#Sand & Gravel Spreader

Explore tagged Tumblr posts

Text

Épandeur de sable et de gravier, Prévisions de la Taille du Marché Mondial, Classement et Part de Marché des 16 Premières Entreprises

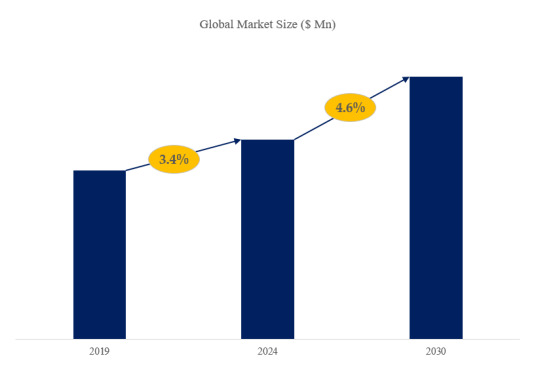

Selon le nouveau rapport d'étude de marché “Rapport sur le marché mondial de Épandeur de sable et de gravier 2024-2030”, publié par QYResearch, la taille du marché mondial de Épandeur de sable et de gravier devrait atteindre 275 millions de dollars d'ici 2030, à un TCAC de 4.6% au cours de la période de prévision.

Figure 1. Taille du marché mondial de Épandeur de sable et de gravier (en millions de dollars américains), 2019-2030

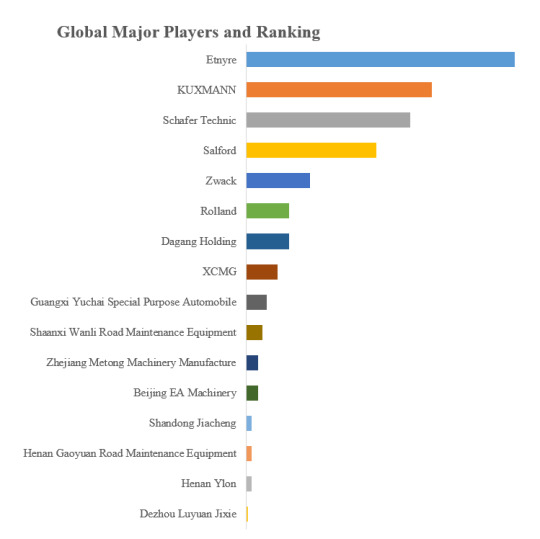

Selon QYResearch, les principaux fabricants mondiaux de Épandeur de sable et de gravier comprennent Etnyre, KUXMANN, Schafer Technic, Salford, Zwack, Rolland, Dagang Holding, XCMG, Guangxi Yuchai Special Purpose Automobile, Shaanxi Wanli Road Maintenance Equipment, etc. En 2023, les dix premiers acteurs mondiaux détenaient une part d'environ 77.0% en termes de chiffre d'affaires.

Figure 2. Classement et part de marché des 16 premiers acteurs mondiaux de Épandeur de sable et de gravier (Le classement est basé sur le chiffre d'affaires de 2023, continuellement mis à jour)

The Sand & Gravel Spreader market is influenced by several key drivers that contribute to its growth and demand. Here are some of the primary drivers for this market:

1. Construction Industry Growth: The construction sector's expansion, including infrastructure development, road construction, residential and commercial building projects, drives the demand for sand and gravel spreaders used for distributing these materials efficiently.

2. Road Maintenance and Repair: Sand and gravel spreaders are essential for road maintenance activities, including filling potholes, leveling surfaces, and improving traction, which are crucial for ensuring road safety and extending the lifespan of roads and highways.

3. Infrastructure Development: Large-scale infrastructure projects, such as airport runways, railways, and municipal projects, require the precise spreading of sand and gravel for various applications, boosting the demand for spreader equipment.

4. Efficiency and Productivity: Sand and gravel spreaders help streamline construction operations by evenly distributing materials, reducing labor costs, and improving efficiency, which is a significant driver for their adoption in the construction industry.

5. Technological Advancements: Innovations in spreader design, such as enhanced control systems, automation, and GPS-guided spreading capabilities, increase the accuracy and efficiency of material distribution, making spreaders more attractive for construction companies.

6. Environmental Regulations: Compliance with environmental regulations, such as dust control measures and erosion prevention, necessitates the use of sand and gravel spreaders to manage material application in a controlled and eco-friendly manner.

7. Maintenance of Landscapes and Green Spaces: Landscaping projects, including parks, gardens, and golf courses, require precise spreading of materials like sand and gravel for ground leveling, drainage improvement, and aesthetic enhancements, driving the demand for spreader equipment.

8. Winter Road Maintenance: Sand and gravel spreaders are essential for winter road maintenance activities, such as de-icing and providing traction on icy roads, making them vital equipment for municipalities and transportation departments in cold climates.

9. Mining and Extraction Operations: Sand and gravel spreaders are used in mining and quarrying operations for efficient material handling, transportation, and stockpile management, contributing to the demand for specialized spreading equipment.

These drivers collectively propel the Sand & Gravel Spreader market by catering to the diverse needs of the construction, infrastructure, landscaping, and transportation industries for effective material spreading solutions.

À propos de QYResearch

QYResearch a été fondée en 2007 en Californie aux États-Unis. C'est une société de conseil et d'étude de marché de premier plan à l'échelle mondiale. Avec plus de 17 ans d'expérience et une équipe de recherche professionnelle dans différentes villes du monde, QYResearch se concentre sur le conseil en gestion, les services de base de données et de séminaires, le conseil en IPO, la recherche de la chaîne industrielle et la recherche personnalisée. Nous société a pour objectif d’aider nos clients à réussir en leur fournissant un modèle de revenus non linéaire. Nous sommes mondialement reconnus pour notre vaste portefeuille de services, notre bonne citoyenneté d'entreprise et notre fort engagement envers la durabilité. Jusqu'à présent, nous avons coopéré avec plus de 60 000 clients sur les cinq continents. Coopérons et bâtissons ensemble un avenir prometteur et meilleur.

QYResearch est une société de conseil de grande envergure de renommée mondiale. Elle couvre divers segments de marché de la chaîne industrielle de haute technologie, notamment la chaîne industrielle des semi-conducteurs (équipements et pièces de semi-conducteurs, matériaux semi-conducteurs, circuits intégrés, fonderie, emballage et test, dispositifs discrets, capteurs, dispositifs optoélectroniques), la chaîne industrielle photovoltaïque (équipements, cellules, modules, supports de matériaux auxiliaires, onduleurs, terminaux de centrales électriques), la chaîne industrielle des véhicules électriques à énergie nouvelle (batteries et matériaux, pièces automobiles, batteries, moteurs, commande électronique, semi-conducteurs automobiles, etc.), la chaîne industrielle des communications (équipements de système de communication, équipements terminaux, composants électroniques, frontaux RF, modules optiques, 4G/5G/6G, large bande, IoT, économie numérique, IA), la chaîne industrielle des matériaux avancés (matériaux métalliques, polymères, céramiques, nano matériaux, etc.), la chaîne industrielle de fabrication de machines (machines-outils CNC, machines de construction, machines électriques, automatisation 3C, robots industriels, lasers, contrôle industriel, drones), l'alimentation, les boissons et les produits pharmaceutiques, l'équipement médical, l'agriculture, etc.

0 notes

Text

Everything Customers Need to Know About Laying Artificial Grass in the Garden or Lawns

Complete Guide on Laying Artificial Grass

It gets easier if buyers know how to lay artificial grass; the first phase is careful preparation and planning. Assessing the space where consumers plan to install the grass should be the initial phase. Take exact measurements of the lawn area to figure out the required size of the artificial grass roll. By doing this, waste is avoided and the proper quantity is purchased. Checking the region for obstructions like trees or rough surfaces is also crucial because these can need extra attention during installation. Obstacles frequently require further alterations to guarantee that the grass flows smoothly around them. It's time to collect the necessary tools after the purchasers have evaluated the area. Being ready with the appropriate tools is essential to knowing how to lay artificial grass. Basic equipment will be required by buyers, including a rake to level the ground, a bladed instrument to trim the grass, a tape measure to measure the space precisely, and a hammer to drive turf pegs into the ground

The supplies needed include turf pegs to hold the grass in place, sand infill to keep the fibres upright and weigh down the grass, adhesive to join seams, a weed membrane to inhibit weeds from growing through, and artificial grass itself. Clearing the area comes next after everything has been gathered. To accomplish this, clear away any waste or turf that may be there. When customers understand how to lay artificial grass, this is a necessary step because a perfect installation depends on a clean, smooth surface. It might be necessary for buyers to dig out the old grass with a shovel, aiming for a depth of two to three inches. This guarantees that the artificial grass and sub-base are appropriately positioned on the ground. Water damage to the grass might occur if drainage is inadequate. Installing a layer of crushed gravel will stop this and encourage appropriate water movement. To construct a sturdy, robust basis, equally distribute the gravel over the space. By taking this step, you can make sure that water stays away from the artificial grass and maintains its aesthetic appeal.

