#Sewage Treatment Plant Diagram

Explore tagged Tumblr posts

Text

How Sewage Treatment Plant Work Explain via Diagram?

Wastewater is treated to help remove toxins, bacteria, and other contaminants. It is treated in multiple stages at treatment facilities before being released back into the environment. The ultimate goal of sewage treatment is to produce effluent that can either be reused in a positive way or released into the environment, with the least amount of water contamination feasible. Sewage treatment plants (STPs) play a crucial role in keeping our water sources clean by treating wastewater before it’s released back into the environment. Understanding how they work can help us appreciate the importance of water conservation and proper waste management. Let’s break down the process step-by-step and explain it with the help of a diagram!

Also Read Us: Sewage Treatment Plant Manufacturer in India

What is Sewage Treatment?

Sewage treatment is the process of removing contaminants from wastewater, which includes household sewage, industrial effluents, and runoff. The objective is to reduce pollutants and treat the water to make it safe for discharge into natural water bodies, or even to reuse for non-potable purposes like irrigation.

Website: https://www.traqua.in/how-sewage-treatment-plant-work-explain-via-diagram/

#Sewage Treatment Plant#How Sewage Treatment Plant Work Explain via Diagram?#What is Sewage Treatment?

0 notes

Text

Sewage Treatment Plant Process Flow Diagram

When it comes to ensuring clean and sustainable water management, R&J Waste Water Treatment Organization excels in delivering advanced sewage treatment solutions. Understanding the sewage treatment plant (STP) process flow diagram is essential to appreciate how wastewater is transformed into clean water. Here’s a detailed explanation of the process. Sewage sludge is obtained from wastewater treatment in sewage treatment plant. The sludge consists of two basic forms, sludge and secondary sludge, also referred to as activated sludge within the case of activated sludge process. Municipal sewage sludge (MSS) or only sewage are often a solid, semi-solid, or liquid muddy residue. It contains mainly proteins, sugars, detergents, phenols, and lipids and also includes toxic and unsafe organic and inorganic pollutants source.

Website: https://www.rjjalraksha.com/blog/sewage-treatment-plant-process-flow-diagram/

0 notes

Text

What is a Reflux Valve? Diagram, Price List & Best Supplier in Delhi

In fluid and pipeline systems, ensuring one-way flow is crucial to avoid backflow and system damage. That’s where reflux valves come into play. Also known as non-return valves (NRVs), reflux valves are used in water supply lines, sewage systems, pumping stations, and more.

As a trusted reflux valve manufacturer and supplier in Delhi, Udhhyog offers premium-quality, long-lasting valves for municipal, commercial, and industrial use.

This article explains what a reflux valve is, how it works, its diagram, pricing, and where to get the best reflux valve in Delhi.

What is a Reflux Valve?

A reflux valve is a type of non-return valve that allows fluid to flow in only one direction and automatically prevents backflow. It is typically installed in pumping systems, especially on the delivery side of pumps.

Reflux Valve is Also Known As:

NRV (Non-Return Valve)

One-Way Valve

Check Valve

Non-Return Check Valve

Reflux Valve Working Principle

The valve has a disc or flap that opens when the fluid flows forward. When reverse flow occurs, the disc automatically closes due to gravity or spring action, preventing backflow.

This makes reflux valves essential in vertical pipelines and pumping applications, especially where system damage due to reverse pressure must be avoided.

Reflux Valve Diagram

The reflux valve diagram typically includes:

Valve body

Disc/flap or check plate

Flow arrow (direction indicator)

Spring (in spring-loaded variants)

The diagram helps engineers and technicians understand installation orientation, internal structure, and maintenance procedure.

Types of Reflux Valves

1. Swing Type Reflux Valve

Disc swings open/close based on flow.

Commonly used in sewage and water supply systems.

2. Lift Type Reflux Valve

Disc lifts vertically during forward flow.

Best for high-pressure applications.

3. Spring-Loaded Reflux Valve

Spring ensures quick closing action.

Suitable for vertical or inclined pipelines.

4. Dual Plate Check Valve

Two spring-loaded plates.

Compact, lightweight option for industrial systems.

Where are Reflux Valves Used?

✔ Water supply systems ✔ Sewage treatment plants ✔ Drainage lines ✔ Firefighting pipelines ✔ Irrigation systems ✔ Industrial fluid transfer lines ✔ Pump delivery pipelines

Reflux Valve Price List in Delhi

Here’s a general pricing range based on valve size and material:Size (mm)TypeMaterialPrice Range (INR)50 mmSwing TypeCast Iron₹1,000 – ₹1,80080 mmSwing TypeCast Iron₹1,500 – ₹2,200100 mmSpring LoadedDuctile Iron₹2,500 – ₹4,500150 mmDual PlateSS/DI₹4,000 – ₹7,000200 mmLift TypeDuctile Iron₹6,000 – ₹10,000250 mm+Custom OptionsSS/CI₹10,000+

📌 Note: Prices vary by brand, pressure class (PN10/PN16), material, and order volume.

For latest rates and discounts, contact Udhhyog directly.

How to Select the Right Reflux Valve

✅ 1. Pipeline Size

Choose valve size based on pipeline diameter and flow rate.

✅ 2. Flow Direction & Orientation

Confirm installation is in the correct flow direction as per diagram.

✅ 3. Valve Type

Use swing type for water and drainage.

Use spring-loaded for vertical pipes.

✅ 4. Material Compatibility

Cast Iron – Cost-effective, suitable for water.

Ductile Iron – Stronger, high pressure.

Stainless Steel – For chemical or corrosive fluids.

✅ 5. Maintenance Access

Prefer bolted cover valves for easy inspection.

Why Choose Udhhyog – Best Reflux Valve Supplier in Delhi

At Udhhyog, we deliver top-quality reflux valves backed by:

⭐ Premium Quality Materials

Valves built from tested CI, DI, and SS with anti-corrosion coatings.

⭐ Custom Sizes & Bulk Supply

Available in 50mm to 600mm sizes, pressure class PN10, PN16.

