production capacities in China with an investment of USD 160.34 million (EUR 150 million). The facility will be capable of manufacturing silicone fluids, silicone emulsions, and silicone elastomer gels.

Key Silicone Companies:

Elkay Chemicals Pvt. Ltd.

Supreme Silicones

Shin-Etsu Chemical Co., Ltd.

Silchem Inc.

Silteq Ltd

Amul Polymers

Wacker Chemie AG

Specialty Silicone Products, Inc.

Illinois Tool Works Inc.

Evonik Industries AG

Hutchinson

Kemira Oyj

Dow Inc.

Nano Tech Chemical Brothers Private Limited

Elkem ASA

Order a free sample PDF of the Silicone Market Study, published by Grand View Research.

0 notes

Text

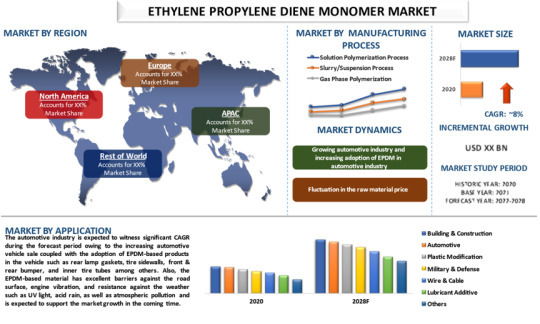

Ethylene Propylene Diene Monomer (EPDM) Market: Current Analysis and Forecast (2022-2028)

According to a new report published by UnivDatos Markets Insights, the Ethylene Propylene Diene Monomer (EPDM) Market is expected to grow at a CAGR of around 8% from 2022-2028. The analysis has been segmented into Manufacturing Process (Solution Polymerization Process, Slurry/Suspension Process, and Gas Phase Polymerization); Application (Building & Construction, Automotive, Plastic Modification, Military & Defense, Wire & Cable, Lubricant Additive, and Others); Region/Country.

The Ethylene Propylene Diene Monomer (EPDM) market report has been aggregated by collecting informative data on various dynamics such as market drivers, restraints, and opportunities. This innovative report makes use of several analyses to get a closer outlook on the Ethylene Propylene Diene Monomer (EPDM) market. The Ethylene Propylene Diene Monomer (EPDM) market report offers a detailed analysis of the latest industry developments and trending factors in the market that are influencing the market growth. Furthermore, this statistical market research repository examines and estimates the Ethylene Propylene Diene Monomer (EPDM) market at the global and regional levels.

Market Overview

Ethylene Propylene Diene Monomer (EPDM) is a synthetic material obtained from natural gas and thermal cracking petroleum products such as naphtha. EPDM is widely used in low-slope buildings, automotive applications, and construction applications due to their longer durability and superior resistance to environmental factors such as UV, ozone, and other weather condition. In recent times, the EPDM witnessed significant demand due to its increasing demand from the automotive industry, manufacturing & construction industry attributed to its lower cost, higher moldability, and longer durability. Also, the EPDM could be used as an alternative to silicon rubber and could also be incorporated in the hose, O-ring, accumulator bladder, diaphragms, and connectors for wire & cables among many other applications on the account of their higher resistance towards tearing, abrasive, solvent, and temperature.

Factors such as technological advancement coupled with the growing number of industries and manufacturing units along with the new product launches in the market are some of the prominent factors that are positively influencing the market growth globally.

Some of the major players operating in the market include DowDuPont Inc., Exxon Mobil Corporation, Lion Elastomers, Johns Manville, SK Global Chemical Co. Ltd, Lanxess AG, Mitsui Chemical Inc., PetroChina Company Limited, Kumho Polychem, and Versalis S.p.A.

COVID-19 Impact

The recent covid-19 pandemic has disrupted the world and has brought a state of shock to the global economy. The global pandemic has impacted the manufacturing industry along with supply chain disruption, regulatory and policy changes, labor reliance, working capital management, and liquidity & solvency management. The Ethylene Propylene Diene Monomer (EPDM) market has been significantly affected during these times owing to the gap between supply and demand.

