#Silica Ramming Mixes

Explore tagged Tumblr posts

Text

Best Ramming Mass Manufactures in Rajasthan, India

Rajasthan, India, renowned for its rich mineral resources, stands as a hub for high-quality industrial materials. Among the many thriving industries, the ramming mass manufacturing sector has witnessed significant growth, with companies like Raj Global Ramming Mass leading the charge.

Raj Global Ramming Mass, based in Rajasthan, has established itself as a frontrunner in the production of superior-grade ramming mass, catering to the diverse needs of various industries. With a rich legacy spanning over two decades, the company has continually upheld its commitment to excellence, garnering trust and acclaim from clients worldwide.

This leading manufacturer distinguishes itself through its unwavering focus on product quality and consistency. Raj Global Ramming Mass boasts state-of-the-art manufacturing facilities equipped with cutting-edge technology and a team of skilled professionals dedicated to producing ramming mass of unparalleled quality. The company's stringent quality control measures ensure that each batch of ramming mass adheres to the highest industry standards, guaranteeing optimal performance and durability.

Raj Global Ramming Mass has built a sterling reputation for delivering tailored solutions to meet the specific requirements of diverse industries, including steel, cement, and foundries. The company's product portfolio encompasses a wide range of ramming masses, tailored to withstand high temperatures and harsh industrial environments, thus enhancing the longevity and efficiency of industrial furnaces and kilns.

Beyond its exceptional product line, Raj Global Ramming Mass prides itself on its commitment to customer satisfaction. The company places a strong emphasis on building lasting relationships with clients by providing exceptional pre- and post-sales support, prompt delivery services, and customized solutions tailored to meet unique customer needs.

As a leading ramming mass manufacturer in Rajasthan, Raj Global Ramming Mass continues to set new benchmarks for excellence in the industry. With a customer-centric approach, unwavering commitment to quality, and a dynamic vision for the future, the company remains a trailblazer in the realm of ramming mass manufacturing, solidifying its position as a trusted partner for industries seeking reliable and high-performance refractory solutions.

#White Ramming Mass Manufacturer#Premixed Ramming Mass Supplier#SILICA RAMMING MASS#White Premix Ramming Mass#ACIDIC RAMMING MASS#ramming mass#Quartz Ramming Mass#Silica Ramming Mixes

1 note

·

View note

Text

Dry Ramming Mass Market worth $3.2 billion by 2028

The report "Dry Ramming Mass Market by Type (Alumina Ramming Mass, Silica Ramming Mass, Magnesia Based Ramming Mass), Application (Foundries, Steel, Electric Arc Furnace, Blast Furnace, Non-Steel), Function, and Region - Global Forecast to 2028", is projected to reach USD 3.2 billion by 2028, at a CAGR of 6.8% from USD 2.3 billion in 2023.

The growth of the dry ramming mass market is primarily driven by global expansion of the steel industry, enhanced cost and operational efficiency coupled with ongoing technological advancements in dry ramming mass, further contributing to its expansion. Dry ramming mass is a refractory material used in the lining of induction furnaces, ladles, and other high-temperature applications. It is a mix of refractory aggregates and binders.

Download pdf-https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=252792065

“Steel by application is projected to be the largest, in terms of value, during the forecast period.”

In the steel industry, dry ramming mass plays a crucial role. It finds diverse applications in various steelmaking processes, including lining ladles for the transportation and pouring of molten steel, constructing covers for ladles to retain heat during transportation, lining tundishes for the temporary holding and distribution of molten metal during continuous casting, and providing refractory lining in reheat furnaces used to bring steel ingots or slabs to desired temperatures. Additionally, dry ramming mass is utilized in the lining of steel crucibles for smaller-scale alloy production, in pouring channels and troughs to guide molten steel from furnaces to molds, ensuring a controlled and smooth flow during casting processes. Furthermore, it contributes to the thermal stability and wear resistance of mixer furnaces employed in blending different grades of steel or alloys. The versatility of dry ramming mass makes it an integral component in enhancing the efficiency, durability, and quality of various steel manufacturing applications.

“Alumina ramming mass by type is projected to be the largest, in terms of value, during the forecast period.”

Alumina ramming mass stands out as a preferred choice in specific applications owing to its distinctive properties that confer several advantages over silica and magnesia-based ramming masses. Comprising primarily high-alumina aggregates, often exceeding 80% alumina content, it ensures excellent refractoriness and resistance to high temperatures. Notably, its commendable thermal shock resistance proves crucial in environments characterized by rapid temperature fluctuations, as commonly encountered in metal melting and casting processes. Well-suited for non-ferrous metal applications, particularly in the melting and holding of metals like aluminum and its alloys, alumina ramming mass boasts chemical inertness, preventing undesirable reactions with molten metals or slags and thereby ensuring the stability of the lining. The material's versatility extends to various non-ferrous metal melting processes, underlining its adaptability to diverse industrial applications. Further enhancing its utility, alumina ramming mass exhibits notable abrasion resistance, contributing to the longevity and durability of refractory linings within furnaces. The adaptability of alumina ramming mass to different furnace designs and operating conditions adds a layer of flexibility to its application, making it a versatile and reliable choice across a spectrum of industrial settings.

“Lining by function is projected to be the largest, in terms of value, during the forecast period.”

Refractory materials play a pivotal role in various industrial facets, primarily during the initial construction and installation of furnaces, kilns, and industrial equipment. The demand for extensive refractory linings in new facilities arises from the necessity to withstand elevated temperatures, corrosive environments, and mechanical stresses. Capitalizing on the long lifecycles of furnaces and industrial equipment, refractory linings endure for extended periods before necessitating significant repairs or replacements, fostering a continuous demand for lining materials. Industries prioritize preventive maintenance to proactively extend equipment lifespan, exemplified by regular inspections and repairs of refractory linings to avert costly downtime, ensuring efficient and safe operations. The critical role of refractory linings in preserving the integrity of industrial processes, and shielding against high temperatures, chemical reactions, and mechanical wear, maintains a consistent need for high-quality refractory materials in lining furnaces and various processing units. Their widespread applications across diverse industries such as steel, cement, glass, non-ferrous metals, and petrochemicals contribute to a substantial market for lining materials. Moreover, the construction of new facilities and the expansion of existing ones, propelled by global industrialization and development projects, propel the demand for refractory materials for lining applications. Continuous advancements in refractory technology, marked by the development of high-performance and specialized lining materials, further contribute to the sustained demand across various industries.

Sample Request- https://www.marketsandmarkets.com/requestsampleNew.asp?id=252792065

“Asia Pacific is expected to be the fastest growing market for dry ramming mass during the forecast period, in terms of value.”

The Asia Pacific region has become a focal point for the increased demand in refractory materials, particularly dry ramming mass, owing to a confluence of factors. Rapid industrialization in countries such as China, India, Japan, Thailand, Vietnam, Malaysia and Indonesia has spurred growth in steel, non-ferrous metals, and foundry industries, amplifying the need for reliable refractory solutions. China, as the world's largest steel producer, stands out as a major consumer of refractories, significantly driving the demand for dry ramming mass. The region's extensive construction and infrastructure projects, coupled with the establishment of new industrial facilities, further contribute to the escalating demand for refractory materials. Diverse manufacturing activities encompassing automotive, electronics, and heavy machinery production in the region intensify the reliance on furnaces and high-temperature equipment, necessitating steadfast refractory linings. The rise in non-ferrous metal production, including aluminum, copper, and zinc, underscores the critical role of dry ramming mass in the construction and maintenance of furnaces for these expanding industries. The energy and petrochemical sectors in countries like China and India are on the ascent, demanding refractory materials for furnaces and reactors, fostering sustained growth. Government initiatives supporting industrial growth and infrastructure development, coupled with a competitive manufacturing landscape featuring numerous refractory material suppliers, contribute to the robust market for dry ramming mass. Moreover, technological advancements in manufacturing processes enhance the quality and performance of refractory materials, driving the adoption of advanced dry ramming mass products across diverse industrial applications in the region.