⭐ Fast Delivery Across North India

We supply across Delhi, Haryana, Punjab, UP, J&K, and Himachal Pradesh.

⭐ Competitive Pricing

Factory-direct rates and bulk discounts.

⭐ After-Sales Support

We provide technical support, installation guidance, and product warranty.

Conclusion

A reflux valve is an essential safeguard in fluid management systems, ensuring smooth one-way flow and preventing costly damage due to backflow.

With multiple valve types and material options available, it's important to choose the right reflux valve based on your system’s size, fluid type, and orientation.

For reliable and affordable reflux valves in Delhi, Udhhyog is your go-to source for quality, service, and support.

Contact Udhhyog – Reflux Valve Manufacturer in Delhi

📞 Call Now or Visit Udhhyog to explore our complete range of check valves and non-return valve solutions.

#RefluxValve#NonReturnValve#NRV#CheckValve#DelhiValveSupplier#Udhhyog#IndustrialValves#WaterPumping#ValveDiagram#PipelineSafety

0 notes

Text

What is a Reflux Valve? Diagram, Price List & Best Supplier in Delhi

In fluid and pipeline systems, ensuring one-way flow is crucial to avoid backflow and system damage. That’s where reflux valves come into play. Also known as non-return valves (NRVs), reflux valves are used in water supply lines, sewage systems, pumping stations, and more.

As a trusted reflux valve manufacturer and supplier in Delhi, Udhhyog offers premium-quality, long-lasting valves for municipal, commercial, and industrial use.

This article explains what a reflux valve is, how it works, its diagram, pricing, and where to get the best reflux valve in Delhi.

What is a Reflux Valve?

A reflux valve is a type of non-return valve that allows fluid to flow in only one direction and automatically prevents backflow. It is typically installed in pumping systems, especially on the delivery side of pumps.

Reflux Valve is Also Known As:

NRV (Non-Return Valve)

One-Way Valve

Check Valve

Non-Return Check Valve

Reflux Valve Working Principle

The valve has a disc or flap that opens when the fluid flows forward. When reverse flow occurs, the disc automatically closes due to gravity or spring action, preventing backflow.

This makes reflux valves essential in vertical pipelines and pumping applications, especially where system damage due to reverse pressure must be avoided.

Reflux Valve Diagram

The reflux valve diagram typically includes:

Valve body

Disc/flap or check plate

Flow arrow (direction indicator)

Spring (in spring-loaded variants)

The diagram helps engineers and technicians understand installation orientation, internal structure, and maintenance procedure.

Types of Reflux Valves

1. Swing Type Reflux Valve

Disc swings open/close based on flow.

Commonly used in sewage and water supply systems.

2. Lift Type Reflux Valve

Disc lifts vertically during forward flow.

Best for high-pressure applications.

3. Spring-Loaded Reflux Valve

Spring ensures quick closing action.

Suitable for vertical or inclined pipelines.

4. Dual Plate Check Valve

Two spring-loaded plates.

Compact, lightweight option for industrial systems.

Where are Reflux Valves Used?

✔ Water supply systems ✔ Sewage treatment plants ✔ Drainage lines ✔ Firefighting pipelines ✔ Irrigation systems ✔ Industrial fluid transfer lines ✔ Pump delivery pipelines

Reflux Valve Price List in Delhi

Here’s a general pricing range based on valve size and material:Size (mm)TypeMaterialPrice Range (INR)50 mmSwing TypeCast Iron₹1,000 – ₹1,80080 mmSwing TypeCast Iron₹1,500 – ₹2,200100 mmSpring LoadedDuctile Iron₹2,500 – ₹4,500150 mmDual PlateSS/DI₹4,000 – ₹7,000200 mmLift TypeDuctile Iron₹6,000 – ₹10,000250 mm+Custom OptionsSS/CI₹10,000+

📌 Note: Prices vary by brand, pressure class (PN10/PN16), material, and order volume.

For latest rates and discounts, contact Udhhyog directly.

How to Select the Right Reflux Valve

✅ 1. Pipeline Size

Choose valve size based on pipeline diameter and flow rate.

✅ 2. Flow Direction & Orientation

Confirm installation is in the correct flow direction as per diagram.

✅ 3. Valve Type

Use swing type for water and drainage.

Use spring-loaded for vertical pipes.

✅ 4. Material Compatibility

Cast Iron – Cost-effective, suitable for water.

Ductile Iron – Stronger, high pressure.

Stainless Steel – For chemical or corrosive fluids.

✅ 5. Maintenance Access

Prefer bolted cover valves for easy inspection.

Why Choose Udhhyog – Best Reflux Valve Supplier in Delhi

At Udhhyog, we deliver top-quality reflux valves backed by:

⭐ Premium Quality Materials

Valves built from tested CI, DI, and SS with anti-corrosion coatings.

⭐ Custom Sizes & Bulk Supply

Available in 50mm to 600mm sizes, pressure class PN10, PN16.

⭐ Fast Delivery Across North India

We supply across Delhi, Haryana, Punjab, UP, J&K, and Himachal Pradesh.

⭐ Competitive Pricing

Factory-direct rates and bulk discounts.

⭐ After-Sales Support

We provide technical support, installation guidance, and product warranty.

Conclusion

A reflux valve is an essential safeguard in fluid management systems, ensuring smooth one-way flow and preventing costly damage due to backflow.

With multiple valve types and material options available, it's important to choose the right reflux valve based on your system’s size, fluid type, and orientation.

For reliable and affordable reflux valves in Delhi, Udhhyog is your go-to source for quality, service, and support.

Contact Udhhyog – Reflux Valve Manufacturer in Delhi

📞 Call Now or Visit Udhhyog to explore our complete range of check valves and non-return valve solutions.

#RefluxValve#NonReturnValve#NRV#CheckValve#DelhiValveSupplier#Udhhyog#IndustrialValves#WaterPumping#ValveDiagram#PipelineSafety

0 notes

Text

What is a Reflux Valve? Diagram, Price List & Best Supplier in Delhi

In fluid and pipeline systems, ensuring one-way flow is crucial to avoid backflow and system damage. That’s where reflux valves come into play. Also known as non-return valves (NRVs), reflux valves are used in water supply lines, sewage systems, pumping stations, and more.

