#SAP SCM

Explore tagged Tumblr posts

Text

Streamline Your Supply Chain with SAP SCM: What You Need to Know

In today’s fast-paced business environment, managing a supply chain is no easy feat. Companies must keep track of inventory, suppliers, production schedules, and customer orders, all while ensuring smooth delivery and minimizing costs. This is where SAP Supply Chain Management (SAP SCM) comes into play, offering a robust solution that can help businesses optimize their supply chain and improve overall operational efficiency.

In this blog, we’ll explore what SAP SCM is, how it works, and why businesses of all sizes are turning to this powerful tool to streamline their supply chain processes.

What is SAP Supply Chain Management?

At its core, SAP Supply Chain Management (SAP SCM) is a software solution designed to help businesses manage and optimize their supply chain operations. It’s part of the broader SAP ERP (Enterprise Resource Planning) suite, and it integrates key aspects of the supply chain, from procurement and production to logistics and customer delivery.

SAP SCM provides tools for companies to plan, track, and execute their supply chain activities efficiently. This software helps improve visibility, enhance communication, and make data-driven decisions that reduce costs and increase overall business performance.

How SAP SCM Works

The primary goal of SAP SCM is to ensure that products and materials move through the supply chain as efficiently as possible. Let’s break down some of the key processes that SAP SCM helps businesses manage:

Demand Planning: SAP SCM helps businesses forecast product demand using historical data, trends, and customer information. This ensures that companies produce or order the right amount of goods at the right time, avoiding overstocking or stockouts.

Procurement and Sourcing: Once the demand is forecasted, SAP SCM helps businesses source materials or finished goods from suppliers. By automating procurement processes, companies can save time, reduce errors, and ensure they’re ordering the right items in the right quantities.

Production Planning: SAP SCM allows companies to plan production schedules, allocate resources, and track progress. By aligning production with demand forecasts, businesses can ensure they’re making the right amount of product and meeting customer needs.

Inventory Management: With SAP SCM, businesses can track inventory levels in real time, ensuring that goods are available when needed and reducing the risk of excess stock. This helps companies lower storage costs and improve cash flow.

Logistics and Distribution: SAP Supply Chain Management coordinates the movement of goods from warehouses to customers, managing everything from transportation to route planning. This ensures timely delivery and helps businesses avoid costly delays.

Sales and Customer Delivery: Finally, SAP SCM ensures that products are delivered to customers on time and in full, improving customer satisfaction and helping businesses build stronger relationships with their clients.

Key Benefits of SAP SCM

SAP SCM isn’t just about improving efficiency—it also offers a range of other benefits that can have a significant impact on a company’s bottom line. Here are some of the key advantages:

Increased Efficiency: By automating manual processes and providing real-time data, SAP SCM allows businesses to operate more efficiently. It helps eliminate bottlenecks and reduces the time spent on administrative tasks, enabling teams to focus on more value-added activities.

Cost Reduction: SAP SCM helps businesses reduce costs in various areas, including inventory management, production, and transportation. By optimizing these processes, companies can lower their operating expenses, improve cash flow, and increase profitability.

Improved Collaboration: With SAP SCM, different departments within a business, as well as external suppliers and distributors, can collaborate more effectively. The software integrates information across the supply chain, ensuring everyone is on the same page and reducing the risk of miscommunication or delays.

Better Decision-Making: With built-in analytics and reporting tools, SAP SCM provides businesses with valuable insights into their supply chain operations. This allows decision-makers to identify trends, predict future demand, and make data-driven decisions that improve performance.

Scalability: As a business grows, so does its supply chain. SAP SCM is highly scalable, meaning it can accommodate increasing complexity as companies expand their operations. Whether a business is entering new markets, adding new products, or managing a larger supply base, SAP SCM can grow with them.

How SAP SCM Supports Digital Transformation

In today’s world, digital transformation is key to staying competitive. SAP SCM plays a pivotal role in this transformation by integrating new technologies like cloud computing, IoT (Internet of Things), and machine learning into supply chain management.

Cloud Computing: Cloud-based SAP SCM enables businesses to access real-time data from anywhere, making it easier for teams to collaborate and make informed decisions on the go.

IoT Integration: By connecting IoT devices like RFID tags and sensors, SAP SCM can track inventory and shipments in real-time, providing valuable data that helps businesses optimize their supply chain operations.

Machine Learning: With machine learning capabilities, SAP SCM can analyze historical data to predict future demand, optimize routes for delivery, and even identify potential supply chain disruptions before they occur.

