#SC Male to LC Female UPC Fiber Optical

Explore tagged Tumblr posts

Text

Fiber Optic Adapter - SC Female to SC Female

A Fiber Optic Adapter (also known as a coupler or connector adapter) is a passive device used to connect two optical fibers with the same or compatible connectors. In this case, an SC Female to SC Female adapter would be designed to connect two SC-terminated fiber optic cables together.

Here's a breakdown of the components:

SC Connector: The SC (Subscriber Connector) is a common type of fiber optic connector with a square-shaped snap-in coupling mechanism. It is widely used in data communication and telecommunication networks. The connector has a push-pull design that ensures a secure connection.

Female Connector: The "Female" designation indicates that the connector has a socket or receptor to accept a male connector. In the case of an SC Female connector, it means that the adapter has an SC port with a socket to accept the male end of an SC-terminated fiber optic cable.

SC Female to SC Female Adapter: This adapter is designed to connect two SC-terminated fiber optic cables that have male SC connectors at their ends. Each side of the adapter has an SC Female port (socket) where the SC connectors from the cables can be inserted. This creates a continuous optical connection between the two cables, allowing light signals to pass from one fiber to another.

These adapters are useful in scenarios where you need to extend the length of a fiber optic cable or connect two cables with SC connectors that are too short to reach each other directly. Fiber optic adapters are commonly used in networking, data centers, telecommunications, and other applications where high-speed and reliable data transmission is crucial.

When choosing a fiber optic adapter, it's important to ensure compatibility between the connector types and the mode of the fiber (single-mode or multi-mode) being used. Additionally, make sure to handle and install fiber optic components with care to avoid damage to the delicate optical fibers and connectors.

#Fiber Optic Adapter#Buy Fiber Optic Cable Adapter Coupler#Fiber Optic Adapter SC to LC Singlemode Simplex#SC Male to LC Female UPC Fiber Optical#Fiber Optic Adapters#Fiber Adapters#Fiber Optic Connector Adapters

0 notes

Text

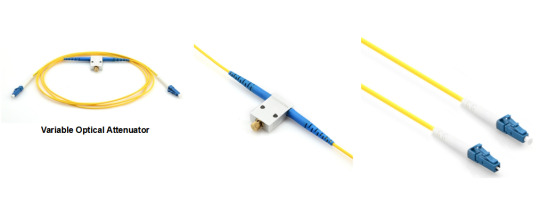

A Complete Guide to Fiber Optic Attenuator

A fiber optic attenuator is mainly used in fiber optics to debug optical power performance and optical instrument calibration correction, and fiber signal attenuation to ensure the optical power is stable and desired level in the link without any changes on its original transmission wave. This article provides a comprehensive understanding of fiber optic attenuators.

What is a Fiber Optic Attenuator?

A fiber optic attenuator also called an optical attenuator is a passive device used to reduce the power level of an optical signal in free space or an optical fiber. It provides low insertion loss, precise attenuation values, and easy operation features. In addition, fiber optic attenuator is usually used in single-mode long-haul applications but is also available in multi-mode attenuators.

Working Principle of Fiber Optic Attenuator

There are three working principles of fiber optic attenuators:gap-loss, absorptive and reflective principle.

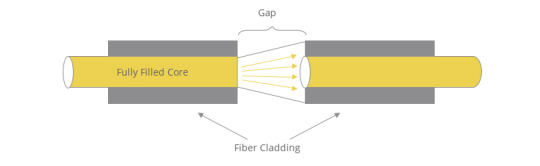

1. Gap-loss Principle

The gap loss principle is used in fiber optic attenuators to reduce the optical power level by inserting the device in the fiber path using an in-line configuration. Gap-loss attenuators are placed close to the transmitter to prevent the saturation of the receiver. They use a longitudinal gap between two optical fibers so that the optical signal passed from one optical fiber to another is attenuated. This principle allows the light from the transmitting optical fiber to spread out as it leaves the optical fiber. When the light gets to the receiving optical fiber, some of the light will be lost in the cladding because of the gap and the spreading that has occurred.

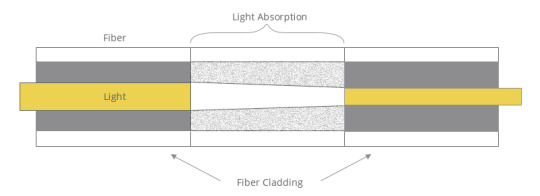

2. Absorptive Principle

The fiber optic has the imperfection to absorb optical energy and convert it to heat. The absorptive principle is used in the design of fiber optic attenuator, using the material in an optical path to absorb optical energy. This principle is simple but can be an effective way to reduce the optical signal power.

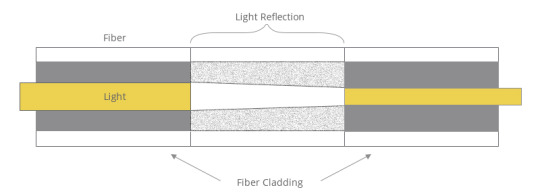

3. Reflective Principle

Another imperfection of fiber optics is also being used to reduce the signal power, which is reflection. The major power loss in optical fiber is caused by the reflection or scattering. The scattered light causes interference in the fiber, thereby reducing the signal power. The reflective principle is used in the planned attenuation of a signal, and the material used in the fiber optic attenuator is manufactured to reflect a known quantity of the signal, thus allowing only the desired portion of the signal to be propagated.

Fiber Optic Attenuator Types

The fiber optic attenuator is divided into fixed optical attenuator (FOA) and optical variable attenuator (VOA) types.

Fixed Optical Attenuator

Fixed optical attenuator (FOA) is used in fiber optic communication systems to reduce the optical fiber power by a certain level. Typical attenuation values are between 1 and 30 dB. Fixed value attenuators consist of in-line type and connector type. The in-line type optical attenuator is incorporated into the patch cable. The connector type attenuator has a male plug connector at one side to allow the fiber attenuator to be plugged directly into receiver equipment or adapters in the patch panel and has a female type fiber optic adapter at the other side to allow the patch cords to plug in. FOA is available in LC, SC, ST, FC, and MU styles with APC and UPC polish.

