#Sewage Treatment Plant flow diagram

Explore tagged Tumblr posts

Text

Process Flow Diagram of Sewage Treatment Plant

Overview of Sewage Treatment Process Flow

At the start of a sewage treatment process flow, wastewater collection comes from a range of sources. This water comes through widespread pipes and moves on to its first treatment phase. Here, crude substances, such as debris and grit, are eliminated to stop equipment damage. As the water fills the primary treatment tanks, the heavier solids sink to the tanks' bottom surface next. Following completion of this phase, access to secondary treatment takes place for the wastewater. During this phase, organic materials biologically decompose as contaminant concentrations are dropping. The water heads to clarifiers to differentiate the rest of the solids. In the end, it arrives at the third treatment phase that unites advanced filtration with disinfection. Treated clean water enters nearby bodies of water or is used again for uses that do not require drinking water. Every phase of the operation is focused on smooth sewage treatment while remaining by environmental requirements.

Key Components of a Sewage Treatment Plant Flow Diagram

A sewage treatment plant flow chart presents a graphic explanation of the treatment steps. The start is where there is the inflow or inlet, which is the point through which wastewater enters the operation. The model illustrates the primary form of treatment, which eradicates big particles like grit. At this point, the primary treatment begins with settling tanks that cause solids to divide. Following that, secondary treatment takes place, in which biological mechanisms remove organic contaminants. At this phase, the diagram clarifies the difference between solid waste. During tertiary treatment, innovative filters together with disinfectants contribute to better processing of the water. Diagrams include systems for sludge processing along with sludge drying techniques. Arrows alongside labels signal the movement of water across every stage. A properly constructed flow diagram facilitates operator understanding and management of the elaborate sewage treatment process.

Step-by-Step Breakdown of the Sewage Treatment Process

Entry of sewage into the facility launches its sewage treatment plant for industries. During the start-up stage, large solids along with grit are eliminated. Eventually, the wastewater falls into tanks for primary treatment after that. Settling happens beneath because sedimentation originates from this point. The liquids that are remaining proceed into the secondary treatment stage. The biological processes presented, including aerobic decomposition, change organic matter. After that, it is essential to clarify by which the leftover solids differentiate from the water. Following secondary treatment, water first moves on to tertiary treatment. This concluding segment applies filters, along with disinfection, in a direction to remove any superfluous impurities. Eventually, the treated water is either sent down rivers or put to use for irrigation. All steps confirm the safety of wastewater for the environment after cleaning.

Understanding the Flow of Wastewater in Treatment Plants

In a treatment facility, a sequence of stages deals with the wastewater treatment plant. The method initiates once the plant obtains wastewater via the inflow pipes. The screening stage removes large debris as the water's first step. Within primary treatment, it migrates to sedimentation tanks.

Lighter materials head towards the surface, in contrast, thicker materials go down towards the bottom. Following completion of the first treatment phase, the wastewater rapidly flows into secondary treatment. Pollutant reductions happen because microorganisms are busy breaking down organic matter.

The flow carries through to clarifiers, the stage at which the final separation of solids happens. The next phase in treatment starts following the clarification of the water. In the phase where filtration combines with chemical disinfection, the quality of the water becomes better. At last, the water treated is out in rivers or storage for purposes of reuse.

Detailed Guide to Sewage Treatment Process Flow Stages

The several stages of sewage treatment are all important for the cleaning of wastewater. The introductory treatment gets underway with screens that remove substantial items including wood and plastic. Flowing water into primary treatment tanks causes solids to sink to the tank's bottom.

After this stage, secondary treatment will take place for the sewage, letting bacteria manage organic matter treatment. The coming phase consists of separating the liquid from what remains of the solids. Wastewater achieves a superior filtering system via tertiary treatment, which discards little particles and impurities.

Only after disinfection can the water be released or made use of it once more. Every phase is important for assuring that sewage is managed to meet environmental standards. A diagram that illustrates visually shows the transport of sewage through a treatment facility.

The inflow area identifies the leading entry location for wastewater to get to the plant. You can see the route water follows while passing through screens and grit chambers designed for debris separation in the flow diagram. The ensuing part of the diagram points out primary settling tanks, where the separation of solids takes place.

At the end of the day, the wastewater is in secondary treatment tanks receiving treatment from microbes that dissolve organic pollutants. The arrows reveal where the movement of water directs towards clarifiers that provide more separation.

For tertiary-level water treatment, advanced filtration combined with disinfection is a requirement. The diagram contains pathways devoted to sludge treatment as well. Due to the diagram, operators can nimbly manage all phases of the process.

Conclusion

The concluding result of the sewage treatment plant process flow diagram shows the necessary progression stages for wastewater treatment. Every phase, from primary inflow to the ultimate finish of discharge, is hugely important in water purification. At the outset, treatment removes big solid particles, and further on, primary treatment resolves the settling of solid waste. Secondary treatment consists of biological approaches that break apart contaminants. In time, tertiary treatment confirms that the water gets both filtration and disinfection all through the entire process. Operators can keep plant operations efficient and effective thanks to the understanding of how water flows through each phase. Every stage of treatment confirms that wastewater receives proper treatment, to maintain environmental and public health. A structured flow helps sewage treatment plants to uniformly meet environmental regulations over time.

#sewage treatment plant#sewage process#sewage management#sewage plant manufacturer#sewage plant equipments#sewage treatment plant in india#sewage treatment plant for industries#stp plant manufacturer#stp plant#stp plant supplier

0 notes

Text

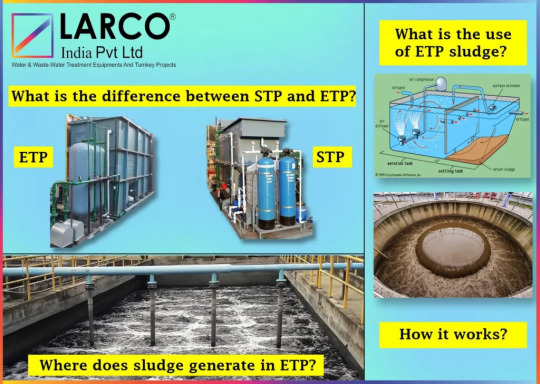

What is the difference between STP and ETP?

In this article, we’ll look What is the difference between STP and ETP?

Certainly! Let’s break down the differences between STP (Sewage Treatment Plant) and ETP (Effluent Treatment Plant) in simpler terms.

To preserve the receiving waterways, two particular treatments, sewage treatment and effluent treatment are used to remove toxins from wastewater (sludge). Both of these treatments are made up of physical, chemical, and biological processes. The primary distinction between the two STP & ETP.

WHAT IS THE DIFFERENCE BETWEEN STP AND ETP?

Sewage Treatment Plant (STP):

What it does: STP handles the treatment of the waste water that is generated by residences, businesses, and other common locations (such as restrooms, sinks, etc.). Sewage is the term for this unsafe water.

Goal: The main duty of a STP is to treat this sewage so that it can be safely discharged into bodies of water like rivers and oceans or even utilized (for example, to water plants).

How it works: It works by separating solid waste from liquid waste, utilizing beneficial bacteria to break down trash, and adding chemicals to the water. STP Industries Inc. develops products to minimize the amount of toxic substances in sewage.

Effluent Treatment Plant (ETP):

What it does: Industrial wastewater, usually referred to as effluent, is the smelly water that is produced by factories and other industrial facilities.

Goal: An ETP, short for “environmental technology product,” is a chemical substance created to clean up industrial effluent so that it may be reused or released back into the environment in a manner that does not threaten the ecosystem.

How it works: The Etp wastewater solutions can be used to clean industrial wastewater. Sometimes these solutions might involve using chemicals, separating various materials, and occasionally using microbes to degrade dangerous materials.

To put it simply, STP cleans the environment by handling the regular, unclean water from households and businesses. ETP, on the other hand, controls the unsavoury water that emanates from industrial facilities, ensuring its safety before releasing or reusing it. With the aid of specialized techniques, each plant is created to manage a particular kind of contaminated water.

WHAT IS THE USE OF ETP SLUDGE?

https://larcoindia.in/wp-content/uploads/2023/10/diagram-package-plant-aeration-treatment-sewage-flows-1-1.png

What is the use of ETP sludge?

