#Sewage treatment plant process

Explore tagged Tumblr posts

Text

https://www.advanceequipment.in/effluent-treatment-plant-manufacturer-supplier-in-punjab-india.php

#sewage treatment plant#water treatment plant#sewage treatment plant process#water treatment#sewage treatment#sewage treatment plant on ships#wastewater treatment#sewage treatment process#sewage treatment plants#marine sewage treatment plant#sewerage treatment plant#wastewater treatment plant#sewage treatment plant animation#sewage treatment plant working model#effluent treatment plant#marine sewage treatment plant working principle#treatment process

3 notes

·

View notes

Text

Sewage Treatment Plant: Meaning & Process

The STP full meaning is a sewage treatment plant that collects, treats, and discharges wastewater safely into the environment. As an STP plant manufacturer, the goal of Ravi Enviro Industries Pvt.Ltd is to prevent water pollution, protect the ecosystem, and ensure the safe disposal of sewage water. To know about how STP plant works, get in touch with REIPL today.

#stp full meaning#stp plant manufacturer in india#sewage treatment plant#sewage treatment plant process#stp plants#wastewater treatment plant manufacturer in india#etp plant

0 notes

Text

For top-quality Industrial Sewage Treatment Plant STP Manufacturers in India, turn to WTE Infra. Industrial Sewage Treatment Plant STP in India. Our cutting-edge STP solutions are designed to meet your industrial wastewater treatment needs and exceed your expectations. Our STP solutions are trusted by industries across the country for their efficiency, reliability, and cost-effectiveness. Trust us for superior quality and reliable service.

#Industrial Sewage Treatment Plant STP Manufacturers in India#Industrial Sewage Treatment Plant Manufacturer#STP Manufacturer#Industrial Sewage Treatment Plant Manufacturer In India#STP Manufacturer In India#Sewage Treatment Plant Process

0 notes

Text

What is an STP plant and how does it work?

Sewage treatment plants are wastewater treatment plants used to treat sewage wastewater before returning it to nature in a safe and eco-friendly form. It has four working stages - preliminary, primary, secondary, and tertiary treatment. Check out the full blog on the STP plant and its working from the link - https://pearlwater23.blogspot.com/2023/04/what-is-stp-plant-and-how-does-it-works.html

0 notes

Note

All the lakes in my state are artificial and filled with Mercury, even the Zodiac Killer one!

The Zodiac Killer probably died from heavy metal poisoning

id believe it

you definately don't want to go swimming in 90% of the lakes/rivers in my area

#this one river in my area is used as an overflow for all the sewage that can't be processed by the local wastewater treatment plant#and said river has this river front area with a restaurant that can barely stay open cause it floods#(with river water that's part sewage) everytime there is a storm

2 notes

·

View notes

Text

Compact QUANTUM 10PE Sewage Treatment Plant – Low Cost, Odourless, and Efficient

The QUANTUM 10PE ASP Sewage Treatment Plant offers efficient, odourless wastewater treatment for up to 10 people. With an ultra-compact design, low installation costs, and low energy demand, it’s perfect for domestic use. CE marked and EN12566-3 certified, the QUANTUM system ensures reliable, hassle-free performance. Contact us for more details.

#QUANTUM 10PE sewage treatment plant UK#ASP sewage treatment UK#compact sewage plant UK#domestic sewage treatment plant UK#odourless wastewater treatment plant UK#low-cost sewage treatment UK#sewage plant with air blower#low energy sewage treatment plant UK#HDPE sewage treatment plant UK#activated sludge process#sewage treatment for 10 people#Packaged Pumping Stations

0 notes

Text

Process Flow Diagram of Sewage Treatment Plant

Overview of Sewage Treatment Process Flow

At the start of a sewage treatment process flow, wastewater collection comes from a range of sources. This water comes through widespread pipes and moves on to its first treatment phase. Here, crude substances, such as debris and grit, are eliminated to stop equipment damage. As the water fills the primary treatment tanks, the heavier solids sink to the tanks' bottom surface next. Following completion of this phase, access to secondary treatment takes place for the wastewater. During this phase, organic materials biologically decompose as contaminant concentrations are dropping. The water heads to clarifiers to differentiate the rest of the solids. In the end, it arrives at the third treatment phase that unites advanced filtration with disinfection. Treated clean water enters nearby bodies of water or is used again for uses that do not require drinking water. Every phase of the operation is focused on smooth sewage treatment while remaining by environmental requirements.