2. Variable Optical Attenuator

A variable optical attenuator (VOA) uses a variable neutral density filter and has the advantages of being stable, wavelength insensitive, mode insensitive, and offering a large dynamic range. VOA includes stepwise variable attenuator and continuously variable attenuator types. The stepwise variable attenuator can change the attenuation of the signal in known steps such as 0.1dB, 0.5dB, or 1 dB. The continuously variable attenuator provides a precise level of attenuation through flexible adjustment.

Applications

A fiber optic attenuator is used in fiber optic communication systems, CWDM and DWDM, CATV systems, data center networks, test equipment, FTTx networks, telecommunication networks, local area network (LAN), digital multimedia transmission systems, etc.

Conclusion

A fiber optic attenuator is a crucial passive component in the fiber optic communication system. It can adjust optical signal levels to increase network flexibility and provide management of optical power. Sun Telecom provides a wide range of fiber optic attenuators. Contact us if you have any needs.

1 note

·

View note

Text

Understanding Optical Fiber Connectors

The use of optical fiber connectors is closely related to optical fiber systems under normal circumstances. When connectors are not widely used and are not easy to use, connector manufacturers standardize and simplify connectors to a large extent. In the process of using optical fiber system, it is more convenient for users to use connectors.

1.What is an optical fiber connector?

Optical fiber connector is a movable mechanism between optical fiber and optical fiber connecting device. Its function is to place the optical fiber on two precise platforms, so that the optical output of the optical energy can reach the optical fiber coupler of the receiving optical fiber to the greatest extent, to form an optical link, and to minimize the impact of the system. This is the basic requirement of optical fiber connectors. To a certain extent, optical fiber connectors also have an impact on the reliability of optical fiber transmission and system performance.

2.Key features of optical fiber connectors

The key characteristics of optical fiber connectors include optical properties, interchangeability, reproducibility, tensile strength, temperature, insertion times, etc.

1) Optical properties: The optical performance requirements of optical fiber connectors are mainly two basic parameters, insertion loss and return loss. The insertion loss is the loss of the effective light intensity of the connection, which is due to the insertion of the connector. The smaller the insertion loss, the better. Normally, the insertion loss should not be about 0.5dB. Echo loss (or reflection loss) refers to the suppression of the light intensity of the reflector in the link. Typical values should not be less than 25dB. In the practical application of connectors, the needle surface after special polishing can make the echo loss greater, usually no less than 45dB.

2)Interchangeability and reproducibility: Fiber optic connectors are general passive devices. The same type of fiber optic connectors can be used in any connection and can be used repeatedly. Therefore, in general, the additional entry loss is less than 0.2dB.

3) Tensile strength: For the connected optical fiber connectors, the tensile strength is not less than 90N in general.

4) Temperature: Usually, optical fiber connectors must be used in the temperature range of - 40 C to + 70 C.

5) Plug-in times: Usually, the current optical fiber connector can be plugged in more than 1,000 times.

3.Structure of Optical Fiber Connecto

Connections, permanent connections, or connectors can form optical fiber to optical fiber connections, which are different from plugging in, and can be disconnected and reconnected. With the development of application field, the types of optical fiber connectors are various. Different connector types have different characteristics, different advantages and disadvantages, and different performance parameters. But all connectors contain four basic components.

Plug-in pin: The optical fiber is installed in a long thin-walled cylinder, and the pin acts as the alignment mechanism of the optical fiber. The diameter of the pin is slightly larger than that of the optical fiber cladding. The end of the optical fiber is at the end of the pin. Generally, pins are made of metal or pottery, but they may also be plastic.

Connector body: Also known as connector housing, connector body accommodates pins. Usually the connector body is made of metal or plastic, including one or more parts, which can keep the optical fibers in proper position. Specific details of these connector assemblies vary depending on the type of connector, but welding and/or flanging are usually used to install reinforcement components and cable sheaths on the connector body. The pin extends and passes over the connector body and is clamped into the bonding device.

Optical cable: The optical cable is mounted on the connector body. Its function is the input point of optical fiber. In general, a strain relief shield is installed on the joint between the cable and the connector body to provide additional strength for the joint.

Connector: Most optical fiber connectors do not use the common head-to-head structure used in electronic connections. The structure adopted is a positioning sleeve for pairing connectors. Similar devices can be installed on optical transmitters and receivers, and these devices can be fitted with a connector. These devices are also known as through-type stuffy adapters.

4.Types of Optical Fiber Connectors

According to different classification methods, optical fiber connectors can be divided into different types. According to different transmission media, optical fiber connectors can be divided into single-mode and multi-mode optical fiber connectors. According to different structures, optical fiber connectors can be divided into various types, such as ST, SC, FC, LC, MT-RJ, MPO/MTP, MU, DIN, E2000, SMA, BICONIC, D4, etc. According to the different surface of pin end of connector, it can be divided into PC, UPC and APC. According to the number of fiber cores, fiber connectors can be divided into single fiber core and multi-fiber core fiber connectors. Overall, about 100 types of fiber optic connectors have been put on the market, but only a few have a larger share of the market. This is the leading list of connectors in the industry.

ST connectors: ST connectors are about the most popular connectors in multimode networks and are widely used in optical fiber wiring frames (ODFs), such as in most buildings and campuses. In this type of fiber optic connector, there is a clamp mounting base and a long cylindrical 2.5mm ceramic (usually) or polymer pin to accommodate the fiber. Most pins are ceramic, but some models are made of metal or plastic. ST connector with metal shell and nickel plated, can easily and quickly insert or pull out the optical cable. These connectors have ceramic pins and can perform 500 pairing cycles. In the long run, it is recommended to use a ST connector with a loss margin of 0.5dB or recommended by the vendor.