The uses of ETP sludge are many and varied:

https://larcoindia.in/wp-content/uploads/2023/10/wastewater-treatment-pool.jpg

Other use of ETP sludge:

the disposal of treated sewage sludge, which is combined with air and oxygen and applied to agricultural soil as a soil conditioner.

Sewage sludge is disposed of through burning, which involves burning it alongside other waste products like paper and plastic to create steam and energy for industrial uses or to create heat for home usage.

Typically, sewage sludge from sewage treatment plants is burned in a facility along with other waste products like paper and plastic. This burning process generates heat, which is then used to create steam that can be used both to heat domestic water in houses and for industrial applications.

The primary issue with using ETP sludge is that it includes a lot of ammonia (NH3), which is extremely harmful to people if consumed in large amounts over an extended period of time.

WHERE DOES SLUDGE GENERATE IN ETP?

So what you think, Where does sludge generate in ETP?

In an Effluent Treatment Plant (ETP), sludge is formed during the process of treating industrial wastewater. This sludge is essentially the solid waste that settles or is removed during the treatment of the wastewater. It contains the solid particles and pollutants that are separated from the water during the treatment process. The sludge includes things like particles of dirt, chemicals, and other materials that were in the wastewater.

To explain further, when the dirty industrial wastewater goes through the treatment steps, certain solid substances and pollutants settle down or are separated from the water. This separation forms a thick, muddy material, which we call sludge. Managing and disposing of this sludge properly is an important part of the overall wastewater treatment process to ensure that the environment is not negatively impacted.

#wastewatertreatment#watertreatmentsolutions#water purification#etp#sewagetreatmentplant#water treatment

0 notes

Text

Effluent Treatment Plant: Process and Flow Diagram in Pharma Industry

The pharmaceutical industry plays a pivotal role in our economy, contributing in multifaceted ways. It encompasses the discovery, development, production, and marketing of drugs and pharmaceuticals for patient treatment and symptom alleviation. Given its water-intensive processes, the industry inevitably discharges wastewater into the environment, whether treated or untreated.

For optimal results, you require top-notch equipment, offered at a more affordable rate compared to our market counterparts. Today, we introduce you to one of our flagship products – the Effluent Treatment Plant (ETP) – and shed light on its pivotal role in the pharmaceutical industry. Not limited to ETP’s we also have expertise and experience as sewage treatment plant manufacturer in Noida.

1 note

·

View note

Text

Cool facts... older US cities may have what's called a "Combined Sewer System." NYC is an older city. It's had updates! So SOME of the storm drain pipes are just for street runoff... but... uh. Bad news for mutant turtles.

Look. I'm just gonna quote from the NYC municipal website (and its nifty diagrams) linked below.

About 60% of New York City has a combined sewer system. In a combined sewer system, there is a single pipe that carries both stormwater runoff and sewage from buildings. This mix of stormwater and sewage is usually sent to a wastewater treatment plant.

During heavy rainstorms, combined sewers receive higher than normal flows. Treatment plants are unable to handle flows that are more than twice the design capacity. When this occurs, a mix of stormwater and untreated sewage discharges directly into the City’s waterways.

During REAAAALLLY bad rainstorms, the whole system floods up into the streets, subways, and basement apartments. You may have seen video clips online of NYC flooding during hurricanes and tropical storms. I'll drop one below.

youtube

So... uh. For mutant turtles--yikes. Might be why they don't wear shoes. Better to wash off feet/legs/wraps than to stick your toes repeatedly into rotting sewage sneakers. (And ninjas don't wear rubber boots. That'd just be silly. 😉)

Every day I’m haunted by the fact the boys happily swim in sewer water

Even if it’s filtered somehow there’s no way it’s not still nasty 😭 Bet they can defeat any of their villains just by accidentally giving them diseases I swear

#tmnt#teenage mutant ninja turtles#donatello#leonardo#michelangelo#raphael#tmnt fandom#tmnt fanfiction#this is also why IRL we do not swim in flood water if at all possible to avoid#flood water can make you so sick for real#Youtube

647 notes

·

View notes

Link

Sharp Engineering Works is the leading manufacturer and supplier of the wastewater treatment plant in India. Our range of wastewater treatment plants consists of RO Plants, Activated Sludge Plants, Flue Gas Desulphurization Plant and Effluent Treatment Plant solutions. For clients in various industries such as Chemical & Pharmaceutical, RO Plants, Medical, Dyes & Intermediates, Food & Beverages etc., we provide customized designs to suit their requirements.

Sharp Engineering Works has experience of more than 20 years in the design and development of Water Treatment plants for Municipal & Industrial Wastewater Treatment. Our Water Treatment plants are manufactured using advanced technology for better performance, longer life, easy maintenance & trouble-free operation.

#Wastewater treatment plant manufacturers#Wastewater treatment in Hyderabad#Sewage Treatment Plant manufacturers in India#Sewage Treatment Plant flow diagram

0 notes

Text

Messung Automation Solutions for Water and Waste Water Projects

industrial automation & control systems suppliers

The Rising Demand

By year 2050, the global demand for water will rise by 55%. The 2015 report by United Nations World Water Development projects this rise across the various sectors.

India’s economy also critically depends on use and management of water for agriculture, industry and domestic consumption. Recognizing this dependence, the Ministry of Water Resources plans to invest significant funds into management of water and wastewater sector.

Some of the aims of good water resources management are:

· Improvement of water quality

· Improving energy efficiency while managing and treating water

· Minimizing leakage and wastage

· Conservation of resources

· Reducing downtime and operating costs

Use of dedicated Industrial Automation & Control Systems effectively meets the above objectives, at a cost-effective price point.

Infrastructure for Water Treatment

To supply quality water in the desired quantities, a typical city may have more than 20 to 30 Water Treatment Plants (WTP’s). At the discharge end, for treating used and polluted water, the city may have an equal number of Waste Water Treatment Plants (WWTP’s).

For optimum efficiency and speed of response, a Centralized Control and Monitoring Station supervises all the equipment and processes of plants from a single location. This Station accepts numerous inputs from all the plants to deliver real-time corrective responses to the changing parameter and conditions. As an upgrade, tech-savvy Municipal authorities now demand a cloud-based solution for supervision of all the water treatment facilities.

High-technology automation solutions conforming to industry standard protocols are essential to implement the future needs of the water treatment plants.

Challenges of Water Supply System

Designing and operating of water supply systems calls for a multi-criteria approach. In every case, water treatment system must reliably produce quality water at the lowest possible costs.

The criteria for water treatment process are:

· Flow of raw and treated water along with dosing of treatment chemicals

· Monitoring of water pressure at upstream and downstream locations and at critical points

· Monitoring levels in rivers, wells and reservoirs

· Disposal of sludge

· Monitoring of temperature for motors, bearings and valves

· Dosing of Fluorine, Chlorine and Calcium

· Monitoring turbidity and water quality

Water Treatment domain consists of several critical processes that can benefit from high technology automation for delivering consistent results.

Water Treatment Automation Solutions from Messung

Messung are the pioneers of Indian automation domain. A leading industrial automation & control systems supplier with over 3 decades of domain expertise, tens of thousands of Messung Programmable Logic Controllers (PLC) and allied products meet the automation challenges of Indian industries, under actual local site conditions.

With a view to the future, Messung now offers NX-ERA, the complete industrial automation solution for monitoring and controlling the entire water management process.

Messung’s NX-ERA PLC Systems can automate a variety of Water Treatment applications.

These include:

· Water Treatment Plant

· Reverse Osmosis Plant

· De-mineralized Water Plant

· Sewage Treatment Plant

· Effluent Treatment Plant

· Pumping Stations

· Reservoir Controls

Features of Messung NX-ERA

· One vendor – many solutions

· Easy to set-up, maintain, operate

· Compatible with all industry standard protocols

· Highly reliable system with high Mean Time Between Failures (MTBF) and low Mean Time to Repair (MTTR), with redundancy

· Local and remote access, with control to private mesh

· Local Human-Machine Interfaces (HMI’s) and Central Supervisory System

· Uses Open Protocols and Networks

· Power efficient with a small footprint

· Adds Distributed Control System (DCS) functionality through multiprocessing capability

· Can operate large numbers of remote Input/Output (I/O) points and backplane racks for implementing distributed architecture with redundancy

· Supports large screen displays and database server

· Interfaces with Supervisory Control and Data Acquisition (SCADA) systems

· Modular and expandable

Programming through the IEC 61131-3 compliant MasterTool IEC XE software.