Challenges of Implementing SAP SCM

While the benefits of SAP SCM are clear, implementing the system can come with some challenges. These may include:

Complexity: SAP SCM is a powerful and comprehensive system, but it can also be complex. Proper training and expertise are required to fully leverage its capabilities.

Cost: The initial cost of implementing SAP SCM can be high, particularly for smaller businesses. However, the long-term benefits often outweigh the initial investment.

Integration: Integrating SAP SCM with other existing systems can be a challenge, especially for businesses that rely on outdated or incompatible software.

Final Thoughts

In an increasingly competitive and fast-moving marketplace, businesses need to leverage every tool at their disposal to stay ahead. SAP Supply Chain Management (SAP SCM) offers a powerful, scalable solution that can streamline your supply chain, improve efficiency, and reduce costs. By automating key processes and integrating real-time data, SAP SCM helps businesses make smarter decisions, collaborate more effectively, and deliver products to customers faster.

If you’re looking to optimize your supply chain operations, SAP SCM is definitely worth considering. With the right implementation and strategy, it can help your business not only survive but thrive in today’s dynamic business landscape.

0 notes

Text

Why Should You Learn SAP SCM Course Today

Boost your career with an SAP SCM course today! Master supply chain processes like planning, procurement, and logistics with hands-on SAP tools. Stay ahead in the competitive market with in-demand skills valued across industries. Enhance efficiency, reduce costs, and drive business growth. Unlock endless opportunities in supply chain management with SAP expertise!

0 notes

Text

Valtitude S & OP

Sales and Operations Planning Process thrives on collaboration and honest communication between key organizational players. This is a unique process embodying several information sharing sessions and decision forums. The final intent here is to generate an organizational plan and key Sales and Operations issues for the top organizational manager to decide on.

We kick off the S&OP implementation with an on-site workshop to be attended by your sponsors and stakeholders. For many companies on the wall about taking the plunge, this workshop will be a key input and bring to fore many company-specific drivers. Our on-site workshop addresses the following key steps in developing and implementing an effective S&OP process.

By having your key stakeholders attend this workshop, you attain a huge competitive advantage in moving forward the idea of integrated business planning.

To know More, Visit Us:

#Demand planning#Forecasting consulting#Value chain planning#Supply chain management#Forecasting#SCM#Valtitude#Demand Planning#S&OP Forecasting Consulting#Supply Chain Management Software#IBP#Supply Chain Optimization#SAP SCM#APO modeling#forecasting tool#SAP#Usability#Analytics#IBP Demand#IBP Inventory#IBP Supply#ForecastPro#Forecasting Tool#Demand Modeling#APS#SAP SCM APO#Solutions Tuning#Re-implementation#SAP IBP#integrated business planning

0 notes

Text

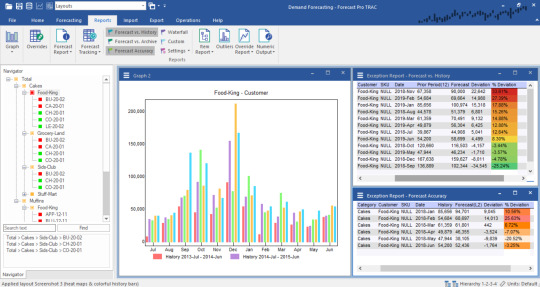

FORECAST VALUE ADD REPORTING

With Forecast Value Add reporting you can track accuracy across each step of your forecasting process. Easily compare the statistical forecast, final forecast, and/or specific overrides to what actually happened. This at-a-glance report helps you quickly identify which steps or participants in your forecasting process are adding value and which are making your forecasts less accurate.

To know More, Visit Us:

#Valtitude#Demand Planning#S&OP Forecasting Consulting#Supply Chain Management Software#IBP#Supply Chain Optimization#Forecasting Consulting#Demand Modeling#Demand Sensing#valtitude#SAP SCM#APO modeling#forecasting tool#SAP#Usability#Analytics#IBP Demand#IBP Inventory#IBP Supply#S&OP Workshop#demand planning workshop#Demand Planning for S&OP Workshop#demand planning workshop in India

0 notes

Text

Create a more streamlined planning process and organization by asking the right questions:

Has APO helped improve our forecast accuracy?

Are there products and customers that are better left to APO's automated modeling strategies?

Am I using a segmented modeling approach?

How many customer/product segmentations are being reviewed by my demand planners each month?

Are the statistical models tuned? How do we set the various model parameters to produce good forecasts?

Am I using an exception-oriented process in my forecasting activity?

How is APO helping us simplify and improve the promotional planning process? Is it integrated into the CRM system?

