#Semiconductor Chemicals Industry

Explore tagged Tumblr posts

Text

Don't miss out on business opportunities in Semiconductor Chemicals Market Industry Download to our Report PDF Brochure & gain crucial industry insights that will help your business grow. Click on Link For PDF Download at https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=191345076&utm_source=linkedin-ks&utm_medium=social&utm_campaign=chksoct24

#Semiconductor Chemicals Market#Semiconductor Chemicals#Semiconductor Chemical#Semiconductor Chemicals Industry#Semiconductor#Chemicals#Chemicals Market#Chemical#Chemicals Industry#Semiconductor Industry

1 note

·

View note

Text

Growth of the Electronic Chemicals CDMO & CRO Market: A Game-Changer for the Electronics Industry

The electronics industry has seen phenomenal growth in recent years, spurred by the demand for advanced technologies in sectors such as semiconductors, optoelectronics, and energy storage solutions. At the heart of this progress is the increasing reliance on high-purity electronic chemicals—a critical component in manufacturing processes. To keep pace with rapid advancements and ever-changing consumer expectations, many companies are turning to Contract Development and Manufacturing Organizations (CDMOs) and Contract Research Organizations (CROs). These specialized firms provide tailored solutions, bridging the gap between innovation and execution while helping businesses stay competitive. Let’s take a closer look at the dynamics of the Electronic Chemicals CDMO & CRO Market and its transformative potential.

Market Overview

CDMOs and CROs have become indispensable partners in the electronics industry. By offering expertise in chemical formulation, scalability, and compliance with stringent regulatory standards, these organizations enable manufacturers to focus on core competencies while accelerating their product development timelines. Furthermore, the outsourcing of critical processes allows businesses to optimize costs and reduce operational risks.

One region leading this market revolution is Asia-Pacific, a powerhouse for technological innovation and manufacturing excellence. The region’s growth trajectory is fueled by foreign investments and a robust ecosystem of research and development (R&D).

Key Applications and End-Uses

Optoelectronics

Optoelectronic devices—including LEDs, lasers, and photodetectors—require precision-engineered chemicals to achieve optimal performance. With the increasing adoption of smart lighting and optical communication technologies, the need for innovative chemical solutions has grown exponentially.

Discrete Semiconductors

Widely used in power management systems across industries like automotive and industrial electronics, discrete semiconductors depend on advanced chemicals for processes such as etching, doping, and wafer cleaning. CDMOs and CROs bring the necessary technical expertise to develop these specialized materials.

Integrated Circuits (ICs)

As the electronics industry embraces miniaturization and enhanced functionality, ICs play a pivotal role in high-performance computing and IoT devices. CDMO & CRO collaborations ensure that photolithography and deposition processes meet the stringent demands of modern IC manufacturing.

Battery Manufacturing

The global shift towards renewable energy and electric vehicles has driven demand for high-purity electrolytes and advanced coating materials. CDMOs and CROs are investing heavily in R&D to support next-generation battery technologies, which are essential for sustainable energy storage.

Sensors

Sensors underpin advancements in IoT, automotive safety, and industrial automation. Their precision and reliability hinge on the availability of ultra-pure chemicals, a niche well-served by CDMO and CRO partnerships.

Asia-Pacific’s Growing Dominance

The Asia-Pacific region has emerged as a key player in the global electronic chemicals market, thanks to its unique blend of technological prowess and manufacturing expertise. Key drivers of growth in the region include:

Technological Advancements: Cutting-edge innovations in semiconductor and electronics manufacturing.

Foreign Investments: Global corporations are increasingly channeling resources into Asia-Pacific to capitalize on its skilled workforce and infrastructure.

Rising Consumer Demand: The proliferation of consumer electronics, electric vehicles, and renewable energy projects has created a thriving demand for electronic chemicals.

Countries like China, South Korea, and Japan are spearheading this growth, leveraging their strong R&D frameworks and established supply chains.

Emerging Trends in the Market

Sustainability at the Forefront

The electronics industry is gradually transitioning to greener and more sustainable chemical solutions, driven by environmental regulations and consumer preferences.

Integration of AI and Automation

Artificial intelligence is revolutionizing the chemical manufacturing process, enabling better quality control, predictive maintenance, and process optimization.

Collaborative Ecosystems

Strategic partnerships between manufacturers, CDMOs, and CROs are fostering innovation and expediting time-to-market for groundbreaking technologies.

To know more Download PDF Brochure :

The rapid expansion of the Electronic Chemicals CDMO & CRO Market offers significant opportunities for:

Optoelectronics Manufacturers seeking customized chemical solutions for cutting-edge technologies.

Semiconductor Producers aiming to optimize processes and reduce operational costs.

Battery Developers exploring innovative materials for energy storage systems.

Sensor Manufacturers focused on enhancing precision and reliability.

Investors poised to capitalize on the surging demand for high-purity electronic chemicals.

Conclusion

The Electronic Chemicals CDMO & CRO Market is at the forefront of transforming the global electronics landscape. By offering tailored solutions to address complex manufacturing challenges, CDMOs and CROs enable companies to innovate and stay competitive. With the Asia-Pacific region leading the charge, the market is set to grow exponentially, driven by advancements in semiconductors, optoelectronics, and energy storage technologies. For stakeholders across the electronics value chain, now is the time to embrace these partnerships and seize the opportunities this dynamic market has to offer.

As the industry continues to evolve, the collaboration between manufacturers and CDMO/CRO organizations will remain a cornerstone of progress, fueling innovation and sustainability for years to come.