SC connector: This is an optical fiber connector developed by NTT Company in Japan. SC connector is a kind of plug-in connector with 2.5mm pin. Because of its excellent performance, it is widely used in various fields. The outer shell of the connector is rectangular and adopts a needle-shaped structure and a connecting sleeve. More PC or APC grinding methods are used on the surface of the end of the needle, while the fastening method uses the inserting needle bolt connection method, which does not need to be rotated when inserting. A simple push-pull action can lock the SC connector. Under the positioning of ceramic pins, SC connectors can be positioned accurately. A typical SC connector for matching can achieve 1000 pairing cycles. SC connectors are characterized by low price, low fluctuation loss, high compressive strength and high installation density

FC connector: FC connector was originally developed by NTT in Japan. The pin connector of FC connector is short. The 2.5mm pin is also used on the connector. The surface of the connector is strengthened by metal sleeve and the fastening method is screw joint. FC connector can locate optical fiber cable transmitted by light source transmitter and receiver optical detector very accurately. FC connector features a positioning notch and a threaded socket for positioning. FC connectors are constructed with nickel-plated metal housing. The connector has ceramic pins and can achieve 500 pairing cycles. This type of connector has simple structure and easy operation.

LC connector: LC connector is developed by the famous Bell Research Laboratory. It is easy to use and operates modular jack (RJ) latch mechanism. The size of pin and sleeve is half of that of conventional SC and FC, which is 1.25mm. The connector can improve the density of the optical fiber connector on the optical fiber distribution frame. In addition, standard ceramic pin connectors can be used on the connector, and any adhesive can be used to bond the connector. LC connectors are characterized by excellent performance and are highly suitable for single-mode optical fibers.

MT-RJ connector: MT-RJ connector is a dual connector, using single-mode and multi-mode fiber optic cables. A pin is used as a positioning device in this type of connector, and the model has a male head and a female head. The MT-RJ connector has a plastic shell and uses metal positioning pins and plastic pins to achieve accurate positioning. MT-RJ connector can achieve 1000 pairing cycles. The typical insertion loss of MT-RJ connectors in matching is 0.25dB for SMF and 0.35dB for MMF.

0 notes

Text

Understanding Optical Fiber Connectors

The use of optical fiber connectors is closely related to optical fiber systems under normal circumstances. When connectors are not widely used and are not easy to use, connector manufacturers standardize and simplify connectors to a large extent. In the process of using optical fiber system, it is more convenient for users to use connectors.

1.What is an optical fiber connector?

Optical fiber connector is a movable mechanism between optical fiber and optical fiber connecting device. Its function is to place the optical fiber on two precise platforms, so that the optical output of the optical energy can reach the optical fiber coupler of the receiving optical fiber to the greatest extent, to form an optical link, and to minimize the impact of the system. This is the basic requirement of optical fiber connectors. To a certain extent, optical fiber connectors also have an impact on the reliability of optical fiber transmission and system performance.

2.Key features of optical fiber connectors

The key characteristics of optical fiber connectors include optical properties, interchangeability, reproducibility, tensile strength, temperature, insertion times, etc.

1) Optical properties: The optical performance requirements of optical fiber connectors are mainly two basic parameters, insertion loss and return loss. The insertion loss is the loss of the effective light intensity of the connection, which is due to the insertion of the connector. The smaller the insertion loss, the better. Normally, the insertion loss should not be about 0.5dB. Echo loss (or reflection loss) refers to the suppression of the light intensity of the reflector in the link. Typical values should not be less than 25dB. In the practical application of connectors, the needle surface after special polishing can make the echo loss greater, usually no less than 45dB.

2)Interchangeability and reproducibility: Fiber optic connectors are general passive devices. The same type of fiber optic connectors can be used in any connection and can be used repeatedly. Therefore, in general, the additional entry loss is less than 0.2dB.

3) Tensile strength: For the connected optical fiber connectors, the tensile strength is not less than 90N in general.

4) Temperature: Usually, optical fiber connectors must be used in the temperature range of - 40 C to + 70 C.

5) Plug-in times: Usually, the current optical fiber connector can be plugged in more than 1,000 times.

3.Structure of Optical Fiber Connecto

Connections, permanent connections, or connectors can form optical fiber to optical fiber connections, which are different from plugging in, and can be disconnected and reconnected. With the development of application field, the types of optical fiber connectors are various. Different connector types have different characteristics, different advantages and disadvantages, and different performance parameters. But all connectors contain four basic components.

Plug-in pin: The optical fiber is installed in a long thin-walled cylinder, and the pin acts as the alignment mechanism of the optical fiber. The diameter of the pin is slightly larger than that of the optical fiber cladding. The end of the optical fiber is at the end of the pin. Generally, pins are made of metal or pottery, but they may also be plastic.

Connector body: Also known as connector housing, connector body accommodates pins. Usually the connector body is made of metal or plastic, including one or more parts, which can keep the optical fibers in proper position. Specific details of these connector assemblies vary depending on the type of connector, but welding and/or flanging are usually used to install reinforcement components and cable sheaths on the connector body. The pin extends and passes over the connector body and is clamped into the bonding device.

Optical cable: The optical cable is mounted on the connector body. Its function is the input point of optical fiber. In general, a strain relief shield is installed on the joint between the cable and the connector body to provide additional strength for the joint.

Connector: Most optical fiber connectors do not use the common head-to-head structure used in electronic connections. The structure adopted is a positioning sleeve for pairing connectors. Similar devices can be installed on optical transmitters and receivers, and these devices can be fitted with a connector. These devices are also known as through-type stuffy adapters.