Key Components of a Sewage Treatment Plant Flow Diagram

A sewage treatment plant flow chart presents a graphic explanation of the treatment steps. The start is where there is the inflow or inlet, which is the point through which wastewater enters the operation. The model illustrates the primary form of treatment, which eradicates big particles like grit. At this point, the primary treatment begins with settling tanks that cause solids to divide. Following that, secondary treatment takes place, in which biological mechanisms remove organic contaminants. At this phase, the diagram clarifies the difference between solid waste. During tertiary treatment, innovative filters together with disinfectants contribute to better processing of the water. Diagrams include systems for sludge processing along with sludge drying techniques. Arrows alongside labels signal the movement of water across every stage. A properly constructed flow diagram facilitates operator understanding and management of the elaborate sewage treatment process.

Step-by-Step Breakdown of the Sewage Treatment Process

Entry of sewage into the facility launches its sewage treatment plant for industries. During the start-up stage, large solids along with grit are eliminated. Eventually, the wastewater falls into tanks for primary treatment after that. Settling happens beneath because sedimentation originates from this point. The liquids that are remaining proceed into the secondary treatment stage. The biological processes presented, including aerobic decomposition, change organic matter. After that, it is essential to clarify by which the leftover solids differentiate from the water. Following secondary treatment, water first moves on to tertiary treatment. This concluding segment applies filters, along with disinfection, in a direction to remove any superfluous impurities. Eventually, the treated water is either sent down rivers or put to use for irrigation. All steps confirm the safety of wastewater for the environment after cleaning.

Understanding the Flow of Wastewater in Treatment Plants

In a treatment facility, a sequence of stages deals with the wastewater treatment plant. The method initiates once the plant obtains wastewater via the inflow pipes. The screening stage removes large debris as the water's first step. Within primary treatment, it migrates to sedimentation tanks.

Lighter materials head towards the surface, in contrast, thicker materials go down towards the bottom. Following completion of the first treatment phase, the wastewater rapidly flows into secondary treatment. Pollutant reductions happen because microorganisms are busy breaking down organic matter.

The flow carries through to clarifiers, the stage at which the final separation of solids happens. The next phase in treatment starts following the clarification of the water. In the phase where filtration combines with chemical disinfection, the quality of the water becomes better. At last, the water treated is out in rivers or storage for purposes of reuse.

Detailed Guide to Sewage Treatment Process Flow Stages

The several stages of sewage treatment are all important for the cleaning of wastewater. The introductory treatment gets underway with screens that remove substantial items including wood and plastic. Flowing water into primary treatment tanks causes solids to sink to the tank's bottom.

After this stage, secondary treatment will take place for the sewage, letting bacteria manage organic matter treatment. The coming phase consists of separating the liquid from what remains of the solids. Wastewater achieves a superior filtering system via tertiary treatment, which discards little particles and impurities.

Only after disinfection can the water be released or made use of it once more. Every phase is important for assuring that sewage is managed to meet environmental standards. A diagram that illustrates visually shows the transport of sewage through a treatment facility.

The inflow area identifies the leading entry location for wastewater to get to the plant. You can see the route water follows while passing through screens and grit chambers designed for debris separation in the flow diagram. The ensuing part of the diagram points out primary settling tanks, where the separation of solids takes place.

At the end of the day, the wastewater is in secondary treatment tanks receiving treatment from microbes that dissolve organic pollutants. The arrows reveal where the movement of water directs towards clarifiers that provide more separation.

For tertiary-level water treatment, advanced filtration combined with disinfection is a requirement. The diagram contains pathways devoted to sludge treatment as well. Due to the diagram, operators can nimbly manage all phases of the process.

Conclusion

The concluding result of the sewage treatment plant process flow diagram shows the necessary progression stages for wastewater treatment. Every phase, from primary inflow to the ultimate finish of discharge, is hugely important in water purification. At the outset, treatment removes big solid particles, and further on, primary treatment resolves the settling of solid waste. Secondary treatment consists of biological approaches that break apart contaminants. In time, tertiary treatment confirms that the water gets both filtration and disinfection all through the entire process. Operators can keep plant operations efficient and effective thanks to the understanding of how water flows through each phase. Every stage of treatment confirms that wastewater receives proper treatment, to maintain environmental and public health. A structured flow helps sewage treatment plants to uniformly meet environmental regulations over time.

