#Siemens Automation Products

Explore tagged Tumblr posts

Text

Why Siemens Industrial Automation is the Key to Your Success

These days, competing has become synonymous with the embracing of innovative technology. Siemens Industrial Automation is the solution for all businesses intending to increase productivity, streamline processes, and reduce operational costs. Siemens is deliberately focused on innovativeness; therefore, it features a variety of top-of-the-line automation products for diverse needs of the industry.

Why Choose Siemens Industrial Automation?

Siemens is the finest industrial automation provider. It has a complete range of products for industries of all sizes. Here is what makes Siemens special:

Advanced Technologies: Garden Industrial Solutions by Siemens construct with preventive innovations, that work flawlessly to automate daily tasks.

Applications: From manufacturing to energy grids, all kinds of applications and extreme efficiency are available from Siemens.

Reliability: Decades of accumulated experience make it last with the utmost reliability in products.

Explore Siemens Automation Products

Siemens has indeed a wide variety of products catering to industrial automation applications and among these popular Siemens Automation Products are:

Siemens Programmable Logic Controller (PLC): These sturdy controllers form the backbone of industrial automation, providing precise control over machinery and processes, whether small or large production lines or huge units, through their Siemens PLCs, which are reliable and scalable.

Siemens Controllers: Optimally designed Siemens controllers boost the efficiency of very large industrial systems. Everything from other Siemens solutions would seamlessly be integrated into a streamlined flexible workflow.

Benefits of Siemens Programmable Logic Controller

Siemens Programmable Logic Controllers are a fundamental part of automation today. They have the following functionalities:

Flexibility: Suitable for usage from small to large.

User-Friendly Programming: Simple programming that saves much time and resources.

Improving Efficiency: Less downtime and higher productivity.

Energy Saving: Help for the industries to achieve their sustainability goals.

Siemens PLCs are fitted according to every requirement be it automotive, food processing, or packaging industry.

Industries Benefiting from Siemens Industrial Automation

Siemens products are revolutionizing industries all around the world. Some examples are:

Manufacturing: Higher Efficacy Automation of Assembly Lines.

Energy: Optimize Grid Performance and Ensure Sustainable Energy Solutions.

Pharmaceuticals: Provide Precision in Production Processes.

Logistics: Optimize Warehouse Operations That Save Time in Deliveries.

Future-Proof Your Business with Siemens Controllers

Siemens Controllers play a major role in all industrial automation systems. They allow an industry to get real-time decision-making insights that can be trusted for quick decision making. Choosing Siemens controllers is investing in a future-proof investment and enables adaptation with evolving industrial demands.

Final Thoughts

Siemens Industrial Automation paves the way for businesses to excel in a competitive market. Unlock new avenues of efficiency and productivity with industry-leading Siemens Automation Products, including Siemens Programmable Logic Controllers and reliable Siemens Controllers.

Start your journey with Naksh Technology Solutions LLP towards smarter automation today. Check out the complete offerings of Siemens to see how you can transform your industrial operations.

#Siemens Industrial automation#Siemens Automation Products#Siemens Controllers#Programmable logic controllers

0 notes

Text

Siemens Industrial Automation Suppliers and Dealers - Naksh Technology

When NAKSH TECHNOLOGY was established, its goal was to become an essential component of the worldwide supply chain for Siemens automation products. This is accomplished by combining the three factors of impeccable quality, cutting-edge technology, and timely delivery.

As a supplier, we work tirelessly to develop new ideas to meet the automation demands of our customers by providing products such as Siemens AC Drive, Siemens PLC, Siemens HMI, Siemens Servo System, SIMOTION Controller, and many more.

The demands on contemporary machines and plants are gradually increasing across all industries. Siemens automation products enable you to meet all criteria while maintaining optimum efficiency, flexibility, and cost effectiveness.

Every action we do is based on your long-term success. Our committed service professionals provide the best solutions for your specific needs today and in the future. This pledge is based on existing and upcoming trustworthy partnerships. Your trust is our pledge. We are there - Siemens Naksh Technology Services.

Why Choose Naksh Technology for Siemens Industrial Automation?

Precision, dependability, and efficiency are the most important features for Siemens industrial automation. It is important to choose the correct provider and ensure that your processes continue to function effectively and efficiently when you are incorporating Siemens automation products into your operations.

Smooth Integration to Maintain Operations

According to Naksh Technologies intelligent personnel, every second is precious in your place of work, and I hope that we have the most knowledgeable staff with us hence making sure that your system works properly as soon as you contact us for any inquiries related to Siemens Automation Products that we specialize in. Our r problem-solving specialists assure you that adoption procedure doesn't require too much effort whether one is setting up drives, sensors, HMIs or PLCs.

Experience

Naksh Technology has proven itself dependable and quality over time. We have several satisfied clients in different sectors. Choose Naksh Technology as your preferred distributor and partner on Siemens Automation Products to see how differently dependable, efficient and focused we are. And here is how you can get in touch with us to get more information about Siemens programmable logic controller and other associated services.

Visit Here fore More

0 notes

Text

Siemens Controllers for Energy Management: Optimizing Efficiency and Reducing Costs

In an era where energy efficiency and cost management are paramount, Siemens controllers have emerged as a crucial tool for optimizing energy management systems. By integrating advanced Siemens controllers into energy management strategies, organizations can significantly enhance their efficiency, cut down operational costs, and contribute to sustainable energy practices. Here’s a comprehensive look at how Siemens controllers can revolutionize energy management and how they can be integrated with IoT technologies for even greater control and connectivity.

The Role of Siemens Controllers in Energy Management

Siemens controllers, including programmable logic controllers (PLCs) and motor controllers, are pivotal in managing and optimizing energy usage within industrial and commercial settings. These controllers provide precise control and monitoring capabilities that are essential for effective energy management.

1. Enhancing Efficiency with Siemens Controllers

Efficiency is at the core of effective energy management. Siemens controllers are designed to automate and optimize various processes, ensuring that energy use is as efficient as possible. For instance, Siemens’ SIMATIC PLCs are used to manage complex systems, from heating and cooling to lighting and machinery operations. By automating these systems, Siemens controllers reduce the need for manual intervention, which not only streamlines operations but also minimizes energy waste.

Siemens motor controllers play a crucial role in optimizing the performance of electric motors, which are significant consumers of energy. These controllers enable precise control over motor speed and operation, ensuring that motors run only as required and operate at peak efficiency. This optimization leads to reduced energy consumption and extended equipment lifespan, contributing to overall cost savings.