4.Types of Optical Fiber Connectors

According to different classification methods, optical fiber connectors can be divided into different types. According to different transmission media, optical fiber connectors can be divided into single-mode and multi-mode optical fiber connectors. According to different structures, optical fiber connectors can be divided into various types, such as ST, SC, FC, LC, MT-RJ, MPO/MTP, MU, DIN, E2000, SMA, BICONIC, D4, etc. According to the different surface of pin end of connector, it can be divided into PC, UPC and APC. According to the number of fiber cores, fiber connectors can be divided into single fiber core and multi-fiber core fiber connectors. Overall, about 100 types of fiber optic connectors have been put on the market, but only a few have a larger share of the market. This is the leading list of connectors in the industry.

ST connectors: ST connectors are about the most popular connectors in multimode networks and are widely used in optical fiber wiring frames (ODFs), such as in most buildings and campuses. In this type of fiber optic connector, there is a clamp mounting base and a long cylindrical 2.5mm ceramic (usually) or polymer pin to accommodate the fiber. Most pins are ceramic, but some models are made of metal or plastic. ST connector with metal shell and nickel plated, can easily and quickly insert or pull out the optical cable. These connectors have ceramic pins and can perform 500 pairing cycles. In the long run, it is recommended to use a ST connector with a loss margin of 0.5dB or recommended by the vendor.

SC connector: This is an optical fiber connector developed by NTT Company in Japan. SC connector is a kind of plug-in connector with 2.5mm pin. Because of its excellent performance, it is widely used in various fields. The outer shell of the connector is rectangular and adopts a needle-shaped structure and a connecting sleeve. More PC or APC grinding methods are used on the surface of the end of the needle, while the fastening method uses the inserting needle bolt connection method, which does not need to be rotated when inserting. A simple push-pull action can lock the SC connector. Under the positioning of ceramic pins, SC connectors can be positioned accurately. A typical SC connector for matching can achieve 1000 pairing cycles. SC connectors are characterized by low price, low fluctuation loss, high compressive strength and high installation density

FC connector: FC connector was originally developed by NTT in Japan. The pin connector of FC connector is short. The 2.5mm pin is also used on the connector. The surface of the connector is strengthened by metal sleeve and the fastening method is screw joint. FC connector can locate optical fiber cable transmitted by light source transmitter and receiver optical detector very accurately. FC connector features a positioning notch and a threaded socket for positioning. FC connectors are constructed with nickel-plated metal housing. The connector has ceramic pins and can achieve 500 pairing cycles. This type of connector has simple structure and easy operation.

LC connector: LC connector is developed by the famous Bell Research Laboratory. It is easy to use and operates modular jack (RJ) latch mechanism. The size of pin and sleeve is half of that of conventional SC and FC, which is 1.25mm. The connector can improve the density of the optical fiber connector on the optical fiber distribution frame. In addition, standard ceramic pin connectors can be used on the connector, and any adhesive can be used to bond the connector. LC connectors are characterized by excellent performance and are highly suitable for single-mode optical fibers.

MT-RJ connector: MT-RJ connector is a dual connector, using single-mode and multi-mode fiber optic cables. A pin is used as a positioning device in this type of connector, and the model has a male head and a female head. The MT-RJ connector has a plastic shell and uses metal positioning pins and plastic pins to achieve accurate positioning. MT-RJ connector can achieve 1000 pairing cycles. The typical insertion loss of MT-RJ connectors in matching is 0.25dB for SMF and 0.35dB for MMF.

0 notes

Text

Understanding Optical Fiber Connectors

The use of optical fiber connectors is closely related to optical fiber systems under normal circumstances. When connectors are not widely used and are not easy to use, connector manufacturers standardize and simplify connectors to a large extent. In the process of using optical fiber system, it is more convenient for users to use connectors.

1.What is an optical fiber connector?

Optical fiber connector is a movable mechanism between optical fiber and optical fiber connecting device. Its function is to place the optical fiber on two precise platforms, so that the optical output of the optical energy can reach the optical fiber coupler of the receiving optical fiber to the greatest extent, to form an optical link, and to minimize the impact of the system. This is the basic requirement of optical fiber connectors. To a certain extent, optical fiber connectors also have an impact on the reliability of optical fiber transmission and system performance.

2.Key features of optical fiber connectors

The key characteristics of optical fiber connectors include optical properties, interchangeability, reproducibility, tensile strength, temperature, insertion times, etc.

1) Optical properties: The optical performance requirements of optical fiber connectors are mainly two basic parameters, insertion loss and return loss. The insertion loss is the loss of the effective light intensity of the connection, which is due to the insertion of the connector. The smaller the insertion loss, the better. Normally, the insertion loss should not be about 0.5dB. Echo loss (or reflection loss) refers to the suppression of the light intensity of the reflector in the link. Typical values should not be less than 25dB. In the practical application of connectors, the needle surface after special polishing can make the echo loss greater, usually no less than 45dB.

2)Interchangeability and reproducibility: Fiber optic connectors are general passive devices. The same type of fiber optic connectors can be used in any connection and can be used repeatedly. Therefore, in general, the additional entry loss is less than 0.2dB.

3) Tensile strength: For the connected optical fiber connectors, the tensile strength is not less than 90N in general.

4) Temperature: Usually, optical fiber connectors must be used in the temperature range of - 40 C to + 70 C.

5) Plug-in times: Usually, the current optical fiber connector can be plugged in more than 1,000 times.

3.Structure of Optical Fiber Connecto

Connections, permanent connections, or connectors can form optical fiber to optical fiber connections, which are different from plugging in, and can be disconnected and reconnected. With the development of application field, the types of optical fiber connectors are various. Different connector types have different characteristics, different advantages and disadvantages, and different performance parameters. But all connectors contain four basic components.

Plug-in pin: The optical fiber is installed in a long thin-walled cylinder, and the pin acts as the alignment mechanism of the optical fiber. The diameter of the pin is slightly larger than that of the optical fiber cladding. The end of the optical fiber is at the end of the pin. Generally, pins are made of metal or pottery, but they may also be plastic.