#sewage treatment plant#sewage process#sewage management#sewage plant manufacturer#sewage plant equipments#sewage treatment plant in india#sewage treatment plant for industries#stp plant manufacturer#stp plant#stp plant supplier

0 notes

Text

Expert Effluent Treatment Plant (ETP) Solutions | Inhibeo Water Solutions

Is your industry struggling with efficient wastewater management? At Inhibeo Water Solutions, we offer customized Effluent Treatment Plant (ETP) solutions to help industries meet regulatory standards and reduce their environmental footprint.

Our ETP solutions: Remove pollutants and contaminants Recycle water for reuse Ensure compliance with regulations Optimize operational costs Discover how our expertise can transform your wastewater management.

Visit:

#effluent treatment plant manufacturers in Indore#zld plant manufacturer#compact effluent treatment plant#sewage treatment plant manufacturers Indore#mee evaporator manufacturer#sewage treatment plant suppliers#zero liquid discharge#wastewater treatment processes#water treatment plant suppliers#wastewater treatment Plant

0 notes

Text

#Sewage Treatment Plants#wastewater treatment#public health protection#environmental conservation#resource recovery#sewage treatment process#types of STPs#sustainable water management#urban wastewater solutions

1 note

·

View note

Text

Real-time access to all significant operational control points of your treatment assets and process

Wipro Water’s remote monitoring systems help lower risks and improve operations at water & wastewater treatment plants. We enable effective remote monitoring by leveraging technology we have developed to monitor plant performance in real time.

#industrial wastewater treatment technologies#industrial wastewater treatment#industrial wastewater treatment plant#industrial effluent treatment#industrial sewage treatment plant#industrial water and wastewater treatment#wastewater treatment process#industrial effluent treatment plant

0 notes

Text

"Revolutionizing Wastewater Management: Advance Equipment & Projects Pvt Ltd – Your Trusted Sewage Treatment Plant Manufacturer and Supplier"

In the realm of environmental sustainability, wastewater management plays a pivotal role in preserving our planet's precious resources. Enter Advance Equipment & Projects Pvt Ltd, a leading name in the field, dedicated to providing state-of-the-art sewage treatment solutions. As a renowned manufacturer and supplier, the company is committed to revolutionizing the way we handle and treat sewage, ensuring a cleaner and healthier environment for generations to come.

Key Features of Advance Equipment & Projects Pvt Ltd:

Cutting-Edge Technology: Advance Equipment & Projects Pvt Ltd is at the forefront of technological innovation in sewage treatment. The company employs cutting-edge technologies to design and manufacture advanced sewage treatment plants that adhere to the highest industry standards.

Customized Solutions: Understanding that each project comes with its unique set of challenges, the company offers tailor-made solutions to meet specific client requirements. Whether it's a large-scale municipal sewage treatment plant or a compact solution for an industrial setting, Advance Equipment & Projects Pvt Ltd has the expertise to deliver.

Environmental Sustainability: The company places a strong emphasis on eco-friendly practices. Their sewage treatment plants are designed to minimize the environmental impact while maximizing efficiency. This commitment to sustainability aligns with global efforts to create a greener and more sustainable future.

Compliance and Quality Assurance: with a focus on quality assurance and compliance with regulatory standards, Advance Equipment & Projects Pvt Ltd ensures that all its sewage treatment plants meet and exceed industry benchmarks. Clients can trust that their wastewater treatment needs are in safe hands with a company that prioritizes quality and adherence to regulations.

Experienced Team: Boasting a team of seasoned professionals and experts in the field of wastewater management, Advance Equipment & Projects Pvt Ltd brings a wealth of experience to every project. This team is dedicated to finding innovative solutions and providing top-notch customer service.

Global Reach: with a commitment to serving clients worldwide, Advance Equipment & Projects Pvt Ltd has established a global presence. This enables the company to contribute to international efforts in addressing water pollution and promoting sustainable water management practices.