Key Players

The key players in this market are Saint-Gobain (France), Dense Refractories Co., Ltd. (China), Imperial World Trade Private Limited (India), Vishva Vishal Refractory Limited (India), Refcast Corporation (India), Henan Xinmi Changxing Refractory Material Co., Ltd. (China), Casco Specialty Products, Inc. (US), Gita Refractories Private Limited (India), Shenghe Refractories (China), RHI Magnesita N.V. (Austria) etc.

0 notes

Text

The Development of Refractory Ramming Mass

The ramming mass refers to ramming (manual or mechanical) method of construction, and hardened in the heating effect is higher than normal temperature under the unshaped refractory materials.

By refractory aggregate, with certain gradation of powder, binder, additive water or other liquid after mixing.According to the material classification with high alumina, clay, magnesite, dolomite, zirconium and silicon carbide carbon refractory ramming material.

Refractory Ramming Mass Function:

ramming material is made of silicon carbide, graphite, electric calcined anthracite as raw material, mixed with a variety of ultra-fine powder additives, fused cement or composite resin as the binder made of bulk cement.To fill the gap or stack cooling equipment and masonry masonry filler.

Refractory Ramming Mass Types:

The leveling layer with acidic, neutral and alkaline ramming material widely used in intermediate frequency coreless furnace core induction furnace, as if furnace ramming material used for melting aluminum and its alloys, melting of copper, brass, copper and bronze and copper alloy etc.

The carbon ramming mass as an example: according to the different type of blast furnace and the material design requirements of different carbon ramming material is mainly used for blast furnace carbon brick and bottom sealing gaps between plates and carbon bricks and the cooling wall, and filling the furnace bottom water cooling tube over the central line of the leveling and cooling wall, all parts are required by ramming carbon ramming after ramming mass has a certain strength and density, and filled every corner of a small gap, to achieve no leakage of hot metal and gas demand,Classification and construction: all ceramic ramming material consisting of material is divided into: clay, high alumina, carbon, magnesium and dolomite.

Refractory Ramming Mass Advantages:

High erosion resistance.

High bonding strength.

Short lead time.

Free engineering services to guarantee service life.

Ramming mass is used in various industrial places for manufacturing of many refractory materials. It is prepared with great precision using modern techniques and quality materials. Corrosion resistant with a high level of thermal stability, it offers maximum output and last longer. It can be used in lining of iron, lining the trough of blast furnaces, lining of induction furnaces, used as insulation for rapid drying. Also, available in a premixed form allows lesser wastage, consistent and longer lining and patching life. Ramming mass is prepared using quality components and other raw material as per the industrial set standards and norms with great precision. The even and regular granule of the powder are appreciated by the clientele.

Neutral Ramming Mass VS Silica Linings

Silica ramming mass can safely be used up to an operating temperature of 1600 deg C. Since it expands very little, it is superior to both alumina and magnesia refractories to resist thermal shocks. Though silica lining has good endurance against thermal shock, it has poor resistance against steelmaking slags. Temperature control is very necessary for a satisfactory lining life.

The addition of right quantity of boric acid is very important for optimum life of lining.

The quantity depends upon (i) temperature of liquid metal bath, (ii) chemical composition of quartzite mass, and (iii) thickness of crucible wall.

Silica linings are the conventional lining solution widely used in both ferrous and non-ferrous foundries. Mainly made of crystalline silica and commonly known as acidic ramming mass, the typical binding agents that aid in the sintering of silica linings are boron-based. This refractory lining exhibits mainly low thermal expansion and have excellent thermal shock resistance.

Neutral ramming mass are a unique, chemically neutral foundry solution that form joint-less linings. The in-situ spinels synthesise at high temperatures inside the refractory lining, creating a unique 3-layer structure. The outermost layer in contact with the molten metal is a hard, sintered surface, followed by an intermediate fritted layer. The innermost layer stays in a powdery form.

Neutral ramming mass

Lining wear and the causes of wear

The lining life of induction furnace lined with silica ramming mass depends upon the lining practice and operating practice of the furnace besides quality of the silica ramming mass. It is quite common to get inconsistent lining life of the furnace. There are cases when sudden failure of lining takes place.

The main factors which affects the lining life of the induction furnace are

(i) incorrect granulometry of the ramming mass,

(ii) non-uniform distribution of the binding agent,

(iii) superheating of the metal bath in the furnace,

(iv) penetration of metal,

(v) minimum slag free metal resulting in minimum erosion at slag line,

(vi) loss of refractory powder, and (vii) topping/lining interface cracking

For the proper failure analysis in case of pre-mature failure of the refractory lining, it is important that proper records about output, working temperature, and other parameters are maintained. These records not only help in finding the cause of failure but also help in the continuous performance of the lining life.

Article Source: The Development of Refractory Ramming Mass Company name: Henan Changxing Refractory Materials Co.,Ltd More refractory products:https://www.cxrefractories.com/en-all-refractory-products Email:[email protected] Website:https://www.cxrefractories.com

0 notes

Text

How Shivam Minerals is Revolutionizing the Ramming Mass Industry

Introduction: In an ever-growing competitive market, it is essential for companies to stay ahead of the game. At Shivam Minerals, we have taken on that challenge head-on and are continually innovating to meet rising customer demands. We are able to provide superior quality products and prompt service to our customers, thanks to the various channels of distribution we have rationalized. Read on to learn more about how we’re revolutionizing the ramming mass industry!

High-Quality Exports

Shivam Minerals is one of a few companies in India that exports high-quality Ramming Mass. Our expertise in export loading has been developed over time, along with an infrastructure that supports this process. Furthermore, our close proximity to ports such as Kandla and Mundra gives us an additional advantage when it comes to exporting our product.

Wide Range of Products

We offer a wide range of products at Shivam Minerals – from packed ramming mass and silica ramming mixes, all the way up to silica ramming mass. Regardless of what product you need, you can count on us for high-quality products tailored exactly according to your needs!

Continuous Innovation

At Shivam Minerals, we understand that it is important for us to stay ahead of the competition by continuously innovating in all aspects of our business – from manufacturing processes and product quality, all the way up to customer service and delivery times. Our commitment to innovation helps us in meeting rising customer demands even better than before!

Conclusion:

In conclusion, Shivam Minerals is committed to revolutionizing the ramming mass industry by staying ahead of customer expectations through ongoing innovation in key areas such as product quality, customer service, and delivery times. With extensive experience exporting high-quality products and close proximity to ports such as Kandla and Mundra, Shivam Minerals provides customers with superior quality products tailored exactly according to their needs – no matter what they may be! If you are looking for a reliable partner who can provide you with top-notch products in short turnaround times – look no further than Shivam Minerals!

#packedrammingmass #silicarammingmixes #silicarammingmass

0 notes

Text

Coping With Eczema - Hemp Seed Oil Will Hydrate Eczema

When you've got a good cleansing shampoo, massage the scalp with it for 2 mins and then leave the shampoo against your own head for minutes more to you should are capturing the layers and dissolving the hardened debris. Plant foods, Canopy CBD especially certain oils, give Omega additional. These include flaxseed oil, soybean oil, and "Cannabidiol Oil". These oils also contain Omega 6 in a sizable ratio to Omega 3's. "cannabidiol oil" provides the ratio of Omega 3 and Omega 6. Flaxseed contains ALA a long chain fatty acid. ALA breaks on to DHA and EPA within blood steady stream.

youtube

Old individuals with an average age of seventy five ate blueberries for twelve weeks and managed to do better with two tests on good old ram. Eating two even a half glasses of blueberries a day, involved with believed that blueberries advice about age related mind affairs. It is suggested from product sales that the nerve cells become insulated. Blueberries have a lot of antioxidants that oxidation has trouble initializing. It turns out that the nerve cells have a nature made weakness of oxidation so antioxidant dish is always essential. The cells work by using oxygen to mail message throughout body, nevertheless the oxygen can overflow without antioxidants in order to them. Erectile dysfunction can be damaging to some man's sexual life and self esteem, so men usually seek ways to treat their sexual problems with prescription medicine (like Viagra) since the time so much in what is the news but they overlook an easy fact - taking Viagra is a short-term formula. Once the harmful chemicals each morning drug wear out, you lose your erection imagine is back to square one once when. You can get addicted to Viagra prefer a heroin abuser gets addicted to heroine. There are wide ranging things undertake it ! do to bring back your esophageal health. For instance, getting teaspoon of honey previous to you go to bed is often a great start off off. Honey will naturally heal all associated with tissue, including skin, the actual a natural 'miracle' "Cannabidiol" in sweetie. The particles in silica gel are impressive at absorbing impurities while excess oil/sebum and unhealthy bacteria. It also has a cooling effect which acts to calm the skin and reduce inflammation. Silica gel has been seen to help rid the skin of pustules/whiteheads, clogged pores and Canopy CBD Review CBD Hemp Oil blackheads. Water is recommended in any detox plan. Different people have different good words. Some suggest that you squeeze several fresh lemons on the glass, mix with water and drink that each morning. Others suggest that you utilize it different green along with other herbal tea. My recommendation is that you possess an eight ounce glass collectively meal an individual also drink another eight ounces every hour or so, throughout the day. If you drink out ounces and you don't require to relieve yourself within 20 minutes, you are not drinking enough.