Connector body: Also known as connector housing, connector body accommodates pins. Usually the connector body is made of metal or plastic, including one or more parts, which can keep the optical fibers in proper position. Specific details of these connector assemblies vary depending on the type of connector, but welding and/or flanging are usually used to install reinforcement components and cable sheaths on the connector body. The pin extends and passes over the connector body and is clamped into the bonding device.

Optical cable: The optical cable is mounted on the connector body. Its function is the input point of optical fiber. In general, a strain relief shield is installed on the joint between the cable and the connector body to provide additional strength for the joint.

Connector: Most optical fiber connectors do not use the common head-to-head structure used in electronic connections. The structure adopted is a positioning sleeve for pairing connectors. Similar devices can be installed on optical transmitters and receivers, and these devices can be fitted with a connector. These devices are also known as through-type stuffy adapters.

4.Types of Optical Fiber Connectors

According to different classification methods, optical fiber connectors can be divided into different types. According to different transmission media, optical fiber connectors can be divided into single-mode and multi-mode optical fiber connectors. According to different structures, optical fiber connectors can be divided into various types, such as ST, SC, FC, LC, MT-RJ, MPO/MTP, MU, DIN, E2000, SMA, BICONIC, D4, etc. According to the different surface of pin end of connector, it can be divided into PC, UPC and APC. According to the number of fiber cores, fiber connectors can be divided into single fiber core and multi-fiber core fiber connectors. Overall, about 100 types of fiber optic connectors have been put on the market, but only a few have a larger share of the market. This is the leading list of connectors in the industry.

ST connectors: ST connectors are about the most popular connectors in multimode networks and are widely used in optical fiber wiring frames (ODFs), such as in most buildings and campuses. In this type of fiber optic connector, there is a clamp mounting base and a long cylindrical 2.5mm ceramic (usually) or polymer pin to accommodate the fiber. Most pins are ceramic, but some models are made of metal or plastic. ST connector with metal shell and nickel plated, can easily and quickly insert or pull out the optical cable. These connectors have ceramic pins and can perform 500 pairing cycles. In the long run, it is recommended to use a ST connector with a loss margin of 0.5dB or recommended by the vendor.

SC connector: This is an optical fiber connector developed by NTT Company in Japan. SC connector is a kind of plug-in connector with 2.5mm pin. Because of its excellent performance, it is widely used in various fields. The outer shell of the connector is rectangular and adopts a needle-shaped structure and a connecting sleeve. More PC or APC grinding methods are used on the surface of the end of the needle, while the fastening method uses the inserting needle bolt connection method, which does not need to be rotated when inserting. A simple push-pull action can lock the SC connector. Under the positioning of ceramic pins, SC connectors can be positioned accurately. A typical SC connector for matching can achieve 1000 pairing cycles. SC connectors are characterized by low price, low fluctuation loss, high compressive strength and high installation density

FC connector: FC connector was originally developed by NTT in Japan. The pin connector of FC connector is short. The 2.5mm pin is also used on the connector. The surface of the connector is strengthened by metal sleeve and the fastening method is screw joint. FC connector can locate optical fiber cable transmitted by light source transmitter and receiver optical detector very accurately. FC connector features a positioning notch and a threaded socket for positioning. FC connectors are constructed with nickel-plated metal housing. The connector has ceramic pins and can achieve 500 pairing cycles. This type of connector has simple structure and easy operation.

LC connector: LC connector is developed by the famous Bell Research Laboratory. It is easy to use and operates modular jack (RJ) latch mechanism. The size of pin and sleeve is half of that of conventional SC and FC, which is 1.25mm. The connector can improve the density of the optical fiber connector on the optical fiber distribution frame. In addition, standard ceramic pin connectors can be used on the connector, and any adhesive can be used to bond the connector. LC connectors are characterized by excellent performance and are highly suitable for single-mode optical fibers.

MT-RJ connector: MT-RJ connector is a dual connector, using single-mode and multi-mode fiber optic cables. A pin is used as a positioning device in this type of connector, and the model has a male head and a female head. The MT-RJ connector has a plastic shell and uses metal positioning pins and plastic pins to achieve accurate positioning. MT-RJ connector can achieve 1000 pairing cycles. The typical insertion loss of MT-RJ connectors in matching is 0.25dB for SMF and 0.35dB for MMF.

0 notes

Text

Understanding Optical Fiber Connectors

The use of optical fiber connectors is closely related to optical fiber systems under normal circumstances. When connectors are not widely used and are not easy to use, connector manufacturers standardize and simplify connectors to a large extent. In the process of using optical fiber system, it is more convenient for users to use connectors.

1.What is an optical fiber connector?

Optical fiber connector is a movable mechanism between optical fiber and optical fiber connecting device. Its function is to place the optical fiber on two precise platforms, so that the optical output of the optical energy can reach the optical fiber coupler of the receiving optical fiber to the greatest extent, to form an optical link, and to minimize the impact of the system. This is the basic requirement of optical fiber connectors. To a certain extent, optical fiber connectors also have an impact on the reliability of optical fiber transmission and system performance.

2.Key features of optical fiber connectors

The key characteristics of optical fiber connectors include optical properties, interchangeability, reproducibility, tensile strength, temperature, insertion times, etc.

1) Optical properties: The optical performance requirements of optical fiber connectors are mainly two basic parameters, insertion loss and return loss. The insertion loss is the loss of the effective light intensity of the connection, which is due to the insertion of the connector. The smaller the insertion loss, the better. Normally, the insertion loss should not be about 0.5dB. Echo loss (or reflection loss) refers to the suppression of the light intensity of the reflector in the link. Typical values should not be less than 25dB. In the practical application of connectors, the needle surface after special polishing can make the echo loss greater, usually no less than 45dB.

2)Interchangeability and reproducibility: Fiber optic connectors are general passive devices. The same type of fiber optic connectors can be used in any connection and can be used repeatedly. Therefore, in general, the additional entry loss is less than 0.2dB.