#Electronic Chemicals Market#CDMO#CRO#Electronics Industry#Market Growth#Chemical Manufacturing#Semiconductor Chemicals#Electronics Innovation#Industry Trends

0 notes

Text

United States industrial PC market size reached USD 1.4 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 2.3 Billion by 2033, exhibiting a growth rate (CAGR) of 5.85% during 2025-2033. The increasing complexity of industrial processes, along with the growing need for real-time data processing and analysis, is driving the industrial PC market.

#United States Industrial PC Market Report by Type (Panel IPC#Rack Mount IPC#Box IPC#Embedded IPC#DIN Rail IPC#and Others)#Display Type (Resistive#Capacitive#Sales Channel (Direct Sales#Indirect Sales)#End Use Industry (Automotive#Healthcare#Chemical#Aerospace and Defense#Semiconductor and Electronics#Energy and Power#Oil and Gas#and Region 2025-2033

0 notes

Text

Rough concept for Curie the Nuclear Flask (genderblind since the unit refers to both Pierre AND Marie Curie), nonspecifically based on mostly British models since they’re the most photographed/documented.

Kind of my pipe dream Dustin/Hydra figure, though it would NEVER fly in Germany because that’s such an anti-nuclear country. Curie is shy and fat, like Dustin (in reference to the nuclear industry using silence as their main PR tactic and nuclear flasks being physically heavy and sometimes downright enormous). They’re also suspicious but secretly benevolent and the real hero of net zero like Hydra. I made the character for my extended protag Electra AU/rewrite but you could kind of fit them in canon as a Rusty ally since nuclear plants technically ARE steam powered (just get rid of the damn anti-nuclear Light At the End of the Tunnel line if it isn’t gone already)

Curie is kind of a sardonic nerd, comparable to Tom Lehrer (though could also be played more as a mad scientist or quirky Miss Frizzle type). Despite showing constant experimental evidence that they’re damn near indestructible (nuclear flasks have been publicly crash tested to spectacular results, most notable in 1984 when a locomotive was rammed into one at 100 mph and got obliterated but the cargo was unscathed) everyone treats them like a terrifying hazard and they’re largely ostracized.

As a nod to Dustin almost singing it in the New Starlight revisions, Curie would probably sing There’s Me because “I may not be the one you want to see” and the message of always being there is just so fitting to nuclear power being a very reliable energy source vs other non-fossil ones. They’d play a basically identical role to Dustin in the final race where the protag finally is willing to trust and team up with them and their size is an advantage in a downhill race (they’d also be GREAT for defending against Greaseball and other physical hazards and him trying to hit them and Curie not selling it while he falls backwards howling would he hilarious)

#my art#i want to like hydra conceptually but i’m very eh because hydrogen isn’t really that green and often comes from natural gas production#i think joule as a hydrogen car would be kind of cool though because it’s used a lot in the semiconductor industry#and it’s flammable/explosive while making more sense than a dynamite truck lol#i don’t think semiconductor factories use trains much vs trucks but they ARE a VERY high tech thing that uses absurdly dangerous chemicals

1 note

·

View note

Text

Biped Robot, Global Top Eight Players Rank and Total Market Size Forecast 2023-2029

Biped Robot Market Summary

In humanoid robots, there are usually two types according to their shape: biped humanoid robots and wheeled humanoid robots. Different from the biped robot driving method, the wheeled robot is mainly driven by the steering wheel and wheels. It has a simple structure, convenient control, and can realize simple forward, turning and backward functions. A biped robot is a bionic type of robot whose structure is similar to that of a human biped. It can realize bipedal walking and related actions of the robot, mainly through the servo system (motor + drive + encoder) to drive the joints, and the servo system is also The core component of motion control. At present, biped robots on the market can be divided into small biped robots and large biped robots.

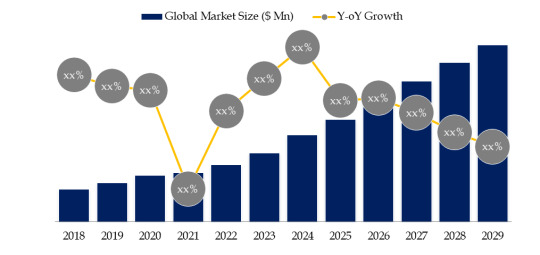

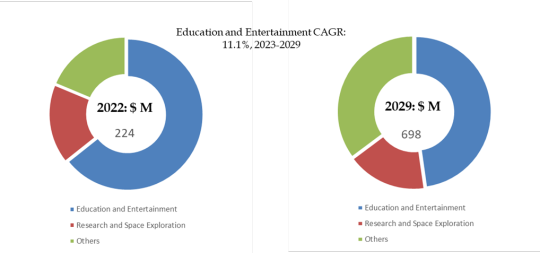

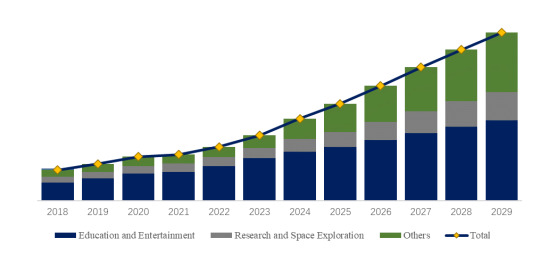

According to the new market research report "Global Biped Robot Market Report 2023-2029", published by QYResearch, the global Biped Robot market size is projected to reach USD 698 million by 2029, at a CAGR of 17% during the forecast period.

Figure. Global Biped Robot Market Size (US$ Million), 2018-2029

Based on or includes research from QYResearch: Global Biped Robot Market Report 2023-2029.

Market Drivers:

1. Core driver: policy support. The support of national policies is always the core driving factor for the development of the industry. The national policy support for biped robots can speed up the penetration of robots in applications, and will also attract funds to invest in the robotics industry, thereby improving the R&D and innovation system of enterprises.