1 note

·

View note

Text

The Environmental Impacts of Products (Laptops)

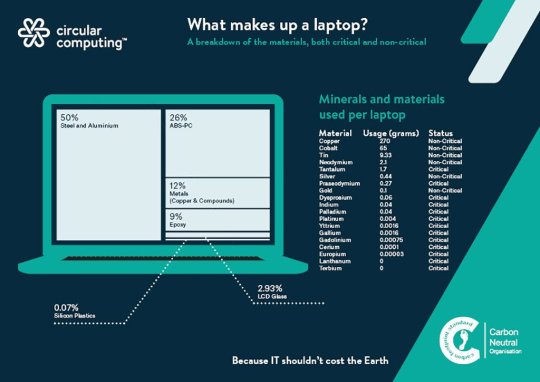

Raw materials used in laptops

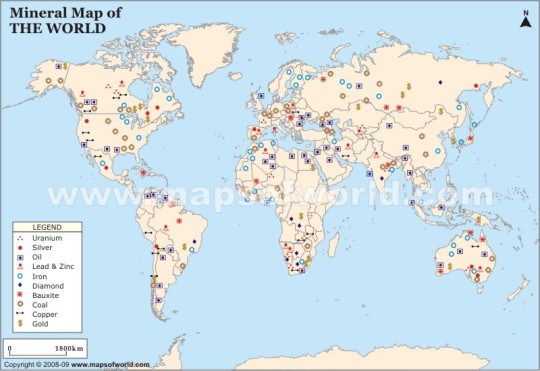

Laptops or even any electronic device are made of different materials. For laptops, most of its components are made of various metals, silicon, and plastic, especially PC/ABS. The raw resources of these materials are primarily extracted from the Earth's surface via mining or drilling. The metals used for electronics are commonly copper, gold, iron, tin, lead, cobalt, and small traces of rarer metals. Mining and refining these metals do affect our environment. Mining causes soil erosion, contamination, destruction of terrain, and loss of floral life which could have been habitats. The process of mining also requires a large amount of water for filtering ores and this water is normally returned to the same source. Mining also releases particles into the air which affects the nearby population. Refining metals to their pure form creates harmful wastewater since the process uses acids and other chemical substances, this waste is even sometimes radioactive. In US most mining sites are located in western states, Missouri, and Tennessee. Silicon is another important element for making electronics, it is a semiconductor that could easily be altered depending on the purpose. It is an abundant element after oxygen and could be found anywhere, however, normally compounded with another element, thus it is impure. The solution is mining quartz which is 90% silicon, a similar process to metal mining is used to extract these crystals. These crystals are also refined similarly to steel, melting it down and separating residues to get a purity close to 100% for maximum efficiency. Surface quarries can be found in Norway. The plastic used for most chassis of laptops and electronic devices is made of thermoplastics such as PC/ABS. Polycarbonate (PC) and acrylonitrile-butadiene-styrene (ABS), are two plastics with different properties mixed to create a material that is durable and heat resistant. The production involves heavy use of chemicals and mechanical processes. The raw or organic resources that these plastics use are oil-based, usually broken down from petroleum or crude oil. And these oil products come from drilling on land and sea, which puts nearby ecosystems at risk of oil spills from pipelines or transportation. Oil can contaminate soil and water and is highly flammable; it could sit on top of water or land which blocks sunlight needs of nutrient cycles. The common issue with most of the production is its high energy use, energy could be generated in various ways, but it was likely generated by carbon-emitting powerplants.

The image above shows mineral deposits globally.

For laptop brands the raw materials for components are imported from suppliers that handle the acquisition, processing, and refinement; these suppliers are spread all over the world, and suppliers change depending on cost. The materials are shipped to Original Design Manufacturers (ODM) that are mostly in China or Taiwan, they make the components such as RAM, CPU, GPU, HDD, etc... These components are then shipped again to assembly lines which are also spread throughout the world. The most local ingredient in the entire process would likely be Silica since Wisconsin has its own deposit, yet it goes around various places before getting back as a final product. At the end of the device's lifetime, it becomes E-Waste, which could be recycled to create new electronics, yet the process can also be harmful and costly. Without proper recycling equipment, individuals can be exposed to lead, cadmium, and chromium which could cause cancer. Some extraction methods are primitive such as burning E-waste to leave only metals that add to carbon emissions.

Laptop E-Waste

So, I suggest keeping your device longer, repairing it, and buying only when completely broken.

References:

Raw Materials In A Laptop - Circular Computing™

9.5 Environmental Impacts of Metallic Mineral Mining – Dynamic Planet: Exploring Geological Disasters and Environmental Change (maricopa.edu)

Environmental Cost of Refineries (mit.edu)

Precious Metal Removal from Electronic Components (conceptmanagement.co.uk)

Metal Mining | US EPA

What is silicon, and why are computer chips made from it? - ExtremeTech

Silicon: mining and processing | Britannica

PC/ABS Resin | Polycarbonate ABS Blend - by Polymer Resources (prlresins.com)

PC-ABS: Polycarbonate Material Properties | Fast Radius

Thermoplastic - Wikipedia

Crude Oil Exports by Country 2021 (worldstopexports.com)

Oil and the environment - U.S. Energy Information Administration (EIA)

List of laptop brands and manufacturers - Wikipedia

How e-waste is harming our world - YouTube

0 notes

Text

refractory brick

Changxing Refractory product portfolio covers shaped products such as refractory brick, refractory nozzle, ceramic fiber products, calcium silicate products, slide gate, etc; unshaped products including repair, construction and casting mixes and mortars, such as silica(acidic) ramming mass, magnesia(basic) ramming mass, alumina ramming mix. Changxing Refractory products have been exported to more…

View On WordPress

0 notes

Text

Information and Applications of Ceramics Products

Ceramics, pronounced suh RAM ihks, are one of the three most important types of engineering materials that are primarily synthetic. The other two are metals and plastics. Ceramics include such everyday materials as brick, cement, glass, and porcelain. They also include unusual materials used in electronics and spacecraft. Most ceramics are hard and can withstand heat and chemicals. These properties give them a variety of uses in industry. Artists also create ceramics. This article discusses the use of ceramics in industry.

Properties of Ceramics:

Manufacturers of Ceramic Products make common ceramics from such minerals as clay, feldspar, silica, and talc. These minerals, called silicates, form most of the earth's crust. Clay is an important silicate. But it is not used in all ceramic materials. Glass, for example, is made from sand. Chemists make materials called advanced ceramics in the laboratory from compounds other than silicates. These compounds include alumina, silicon carbide, and barium titanate.

Most ceramic products, like their mineral ingredients, can withstand acids, gases, salts, water, and high temperatures. But not all ceramic products have the same properties. Common ceramics are good insulators--that is, they conduct electricity poorly. However, certain ceramics lose their electrical resistance and become superconductors when they are cooled. Some ceramic materials are magnetic. Engineers control the properties of ceramics by controlling the proportion and type of materials used in Ceramic Tower Packing company.

Kinds of ceramic products:

The properties of ceramics make them especially suitable for certain products. Products made of ceramic materials include abrasives (materials used for grinding), construction materials, dinnerware, electrical equipment, glass products, and refractories (heat-resistant materials).

Abrasives: Manufacturers use some extremely hard ceramic materials for cutting metals and for grinding, polishing, and sanding various surfaces. These Ceramic materials include alumina and silicon carbide.