3) Tensile strength: For the connected optical fiber connectors, the tensile strength is not less than 90N in general.

4) Temperature: Usually, optical fiber connectors must be used in the temperature range of - 40 C to + 70 C.

5) Plug-in times: Usually, the current optical fiber connector can be plugged in more than 1,000 times.

3.Structure of Optical Fiber Connecto

Connections, permanent connections, or connectors can form optical fiber to optical fiber connections, which are different from plugging in, and can be disconnected and reconnected. With the development of application field, the types of optical fiber connectors are various. Different connector types have different characteristics, different advantages and disadvantages, and different performance parameters. But all connectors contain four basic components.

Plug-in pin: The optical fiber is installed in a long thin-walled cylinder, and the pin acts as the alignment mechanism of the optical fiber. The diameter of the pin is slightly larger than that of the optical fiber cladding. The end of the optical fiber is at the end of the pin. Generally, pins are made of metal or pottery, but they may also be plastic.

Connector body: Also known as connector housing, connector body accommodates pins. Usually the connector body is made of metal or plastic, including one or more parts, which can keep the optical fibers in proper position. Specific details of these connector assemblies vary depending on the type of connector, but welding and/or flanging are usually used to install reinforcement components and cable sheaths on the connector body. The pin extends and passes over the connector body and is clamped into the bonding device.

Optical cable: The optical cable is mounted on the connector body. Its function is the input point of optical fiber. In general, a strain relief shield is installed on the joint between the cable and the connector body to provide additional strength for the joint.

Connector: Most optical fiber connectors do not use the common head-to-head structure used in electronic connections. The structure adopted is a positioning sleeve for pairing connectors. Similar devices can be installed on optical transmitters and receivers, and these devices can be fitted with a connector. These devices are also known as through-type stuffy adapters.

4.Types of Optical Fiber Connectors

According to different classification methods, optical fiber connectors can be divided into different types. According to different transmission media, optical fiber connectors can be divided into single-mode and multi-mode optical fiber connectors. According to different structures, optical fiber connectors can be divided into various types, such as ST, SC, FC, LC, MT-RJ, MPO/MTP, MU, DIN, E2000, SMA, BICONIC, D4, etc. According to the different surface of pin end of connector, it can be divided into PC, UPC and APC. According to the number of fiber cores, fiber connectors can be divided into single fiber core and multi-fiber core fiber connectors. Overall, about 100 types of fiber optic connectors have been put on the market, but only a few have a larger share of the market. This is the leading list of connectors in the industry.

ST connectors: ST connectors are about the most popular connectors in multimode networks and are widely used in optical fiber wiring frames (ODFs), such as in most buildings and campuses. In this type of fiber optic connector, there is a clamp mounting base and a long cylindrical 2.5mm ceramic (usually) or polymer pin to accommodate the fiber. Most pins are ceramic, but some models are made of metal or plastic. ST connector with metal shell and nickel plated, can easily and quickly insert or pull out the optical cable. These connectors have ceramic pins and can perform 500 pairing cycles. In the long run, it is recommended to use a ST connector with a loss margin of 0.5dB or recommended by the vendor.

SC connector: This is an optical fiber connector developed by NTT Company in Japan. SC connector is a kind of plug-in connector with 2.5mm pin. Because of its excellent performance, it is widely used in various fields. The outer shell of the connector is rectangular and adopts a needle-shaped structure and a connecting sleeve. More PC or APC grinding methods are used on the surface of the end of the needle, while the fastening method uses the inserting needle bolt connection method, which does not need to be rotated when inserting. A simple push-pull action can lock the SC connector. Under the positioning of ceramic pins, SC connectors can be positioned accurately. A typical SC connector for matching can achieve 1000 pairing cycles. SC connectors are characterized by low price, low fluctuation loss, high compressive strength and high installation density

FC connector: FC connector was originally developed by NTT in Japan. The pin connector of FC connector is short. The 2.5mm pin is also used on the connector. The surface of the connector is strengthened by metal sleeve and the fastening method is screw joint. FC connector can locate optical fiber cable transmitted by light source transmitter and receiver optical detector very accurately. FC connector features a positioning notch and a threaded socket for positioning. FC connectors are constructed with nickel-plated metal housing. The connector has ceramic pins and can achieve 500 pairing cycles. This type of connector has simple structure and easy operation.

LC connector: LC connector is developed by the famous Bell Research Laboratory. It is easy to use and operates modular jack (RJ) latch mechanism. The size of pin and sleeve is half of that of conventional SC and FC, which is 1.25mm. The connector can improve the density of the optical fiber connector on the optical fiber distribution frame. In addition, standard ceramic pin connectors can be used on the connector, and any adhesive can be used to bond the connector. LC connectors are characterized by excellent performance and are highly suitable for single-mode optical fibers.

MT-RJ connector: MT-RJ connector is a dual connector, using single-mode and multi-mode fiber optic cables. A pin is used as a positioning device in this type of connector, and the model has a male head and a female head. The MT-RJ connector has a plastic shell and uses metal positioning pins and plastic pins to achieve accurate positioning. MT-RJ connector can achieve 1000 pairing cycles. The typical insertion loss of MT-RJ connectors in matching is 0.25dB for SMF and 0.35dB for MMF.

0 notes

Text

Understanding Optical Fiber Connectors

The use of optical fiber connectors is closely related to optical fiber systems under normal circumstances. When connectors are not widely used and are not easy to use, connector manufacturers standardize and simplify connectors to a large extent. In the process of using optical fiber system, it is more convenient for users to use connectors.

1.What is an optical fiber connector?