·Easy to learn with rich graphics and intuitive textual language

·Function Block Diagram (FBD) that enables segmentation of block system to simplify maintenance and simultaneous execution of different tasks

·Multiple languages available within these blocks for versatility across the globe

Conclusion

Messung’s NX-ERA process automation and control solutions optimize complex control for water treatment and distribution systems. These solutions help implement highly efficient WTP designs that help treat and conserve water, an increasingly scarce resource.

The water-scarce future mandates a high degree of precision and reliability of water treatment plants. Messung’s process control and automation solutions effectively meet the monitoring and control requirements of water treatment with increased plant safety and availability.

Contact Messung for process automation & control solutions in India as well as smart factory automation & control solutions with Scada and power system automation, and machine automation & control solutions with cutting-edge Servo & Motion controls.

#industrial automation & control systems suppliers#industrial automation & control solutions in India#process automation & control solutions in India#process automation & control solutions in#factory automation & control solutions#smart factory automation & control solution in India#plc automation control panel

1 note

·

View note

Text

Form Follows Flow

Ooze architects were founded in 2003 by Eva Pfannes and Sylvain Hartenberg. They are based in Rotterdam and work internationally for different municipalities, property developers, arts and cultural institutions and private clients.

Eva Pfannes and Sylvain Hartenberg at the Sitio Burle Marx presentation in Rio de Janeiro, Brazil | Photo © Rodrigo

With Eva and Sylvain we discussed how they combine understanding of natural processes with technological expertise either in temporary art works or regional urban strategies. The cyclic closed-loop processes found in nature are the foundation for each intervention of Ooze’s work.

Ooze (üz) is a soft deposit on the bottom of a body of water, a marsh or bog that results from the flow of a spring. Let the water flows begin.

---

What is a role of an architect today?

Sylvain: There are many different levels of practicing architecture. The future architect is a mediator, integrator of social, built and financial processes. The role of the architect is expanding and becoming linked to financial issues, to heal specific community or social context and remediate broken urban fabrics.

Eva: In the past lots of project strings happened separately. There architect, developer, landscape architect, engineer, water engineer was separated but with the climate changes we need to integrate all experts together and make solutions that works. If we separated it, many cities prove the social or financial suffering.

In which sense visualize the processes?

Eva: To visualize the processes means to visualize the unbuilt for. As working with water, we could say that Form Follows Flow. These flows in urban environments are mostly hidden under the ground. The more modern society has become the more hidden are its processes. With all the question how can we live more sustainable and in harmony with the planet, we need to visualize and understand those processes and how we can work with them. That’s where we also see our role to visualize processes and then use them to connect them to many complex parts.

Diagram visualization for the project The City of 1000 Tanks. | Source © Ooze

In a way you need to invent your own approach? Like your system-thinking on the practical base?

Sylvain: Both of us have a more standard (European) German and French education but also studied in Bartlett UCL London where we learn to work with the narrative and process. The hybrid between these two is what we are doing in our practice now. We try to address much bigger and important issue and to bridge and question what is really needed in specific situation.

So, it depends a lot about the education?

Eva: When we start working on an art piece with Marjetica Potrč, we start with the intact research of the context. This way of working we developed intuitively. It was not something that we learn in school but part we learn by doing. Right now, we are working on an urban strategy and implementation project The City of 1000 Tanks in India where we very much getting into the financing of projects.

Between Waters in collaboration with Marjetica Potrč. | Photo © Hans Blossey

A simple diagram was created in a real scale on the location. | Photo © Bas Princen (up) © Roman Mensing (down)

How you deal with the project funding?

Eva: We can take the example of the Rio de Janeiro, where we were very much self-driven by the idea if there is possible to realize a project because there is no sewage system, especially on vulnerable parts of the city. We were driven by the idea that it must be possible to integrate nature that this locally becomes the treatment of the polluted water. After four years of investigations research production of pilot projects and events, we finally understood that we could not operate outside the system of public works. Although those services are not provided in the zone we were operating in, when we talk about water and sewage we need to get engaged with the public realm. Tendering processes are protected, concessions are given after a long time, like ten years in advance. Innovation in this area is incredibly difficult. To find funding as well is very long term.

How can you survive?

Sylvain: Only when you are supported by the government program or heavy weight stakeholders. That’s the case of the project in India with the Dutch Ministry of the Foreign Affair as a client. In such way you have access to financial mechanism and you can deal with the big scale reality. In the project of Rio we were pioneers, supported only by the Dutch Creative Industry with no political anchorage nor local financial support except for the cultural institutions we partner for the various phase of the project.

Can a small-scale art project become a learning process?

Eva: Of course. With the given budget we realized that we become the clients and the contractors. In such way we take the risk but then you can also execute it with no one in-between. You learn how to lead it, so the learning process is not only for the users but also for the creators.

Diagram of The Pond Club in King's Cross London. | Source via © Ooze

How do you incorporate the natural environment into the urban areas?

Eva: The participatory process especially working with nature is very context related. You need to the people to make something that works for them and it is very important to listen before you come up with ideas.

Sylvain: In all our recent projects you can see how all our thinking is conceived by disturbing processes. As the eternal investment is driving the world, we kind of intrigue this crazy jungle. That makes our principle and activities dealing with the social.

When nature becomes a part of the planning process, how do you deal with unpredicted?

Eva: Look for example the Pond. The client wanted us to sign the contract where we agreed that the landscape would be beautiful. We declined this very subjective impression. Instead we took a part of the landscape and start to work as a contractor for the wild plants on the site. We started to interact with the client. In the begging was the earth, later the plants grew and created a new wildlife. It is important to communicate the narrative and people need to understand that nature cannot be always the same and predicted. In the case of the project of the Kings cross pond club, people for example would come back every two weeks to check the changing landscape.

The realization of The Pond Club in King's Cross. | Photo © John Sturrock

What is engineered nature? What is a difference between a natural and constructed wetland?

Eva: When we mentioned constructing wetlands people were thinking about a lake. Natural wetlands are everywhere where water meet the land. Many places of our cities used to be wetlands as floods are specific and can enrich the water and soil with oxygen, which then removes polluters from the water. The wetlands can clean the water and with engineering this you make a controlled environment. For example, the volume of water in the Pond could take care exactly of 163 swimmers per day. That is what nature can deal with. The same for a constructed wetland, a certain area of it can take care of the sewage waste of a certain number of people just by using and guiding the natural processes which exist in nature already.

The changing nature of The Pond in London. | Photo © John Sturrock

Sylvain: If for instance we would have put more mineral filters then we could change the volume of the water and the surfaces of filters. Nature reaches the goal so you need to understand these processes and replicate them.

What is important in a partnership with the local community? How do you create trust?

Eva: As for example on Agua Carioca we went into communities where we had connections. Somebody introduced us to the community. The next were interviews. We were listening to the people, which makes people empowered as this in favelas doesn’t happen very often. People were extremely aware of the environment because it was so close to them. The next step was invitation to the events. You come back again and again and again. That builds trust.

The excursion in the community of the Agua Carioca. | Photo © Rodrigo

Sylvain: For the project development is also important the identification of the spokesman in community.

What about the trust in the commercial locations?

Eva: Yes, the Pond was not in the slum but in the middle of London. As everybody had access to the project, the community embraced it. They formed the group, which came up with the petition to keep the pond signed by 5000 people. From this number 1500 people left online message and 300 people talked about love.

Are your interventions systems of disobedience (it is not necessary to use chloride in water as the human body reacts to water)?