The Complete Process from Sand Infill to Final Inspection and Care

The next crucial step is to add sand infill once the artificial grass has been laid and firmly secured. The two primary functions of the sand are to assist the fibres stand erect for a genuine, natural appearance and to give weight to hold the grass in place. First, consistently distribute a layer of silica sand over the grass's whole surface. Customers can sprinkle the sand with their hands or a spreader for a more even distribution. Applying an even amount will prevent any areas from having too much or too little sand, which could compromise the lawn's longevity and ultimate look. The grass needs to be brushed one more after the sand has been placed. To make sure the sand settles into the base properly, use a broom with stiff bristles to remove the grass fibres.

Additionally, brushing gives the grass a richer, more realistic appearance by making the strands stand taller. This procedure is essential for the artificial grass's durability and natural look because it keeps the fibers erect and stops them from flattening out over time.After the grass has grown tall and the sand has settled, pause for one last look. Inspect that the grass is firmly fixed and that there are no obvious creases, spaces, or spots where it has moved. Make sure the edges are securely fastened in place and smooth out any flaws. This step is crucial to guarantee a polished finish and avoid any installation-related problems down the road.Finally, keeping the artificial grass clean and looking new requires easy maintenance. To keep the fibers, erect and the grass looking its best, regular brushing is required. To get rid of any dust or debris that might accumulate, buyers should also regularly clean the surface with water.

The Benefits of Choosing High-Quality Artificial Grass

To achieve a realistic and long-lasting result when installing artificial grass, quality investment is crucial. When compared to inferior alternatives, premium artificial grass not only improves the visual appeal of your outdoor area but also provides better performance and durability. Cheaper alternatives could at first glance seem like a better option because they are less expensive, but they frequently don't have the same realistic appearance, texture, and durability as premium a fake grass garden. The aesthetic appeal of high-end artificial grass is one of its key benefits. Compared to less expensive versions, premium grass has sophisticated yarn technology that more closely resembles the texture and appearance of genuine grass. With hues of green that closely mimic genuine grass, the strands are frequently more variegated in colour, giving your lawn a new, authentic look.

Furthermore, high-quality grass feels softer underfoot, making it pleasant to play on or stroll on. It also maintains its immaculate appearance even when there is a lot of foot traffic.Another important consideration when selecting artificial grass is durability. High-quality materials which are intended to endure the weather and endure over time, are used to make premium products. Because these grasses get extended exposure to the sun won't cause them to deteriorate or fade. However, after only a few years of usage, inferior artificial grass can break and get discolored, leaving a lawn that is unsightly and worn out.Selecting high-quality artificial grass benefits the environment as well. Eco-friendly materials are frequently used to make higher-quality solutions, guaranteeing that they are free of dangerous chemicals at the end of their useful lives. This option offers the aesthetic appeal and practicality of a flawless lawn while also supporting sustainability.

Proper Drainage Keeps the Fake Grass Garden Look Perfect

For a fake grass garden to be long-lasting and functional, adequate drainage is essential. Good drainage keeps water from collecting on the ground, which can lead to problems like bad smells and even grass damage. In addition to remaining functional during periods of intense precipitation, a well-drained artificial garden also keeps its aesthetic appeal, making it a delightful and low-maintenance addition to the outdoors. The first step is to have the garden's foundation ready. Make a foundation that lets water run freely after clearing away any existing grass and garbage. Usually, this entails covering the artificial grass with gravel or crushed stone. This layer stabilizes the surface and serves as a drainage system, letting rainwater seep through to the earth below. To guarantee a level basis that supports the fake grass garden and avoids sinking or uneven spots over time spread the gravel evenly and compact it completely.

People can place a weed membrane underneath the artificial grass for added security. Water can easily flow through this barrier, which also keeps weeds from sprouting through the faux garden. Furthermore, a lot of high-end fake grass alternatives have perforated backing that is specially made for better drainage. Maintaining a dry and hassle-free lawn can be greatly improved by selecting premium grass with these qualities. In a fake grass garden, poor drainage can result in sagging grass, dangerous slick areas, and water gathering. Making drainage a top priority during installation guarantees effective water movement, maintaining the garden's dryness and aesthetic attractiveness. Regular brushing and debris removal are crucial to keep the drainage system from becoming clogged. A clean artificial garden guarantees longevity and the best drainage possible, keeping the garden looking fantastic for many years to come.

0 notes

Text

SHAKTIMAN COMPOST SPREADER SHCS is a unique, economic and durable machine which increases soil fertility by uniform spreading of compost in large fields. It doesn’t require manual help and hence labour cost is reduced. It can also spread gravel, sand, gypsum, saw dust, vermi compost and other granular material. Its operation can be hydraulic as well as mechanical with same efficiency.

Features :

1. Hydraulic motor driven rotor

2. Three point hitch Cat II

3. Working width of 1.5 & 1.8 m

4. Rubber guard to protect from lodging of stones

5. Hydraulic cylinders for door movement

6. Tractor pressure controlled spreading layer thickness

* The Company reserves absolute rights to modify the specifications of machine and components therein without any prior notice.

1 note

·

View note

Text

Haul Smarter, Not Harder: The Dhaul Advantage for Modern Construction Projects

In today’s fast-paced construction industry, efficiency is paramount. As projects grow in complexity and scale, so does the need for smarter solutions that streamline operations without compromising quality. One such solution that has been gaining traction among construction professionals is the use of dump trailers, specifically from Dhaul. These trailers are not just about transporting materials; they represent a significant leap forward in how construction projects are managed. This blog explores the Dhaul advantage and how it empowers modern construction projects to haul smarter, not harder.

Understanding the Role of Dump Trailers in Construction

Before delving into the specifics of Dhaul dump trailers, it’s essential to understand the role that dump trailers play in construction. These trailers are crucial for transporting heavy materials such as gravel, sand, demolition waste, and other bulk items. The efficiency of these operations directly impacts the overall productivity and cost-effectiveness of a construction project.

Dump trailers are designed to be robust and durable, capable of withstanding the harsh conditions of construction sites. They come in various sizes and configurations, each tailored to specific hauling needs. However, not all dump trailers are created equal. The choice of trailer can significantly influence the ease and efficiency of material handling on-site.

The Dhaul Difference: What Sets It Apart?

Dhaul dump trailers have quickly become a preferred choice in the construction industry for several reasons. They are engineered with a focus on durability, versatility, and ease of use, making them an invaluable asset for any construction project.

1. Built for Durability

One of the standout features of Dhaul dump trailers is their exceptional durability. Constructed from high-quality materials, these trailers are designed to endure the toughest conditions. Whether it’s navigating rough terrain or handling heavy loads, Dhaul trailers are built to last.

The durability of Dhaul trailers is a result of meticulous engineering and rigorous testing. The frames are reinforced with heavy-duty steel, and the beds are lined with wear-resistant materials that protect against dents, scratches, and corrosion. This level of durability ensures that the trailers can withstand the wear and tear of daily use, reducing the need for frequent repairs and replacements.

2. Versatility in Design

Dhaul understands that construction projects vary widely in scope and requirements. That’s why their dump trailers are designed with versatility in mind. From small-scale residential projects to large commercial developments, Dhaul offers a range of trailer sizes and configurations to suit different needs.