2. Reducing Costs through Advanced Automation

Cost reduction is a critical goal for any energy management strategy. Siemens controllers help achieve this by automating energy-intensive processes, which leads to more efficient energy use and lower utility bills. For example, by implementing Siemens’ automation technology, facilities can automate lighting, HVAC systems, and other energy-consuming equipment based on real-time data and operational needs.

The use of Siemens controllers in factory automation allows for the precise scheduling of machinery and equipment operations. This means that energy is used only when necessary, and equipment is operated under optimal conditions, leading to significant cost savings. Additionally, Siemens controllers provide real-time monitoring and data analysis, which helps identify inefficiencies and areas where further cost reductions can be achieved.

Integrating Siemens Controllers with IoT Technologies

The integration of Siemens controllers with Internet of Things (IoT) technologies offers enhanced connectivity and control, taking energy management to the next level. IoT integration allows Siemens controllers to collect and analyze data from various sensors and devices, providing a comprehensive view of energy usage and system performance.

1. Improved Connectivity and Control

By connecting Siemens controllers with IoT platforms, organizations can achieve improved connectivity across their energy management systems. This integration enables seamless communication between controllers, sensors, and other devices, facilitating real-time monitoring and control. For instance, energy consumption data from various sources can be aggregated and analyzed through IoT platforms, providing valuable insights into energy usage patterns and system performance.

This enhanced connectivity allows for more precise control over energy systems. For example, IoT-enabled Siemens controllers can adjust lighting levels, HVAC settings, and equipment operation based on real-time data, optimizing energy use and improving overall efficiency. The ability to remotely monitor and control energy systems also offers increased flexibility and responsiveness, enabling quick adjustments to address changing conditions and requirements.

2. Data-Driven Insights for Better Decision-Making

The integration of Siemens controllers with IoT technologies provides access to a wealth of data that can be used to drive better decision-making. Through advanced analytics and reporting tools, organizations can gain deep insights into their energy usage, identify trends and anomalies, and make informed decisions to further optimize their energy management strategies.

For example, IoT platforms can generate reports on energy consumption, equipment performance, and operational efficiency. These reports can be used to identify areas where energy is being wasted, track the performance of energy-saving initiatives, and set benchmarks for future improvements. By leveraging these data-driven insights, organizations can continuously refine their energy management practices and achieve long-term cost savings.

Implementing Siemens Controllers for Energy Management

To effectively implement Siemens controllers for energy management, organizations should follow several key steps:

Assess Current Systems: Evaluate existing energy management systems and identify areas where Siemens controllers can provide the most benefit. Consider factors such as equipment types, energy consumption patterns, and automation needs.

Select the Right Siemens Controllers: Choose Siemens controllers that best match your energy management requirements. Options include SIMATIC PLCs for complex automation tasks and motor controllers for precise motor control.

Integrate with IoT Technologies: Connect Siemens controllers with IoT platforms to enhance data collection, connectivity, and control. This integration will enable real-time monitoring and advanced analytics.

Configure and Deploy: Configure Siemens controllers and IoT integrations according to your specific energy management needs. Deploy the system and ensure that all components are properly calibrated and optimized.

Monitor and Optimize: Continuously monitor system performance and use data-driven insights to make ongoing improvements. Regularly review energy consumption data and adjust settings to maximize efficiency and cost savings.

Conclusion

Siemens controllers are revolutionizing energy management by providing advanced automation technology that enhances efficiency and reduces costs. Through precise control and real-time monitoring, Siemens controllers optimize energy usage, streamline operations, and contribute to significant cost savings. When integrated with IoT technologies, these controllers offer improved connectivity and data-driven insights, further enhancing their effectiveness in energy management. By adopting Siemens controllers, organizations can achieve a more efficient and cost-effective approach to energy management, driving both operational excellence and sustainability.

#siemens#siemens controller#siemens controllers#simatic#controllers#automation#controller#production#automated

0 notes

Text

Why Siemens is a Leader in Industrial Automation

Siemens, a global powerhouse in automation technology, has long been recognized as a leader in industrial automation. With its extensive range of products and solutions designed to enhance factory operations, Siemens is at the forefront of revolutionizing manufacturing and production processes. This leadership stems from a combination of innovative technologies, a commitment to research and development, and a deep understanding of industrial needs.

Pioneering Automation Technology

Siemens’ automation technology portfolio is comprehensive and versatile, addressing the diverse needs of modern factories. Central to this portfolio is the Siemens Simatic line, which includes programmable logic controllers (PLCs), human-machine interfaces (HMIs), and industrial software. These tools are the backbone of automated manufacturing systems, enabling precise control and monitoring of production processes.

Simatic PLCs, for example, are renowned for their reliability and performance. They provide robust solutions for automating complex tasks, reducing manual intervention, and enhancing operational efficiency. Siemens HMIs offer intuitive interfaces for operators, ensuring seamless interaction with automated systems. Together, these components create a cohesive and powerful automation environment.

Advanced Motion Control Solutions

Siemens’ Motion Control technology is another critical component of its industrial automation leadership. Motion Control systems are essential for applications that require precise movements, such as robotics, CNC machines, and high-speed production lines. Siemens provides a range of Motion Control products, including servo drives and motors, that deliver exceptional accuracy and responsiveness.

By integrating Motion Control with automation systems, Siemens ensures that manufacturing processes are not only efficient but also highly precise. This precision is vital for industries such as automotive, aerospace, and electronics, where even minor deviations can lead to significant quality issues.

Innovation through Simatic and Beyond

The Simatic brand represents Siemens’ commitment to innovation in industrial automation. Beyond traditional PLCs and HMIs, Simatic encompasses a wide range of advanced automation solutions, including edge computing devices, industrial IoT gateways, and cloud-based analytics platforms. These technologies enable factories to harness the power of data, driving insights that lead to continuous improvement.

Edge computing devices, for instance, allow real-time processing of data at the factory floor level, reducing latency and improving decision-making. Industrial IoT gateways connect machines and systems, facilitating seamless data exchange and enabling predictive maintenance and remote monitoring. Cloud-based analytics platforms provide powerful tools for analyzing production data, uncovering trends, and optimizing processes.

Comprehensive Industrial Solutions

Siemens offers end-to-end solutions for industrial automation, from design and engineering to implementation and maintenance. Their portfolio includes software tools for simulation and digital twin modeling, which help manufacturers design and optimize production systems before physical implementation. This approach reduces time-to-market and minimizes the risk of costly errors.