Eva: Our systems are about empowerment in a positive way. It is giving people the tools to understand the processes and deal with them. Project Between the Waters with Marjetica Potrč was a diagram of the water sewage treatment. Every part was visible, colorful and understandable. At the end we engage the people into trusting the different steps of natural base solution processes which manages to treat sewage and render it drinkable. the people could see all the steps and engage in this cycle by drinking the water at the last step of the filtration process. They could see and perceive the steps from urine to drinkable water, and that is what they would drink. This is how simple it is, it is the same how you treat the water. It is disobedience but also empowerment because you understand how simple is to get off the grid. A political act how to show people to live off the grid.

7 notes

·

View notes

Text

Do-It-Yourself Septic Tank Installation Leander TX: Types, Diagrams And Production

The dream of the owner of a country house is the septic tank installation leander tx system, which works without interruption and the cost of a large amount of electricity. It is precisely these qualities of a septic tank that allow a high rate of wastewater treatment. It is not always possible to acquire these mechanisms, since the cost of such structures from well-known manufacturers is quite high. But you can find to solve this problem by building a structure with your own hands. We provide good quality service connect us 254-263-4141.

Several years ago, treatment facilities included sumps in which the accumulation of wastewater took place and its subsequent pumping. The modern construction market offers an improved mechanism for collecting and pumping wastewater. In a private or rural house, designed for permanent residence, a sewage treatment system is simply necessary.

The design consists of 2 or 3 tanks connected to each other by a pipe.

Each tank has vents.

The tanks are fitted with waterproof lids.

Filtration area, in which the final treatment of wastewater. Traditional filters are: drainage wells, infiltrators.

The most effective are the mechanisms made up of 3 chambers. In this case, the cleaning of septic tank installation leander tx is more thorough. When preparing to make even a homemade mini-septic tank, you need to remember that the structure of the future cleaning mechanism will include 2 cameras.

The principle of the treatment plant:

the drains enter the receiving chamber of the mechanism (colon);

large waste is sorted by settling;

all waste elements undergo a fermentation process through bacteria living in the cleaning system;

impurities decompose and release gases which escape through the air vents;

within a certain time, the contaminating components dissolve in the liquid;

at the exit of the septic tank, a purified liquid at 95% flows, this water being able to be used for the household and the domestic needs.

The budget septic tank without pumping due to its performance in most parameters exceeds the sump, because It has many advantages:

high level of wastewater treatment;

no unpleasant odors;

The hermetic system does not allow wastes to fall into the soil layers and does not harm the ecosystem;

pumping of the liquid is carried out once a year.

When installing the sewage system, it is necessary to take into account the remoteness of the structure from residential buildings, open tanks and sources of drinking water.

The basic sanitary and technical requirements are specified in the SNIP:

treatment facilities can be installed at a distance of 5 m from residential premises, 1 m from agricultural buildings;

the distance from sources of septic tank installation leander tx water (wells, wells) depending on the type of soil can vary from 20 to 50 meters.

The principle of the cleaning mechanism is similar to the previous variant. But in this case, the construction of the septic tank will be simplified: it is enough to dig a pit and divide it into 2 rooms with the help of a concrete partition.

0 notes

Text

WQGS Hot Sell 2 Inches Submersible centrifugal sewage water pump price in pakistan

Product Description WQGS and GWQ series non-clog submerged motor pumps are strictly designed ,manufactured and tested according to relative national standards, they are applicable for commercial waste water, daily waste water,drainage system of city waste water. WQGS Hot Sell 2 Inches Submersible Water Pump And Domestic Water Pump Prices in kenya For Waste Water Treatment Plant General Performance Application Limits: 1. Ambient temperature: 0-40℃ 2. Maximum liquid temperature +40℃ 3. PH level from 4-10 4. Maximum liquid density 1.2*10kg/m³ 5. Power frequency is 50Hz. Nominal voltage is 220VAC for single phase and 380VAC for three phase with the range from -100% to 10%. 6. Immersion depth from 0.5m-5m Application Fields: WQGS series non-clog submerged motor pumps are applicable for the discharge of seriously polluted waste water in factories and commercial sites,sewage draining station in residential area, drainage system in city waste water treatment plant,draining station for civil defense, water supply in tap water plant, sewage discharge in hospitals and hotels,construction sites of municipal projects, exploration,mines, rural methane pool,agricultural irrigation etc. To deliver waste water and pollutants containing granules, as well as clean water and corrosive mediums. Features: 1.Insulation class:F 2.The water-resistant impeller of QT 450-10 material. 3.Stainless steel shaft extension, carbide double -sides mechanical sealing. 4.Double channel impeller, good flow capacity, excellent hydraulic performance. Optional Available on Request Other voltage or frequency is 60HZ Technical Parameter Model Q H Speed Voltage Motor (m³/h) (m) (r/min) (V) (kW) 50WQGS10-10-0.75 10 10 2900 380 0.75 50WQGS10-12-1.1 12 10 2900 380 1.1 50WQGS15-15-1.5 15 15 2900 380 1.5 65WQGS20-10-1.5 15 15 2900 380 1.5 50WQGS15-20-2.2 15 20 2900 380 2.2 65WQGS25-15-2.2 25 15 2900 380 2.2 80WQGS30-12-2.2 30 12 2900 380 2.2 50WQGS20-25-3 20 25 2900 380 3 65WQGS25-22-3 25 22 2900 380 3 80WQGS35-15-3 35 15 2900 380 3 65WQGS35-18-4 35 18 2900 380 4 80WQGS45-15-4 45 15 2900 380 4 100WQGS50-12-4 50 12 2900 380 4 65WQGS40-20-5.5 40 20 2900 380 5.5 80WQGS60-18-5.5 60 18 2900 380 5.5 100WQGS65-15-5.5 65 15 2900 380 5.5 80WQGS80-18-7.5 80 18 2900 380 7.5 100WQGS100-15-7.5 100 15 2900 380 7.5 100WQGS120-18-11 120 18 1450 380 11 150WQGS150-15-11 150 15 1450 380 11 100WQGS150-18-15 150 18 1450 380 15 200WQGS200-15-15 200 15 1450 380 15 150WQGS180-20-18.5 180 20 1450 380 18.5 200WQGS250-15-18.5 250 15 1450 380 18.5 150WQGS200-20-22 200 20 1450 380 22 200WQGS300-15-22 300 15 1450 380 22 WQGS Hot Sell 2 Inches Submersible Water Pump And Domestic Water Pump Prices in kenya For Waste Water Treatment Plant Pump Details Sectional View: Installation Diagram A) It is forbidden to pull cables with force in the installation and removal of electric pump to avoid wires breaking and joint delinking which lead to normal operation failure and even burns; B) Please ensure correct and reliable cable earthing in the installation of electric pump. It is forbidden for humans or animals to approach operational water area or touch the electric pump when it is working. In order to reduce electric shock risks, it can only be connected with earthing plug; C) Overload operation is forbidden; D) The cables associated with pumps should not be less than 1.2 times of the electric pump area; E)The electric pump must be fastened in the installation. But the cables can not be stressed or rotate together with the electric pump once it is started; F) Once the pump does not produce water in the operation, the electric pump should be checked for any reverse rotation or the check valve at the water outlet mouth should be checked for any residual air; G) Phase-to-phase and relative ground-to-ground insulation resistance of the motor of electric pump should be inspected on a regular basis with the resistance no lower than 2MΩ. Otherwise, the equipment should be disassembled for inspection and repair; H) After half a year of normal operation under stipulated working conditions, the electric pump should be checked for oil room sealing condition. Once the oil is emulsified or sedimented water comes out, 10# machine oil and mechanical seal parts should be replaced in a timely manner; I) One large-scale repair work should be conducted after normal operation for one year: worn parts should be replaced, fasteners should be inspected and lubricant should be supplemented and replaced to ensure excellent lubrication in the normal operation; J) Please clean the electric pump and wipe out beads if not in use. Maintenance Instruct Company Information Packing Details FAQ Q: What kind of company you are? A: Shanghai SOG Pump Company is a professional pump manufacturer ,minaly applied in high raise building ,industry,waste water treatment, seawater RO system etc. After 13 years of development and research,we have formed a complete system of pump design, selection, application, manufacture, marketing and maintenance. We have passed ISO, SGS, MA certificate. Our customers are from over 30 oversea countries. Hope to coorperate with the worldwide friends. Q: 1. How to get our quotation in time, pls answer following questions: 1)What liquid do you transfer ? Oil, Water, Seawater or Corrosive Chemical liquid,with solid particle or not, and so on~ 2) What's the flow or capacity (m3/h, L/m)? 3) What's the discharge head (m, feet, Mpa, bar ) If you do not have any request, we will do as our normal standard. Good quality with competitive pirce ISO9001: 2008, SGS certificate Q: What are your payment terms? A: T/T, L/C at sight, D/P, D/A or as customer required Q: How about the warranty? A: One year warranty for pumps expect the easy-wearing parts,it depends on pump working condition details. Q: What is the delivery time? A: 7-30 days according to pump materials and quantities. Q: Can you do OEM brand? A: Yes, Welcome. Contacts: chaars Mob:+86 15921388472 Wechat: +86 15850389732 (same as whatsapp) Read the full article

0 notes

Text

"Going Beyond the Rules" on Food Waste May Mean Breaking the Rules

[By Wei Chen, Oliver Jost, Niclas Karlsson, Markus Joswig and Mark Beavis]

This short paper reviews food waste and food waste reject water (FWRW) from ships and how FWRW has been caught up in non-compliant practices across much of the passenger ship sector.