For example, Dhaul offers both single-axle and tandem-axle trailers, allowing contractors to choose the best option based on the load size and terrain. Additionally, the trailers are equipped with adjustable hitch heights and a variety of gate options, including barn doors and spreader gates, to accommodate different material types and dumping methods.

3. Ease of Use

Efficiency on a construction site often comes down to how easily and quickly equipment can be operated. Dhaul dump trailers are designed with user-friendliness in mind, ensuring that operators can quickly and safely load, transport, and unload materials.

One of the key features that enhance the ease of use is the hydraulic lift system. This system allows for smooth and controlled dumping of materials, reducing the risk of spillage and accidents. The trailers are also equipped with intuitive controls and safety features, such as lockable sidewalls and reinforced tie-down points, to secure loads during transit.

4. Enhanced Safety Features

Safety is a top priority on any construction site, and Dhaul dump trailers are equipped with features that promote safe operation. These trailers are designed to minimize the risk of accidents during loading, transportation, and unloading.

For instance, Dhaul trailers come with advanced braking systems that provide reliable stopping power, even when carrying heavy loads. The trailers are also equipped with LED lighting for increased visibility in low-light conditions, as well as reflective tape and markers to ensure that they are easily seen on the road.

5. Cost-Effective Operation

In addition to their durability and versatility, Dhaul dump trailers are also designed to be cost-effective. By reducing the need for frequent repairs and replacements, these trailers help contractors save money in the long run. Moreover, the efficient design of the trailers means that less fuel is required to transport materials, further reducing operational costs.

Dhaul trailers also contribute to cost savings by enhancing productivity. With their easy-to-use features and reliable performance, these trailers allow contractors to complete projects more quickly, reducing labor costs and increasing profitability.

Real-World Applications: How Dhaul Trailers Improve Construction Projects

To truly appreciate the Dhaul advantage, it’s helpful to look at real-world applications of these trailers in modern construction projects. Here are a few examples of how Dhaul trailers are making a difference on construction sites:

1. Residential Construction

In residential construction, where space is often limited, Dhaul’s compact yet powerful trailers shine. Contractors working on home renovations, landscaping, or new builds benefit from the trailers’ ability to navigate tight spaces while still carrying substantial loads. The adjustable hitch height and versatile gate options make it easy to dump materials exactly where they are needed, minimizing manual labor and speeding up the project timeline.

2. Commercial Development

Commercial construction projects, such as office buildings and shopping centers, require the movement of large volumes of materials. Dhaul’s tandem-axle trailers, with their high load capacity and durable construction, are ideal for these demanding tasks. The trailers’ hydraulic lift systems allow for efficient unloading, ensuring that materials are delivered on time and in the right quantities. This reliability is crucial in large-scale projects where delays can have significant financial implications.

3. Infrastructure Projects

Infrastructure projects, such as road construction and bridge building, involve the transportation of heavy and often uneven materials like asphalt, gravel, and concrete. Dhaul dump trailers are built to handle these challenging materials with ease. Their reinforced frames and wear-resistant beds ensure that they can carry heavy loads without sustaining damage. Additionally, the trailers’ advanced braking systems and safety features provide peace of mind when navigating busy construction zones.

4. Demolition and Waste Removal

Demolition projects generate a significant amount of waste that needs to be hauled away quickly and efficiently. Dhaul dump trailers are up to the task, offering the durability and capacity needed to handle large volumes of debris. The trailers’ hydraulic lift systems make it easy to dump waste at designated sites, while the reinforced tie-down points ensure that loads remain secure during transit. This combination of features allows contractors to complete demolition projects more efficiently, reducing downtime and costs.

The Environmental Impact: Dhaul’s Commitment to Sustainability

In today’s construction industry, sustainability is more important than ever. Dhaul is committed to reducing the environmental impact of its products by incorporating eco-friendly practices into its manufacturing processes and design.

1. Energy-Efficient Manufacturing

Dhaul trailers are manufactured using energy-efficient processes that minimize waste and reduce carbon emissions. The company has implemented advanced recycling programs to ensure that scrap materials are repurposed, further reducing the environmental impact of production. By choosing Dhaul, contractors can be confident that they are supporting a company that prioritizes sustainability.

2. Fuel Efficiency

The design of Dhaul dump trailers also contributes to fuel efficiency. The trailers are engineered to be lightweight yet durable, reducing the amount of fuel required to haul materials. This not only lowers operational costs but also reduces the carbon footprint of construction projects. In an industry where every gallon of fuel counts, the fuel efficiency of Dhaul trailers is a significant advantage.

3. Durability and Longevity

The durability of Dhaul trailers means that they have a longer lifespan than many other trailers on the market. This longevity reduces the need for frequent replacements, which in turn reduces the demand for raw materials and energy required for manufacturing. By investing in a Dhaul trailer, contractors are making a sustainable choice that benefits both their business and the environment.

Customer Success Stories: The Dhaul Advantage in Action

To further illustrate the benefits of Dhaul dump trailers, here are a few customer success stories that highlight how these trailers have made a difference in various construction projects.

1. Speeding Up Residential Renovations

A construction company specializing in residential renovations was facing delays due to inefficient material handling. After switching to Dhaul dump trailers, the company saw a significant improvement in productivity. The trailers’ compact design allowed them to navigate narrow streets and driveways, while the hydraulic lift system made it easy to dump materials in precise locations. As a result, the company was able to complete projects more quickly, leading to increased customer satisfaction and repeat business.

2. Enhancing Efficiency in Commercial Construction

A contractor working on a large commercial development needed a reliable way to transport materials across a sprawling job site. Dhaul’s tandem-axle trailers provided the perfect solution, with their high load capacity and durable construction. The trailers’ advanced braking systems ensured safe operation even when navigating uneven terrain, while the hydraulic lift system allowed for quick and efficient unloading. The contractor was able to stay on schedule and within budget, thanks to the efficiency and reliability of Dhaul dump trailers.

3. Sustainable Waste Management in Demolition Projects

A demolition company was looking for a more sustainable way to manage waste removal on job sites. Dhaul dump trailers offered the durability and capacity needed to handle large volumes of debris, while their fuel-efficient design helped reduce the company’s carbon footprint. The trailers’ reinforced tie-down points and wear-resistant beds ensured that waste was transported safely and securely, reducing the risk of spills and accidents. The company was able to improve its waste management practices and reduce its environmental impact, all while maintaining high levels of productivity.

Conclusion: The Future of Construction with Dhaul

As the construction industry continues to evolve, the need for smarter, more efficient solutions will only grow. Dhaul dump trailers represent the future of material handling in construction, offering a combination of durability, versatility, and ease of use that is unmatched in the industry. By choosing Dhaul,

Visit Our Page: https://www.instagram.com/dhauldumptrailers/

#dumptrailerrentals#dumptrailers#hauling#california#los angeles#waste management services#construction management#shifting services#losangeles#hauling services

0 notes

Text

Artificial Grass Installation: A Comprehensive Guide to Synthetic Turf

Artificial grass has rapidly gained popularity as a viable alternative to natural grass, particularly for those seeking a low-maintenance, aesthetically pleasing solution for their outdoor spaces. Its versatility extends to residential lawns, commercial landscapes, sports fields, and even indoor areas. The installation of synthetic turf, however, requires careful planning and execution to ensure optimal results. This guide delves into the nuances of artificial grass installation, from initial considerations to the final touches.

The first step in installing artificial grass installation is understanding the specific needs of your space. Synthetic turf comes in various types and qualities, designed to mimic the look and feel of natural grass. Factors such as the intended use, local climate, and budget will influence your choice of turf. For example, high-traffic areas, such as sports fields, require durable, high-density turf, while decorative residential lawns may benefit from softer, more aesthetically pleasing options.

Once you have selected the appropriate type of synthetic turf installation, the next stage is site preparation. Proper preparation is crucial for ensuring the longevity and performance of your artificial grass sydney. Begin by marking out the area where the turf will be installed. Remove any existing grass, weeds, or debris from the site. This process may involve digging up the old grass and using a weed killer to prevent regrowth. Ensure the area is level, as an uneven surface can lead to problems with drainage and the overall appearance of the turf.