Furthermore, Siemens’ commitment to open standards ensures that their automation solutions are compatible with a wide range of third-party systems. This interoperability is crucial for modern factories, which often rely on equipment from multiple vendors. By providing seamless integration, Siemens helps manufacturers create cohesive and efficient production environments.

Commitment to Research and Development

One of the key reasons Siemens remains a leader in industrial automation is its unwavering commitment to research and development. Siemens invests heavily in developing new technologies and enhancing existing ones. This investment ensures that Siemens stays ahead of industry trends and continues to provide cutting-edge solutions.

Siemens’ R&D efforts focus on several key areas, including artificial intelligence (AI), machine learning (ML), and digitalization. By incorporating AI and ML into their automation systems, Siemens enables smarter and more adaptive manufacturing processes. Digitalization efforts, such as the development of digital twins and advanced analytics, empower manufacturers to optimize their operations and make data-driven decisions.

Real-World Impact

Siemens’ leadership in industrial automation is evident in its extensive track record of successful implementations across various industries. In automotive manufacturing, for instance, Siemens’ automation solutions have streamlined assembly lines, improved quality control, and increased production rates. In the food and beverage industry, Siemens’ technologies have enhanced processing and packaging efficiency, ensuring high standards of hygiene and product quality.

Future of Manufacturing

Looking ahead, Siemens is poised to continue leading the industrial automation sector. The company’s focus on integrating emerging technologies, such as AI, IoT, and 5G, will drive the next wave of innovation. These advancements will enable even greater levels of automation, connectivity, and flexibility in manufacturing.

The future of factory automation will be characterized by smart, self-optimizing systems that can adapt to changing conditions and demands. Siemens is at the forefront of this transformation, providing the tools and technologies that will define the factories of tomorrow.

Conclusion

Siemens’ leadership in industrial automation is the result of decades of innovation, a comprehensive portfolio of automation technology, and a deep commitment to advancing manufacturing processes. Through products like Simatic and advanced Motion Control systems, Siemens has set the standard for efficiency, precision, and reliability in industrial operations. As the industry continues to evolve, Siemens is well-positioned to remain a driving force in shaping the future of factory automation.

#automation#simatic#motion control#automation technology#industrial#manufacturing#factory#production#siemens

0 notes

Text

Siemens Launches Comprehensive Private 5G Solution for the Industrial Sector

Siemens, a leading global technology company, has introduced a groundbreaking private 5G infrastructure, marking a significant advancement in mobile communication standards for the industrial sector. This development is set to revolutionize how industrial companies approach automation applications and connected production. Innovative 5G InfrastructureSiemens has developed, for the first time, an…

View On WordPress

#5G Network#Connected Production#connectivity#Customization#Data Control#digital transformation#Industrial Applications#Industrial Automation#Innovation#Mobile Communications#Private 5G Infrastructure#Radio Access Network#Salzgitter AG#Siemens#Siemens Digital Industries

0 notes

Text

Need Siemens LOGO! PLC Installation Services in Dhaka?

Looking to boost your business's automation systems in Bangladesh? Apical Industrial Solution & Technology is your trusted provider for Siemens LOGO! PLC services. Our skilled engineers specialise in the installation and maintenance of Siemens LOGO! PLCs, ensuring seamless automation for your operations. Whether you're based in Dhaka, Chittagong, or anywhere across the country, we've got you covered!

Why Choose Us?

✅ Expert Siemens LOGO! PLC Installation✅ Local support across Dhaka and beyond ✅ Tailored solutions for small to medium-sized automation projects ✅ On-site troubleshooting and maintenance services

Take your business automation to the next level with our expert team!

Call Us Today to schedule your consultation or visit our website for more information. Let's transform your automation processes and elevate your productivity!

📍 Apical Industrial Solution & Technology, Dhaka, Bangladesh 📞https://maps.app.goo.gl/FnY8mTekL35zSLxT9 🌐 https://apicalindustrialsolution.com/

#DhakaAutomation #SiemensLOGOPLC #BangladeshAutomation #PLCServicesDhaka #IndustrialAutomationBangladesh #ApicalIndustrialSolutions

#DhakaAutomation#SiemensLOGOPLC#BangladeshAutomation#ApicalIndustrialSolutions#IndustrialAutomationBangladesh#PLCServicesDhaka

2 notes

·

View notes

Text

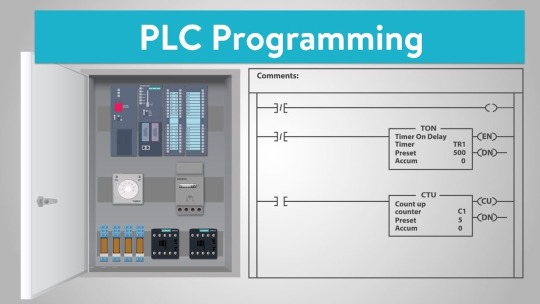

The Basics of PLC Programming: A Comprehensive Guide

If you're interested in the field of industrial automation or looking to enhance your skills in the industry, PLC programming is a crucial skill to possess. Programmable Logic Controllers (PLCs) are widely used in manufacturing and process control systems, and understanding how to program them is essential for ensuring efficient and reliable operation.

In this comprehensive guide, we will explore the basics of PLC programming, covering key concepts and providing valuable insights for beginners in the field.

1. What is PLC Programming?

PLC programming involves creating a set of instructions that control the behavior of a programmable logic controller. PLCs are used to monitor inputs from various sensors, process that data, and execute specific actions based on pre-defined logic. By programming a PLC, you can automate complex industrial processes, making them more efficient and reliable.

2. Why Learn PLC Programming?

PLC programming offers numerous benefits in the industrial automation realm. By acquiring this skill, you can:

Improve productivity: PLCs enable automation, reducing manual labor and increasing overall productivity.

Enhance efficiency: Automation minimizes human error and optimizes processes, resulting in higher efficiency levels.

Facilitate troubleshooting: Understanding PLC programming allows you to diagnose and fix issues efficiently, minimizing downtime.

Expand career opportunities: PLC programming expertise is in high demand, with many industries seeking professionals with these skills.

3. PLC Programming Training Courses:

To learn PLC programming effectively, it's essential to enroll in specialized training courses. These courses provide a structured curriculum, hands-on exercises, and expert guidance. Here are a few key aspects to consider when choosing a PLC programming training institute or center:

Comprehensive curriculum: Look for a training program that covers both theoretical concepts and practical implementation.