Optical fiber connector is a movable mechanism between optical fiber and optical fiber connecting device. Its function is to place the optical fiber on two precise platforms, so that the optical output of the optical energy can reach the optical fiber coupler of the receiving optical fiber to the greatest extent, to form an optical link, and to minimize the impact of the system. This is the basic requirement of optical fiber connectors. To a certain extent, optical fiber connectors also have an impact on the reliability of optical fiber transmission and system performance.

2.Key features of optical fiber connectors

The key characteristics of optical fiber connectors include optical properties, interchangeability, reproducibility, tensile strength, temperature, insertion times, etc.

1) Optical properties: The optical performance requirements of optical fiber connectors are mainly two basic parameters, insertion loss and return loss. The insertion loss is the loss of the effective light intensity of the connection, which is due to the insertion of the connector. The smaller the insertion loss, the better. Normally, the insertion loss should not be about 0.5dB. Echo loss (or reflection loss) refers to the suppression of the light intensity of the reflector in the link. Typical values should not be less than 25dB. In the practical application of connectors, the needle surface after special polishing can make the echo loss greater, usually no less than 45dB.

2)Interchangeability and reproducibility: Fiber optic connectors are general passive devices. The same type of fiber optic connectors can be used in any connection and can be used repeatedly. Therefore, in general, the additional entry loss is less than 0.2dB.

3) Tensile strength: For the connected optical fiber connectors, the tensile strength is not less than 90N in general.

4) Temperature: Usually, optical fiber connectors must be used in the temperature range of - 40 C to + 70 C.

5) Plug-in times: Usually, the current optical fiber connector can be plugged in more than 1,000 times.

3.Structure of Optical Fiber Connecto

Connections, permanent connections, or connectors can form optical fiber to optical fiber connections, which are different from plugging in, and can be disconnected and reconnected. With the development of application field, the types of optical fiber connectors are various. Different connector types have different characteristics, different advantages and disadvantages, and different performance parameters. But all connectors contain four basic components.

Plug-in pin: The optical fiber is installed in a long thin-walled cylinder, and the pin acts as the alignment mechanism of the optical fiber. The diameter of the pin is slightly larger than that of the optical fiber cladding. The end of the optical fiber is at the end of the pin. Generally, pins are made of metal or pottery, but they may also be plastic.

Connector body: Also known as connector housing, connector body accommodates pins. Usually the connector body is made of metal or plastic, including one or more parts, which can keep the optical fibers in proper position. Specific details of these connector assemblies vary depending on the type of connector, but welding and/or flanging are usually used to install reinforcement components and cable sheaths on the connector body. The pin extends and passes over the connector body and is clamped into the bonding device.

Optical cable: The optical cable is mounted on the connector body. Its function is the input point of optical fiber. In general, a strain relief shield is installed on the joint between the cable and the connector body to provide additional strength for the joint.

Connector: Most optical fiber connectors do not use the common head-to-head structure used in electronic connections. The structure adopted is a positioning sleeve for pairing connectors. Similar devices can be installed on optical transmitters and receivers, and these devices can be fitted with a connector. These devices are also known as through-type stuffy adapters.

4.Types of Optical Fiber Connectors

According to different classification methods, optical fiber connectors can be divided into different types. According to different transmission media, optical fiber connectors can be divided into single-mode and multi-mode optical fiber connectors. According to different structures, optical fiber connectors can be divided into various types, such as ST, SC, FC, LC, MT-RJ, MPO/MTP, MU, DIN, E2000, SMA, BICONIC, D4, etc. According to the different surface of pin end of connector, it can be divided into PC, UPC and APC. According to the number of fiber cores, fiber connectors can be divided into single fiber core and multi-fiber core fiber connectors. Overall, about 100 types of fiber optic connectors have been put on the market, but only a few have a larger share of the market. This is the leading list of connectors in the industry.

ST connectors: ST connectors are about the most popular connectors in multimode networks and are widely used in optical fiber wiring frames (ODFs), such as in most buildings and campuses. In this type of fiber optic connector, there is a clamp mounting base and a long cylindrical 2.5mm ceramic (usually) or polymer pin to accommodate the fiber. Most pins are ceramic, but some models are made of metal or plastic. ST connector with metal shell and nickel plated, can easily and quickly insert or pull out the optical cable. These connectors have ceramic pins and can perform 500 pairing cycles. In the long run, it is recommended to use a ST connector with a loss margin of 0.5dB or recommended by the vendor.

SC connector: This is an optical fiber connector developed by NTT Company in Japan. SC connector is a kind of plug-in connector with 2.5mm pin. Because of its excellent performance, it is widely used in various fields. The outer shell of the connector is rectangular and adopts a needle-shaped structure and a connecting sleeve. More PC or APC grinding methods are used on the surface of the end of the needle, while the fastening method uses the inserting needle bolt connection method, which does not need to be rotated when inserting. A simple push-pull action can lock the SC connector. Under the positioning of ceramic pins, SC connectors can be positioned accurately. A typical SC connector for matching can achieve 1000 pairing cycles. SC connectors are characterized by low price, low fluctuation loss, high compressive strength and high installation density

FC connector: FC connector was originally developed by NTT in Japan. The pin connector of FC connector is short. The 2.5mm pin is also used on the connector. The surface of the connector is strengthened by metal sleeve and the fastening method is screw joint. FC connector can locate optical fiber cable transmitted by light source transmitter and receiver optical detector very accurately. FC connector features a positioning notch and a threaded socket for positioning. FC connectors are constructed with nickel-plated metal housing. The connector has ceramic pins and can achieve 500 pairing cycles. This type of connector has simple structure and easy operation.

LC connector: LC connector is developed by the famous Bell Research Laboratory. It is easy to use and operates modular jack (RJ) latch mechanism. The size of pin and sleeve is half of that of conventional SC and FC, which is 1.25mm. The connector can improve the density of the optical fiber connector on the optical fiber distribution frame. In addition, standard ceramic pin connectors can be used on the connector, and any adhesive can be used to bond the connector. LC connectors are characterized by excellent performance and are highly suitable for single-mode optical fibers.