After clearing and leveling the site, the next step is to lay a suitable base. A well-constructed base supports the turf, provides stability, and facilitates proper drainage. Typically, a base consists of a layer of crushed rock or gravel, which should be compacted to create a firm foundation. The thickness of the base layer can vary depending on the intended use and local soil conditions, but a common recommendation is to lay a 3 to 4-inch deep layer. Once compacted, the base should be leveled and smoothed to ensure an even surface for the turf.

Installing a weed barrier fabric over the base layer is another important step. This fabric prevents weeds from growing through the synthetic turf sydney and helps to maintain the cleanliness and appearance of the turf. Cut the fabric to size and secure it in place using landscape staples or similar fasteners. Overlapping the edges of the fabric slightly can help to ensure complete coverage and prevent any gaps.

With the base and weed barrier in place, you can now begin laying the synthetic turf. Roll out the turf over the prepared area, ensuring that it fits correctly and covers the entire space. It’s essential to allow the turf to acclimate to the outdoor temperature for a few hours before cutting and fitting, as this helps to reduce any expansion or contraction that might occur.

When cutting the turf to fit the area, use a sharp utility knife or a specialized turf cutter. Make precise cuts around edges and obstacles to ensure a clean, professional finish. If you are working with multiple rolls of turf, make sure to align the seams carefully to create a seamless appearance. Seaming tape and adhesive are often used to join pieces of turf together, and it’s important to follow the manufacturer’s instructions for these products to ensure a strong and durable bond.

Once the turf is in place and seams are secure, the next step is to infill the turf with a suitable material. Infill helps to support the blades of grass, provides stability, and contributes to the realistic feel of the turf. Common infill materials include silica sand and crumb rubber. The infill is spread evenly over the surface using a broom or a specialized infill spreader. After application, use a power broom or a stiff-bristled brush to work the infill into the turf, ensuring that the blades are properly supported and that the surface is evenly distributed.

After the infill has been applied and brushed in, it’s important to secure the edges of the turf to prevent shifting or lifting. This can be achieved by anchoring the turf with landscape spikes or nails, placed around the perimeter and at any seams or joints. Ensure that the spikes or nails are driven in flush with the surface of the turf to avoid any tripping hazards.

The final step in the installation process is to thoroughly clean the area. Remove any debris, excess infill, or construction materials to leave a clean and polished finish. For a pristine look, a final brushing of the turf can help to lift and separate the grass blades, enhancing the overall appearance and ensuring a natural, uniform look.

Maintaining artificial grass is relatively simple compared to natural grass. Regular brushing helps to keep the turf looking fresh and prevents the infill from compacting. Occasional rinsing with water can help to remove dust and debris, and spot cleaning is effective for removing any stains or spills. Ensuring proper drainage is also crucial to prevent water pooling and maintain the integrity of the turf.

In conclusion, the installation of artificial grass involves several key steps, from site preparation and base construction to turf placement and finishing touches. By carefully selecting the right type of turf and following a thorough installation process, you can achieve a beautiful, low-maintenance outdoor space that enhances the functionality and aesthetics of your environment. With proper care, synthetic turf can provide years of enjoyment and functionality, making it a worthwhile investment for a variety of applications.

0 notes

Text

8 Bobcat Skid Steer Snow Removal Attachments

I searched the web for 8 Bobcat skid steer snow removal attachments and found some results that might be helpful for you. Here is a summary of what I found:

• Snow Pusher Pro: This attachment can push or scrape snow from roads or parking areas. It can transition from snow plow to box plow and handle uneven surfaces without damaging them

• Angle Broom: This attachment can clear light snow, dirt, mud, and other debris from smooth or flat surfaces. It can angle 30 degrees to the right or left.

• Scraper: This attachment can break up hard-packed snow, ice, mud, or other materials with its self-sharpening cutting edge. It can slide under the surface and lift it up.

• Snow Blade: This attachment can move light or moderate snow from sidewalks, driveways, parking lots, and roads. It can angle 30 degrees to the right or left and has high visibility masts at each end of the mold board.

• Snow Bucket: This attachment can haul heavy snow from large areas with heavy snowfall. It has a large capacity and a low-profile.

• Snow V-Blade: This attachment can cut through deep snow drifts and clear large areas quickly. It can adjust to four positions: V, scoop, left, and right.

• Snowblower: This attachment can blow snow off and away from concrete or gravel surfaces. It has a two-stage design and a hydraulic chute rotator.

• Spreader: This attachment can spread salt, sand, or other materials on icy or slippery surfaces. It has a variable speed control and a 10.6 cubic foot hopper.

I hope this helps you with your snow removal needs.

0 notes

Text

0 notes

Text

How to Install Your Artificial Grass Lawn

After you buy artificial grass from an artificial grass supplier, dealer or importer follows these steps to lay artificial grass are -

Steps for Artificial Grass Installation

Step 1

If you're installing artificial grass carpet over a soil, to make the space for a new base, dig the soil up to 3 to 4 inches from the top and remove the existing grass and plants.

To prevent slumping, allow rain soaked soil to dry before excavation. Compact the loose soil with the help of hand tamp or by walking over it. A small slope is recommended for better drainage.

Step 2

Install the grass turf over a well-draining soil such that the artificial grass is permeable to the water and aggregate bases offer a good drainage layer. If there is no drain near the lawn, before you continue the installation, install a drainage system. If the area receives light rainfall, around the perimeter leave a small drainage gap after every 15 cm.

Step 3

To prevent the lawn from separating or slumping over time, install a waterproof border along the perimeter. You can use a plastic bender board or pour a concrete curb around the perimeter. The border shouldn't protrude above grass level else it might inhibit drainage.

Step 4

To prevent the growth of weeds, at the bottom of the excavated area or over the base material, add a Geo textile barrier. This barrier discourages earthworms and gophers from digging through synthetic grass. If you have rodent problems, you can also install a layer of rodent wires.

Step 5

Fill the excavated material with a mixture of finely crushed rock, decomposed granite with particles size less than 10 mm and gravel; up to 3 to 4 inches for improved drainage and prevent slumping. If you are installing the artificial grass carpet over a hard surface or concrete you can use a rubber shock self-leveling compound.

Step 6

Smooth out the base material via a landscaping rake. To grade a flat surface to a 2-3% slope use string, ruler and bubble level.

Step 7

To lubricate the particles for compaction, sprinkle garden hose on gravel or sand. To compact the base to a depth 90% less than its original depth, compact the base with the help of roller compactor, plate compactor, or hand tamp.

Step 8

While the base dries, unroll the artificial grass carpet on the sides. After the base dries off and it's smooth and firm, continue the process.

Step 9

With the help of a friend, stretch out each strip of artificial turf grass over the prepared base. The turf should be install in such a way that all the blades of the turf are in same direction else the grass will not give a natural look and feel.

Step 10

When required by the shape of the projected area, cut out the underside of the grass turf via a carpet cutter.

Step 11

You can use a carpet stretcher to stretch out the turf strips before you fasten them to secure the surface to the ground, lower the expansion due to heat and remove wrinkles.

Step 12

Place two strips close to each other and fold the edges back. Apply the lawn seaming material on the exposed base and cover it with an adhesive product. Fold the strip back on the seaming material and allow it to dry. You can also lay a seaming tape on the ground and keep the strip over it or fasten them together with a stake

Step 13

Fasten the trip around the perimeter with the help of landscaping anchor pin or galvanized stakes at the interval of 6 inch.

Step 14

When the lawn is completely dry, apply a thin layer of washed silica sand, black crumb rubber, or copper slag with the help of a drop spreader or sand.

Step 15

After every raking of infill material, bloom your turf via a boom or rake

Step 16

After the installation of artificial grass, water the lawn.

Before to purchase the artificial grass from the different suppliers and dealers you need to work out for them like in their quality, prices, product life, backing more many things. These things also help in installing artificial grass at lawn or garden area.

Source: How to Install Your Artificial Grass Lawn

1 note

·

View note

Text

The Basics and Benefits of Asphalt Paving

Asphalt paving is installing a paved surface using asphalt concrete. It is a common choice for roads, parking lots, and driveways because it is durable and easy to install.

You might be considering a few concreting contractors for your home driveway or parking lot. So, let’s discuss asphalt paving in this article.

We will give you an overview of asphalt paving, including what it is and how to install it. But, first things first!