Construction materials: Clay and shale are used in making strong, durable bricks and drain pipes for homes and other buildings. Tiles are made of clay and talc. Cement consists chiefly of calcium silicates and is used primarily in making concrete. Gypsum is used to produce plaster for the surfaces of walls and ceilings. Bathtubs, sinks, and toilets are made of porcelain, which consists chiefly of clay, feldspar, and quartz.

Dinnerware: Ceramics make excellent containers for food and drinks. They do not absorb liquids, and they resist acids, salts, detergents, and changes in temperature. Most ceramic dinnerware is made from a mixture of clays, feldspar, and quartz.

Making ceramics.

The clays and other minerals used in ceramics are dug from the earth and refined to improve their purity. Machines crush and grind the materials into fine particles. The particles are mixed in the proper proportion, and water or other liquid is added to produce a mixture that can be shaped. A gluelike substance is sometimes added to mixtures that do not contain clay. Glass and some refractory products are made by melting the particles and shaping them when they are molten.

For More Information

Website - https://www.mbctower.in/

Call - +91-8827697111, +91-9425105256

Mail - [email protected]

#Ceramic Tower Packing Company#Ceramic Ultra manufacturers#Ceramic Tower Packing Exporters#Ceramic Saddles Suppliers#Inert Ceramic Ball Suppliers#Ceramic Tower Packing Suppliers#Ceramic Honeycomb manufacturers

0 notes

Text

Rs 108 to Rs 750: This stock turned into a multibagger in three years

An amount of Rs 1 lakh invested in the micro cap stock three years ago would have turned into Rs 6.94 lakh today.

Stock of Raghav Productivity Enhancers has delivered 594% returns to shareholders in the last three years. The microcap share, which closed at Rs 108 on December 14, 2018 rose to Rs 749.95 on BSE today. An amount of Rs 1 lakh invested in Raghav Productivity Enhancers stock three years ago would have turned into Rs 6.94 lakh today. In comparison, Sensex has surged 61.49% during the period.

During the current session, Raghav Productivity Enhancers stock hit upper circuit of 5% in afternoon trade. The stock rose 5% to Rs 749.95 against the previous close of Rs 714.25 on BSE. It opened lower at Rs 700 today.

The share trades higher than 5 day, 20 day, 50 day and 200 day moving averages but lower than 100 day moving averages. The stock has gained after three days of consecutive fall. Market cap of the firm rose to Rs 815.67 crore.

Total 2,447 shares changed hands amounting to a turnover of Rs 18.03 lakh on BSE. The stock has gained 210% since the beginning of this year and risen 260% in one year.

The firm has outperformed its peers in terms of stock market returns during the last three years.

While share of Tata Steel has gained 124.96%, JSW Steel stock has risen 124.37% in three years.

Another player in the industry SAIL's stock climbed 122.93% in one year and Jindal Steel share could manage decent gains of 151.6% for its shareholders during the period under consideration.

The stellar performance of the stock is in line with the financials of the firm.

Profit in the September quarter rose 139.47% to Rs 4.55 crore against Rs 1.90 crore net profit in the corresponding period of last fiscal. Sales climbed 60.27% to Rs 23.88 crore in Q2 against Rs 14.90 crore sales in the corresponding quarter of last fiscal.

During the last four fiscals, profit has risen steadily to Rs 9.19 crore in March 2021 fiscal from Rs 5.87 crore for the fiscal ended March 2018.

During the last fiscal, the firm reported profit of Rs 9.19 crore against Rs 9.44 crore profit in the previous fiscal.

For fiscal ended March 2019, profit stood at Rs 8.05 crore against Rs 5.87 crore profit for the fiscal ended March 2018.

Promoters held 69.61% stake in the firm at the end of September quarter. Public shareholders owned 30.39% stake in the firm during the same period. Seven promoters held 69.61 per cent stake in the firm and public shareholders owned 30.39 per cent at the end of September quarter.

6,376 public shareholders owned 33.05 lakh shares of the firm. Of these, 6,155 shareholders held 8.39% stake with capital up to Rs 2 lakh.

Only 19 shareholders with 13.47% stake held capital above Rs 2 lakh at the end of September quarter.

The Jaipur-based firm is engaged in offering ramming mass mineral and operates as a stone supplier. The company manufactures and exports ferro alloys, ramming mass, silica ramming mixes, and pig iron.

0 notes

Text

The Ultra-Pure, Super-Secret Sand That Makes Your Phone Possible

Vince Beiser, Wired, Aug. 6, 2018

FRESH FROM CHURCH on a cool, overcast Sunday morning in Spruce Pine, North Carolina, Alex Glover slides onto the plastic bench of a McDonald’s booth. He rummages through his knapsack, then pulls out a plastic sandwich bag full of white powder. “I hope we don’t get arrested,” he says. “Someone might get the wrong idea.”

GLOVER IS A recently retired geologist who has spent decades hunting for valuable minerals in the hillsides and hollows of the Appalachian Mountains that surround this tiny town. He is a small, rounded man with little oval glasses, a neat white mustache, and matching hair clamped under a Jeep baseball cap. He speaks with a medium-strength drawl that emphasizes the first syllable and stretches some vowels, such that we’re drinking CAWWfee as he explains why this remote area is so tremendously important to the rest of the world.

Spruce Pine is not a wealthy place. Its downtown consists of a somnambulant train station across the street from a couple of blocks of two-story brick buildings, including a long-closed movie theater and several empty storefronts.

The wooded mountains surrounding it, though, are rich in all kinds of desirable rocks, some valued for their industrial uses, some for their pure prettiness. But it’s the mineral in Glover’s bag--snowy white grains, soft as powdered sugar--that is by far the most important these days. It’s quartz, but not just any quartz. Spruce Pine, it turns out, is the source of the purest natural quartz--a species of pristine sand--ever found on Earth. This ultra-elite deposit of silicon dioxide particles plays a key role in manufacturing the silicon used to make computer chips. In fact, there’s an excellent chance the chip that makes your laptop or cell phone work was made using sand from this obscure Appalachian backwater. “It’s a billion-dollar industry here,” Glover says with a hooting laugh. “Can’t tell by driving through here. You’d never know it.”

In the 21st century, sand has become more important than ever, and in more ways than ever. This is the digital age, in which the jobs we work at, the entertainment we divert ourselves with, and the ways we communicate with one another are increasingly defined by the internet and the computers, tablets, and cell phones that connect us to it. None of this would be possible were it not for sand.

Most of the world’s sand grains are composed of quartz, which is a form of silicon dioxide, also known as silica. High-purity silicon dioxide particles are the essential raw materials from which we make computer chips, fiber-optic cables, and other high-tech hardware--the physical components on which the virtual world runs. The quantity of quartz used for these products is minuscule compared to the mountains of it used for concrete or land reclamation. But its impact is immeasurable.

Spruce Pine’s mineralogical wealth is a result of the area’s unique geologic history and the deposits of what are known as pegmatites. Generally speaking, these pegmatites are about 65 percent feldspar, 25 percent quartz, 8 percent mica, and the rest traces of other minerals, and they lie near the surface.

Native Americans mined the shiny, glittering mica and used it for grave decorations and as currency. American settlers began trickling into the mountains in the 1800s, scratching out a living as farmers. A few prospectors tried their hands at the mica business, but were stymied by the steep mountain geography. “There were no rivers, no roads, no trains. They had to haul the stuff out on horseback,” says David Biddix, a scruffy-haired amateur historian who has written three books about Mitchell County, where Spruce Pine sits.

The region’s prospects started to improve in 1903 when the South and Western Railroad company, in the course of building a line from Kentucky to South Carolina, carved a track up into the mountains, a serpentine marvel that loops back and forth for 20 miles to ascend just 1,000 feet. Once this artery to the outside world was finally opened, mining started to pick up. Locals and wildcatters dug hundreds of shafts and open pits in the mountains of what became known as the Spruce Pine Mining District, a swath of land 25 miles by 10 miles that sprawls over three counties.