Food waste and its characteristics

A ship’s food waste is regulated under the IMO’s MARPOL Annex V Convention. When food waste is offloaded from an international ship to ports, it is also regulated under the national biosecurity regulations in force in countries such as the EU Member States, the UK, the US, Canada, Australia and New Zealand, among others.

Studies showed that there are significant variations in the food waste characteristics and generation rate, depending on the system designs, operational practices, passenger behaviours, food services, and voyage itineraries. Each study has its own unique circumstances. Taking representative food waste samples and having them suitably prepared for analysis is not without challenges. To simplify and rationalise a broad spectrum of findings, a cruise ship generates approximately 1 kg/person/day at 25 percent dry solids (DS), as collected in the bins, which has an organic content of about 1,200 g COD/kg DS or 600 g BOD/kg DS.

Food waste reject water (FWRW) and its characteristics

Many merchant ships dispose food waste from the bin to the sea. This is simple, compliant, and sustainable. To take food waste bins up and down a cruise ship is prohibitive due to hygiene and resource constraints. Instead, food waste is sorted at the pulper station to remove bones, plastics, and occasionally cutlery. It is then macerated and transferred from the pulper station to a holding tank by pumping or vacuum. Fresh water is added to aid the transfer and cleaning. This results in a food waste slurry of about 10 percent DS in the holding tank, accumulating at a rate of about 2.5 kg/person/day. 30~50 percent of the organics can be soluble, with most particles being less than 2 mm.

Not many facilities on land can receive this slurry. It causes odour, is too thick to flow freely in the sewers and too wet to be incinerated. It carries the risks of disease or pests, which may prevent it from being anaerobically digested under biosecurity rules. Traditionally, this slurry has been discharged into the sea 3 or 12 nm from the nearest land, which is simple and compliant.

In order to achieve zero-discharge and to ‘go beyond the rules’, the food waste slurry is dewatered to a paste of 20~25 percent DS, then dried to a powder of 70~90 percent DS for incinerating on board. This is done at great expense in terms of capital costs, space, fuel, chemicals, and man-hours.

The waste management hierarchy governing the waste policies of our society would suggest that food waste incineration is a worse option than compliant discharge at sea. The absence of effective heat recovery during drying and incineration blurs the line between ‘waste to energy’ and wasting energy.

There are also mixed messages on system availability. But when they are operating, it is evident that only half of the food waste is converted into incineration emissions and ashes. The other half is in the so-called food waste reject water (FWRW) which is produced during dewatering of the food waste slurry.

Grey water or FWRW?

Setting aside the issue of efficiencies, the industry’s zeal for ‘zero-discharge’ can be well intended and compliant. The problem starts when the FWRW is wrongly considered as being grey water.

Is FWRW grey water? No, being a food waste derivative and carrying half of the food waste, FWRW is clearly not grey water. Grey water is generated from showers, wash basins, laundries and kitchen sinks, and is unregulated by the IMO rules. The definition of grey water does not include food waste or food waste derivatives. When FWRW goes into a spider web of piping diagrams and reappears as grey water, it renders compliant entries to the Garbage Record Book impossible. The practice does not comply with the IMO’s MARPOL Annex IV Convention. When this ‘grey water’ is connected to the sewage treatment plant onboard, it also causes non-compliance with the MARPOL Annex IV convention.

But the implications do not stop here.

Some insist the FWRW is grey water because ‘it looks better than grey water’. But its clarity or concentration are never the criteria when it comes to the risks of diseases and pests under the national biosecurity rules. Foreign food waste must be kept separately in tightly covered containers and transported to the approved facilities ashore for safe disposal. It is not permitted to change the physical structure of such food waste. These national rules are recognized and respected by the IMO’s Guidelines. To consider food waste derivatives as grey water and to allow it into the coastal waters and local sewers flouts the biosecurity rules.

However, such non-compliant designs and practices were often approved by the approval authorities serving some of the flag states at the expense of the agricultural interests of some of the port states.

Such approvals make any corrective actions difficult if not impossible. There is safety in numbers. But the issues will not go away. They serve as a long-lasting reminder to maritime and biosecurity professionals about the status of some of the marine rules.

The industry is innovative by nature. The regulations are often playing catch-up. But when we crave to be green, to achieve zero discharge, to ‘go beyond the rules’, can we do so without breaking the rules?

Co-authored by:

Dr Wei Chen, Future Program Development Manager, Wartsila UK Ltd, UK Oliver Jost, Maritime Environmental Affairs, Wasserschutzpolizei (Water Police) Hamburg, Germany Niclas Karlsson, Managing Director, Clean Ship Scandinavia AB, Sweden Markus Joswig, Head of Marine Department, PIA GmbH, Germany Mark Beavis, IEng IMarEng FIMarEST, Sales & Special Projects Director, ACO Marine s.r.o., Czech Republic, ACO Marine Systems GmbH, Germany

Endorsed by:

Benny Carlson, Chairman and owner, Marinfloc, Sweden Ed White, Environmental Consultant, former Alaska DEC cruise ship compliance manager Felix von Bredow, Board of Hamman AG, Hamman AG, Germany Antony Chan, Engineering Manager, Victor Marine Ltd., UK Helge Østby, Senior Technical Advisor, Jets Vacuum AS, Norway

from Storage Containers https://www.maritime-executive.com/article/going-beyond-the-rules-on-food-waste-may-mean-breaking-the-rules via http://www.rssmix.com/

0 notes

Text

Top Sewage Treatment Plant in India Save Mother Earth

Netsol Water Solutions pioneers in Water Treatment Solutions has a wide range of Sewage Treatment Plant variants and is currently serving more than 500 + clients.

The use of STP is to treat wastewater into treatable form. One of the key strengths of Netsol Water Solutions Pvt Ltd is its manufacturing base. It offers Reverse osmosis systems for process & drinking, effluent/sewage treatment plant, water treatment plant and many more.

Sewage Treatment Plant are widely used in the manufacturing sector, defence sector, agricultural sector, hospitals, a government organisation.

The latest technology that is implemented:

Moving Bed Bio Reactor: The moving bed biofilm reactor technology is a biological solution for wastewater treatment, based on a core understanding of microbiology and treatment process.

The Flow Diagram Process of Sewage Treatment Plant is as follows:

Screen Chamber

Oil & Grease Trap

Equalisation Tank

Aeration tank

Clarifier / Tube Settler

Clear Water Tank

Tertiary Treatment

Treated Water

The above flow diagram will well explain the working and process of a sewage treatment plant.