What is Asphalt?

Asphalt is a dark brown or black petroleum product that has varying consistency. You can also recycle it from your old pavements.

Once extracted, the asphalt is transported to an asphalt plant, where it is heated and mixed with other materials to create asphalt concrete.

How is Asphalt Pavement Installed?

The first step in installing asphalt paving is to excavate the area where the pavement will be located. This includes removing any existing vegetation, grading the soil, and compacting the subgrade.

Next, a foundation of gravel or other material is placed and compacted on top of the subgrade. After the foundation is set in place, asphalt concrete can be applied in one of two ways:

Hot mix or

Cold mix.

Hot mix asphalt concrete is produced at an asphalt plant and then transported to the job site, where it is installed while still hot.

But, cold mix asphalt concrete is produced at the job site either by using a portable mixing plant or by manual mixing.

After installing the asphalt concrete, it needs to cool down before it is ready to use. This can take somewhere from a few hours to a few days, depending on the weather conditions.

Benefits of Asphalt Paving

Asphalt paving has its fair share of benefits in both industrial and commercial settings.

Asphalt is eco-friendly: Asphalt roads have a lower carbon footprint than other alternatives. It is also possible to mix and pour asphalt pavement material at lower temperatures. It has the obvious benefits of cutting fuel consumption and the production of greenhouse gases.

Asphalt is affordable: Asphalt has lower initial costs, lasts longer, and has a higher residual value than alternative pavements.

Asphalt is 100% reusable: Asphalt is among the most recycled building materials. It extends the life of asphalt surfaces. Also, it requires less new asphalt to create new asphalt pavements, which saves tonnes of new aggregate. It is also possible to build pavement out of entirely recycled asphalt.

Asphalt is easy to maintain: The absence of pavement joints decreases the need for maintenance. Asphalt pavements are substantially less costly to maintain since there are no joints to replace, and they are not damaged by freeze-thaw cycles.

Asphalt lasts indefinitely: The wearing course of asphalt mixtures (such as Stone Mastic Asphalt) can endure for more than 30 years. Moreover, the latest developments in self-healing asphalt suggest that the service life of deteriorating courses on current highways might be drastically extended.

Asphalt is flexible: Asphalt pavements can be 'custom fit.' It means they can be specifically created and built to sustain the traffic load and weather conditions of a particular region. There are unique asphalt mix options for highways and urban, suburban, and rural roads.

Asphalt reduces noise: This is a great choice for the construction of roads as it can also reduce noise from vehicles. So, opting for noise-reducing asphalt can cancel the need for more expensive noise-reduction solutions such as noise barriers.

Drawbacks to Asphalt Paving

Now, let’s see the other side of asphalt paving—the disadvantages.

Breaks: When asphalt paving is incorrectly laid, it cracks and pits. Uneven blacktop surfaces, improper mixing, and paving over existing breaks are all causes of cracks.

Need for heavy machinery: It required the use of heavy machinery, regardless of the type of asphalt employed. Wholesaler trucks, paving equipment, sand spreaders, and graders are all necessary to create blacktop surfaces. You can hire this type of equipment for a small-scale driveway project, but it is pricey.

Conclusion

These are the basics of asphalt paving that you should know.

If you are considering having asphalt paving installed on your property, we recommend that you consult with a professional Industrial concreting company to get an accurate estimate of the cost and timeline for your project.

0 notes

Text

How To Top Dress a Lawn?

Introduction

A well-maintained lawn can enrich soil and anchor turf roots, making it resilient to drought, pests and other stresses.

How, when and why to top dress a lawn

When you top dress a lawn, you are adding new soil to it. This can improve the quality of your lawn in several ways:

It helps improve the health of the grass.

It can make your lawn more resilient by improving its root system.

It can make it easier for water and nutrients to penetrate into your soil, which will help keep your grass healthy while also reducing weeds and other pests that could damage it over time (more on this later).

Why to top dress a lawn?

Topdressing your lawn is a great way to improve the quality of your lawn. It helps to improve soil quality and health, it helps to improve the lawn’s ability to retain water, it also helps to improve the lawn’s ability to retain nutrients and finally it can help you to retain air.

Top dressing will help your grass grow better because it improves all of these things which are essential in helping a plant grow healthy roots. By improving these things you help your grass become stronger and healthier than before meaning that you will be able to get longer periods of growth between each mowing session which means less work for you!

Topdressing your Lawn

Topdressing is the process of adding a layer of soil or compost to the top of a lawn. This can be done at any time of the year, but it’s best done in late summer or early fall when grass growth is slow and plants aren’t actively taking up nutrients from the soil.

Topdressing your lawn improves its health by providing nutrients for new growth, reducing compaction and improving drainage. To topdress your lawn:

Mow it short (1–2 inches)

Spread the fertilizer at a rate that matches how much you’ve mowed off – approximately 1 pound per 1 inch of height removed (or more if you’re applying manure).

1. Prepare your soil mix (If you are not using an off the shelf mix)

If you are mixing your own soil, it may seem overwhelming at first. But don’t worry, there are many options for mixes and ratios. The most important thing is to base your mix on a non-compacting soil or loam, such as peat moss or compost. This will allow the nutrients to remain in the soil while preventing compaction and erosion over time.

What materials should you use? If you have access to them, use sand (which helps with drainage), lime (to add calcium), and fertilizer with nitrogen and potassium in it. You can also mix these things together yourself if needed! Once again, remember that consistency is key here: some people prefer working with sifted sand or clay while others prefer coarsely ground materials like gravels or crushed stones.

2. Remove weeds.

Weed control is important to the health of your lawn. Weeds can compete with grass for nutrients and water, spread disease, make your lawn look bad and cause a fire hazard.

Weed control starts with knowing what weeds you have in your lawn and when to use herbicides like Roundup, which kills broadleaf plants including dandelions, clover and other wildflowers as well as grasses.

3. Aerate the lawn with a Corer

Aeration is the process of removing cores from your lawn. The idea is to remove the cores, which are small plugs of soil and debris in your lawn, so that water and nutrients can get through to the roots. Aeration helps relieve compaction, improve drainage, and prepare for top dressing by removing thatch (which also contributes to poor drainage). Aeration shouldn’t be done more than once per year as it can damage grass plants if done too often; however, it’s an important part of the lawn care process so don’t skip it!

To aerate a large area like a yard or field requires renting equipment or hiring someone else to do it. However you choose to do it though, make sure you choose an aerator designed specifically for lawns rather than one designed for golf courses or fields!

4. Spread the material on by hand or use a spreader (not a fertilizer spreader).

If you’re applying topsoil, compost or peat moss, for example, spread it with your hands in the same way you would spread mulch around plants. Use a small rake to level out any clumps and break up any large lumps of material if needed.

For grass seed, apply it with a drop-spreader instead of your hands. Drop-spreaders are designed specifically for grass seed and other fine materials; they put out small even amounts at regular intervals as you walk along spreading them across your lawn. If you don’t have access to one of these specialty tools then just toss handfuls of grass seed over each area where it needs to go until all areas are covered with enough seeds that they can germinate. You’ll want to make sure that no bare patches remain uncovered when doing this step because bare patches may not survive once they’ve been planted over by new grass growth!

5. Using a rake or roller even out the spread of material.

Next, use a rake or roller to even out your spread of material so it is level. This will help ensure that you have no bumps or ridges in your lawn and that all of the grass gets access to nutrients evenly.

You can also use your rake to remove stones and debris from the surface of the soil as well as twigs, leaves and anything else that may be hiding under your topsoil.

Finally, if there is any thatch on top of your soil (thatch is dead grass roots) then use your rake to remove this layer first before adding new soil

6. Water in throughly.

Water in throughly. It’s important to water thoroughly and deeply to avoid compaction and help the soil mix settle. This will also help the soil mix be absorbed by your lawn’s roots, which is where it will do its best work in terms of feeding and growing your lawn.

Apply fertilizer at a rate that matches what the manufacturer recommends for your specific brand of top dressing fertilizer. Make sure to follow their directions carefully!

Top dressing a lawn is one of the best ways to improve its quality and health. A well-maintained lawn can enrich soil and anchor turf roots, making it resilient to drought, pests and other stresses.