Mica used to be prized for wood- and coal-burning stove windows and for electrical insulation in vacuum tube electronics. It’s now used mostly as a specialty additive in cosmetics and things like caulks, sealants, and drywall joint compound. During World War II, demand for mica and feldspar, which are found in tremendous abundance in the area’s pegmatites, boomed. Prosperity came to Spruce Pine. The town quadrupled in size in the 1940s. At its peak, Spruce Pine boasted three movie theaters, two pool halls, a bowling alley, and plenty of restaurants. Three passenger trains came through every day.

Toward the end of the decade, the Tennessee Valley Authority sent a team of scientists to Spruce Pine tasked with further developing the area’s mineral resources. They focused on the money-makers, mica and feldspar. The problem was separating those minerals from the other ones. A typical chunk of Spruce Pine pegmatite looks like a piece of strange but enticing hard candy: mostly milky white or pink feldspar, inset with shiny mica, studded with clear or smoky quartz, and flecked here and there with bits of deep red garnet and other-colored minerals.

For years, locals would simply dig up the pegmatites and crush them with hand tools or crude machines, separating out the feldspar and mica by hand. The quartz that was left over was considered junk, at best fit to be used as construction sand, more likely thrown out with the other tailings.

Working with researchers at North Carolina State University’s Minerals Research Laboratory in nearby Asheville, the TVA scientists developed a much faster and more efficient method to separate out minerals, called froth flotation. “It revolutionized the industry,” Glover says. “It made it evolve from a mom-and-pop individual industry to a mega-multinational corporation industry.”

Froth flotation involves running the rock through mechanical crushers until it’s broken down into a heap of mixed-mineral granules. You dump that mix in a tank, add water to turn it into a milky slurry, and stir well. Next, add reagents--chemicals that bind to the mica grains and make them hydrophobic, meaning they don’t want to touch water. Now pipe a column of air bubbles through the slurry. Terrified of the water surrounding them, the mica grains will frantically grab hold of the air bubbles and be carried up to the top of the tank, forming a froth on the water’s surface. A paddle wheel skims off the froth and shunts it into another tank, where the water is drained out. Voilà: mica.

The remaining feldspar, quartz, and iron are drained from the bottom of the tank and funneled through a series of troughs into the next tank, where a similar process is performed to float out the iron. Repeat, more or less, to remove the feldspar.

IT WAS THE feldspar, which is used in glassmaking, that first attracted engineers from the Corning Glass Company to the area. At the time, the leftover quartz grains were still seen as just unwanted by-products. But the Corning engineers, always on the lookout for quality material to put to work in the glass factories, noticed the purity of the quartz and started buying it as well, hauling it north by rail to Corning’s facility in Ithaca, New York, where it was turned into everything from windows to bottles.

One of Spruce Pine quartz’s greatest achievements in the glass world came in the 1930s, when Corning won a contract to manufacture the mirror for what was to be the world’s biggest telescope, ordered by the Palomar Observatory in Southern California. Making the 200-inch, 20-ton mirror involved melting mountains of quartz in a giant furnace heated to 2,700 degrees Fahrenheit, writes David O. Woodbury in The Glass Giant of Palomar.

Once the furnace was hot enough, “three crews of men, working day and night around the clock, began ramming in the sand and chemicals through a door at one end. So slowly did the ingredients melt that only four tons a day could be added. Little by little the fiery pool spread over the bottom of the furnace and rose gradually to an incandescent lake 50 feet long and 15 wide.” The telescope was installed in the observatory in 1947. Its unprecedented power led to important discoveries about the composition of stars and the size of the universe itself. It is still in use today.

Significant as that telescope was, Spruce Pine quartz was soon to take on a far more important role as the digital age began to dawn.

In the mid-1950s, thousands of miles from North Carolina, a group of engineers in California began working on an invention that would become the foundation of the computer industry. William Shockley, a pathbreaking engineer at Bell Labs who had helped invent the transistor, had left to set up his own company in Mountain View, California, a sleepy town about an hour south of San Francisco, near where he had grown up. Stanford University was nearby, and General Electric and IBM had facilities in the area, as well as a new company called Hewlett-Packard. But the area known at the time as the Santa Clara Valley was still mostly filled with apricot, pear, and plum orchards. It would soon become much better known by a new nickname: Silicon Valley.

At the time, the transistor market was heating up fast. Texas Instruments, Motorola, and other companies were all competing to come up with smaller, more efficient transistors to use in, among other products, computers. The first American computer, dubbed ENIAC, was developed by the army during World War II; it was 100 feet long and 10 feet high, and it ran on 18,000 vacuum tubes.

Transistors, which are tiny electronic switches that control the flow of electricity, offered a way to replace those tubes and make these new machines even more powerful while shrinking their tumid footprint. Semiconductors--a small class of elements, including germanium and silicon, which conduct electricity at certain temperatures while blocking it at others--looked like promising materials for making those transistors.

At Shockley’s startup, a flock of young PhDs began each morning by firing up kilns to thousands of degrees and melting down germanium and silicon. Tom Wolfe once described the scene in Esquire magazine: “They wore white lab coats, goggles, and work gloves. When they opened the kiln doors weird streaks of orange and white light went across their faces . . . they lowered a small mechanical column into the goo so that crystals formed on the bottom of the column, and they pulled the crystal out and tried to get a grip on it with tweezers, and put it under microscopes and cut it with diamond cutters, among other things, into minute slices, wafers, chips; there were no names in electronics for these tiny forms.”

Shockley became convinced that silicon was the more promising material and shifted his focus accordingly. “Since he already had the first and most famous semiconductor research and manufacturing company, everyone who had been working with germanium stopped and switched to silicon,” writes Joel Shurkin in his biography of Shockley, Broken Genius. “Indeed, without his decision, we would speak of Germanium Valley.”

Shockley was a genius, but by all accounts he was also a lousy boss. Within a couple of years, several of his most talented engineers had jumped ship to start their own company, which they dubbed Fairchild Semiconductor. One of them was Robert Noyce, a laid-back but brilliant engineer, only in his mid-20s but already famous for his expertise with transistors.

The breakthrough came in 1959, when Noyce and his colleagues figured out a way to cram several transistors onto a single fingernail-sized sliver of high-purity silicon. At almost the same time, Texas Instruments developed a similar gadget made from germanium. Noyce’s, though, was more efficient, and it soon dominated the market. NASA selected Fairchild’s microchip for use in the space program, and sales soon shot from almost nothing to $130 million a year. In 1968, Noyce left to found his own company. He called it Intel, and it soon dominated the nascent industry of programmable computer chips.

Intel’s first commercial chip, released in 1971, contained 2,250 transistors. Today’s computer chips are often packed with transistors numbering in the billions. Those tiny electronic squares and rectangles are the brains that run our computers, the Internet, and the entire digital world. Google, Amazon, Apple, Microsoft, the computer systems that underpin the work of everything from the Pentagon to your local bank--all of this and much more is based on sand, remade as silicon chips.

Making those chips is a fiendishly complicated process. They require essentially pure silicon. The slightest impurity can throw their tiny systems out of whack.

Finding silicon is easy. It’s one of the most abundant elements on Earth. It shows up practically everywhere bound together with oxygen to form SiO2, aka quartz. The problem is that it never occurs naturally in pure, elemental form. Separating out the silicon takes considerable doing.

Step one is to take high-purity silica sand, the kind used for glass. (Lump quartz is also sometimes used.) That quartz is then blasted in a powerful electric furnace, creating a chemical reaction that separates out much of the oxygen. That leaves you with what is called silicon metal, which is about 99 percent pure silicon. But that’s not nearly good enough for high-tech uses. Silicon for solar panels has to be 99.999999 percent pure--six 9s after the decimal. Computer chips are even more demanding. Their silicon needs to be 99.99999999999 percent pure--eleven 9s. “We are talking of one lonely atom of something that is not silicon among billions of silicon companions,” writes geologist Michael Welland in Sand: The Never-Ending Story.

Getting there requires treating the silicon metal with a series of complex chemical processes. The first round of these converts the silicon metal into two compounds. One is silicon tetrachloride, which is the primary ingredient used to make the glass cores of optical fibers. The other is trichlorosilane, which is treated further to become polysilicon, an extremely pure form of silicon that will go on to become the key ingredient in solar cells and computer chips.