For More Information:

Read more topic:

Sewage Treatment Plant Manufacturer

Compact Sewage Treatment Plant Manufacturer

Effluent Treatment Plant Manufacturers

Effluent Treatment Plant Supplier

Sewage Treatment Plant Supplier

Sewage Treatment Plant Manufacturer In Delhi Ncr

Effluent Treatment Plant Manufacturer In Delhi Ncr

Compact Sewage Treatment Plant Manufacturers

MS Compact Sewage Treatment Plant Manufacturers

MS Compact Sewage Treatment Plant Manufacturer

Compact Sewage Treatment Plant Manufacturer in India

Compact Sewage Treatment Plant Manufacturers in India

MS Compact Sewage Treatment Plant Manufacturers in India

MS Compact Sewage Treatment Plant Manufacturer in India

Compact Sewage Treatment Plant Manufacturer in Delhi - NCR

Compact Sewage Treatment Plant Manufacturers in Delhi - NCR

MS Compact Sewage Treatment Plant Manufacturers in Delhi - NCR

MS Compact Sewage Treatment Plant Manufacturers in Delhi - NCR

Compact Sewage Treatment Plant Manufacturer in Noida

Compact Sewage Treatment Plant Manufacturers in Noida

MS Compact Sewage Treatment Plant Manufacturer in Noida

MS Compact Sewage Treatment Plant Manufacturers in Noida

Effluent Treatment Plant Manufacturers in Noida

Effluent Treatment Plant Manufacturers in Delhi-NCR

Compact Effluent Treatment Plant Manufacturers in Noida

Compact Effluent Treatment Plant Manufacturers in Delhi NCR

MS Compact Effluent Treatment Plant Manufacturers in Delhi NCR

MS Compact Effluent Treatment Plant Manufacturer in Delhi NCR

MS Compact Effluent Treatment Plant Manufacturers in India

MS Compact Effluent Treatment Plant Manufacturer in India

MS Compact Effluent Treatment Plant Manufacturers in Delhi

MS Compact Effluent Treatment Plant Manufacturers in Noida

MS Compact Effluent Treatment Plant Manufacturer in Noida

#Sewage Treatment Plant Manufacturer#Compact Sewage Treatment Plant Manufacturer#Effluent Treatment Plant Manufacturers#Effluent Treatment Plant Supplier#Sewage Treatment Plant Supplier#Sewage Treatment Plant Manufacturer In Delhi Ncr#Effluent Treatment Plant Manufacturer In Delhi Ncr#Compact Sewage Treatment Plant Manufacturers#MS Compact Sewage Treatment Plant Manufacturers#MS Compact Sewage Treatment Plant Manufacturer#Compact Sewage Treatment Plant Manufacturer in India#Compact Sewage Treatment Plant Manufacturers in India#MS Compact Sewage Treatment Plant Manufacturers in India#MS Compact Sewage Treatment Plant Manufacturer in India#Compact Sewage Treatment Plant Manufacturer in Delhi - NCR#Compact Sewage Treatment Plant Manufacturers in Delhi - NCR#MS Compact Sewage Treatment Plant Manufacturers in Delhi - NCR#Compact Sewage Treatment Plant Manufacturers in Noida#Effluent Treatment Plant Manufacturers in Noida#Effluent Treatment Plant Manufacturers in Delhi-NCR#Compact Effluent Treatment Plant Manufacturers in Delhi NCR#MS Compact Effluent Treatment Plant Manufacturer in Noida#MS Compact Effluent Treatment Plant Manufacturers in Noida#Compact Effluent Treatment Plant Manufacturers in Bangladesh#MS Compact Effluent Treatment Plant Manufacturer in Bangladesh#MS Compact Effluent Treatment Plant Manufacturer in Nepal

0 notes

Text

Air Separation Plant

youtube

The Ecology of Nitrogen Fixing Plants

The Significance of Plant Maintenance

A nitrogen plant oxygen plant manufacturer provides an essential function as it makes a product that crops will need to be able to flourish. All living things require the evolution of trees and plants to be able to thrive. All of this often continues behind the scenes, and most people consider it for granted. Fortunately, there are professionals in place that take care of all of this so we do not need to be concerned about doing it cryogenic air separation process flow diagram.

A nitrogen plant can help with powerful soil management. When the soil has what it needs, crops, plants, and other living things are able to thrive. There may be a number of factors with the growth of these elements. However starting out them with the right balance in the soil can increase the chances of a very good outcome.

The Ideal System

With a nitrogen plant on website for your industrial organization, you can produce what you need to take care of your business needs. It doesn't have to be a complex endeavour to have it all setup. With the ideal provider, you can learn about the choices for generators. You are able to find the capacity that will work for your requirements. Not only now, but looking at the forecasted growth in the long run.

The ideal system will meet or exceed your requirements concerning circulation, stress, and quality. Based on the sort of business you're in, there may be specifications concerning the purity of this product generated in the nitrogen plant. You should continually be within those guidelines or you can get into legal trouble.

Customized for Your Demands

Should youn't have a nitrogen plant set up, this may be the ideal time for you to think about having one built. They can be made to your specifications including the dimensions and the place. The outcome you Air Separation Plant liquid nitrogen need can influence what you approve. Talking to an expert in this domain will be able to help you to assess the options. You can look at the advantages and disadvantages of each to make a determination.

That is a wise investment as it can help you to have better production. It can lower the dangers of merchandise not increasing as they should. It can decrease the risk of depleting the soil of nutrients it will fight to naturally add back on its own. The delicate balance that has to be set up can't be overlooked or taken for granted.

Tech and Upgrades

An older nitrogen plant may gain from several upgrades over time too. Technology changes and new approaches are made to make it even more efficient. If the plant is behind the times, it isn't as effective as it might be. It isn't offering the exact general value as the newer ones. It may be costly and time consuming to make those updates but it's a wise alternative.

There are many benefits with this sort of set up, and it may save you both money and time. Having a plant on website, you don't need to pay to own nitrogen brought in on a regular basis. You can also have more control over the purity it gives. This is a wonderful way to be more efficient and to enhance your results. Consider your company goes and consider this an investment.

It may allow you to become a leader in your industry. It can build your reputation so you are well called a solid company. Extra resources That will encourage you to get more clients and it'll also help you to create a base you can always build upon.

Air separation plants could be set up easily and doesn't need any particular buildings and requires a short erection time. Power price is your major operating cost involved in air separation plants and may account for almost two thirds of their complete operating expenses. Electric motors are used in running the engine and in the heating and cooling procedures.

Different Kinds of Air Separation Processes are used for various software. Cryogenic separation is based on differences in boiling points of the many gases found in air. Non-cryogenic plants are much less energy efficient than plant plants and are more suited for medium and small plants.

Cryogenic air separation procedures rely on differences in boiling points to purify and separate products. The fundamental procedure was commercialized early in the 20th century. Ever since that time, numerous procedure configuration variations have emerged, driven by the desire to generate particular gasoline products and product mixes as efficiently as possible at various required heights of purity and pressure. These procedure cycles have evolved in parallel with advances in compression machines, he

The cryogenic air separation plant involves a refrigeration cycle in which the gases are cooled to a low distillation temperature. Only pure gases can be used in cryogenic distillation as water and carbon dioxide of air can freeze from the cryogenic equipment. For bulk manufacturing, cryogenic processes would be the most cost-effective selection and these can produce very pure solutions.

PSA Nitrogen plants are called so as these Nitrogen Generators work on Stress Saving Adsorption commonly Called PSA Technology. The nitrogen that I gas is separated from atmospheric air by utilizing carbon molecular service that prevents oxygen from air. The compressed air is first passed through the adsorption tower in which water oxygen and other pollutants are adsorbed, leaving behind nitrogen, which is subsequently accumulated in a surge vessel. This process is efficiently utilized to create ultra pure Nitrogen gas of 99.9999% purity for business purposes. High purity is ensured by using De-Oxo purification. This approach is used in many different applications such as pharmaceuticals, cold rolling, steel sector, metallurgy, fertilizers and electronics rectifier industry.

B2B markets are excellent place to gather info about the latest kinds of air separation plants and the numerous sellers Air Separation Plant Social Network and buyers of the item. These online hubs will keep you well informed regarding events and sidewalks as well.

Heat exchangers are common elements of several devices and machines used in many industries today. Heavy industries such as petroleum gas plants, power plants, sewage treatment facilities and petroleum refineries use them within their equipments. The machines employed in these industries not only need continuous tune up, they also need constant cooling. Heat exchangers perform this job for them.