Top dressing a lawn is one of the best ways to improve its quality and health. A well-maintained lawn can enrich soil, making it resilient to drought, pests and other stresses. Top dressing ensures that you have healthy soil for your grass to grow in, which will make mowing more pleasant and easier on your lawn.

The process consists of spreading an organic material over the topsoil layer. This material covers up any fertilizers or pesticides that were put down previously in order to prevent them from leaching into the ground water table.

Conclusion

As we’ve seen, there are a number of reasons why top dressing your lawn is worth considering. It can improve the quality and health of your grass, make it more resilient to drought and other stresses, as well as saving you time in the long run. It may seem like a lot of work when you first start out but after doing it once or twice it will become second nature! So if you have some extra time on your hands this summer why not give it a try? You’ll be glad that you did!

dress a lawn

,

Lawn Mowing Adelaide

0 notes

Text

Kuhn Gmd 44 Service Manual

Kuhn Gmd 44 Service Manual Transfer Switch

Kuhn Gmd 44 Service Manual Pdf

Kuhn Gmd 44 Service Manual Transmissions

Kuhn Gmd 44 Service Manual Transmission

KUHN SAS - BP 50060 - F-67706 Saverne CEDEX - Phone:+33(0)3 88 01 81 00 - Fax: +33(0)3 88 01 81 01. GMD 25 F; Trailed Mowers. GMD 51 TL; GMD 51 TC; GMD 50 TL; Mounted Mowers. GMD 11 Series; GMD Premium; GMD Select; GMD 11 Series; GMD 25 F; Drum Mowers. PZ Series; Mower Conditioners. Triple Mower Conditioners. FC 25 F; FC 30; Trailed. FC 60 TC; FC 60 TL; Mounted. FC 4 D; FC 25 F; Mergers. MM 300; MERGE MAXX 700; MERGE MAXX 890; MM 1100 and MM.

Read and choose the spare parts for your equipment KUHN you can in our online directory below.

This section contains the online catalog of spare Kuhn. Here you'll find Kuhn spare parts for such equipment and facilities, both

1. Kuhn Spare parts for equipment for plowing:

Tractors Kuhn GMD 44, 55, & 66 Multidisc Mower Assembly & Manual Service, Repair & Owners Operators Manuals Shop kuhn mower service manuals at greenbookee.org - Download free pdf files,ebooks and documents of kuhn mower service manuals Download delayed (confirmed in 24 hours max) KUHN User's Guide KUHN. Online Library Kuhn Gmd 44 Manual Download Kuhn Gmd 44 Manual.com book pdf free download link or read online here in PDF. Read online Kuhn Gmd 44 Manual.com book pdf free download link book now. All books are in clear copy here, and all files are secure so don't worry about it. This site is like a library, you could find.

Mounted reversible plows

Semi-mounted reversible plows

2. equipment parts for the equipment kuhn Soil preparation:

Cultivators - subsoilers

rod cultivators

Ccproxy 8 serial number register code. Harrows

Cannon seedbed pochvopodgotovki

3. Spare parts for seeding equipment Kuhn (Kuhn Parts) :

Front Hoppers

mechanical seeders

Drills pneumatic

Pneumatic precision seed drills

4. The equipment for application of fertilizers, as well as spare parts KUHN (spare parts Kuhn)

Kuhn Gmd 44 Service Manual Transfer Switch

Loaders

Fertiliser Spreaders

5. Kuhn Spare parts (spare parts Kuhn) spray systems

trailed sprayers

6. Care roadsides and parks

Shredder for roadside

Machines for Hedge and grass mowing

Salt spreaders, sand and gravel

7. Shredders

Shredder with horizontal axis

8. The blank feed

Kuhn Gmd 44 Service Manual Pdf

disc Mowers

Mower Conditioners

Tedders

Rakes

9. Parts Balers Kuhn (Kuhn)

Round balers

Combinations round baler - wrappers

Square baler

10. Feeding

Bale

bale Wrappers

11. Choppers

corn Grinders

12. Livestock

Mixer Feeder

Propelled Mixer-Feeder

Blowers, straw distributors and silage

13. Manure spreading

Fertilizer spreaders with rear discharge

Fertiliser dropside

Read and choose the spare parts for your equipment KUHN you can in our online directory below.

This section contains the online catalog of spare Kuhn. Here you'll find Kuhn spare parts for such equipment and facilities, both

1. Kuhn Spare parts for equipment for plowing:

Mounted reversible plows

Semi-mounted reversible plows

2. equipment parts for the equipment kuhn Soil preparation:

Cultivators - subsoilers

rod cultivators

Harrows

Cannon seedbed pochvopodgotovki

3. Spare parts for seeding equipment Kuhn (Kuhn Parts) :

Front Hoppers

mechanical seeders

Drills pneumatic

Pneumatic precision seed drills

4. The equipment for application of fertilizers, as well as spare parts KUHN (spare parts Kuhn)

Loaders

Fertiliser Spreaders

5. Kuhn Spare parts (spare parts Kuhn) spray systems

trailed sprayers

6. Care roadsides and parks

Shredder for roadside

Machines for Hedge and grass mowing

Salt spreaders, sand and gravel

7. Shredders

Shredder with horizontal axis

8. The blank feed

disc Mowers

Mower Conditioners

Tedders

Rakes

9. Parts Balers Kuhn (Kuhn)

Round balers

Combinations round baler - wrappers

Gmail create account download. Square baler

10. Feeding

Bale Download reason 5 for mac free full version.

bale Wrappers

11. Choppers

corn Grinders

12. Livestock

Mixer Feeder

Propelled Mixer-Feeder

Kuhn Gmd 44 Service Manual Transmissions

Blowers, straw distributors and silage

13. Manure spreading

Fertilizer spreaders with rear discharge

Kuhn Gmd 44 Service Manual Transmission

Fertiliser dropside

0 notes

Text

How To Level a Garden: Step-by-step Guide (2020) | Konservatory@|how do you level a garden@|https://cdn.konservatory.co.uk/wp-content/uploads/2020/03/lawn-care.jpg@|21

A well-manicured lawn, colourful flowers and birds chirping on the trees – life sounds complete bliss. It is every homeowner’s desire to have a picture perfect garden. It all starts with levelling the garden.

If you don’t have level ground you are likely to be frustrated every time the lawnmower refuses to glide over the blades of grass. You may have also have issues getting the best our of your lawn spreader to fertilize your lawn as well.

[external_link_head]

You can scan though all the inspirational garden images that you find on the Internet and there would be one thing in common – the gardens are perfectly levelled and there are no bumps and slopes in between.

To achieve a garden that others envy you need to start by levelling it. This brings us to the first question – how do you level a garden lawn? It might involve hard labour and getting your hands dirty, but the outcome is surely priceless.

Why is Levelling a Garden Is Important?

Before we get into the step-by-step guide of levelling a garden it is important for us to understand importance of having an even garden without bumps and slopes.

The first and the most important reason is surely the usability. If you have an uneven garden it will be of little use other than growing plants and trees. You’ll be out constantly with the weed killer, trying to keep the plants at bay. Walking over it or your kids running on an uneven garden is fraught with risks.

A flat lawn is a more functional lawn, allowing you to make use of a retractable washing line which would be handy for the warmer seasons, as would a hammock stand. A game of garden cricket, football or playing around with a Frisbee is only possible when you have a level garden.

[external_link offset=1]

You may also been an avid bird watcher, and a flat lawn would allow you to set-up a bird table and fill it with niger seeds of sunflower hearts bird food. The additional benefit is that birds often find their way to unwanted moss, eradicating the need for a moss killer and letting nature take care of itself.

Second and without doubt another important reason is the aesthetic beauty of the garden. If you have one with slopes and bumps it turns into an eyesore. Set up a garden storage bench, kick back and enjoy the beauty of your back garden. You can even do this from the comfort of your conservatory should you have a recliner conservatory chair and a suitable pair of binoculars.

Think about the winter months and you will see layers of snow accumulating in certain areas of the garden while other places seem to resist it. When it rains, your garden can turn into a swamp, none of which is desirable. This is even worse if you’ve recently built a greenhouse and rely on a greenhouse heater to keep the plants inside growing.