Have I created the correct customer grouping for leveraging correlations across customer forecast errors?

Has the system simplified and improved forecast reporting process?

Are we using the system defined error metrics in APO?

To know More, Visit Us:

#Valtitude#Demand Planning#S&OP Forecasting Consulting#Supply Chain Management Software#IBP#Supply Chain Optimization#SAP SCM#APO modeling#forecasting tool#Forecasting Consulting#Demand Modeling#Demand Sensing#valtitude#SAP#Usability#Analytics#IBP Demand#IBP Inventory#IBP Supply

0 notes

Text

INVENTORY OPTIMIZATION FOR SUPPLY CHAIN PLANNING HANDS-ON WORKSHOP

This program has been developed to communicate industry best practices in the area of inventory management to Supply Chain professionals.

It aims to provide the necessary technical background to enable attendees to develop & implement best practices & procedures in materials management into their own business units. It will holistically present the best practices and explain the concepts and calculations for optimizing your inventory parameters.

We preach true inventory optimization - help you to establish the right parameters your process and systems may need to run a lean machine with just optimal inventories to deliver the service and fill rates. This is a hands-on, practical workshop with many exercises and case studies and excel-based work out problems. Every planner and material manager will leave the training hall with a diverse skill set to do their day to day jobs.

To know More, Visit Us:

#Valtitude#Demand Planning#S&OP Forecasting Consulting#Supply Chain Management Software#IBP#Supply Chain Optimization#SAP SCM#APO modeling#forecasting tool#SAP#Usability#Analytics#IBP Demand#IBP Inventory#IBP Supply#Forecasting Consulting#Demand Modeling#Demand Sensing#valtitude#S&OP Workshop#demand planning workshop#Demand Planning for S&OP Workshop#demand planning workshop in India#demandplanning#forecasting consulting#advancedplanning#digitalsupplychain#forecasting#inventoryoptimization#realtimeplanning

0 notes

Text

WORKSHOP ON Demand Planning for S&OP :

An accurate demand plan helps you reduce inventory costs and increase customer service levels. When properly implemented, the demand plan helps create a lean and customer-centric supply chain.

In this workshop, you will learn how to develop a baseline statistical forecast and leverage a collaborative process to add customer intelligence. The result is a more accurate plan that includes promotional activity, customer intelligence, and display activity.

This two-day intensive workshop will take you through an overview of the demand planning process, and the organization and structure within a supply chain. Our course comprehensively covers statistical modeling to create accurate forecasts, in-depth discussion on model diagnostics to improve the quality of the forecast models with specific references to popular applications such as SAP IBP, Oracle, Demantra, ForecastPro, etc.

To know More, Visit Us:

#Forecasting Consulting#demand planning workshop#demand planning#Valtitude#Demand Planning#S&OP Forecasting Consulting#Supply Chain Management Software#IBP#Supply Chain Optimization#SAP SCM#APO modeling#forecasting tool#SAP#Usability#Analytics#IBP Demand#IBP Inventory#IBP Supply#Demand Modeling#Demand Sensing#valtitude#S&OP Workshop#Demand Planning for S&OP Workshop#demand planning workshop in India

0 notes

Text

IBP Process brings together all elements of Sales, Marketing, Finance and Operations into one integrated set of plans.

Our approach is two-pronged - we help with the diagnostics for implementing a holistic Integrated Business Planning process that is agnostic to the tool. Then we evaluate your systems landscape and resource readiness to implement SAP IBP.

Three weeks on-site

IBP Subject Matter Experts

SCM Data analytics to uncover the opportunity

50% of the diagnostics engagement fee rebated if we implement the IBP Solution

Analyze your existing processes to identify potential gaps to best practices

Let Data drive the Design: Leverage big data and analytics to build the infrastructure and capabilities. What type of analytics and KPIs do we need for a successful implementation.

What is the value opportunity for the IBP implementation?

If you are a company with a well established SAP APO Process, what are the steps necessary for conversion from APO to SAP IBP?

How does IBP add value to your planning process?