As a trusted reflux valve manufacturer and supplier in Delhi, Udhhyog offers premium-quality, long-lasting valves for municipal, commercial, and industrial use.

This article explains what a reflux valve is, how it works, its diagram, pricing, and where to get the best reflux valve in Delhi.

What is a Reflux Valve?

A reflux valve is a type of non-return valve that allows fluid to flow in only one direction and automatically prevents backflow. It is typically installed in pumping systems, especially on the delivery side of pumps.

Reflux Valve is Also Known As:

NRV (Non-Return Valve)

One-Way Valve

Check Valve

Non-Return Check Valve

Reflux Valve Working Principle

The valve has a disc or flap that opens when the fluid flows forward. When reverse flow occurs, the disc automatically closes due to gravity or spring action, preventing backflow.

This makes reflux valves essential in vertical pipelines and pumping applications, especially where system damage due to reverse pressure must be avoided.

Reflux Valve Diagram

The reflux valve diagram typically includes:

Valve body

Disc/flap or check plate

Flow arrow (direction indicator)

Spring (in spring-loaded variants)

The diagram helps engineers and technicians understand installation orientation, internal structure, and maintenance procedure.

Types of Reflux Valves

1. Swing Type Reflux Valve

Disc swings open/close based on flow.

Commonly used in sewage and water supply systems.

2. Lift Type Reflux Valve

Disc lifts vertically during forward flow.

Best for high-pressure applications.

3. Spring-Loaded Reflux Valve

Spring ensures quick closing action.

Suitable for vertical or inclined pipelines.

4. Dual Plate Check Valve

Two spring-loaded plates.

Compact, lightweight option for industrial systems.

Where are Reflux Valves Used?

✔ Water supply systems ✔ Sewage treatment plants ✔ Drainage lines ✔ Firefighting pipelines ✔ Irrigation systems ✔ Industrial fluid transfer lines ✔ Pump delivery pipelines

Reflux Valve Price List in Delhi

Here’s a general pricing range based on valve size and material:Size (mm)TypeMaterialPrice Range (INR)50 mmSwing TypeCast Iron₹1,000 – ₹1,80080 mmSwing TypeCast Iron₹1,500 – ₹2,200100 mmSpring LoadedDuctile Iron₹2,500 – ₹4,500150 mmDual PlateSS/DI₹4,000 – ₹7,000200 mmLift TypeDuctile Iron₹6,000 – ₹10,000250 mm+Custom OptionsSS/CI₹10,000+

📌 Note: Prices vary by brand, pressure class (PN10/PN16), material, and order volume.

For latest rates and discounts, contact Udhhyog directly.

How to Select the Right Reflux Valve

✅ 1. Pipeline Size

Choose valve size based on pipeline diameter and flow rate.

✅ 2. Flow Direction & Orientation

Confirm installation is in the correct flow direction as per diagram.

✅ 3. Valve Type

Use swing type for water and drainage.

Use spring-loaded for vertical pipes.

✅ 4. Material Compatibility

Cast Iron – Cost-effective, suitable for water.

Ductile Iron – Stronger, high pressure.

Stainless Steel – For chemical or corrosive fluids.

✅ 5. Maintenance Access

Prefer bolted cover valves for easy inspection.

Why Choose Udhhyog – Best Reflux Valve Supplier in Delhi

At Udhhyog, we deliver top-quality reflux valves backed by:

⭐ Premium Quality Materials

Valves built from tested CI, DI, and SS with anti-corrosion coatings.

⭐ Custom Sizes & Bulk Supply

Available in 50mm to 600mm sizes, pressure class PN10, PN16.

⭐ Fast Delivery Across North India

We supply across Delhi, Haryana, Punjab, UP, J&K, and Himachal Pradesh.

⭐ Competitive Pricing

Factory-direct rates and bulk discounts.

⭐ After-Sales Support

We provide technical support, installation guidance, and product warranty.

Conclusion

A reflux valve is an essential safeguard in fluid management systems, ensuring smooth one-way flow and preventing costly damage due to backflow.

With multiple valve types and material options available, it's important to choose the right reflux valve based on your system’s size, fluid type, and orientation.

For reliable and affordable reflux valves in Delhi, Udhhyog is your go-to source for quality, service, and support.

Contact Udhhyog – Reflux Valve Manufacturer in Delhi

📞 Call Now or Visit Udhhyog to explore our complete range of check valves and non-return valve solutions.

#RefluxValve#NonReturnValve#NRV#CheckValve#DelhiValveSupplier#Udhhyog#IndustrialValves#WaterPumping#ValveDiagram#PipelineSafety

0 notes

Text

LPH in RO Water Purifier

Understanding LPH in RO Water Purifiers: What It Means for Your Water Needs

The global demand for safe, pure, and healthy drinking water is enormous. Establishments such as workplaces, schools, hotels, and restaurants may give customers and staff with high-quality pure water that is free of all sediments, pollutants, and hazardous chemicals by employing RO water purifiers for commercial usage. It’s an important specification that gives you a clearer idea of how quickly the purifier can process water. But what does it really mean for your daily water consumption? Let’s break down everything you need to know about LPH in RO water purifiers and why it matters. At TR Aqua Pvt. Ltd., we are committed to providing top-quality water purification solutions that cater to your unique water needs.

Also Read Us: How Sewage Treatment Plant Work Explain via Diagram?

What is LPH?

LPH is a unit of measurement that indicates how much water an RO water purifier can filter in one hour. For example, if an RO purifier is rated at 12 LPH, it means that the purifier can process 12 liters of water per hour. This rate determines the speed at which water is filtered, which is particularly important in homes and businesses where there are varying water demands throughout the day.

Website: https://www.traqua.in/lph-in-ro-water-purifier/

0 notes

Text

Process of Obtaining CTE | Sewage Treatment Plant (STP) Kolhapur

Step-by-Step Process to Obtain CTE for STP in Kolhapur

Project Planning and Design

Prepare a comprehensive project report detailing the design, capacity, and technology of the Sewage Treatment Plant.