#sewage treatment plant#sewage treatment plant manufacturer#effluent treatment plant manufacturer#sewage treatment#sewage treatment plant in india#sewage treatment plant supplier#wastewater treatment plant#effluent treatment plant#mbbr sewage treatment plant manufacturer#sewage treatment plant project#sewage treatment plant (stp) manufacturer#sewage treatment plant manufacturer in panipat#sewage treatment plant process#water treatment plant#sewage treatment plant on ships#marine sewage treatment plant working principle#stp#marine sewage treatment plant#sewage treatment plant animation#water treatment

1 note

·

View note

Text

Evaluating the Environmental Impacts of Wastewater Treatment Processes

Wastewater treatment is an essential process that helps remove harmful contaminants and pollutants from wastewater, making it safe to release back into the environment. However, while wastewater treatment is necessary for protecting public health and the environment, it also has its own set of environmental impacts. Evaluating these impacts is crucial for developing sustainable wastewater treatment processes that minimize negative environmental effects.

The first step in evaluating the environmental impacts of wastewater treatment process is understanding the various treatment processes used. Some common wastewater treatment processes include physical treatment, biological treatment, and chemical treatment. Physical treatment involves removing solid waste and debris from wastewater through screening and sedimentation. Biological treatment uses microorganisms to break down organic matter in wastewater. Chemical treatment involves using chemicals to remove specific contaminants from wastewater.

Each of these treatment processes has its own set of environmental impacts. For example, physical treatment may generate large amounts of solid waste that need to be disposed of properly. Biological treatment can require significant energy consumption and produce large amounts of sludge, which can pose risks to soil and water quality. Chemical treatment often involves the use of harsh chemicals, which can have negative impacts on aquatic life and the environment.

To evaluate the environmental impacts of wastewater treatment processes, it's essential to consider the entire treatment process from start to finish, including energy consumption, raw material inputs, and waste generation. A useful tool for assessing the environmental effects of wastewater treatment is a life cycle assessment (LCA).LCA involves analyzing the environmental impacts associated with every stage of a product or process, from raw material extraction to disposal.

The results of an LCA can help identify opportunities for improving the sustainability of wastewater treatment processes. For example, the results of an LCA may show that switching to renewable energy sources could significantly reduce greenhouse gas emissions associated with wastewater treatment. Alternatively, an LCA may show that using different chemicals or treatment processes could reduce the environmental impact of wastewater treatment.

Another important factor to consider when evaluating the environmental impacts of wastewater treatment is the location and scale of the treatment plant. Wastewater treatment plants located near sensitive ecosystems, such as wetlands or coastal areas, may have a greater impact on the environment than those located in less sensitive areas. Additionally, larger treatment plants may have a greater environmental impact than smaller plants due to increased energy consumption and waste generation.

One potential solution for minimizing the environmental impacts of wastewater treatment is to implement green infrastructure practices. Green infrastructure refers to using natural or engineered systems, such as wetlands, green roofs, or rain gardens, to manage stormwater and wastewater. Green infrastructure can help reduce the need for traditional wastewater treatment processes, which can be energy-intensive and have negative environmental impacts. Additionally, green infrastructure can provide multiple benefits beyond wastewater treatment, such as improving air and water quality, enhancing habitat, and reducing urban heat island effects.

In conclusion, evaluating the environmental impacts of wastewater treatment processes is crucial for developing sustainable and environmentally friendly wastewater treatment solutions. Using tools like life cycle assessment and implementing green infrastructure practices can help minimize negative environmental impacts associated with wastewater treatment. Ultimately, by evaluating and addressing the environmental impacts of wastewater treatment, we can ensure that we are protecting public health and the environment for generations to come.

#wastewater treatment systems#wastewater recycling#wastewater treatment plant#industrial wastewater treatment#water treatment process#sewage treatment process#domestic wastewater treatment#advanced wastewater treatment#waste water purification process

0 notes

Text

"Namibia is the driest country in Sub-Saharan Africa, and home to two of the world’s most ancient deserts, the Kalahari and the Namib. The capital, Windhoek, is sandwiched between them, 400 miles away from the nearest perennial river and more than 300 miles away from the coast. Water is in short supply.

It’s hard to imagine life thriving in Windhoek, yet 477,000 people call it home, and 99 per cent of them have access to drinking water thanks to technology pioneered 55 years ago on the outskirts of the city. Now, some of the world’s biggest cities are embracing this technology as they adapt to the harshest impacts of climate change. But Namibia leads the way.

How did this come about? In the 1950s, Windhoek’s natural resources struggled to cope with a rapidly growing population, and severe water shortages gripped the city. But disaster forced innovation, and in 1968 the Goreangab Water Reclamation Plant in Windhoek became the first place in the world to produce drinking water directly from sewage, a process known as direct potable reuse (DPR).