Definition air separation equipment

Heat exchangers are devices which are set up to facilitate efficient heat transports from 1 medium to another. These mediums are normally in the form of water and other liquids. The method involves liquids being separated by a thin solid wall which will keep it from being in direct contact with each other. There are also heat exchangers that allow these fluids mix during the transport process.

Different kinds

There are numerous types of heat exchangers. Along with the tube and shell, here are just three more Kinds of frequent exchangers typically used in most of today's devices:

· Plate Heat

These kinds has many plates that are generally thin and slightly split when put in the machines. They are generally high in surface area which enables it to process heat transfers between mediums easily. In comparison with the tube and shell, the plate heat exchanger is thought to be more effective since it comes with a stacked-plate structure.

Over time, many machines have switched to such type because of its practicality and efficiency of use. In machines such as a fridge, these can either be one of 2 kinds: dip-brazed or even vacuum-brazed.

These devices may also be classified based on the kinds of plates that they use. They may also be discerned from the configurations of the plate being used. Some plates can have their very own unique designs with unique stamps, patterns, fins or grooves.

· Plate Fin

A plate fin uses pairs of passages, commonly called sandwich passages, which raise the efficacy of the whole machine. Various fin configurations is featured in a plate fin heat exchanger. These include directly fins, wavy fins and offset fins. The plan of this specific exchanger also has some cross flow and counter flow designs.

The greater heat transfer efficiency exhibited with a plate fin exchanger can be credited into the aluminum alloy which it is made from. This particular mixture enables the plate fin to work in a much lower temperature all while decreasing the burden of the equipment it had been set up to.

This kind can be generally found on machines which are used for the processes of natural gas plants, liquefaction plants, air separation plants and many more. It can also be found inside engine engines.

· Adiabatic Wheel

This kind of heat exchanger uses intermediate fluid and strong during its heat transport procedures. Adiabatic wheels include a large wheel together read more on wikipedia here with really nice threads which rotate throughout the hot and cold mediums. This enables the efficient heat transfer between the two fluids.

Nitrogen Gas Plants are available in small, medium and big capacity. Widely utilised in Water Process, Ferrous Metallurgy, Non-ferrous Metal Refinery, Coal mines and Pharmacy, these may be availed at market leading prices. N2 gas plants have been integrated with exceptional technology and faultless quality. Highest standards of quality of goods & services are provided to fulfill client's expectations by using the latest technologies and the highest quality components.

Nitrogen Gas Plant are famous AirSeparation Plant for the following features:

Skid Mounted Version

Low Pressure Technology

Low Electricity air separation plant locations Consumption

24 Hrs Continuous liquid nitrogen plant cost Duty Operation

Just One Operator Required To Run The Plant

Heavy Duty Air Compressor (Water Cooled.)

Built In Liquid Oxygen/Nitrogen Pump For High Stress Oxygen/Nitrogen Filling

Built In Integral Gas Vaporizer

High Efficiency Trays for High Purity

Extremely Safe To Use And Run

Trouble Free Operation Due To Proven Design and Performance.

PSA Nitrogen Plants:

PSA generally means "Pressure swing Adsorption Process", therefore PSA Gas Plants are the plants or equipment supplying nitrogen gas with an outlet in purity of 99.99%.

Nitrogen Plants incorporates qualified engineers for Supervision, Installation and start up of all our crops as well as training of work in customer's site. The different sort of PSA nitrogen system are offered at varied ranges.

Dealing in top excellent Nitrogen Generators, world class nitrogen gas generator operates on PSA technology.

Salient Characteristics of PSA Air Separation Plant liquid oxygen N2 Gas Plants are as follows:

Skid mounted units

Easy installations

Air Separation Plant oxygen manufacturer

Safe & Economical

Assures innocence

Maintenance free nitrogen and plant disease of cost

Continuous supply.

There are various types of gases which are categorised as majority gases, and such are: Argon, Carbon Dioxide, Hydrogen, Helium, Oxygen, Nitrogen, Nitrous Oxide, Propane and Propylene.

Bulk Carbon address Dioxide

Source: Fermentation in distilleries and breweries are http://www.airseparation-plant.cn/ the main source of carbon dioxide, and it'll be pure.

Production: Raw carbon dioxide is purified in several phases, it's compressed and cooled to get liquid carbon dioxide at a pressure of 20bg (bar gauge) and at a temperature of 20 degrees, it's gathered and stored in massive tanks; if the tanks are complete they are isolated and made readily available for supply.

Quality: Bulk Liquefied carbon dioxide, which is supplied into the beverage and food industries, has the most rigorous and comprehensive product specifications.

Gaseous properties: Colourless, tasteless and odourless. Inert when the gas is dry. Highly soluble in water.

Liquid properties: At atmospheric pressure, it cannot exist. It becomes oxygen plant manufacturer super crucial when it's pumped and heated above its critical point.

Volume liquid Nitrogen

Nitrogen (N2) is the significant gas in our atmosphere; making up roughly 78 percent of it. The commercially available N2 is created from larger 'cryogenic air separation plants' and within this type of plant atmospheric air is totally cleaned and the gas is compressed and after it is cooled by expansion to create the liquid gas. This liquid gasoline is stored or transported at a temperature ranging from -196 to155 degrees Celsius.

Gaseous properties: Colourless, tasteless and odourless. Non-flammable at quite significant temperatures. Slightly soluble in water.

Liquid properties: When it vaporizes, it consumes a good deal of heat. Has very significant heat transfer rate.

Bulk Liquid oxygen

Oxygen (O2) is among the vital gases that the air, and it contains approximately 21% of atmosphere. The commercially available O2 consists of larger 'cryogenic air separation plants' and in this kind of plant, atmospheric air is totally cleaned and the gas is pressurized and later it is cooled by expansion to create the liquid gas, and will be separated by fractional distillation. This liquid gasoline is stored or transported in a temperature ranging from -183 into 143 degrees Celsius.

Gaseous possessions: Colourless, tasteless and odourless. Non flammable, but encourages and enhances combustion of other materials.

Liquid possessions: Blue in color.

Bulk Liquid Argon

This gasoline comprises just 1 percent of the planet's atmosphere. The commercially available argon consists of larger 'cryogenic air separation plants' and within this type of plant atmospheric air is completely cleaned and the gas is pressurized and later it's cooled by expansion to create the liquid gas and will be separated by fractional distillations. Industrial based argon contains slight amounts of oxygen, and when pure argon is desired, the gas needs more purification and distillation. Liquefied argon should be kept at temperatures ranging from - 186 to - 143 º C as well as the pressure requirement should be about 20bar. Ordinarily this liquid argon needs to be transported at low pressure.

Gaseous possessions: Colourless, tasteless and odourless. Soluble only in water. Non flammable. Extremely inert.

1 note

·

View note

Text

Effluent Treatment Plant: Process and Flow Diagram in Pharma Industry

The pharmaceutical industry plays a pivotal role in our economy, contributing in multifaceted ways. It encompasses the discovery, development, production, and marketing of drugs and pharmaceuticals for patient treatment and symptom alleviation. Given its water-intensive processes, the industry inevitably discharges wastewater into the environment, whether treated or untreated.

For optimal results, you require top-notch equipment, offered at a more affordable rate compared to our market counterparts. Today, we introduce you to one of our flagship products – the Effluent Treatment Plant (ETP) – and shed light on its pivotal role in the pharmaceutical industry. Not limited to ETP’s we also have expertise and experience as sewage treatment plant manufacturer in Noida.

1 note

·

View note

Text

Throw off your black water chains with ECOmar (sponsored post)

Why fitting an ECOmar treatment plant will free you from one of boating's most unpleasant chores

The ECOmar 20 is suitable for boats from 60-120ft

Everyone hates pumping out black water tanks but is there a cleaner alternative? Yes, instead of storing all your waste on board until you head offshore or find a convenient pump out station you can install a compact ECOmar sewage treatment plant.

This will neutralise the waste and make it completely safe to discharge even in environmentally sensitive areas such as rivers and marinas.

How does an ECOmar system work? A probe constantly measures the level of your black water tank, doses it with the precise amount of hydrogen peroxide to neutralise any harmful bacteria and unpleasant odours, processes it twice to purify the contents then flushes out the harmless waste water and discharges it overboard.