MT-RJ connector: MT-RJ connector is a dual connector, using single-mode and multi-mode fiber optic cables. A pin is used as a positioning device in this type of connector, and the model has a male head and a female head. The MT-RJ connector has a plastic shell and uses metal positioning pins and plastic pins to achieve accurate positioning. MT-RJ connector can achieve 1000 pairing cycles. The typical insertion loss of MT-RJ connectors in matching is 0.25dB for SMF and 0.35dB for MMF.

0 notes

Text

Fiber Optics Attenuators - The Ultime Guide on How they work?

An optical attenuator is a passive device used to reduce the power level of an optical signal, either in free space or in an optical fiber. There are various types of them from the fixed ones, step-wise variable, and continuously variable. Attenuators are usually used when the signal arriving at the receiver is too strong and hence may overpower the receiving elements. This may occur because of a mismatch between the transmitters/receivers, or because the media converters are designed for a much longer distance than for which they are being used. Sometimes attenuators are also used for stress testing a network link by incrementally reducing the signal strength until the optical link fails, determining the signal’s existing safety margin. Although fiber optic attenuators are normally used in SM (Single Mode) circuits, because this is where the stronger lasers are used for distance transmission, there are also multi mode attenuators available. The most common version of attenuators are male to female units, often called plug-style or buildout style. These plug-style attenuators simply mount on one end of a fiber optic cable, allowing that cable to be plugged into the receiving equipment or panel. There are also female to female (bulkhead) attenuators, often used to mount in patch panels or for connecting two fiber optic cables together. More expensive, but useful for testing, are variable attenuators which are adjustable between 1dB and 30dB. Bear in mind that the dB ratings are a measure of signal strength and can sometimes be confusing. The chart below will give you an idea of the percent of attenuation of your signal for specific dB values. Fiber optic attenuators are usually used in two scenarios. The first case is in power level testing. Optical attenuators are used to temporarily add a calibrated amount of signal loss in order to test the power level margins in a fiber optic communication system. In the second case, optical attenuators are permanently installed in a fiber optic communication link to properly match transmitter and receiver optical signal levels. How many types of Optical Attenuators (OA) can you find? There are four different types of OA and they can take a number of different forms and are typically classified as fixed or variable attenuators. What's more, they can be classified as LC, SC, ST, FC, MU, E2000 etc. according to the different types of connectors. 1. Fixed Attenuators: Fixed optical attenuators used in fiber optic systems may use a variety of principles for their functioning. Preferred attenuators use either doped fibers, or misaligned splices, or total power since both of these are reliable and inexpensive. Inline style attenuators are incorporated into patch cables. The alternative build out style attenuator is a small male-female adapter that can be added onto other cables. Non-preferred attenuators often use gap loss or reflective principles. Such devices can be sensitive to modal distribution, wavelength, contamination, vibration, temperature, damage due to power bursts, may cause back reflections, may cause signal dispersion etc. 2. Loopback Attenuators: Loopback fiber optic attenuator is designed for testing, engineering and the burn-in stage of boards or other equipment. Available in SC/UPC, SC/APC, LC/UPC, LC/APC, MTRJ, MPO for single mode application. 3. Built-in Variable Attenuators: Built-in variable optical attenuators may be either manually or electrically controlled. A manual device is useful for one-time set up of a system, and is a near-equivalent to a fixed attenuator, and may be referred to as an "adjustable attenuator". In contrast, an electrically controlled attenuator can provide adaptive power optimization. Attributes of merit for electrically controlled devices, include speed of response and avoiding degradation of the transmitted signal. Dynamic range is usually quite restricted, and power feedback may mean that long-term stability is a relatively minor issue. The speed of response is a particularly major issue in dynamically reconfigurable systems, where a delay of one millionth of a second can result in the loss of large amounts of transmitted data. Typical technologies employed for high-speed response include liquid crystal variable attenuator (LCVA), or lithium niobate devices. There is a class of built-in attenuators that is technically indistinguishable from test attenuators, except they are packaged for rack mounting, and have no test display. 4. Variable Optical Test Attenuators: this type generally uses a variable neutral density filter. Despite the relatively high cost, this arrangement has the advantages of being stable, wavelength insensitive, mode insensitive, and offering a large dynamic range. Other schemes such as LCD, variable air gap etc. have been tried over the years, but with limited success. They may be either manually or motor control. Motor control gives regular users a distinct productivity advantage since commonly used test sequences can be run automatically.

0 notes

Text

Tripp Lite - 1ft Lc Sc 62.5 125 Fiber Adapt Free Shipping

New Post has been published on https://vellicore.com/product/tripp-lite-1ft-lc-sc-625-125-fiber-adapt-dhn45800162/

Tripp Lite - 1ft Lc Sc 62.5 125 Fiber Adapt Free Shipping – $33.75 – https://vellicore.com/product/tripp-lite-1ft-lc-sc-625-125-fiber-adapt-dhn45800162/

Tripp Lite 1ft Lc Sc 62 5 125 Fiber Adapt 0 3M (1 ft ) Duplex MMF 62 5/125 Adapter (LC Male/SC Female) Tripp Lites N458 001 62, 62 5/125 micron, LC/SC, Male to Female Fiber adapter cable allows you to utilize older installed SC fiber cables when upgrading to newer switches using LC type SFP or GBIC transceivers Simply plug the LC male end into the new switch, and plug your existing SC cables into the Female SC ends No need to scrap your existing fiber cable plant with all new cables For installations utilizing 50/125 micron cable, see N458 001 50 Tripp Lite warrants its cables to be free from defects in material and workmanship for life MPN: N458 001 62 Manufacturer: Tripp Lite UPC: 037332135391

Tripp Lite – 1ft Lc Sc 62.5 125 Fiber Adapt Free Shipping Cables Computer & AV Fiber Optic Cables

Manufacturer Number: N45800162

0 notes