That may sound revolting, but it’s completely safe. Dr Lucas van Vuuren, who was among those who pioneered Windhoek’s reclamation system, once said that “water should not be judged by its history, but by its quality”. And DPR ensures quality.

This is done using a continuous multi-barrier treatment devised in Windhoek during eight years of pilot studies in the 1960s. This process – which has been upgraded four times since 1968 – eliminates pollutants and safeguards against pathogens by harnessing bacteria to digest the human waste and remove it from the water. This partly mimics what happens when water is recycled in nature, but Windhoek does it all in under 24 hours...

Pictured: These ultrafiltration membranes help to remove bacteria, viruses and pathogens. Image: Margaret Courtney-Clarke

“We know that we have antibiotics in the water, preservatives from cosmetics, anti-corrosion prevention chemicals from the dishwasher,” Honer explains. “We find them and we remove them.”

Honer adds that online instruments monitor the water continuously, and staff ensure that only drinking water that meets World Health Organisation (WHO) guidelines is sent to homes. If any inconsistencies are detected, the plant goes into recycle mode and distribution is halted until correct values are restored.

“The most important rule is, and was, and always will be ‘safety first’,” says Honer. The facility has never been linked to an outbreak of waterborne disease, and now produces up to 5.5m gallons of drinking water every day – up to 35 per cent of the city’s consumption.

Namibians couldn’t survive without it, and as water shortages grip the planet, Windhoek’s insights and experience are more important than ever.

Interest from superpowers across the globe

In recent years, delegations from the US, France, Germany, India, Australia, Singapore, and the United Arab Emirates have visited Windhoek seeking solutions to water shortages in their own countries.

Megadrought conditions have gripped the US since 2001, and the Colorado River – which provides 40 million people with drinking water – has been running at just 50 per cent of its traditional flow. As a result, several states including Texas, California, Arizona and Colorado are beginning to embrace DPR.

Troy Walker is a water reuse practice leader at Hazen and Sawyer, an environmental engineering firm helping Arizona to develop its DPR regulations. He visited Windhoek last year. “It was about being able to see the success of their system, and then looking at some of the technical details and how that might look in a US facility or an Australian facility,” he said. “[Windhoek] has helped drive a lot of discussion in industry. [Innovation] doesn’t all have to come out of California or Texas.”

Pictured: The internal pipes and workings of Namibia's DPR plant. As water becomes scarcer in some parts, countries are looking to DPR for solutions. Image: Margaret Courtney-Clarke

Namibia has also helped overcome the biggest obstacle to DPR – public acceptance. Disgust is a powerful emotion, and sensationalist ‘toilet to tap’ headlines have dismantled support for water reuse projects in the past. Unfortunately, DPR’s biggest strength is also its biggest weakness, as the speed at which water can re-enter the system makes it especially vulnerable to prejudice, causing regulators to hesitate. “Technology has never been the reason why these projects don’t get built – it’s always public or political opposition,” says Patsy Tennyson, vice president of Katz and Associates, an American firm that specialises in public outreach and communications.

That’s why just a handful of facilities worldwide are currently doing DPR, with Windhoek standing alongside smaller schemes in the Philippines, South Africa and a hybrid facility in Big Spring, Texas. But that’s all changing. Drought and increased water scarcity worldwide are forcing us to change the way we think about water.

Now, the US is ready to take the plunge, and in 2025, El Paso Water will begin operating the first ‘direct to distribution’ DPR facility in North America, turning up to 10m gallons of wasterwater per day into purified drinking water – twice as much as Windhoek. San Diego, Los Angeles, California, as well as Phoenix, Arizona are also exploring the technology."

Of course, DPR is not a silver bullet in the fight against climate change. It cannot create water out of thin air, and it will not facilitate endless growth. But it does help cities become more climate resilient by reducing their reliance on natural sources, such as the Colorado River.

As other nations follow in Namibia’s footsteps, Windhoek may no longer take the lead after almost six decades in front.

“But Windhoek was the first,” Honer reminds me. “No one can take that away.”"

-via Positive.News, August 30, 2023

#namibia#africa#desert#water shortage#water conservation#dpr#potable water#water recycling#clean water#drought#united states#colorado river#science and technology#sanitation#good news#hope

2K notes

·

View notes

Text

The Flood-Protection Rule That Trump Rolled Back. (New York Times)

Excerpt from this New York Times story:

In the summer of 2017, Donald Trump stood in the lobby of Trump Tower and declared he would heal a “massive self-inflicted wound on our country” by eliminating red tape that he said was making construction in America an arduous, expensive process.