Experienced instructors: Ensure that the training institute has qualified instructors with industry experience to guide you effectively.

Hands-on practice: Practical exercises and projects are crucial for gaining proficiency in PLC programming.

Industry relevance: Verify that the training course aligns with current industry standards and practices.

Certification: Opt for courses that offer certifications upon completion, as they enhance your credibility in the job market.

4. Key Concepts in PLC Programming:

Ladder Logic: Ladder Logic is the most commonly used programming language for PLCs. It employs graphical symbols to represent logic functions and control sequences, making it easy to understand and implement.

Inputs and Outputs: PLCs interact with the physical world through inputs (sensors) and outputs (actuators). Understanding how to read inputs and control outputs is fundamental in PLC programming.

Programming Instructions: PLCs execute a set of instructions to perform desired operations. These instructions can include timers, counters, mathematical operations, logic gates, and more.

Program Execution: PLC programs are executed in a cyclical manner. The PLC scans inputs, processes logic, updates outputs, and repeats the cycle continuously.

5. Programming Tools and Software:

PLC programming software provides an interface to create, edit, and debug programs. Familiarize yourself with popular software tools such as Siemens TIA Portal, Allen-Bradley RSLogix, or Schneider Electric Unity Pro, as they are widely used in the industry.

Conclusion:

PLC programming is an essential skill for individuals aspiring to succeed in the field of industrial automation. By learning the basics of PLC programming, you open up a world of opportunities to streamline processes, enhance productivity, and contribute to the advancement of various industries. Enroll in a reputable PLC programming training institute or center, explore the key concepts, and start your journey towards becoming a proficient PLC programmer.

#plc-programming#learn plc programming#plc programming training#plc programming courses#plc training course in india

3 notes

·

View notes

Text

Building Power Monitoring Solutions Market Share, Size, Demand, Key Players by Forecast 2032

The global building power monitoring solutions market refers to the market for systems and devices that monitor and manage energy usage in buildings. These solutions help building owners and managers to reduce energy consumption, improve energy efficiency, and save costs.

The market is driven by factors such as the need for energy efficiency, government regulations for energy efficiency, increasing demand for smart buildings, and the growing adoption of renewable energy sources. Additionally, the increasing awareness about the benefits of building power monitoring solutions is expected to further drive the market growth.

Download a Sample Copy of Building Power Monitoring Solutions Market: https://stringentdatalytics.com/sample-request/building-power-monitoring-solutions-market/3768/

The market can be segmented based on component, building type, end-user, and geography. Based on the component, the market can be segmented into hardware, software, and services. Based on building type, the market can be segmented into commercial buildings, industrial buildings, and residential buildings. Based on end-users, the market can be segmented into building owners, facility managers, and energy service companies.

Geographically, the market is segmented into North America, Europe, Asia-Pacific, and the Rest of the World. North America is expected to hold the largest market share due to the increasing adoption of smart buildings and the presence of major market players in the region. Asia-Pacific is expected to witness significant growth due to the increasing demand for energy efficiency and the growth of the construction industry in the region.

Market Segmentations:

Global Building Power Monitoring Solutions Market: By Company

Schneider Electric

Vertiv

Broadcom

Rittal GmbH & Co. KG

Siemens AG

ABB

Raritan

Sunbird

Packet Power

Wattics

En-trak

Rockwell Automation

Global Building Power Monitoring Solutions Market: By Type

Cloud-based

On Premise

Global Building Power Monitoring Solutions Market: By Application

Commercial Building

Residential Building

Industrial Building

Visit Report Page: https://stringentdatalytics.com/reports/building-power-monitoring-solutions-market/3768/

Reasons to Purchase Building Power Monitoring Solutions Market Report:

To gain insights into market trends and dynamics: this reports provide valuable insights into industry trends and dynamics, including market size, growth rates, and key drivers and challenges.

To identify key players and competitors: this research reports can help businesses identify key players and competitors in their industry, including their market share, strategies, and strengths and weaknesses.

To understand consumer behavior: this research reports can provide valuable insights into consumer behavior, including their preferences, purchasing habits, and demographics.

To evaluate market opportunities: this research reports can help businesses evaluate market opportunities, including potential new products or services, new markets, and emerging trends.

To make informed business decisions: this research reports provide businesses with data-driven insights that can help them make informed business decisions, including strategic planning, product development, and marketing and advertising strategies. Overall, market research reports provide businesses and organizations with valuable information that can help them make informed decisions and stay competitive in their industry. They can provide a solid foundation for business planning, strategy development, and decision-making.

About US: Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Contact US: Stringent Datalytics Contact No - 91-9763384149 Email Id - [email protected] Web - https://stringentdatalytics.com/

2 notes

·

View notes

Text

What Is the Main Difference Between

1734-IB8S Series A & B

What Is the Main Difference Between 1734-IB8S Series A & B?

Asteam Techno Solutions Pvt Ltd is familiar in the industry of Automation Parts Supplier. You can buy industrial automation parts here; we have high-quality products with unbeatable customer service. We are an online seller of new & used parts, and have a huge volume of supplies from the most popular brands, including Allen Bradley, Schneider, Siemens, Moxa, Vipa and more. We believe in giving high-quality products from reliable suppliers, and using the vast experience to help them.

The 1769-IF unit will be located between the PLC controllers & the ECR module. Close the connecting tab after sliding it into the same position as you did with the End Cap Controller. Note that the tab is now located at the top this time around due to the size of the module.

The 1769-IF8 Analogue Input unit's reverse side will be connected to the End Cap Device as the final step in the process. Once more, the device's purpose is to turn off the back-plane and allow the PLC to recognise the units that are attached to it. In other words, having it in place is crucial.

What is the main difference between 1734-IB8S Ser A & B?

Ser B can use up to 110 mA of electricity while Ser A can use up to 175 mA. The maximum power indulgence for Sers B and A is 3.0 W and 3.4 W, respectively.

The PLC's I/O configuration may easily be expanded by adding peripheral modules using RSLogix & Studio 5000.

Analogue signals come in a variety of "input types". Generally speaking, depending on the device on the other end, you would typically be dealing with either a current input. Use the 4-20mA signal range instead. It is incredibly dependable, simple to use, and supported by a variety of suppliers.