Ensure the proposed STP meets the discharge standards prescribed by the MPCB.

Documentation Preparation The following documents are required for the CTE application:

Project report with technical specifications

Site plan and layout

Consent from the local municipal authority (if applicable)

Land ownership or lease documents

Environmental Management Plan (EMP)

Manufacturing process flow diagram (if applicable)

Online Application Submission

Register and log in to the MPCB’s official website.

Fill in the CTE application form accurately and upload all necessary documents.

Pay the required processing fee based on the scale of the STP project.

Inspection and Site Verification

After submitting the application, the MPCB officials will conduct a site inspection.

Ensure that the site aligns with the proposed plan and adheres to environmental guidelines.

Approval and Issuance of CTE

Upon satisfactory inspection and document verification, the MPCB will grant the Consent to Establish.

This approval is typically valid for a specified period during which the STP must be constructed and commissioned.

Why Choose Ecocivic Solutions?

At Ecocivic Solutions, we simplify the process of obtaining CTE for STPs in Kolhapur by offering:

Expert consultation on regulatory compliance

Preparation and submission of all required documents

Liaison with the MPCB for inspections and approvals

Customized STP solutions aligned with environmental standard

Our team ensures a hassle-free process, allowing you to focus on project execution while we manage the legal and technical intricacies.

Obtaining Consent to Establish (CTE) for a Sewage Treatment Plant in Kolhapur is a crucial step to ensure environmental compliance. With Ecocivic Solutions as your partner, you can navigate the regulatory landscape efficiently and establish a sustainable wastewater management system. Contact us today to learn more about our STP solutions and CTE assistance.

For expert guidance and end-to-end support, reach out to Ecocivic Solutions — your trusted environmental engineering partner in Kolhapur.

Get in touch with : https://ecocivicsolutions.com/

#EnvironmentalEngineering#ConsultancyServices#SustainableSolutions#EcoFriendly#GreenConsulting#EnvironmentalImpact#WasteManagement#Sustainability#CleanTech#ClimateAction#ResourceConservation#InnovationInEngineering#ProfessionalConsultants#EnvironmentalAwareness#EngineeringSolutions#EcosystemHealth#RenewableEnergy#ConsultingExperts#FutureOfEngineering

0 notes

Text

Process Flow Diagram of Sewage Treatment Plant

Overview of Sewage Treatment Process Flow

At the start of a sewage treatment process flow, wastewater collection comes from a range of sources. This water comes through widespread pipes and moves on to its first treatment phase. Here, crude substances, such as debris and grit, are eliminated to stop equipment damage. As the water fills the primary treatment tanks, the heavier solids sink to the tanks' bottom surface next. Following completion of this phase, access to secondary treatment takes place for the wastewater. During this phase, organic materials biologically decompose as contaminant concentrations are dropping. The water heads to clarifiers to differentiate the rest of the solids. In the end, it arrives at the third treatment phase that unites advanced filtration with disinfection. Treated clean water enters nearby bodies of water or is used again for uses that do not require drinking water. Every phase of the operation is focused on smooth sewage treatment while remaining by environmental requirements.

Key Components of a Sewage Treatment Plant Flow Diagram

A sewage treatment plant flow chart presents a graphic explanation of the treatment steps. The start is where there is the inflow or inlet, which is the point through which wastewater enters the operation. The model illustrates the primary form of treatment, which eradicates big particles like grit. At this point, the primary treatment begins with settling tanks that cause solids to divide. Following that, secondary treatment takes place, in which biological mechanisms remove organic contaminants. At this phase, the diagram clarifies the difference between solid waste. During tertiary treatment, innovative filters together with disinfectants contribute to better processing of the water. Diagrams include systems for sludge processing along with sludge drying techniques. Arrows alongside labels signal the movement of water across every stage. A properly constructed flow diagram facilitates operator understanding and management of the elaborate sewage treatment process.

Step-by-Step Breakdown of the Sewage Treatment Process

Entry of sewage into the facility launches its sewage treatment plant for industries. During the start-up stage, large solids along with grit are eliminated. Eventually, the wastewater falls into tanks for primary treatment after that. Settling happens beneath because sedimentation originates from this point. The liquids that are remaining proceed into the secondary treatment stage. The biological processes presented, including aerobic decomposition, change organic matter. After that, it is essential to clarify by which the leftover solids differentiate from the water. Following secondary treatment, water first moves on to tertiary treatment. This concluding segment applies filters, along with disinfection, in a direction to remove any superfluous impurities. Eventually, the treated water is either sent down rivers or put to use for irrigation. All steps confirm the safety of wastewater for the environment after cleaning.

Understanding the Flow of Wastewater in Treatment Plants

In a treatment facility, a sequence of stages deals with the wastewater treatment plant. The method initiates once the plant obtains wastewater via the inflow pipes. The screening stage removes large debris as the water's first step. Within primary treatment, it migrates to sedimentation tanks.

Lighter materials head towards the surface, in contrast, thicker materials go down towards the bottom. Following completion of the first treatment phase, the wastewater rapidly flows into secondary treatment. Pollutant reductions happen because microorganisms are busy breaking down organic matter.

The flow carries through to clarifiers, the stage at which the final separation of solids happens. The next phase in treatment starts following the clarification of the water. In the phase where filtration combines with chemical disinfection, the quality of the water becomes better. At last, the water treated is out in rivers or storage for purposes of reuse.

Detailed Guide to Sewage Treatment Process Flow Stages

The several stages of sewage treatment are all important for the cleaning of wastewater. The introductory treatment gets underway with screens that remove substantial items including wood and plastic. Flowing water into primary treatment tanks causes solids to sink to the tank's bottom.

After this stage, secondary treatment will take place for the sewage, letting bacteria manage organic matter treatment. The coming phase consists of separating the liquid from what remains of the solids. Wastewater achieves a superior filtering system via tertiary treatment, which discards little particles and impurities.

Only after disinfection can the water be released or made use of it once more. Every phase is important for assuring that sewage is managed to meet environmental standards. A diagram that illustrates visually shows the transport of sewage through a treatment facility.