Each of these steps might be carried out by more than one company, and the price of the material rises sharply at each step. That first-step, 99 percent pure silicon metal goes for about $1 a pound; polysilicon can cost 10 times as much.

The next step is to melt down the polysilicon. But you can’t just throw this exquisitely refined material in a cook pot. If the molten silicon comes into contact with even the tiniest amount of the wrong substance, it causes a ruinous chemical reaction. You need crucibles made from the one substance that has both the strength to withstand the heat required to melt polysilicon, and a molecular composition that won’t infect it. That substance is pure quartz.

THIS IS WHERE Spruce Pine quartz comes in. It’s the world’s primary source of the raw material needed to make the fused-quartz crucibles in which computer-chip-grade polysilicon is melted. A fire in 2008 at one of the main quartz facilities in Spruce Pine for a time all but shut off the supply of high-purity quartz to the world market, sending shivers through the industry.

Today one company dominates production of Spruce Pine quartz. Unimin, an outfit founded in 1970, has gradually bought up Spruce Pine area mines and bought out competitors, until today the company’s North Carolina quartz operations supply most of the world’s high- and ultra-high-purity quartz. (Unimin itself is now a division of a Belgian mining conglomerate, Sibelco.)

In recent years, another company, the imaginatively titled Quartz Corp, has managed to grab a small share of the Spruce Pine market. There are a very few other places around the world producing high-purity quartz, and many other places where companies are looking hard for more. But Unimin controls the bulk of the trade.

The quartz for the crucibles, like the silicon they will produce, needs to be almost absolutely pure, purged as thoroughly as possible of other elements. Spruce Pine quartz is highly pure to begin with, and purer still after being put through several rounds of froth flotation. But some of the grains may still have what Glover calls interstitial crystalline contamination--molecules of other minerals attached to the quartz molecules.

That’s frustratingly common. “I’ve evaluated thousands of quartz samples from all over the world,” says John Schlanz, chief minerals processing engineer at the Minerals Research Laboratory in Asheville, about an hour from Spruce Pine. “Near all of them have contaminate locked in the quartz grains that you can’t get out.”

Some Spruce Pine quartz is flawed in this way. Those grains are used for high-end beach sand and golf course bunkers--most famously the salt-white traps of Augusta National Golf Club, site of the iconic Masters Tournament. A golf course in the oil-drunk United Arab Emirates imported 4,000 tons of this sand in 2008 to make sure its sand traps were world-class, too.

The very best Spruce Pine quartz, however, has an open crystalline structure, which means that hydrofluoric acid can be injected right into the crystal molecules to dissolve any lingering traces of feldspar or iron, taking the purity up another notch. Technicians take it one step further by reacting the quartz with chlorine or hydrochloric acid at high temperatures, then putting it through one or two more trade-secret steps of physical and chemical processing.

The result is what Unimin markets as Iota quartz, the industry standard of purity. The basic Iota quartz is 99.998 percent pure SiO2. It is used to make things like halogen lamps and photovoltaic cells, but it’s not good enough to make those crucibles in which polysilicon is melted. For that you need Iota 6, or the tip-top of the line, Iota 8, which clocks in at 99.9992 percent purity--meaning for every one billion molecules of SiO , there are only 80 molecules of impurities. Iota 8 sells for up to $10,000 a ton. Regular construction sand, at the other end of the sand scale, can be had for a few dollars per ton.

At his house, Glover shows me some Iota under a microscope. Seen through the instrument’s lens (itself made from a much less pure quartz sand), the jagged little shards are as clear as glass and bright as diamonds.

Unimin sells this ultra-high-purity quartz sand to companies like General Electric, which melts it, spins it, and fuses it into what looks like a salad bowl made of milky glass: the crucible. “It’s safe to say the vast majority of those crucibles are made from Spruce Pine quartz,” Schlanz says.

The polysilicon is placed in those quartz crucibles, melted down, and set spinning. Then a silicon seed crystal about the size of a pencil is lowered into it, spinning in the opposite direction. The seed crystal is slowly withdrawn, pulling behind it what is now a single giant silicon crystal. These dark, shiny crystals, weighing about 220 pounds, are called ingots.

The ingots are sliced into thin wafers. Some are sold to solar cell manufacturers. Ingots of the highest purity are polished to mirror smoothness and sold to a chipmaker like Intel. It’s a thriving multi-billion dollar industry in 2012.

The chipmaker imprints patterns of transistors on the wafer using a process called photolithography. Copper is implanted to link those billions of transistors to form integrated circuits. Even a minute particle of dust can ruin the chip’s intricate circuitry, so all of this happens in what’s called a clean room, where purifiers keep the air thousands of times cleaner than a hospital operating room. Technicians dress in an all-covering white uniform affectionately known as a bunny suit. To ensure the wafers don’t get contaminated during manufacture, many of the tools used to move and manipulate them are, like the crucibles, made from high-purity quartz.

The wafers are then cut into tiny, unbelievably thin quadrangular chips--computer chips, the brains inside your mobile phone or laptop. The whole process requires hundreds of precise, carefully controlled steps. The chip that results is easily one of the most complicated man-made objects on Earth, yet made with the most common stuff on Earth: humble sand.

The total amount of high-purity quartz produced worldwide each year is estimated at 30,000 tons--less than the amount of construction sand produced in the United States every hour. (And even construction sand is in high demand; there’s a thriving black market in the stuff.) Only Unimin knows exactly how much Spruce Pine quartz is produced, because it doesn’t publish any production figures. It is an organization famously big on secrecy. “Spruce Pine used to be mom-and-pop operations,” Schlanz says. “When I first worked up there, you could just walk into any of the operations. You could just go across the street and borrow a piece of equipment.”

NOWADAYS UNIMIN WON’T even allow staff of the Minerals Research Laboratory inside the mines or processing facilities. Contractors brought in to do repair work have to sign confidentiality agreements. Whenever possible, vice-president Richard Zielke recently declared in court papers, the company splits up the work among different contractors so that no individual can learn too much.

Unimin buys equipment and parts from multiple vendors for the same reason. Glover has heard of contractors being blindfolded inside the processing plants until they arrive at the specific area where their jobs are and of an employee who was fired on the spot for bringing someone in without authorization. He says the company doesn’t even allow its employees to socialize with those of their competitors.

It was hard to check out Glover’s stories, because Unimin wouldn’t talk to me. Unlike most big corporations, its website lists no contact for a press spokesperson or public relations representative. Several emails to their general inquiries address went unanswered. When I called the company’s headquarters in Connecticut, the woman who answered the phone seemed mystified by the concept of a journalist wanting to ask questions.

She put me on hold for a few minutes, then came back to tell me the company has no PR department, but that if I faxed (faxed!) her my questions, someone might get back to me. Eventually I got in touch with a Unimin executive who asked me to send her my questions by email. I did so. The response: “Unfortunately, we are not in a position to provide answers at this point in time.”

So I tried the direct approach. Like all the quartz mining and processing facilities in the area, Unimin’s Schoolhouse Quartz Plant, set in a valley amid low, thickly treed hills, is surrounded by a barbed-wire-topped fence. Security isn’t exactly at the level of Fort Knox, but the message is clear.

One Saturday morning I go to take a look at the plant with David Biddix. We park across the street from the gate. A sign warns that the area is under video surveillance, and that neither guns nor tobacco are allowed inside. As soon as I hop out to snap a few photos, a matronly woman in a security guard uniform popped out of the gatehouse. “Watcha doin’?” she asks conversationally. I give her my friendliest smile and tell her I am a journalist writing a book about sand, including about the importance of the quartz sand in this very facility. She takes that all in skeptically, and asks me to call Unimin’s local office the following Monday to get permission.

“Sure, I’ll do that,” I say. “I just want to take a look, as long as I’m here.” “Well, please don’t take pictures,” she says. There isn’t much to see--some piles of white sand, a bunch of metal tanks, a redbrick building near the gate--so I agree. She lumbers back inside. I put away my camera and pull out my notebook. That brings her right back out.

“You don’t look like a terrorist”--she laughs apologetically--”but these days you never know. I’m asking you to leave before I get grumpy.”

“I understand,” I say. “I just want to take a few notes. And anyway, this is a public road. I have the right to be here.”