One policy he eradicated that day was a set of standards aimed at ensuring that anything built with taxpayer money — including hospitals, sewage treatment plants, bridges and libraries — could withstand flooding and rising seas caused by climate change.

Seven years later and in the wake of hurricanes Helene and Milton, federal officials and flood experts say Trump’s decision to roll back those federal infrastructure standards has had financial ramifications. Those are just starting to come into view as officials continue to tally the damage from the storms.

According to state and federal data, at least five water treatment plants in Florida that were in the path of Helene and Milton were exempt from tougher national building standards and sustained damage from the hurricane ranging from water line breaks to power losses. In total, they were funded with about $200 million in federal spending.

Another seven water plants across the Southeast that together received more than $100 million in federal funding were built to lower flood standards and didn’t receive damage during Helene or Milton. But the plants are considered at high risk for damage in the future, and what worries experts is how many crucial infrastructure plants are similarly exposed.

“We can definitively say that risk increased,” said Alice C. Hill, a senior fellow in energy and environment at the Council on Foreign Relations. “The federal government continues to invest in infrastructure destined to fail in the light of worsening climate impacts.”

“Hurricanes Helene and Milton are a stark reminder that catastrophic flooding, and the climate crisis more broadly, present ongoing and worsening challenges for America’s critical water infrastructure,” said Zealan Hoover, a senior adviser to the E.P.A. administrator, Michael Regan.

Hoover said policies like the flood standard “have real consequences for Americans,” including ensuring that communities can maintain access to drinking water in the wake of disasters.

The standards in question were created under President Obama in 2015, who made the case that climate change would make floods more common and much more destructive.

The rules called for building structures two or three feet above the 100-year flood level, or built at the 500-year level. Alternately, federal agencies could analyze future climate change scenarios like sea-level rise or expected heavier floods, and build according to those projections. But the policy ran into opposition, particularly from homebuilders who argued that new restrictions would lead to higher construction costs even outside federally funded projects.

28 notes

·

View notes

Note

Does on boats the poop stored then thrown once the boat is on land, or thrown directly in the sea ? HOW TOILETS ON BOATS WORKS ????

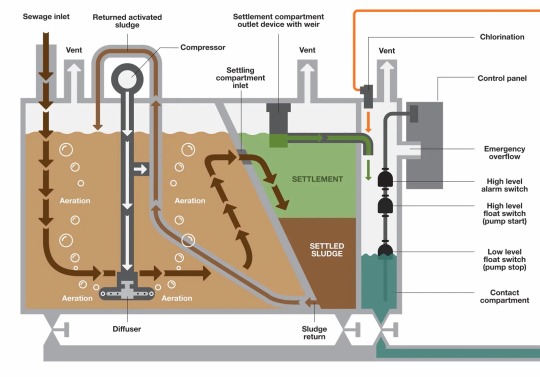

the toilet is a vacuum system like on aircrafts. the poop is sucked thru the vacuum to the STP, the sewage treatment plant. there are a few different types of STP but for simplicity we'll talk abt the 3 stage STP.

raw sewage enters the first stage on the left where it is decomposed by aerobic bacteria. the aerobic bacteria are supplied air by air blowers. the resulting effluent overflows into the second stage where it seperates into water and sludge. the water overflows and is chlorinated before being discharged into the ocean. the sludge left over feeds back into the first stage until it is processed.

if the ship is more than 12 nautical miles from shore it's legal to discharge raw, untreated sewage, but this isnt common in my experience.

13 notes

·

View notes

Text

QUANTUM 8PE Activated Sludge Process (ASP) Sewage Treatment Plant: Advanced ASP sewage treatment with low cost, ultra-compact, odourless, quiet, and low energy. 100% aerobic for no smell, 1/5 size of competitors, made from durable HDPE in UK, optional pumped outlet, integrated air blower for minimal visual impact. CE and EN12566-3 certified.

#QUANTUM 8PE#Activated Sludge Process#ASP#sewage treatment plant#low-cost sewage treatment#ultra-compact sewage system#odourless wastewater treatment#low-noise sewage plant#low electricity sewage plant#adjustable sewage treatment#UK sewage treatment

0 notes