2. The second driver: terminal application. Bipedal robots are used downstream in education, medical care, retail and other scenarios. The growth in application demand is conducive to the development of bipedal robots.

Restraint:

At present, the main obstacles to the development of bipedal robots are funds and technical talents. The robot industry belongs to the high-tech industry, and the biped robot integrates multiple technologies, which also means that its manufacturing cost is high, which limits the commercialization process of biped robots to a certain extent.

Opportunity:

Opportunities and favorable factors for the development of the bipedal robot industry are mainly reflected in three aspects: policy support, breakthrough of technical bottlenecks, and market size.

This year, many regions have introduced policies for bipedal humanoid robots, such as Beijing, Shenzhen, Shanghai and other places. The common point of the policies is to accelerate the deployment of humanoid robots, which is a great benefit to the development of bipedal robots.

In addition, the Chinese market is huge. In the industrial robot market, China’s consumption has ranked first for several consecutive years. Bipedal robots belong to a subdivision of industrial robots. The rapid development of industrial robots and the growing market size have also brought huge development opportunities to bipedal robots.

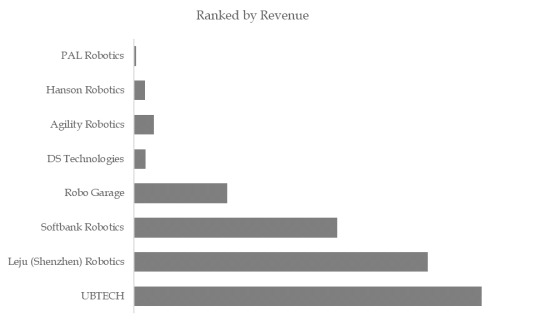

Figure. Biped Robot, Global Market Size, The Top Five Players Hold 50% of Overall Market

Based on or includes research from QYResearch: Global Biped Robot Market Report 2023-2029.

Globally, the major manufacturers of bipedal robots include UBTECH, Leju, SoftBank Robotics, Robo Garage, DS Technologies, Agility Robotics, Hanson Robotics and PAL Robotics, among which the top five manufacturers account for approximately 65% of the market share.

At present, the world's core commercial manufacturers are mainly distributed in China and the United States. Among them, Chinese companies Youbixuan and Leju mainly focus on small bipedal robots, while large-scale robot companies that have not commercialized include Xiaomi and Unitree Robotics; foreign companies include Boston Dynamics, Honda, Toyota, Tesla, Sanctuary AI, 1X Technologies and Figure AI, etc.

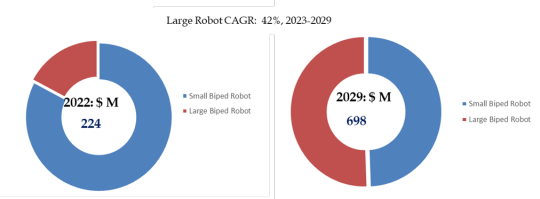

Figure. Biped Robot, Global Market Size, Split by Product Segment

Based on or includes research from QYResearch: Global Biped Robot Market Report 2023-2029.

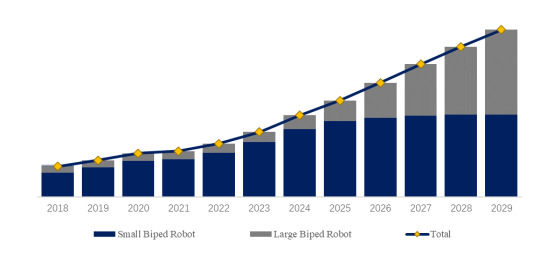

In terms of product types, small biped robots are currently the most important subdivided product, accounting for about 80% of the market in 2022. From the perspective of product type and technology, small bipedal robots occupy a large market share due to their low manufacturing cost and high degree of commercialization. Most of them are used in education and entertainment fields. Large-scale bipedal robots are costly and difficult to produce, and their selling prices are quite different from small ones. Currently, due to cost and technical issues, terminal applications are relatively limited. Although enterprises can produce them, their commercialization is not high. With the development of future technology, AI and deep learning technology will become more mature, and large-scale bipedal robots are expected to be controlled on the cost side, thereby achieving large-scale production and sales. It is estimated that by 2029, the market size of large biped robots is expected to dominate, and the CAGR 2023-2029 will reach 42%.

Figure. Biped Robot, Global Market Size, Split by Application Segment

Based on or includes research from QYResearch: Global Biped Robot Market Report 2023-2029.

In terms of product applications, education and entertainment are currently the main sources of demand, accounting for approximately 65% of the market share in 2022. Humanoid robots (wheeled and bipedal) are robots designed and manufactured to imitate human form and behavior. They have a human-like appearance, can adapt to human living and working environments, replace or assist humans in completing various tasks, and can It expands human capabilities in many aspects and has broad application prospects in services, medical care, education, entertainment and other fields. Among them, wheeled humanoid robots are more widely used than bipedal robots because of their simple structure and convenient control.

Bipedal robots are currently mainly used in education, entertainment, research and space exploration, and a small number of them are used in the medical and logistics fields.

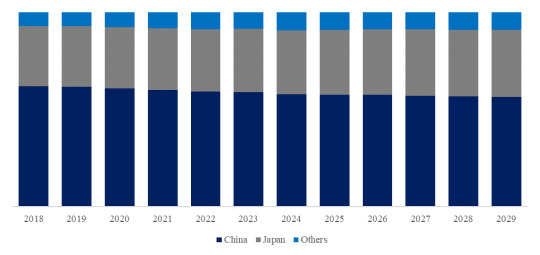

Figure. Biped Robot, Global Market Size, Split by Region (Production)

Based on or includes research from QYResearch: Global Biped Robot Market Report 2023-2029.