As water rests over the surface for long it can also lead to diseases in your garden which can become hard to control. There are people who have seen their months of mowing get literally drenched in water once the skies open up.

Finally as and when you undertake the task of lawn mowing, it would become a huge challenge. You won’t be able to cut the grass evenly and the odd of peeling off the turf is high.

Working your lawn mower around your garden would be similar to driving on a road full of potholes. The risk of damaging the lawn, the lawnmower and inflicting wounds on a bumpy lawn remains high.

What Causes Slope To Occur In The Garden And What Causes A Garden To Become Uneven

Before you pick up your tools and get started with levelling the garden it is important for you to understand the root cause of the problem.

So what causes slopes to occur in a garden or for them to become uneven in the first place? There are several reasons that can cause bumps and pits in a lawn that was perfectly levelled few years back. Let us ta a look at some of these reasons –

The topsoil in your garden may be extremely thin and prone to erosion. As the soil erodes during the dry months the bumps and slopes become prominent during the wet months. However you are less likely to notice this problem in a dense and thick lawn.

Soil in your garden may heave due to freezing during late winter months and this might leave behind bumps. In many cases these bumps aren’t noticeable to the naked eye and only when you walk in the garden you are likely to sense the bumpy ground underneath.

Earthworms are common in garden and they play a very important role in enriching the soil in your garden. But their castings also cause the garden to become bumpy. While you must deal with this scenario make sure you don’t turn them away from your lawn completely.

The absence of proper drainage system in your garden and accumulation of water during heavy showers can also aggravate the problem of bumps and slopes in the garden. Every spell of rain can make this problem more acute.

If you have pets at home especially cats their activity during certain seasons of the year can also cause uneven surfaces in your lawn. It is important to restrict their activity in the lawns when the grass is in its most vulnerable state.

Uneven Garden Undoes a Conservatory

Over the last few decades conservatories have become very popular in the United Kingdom and we are seeing more and more people adding conservatories to their homes.

A beautiful garden and a conservatory complement each other and increase the curb appeal of your property. But a conservatory is more than just a glasshouse in your property.

It is a part of a larger environ in your house and needs to be in perfect union with the garden outside. As you sit comfortably on a set of replacement cushions for your conservatory furniture, you should also be able to admire the beautiful garden outside. It may be a case of wanting to keep wildlife away from your flowerbed though, so picking up a mesh bird netting may be worth doing.

[external_link offset=2]

This is where we must ask you these questions – Are you seeing a picture that you’d like to share in Instagram? Are you seeing something that you can take pride in?

If bumps and pits are the first thing you notice in the conservatory your entire experience of having a conservatory is spoiled. The pits and bumps in your garden that may otherwise not be visible when you are walking in the garden are prominently visible from the conservatory.

Your whole investment in a conservatory can go waste if you don’t have a picturesque garden outside. This is why it is important for you to start levelling the garden.

Steps to Level a Garden Lawn?

We have already discussed the reasons behind an uneven lawn and how it can spoil the aesthetics of the landscape. Now we are ready to get started with levelling the garden. It is important that you take up such a project at the right time. Spring is surely the best time of the year as far as levelling a lawn is concerned.

You can also undertake this project before the onset of the winter but try scheduling it for spring. This will ensure grass seeds have enough time to grow and also not leave you with a bumpy lawn or barren piece of land in your garden for too long. Now that you are ready to hit the ground here are the steps you need to follow to level your garden lawn-

Start With A Lawn Audit: Before you get going with the business you need to first carry out an inspection of the lawn. This step will help you determine the amount of levelling your lawn would require and also identify drainage issues if any. Lack of a plan and discovering new problems midway through the project can further complicate it. As we have mentioned previously in many cases an uneven lawn often results from drainage issue.

Adjust the Gradient: If you have identified drainage as a major concern it is important for you to adjust the gradient to ensure water gets drained out during heavy showers.

Here you might need to remove the grass before you start with the levelling. You can do so using a shovel and by doing so you will be creating a barren land with only the top soil. However you should get into this step only when your lawn resembles the surface of the moon.

For home gardens you can follow a 48:1 ratio of grading where for every 48 inches or 4 feet of the garden there is a 1 inch fall which will prevent water from accumulating in the garden. Along with the gradient you can also work on an underground drainage system using drainage pipes and gravel if the drainage issue is a major concern and reworking the gradient on your entire lawn sounds an expensive affair.

Pre-water the Lawn: Once you are done with removing the grass your lawn is likely to be dry given the time of the year (we are assuming you are taking up the project during spring).

You need to water the lawn for few days as this will help you get rid of the dryness and powdery texture of the soil. However keep this minimal as too much will result in mud which is equally tough to work with as is the case with dry soil.

Levelling Shallow Spots: For the shallow spots of the lawn which are usually 1-2 cm lower than the adjacent area of your lawn you can pour in a top dressing mixture (peat, sand and topsoil) and shake it up using a garden rake till you have levelled it to the surrounding area of the lawn.

Follow it up by tapping it with your feet or the flat end of the rake to compact it. Watering this part will help in further compaction. Once this settles you can pour in the grass seeds and wait for these seeds to germinate.

Levelling Deep Spots: If you are dealing with deep spots that are more than 2cm deep you will need to adopt a different approach. You will need to remove the grass and the top soil and reach depth of about 4-5 cm using a shovel.

Remove any stones and break down the clumps that you dig out. Compact the soil below using a manual hand tamper and by doing so you will prevent further sinking of the surface. Fill this with a top dressing mixture and compact it using the same steps we followed fir shallow spots. Once the soil has settled down you can pour in the grass seeds.

Levelling Bumps: Levelling bumps is rather easier. Mark the bump you wish to remove using the shovel and create incision deep enough to lift the turf. Next you need to remove the excess soil using the shovel till you are able to achieve an even surface compared the adjacent areas.

You need to do this slowly to avoid creating further spots in the adjacent areas. Once done lay the turf back over and gently compact it to the top layer of the soil with your hands.

How to Level a Garden before Turfing

There are many who prefer laying a turf over planting grass seeds as it offers an instant lawn that can be used straight away. In case you have missed the spring deadline to level your garden turfing would be a wise choice. While buying turf may cost you more than plating grass seeds it is definitely the easier way out for many gardeners. Let us now take you through the basic steps of levelling your garden before you lay the turf:

Clear The Soil: You need to get rid of all the stones and weeds that you have in the soil. You can spray a weed killer days before you start this process if the problem of weed is acute. You need to allow enough time for the weed killer to work its magic as may be prescribed the manufacturer.

Till the Soil: If you wish to have a beautiful garden it pays putting in extra effort while you are tilling the soil. It is also known as rotavate and you should go to a depth of about 6 inches and make sure the soil is of coarse consistency breaking all the lumps. Use the shovel to achieve the right consistency in the soil.

Fertilize the Soil: The health of your turf would depend on the quality of the soil underneath and hence you should fertilize the soil with compost or rated manure. Make use of your tiller to spread and mix the manure evenly with the soil.

Spring fertilizer or those that are rich in nitrogen would be your best choice as they replenish the soil with the necessary ingredients. But you can also opt for those that come with potassium and phosphorous along with nitrogen for better results.

Work on the Gradient: Drainage is one of the most important elements of a perfect garden lawn and you need to be careful with the gradient. There should be no scope for water to rest on the surface of the lawn after heavy rains. You can follow the same steps for creating a drainage system as we have mentioned previously in this post.

Level The Soil: This is perhaps the most important step in the process and you should either opt for a lawn roller or do it with your feet. However experts suggest you to do the process with feet. While the process would be time-consuming you will be able to achieve an even spread when you are doing it manually. Even if you make use of a lawn roller inspect the whole lawn carefully after you have levelled it with a roller. The last thing you want to be left with is bumps and pits in your lawn after this stage.

Rake The Site: After you are done with the levelling you need to rake the entire lawn gently. Go slow with the process to ensure you are raking only the top layer of the soil is raked and loosened as this will allow you’re the roots of the grass to transplant firmly.

Lay The Turf – In the final step you need to start unrolling the strips of turf in the garden starting around the perimeter. Don’t use small pieces around the edges as they are prone to perishing. While laying the turf you must make sure the underside of the turf is in full contact with the soil underneath. Gently tap every strip of the turf to help it contact the soil.