The inflow area identifies the leading entry location for wastewater to get to the plant. You can see the route water follows while passing through screens and grit chambers designed for debris separation in the flow diagram. The ensuing part of the diagram points out primary settling tanks, where the separation of solids takes place.

At the end of the day, the wastewater is in secondary treatment tanks receiving treatment from microbes that dissolve organic pollutants. The arrows reveal where the movement of water directs towards clarifiers that provide more separation.

For tertiary-level water treatment, advanced filtration combined with disinfection is a requirement. The diagram contains pathways devoted to sludge treatment as well. Due to the diagram, operators can nimbly manage all phases of the process.

Conclusion

The concluding result of the sewage treatment plant process flow diagram shows the necessary progression stages for wastewater treatment. Every phase, from primary inflow to the ultimate finish of discharge, is hugely important in water purification. At the outset, treatment removes big solid particles, and further on, primary treatment resolves the settling of solid waste. Secondary treatment consists of biological approaches that break apart contaminants. In time, tertiary treatment confirms that the water gets both filtration and disinfection all through the entire process. Operators can keep plant operations efficient and effective thanks to the understanding of how water flows through each phase. Every stage of treatment confirms that wastewater receives proper treatment, to maintain environmental and public health. A structured flow helps sewage treatment plants to uniformly meet environmental regulations over time.

#sewage treatment plant#sewage process#sewage management#sewage plant manufacturer#sewage plant equipments#sewage treatment plant in india#sewage treatment plant for industries#stp plant manufacturer#stp plant#stp plant supplier

0 notes

Text

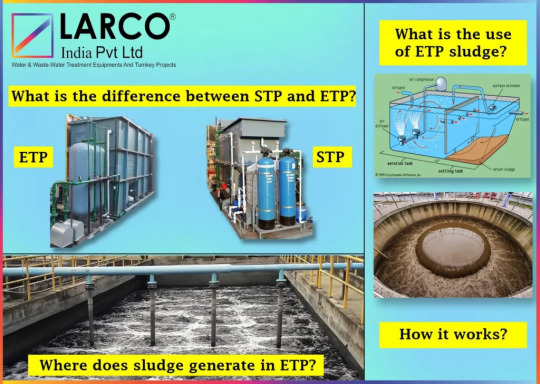

What is the difference between STP and ETP?

In this article, we’ll look What is the difference between STP and ETP?

Certainly! Let’s break down the differences between STP (Sewage Treatment Plant) and ETP (Effluent Treatment Plant) in simpler terms.

To preserve the receiving waterways, two particular treatments, sewage treatment and effluent treatment are used to remove toxins from wastewater (sludge). Both of these treatments are made up of physical, chemical, and biological processes. The primary distinction between the two STP & ETP.

WHAT IS THE DIFFERENCE BETWEEN STP AND ETP?

Sewage Treatment Plant (STP):

What it does: STP handles the treatment of the waste water that is generated by residences, businesses, and other common locations (such as restrooms, sinks, etc.). Sewage is the term for this unsafe water.

Goal: The main duty of a STP is to treat this sewage so that it can be safely discharged into bodies of water like rivers and oceans or even utilized (for example, to water plants).

How it works: It works by separating solid waste from liquid waste, utilizing beneficial bacteria to break down trash, and adding chemicals to the water. STP Industries Inc. develops products to minimize the amount of toxic substances in sewage.

Effluent Treatment Plant (ETP):

What it does: Industrial wastewater, usually referred to as effluent, is the smelly water that is produced by factories and other industrial facilities.

Goal: An ETP, short for “environmental technology product,” is a chemical substance created to clean up industrial effluent so that it may be reused or released back into the environment in a manner that does not threaten the ecosystem.

How it works: The Etp wastewater solutions can be used to clean industrial wastewater. Sometimes these solutions might involve using chemicals, separating various materials, and occasionally using microbes to degrade dangerous materials.

To put it simply, STP cleans the environment by handling the regular, unclean water from households and businesses. ETP, on the other hand, controls the unsavoury water that emanates from industrial facilities, ensuring its safety before releasing or reusing it. With the aid of specialized techniques, each plant is created to manage a particular kind of contaminated water.

WHAT IS THE USE OF ETP SLUDGE?

https://larcoindia.in/wp-content/uploads/2023/10/diagram-package-plant-aeration-treatment-sewage-flows-1-1.png

What is the use of ETP sludge?

The uses of ETP sludge are many and varied:

https://larcoindia.in/wp-content/uploads/2023/10/wastewater-treatment-pool.jpg

Other use of ETP sludge:

the disposal of treated sewage sludge, which is combined with air and oxygen and applied to agricultural soil as a soil conditioner.

Sewage sludge is disposed of through burning, which involves burning it alongside other waste products like paper and plastic to create steam and energy for industrial uses or to create heat for home usage.

Typically, sewage sludge from sewage treatment plants is burned in a facility along with other waste products like paper and plastic. This burning process generates heat, which is then used to create steam that can be used both to heat domestic water in houses and for industrial applications.

The primary issue with using ETP sludge is that it includes a lot of ammonia (NH3), which is extremely harmful to people if consumed in large amounts over an extended period of time.

WHERE DOES SLUDGE GENERATE IN ETP?

So what you think, Where does sludge generate in ETP?

In an Effluent Treatment Plant (ETP), sludge is formed during the process of treating industrial wastewater. This sludge is essentially the solid waste that settles or is removed during the treatment of the wastewater. It contains the solid particles and pollutants that are separated from the water during the treatment process. The sludge includes things like particles of dirt, chemicals, and other materials that were in the wastewater.

To explain further, when the dirty industrial wastewater goes through the treatment steps, certain solid substances and pollutants settle down or are separated from the water. This separation forms a thick, muddy material, which we call sludge. Managing and disposing of this sludge properly is an important part of the overall wastewater treatment process to ensure that the environment is not negatively impacted.