A flow diagram of the ECOmar system's inner workings

What do you need to do? Almost nothing, the whole process is automated leaving you to get on with enjoying your boat.

From time to time you'll need to top up with hydrogen peroxide but most owners find that a single 25-litre tank lasts a full season and refills are readily available at marinas for around 90.

How easy is it to install? Because the whole system plumbs into your existing black water tank with no need for a separate sludge tank, it's all very simple.

The smallest ECOmar 20 is no bigger than a domestic washing machine and usually has no trouble fitting into the engineroom or lazerette of boats over 50ft.

It can process up to 2,000 litres per day more than enough for even the busiest of charter yachts.

A typical ECOmar 20 installation

Who needs one? Almost all boats benefit from the reduced hassle and unpleasant odours associated with untreated black tanks but particularly larger craft based in environmentally sensitive areas.

Most countries insist on craft being a minimum of 3 miles offshore before discharging untreated sewage while many marinas, port authorities and rivers operate a strict zero discharge policy.

In Monaco and the South of France some marinas won't even allow boats to berth until they are satisfied with the boat's plumbing arrangements. An ECOmar system will satisfy even the most stringent demands.

ECOmar treatment systems can be fitted to all types of vessels over 50ft

Sounds good, what does it cost? The ECOmar 20 costs 11,592 ex VAT and should take no more than two days to fit.

Aquamare is the UK dealer for all Technicomar products including the ECOmar range of sewage treatment plants.

Its team of trained specialists have been installing ECOmar treatment plants for the past ten years to all different types of craft from the Red Jet ferries on the Isle of Wight to houseboats on the Thames and superyachts in the South of France but increasingly it's 60-90ft motoryachts that are starting to adopt them.

How do I find out more? Click on the link to visit the aquamare.co.uk website or give one of its specialists a call on +44 (0)1752 604603

This article Throw off your black water chains with ECOmar (sponsored post) appeared first on Motor Boat & Yachting.

0 notes

Text

Sustainable Development on the Local Scale

Lessons from a coastal town in California

People seem to have trouble describing my hometown. I call it a “socially acknowledged nature-loving town.��� The New York Times takes a different perspective, calling it “the Howard Hughes of towns.” According to my college friends, it’s “the hippie commune Chels escaped from.” Some of them don’t believe it’s real.

It’s a pretty idyllic place. Bolinas is on the elevated, natural (and better) peninsula. We don’t mess around with manmade lagoons like the town in the lower right. That’s Stinson Beach, the Eagleton to our Pawnee.

This is the Jimi Hendrix Revival Drum Corps (they know that none of their instruments are drums) at our annual 4th of July parade. I will take this opportunity to clarify that the majority of my college friends don’t believe Bolinas is real.

Regardless, environmentalism and plain-old reclusiveness are perhaps the most important pillars of local Bolinas culture. In the 1960s, residents voted to dissolve a proposed plan to turn the lagoon into a marina and housing complex. On a night in 1971, locals constructed an oil boom to protect the lagoon and its ecosystem from an oil tanker spill off the coast of San Francisco. In 1975, they established a water moratorium to prevent further development, and overturned a proposed chemical treatment plant in favor of organic sewage treatment ponds. Forty years later, when I go home on break, I walk my dog at the “Sewer Ponds,” where there are bike paths, wild birds, a thriving ecosystem, and now an extension of a local organic farm located somewhat concerningly downhill of the ponds. Local environmental protection initiatives form the foundation of our culture. My peers and I learned about this aspect of our history in our local elementary school and we still take pride in it.

So when a lagoon restoration project was proposed in the late 1990s, it was a very contentious subject. Our lagoon illustrates perfectly the fragility of nature and the fragility of human development. The timber industry sped up sediment flow in the early 1800s, and residents used the lagoon as a dump for decades. Today, flooding and mudslides can block off the only road into town, effectively trapping us on the small peninsula. We didn’t have snow days in California, but sometimes the school bus couldn’t get to our town. You win some, you lose some.

The restoration project’s divisiveness wasn’t so much a question of allocating funding or local energy as it was of figuring out what restoration actually looked like for our lagoon. My parents grew up in Bolinas. According to them and other long-term residents, in the 1960s you could bring a boat into the inner lagoon and fish for larger marine life like salmon and halibut. In my lifetime though, fishermen have had to wait until high tide to dock their boats in the inner channel. Steering a boat into the inner lagoon without beaching it would be impossible today. In the late 1990s, it was clear that the lagoon was filling with silt, but the community disagreed as to whether it was right to interfere. Was the siltation a natural process or the result of centuries of development in the area?

The United States Army Corps of Engineers compiled a draft feasibility plan in 2002. It suggested dredging over 1.4 million cubic yards of wet sediment to help restore the tidal prism.

Dredging has clearly gone well before. This one, visible from my elementary school, has been stuck in the lagoon since 1962.

Dredging would restore the lagoon to a state more familiar to older residents, increasing its depth and tidal movement. However, dredging could also fatally disrupt the ecosystem, damaging native flora and fauna and providing a window for invasive species to take over. An unfounded conspiracy additionally confused matters: some residents were certain that dredging would really only benefit wealthy waterfront-property owners in Eagleton—I mean Stinson Beach—and their goddamned yachts. Because the proposed dredging plan would cost upwards of $100 million dollars and take seven years (year round dredging was quickly nixed due to seal pupping season), someone in the county office realized that it would probably be a good idea to determine the source of the silt.

A contracted hydrology firm revealed that the majority of the silt was not, in fact, from the human-damaged watershed. Interestingly, shoreline armoring had had little effect on the siltation. It was mainly coming in from the ocean as part of a natural process.

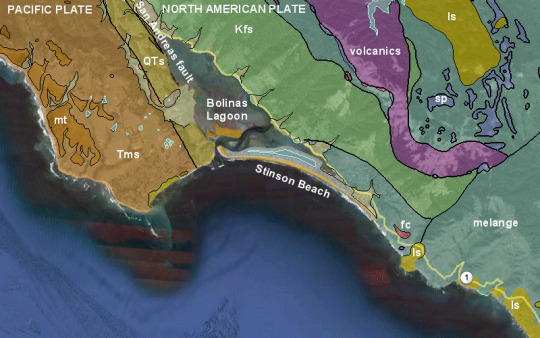

The Bolinas Lagoon actually straddles the North American and Pacific plates, with the San Andreas fault line running directly through it.

Here is an academic diagram of how our lagoon is affected by geology, courtesy of our local PBS affiliate.

Here is a less academic diagram.

If left to its natural cycle, the lagoon would slowly fill in with sediment over hundreds of years, then, when a major crippling earthquake struck, regenerate.

This was taken as evidence by most people that the lagoon should be left to its cycle. Restoration projects moving forward were contained to the removal of invasive species and the restoration of floodplains and deltas, which were malfunctioning due to human interference. There is still some community concern about future boat access, but it’s generally acknowledged that reduced access for the mostly dead Bolinas fishing industry is a result of a natural process.

At this point, the Army Corps of Engineers suggested removing the shipwrecked dredge I mentioned earlier to measure the speed of sedimentation in the remaining hole, a well-informed scientific way to assess the situation. Bravo, Army Corps of Engineers, bravo.

The shipwrecked dredge can still be seen from my old elementary school.

Despite this loose end, restoration has significantly moved forward. In 2008, representatives of the very, very many groups involved in protecting our lagoon finally came out with a list of recommendations. Since then, agencies and the community have divided the restoration effort into smaller projects for scalability and efficiency.

Community efforts have led to fewer numbers of invasive European green crabs, which threaten native animals and plants. Volunteers also removed non-native plants on the inner island. This not only helped to restore the natural habitat, but also aided in the natural release of captured sediment, increased water movement, and strengthened resilience in the event of an earthquake or large storm. The California Department of Transportation reworked the highway and culverts around the lagoon’s perimeter, specifically reducing the amount of sediment coming in from the nearby hills and streams. The rocks placed at the lagoon shoreline also reduced erosion of soil at the water’s edge.

Plans for restoring the North End of the lagoon were released in October 2016. The three options put forward focused on sea level adaptation, restoring the tributaries in that area, and addressing flooding of the road.