You can choose from a variety of "grading" options. To put it simply, the objective is to convert a 4-20 mA signal—or whatever signal you chose—into a useful number. A level sensor would be an excellent illustration. The sensor is programmed to read at a distance of 5 feet and transmit a 20mA signal, and at a distance of 1 foot and send a 4mA signal. The 4-20mA signal will be translated by the grading back into feet or a percentage-based value. Since they make sense to system users, they can be implemented and used considerably more easily. Get more information on Asteam Techno Solutions Pvt Ltd

#allen bradley#tumblr trends#automation#viralpost#trending#viral#bestdeals#rockwell automation#trendingnow

1 note

·

View note

Text

Siemens Industrial Automation: Transforming the Future of Industry

Among the many changes taking place in production and manufacturing today, industrial automation stands out as a touchstone in achieving efficiency, reliability, and innovation. A clear leader among all the many contenders in this area, Siemens Industrial Automation offers innovative, cutting-edge solutions that redefine excellence in operation across many industries.

What is Siemens Industrial Automation?

Siemens Industrial Automation is an innovative and customized technology that has been developed for all automation and optimizing industrial processes. Solutions concern all industries, such as manufacturing, energy, healthcare, automotive, and many others. It offers a more advanced solution that can provide significantly increased productivity, reduced costs, and improved accuracy for industries by incorporating new technologies such as IOT, Artificial Intelligence, and robotics efficiencies in most industries.

Key Features of Siemens Industrial Automation

Scalable Solutions: From the very beginning, Siemens has presented a well-rounded range of products and systems for enterprises of all sizes, from small businesses to huge industrial companies.

Integrated Systems: Their systems for automation are seamlessly integrated into hardware and software for smooth machine communication and management of operational flows.

Advanced Technologies: To deliver a new automation solution, Siemens had to integrate modern technologies like artificial intelligence, the digital twin, and cloud computing into its business model.

Energy Efficiency: Siemens automation systems and solutions will optimize energy consumption and costs while backing sustainability.

Popular Siemens Automation Products

SIMATIC Controllers: These programmable logic controllers (PLCs) deliver performance-leading automation of complex processes with reliability and precision.

SINAMICS Drives: A wide and versatile range of AC, DC, and Servo drives optimized for motion control, hence enhancing better operational efficiency.

SIMOTION: Such a motion control architecture would provide sophisticated solutions for control of highly dynamic and accurate motion processes.

HMI Systems: The HMI systems of Siemens allow industrial equipment to be used and supervised in an easy way.

Industrial IoT Solutions: Scalable and industrial-strength IoT-ready platforms such as MindSphere are offered by Siemens, facilitating real-time analytics and decisions by connecting machines and systems.

Benefits of Siemens Industrial Automation

Increased Productivity: Such manual interventions can thus be reduced with the help of automation, thereby leading to an improved speed and efficiency in production.

Enhanced Quality: All aspects of production can be managed effectively through precision control.

Cost Optimization: Automation reduces the operational costs by reducing waste, minimizing energy consumption, and increasing efficiency.

Scalability and Flexibility: Siemens has engineered its solutions to meet the ever-growing demands of industries, thereby making it easy for businesses to expand their operations.

Improved Safety: Automation reduces the risk of human errors and enhances workplace safety by minimizing hazardous manual tasks.

Applications Across Industries

Manufacturing: Automation of production lines for precision and speed.

Energy: Enhancing energy distribution and reliability in power generation systems.

Automotive: Facilitating Production Lines and Quality Assurance Operations.

Healthcare: Enable the growth and manufacturing of medical devices and their accessories.

Food and Beverage: Having a consistent and quality product through efficient and effective packaging, labeling, and production processes.

Conclusion

Siemens Industrial Automation by Naksh Technology Solutions LLP is changing the dynamics of industrial operations. The solutions offered by Siemens are meant to empower businesses with a competitive and leadership advantage in the market. Be it a small company needing to automate one process or a gigantic establishment going for an end-to-end solution, Siemens has it all, with the arsenals you need to make it happen.

To invest in Siemens Industrial Automation is not just to renew the technology, it is to move into the future where efficiency, innovation, and sustainability determine your success. Discover Siemens opportunities today - grab the first chance to transform your industry.

0 notes

Text

Digital Tachograph System Market To Witness the Highest Growth Globally in Coming Years

The report begins with an overview of the Digital Tachograph System Market 2025 Size and presents throughout its development. It provides a comprehensive analysis of all regional and key player segments providing closer insights into current market conditions and future market opportunities, along with drivers, trend segments, consumer behavior, price factors, and market performance and estimates. Forecast market information, SWOT analysis, Digital Tachograph System Market scenario, and feasibility study are the important aspects analyzed in this report.

The Digital Tachograph System Market is experiencing robust growth driven by the expanding globally. The Digital Tachograph System Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Digital Tachograph System Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing. Digital Tachograph System Market Size, Share & Industry Analysis, By Product Type (Integrated, Portable), By Vehicle Type (Passenger Cars, Light Commercial Vehicles, Heavy Commercial Vehicles) and Regional Forecast 2021-2028

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/103646

Key Strategies

Key strategies in the Digital Tachograph System Market revolve around optimizing production efficiency, quality, and flexibility. Integration of advanced robotics and machine vision technologies streamlines assembly processes, reducing cycle times and error rates. Customization options cater to diverse product requirements and manufacturing environments, ensuring solution scalability and adaptability. Collaboration with industry partners and automation experts fosters innovation and addresses evolving customer needs and market trends. Moreover, investment in employee training and skill development facilitates seamless integration and operation of Digital Tachograph System Market. By prioritizing these strategies, manufacturers can enhance competitiveness, accelerate time-to-market, and drive sustainable growth in the Digital Tachograph System Market.

Major Digital Tachograph System Market Manufacturers covered in the market report include:

The major companies in the global digital tachograph system market include Siemens, Veridos, Continental Automotive, Stoneridge Electronics, Gemalto, Teletrac Navman, Novadata, Transics, Descartes Systems, and ASELSAN, among others.

Moreover, the advancement in the technologies, improvement in computing, and the cost efficiency are compelling to upgrade the traditional tachographs with digital tachographs devices. The digital tachographs are also used to avoid road accidents and bring enhancement in safety management. Some OEMs provide solutions for batteries and integrated circuits.

Trends Analysis

The Digital Tachograph System Market is experiencing rapid expansion fueled by the manufacturing industry's pursuit of efficiency and productivity gains. Key trends include the adoption of collaborative robotics and advanced automation technologies to streamline assembly processes and reduce labor costs. With the rise of Industry 4.0 initiatives, manufacturers are investing in flexible and scalable Digital Tachograph System Market capable of handling diverse product portfolios. Moreover, advancements in machine vision and AI-driven quality control are enhancing production throughput and ensuring product consistency. The emphasis on sustainability and lean manufacturing principles is driving innovation in energy-efficient and eco-friendly Digital Tachograph System Market Solutions.