As far as the production side is concerned, currently commercialized bipedal robots are mainly produced in China and Japan, and other regions are mainly the United States and Europe. Among them, China's output accounts for a large share, reaching 59% in 2022; followed by Japan, accounting for 32%. In the past two years, Chinese, American, Canadian and European companies have continuously poured into the bipedal robot market and launched new products. For example, China: Xiaomi’s CyberOne, Unitree’s Unitree H1, the United States: Tesla’s Optimus, Figure AI’s Figure 01, Canada: Sanctuary AI’s Phoenix, etc. In the future, the share of North American and European countries is expected to exceed 10%.

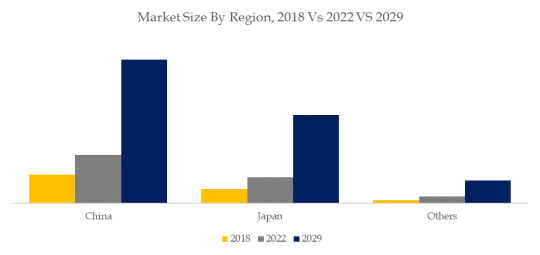

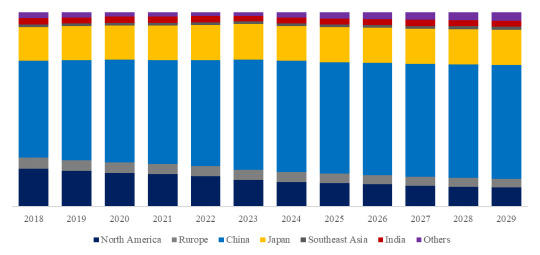

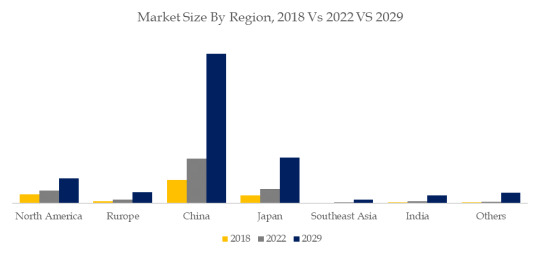

Figure. Biped Robot, Global Market Size, Split by Region

Based on or includes research from QYResearch: Global Biped Robot Market Report 2023-2029.

As far as the consumption area is concerned, it is currently mainly North America, Europe, China, Japan, India and Southeast Asia. Among them, China, Japan and North America have a market share of more than 85%. With the development of China's robot industry, the volume of the robot market will continue to expand, which is expected to improve the biped robot industry technology and reduce costs. It is estimated that by 2029, China's biped robot market share will reach 60%.

About The Authors

Junping Yang - Lead Author

Email: [email protected]

Junping Yang is a technology & market senior analyst specializing in semiconductor devices, materials, and equipment. Yang has 9 years’ experience in semiconductor and focuses on ICs, semiconductor materials, package & testing, power semiconductor (IGBT, SiC, diode, MOSFET, modules and discrete), compound semiconductor (SiC, GaN, etc.), power, RF, optoelectronics, ceramic substrates (HTCC, LTCC, DBC, AMB, DPC, DBA), CMP, equipment & parts (wafer transfer robot, EFEM/Sorter, heaters, etc.). He is engaged in the development of technology and market reports and is also involved in custom projects.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

New PFAS removal process aims to stamp out pollution ahead of semiconductor industry growth

A University of Illinois Urbana-Champaign study is the first to describe an electrochemical strategy to capture, concentrate and destroy mixtures of diverse chemicals known as PFAS—including the increasingly prevalent ultra-short-chain PFAS—from water in a single process. This new development is poised to address the growing industrial problem of contamination with per- and polyfluoroalkyl substances, particularly in semiconductor manufacturing. The study findings are published in Nature Communications. A previous U. of I. study showed that short- and long-chain PFAS can be removed from water using electrochemically driven adsorption, referred to as electrosorption, but this method is ineffective for ultra-short-chain molecules because of their small size and different chemical properties.

Read more.

#Materials Science#Science#Semiconductors#PFAS#Pollutants#Manufacturing#University of Illinois#Electrochemistry#Reactions

19 notes

·

View notes

Text

“As US semiconductor production ramps up, the hastened reviews could sharply increase pollution containing little-studied PFAS that are likely toxic, accumulative in the environment and contribute to climate change.”

6 notes

·

View notes

Text

3 notes

·

View notes

Text

Investigations by European NGOs and newspapers point to a concerted industry campaign to limit incoming EU restrictions on PFAS, toxic substances dubbed ‘forever chemicals’ because they can persist for centuries in the environment. The European Commission denies it is being unduly influenced. Environmental groups have launched a broadside at the chemicals industry, accusing lobbyists of a massive campaign to block planned restrictions on per- and polyfluoroalkyl substances (PFAS) after a pan-European investigation by collaborative investigation. PFAS, first produced in the 1940s, are used in a wide variety of products and industrial processes, from non-stick pans to semiconductor manufacturing, due to their stability, low friction and ability to repel water and fats. They have been linked to liver disease, hormonal disruption and cancer, among other diseases. Now – two years and a day since Denmark, Germany, the Netherlands, Norway and Sweden submitted a proposal for a blanket restriction of the substances with the European Chemicals Agency (ECHA) – the Forever Pollution Project led by newspapers such as France’s Le Monde and the Süddeutsche Zeitung in Germany has published the finding of an investigation exposing intense lobbying of EU officials and a vigorous PR campaign. The five countries called for a blanket ban because the prevailing EU system of tackling chemical substances one by one meant that any of the handful of PFAS already banned could simply be replaced by another from the family of thousands of compounds.

continue reading

2 notes

·

View notes

Text

🌟 Protect Your Hands, Ensure Your Work Safety 🌟

In high-risk fields such as the semiconductor industry, the chemical industry, and laboratories, using effective chemical-resistant gloves is crucial for operational safety. The HANAKI Strong Acid and Alkali-Resistant Gloves are specifically designed to handle strong acids and alkalis like hydrofluoric acid, nitric acid, and aqua regia, offering exceptional chemical protection.