Once you are done with this you will have a beautiful garden lawn that is even and drains out within few hours of a heavy shower. It is now the time to invite the birds in your garden. Unless you hear the birds chirping in your garden your whole experience of owning a beautiful garden is incomplete. Why not invest in some conservatory dining furniture so that you can look out of the window at the lawn you have just laid.

[external_footer]

source https://livingcorner.com.au/how-to-level-a-garden-step-by-step-guide-2020-konservatoryhow-do-you-level-a-gardenhttps-cdn-konservatory-co-uk-wp-content-uploads-2020-03-lawn-care-jpg21/

0 notes

Text

Top 15 Most Useful 3-Point Tractor Attachments

After making a list of all the tasks you need to do around your place, it’s time to pick the best implements. Choosing the right attachment for your tractor will help save your time and effort.

Here is our list of the most useful 3 point tractor attachments in no particular order of importance.

15 Most Useful 3-point Tractor Attachments

1. 3-point Post Hole Digger

Digging holes may sound simple but it requires a lot of labor, especially when you need deep holes for fence building, signs installation, or plantation. That’s when a post-hole digger comes in handy.

This piece of equipment can assist your tractor in digging vertical holes from 800 to 1,300 mm deep. You can also have different hole widths (6, 9, or 12 inches) by altering its drill, which is usually sold separately.

It will be so helpful if you are planting mango, coconut, teak, pomegranate, or lemon. It can work with all types of soil and is compatible with any standard or compact tractors.

2. 3-point Rotary Cutter

After a long while, your farm might be inundated with thick brush, grass, or weed. A rotary cutter is used to cut overgrown grass or pasture, which is an essential part of farm management.

It is designed to make strong cuts through grass or tree saplings that are 1 inch thick, with 1-9 inches in height. But it will leave a little rough finishing surface.

3. Finish Mower

A finish mower, also known as a grooming mower, is a tractor attachment that helps create a professional, manicured-looking lawn like golf courses or sports fields.

This tool comes in many sizes and can fit many types of tractors with their standard 3-point attachment.

Running on rubber tires, the mower can cut your grass evenly without ruining the territory. If kept and maintained properly, it can last for many years.

4. Box Blade

A box blade is probably the top common implement that everyone owning a tractor should have. It is a metal box that has 3 sides, with scraping blades across the front and the rear panel. Like many other 3-point attachments, this tool can be easily attached to any tractor.

Once you get a hang of it, it can release a lot of burden for your farm duty.

The main uses of a box blade include leveling, grading, and backfilling land. You can also add scarifiers, which are angled metal teeth that can help break up hard surfaces before shaping.

5. Rotary Tiller

A rotary tiller will be very useful for someone who works on large vegetable farms. It is a PTO attachment that has a rotating shaft. On the shaft lines, a set of tines can dig into the soil and make a well-tilled seedbed ready for planting.

It comes with adjustable digging depth, which is more convenient for various types of plants. Generally, it can till 6 inches at maximum. But, larger models can offer greater depths.

6. 3-point Yard Rake (Landscape Rake)

A landscape rake is made to clean up the soil. The small gaps between curve-shaped tines allow this tool to go into the dirt, pull up chunks like roots, rock & gravel, and leave an even surface.

The rake can also be rotated to the left and right thanks to its 360-degree pivot.

7. 3-point Chain Harrow

A chain harrow is attached to the tractor for pasture land and paddock maintenance. It helps spread out dung, exposing it to sunlight to kill parasites and at the same time distribute nutrition to the rest of the field.

It is also used to maintain surfaces for sports events, like leveling the ground or removing footmarks. On the farm, it assists the seed germination process by bringing the soil clumps onto the surface, which will then be broken down by the weather.

8. 3-point Fertilizer Spreader and Seeder

Source: Wikipedia.org

This tractor attachment is used for a variety of spreading duties, such as seed, fertilizer, sand, etc. It is much bigger than a handheld hopper, which drops the seed manually from your hand cranking.

Its function is quite basic. There’s a spinning disk that throws materials from the hopper above onto the ground.

#9. Harrow Disc

A harrow disc tills the soil before crops are planted. Besides, it can cut off weeds or break down crop residue.

The 2 sets of steel discs vary in size, shape, and spacings to match the conditions of different types of soil. They are placed crossing each other, like an “X” letter. This helps the disc optimize the outcome when it tills the soil.

10. Cultipacker

A cultipacker does a very good job in firming up your soil before planting, especially for freshly tilled soil. It reduces the fluffiness of new soil and thus improves seed germination. As for small seeds like clover or alfalfa, it is crucial to not plant them too deep into the soil.

Other great benefits of this attachment are breaking up clods, leveling the ground, and keeping the soil moisture.

11. 3-point Flail mower

To cut heavier grass and scrub in agriculture, a lawnmower isn’t strong enough to handle. Instead, we use a flail mower.

Like other 3-point attachments, the flail mower is powered by the tractor’s PTO and can cut through thick grass or even brambles.

What makes this implement better than a lawnmower or brushcutter is that it can shred thick shrubs in a large area. Flail mowers can also be used vertically, making them perfect for trimming tasks.

12. Middle Buster

A middle buster is an extremely useful implement when it comes to planting vegetables. Farmers use it widely to dig a furrow, which can be as deep as 12 inches.

This attachment can also help harvest, especially with root vegetables like potatoes. Simply attach it to the tractor, run it through the crop and all the roots will be brought up to the surface which is ready to be gathered.

13. Grader Blade

A grader blade has a wide range of applications, making it one of the most useful tractor attachments. It can fix the driveway, clean the fence line, or shift gravel for shed pads. In forestry, people use grader blades for making trails or creating fire breaks.

It is also used to repair the shoulders or open fire access on roads.

14. 3-point Corn & Bean Planter

Exactly like how it is called, a corn & bean planter is a device attached to a tractor to help sow corn and beans onto the field. The corn planter can dig holes, drop the seed in, and then cover it with soil.

Large planters can carry tons of corn and bean seeds to sow on over 100 acres. This saves farmers a lot of effort.

Some models are equipped with sensors to control the distance between each seed for optimal growth.

15. 3-point Wood Chipper

A 3pt wood chipper is a very common tractor implement that breaks down wood using its sharp and strong blades.

This attachment can chop down big, solid logs of wood, either fresh or dry, and turn them into smaller wood chips. A wood chipper is especially valuable when it comes to cleaning and making use of debris from trees.

Related Questions To 3-point Tractor Attachments

1. Are Tractor Attachments Interchangeable?

Yes. Interchangeability is a great feature of those attachments. Once the 3-point hitch is attached to the tractor, each different implement will turn it into different “machines”.

2. Is The Dimension A Matter Of Choice?

Yes, it is. Based on the specific task you are doing, it’s important to choose the right size for the attachment to ensure the expected outcomes.

Otherwise, the attachment might be too small to fit the item you want to move. Or, it might be too large to fit where you want it to move.

3. How Important Is The Weight Of The Tractor Implement?

Weight is another crucial factor you need to pay attention to when purchasing a tractor implement.

As an attachment will add more weight to the tractor, it will reduce the overall weight capacity. For small machines, this is much more important. So, it’s recommended to opt for a lighter-duty attachment for better performance.

Final Words

In the end, the best implements are the ones that suit your own needs the most. Above is our 3-point tractor implements list that we think you should consider first. We hope it has helped you make up your mind!

Source: Top 15 Most Useful 3-Point Tractor Attachments

source https://sandcreekfarm.net/3-point-tractor-attachments/

0 notes

Text

Metal Recycling Machines EUROPE Market Research Report 2021-2026

The Metal Recycling Machines market report provides a detailed analysis of global market size, regional and country-level market size, segmentation market growth, market share, competitive Landscape, sales analysis, impact of domestic and global market players, value chain optimization, trade regulations, recent developments, opportunities analysis, strategic market growth analysis, product launches, area marketplace expanding, and technological innovations.

ALSO READ: http://www.marketwatch.com/story/metal-recycling-machines-market-research-report-with-size-share-value-cagr-outlook-analysis-latest-updates-data-and-news-2021-2028-2021-07-18