#wastewatertreatment#watertreatmentsolutions#water purification#etp#sewagetreatmentplant#water treatment

0 notes

Text

Effluent Treatment Plant: Process and Flow Diagram in Pharma Industry

The pharmaceutical industry plays a pivotal role in our economy, contributing in multifaceted ways. It encompasses the discovery, development, production, and marketing of drugs and pharmaceuticals for patient treatment and symptom alleviation. Given its water-intensive processes, the industry inevitably discharges wastewater into the environment, whether treated or untreated.

For optimal results, you require top-notch equipment, offered at a more affordable rate compared to our market counterparts. Today, we introduce you to one of our flagship products – the Effluent Treatment Plant (ETP) – and shed light on its pivotal role in the pharmaceutical industry. Not limited to ETP’s we also have expertise and experience as sewage treatment plant manufacturer in Noida.

1 note

·

View note

Text

LPH in RO Water Purifier

Understanding LPH in RO Water Purifiers: What It Means for Your Water Needs

The global demand for safe, pure, and healthy drinking water is enormous. Establishments such as workplaces, schools, hotels, and restaurants may give customers and staff with high-quality pure water that is free of all sediments, pollutants, and hazardous chemicals by employing RO water purifiers for commercial usage. It’s an important specification that gives you a clearer idea of how quickly the purifier can process water. But what does it really mean for your daily water consumption? Let’s break down everything you need to know about LPH in RO water purifiers and why it matters. At TR Aqua Pvt. Ltd., we are committed to providing top-quality water purification solutions that cater to your unique water needs.

Also Read Us: How Sewage Treatment Plant Work Explain via Diagram?

What is LPH?

LPH is a unit of measurement that indicates how much water an RO water purifier can filter in one hour. For example, if an RO purifier is rated at 12 LPH, it means that the purifier can process 12 liters of water per hour. This rate determines the speed at which water is filtered, which is particularly important in homes and businesses where there are varying water demands throughout the day.

Website: https://www.traqua.in/lph-in-ro-water-purifier/

0 notes

Text

How Sewage treatment plant work explain via diagram?

Welcome to R&J Waste Water Treatment Organization, your trusted partner in sustainable water management. Today, we’re diving into an essential topic: How Sewage Treatment Plants (STPs) Work. We’ll break down the process into simple steps and include a clear diagram to make it easy to understand. A sewage treatment plant is a facility that receives waste from residential, commercial, and industrial sources and removes contaminants that harm water quality and endanger public health and safety when discharged into receiving systems or on land. It is a collection of unit operations and unit procedures designed to treat sewage to desirable standards in accordance with regulating authority effluent requirements.

Website: https://www.rjjalraksha.com/stp-plant/how-sewage-treatment-plant-work-explain-via-diagram/

0 notes

Text

Cool facts... older US cities may have what's called a "Combined Sewer System." NYC is an older city. It's had updates! So SOME of the storm drain pipes are just for street runoff... but... uh. Bad news for mutant turtles.

Look. I'm just gonna quote from the NYC municipal website (and its nifty diagrams) linked below.

About 60% of New York City has a combined sewer system. In a combined sewer system, there is a single pipe that carries both stormwater runoff and sewage from buildings. This mix of stormwater and sewage is usually sent to a wastewater treatment plant.

During heavy rainstorms, combined sewers receive higher than normal flows. Treatment plants are unable to handle flows that are more than twice the design capacity. When this occurs, a mix of stormwater and untreated sewage discharges directly into the City’s waterways.

During REAAAALLLY bad rainstorms, the whole system floods up into the streets, subways, and basement apartments. You may have seen video clips online of NYC flooding during hurricanes and tropical storms. I'll drop one below.

youtube

So... uh. For mutant turtles--yikes. Might be why they don't wear shoes. Better to wash off feet/legs/wraps than to stick your toes repeatedly into rotting sewage sneakers. (And ninjas don't wear rubber boots. That'd just be silly. 😉)

Every day I’m haunted by the fact the boys happily swim in sewer water

Even if it’s filtered somehow there’s no way it’s not still nasty 😭 Bet they can defeat any of their villains just by accidentally giving them diseases I swear

#tmnt#teenage mutant ninja turtles#donatello#leonardo#michelangelo#raphael#tmnt fandom#tmnt fanfiction#this is also why IRL we do not swim in flood water if at all possible to avoid#flood water can make you so sick for real#Youtube

658 notes

·

View notes

Text

Best Sluice Valve Supplier in Delhi – Price, Function & Comparison with Gate Valves

Sluice valves, also known as gate valves, are widely used in water supply, sewage systems, fire protection, and irrigation networks. They are designed to control water flow by raising or lowering a gate, and are ideal for full-flow or full-stop applications.

As a trusted sluice valve manufacturer and supplier in Delhi, Udhhyog offers a complete range of cast iron, ductile iron, and stainless-steel sluice valves. Our products are engineered for durability, high performance, and smooth operation in tough industrial environments.

In this article, we will explore the function of sluice valves, their working principle, comparison with gate valves, diagrams, price list, and how to select the right valve.

What is a Sluice Valve?

A sluice valve is a type of isolation valve that regulates the flow of liquid by lifting a round or rectangular gate out of the path of the fluid. It is mainly used in on/off flow control rather than throttling.

Sluice valves are typically used in underground pipelines and large water distribution networks where minimal flow resistance is required when fully open.

Sluice Valve Function & Working Principle

A handwheel is used to raise or lower the gate.

When the gate is lifted, fluid flows freely through the valve body.

When lowered, the gate seals the flow path, completely stopping the flow.

Sluice Valve Applications:

✔ Municipal water distribution ✔ Wastewater treatment plants ✔ Fire hydrant systems ✔ Irrigation & agricultural networks ✔ Industrial fluid control

Sluice Valve Diagram

A typical sluice valve diagram shows:

Valve body

Rising or non-rising stem

Wedge-type gate

Handwheel or actuator

Flanged or socket ends

The diagram helps engineers and plumbers understand installation and maintenance procedures.