🔹 Application Scenarios:

Semiconductor manufacturing Chemical production Laboratory research 🔹 Product Features:

Excellent Protection: Resistant to high concentrations of strong acids and alkalis such as hydrofluoric acid, nitric acid, and aqua regia High-Quality Materials: Chlorosulfonated polyethylene (CSM) outer layer, nitrile rubber (NBR) inner layer Multiple Specifications: Available in different lengths and thicknesses to meet various needs Comfortable Fit: Designed specifically for women, providing a comfortable wear and flexible operation 🛡️ Protect you from chemical hazards and ensure your safety! If you engage in high-risk chemical operations, choose HANAKI Strong Acid and Alkali-Resistant Gloves to provide comprehensive protection for your hands!

🔗 Click to learn more: [https://yousuto.com/product/hanaki-strong-acid-and-alkali-resistant-gloves-towa-a-20l-a-22-b-22l/]

#ChemicalResistantGloves#ChemicalProtection#HANAKI#Semiconductor#LabSafety#StrongAcidAndAlkaliProtection#ChemicalIndustry#SafetyFirst

2 notes

·

View notes

Text

Electropolishing for Deburring Critical Metal Parts

Stamping and machining processes can leave metal parts with burrs that can affect the fit, function and durability of metal parts.

When these parts are destined for food or pharmaceutical production equipment or fuel lines and gear assemblies used in aerospace manufacturing, burrs are more than just a surface imperfection – they’re a potentially catastrophic defect that can prevent the proper sealing or connection between two parts, become dislodged near moving parts, or cause seizing of screws and other fasteners.

To prevent such risks, manufacturers in many industries often specify electropolishing as the final step in finishing their critical metal parts.

How Does Electropolishing Work?

Electropolishing is a highly effective finishing process for removing metal surface defects like microburrs caused by processes like broaching, fine blanking, grinding, lapping or milling.

Using a combination of a chemical bath and a rectified electrical current, electropolishing removes a precise and uniform layer of surface material, leaving behind a shiny, smooth, passive and defect-free surface.

Among other advantages, electropolishing can remove a microscopically precise amount of surface material with surface roughness improvement of up to 50%, eliminating surface defects for high-quality results within very tight tolerances.

By eliminating microcracks and other defects that can harbor bacteria or become initiation sites for corrosion, electropolishing also leaves metal parts with significantly improved resistance to corrosion and pathogen growth. The ultrasmooth surface finish that electropolishing leaves behind has been shown to inhibit the formation of bacterial biofilms that can be resistant to ordinary cleaning methods. The finish also leaves behind a surface that is easier to clean, without cracks or defects where pathogens can hide – a critical advantage for medical, pharmaceutical and food and beverage production.

Why Use Electropolishing for Deburring?

Fragile or intricate metal parts, like those used for medical devices and implants, are not well suited for finishing processes like mechanical or vibratory polishing, which can damage fragile parts or create inconsistent results for parts with complex shapes.

Successful deburring for critical metal parts is contingent upon the ability to remove a precise layer of surface material. No other process can match electropolishing for its ability to control the material removal to +/- .0002”.

By deburring the threads on metal fasteners, for example, electropolishing can reduce the risk of adhesion between two mating surfaces, also known as “galling,” which can cause material between the surfaces to deteriorate and seize up when parts are pressed together.

Burrs can also shorten the lifespan of a part, by breaking off or becoming an initiation site for corrosion.

Larger burrs that occur as the result of rough milling or displaced metal from drilling operations, however, may need pre-treatment using other methods. Likewise, heavy die break burrs caused by improper tooling maintenance will generally require additional treatment.

Much in the way that lightning is drawn to the highest points, electropolishing delivers higher current density on the high points or edges which makes it ideal for micro-deburring The customized nature of the electropolishing process, from racking to chemical formulation to timing, would be of little value if it could not be reproduced consistently. But unlike other finishing processes, electropolishing is prized for its consistent results.

Electropolishing also offers a key advantage for parts with critical microfinishes or made from the lighter, more fragile materials increasingly used in the manufacturing of medical devices, electrical components and semiconductors, among other industries. These parts are not suitable for mass finishing techniques that can create distortion, nicks and scratches. Electropolished parts are individually racked to prevent contact and ensure the even application of the process for even the most fragile parts.

Advantages of Electropolishing for Deburring

The electropolishing process can be customized by alloy, by application and by the desired results. Beyond its ability to remove a uniform layer of surface material to eliminate surface defects like microburrs, microcracks, scale and staining, electropolishing offers many collateral benefits for the manufacturers of critical metal parts.

Microscopically precise removal of surface material with control to +/-.0002”

Customized racking to accommodate fragile and complex parts small and large

Leaves parts with enhanced durability and cycle life

Creation of a pathogen-resistant surface

Superior cleanability

Ultraclean finish

Decorative finish

One stop process for cleaning and removing surface defects

30X more corrosion resistance than passivation alone

Parts are also left passivated in the process

Improves conductivity of copper and aluminum alloys

What Alloys Can Be Electropolished?

A long list of alloys can be effectively deburred using electropolishing. The process is also equally effective on parts that are fully annealed or hardened. That is one reason that electropolishing is frequently specified for the final deburring and finishing of parts after all fabrication and heat treating processes have been completed.