Regions Included in this Digital Tachograph System Market Report are as follows:

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Significant Features that are under offering and key highlights of the reports:

- Detailed overview of the Digital Tachograph System Market.

- Changing the Digital Tachograph System Market dynamics of the industry.

- In-depth market segmentation by Type, Application, etc.

- Historical, current, and projected Digital Tachograph System Market size in terms of volume and value.

- Recent industry trends and developments.

- Competitive landscape of the Digital Tachograph System Market.

- Strategies of key players and product offerings.

- Potential and niche segments/regions exhibiting promising growth.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2025 to 2032?

► What are the key market dynamics influencing growth in the Global Digital Tachograph System Market?

► Who are the prominent players in the Global Digital Tachograph System Market?

► What is the consumer perspective in the Global Digital Tachograph System Market?

► What are the key demand-side and supply-side trends in the Global Digital Tachograph System Market?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global Digital Tachograph System Market?

Table Of Contents:

1 Market Overview

1.1 Digital Tachograph System Market Introduction

1.2 Market Analysis by Type

1.3 Market Analysis by Applications

1.4 Market Analysis by Regions

1.4.1 North America (United States, Canada and Mexico)

1.4.1.1 United States Market States and Outlook

1.4.1.2 Canada Market States and Outlook

1.4.1.3 Mexico Market States and Outlook

1.4.2 Europe (Germany, France, UK, Russia and Italy)

1.4.2.1 Germany Market States and Outlook

1.4.2.2 France Market States and Outlook

1.4.2.3 UK Market States and Outlook

1.4.2.4 Russia Market States and Outlook

1.4.2.5 Italy Market States and Outlook

1.4.3 Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

1.4.3.1 China Market States and Outlook

1.4.3.2 Japan Market States and Outlook

1.4.3.3 Korea Market States and Outlook

1.4.3.4 India Market States and Outlook

1.4.3.5 Southeast Asia Market States and Outlook

1.4.4 South America, Middle East and Africa

1.4.4.1 Brazil Market States and Outlook

1.4.4.2 Egypt Market States and Outlook

1.4.4.3 Saudi Arabia Market States and Outlook

1.4.4.4 South Africa Market States and Outlook

1.5 Market Dynamics

1.5.1 Market Opportunities

1.5.2 Market Risk

1.5.3 Market Driving Force

2 Manufacturers Profiles

Continued…

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

US:+18339092966

UK: +448085020280

APAC: +91 744 740 1245

#Digital Tachograph System Market#Digital Tachograph System Market Share#Digital Tachograph System Market Size#Digital Tachograph System Market Trends#Digital Tachograph System Market Insights

0 notes

Text

How Siemens Controllers Are Revolutionizing Music Production Studios

In the rapidly evolving world of music production, the quest for greater efficiency, precision, and creative control has led to significant advancements in technology. Among the innovations driving these changes are Siemens controllers, which are revolutionizing how music is produced, mixed, and mastered. By integrating Siemens' cutting-edge automation technology into music production studios, professionals are achieving new levels of productivity and sonic quality. Here's how Siemens controllers are making waves in the music industry.

Siemens Controllers: The Backbone of Modern Music Studios

Siemens controllers, including programmable logic controllers (PLCs) and motor controllers, are renowned for their reliability and precision in various industrial applications. However, their impact extends beyond traditional manufacturing environments. In modern music production studios, Siemens controllers are enhancing automation, improving control over studio equipment, and streamlining production processes.

One notable example is the use of Siemens’ SIMATIC PLCs in controlling and automating audio equipment. These advanced controllers manage everything from digital mixing consoles to automated fader adjustments, providing sound engineers and producers with a level of control that was previously unattainable.

Enhancing Efficiency with Siemens Automation Technology

Efficiency is paramount in a music production studio, where time is often as valuable as creativity. Siemens controllers play a crucial role in automating repetitive tasks and optimizing workflows. For instance, automated mixing and mastering processes are facilitated by Siemens controllers, which handle complex signal routing and processing tasks with precision.

By integrating Siemens’ automation technology, studios can reduce the time spent on manual adjustments and focus more on the creative aspects of music production. Automated systems controlled by Siemens controllers ensure that equipment settings are consistent and repeatable, which is essential for achieving high-quality results across multiple sessions and projects.

Precision Control with Siemens Motor and Motion Controllers

In a music studio, precise control over equipment is essential for achieving the desired sound quality. Siemens motor controllers and motion control systems provide unparalleled accuracy in adjusting audio equipment. Whether it’s controlling the movement of a motorized microphone stand or fine-tuning the position of speakers and monitors, Siemens controllers ensure that every adjustment is executed with pinpoint accuracy.

The ability to program and control these adjustments via Siemens’ programmable logic controllers allows sound engineers to create intricate setups and configurations that can be replicated with ease. This level of control enhances the overall quality of recordings and ensures that the production process is smooth and efficient.

Streamlining Production with Advanced Automation and Process Automation

Process automation is transforming music production studios by automating complex workflows and enhancing overall efficiency. Siemens controllers are at the heart of this transformation, offering solutions that streamline various aspects of the production process.

For example, Siemens controllers can automate the setup and calibration of audio equipment, reducing the time needed for manual adjustments. This automation extends to the management of recording sessions, where Siemens controllers handle tasks such as track switching, level adjustments, and signal routing with minimal human intervention.

Additionally, the integration of Siemens controllers into digital audio workstations (DAWs) allows for seamless control of software and hardware components. This integration ensures that all elements of the production process work in harmony, resulting in a more cohesive and efficient workflow.

The Impact of Siemens Controllers on Creative Processes

Beyond improving efficiency and precision, Siemens controllers also have a significant impact on the creative processes within music production studios. By automating routine tasks, these controllers free up time for producers and engineers to focus on creative experimentation and innovation.

The ability to program complex automation sequences and recall them with ease enables sound engineers to explore new creative possibilities. For instance, automated dynamic changes in a mix or the creation of intricate effects can be accomplished effortlessly using Siemens controllers, allowing for greater experimentation and artistic expression.

Implementing Siemens Controllers in Your Music Studio

Integrating Siemens controllers into a music production studio involves several key steps. First, assess your studio’s current setup and identify areas where automation and control improvements can be made. Siemens offers a range of controllers and automation solutions, including the SIMATIC PLCs and motor controllers, that can be customized to meet your specific needs.