Difference Between Sluice Valve and Gate Valve

Though the terms are often used interchangeably, there are some key distinctions:FeatureSluice ValveGate ValveUsagePrimarily for water pipelinesUsed in multiple industries (oil, gas, water)SizeTypically larger sizes (100mm and above)Available in a wide range of sizesFlow TypeIdeal for full open/full closeSuitable for both isolation and limited throttlingCostUsually more economical in bulkCan be expensive depending on materialDesignSimpler constructionMore variants and precise engineering

📌 Note: Sluice valve is often referred to as a type of gate valve, but in water supply applications, it has specific design standards.

Sluice Valve Price List in Delhi

Here is an indicative price list for sluice valves (flanged type, CI/DI body):Size (mm)Price Range (INR)50 mm₹1,800 – ₹2,50080 mm₹2,800 – ₹4,000100 mm₹3,500 – ₹5,500150 mm₹5,500 – ₹9,000200 mm₹8,000 – ₹12,000300 mm₹12,000 – ₹20,000

📞 Contact Udhhyog for bulk orders and discounted pricing.

How to Select the Right Sluice Valve?

✅ 1. Application

For water and irrigation – Use cast iron or ductile iron sluice valves.

For corrosive fluids – Opt for stainless steel variants.

✅ 2. Size & Pressure Class

Select size based on pipeline diameter.

Choose pressure rating (PN10, PN16, PN25) based on operating conditions.

✅ 3. Type of Stem

Rising stem for visual position indication.

Non-rising stem for space-constrained installations.

✅ 4. End Connections

Flanged ends for large pipelines.

Socket/spigot ends for easy underground installation.

✅ 5. Material Compatibility

Ensure valve body, stem, and wedge materials match fluid type and temperature.

Why Choose Udhhyog – Best Sluice Valve Supplier in Delhi?

🌟 Top-Quality Materials

We manufacture valves using CI, DI, and SS for long-term durability and resistance to corrosion.

🌟 Wide Range & Customization

We offer sluice valves from 50mm to 600mm, with customization for pressure class and actuator options.

🌟 Affordable Pricing

Our valves are priced competitively without compromising quality.

🌟 Trusted Supplier Network

We serve industries across Delhi, Haryana, Uttar Pradesh, Punjab, and Jammu & Kashmir.

🌟 On-Time Delivery & Support

We ensure timely delivery with after-sales support and technical consultation.

Conclusion

Sluice valves are an indispensable part of modern infrastructure and industrial piping. From controlling large volumes of water in municipal lines to ensuring safety in fire networks, their role is vital.

With Udhhyog, you can be assured of quality, reliability, and cost-effective solutions for all your valve requirements.

Contact Udhhyog – Your Trusted Sluice Valve Partner

📞 Call Now or Visit Udhhyog Website to explore our range of sluice valves, gate valves, and industrial piping solutions.

#SluiceValve#GateValve#ValveSupplierDelhi#WaterPipeline#IndustrialValves#Udhhyog#ValveManufacturer#NonReturnValve#PipingSolutions#PlumbingInfrastructure

0 notes

Text

Best Sluice Valve Supplier in Delhi – Price, Function & Comparison with Gate Valves

Sluice valves, also known as gate valves, are widely used in water supply, sewage systems, fire protection, and irrigation networks. They are designed to control water flow by raising or lowering a gate, and are ideal for full-flow or full-stop applications.

As a trusted sluice valve manufacturer and supplier in Delhi, Udhhyog offers a complete range of cast iron, ductile iron, and stainless-steel sluice valves. Our products are engineered for durability, high performance, and smooth operation in tough industrial environments.

In this article, we will explore the function of sluice valves, their working principle, comparison with gate valves, diagrams, price list, and how to select the right valve.

What is a Sluice Valve?

A sluice valve is a type of isolation valve that regulates the flow of liquid by lifting a round or rectangular gate out of the path of the fluid. It is mainly used in on/off flow control rather than throttling.

Sluice valves are typically used in underground pipelines and large water distribution networks where minimal flow resistance is required when fully open.

Sluice Valve Function & Working Principle

A handwheel is used to raise or lower the gate.

When the gate is lifted, fluid flows freely through the valve body.

When lowered, the gate seals the flow path, completely stopping the flow.

Sluice Valve Applications:

✔ Municipal water distribution ✔ Wastewater treatment plants ✔ Fire hydrant systems ✔ Irrigation & agricultural networks ✔ Industrial fluid control

Sluice Valve Diagram

A typical sluice valve diagram shows:

Valve body

Rising or non-rising stem

Wedge-type gate

Handwheel or actuator

Flanged or socket ends

The diagram helps engineers and plumbers understand installation and maintenance procedures.

Difference Between Sluice Valve and Gate Valve

Though the terms are often used interchangeably, there are some key distinctions:FeatureSluice ValveGate ValveUsagePrimarily for water pipelinesUsed in multiple industries (oil, gas, water)SizeTypically larger sizes (100mm and above)Available in a wide range of sizesFlow TypeIdeal for full open/full closeSuitable for both isolation and limited throttlingCostUsually more economical in bulkCan be expensive depending on materialDesignSimpler constructionMore variants and precise engineering

📌 Note: Sluice valve is often referred to as a type of gate valve, but in water supply applications, it has specific design standards.

Sluice Valve Price List in Delhi

Here is an indicative price list for sluice valves (flanged type, CI/DI body):Size (mm)Price Range (INR)50 mm₹1,800 – ₹2,50080 mm₹2,800 – ₹4,000100 mm₹3,500 – ₹5,500150 mm₹5,500 – ₹9,000200 mm₹8,000 – ₹12,000300 mm₹12,000 – ₹20,000

📞 Contact Udhhyog for bulk orders and discounted pricing.

How to Select the Right Sluice Valve?

✅ 1. Application

For water and irrigation – Use cast iron or ductile iron sluice valves.

For corrosive fluids – Opt for stainless steel variants.

✅ 2. Size & Pressure Class

Select size based on pipeline diameter.

Choose pressure rating (PN10, PN16, PN25) based on operating conditions.

✅ 3. Type of Stem

Rising stem for visual position indication.

Non-rising stem for space-constrained installations.

✅ 4. End Connections

Flanged ends for large pipelines.

Socket/spigot ends for easy underground installation.