The global Ethylene Propylene Diene Monomer (EPDM) market report is studied thoroughly with several aspects that would help stakeholders in making their decisions more curated.

Based on application, the market is segmented into building & construction, automotive, plastic modification, military & defense, wire & cable, lubricant additive, and others. The automotive industry is expected to witness significant CAGR during the forecast period owing to the increasing automotive vehicle sale coupled with the adoption of EPDM-based products in the vehicle such as rear lamp gaskets, tire sidewalls, front & rear bumper, and inner tire tubes among others. Also, the EPDM-based material has excellent barriers against the road surface, engine vibration, and resistance against the weather such as UV light, acid rain, as well as atmospheric pollution and is expected to support the market growth in the coming time.

Based on the manufacturing process, the market is segmented into solution polymerization process, slurry/suspension process, and gas phase polymerization. The solution polymerization segment is expected to witness significant growth during the forecast period due to the higher concentration and lower required amount for the optimized performance. Additionally, solution polymerization is used to manufacture both crystalline and amorphous polymer grades and is expected to support market growth.

Ethylene Propylene Diene Monomer (EPDM) Market Geographical Segmentation Includes:

North America (United States, Canada, and Rest of North America)

Europe (Germany, United Kingdom, Spain, Italy, France, and the Rest of Europe)

Asia-Pacific (China, Japan, India, and the Rest of Asia-Pacific)

Rest of the World

Asia-Pacific is anticipated to grow at a substantial CAGR during the forecast period. This is mainly due to the rapid industrialization and growing automotive industries along with the electronic & electrical industry, consumer goods industry, and medical sector in the region. Also, the ongoing infrastructural projects and increasing disposable income of the individual are expected to support market growth in the coming time. Furthermore, EPDM has also been used as a substitute for thermoplastic olefins and thermoplastic vulcanizate in the manufacturing industry. Also, the lower cost of the raw material coupled with the lower cost of production associated with the lower labor cost propels the market for the EPDM. Moreover, the growing research & development activities, increasing investment, and technological investment are expected to derive the market in the coming time. For instance, in March 2022, Arlanxeo a Netherland-based firm announced to increase in its production capacity by 15% for its EPDM plant based in Changzhou, China.

The major players targeting the market include:

DowDuPont Inc.

Exxon Mobil Corporation

Lion Elastomers

Johns Manville

SK Global Chemical Co. Ltd

Lanxess AG

Mitsui Chemical Inc.

PetroChina Company Limited

Kumho Polychem

Versalis S.p.A.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=31683

Competitive Landscape

The degree of competition among prominent global companies has been elaborated by analyzing several leading key players operating worldwide. The specialist team of research analysts sheds light on various traits such as global market competition, market share, most recent industry advancements, innovative product launches, partnerships, mergers, or acquisitions by leading companies in the Ethylene Propylene Diene Monomer (EPDM) market. The major players have been analyzed by using research methodologies for getting insight views on global competition.

Key questions resolved through this analytical market research report include:

• What are the latest trends, new patterns, and technological advancements in the Ethylene Propylene Diene Monomer (EPDM) market?

• Which factors are influencing the Ethylene Propylene Diene Monomer (EPDM) market over the forecast period?

• What are the global challenges, threats, and risks in the Ethylene Propylene Diene Monomer (EPDM) market?

• Which factors are propelling and restraining the Ethylene Propylene Diene Monomer (EPDM) market?

• What are the demanding global regions of the Ethylene Propylene Diene Monomer (EPDM) market?

• What will be the global market size in the upcoming years?

• What are the crucial market acquisition strategies and policies applied by global companies?

We understand the requirement of different businesses, regions, and countries, we offer customized reports as per your requirements of business nature and geography. Please let us know If you have any custom needs.

Browse Related Newsletter from UnivDatos Market Insights

Titanium Dioxide Market - SWOT Analysis [2023-2028]

Recycled Carbon Fiber Market - SWOT Analysis [2023-2028]

About Us:

UnivDatos Market Insights: Your Partner in Data-Driven Market Strategies. Unlock growth opportunities and make smart decisions with our expert research and insights.