Once the appropriate Siemens controllers are selected, the next step is to implement them into your studio’s infrastructure. This process may include configuring the controllers, integrating them with existing equipment, and training staff to utilize the new technology effectively.

Ongoing maintenance and support are essential to ensure that Siemens controllers continue to perform optimally. Siemens provides comprehensive support services, including technical assistance and software updates, to help you maximize the benefits of their controllers and maintain peak performance.

Conclusion

Siemens controllers are revolutionizing music production studios by enhancing efficiency, precision, and creativity. With their advanced automation technology, including programmable logic controllers (PLCs) and motor controllers, Siemens is setting new standards for control and automation in the music industry. By integrating Siemens controllers into your music production setup, you can streamline workflows, improve the quality of your productions, and unlock new creative possibilities. As the music industry continues to evolve, Siemens controllers will remain at the forefront of innovation, driving the future of music production.

#siemens#siemens controller#siemens controllers#industrial automation#programmable logic controllers#motor controllers#motion control#factory automation#automation technology#process automation#simatic#controllers#automation#controller#production#automated

0 notes

Text

Tin Plated Copper Busbar Market: Growth, Trends, and Future Outlook

Introduction

The tin plated copper busbar market is witnessing significant growth, driven by the increasing demand for efficient electrical conductivity, corrosion resistance, and enhanced durability in power distribution applications. Tin plated copper busbars are widely used in electrical substations, automotive systems, renewable energy installations, and industrial power solutions, offering superior performance and reliability.

Market Overview

Current Market Size and Growth Trends

The global tin plated copper busbar market was valued at USD 1.2 billion in 2023 and is expected to grow at a CAGR of 5.4% from 2024 to 2032, reaching approximately USD 2.1 billion by the end of the forecast period. Growth in power infrastructure development, increasing adoption of renewable energy, and rising investments in industrial automation are key market drivers.

Regional Market Insights

North America: A leading market, fueled by modernization of electrical grids and increased demand for energy-efficient components.

Europe: Strong growth due to stringent energy regulations and expansion in industrial automation.

Asia-Pacific: Fastest-growing region, driven by rapid industrialization in China, India, and Japan.

Middle East & Latin America: Increasing investments in renewable energy projects and smart grid infrastructure.

Key Market Drivers

Growing Demand for Efficient Power Distribution: Industries and commercial facilities require high-performance electrical conductors.

Rising Adoption of Renewable Energy: Tin plated copper busbars are extensively used in solar and wind energy installations.

Corrosion Resistance & Durability: Tin plating enhances the lifespan of copper busbars, making them ideal for harsh environments.

Advancements in Electrical Infrastructure: Smart grids and electrification projects boost demand for high-quality busbars.

Leading Players in the Tin Plated Copper Busbar Market

Several major companies dominate the tin plated copper busbar market with innovative solutions:

Schneider Electric (France) – A global leader in electrical distribution systems.

Siemens AG (Germany) – Manufactures high-performance busbars for industrial applications.

Eaton Corporation (USA) – Offers advanced power distribution solutions.

Legrand SA (France) – Specializes in busbars for residential, commercial, and industrial use.

Storm Power Components (USA) – Provides customized tin plated copper busbar solutions.

Challenges and Roadblocks

Despite strong growth, the tin plated copper busbar market faces several challenges:

High Raw Material Costs: Copper price fluctuations impact overall production costs.

Increasing Competition from Aluminum Busbars: Lightweight aluminum alternatives pose a challenge.

Complex Manufacturing Process: High precision and specialized coating technologies required.

Stringent Environmental Regulations: Compliance with energy efficiency and sustainability standards is essential.

Future Outlook

The tin plated copper busbar market is set for continued innovation, with key trends shaping its trajectory:

Growing Use in Electric Vehicles (EVs): Expansion of EV charging infrastructure will drive demand.

Sustainable and Recyclable Materials: Manufacturers are focusing on eco-friendly production processes.

Increased Adoption in Data Centers: Growing data processing needs require reliable electrical infrastructure.

Smart Grid Integration: Enhanced electrical systems for more efficient power distribution.

Conclusion

The tin plated copper busbar market is growing steadily, driven by technological advancements, increasing energy demands, and rising infrastructure investments. Companies investing in sustainability, efficiency, and high-performance materials will gain a competitive edge in this evolving market.

Looking to stay ahead in the tin plated copper busbar industry? Follow our blog for the latest market insights and trends!

0 notes

Text

Semiconductor-Enabled Smart Grids Market to Reach $15.8B by 2034 (CAGR: 11.4%) ⚡🔌

Semiconductor-Enabled Smart Grids Market is set to grow at a CAGR of 11.4%, reaching $15.8 billion by 2034 from $5.2 billion in 2024. Smart grids leverage semiconductor innovations to enhance energy efficiency, grid reliability, and renewable energy integration. With the rise of IoT, AI, and real-time energy management, semiconductor-enabled smart grids are revolutionizing power distribution for a more sustainable future.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS10730 &utm_source=SnehaPatil&utm_medium=Article

The power distribution segment leads the market, holding a 45% share, driven by demand for real-time monitoring and automation. Energy storage solutions follow at 30%, as battery-backed smart grids ensure resilience. Energy management systems account for 25%, propelled by smart meters and intelligent demand-response mechanisms.

North America dominates the market, fueled by early adoption of smart grid infrastructure and significant government investments. Europe follows closely, led by Germany and the UK, where sustainability initiatives drive smart grid deployment. Asia-Pacific is experiencing rapid growth, as China and India push for urbanization and carbon footprint reduction through semiconductor-powered energy solutions.

Key players, including Siemens AG, General Electric, and Schneider Electric, are spearheading innovation through AI-driven automation, blockchain security, and grid modernization solutions. With cloud-based and hybrid deployment models gaining traction, the market is expected to witness widespread adoption across utilities, industrial sectors, and smart cities.

Market Segmentation:

✔ Type: Hardware, Software, Services ✔ Product: Smart Meters, Sensors, Controllers, Communication Devices ✔ Technology: IoT, AI, Blockchain, Big Data, Cloud Computing ✔ Application: Residential, Commercial, Industrial, Utilities ✔ Deployment: On-Premise, Cloud-Based, Hybrid

#SmartGrids #SemiconductorTech #EnergyInnovation #IoT #RenewableEnergy #GridModernization #SmartEnergy #GreenTech #TechInnovation #AIinEnergy #SustainableFuture #EnergyStorage #PowerManagement #DigitalTransformation #CyberSecurity #CleanEnergy #IoTSolutions #CloudComputing #DataAnalytics #EnergyEfficiency #UtilityTech #SmartInfrastructure #FutureOfEnergy #ResilientGrid #GreenEnergy

0 notes

Text

Gas Sensors Market Industry, Trends, Share by 2032 | Reports and Insights

The Reports and Insights, a leading market research company, has recently releases report titled “Gas Sensors Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Gas Sensors Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Gas Sensors Market?