Electropolishing is effective for a wide variety of alloys including:

Stainless Steel 200-300 Series

Stainless Steel 400 Series

Stainless Steel: Precipitating Hardening Grades

Nitinol

Titanium

Aluminum

Carbon Steels

Copper

Brass

Nickel Alloys

Specialty Alloys

And more

Electropolishing for Critical Metal Parts

As the world’s largest electropolishing specialist with seven decades of electropolishing expertise and innovation, Able Electropolishing provides consultation and collaboration from the earliest stages of prototyping through production to create highly customized electropolishing processes for a wide variety of metal parts.

6 notes

·

View notes

Text

Elevating Industry Standards: PVDF Materials by Petron Thermo Plast

In the dynamic landscape of industrial materials, Polyvinylidene Fluoride (PVDF) emerges as a standout choice, renowned for its exceptional properties and diverse applications. Petron Thermo Plast, a leading manufacturer in the field, specializes in delivering top-tier PVDF Materials crafted to surpass industry expectations. This blog meticulously explores the features, benefits, and applications of PVDF materials by Petron Thermo Plast, showcasing why they are the preferred solution for professionals worldwide.

Unveiling PVDF Materials

PVDF materials represent a pinnacle of innovation, characterized by their remarkable chemical resistance, thermal stability, and mechanical strength. Petron Thermo Plast’s PVDF materials are engineered with precision to offer unparalleled performance across a multitude of industrial settings.

Key Attributes of PVDF Materials

1. Chemical Resistance:

PVDF materials exhibit exceptional resistance to a wide spectrum of chemicals, including acids, bases, and solvents, making them ideal for corrosive environments.

2. Thermal Stability:

With a high melting point and remarkable heat resistance, PVDF materials maintain their integrity even under extreme temperatures, ensuring reliability in demanding conditions.

3. Mechanical Strength:

PVDF materials boast high tensile strength and durability, enabling them to withstand mechanical stress and pressure, thus guaranteeing longevity in challenging applications.

4. Low Permeability:

The low permeability of PVDF materials to gases and liquids prevents leakage, making them suitable for applications requiring excellent barrier properties.

5. Weatherability:

PVDF materials exhibit exceptional weather resistance, making them suitable for outdoor applications where exposure to UV radiation and harsh weather conditions is common.

6. Non-Toxicity:

PVDF materials are non-toxic and safe for use in applications involving potable water and food processing, adhering to stringent health and safety standards.

Applications of PVDF Materials

PVDF materials by Petron Thermo Plast find extensive applications across diverse industries:

Chemical Processing: Used for fabricating pipes, fittings, and linings in chemical plants due to their resistance to corrosive chemicals.

Construction: Employed in architectural cladding, roofing, and facades for their durability and weather resistance.

Electronics: Utilized in printed circuit boards and semiconductor manufacturing for their electrical insulation properties.

Transportation: Applied in aerospace and automotive industries for interior and exterior components due to their lightweight and high strength-to-weight ratio.

Medical: Used in medical equipment and devices requiring sterilizability and chemical resistance.

Advantages of Choosing Petron Thermo Plast

Advanced Manufacturing Techniques:

Petron Thermo Plast employs cutting-edge manufacturing processes and rigorous quality control measures to ensure PVDF materials meet the highest standards.

Customization Options:

The company offers PVDF materials in various formulations, sizes, and colors to meet specific customer requirements.

Expert Technical Support:

Comprehensive technical support and guidance are provided to assist customers in selecting the right PVDF materials and ensuring proper integration into their projects.

Sustainability Commitment:

Petron Thermo Plast is committed to sustainable manufacturing practices, ensuring their PVDF materials are environmentally friendly and compliant with global standards.

Why Choose PVDF Materials from Petron Thermo Plast?

Investing in PVDF materials from Petron Thermo Plast guarantees superior quality, reliability, and performance. Here are some compelling reasons to choose Petron Thermo Plast:

Unmatched Quality: PVDF materials from Petron Thermo Plast adhere to the highest quality standards, ensuring consistency and reliability.

Tailored Solutions: With a wide range of formulations and customization options available, you can find the perfect PVDF material for your specific application.

Technical Expertise: Petron Thermo Plast provides expert technical support to guide you through every stage, from material selection to project completion.

Sustainability: By choosing PVDF materials from Petron Thermo Plast, you are supporting environmentally friendly manufacturing practices and contributing to a greener future.

Conclusion

PVDF materials by Petron Thermo Plast redefine excellence in the industrial sector. Their unparalleled properties, reliability, and versatility make them indispensable across various industries. Choose Petron Thermo Plast for PVDF materials that exceed your expectations and elevate your projects to new heights of success.

#pvdf material#engineering plastics#pvc ball valve#pvc butterfly valve#pvdf pipe#explore#union ball valve#hdpe pipe fittings

2 notes

·

View notes

Text

Millennium Semiconductors - Leading Innovation and Powering the Future

Millennium Semiconductors India Pvt. Ltd.: Pioneering Excellence in Electronic Components Distribution.

With an illustrious journey spanning 28 years, Millennium Semiconductors India Pvt. Ltd. stands as a beacon in the domain of electronic component distribution. Our portfolio encompasses a diverse range of active, passive, wireless communication, power, and electromechanical products and Specialty Chemicals and Materials.

What sets us apart is our unwavering commitment to operational excellence paired with innovative business solutions, ensuring we not only meet but exceed our customers' expectations.

Credibility & Recognitions: As an ISO 9001:2015 certified company, our credentials are further accentuated by recognitions from esteemed institutions such as Dun & Bradstreet, CRISIL, and the distinction of being a Great Place to Work.

Our Distinctive Edge:

• R&D Centre: Spearheading innovations and advancements.