That really displeased her. “I’m doing my job,” she snaps. “I’m doing mine,” I reply.

“All right, I’m taking notes, too,” she declares. “And if anything happens . . .” Leaving the consequences unspecified, she strides over to my rental car and officiously writes down its license plate number, then asks for the name of “my companion” in the passenger seat. I don’t want to get Biddix in any trouble, so I politely decline, hop in, and drive off.

IF YOU REALLY want a sense of how zealously Unimin guards its trade secrets, ask Tom Gallo. He used to work for the company, and then for years had his life ruined by it.

Gallo is a small, lean man in his 50s, originally from New Jersey. He relocated to North Carolina when he was hired by Unimin in 1997. His first day on the job, he was handed a confidentiality agreement; he was surprised at how restrictive it was and didn’t think it was fair. But there he was, way out in Spruce Pine, with all his possessions in a moving truck, his life in New Jersey already left behind. So he signed it.

Gallo worked for Unimin in Spruce Pine for 12 years. When he left, he signed a noncompete agreement that forbade him from working for any of the company’s competitors in the high-purity quartz business for five years. He and his wife moved to Asheville and started up an artisanal pizza business, which they dubbed Gallolea--his last name plus that of a friend who had encouraged him.

It was a rough go. The pizza business was never a big money-maker, and it was soon hit with a lawsuit over its name from the E. & J. Gallo Winery. Gallo spent thousands of dollars fighting the suit--it’s his name, after all--but eventually decided the prudent course would be to give up and change the company’s name. The five-year noncompete term had run out by then, so when a small startup quartz company, I-Minerals, called to offer Gallo a consulting gig, he gladly accepted. I-Minerals put out a press release bragging about the hire and touting Gallo’s expertise.

That turned to be a big mistake. Unimin promptly filed a lawsuit against Gallo and I-Minerals, accusing them of trying to steal Unimin’s secrets. “There was no call, no cease-and-desist order, no investigation,” Gallo says. “They filed a 150-page brief against me on the basis of a press release.”

Over the next several years, Gallo spent tens of thousands of dollars fighting the suit. “That’s how billion-dollar corporations terrify people,” he says. “I had to take money out of my 401(k) to defend myself against this totally baseless lawsuit. We were afraid we would lose our house. It was terrifying. You can’t imagine how many sleepless nights my wife and I have had.” His pizza business collapsed. “When Unimin filed suit, we had just gotten over the Gallo thing. It was the sledgehammer that broke the camel’s back. We’d worked on it for five years. It was more than we could handle emotionally, psychologically, and financially.”

Unimin eventually lost the case, appealed it to federal court, and finally dropped it. I-Minerals and Gallo separately countersued Unimin, calling its suit an abuse of the judicial process aimed at harassing a potential competitor. Unimin eventually agreed to pay an undisclosed sum to have the suits withdrawn. Under the terms of the settlement, Gallo can’t disclose the details, but says bitterly, “When you get sued by a big corporation, you lose no matter what.”

For all the wealth that comes out of the ground in the Spruce Pine area, not much of it stays there. Today the mines are all owned by foreign corporations. They’re highly automated, so they don’t need many workers. “Now there’s maybe 25 or 30 people on a shift, instead of 300,” Biddix says. The area’s other jobs are vanishing. “We had seven furniture factories here when I was a kid,” he says. “We had knitting mills making blue jeans and nylons. They’re all gone.”

Median household income in Mitchell County, where Spruce Pine sits, is just over $37,000, far below the national average of $51,579. Twenty percent of the county’s 15,000 people, almost all of whom are white, live below the poverty line. Fewer than one in seven adults has a college degree.

People find ways to get by. Glover has a side business growing Christmas trees on his property. Biddix makes his living running the website of a nearby community college.

One of the few new sources of jobs are several huge data processing centers that have opened up in the area. Attracted by the cheap land, Google, Apple, Microsoft, and other tech companies have all opened up server farms within an hour’s drive of Spruce Pine.

In a sense, Spruce Pine’s quartz has come full circle. “When you talk to Siri, you’re talking to a building here at the Apple center,” Biddix says.

I pull out my iPhone and ask Siri if she knows where her silicon brains came from.

“Who, me?” she replies the first time. I try again.

“I’ve never really thought about it,” she says.

From THE WORLD IN A GRAIN by Vince Beiser. Published by arrangement with Riverhead Books, an imprint of Penguin Publishing Group, a division of Penguin Random House LLC. Copyright © 2018 by Vince Beiser.

2 notes

·

View notes

Text

How to Use Silica Ramming Mass for Optimal Performance in Induction Furnace

When operating an induction furnace efficiently, one of the most critical factors is the lining material used. Silica ramming mass, a highly popular refractory material, plays a crucial role in increasing induction furnaces’ performance and longevity. For industries in Rajasthan and across India, Raj Global Ramming Mass offers top-quality silica ramming mass for the specific needs of the furnace lining process.

In this blog, we’ll discuss the importance of silica ramming mass, how to use it effectively, and why Raj Global Ramming Mass is the preferred choice for many industries.

What is Silica Ramming Mass?

Silica ramming mass is a type of refractory material primarily composed of silica (SiO2). It is widely used in the lining of induction furnaces due to its excellent thermal stability, high purity, and resistance to thermal shock. The material is known for its ability to withstand high temperatures and maintain the structural integrity of the furnace lining over time.

The use of silica ramming mass is essential for creating a durable and efficient furnace lining, which is crucial for maintaining consistent production quality and reducing downtime due to repairs or relining.

Why is Silica Ramming Mass Important?

Using the right silica ramming mass in your induction furnace can significantly impact the overall performance and efficiency of your operations. Here are some of the key benefits:

Thermal Stability:

Silica ramming mass can withstand the high temperatures typically encountered in induction furnaces, ensuring that the lining remains stable and effective throughout the furnace’s operating life.

High Purity:

The purity of the silica in the ramming mass is crucial for preventing contamination of the molten metal. High-purity ramming mass, such as that provided by Raj Global Ramming Mass, ensures that the final product is free from impurities.

Resistance to Thermal Shock:

Rapid temperature changes can cause significant stress on the furnace lining. Silica ramming mass is designed to resist thermal shock, reducing the risk of cracks and prolonging the lining’s life.

Improved Furnace Life:

Proper application of silica ramming mass enhances the lifespan of the furnace lining, reducing the frequency of relining and maintenance costs.

How to Use Silica Ramming Mass for Optimal Performance

To achieve the best results with silica ramming mass, it needs to follow proper application procedures. Here’s a step-by-step guide on how to use silica ramming mass for optimal performance in an induction furnace:

Preparation of the Furnace

Before applying the silica ramming mass, ensure that the furnace is properly prepared. This involves cleaning the furnace shell and removing any remnants of the old lining material. The furnace should be free from dust, dirt, and moisture to ensure a strong bond between the ramming mass and the furnace shell.

Mixing the Ramming Mass

Silica ramming mass is typically supplied in dry powder form. To activate the material, it needs to be mixed with the right amount of water. The amount of water used will depend on the specific product and the manufacturer’s recommendations. For Raj Global Ramming Mass, it’s important to follow the guidelines provided to achieve the correct consistency.

Mix the ramming mass thoroughly to ensure that the water is evenly distributed. The mixture should have a uniform texture, free from lumps or dry spots.

Application of the Ramming Mass

Once the ramming mass is mixed, it can be applied to the furnace shell. The application process involves ramming the material into place using pneumatic or manual ramming tools. The ramming mass should be applied in layers, with each layer being compacted thoroughly to eliminate air pockets and achieve a dense, uniform lining.

The thickness of the lining will depend on the specific requirements of your furnace. Typically, a lining thickness of around 80-120 mm is recommended for most induction furnaces.

Drying and Firing

After the silica ramming mass has been applied and compacted, it needs to be dried and fired to achieve its full strength and stability. The drying process typically involves heating the furnace to gradually remove any moisture from the lining. This is followed by firing at high temperatures to cure the ramming mass and form a solid, durable lining.

The drying and firing process should be done slowly to avoid thermal shock and ensure that the lining is properly cured. The furnace should be gradually heated to its operating temperature, typically around 800-1000°C, over a period of several hours.