The global gas sensors market was valued at US$ 2.8 Billion in 2023 and is expected to register a CAGR of 9.1% over the forecast period and reach US$ 6.1 Billion in 2032.

What are Gas Sensors?

Gas sensors are instruments used to detect and measure the levels of specific gases in the environment. They function by detecting changes in electrical, optical, or chemical properties triggered by the presence of target gases like carbon monoxide, methane, or oxygen. These sensors are essential in various applications, including industrial safety, environmental monitoring, automotive systems, and consumer electronics. By delivering real-time information on gas concentrations, gas sensors are critical for maintaining safety, meeting regulatory standards, and improving operational efficiency across different fields.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/2392

What are the growth prospects and trends in the Gas Sensors industry?

The gas sensors market growth is driven by various factors and trends. The gas sensors market is growing significantly due to rising needs for safety and environmental monitoring across various sectors. This growth is driven by increased industrial activity, stricter environmental regulations, and advancements in sensor technology. Key applications include industrial safety, air quality monitoring, automotive systems, and smart homes, where gas sensors play a crucial role in providing real-time data. Major market players are focusing on developing advanced sensors with improved sensitivity and accuracy. Despite challenges such as high costs and the necessity for ongoing technological updates, the market is expanding due to continuous innovation and the broader adoption of gas sensors across multiple industries. Hence, all these factors contribute to gas sensors market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product

Oxygen (O2)/Lambda Sensors

Carbon Dioxide (CO2) Sensors

Carbon Monoxide (CO) Sensors

Nitrogen Oxide (NOx) Sensors

Methyl Mercaptan Sensor

Others (Hydrogen, Ammonia, and Hydrogen Sulfide)

By Type

Wireless

Wired

By Technology

Electrochemical

Semiconductor

Solid State/MOS

Photo-ionization Detector (PID)

Catalytic

Infrared (IR)

Others

By End-Use

Medical

Building Automation & Domestic Appliances

Environmental

Petrochemical

Automotive

Industrial

Agriculture

Others

North America

United States

Canada

Europe

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

Benelux

Nordic

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America

Brazil

Mexico

Argentina

Middle East & Africa

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

ABB Ltd.

AlphaSense Inc.

City Technology Ltd.

Dynament

FLIR Systems, Inc.

Figaro Engineering Inc.

GfG Gas Detection UK Ltd.

Membrapor

Nemoto & Co. Ltd.

Robert Bosch LLC

Siemens

Among Others

View Full Report: https://www.reportsandinsights.com/report/Gas Sensors-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

Siemens Products Supplier Oman: Your Reliable Partner for Quality Solutions

When it comes to industrial and technological advancements, Siemens products supplier Oman stands out as a trusted partner for high-quality, innovative solutions. Siemens is renowned globally for its advanced technology and reliable products across various industries, including energy, automation, healthcare, and infrastructure. In Oman, trusted suppliers ensure businesses and industries have access to Siemens' cutting-edge products, providing solutions tailored to meet specific operational needs.

Comprehensive Range of Siemens Products

Siemens products supplier Oman offers a wide range of products designed to enhance efficiency and productivity. These include industrial automation equipment, electrical distribution systems, and energy-efficient solutions. From state-of-the-art programmable logic controllers (PLCs) to advanced switchgear and drives, Siemens products are engineered to deliver optimal performance.

Moreover, Siemens' innovative solutions are not limited to industrial automation. Suppliers in Oman also provide healthcare equipment and smart building solutions that cater to modern infrastructural demands. This extensive product range ensures that businesses and organizations across different sectors can find the right solutions to meet their needs.

Why Choose Siemens Products?

Siemens products are synonymous with innovation, quality, and efficiency. Businesses in Oman can benefit from the following features:

Advanced Technology: Siemens incorporates the latest technological advancements to ensure its products stay ahead of market trends.

Energy Efficiency: Many Siemens products are designed to reduce energy consumption, contributing to sustainability and cost savings.

Durability and Reliability: Built with high-quality materials and precise engineering, Siemens products offer long-lasting and dependable performance.

Custom Solutions: Siemens provides versatile products that can be tailored to meet the unique requirements of different industries.

Reliable and Certified Suppliers

Working with a trusted Siemens products supplier Oman ensures that you receive genuine and certified products. Reliable suppliers provide comprehensive support, from product selection and installation to maintenance and after-sales services. Their expertise helps businesses make informed decisions and achieve seamless operations.

Additionally, these suppliers often have trained professionals who understand the specifications and applications of Siemens products. Their guidance ensures that clients in Oman get the most out of their investments, improving overall operational efficiency.

Industries Benefiting from Siemens Products in Oman

Siemens products are widely used across various industries in Oman, including:

Oil and Gas: Siemens automation and electrical solutions help optimize processes and improve safety in oil and gas operations.

Manufacturing: Factories and production facilities benefit from Siemens automation equipment, drives, and control systems that enhance productivity.

Healthcare: Siemens' medical imaging and diagnostic equipment enable hospitals and healthcare providers to offer high-quality services.

Construction and Infrastructure: Smart building solutions from Siemens contribute to more efficient and sustainable infrastructure development.

After-Sales Support and Maintenance

Another advantage of working with a reliable Siemens products supplier Oman is the availability of after-sales support and maintenance services. Suppliers offer technical assistance and troubleshooting to ensure that your Siemens equipment operates optimally. Regular maintenance services help extend the lifespan of products and minimize operational downtime.

Conclusion

For businesses and industries in Oman seeking advanced technological solutions, a trusted Siemens products supplier Oman is essential. Siemens’ reputation for innovation, energy efficiency, and quality makes it a preferred choice across various sectors. Collaborating with a reliable supplier ensures access to genuine products, professional support, and customized solutions that cater to specific needs.

Whether you are looking to enhance your industrial processes or upgrade your infrastructure, partnering with a reputable Siemens products supplier Oman is a step towards achieving your operational goals. Contact a trusted supplier today and experience the difference Siemens products can make in your business.

1 note

·

View note