• Design Excellence: From the nascent concept to prototype or production, tailored to specific needs.

• Optimization: Upgrading designs for enhanced features and cost-effectiveness.

• Re-engineering: Revamping projects for cost reductions and functional enhancements.

• Component Expertise: Recommending proven components for precise applications and providing embedded design support.

• Training Initiatives: Collaborative technical sessions with suppliers to enhance product understanding.

• IoT Enablement: Driving the future with IoT solutions for industrial and smart devices.

• Robust Supply Chain: Ensuring consistent and timely deliveries.

• Flexible Billing: Offering multi-currency billing options.

• Systematic Approach: Leveraging tools like Salesforce, SAP S4 Hana, WMS, and our dedicated Customer Portal.

At Millennium Semiconductors, our essence is to provide a holistic solution, affirming our position as the premier choice in our domain.

Millennium Semiconductors, we're not just a provider; we're your partner in progress.

For More Details Visit - https://www.millenniumsemi.com/

2 notes

·

View notes

Text

Silicone Rubber Heaters, designed to endure temperatures up to 450 ⁰F, boast premium quality features like exceptional dielectric strength and resilience to moisture, chemicals, and acids in industrial settings. These heaters, constructed with a heating element vulcanized between two layers of silicone rubber, ensure top-notch insulation with fiberglass reinforcement, providing a flame-retardant, moisture-proof, and flexible structure. Their adaptability spans across industries, excelling in freeze protection, condensation prevention, medical equipment, aerospace, semiconductor and processing equipment, automotive, heated press machinery, and various other applications due to their remarkable ability to maintain temperatures and adapt to diverse conditions, marking them as a pivotal innovation in the field of heating solutions. For More Information Go To Our Site https://heatersandsensors.ca

#SiliconeRubberHeaters#HeatingInnovations#IndustrialHeating#FlexibleHeatingSolutions#TemperatureControl#InnovativeTechnology#IndustrialApplications#VersatileHeaters#AdvancedHeating#HighQualityMaterials

2 notes

·

View notes

Text

Unlocking the Power of Silicon Manganese: Sarda Metals

Silicon manganese is a critical alloy used in various industries, each benefiting from its unique properties and versatility. Sarda Metals, a renowned producer and leading metals manufacturer in India, has been at the forefront of supplying high-quality silicon manganese for countless applications. In this article, we explore the diverse areas where silicon manganese makes a significant impact.

Electronics: Powering the Digital World

Silicon manganese is a key ingredient in the world of electronics. Its exceptional conductivity and durability make it an ideal component for semiconductors, transistors, and integrated circuits. These tiny yet powerful devices are the backbone of our digital world, driving everything from smartphones to computers.

Solar Panels: Harnessing Clean Energy

The renewable energy sector relies on silicon manganese for the production of solar panels. These panels use silicon as a semiconductor to convert sunlight into electricity efficiently. As the world shifts toward sustainable energy sources, silicon manganese plays a pivotal role in supporting this transition.

Construction: Building for the Future

In the construction industry, silicon manganese is used in high-strength materials such as silicones and sealants. These materials provide durability and weather resistance, making them invaluable for sealing structures against the elements.

Medical Devices: Precision and Biocompatibility

Silicon manganese-derived silicones find applications in the medical field. They are used in the production of biocompatible medical implants, such as breast implants and catheters, due to their non-reactive nature and flexibility.

Automotive Industry: Driving Innovation

The automotive sector benefits from silicon manganese in various components, including sensors, engine control units (ECUs), and tire pressure monitoring systems (TPMS). These components enhance vehicle performance, safety, and efficiency.

Aerospace: Soaring to New Heights

Silicon manganese-based materials are essential in aerospace applications, thanks to their lightweight and high-temperature resistance. They contribute to the construction of aircraft components and spacecraft, ensuring safe and efficient travel beyond our atmosphere.

Kitchenware: Enhancing Culinary Experiences

In the kitchen, silicon manganese-derived silicones are used to create non-stick cookware, baking molds, and kitchen utensils. Their heat resistance and non-reactive properties make cooking a breeze.

Glass Industry: A Clear Choice

Silicon dioxide (silica), derived from silicon, is a fundamental component in the glass manufacturing process. It enhances the transparency, strength, and heat resistance of glass products.

Chemical Industry: Catalyzing Innovation

Silicon compounds play a pivotal role in various chemical processes, acting as catalysts that drive the production of a wide array of products, ranging from plastics to pharmaceuticals.

But let's delve deeper into the world of silicon manganese, expertly manufactured by the industry leader, Sarda Metals, a renowned metals manufacturer in India. It's more than just an alloy; it stands as a catalyst for progress and innovation across a multitude of sectors. As we forge ahead in the realms of technology and environmental sustainability, silicon manganese emerges as a critical player in shaping our future.

Silicon manganese isn't merely an alloy—it's the very foundation upon which countless innovations are built. Join us in recognizing its profound significance as we strive to construct a brighter and more sustainable future together.

🏠 Address: 50-96-4/1, 2nd & 3rd Floor, Sri Gowri Nilayam, Seethammadhara NE, Visakhapatnam, Andhra Pradesh, 530013 - India.