✅ 5. Material Compatibility

Ensure valve body, stem, and wedge materials match fluid type and temperature.

Why Choose Udhhyog – Best Sluice Valve Supplier in Delhi?

🌟 Top-Quality Materials

We manufacture valves using CI, DI, and SS for long-term durability and resistance to corrosion.

🌟 Wide Range & Customization

We offer sluice valves from 50mm to 600mm, with customization for pressure class and actuator options.

🌟 Affordable Pricing

Our valves are priced competitively without compromising quality.

🌟 Trusted Supplier Network

We serve industries across Delhi, Haryana, Uttar Pradesh, Punjab, and Jammu & Kashmir.

🌟 On-Time Delivery & Support

We ensure timely delivery with after-sales support and technical consultation.

Conclusion

Sluice valves are an indispensable part of modern infrastructure and industrial piping. From controlling large volumes of water in municipal lines to ensuring safety in fire networks, their role is vital.

With Udhhyog, you can be assured of quality, reliability, and cost-effective solutions for all your valve requirements.

Contact Udhhyog – Your Trusted Sluice Valve Partner

📞 Call Now or Visit Udhhyog Website to explore our range of sluice valves, gate valves, and industrial piping solutions.

#SluiceValve#GateValve#ValveSupplierDelhi#WaterPipeline#IndustrialValves#Udhhyog#ValveManufacturer#NonReturnValve#PipingSolutions#PlumbingInfrastructure

0 notes

Text

Best Sluice Valve Supplier in Delhi – Price, Function & Comparison with Gate Valves

Sluice valves, also known as gate valves, are widely used in water supply, sewage systems, fire protection, and irrigation networks. They are designed to control water flow by raising or lowering a gate, and are ideal for full-flow or full-stop applications.

As a trusted sluice valve manufacturer and supplier in Delhi, Udhhyog offers a complete range of cast iron, ductile iron, and stainless-steel sluice valves. Our products are engineered for durability, high performance, and smooth operation in tough industrial environments.

In this article, we will explore the function of sluice valves, their working principle, comparison with gate valves, diagrams, price list, and how to select the right valve.

What is a Sluice Valve?

A sluice valve is a type of isolation valve that regulates the flow of liquid by lifting a round or rectangular gate out of the path of the fluid. It is mainly used in on/off flow control rather than throttling.

Sluice valves are typically used in underground pipelines and large water distribution networks where minimal flow resistance is required when fully open.

Sluice Valve Function & Working Principle

A handwheel is used to raise or lower the gate.

When the gate is lifted, fluid flows freely through the valve body.

When lowered, the gate seals the flow path, completely stopping the flow.

Sluice Valve Applications:

✔ Municipal water distribution ✔ Wastewater treatment plants ✔ Fire hydrant systems ✔ Irrigation & agricultural networks ✔ Industrial fluid control

Sluice Valve Diagram

A typical sluice valve diagram shows:

Valve body

Rising or non-rising stem

Wedge-type gate

Handwheel or actuator

Flanged or socket ends

The diagram helps engineers and plumbers understand installation and maintenance procedures.

Difference Between Sluice Valve and Gate Valve

Though the terms are often used interchangeably, there are some key distinctions:FeatureSluice ValveGate ValveUsagePrimarily for water pipelinesUsed in multiple industries (oil, gas, water)SizeTypically larger sizes (100mm and above)Available in a wide range of sizesFlow TypeIdeal for full open/full closeSuitable for both isolation and limited throttlingCostUsually more economical in bulkCan be expensive depending on materialDesignSimpler constructionMore variants and precise engineering

📌 Note: Sluice valve is often referred to as a type of gate valve, but in water supply applications, it has specific design standards.

Sluice Valve Price List in Delhi

Here is an indicative price list for sluice valves (flanged type, CI/DI body):Size (mm)Price Range (INR)50 mm₹1,800 – ₹2,50080 mm₹2,800 – ₹4,000100 mm₹3,500 – ₹5,500150 mm₹5,500 – ₹9,000200 mm₹8,000 – ₹12,000300 mm₹12,000 – ₹20,000

📞 Contact Udhhyog for bulk orders and discounted pricing.

How to Select the Right Sluice Valve?

✅ 1. Application

For water and irrigation – Use cast iron or ductile iron sluice valves.

For corrosive fluids – Opt for stainless steel variants.

✅ 2. Size & Pressure Class

Select size based on pipeline diameter.

Choose pressure rating (PN10, PN16, PN25) based on operating conditions.

✅ 3. Type of Stem

Rising stem for visual position indication.

Non-rising stem for space-constrained installations.

✅ 4. End Connections

Flanged ends for large pipelines.

Socket/spigot ends for easy underground installation.

✅ 5. Material Compatibility

Ensure valve body, stem, and wedge materials match fluid type and temperature.

Why Choose Udhhyog – Best Sluice Valve Supplier in Delhi?

🌟 Top-Quality Materials

We manufacture valves using CI, DI, and SS for long-term durability and resistance to corrosion.

🌟 Wide Range & Customization

We offer sluice valves from 50mm to 600mm, with customization for pressure class and actuator options.

🌟 Affordable Pricing

Our valves are priced competitively without compromising quality.

🌟 Trusted Supplier Network

We serve industries across Delhi, Haryana, Uttar Pradesh, Punjab, and Jammu & Kashmir.

🌟 On-Time Delivery & Support

We ensure timely delivery with after-sales support and technical consultation.

Conclusion

Sluice valves are an indispensable part of modern infrastructure and industrial piping. From controlling large volumes of water in municipal lines to ensuring safety in fire networks, their role is vital.

With Udhhyog, you can be assured of quality, reliability, and cost-effective solutions for all your valve requirements.

Contact Udhhyog – Your Trusted Sluice Valve Partner

📞 Call Now or Visit Udhhyog Website to explore our range of sluice valves, gate valves, and industrial piping solutions.

#SluiceValve#GateValve#ValveSupplierDelhi#WaterPipeline#IndustrialValves#Udhhyog#ValveManufacturer#NonReturnValve#PipingSolutions#PlumbingInfrastructure

0 notes