Regular Maintenance

To maintain optimal performance, regular inspection and maintenance of the furnace lining are essential. Look for signs of wear or damage, such as cracks or thinning of the lining. If any issues are detected, they should be addressed promptly to prevent further damage and avoid costly downtime.

Using high-quality silica ramming mass, such as that provided by Raj Global Ramming Mass, can significantly reduce the frequency of repairs and extend the lifespan of your furnace lining.

Why Choose Raj Global Ramming Mass?

Raj Global Ramming Mass is a trusted Silica Ramming Mass manufacturer and Supplier in the industry, known for providing high-quality silica ramming mass in Jaipur, Rajasthan, and across India. Their products are designed for the specific needs of induction furnaces, offering exceptional thermal stability, purity, and resistance to thermal shock.

By choosing Raj Global Ramming Mass, you can be confident that you are using a product that will enhance the performance and lifespan of your induction furnace. Whether you’re operating in Rajasthan or any other part of the country, Raj Global Ramming Mass is the go-to choice for reliable and efficient furnace lining materials.

Silica ramming mass is a critical component in the successful operation of an induction furnace. By following the proper application procedures and using high-quality materials like Raj Global Ramming Mass, you can ensure that your furnace operates at peak efficiency, with a lining that is both durable and resistant to the demands of high-temperature operations.For industries in Rajasthan and beyond, investing in quality silica ramming mass is a smart decision that will pay off in the form of reduced maintenance costs, improved product quality, and extended furnace life.

#acidic ramming mass#ramming mass#silica ramming mass#premix ramming mass#acidic ramming mass manufactures#premixed ramming mass supplier#ramming mass manufactures#silica ramming mass manufactures#white ramming mass manufacturer#silica ramming mass supplier

0 notes

Text

How to choose right refractory castable for your needs

1.Refractory castable based on Application

Generally, the refractory material is engineered to perfection. But, it might not suit your refractory lining. Focus on the type of application of your refractory insulation. Choose suitable refractory products.

2. Choose Common Refractory Materials

Basically, everyone wants fast and cheap options, no matter the industry.

However, choosing cheap refractories ceramics will cost more in the future. So, consider buying the tried and tested refractory material regardless of price.Because refractory contractors know they are best for boiler refractory and furnaces.

3. Research Refractory Lining Trends

Although there is new refractory insulation technology, discuss with your refractory contractor first.This is because trends may seem too good to be true. Avoid asking for new types of furnace bricks for your refractory contractor to use.The engineering contractor will suggest a material that suits your refractory insulation.

4. Choose the Right Refractory Contractor

Basically, everyone thinks they are the best. But, in the end, the most experienced engineer will make the correct decision. Therefore, choose a refractoryfactory that fits your criteria. Then, they will provide refractory products and services that suit your refractory lining.

Different Refractory Castable

Things To Remember When Using Castable

Castables must always be stored in a cool and dry area.

One must ensure that the mixers and tools are free from old castable or any other material that can contaminate the product. Such contamination could affect the strength of the castable mix.

Only drinking suitable water should be used to mix castable. The temperature of the mix should be optimal as well.

Be careful while mixing castable, like castable refractory cement. Too much mixing generates heat and speeds up the setting time.

The forms should be covered with oil or grease to prevent moisture loss.

After placing the mix, the castable needs to be cured for 18 to 24 hours straight. Cover it with polyethylene sheets and spray it with cold water periodically. It will maintain the moisture of the mix and promote uniform curing at the applied area.

Silica Ramming Mass

Advantages Of Castable Refractories

Saves Time

Ease in usage

Significantly Better Structure Performance

Choosing refractory castable for the insulation process is one of the most thoughtful decisions. Their advantages and wide application seal the deal. But what is even more important is finding a reliable refractory material supplier. Welcome to contact us anytime.

Article Source: How to choose right refractory castable for your needs Company name: Henan Changxing Refractory Materials Co.,Ltd More refractory products:https://www.cxrefractories.com/en-all-refractory-products Email:[email protected] Website:https://www.cxrefractories.com

0 notes

Text

What are refractory materials, Classifications And Types ?

Refractories are inorganic non-metallic material which may withstand heat without undergoing chemical changes while remaining in touch with molten slag, metal and gases.

Refectory may be classified on the basis of

• Chemical composition

• The methods of manufacture

• Their physical forms

Classification Based on Chemical

Composition

(I) Acid Refractories: Acid refractories are those which are attacked by alkalis (basic slags). These

are utilized in areas where slag and atmosphere are acidic. Examples of acid refractories are:

Silica (SiO2), Zirconia (ZrO2).

(II) Basic Refractories:-

Basic refractories get reacted with acid slags but they don’t react to alkaline slags. Since they do not react with alkaline slags, these refractories are of oxidation can be controlled.

Classification Based on Physical Form

• Shaped Refractories: These refractories have fixed shaped when delivered to the user. These are what we call bricks. Brick shape can be divided into two: standard shapes and special shapes. Standards shapes have dimension that are conformed to by most refractory manufacturers and are generally applicable to kilns and furnaces of an equivalent type.

Special shapes are specifically made for particular kilns and furnaces. This may not be applicable to another furnaces or kiln of the same type.

Shaped refractories are nearly always machine pressed, thus, high uniformity in properties are expected. Special shapes are most frequently hand-molded and are expected to exhibit slight variations in properties.

• Unshaped Refractories:

These refractories don’t have a definite form or shapes. They are only given shape upon application. It forms joint less lining and are better referred to as monolithic refractories. These are categorized as Plastic refractories, ramming mixes, gunning mixes

Refractories are classified as dense or insulating types. The most high-temperature refractories, like firebricks, are high-density (>120 lb/ft3). They offer excellent resistance in challenging operating environments, like slags with different chemical compositions, fumes, dust, and gases.

• Insulating refractories have lower densities (4 to 70 lb/ft3) and supply insulating properties, while offering resistance to corrosion and chemical reactions with the operating environment.

Fire-clay brick Refractories

• Fire-clay brick comprise about 75% of the assembly of refractories on a volume basis and are essentially hydrated aluminum silicates with minor proportions of other minerals.

They are extremely versatile; least costly of all refractory bricks and are extensively used in the iron and steel industry, non ferrous metallurgy, glass industry, cement industry etc.

Characteristically, fire-clay brick begin to melt far below their fusion temperature and under load actual deformation takes place. The amount of deformation depends upon the load, and, once started, this deformation is a slow but continuous process unless either the load or the temperature is reduced.

Global Recycling is one of the topmost rice husk ash manufacturers & suppliers of India. We offer rice hull ash, rice husk ash. We are one of the most reliable and well-known manufacturers of the high-grade Heat insulation compound and ladle covering compounds too. Our products are made of high-quality raw materials. This is the reason why our products contain high insulating power, spread ability, and expandability. Products provided by us spreads quickly and easily to cover the whole surface of the steel. Rice husk has lots of utilities as a tundish covering compound

#rice husk ash#rice hull ash#tundish covering compound#ladle covering compound#heat insulation compound

0 notes

Text

Silica Ramming Mass

Silica Ramming MassSilica Ramming Mass. This refractory product is silica ramming mass which can be also called acid ramming mix, and the furnace lining material is called mixed sand for short. This product is the main refractories of the medium frequency induction furnace used by small steel enterprises. Its effect is in leading…

View On WordPress

0 notes

Text

The hydraulic ram features

The hydraulic ram features a cylinder mounted to the decrease plunger meeting and a ram housed in the cylinder and tailored to selectively drive the higher plunger assembly downwardly. As a number one authority in electrical contact applied sciences, together with contact tips, our multidisciplinary team ensures that our electrical contact assemblies deliver the very best value and trade-main performance and reliability. ZRCI Supplies might be machined to tight tolerance with customary instruments. Insulating refractories include calcium silicate supplies, kaolin, and zirconia. The amount of CaZrO3 didn't increase with the rise of nano-ZrO2 concentration, because the CaO was an impurity (1 wt. %) of the uncooked material, and at greater focus of ZrO2, the CaO particles had been consumed to form CaZrO3. Our new web site permits artists to buy a variety of products together with scorching glass casting mould mixes, ceramic papers, ceramic boards and shapes, thermal blankets and coatings.