📞 Phone: 9493549632

📧 Email: [email protected]

#SiliconManganese#SardaMetals#Metallurgy#Alloys#SteelProduction#IndustrialMaterials#Mining#MetalIndustry#RawMaterials#Manufacturing#Steel#Metals#Production#ManganeseAlloy#QualityMaterials#SustainableIndustry

3 notes

·

View notes

Text

hey if youre on turtle island or still tuesday and feel like trying a quick silly browser game you should check out tradle. (i think it updates at midnight based on time zones?) todays is real fun i prommy.

you get five guesses to figure out a country from its export data, and after each guess they tell you how far away you are and what direction the county youre looking for is. i know it sounds like a ridiculous challenge but this one has a bunch of easy hints and giveaways that are accessible to your average westerner

if its wednesday by now or you want to see the data presented differently check out this silly economy under the cut (bolded 'spoilers' ig)

total export value: 371b (usd)

gold: 86.7b (23%}

packaged meds: 48.5b (13%)

vaccines, blood, cultures, etc: 40.3b (11%)

base metal watches: 15.2b (4%)

nitrogen heterocyclic compounds: 14.2b (4%)

jewlery: 9.35b (2.5%)

precious metal watches: 8.97b (2.5%)

orthopedic appliances: 7.02b (2%)

hormones: 3.38b

coffee: 3.36b

electricity: 3.19b

medical instruments: 3.09b

machinery w indv functions: 3.04b

platinum: 2.54b

chemical analysis instruments: 2.27b

nucleic acids: 2.17b

valves: 2.17b

silver: 2.01b

electric motors: 1.78b

scented mixtures: 1.72b

sulfonamides: 1.71b

diamonds: 1.64b

planes, helicopters, and spacecraft: 1.63b

beauty products: 1.58b

other heating machinery: 1.43b

flavored water: 1.43b

gas turbines: 1.38b

low voltage protection eq: 1.34b

gas and liquid flow measuring inst: 1.3b

carboxyamide compounds: 1.26b

other measuring instruments: 1.24b

air pumps: 1.16b

motor vehicles, parts, and acc: 1.14b

petroleum gas: 1.12b

electrical transformers: 1.11b

aluminum plating: 1.07b

other plastic products: 1.01b

metal working machine parts: 988m

vitamins: 965m

polyamides: 963m

washing and bottling machines: 925m

chocolate: 887m

oxygen amino compounds: 885m

integrated circuits: 884m

iron fasteners: 881m

paintings: 873m

transmissions: 855m

special pharmaceuticals: 837m

insulated wire: 828m

electrical power accessories: 826m

plastic lids: 818m

cheese: 800m

antibiotics: 797m

liquid pumps: 797m

cars: 789m

ink: 752m

non mechanical removal machinery: 737m

trunks and cases: 734m

centrifuges: 730m

interchangeable tool parts: 728m

high voltage protection eq: 705m

hand saws: 693m

other edible preparations: 680m

electric heaters: 679m

electrical control boards: 672m

polyacetals: 664m

plastic pipes: 636m

electric soldering equipment: 616m

precious metal compounds: 608m

industrial fatty acids, oils, and alcohols: 608m

hot rolled iron bars: 590m

self propelled rail transport: 582m

refined petroleum: 577m

hydrazine or hydroxylamine derivatives: 565m

precious stones: 563m

rubber working machinery: 561m

unpackaged meds: 557m

other iron products: 553m

precious metal scraps 550m

computers: 545m

surveying equipment: 523m

other plastic sheetings: 519m

metal finishing machines: 516m

scrap copper: 514m

semiconductor devices: 511m

raw plastic sheeting: 494m

documents or title and stamps: 490m

rolled tobacco: 487m

malt extract: 469m

other electrical machinery: 467m

other paper machinery: 450m

oxygen heterocyclic compounds: 441m

non knit mens suits: 441m

synthetic coloring matter: 436m

locomotive parts: 432m

non knit womens suits: 428m

iron structures: 424m

leather footwear: 421m

industrial printers: 415m

lifting machinery: 415m

scrap iron: 412m

therapeutic appliances: 410m

office machine parts: 410m

other clocks and watches: 405m

metal molds: 403m

other furniture: 403m

glaziers putty: 377m

liquid dispersing machines: 376m

knitting machine accessories: 370m

other small iron pipes: 369m

broadcasting equipment: 367m

aircraft parts: 363m

industrial food prep machinery: 362m

glues: 357m

pesticides: 349m

oscilloscopes: 344m

raw aluminum: 344m

knit sweaters: 339m

optical fibers and bundles: 334m

excavation machinery: 332m

non iron/steel slag ash and residue: 319m

carboxylic acids: 315m

xray equipment: 315m

electric motor parts: 315m

watch straps: 313m

tanks and armoured vehicles: 310m

forging machines: 309m

cleaning products: 306m

metalworking transfer machines: 298m

animal food: 294m

combustion engines: 282m

engine parts: 271m

electric generating sets: 254m

scrap aluminum: 249m

laboratory reagents: 249m

perfumes: 244m

other rubber products: 241m

photo lab equipment: 240m

wheat: 236m

lubricating products: 234m

printed circuit boards: 233m

aluminum bars: 230m

explosive ammunition: 230m

brooms: 224m

lcds: 223m

refrigerators: 223m

motorcycles and cycles: 221m

large construction vehicles: 221m

coal briquettes: 221m

corn: 220m

aluminum cans: 219m

textile footwear: 217m

thermostats: 207m

coffee and tea extracts: 206m

other aluminum products: 204m

ball bearings: 203m

knives: 199m

machines for additive mnf: 195m

raw iron bars: 187m

delivery trucks: 185m

milling stones: 176m

aluminum foil: 170m

collectors items: 169m

soybean oil: 169m

wood fiberboard: 166m

other stainless steel bars: 164m

sculptures: 160m

cutting blades: 159m

baked goods: 150m

navigation equipment: 146m

hydrometers: 137m

watch cases and parts: 134m

laboratory ceramic wear: 134m

wood carpentry: 124m

mirrors and lenses: 117m

#the plastic lids is the most astonishing thing out of all this i think. 800m usd in exports.... to go on what??#i wanted to visualize the data by smaller category#ig sharing my autism again stayed up til 3 last night transfering this lol

2 notes

·

View notes