OUR CONSULTING MODEL EMPLOYS THE SIX-SIGMA METHODOLOGY OF DMAIC:

Define

Measure

Analyze

Improve and Control

Because of the diverse experience of DemandPlanning.Net Consultants, we can design and deliver the process in almost half the time and resource costs required by some of the bigger consulting houses. We add value to your process design in two ways:

With our knowledge base of best practices and the benchmark industry process, we can analyze and recommend processes and benchmarks rather quickly

Our central philosophy is exception management grounded in the Six-Sigma principles. This helps design a very effective process that is time-efficient as well

A quick three week engagement to assess your organizational readiness for implementing IBP

#IBP#Planning#SAP IBP#APO#Valtitude#Integrated Business Planning Process#Demand Planning#S&OP Forecasting Consulting#Supply Chain Management Software#Supply Chain Optimization#SAP SCM#APO modeling#forecasting tool#forecasting#supplychainvisibility#realtimeplanning#sapdigitalcore#advancedplanning#inventoryoptimization#supplychainmanagement#digitalsupplychain#sapcloud

0 notes

Text

What should be the Guiding objective of the Corporate supply chain?

Improving forecast accuracy?

Customer in-stock levels

Minimize inventory

Lowest cost production and distribution?

The essence of Supply Chain Planning is the Order to Cash process or the continuum of Plan - Source - Make - Deliver.

Popularly nicknamed as SCM Transformation Consulting refers to helping organizations transform their Supply Chain Management Process. We design and implement the S&OP process and help our clients roll-out the optimal technology.

#Supply Planning#Consulting#SCM#Valtitude#SAP SCM#APO modeling#forecasting tool#Demand Planning#S&OP Forecasting Consulting#Supply Chain Management Software#IBP#Supply Chain Optimization#forecasting#realtimeplanning#supplychainvisibility#inventoryoptimization#sapdigitalcore#supplychainmanagement#advancedplanning#digitalsupplychain#sapcloud#demandplanning

0 notes

Text

With a variety of statistical models and demand planning features, SAP SCM is a powerful forecasting tool. It includes Life cycle planning, Time series profiling, Outlier Detection and Exception Management as well.

So is your company leveraging the full functionality of APO modeling and exception management?

At Valtitude, we help you develop consistent processes to leverage the modeling power of the SAP SCM engine from basic time series models to multiple regression models.

If your planning process with SAP needs to be re-engineered, we offer Re-design and configuration. Configure and implement a brand new APO planning environment or fix challenges created by the original implementation with better performance usability.

Our Model Tuning Consulting Service will leverage the features in the existing configuration and optimize the Statistical capabilities.

#forecasting#supplychainvisibility#realtimeplanning#sapdigitalcore#advancedplanning#inventoryoptimization#supplychainmanagement#digitalsupplychain#sapcloud#demandplanning#SAP SCM#APO modeling#forecasting tool#Valtitude#Demand Planning#S&OP Forecasting Consulting#Supply Chain Management Software#IBP#Supply Chain Optimization

0 notes

Text

SAP SCM Certification

Achieve SAP SCM Certification to master supply chain management processes. Learn to optimize logistics, planning, and procurement using SAP software. Enhance your expertise in inventory management, demand planning, and production scheduling, gaining recognition as a proficient SAP Supply Chain Management professional.

2 notes

·

View notes

Text

VALTITUDE SALES AND OPERATIONS PLANNING

Manufacturers in the Consumer Packages Goods Sector were the early adopters of Supply Chain Forecasting. Catering to the firm's demand of the retail partners, CPG manufacturers focused on minimizing the forecast error to drive fill rates and lower inventory carrying costs.

As a natural progression, CPG companies started adopting the S&OP process to develop forecast consensus and holistic planning.

Most of their supply chains have an active S&OP process, which is cross-functional with participation from Sales, Marketing, Logistics, Supply Planning, Finance, Sales Planning, and Demand Planning. Typically, there is a one-number philosophy although the more practical processes advocate tolerances between forecasts with different objectives.

To know More, Visit Us:

#Demand planning#Forecasting consulting#Value chain planning#Supply chain management#Forecasting#SCM#Valtitude#Demand Planning#S&OP Forecasting Consulting#Supply Chain Management Software#IBP#Supply Chain Optimization#SAP SCM#APO modeling#forecasting tool#SAP#Usability#Analytics#IBP Demand#IBP Inventory#IBP Supply#ForecastPro#Forecasting Tool#Demand Modeling#APS#SAP SCM APO#Solutions Tuning#Re-implementation#SAP IBP#integrated business planning

0 notes

Text

EXCEPTION REPORTING

Forecast Pro’s flexible exception reporting allows you to focus on areas that need your attention. The reports are easily customizable to reflect different performance metrics ? such as forecast vs. history or whether forecast error exceeds a pre-defined threshold – and give you a quick way to identify potential problem areas.

To know More, Visit Us:

#Valtitude#Demand Planning#S&OP Forecasting Consulting#Supply Chain Management Software#IBP#Supply Chain Optimization#Forecasting Consulting#Demand Modeling#Demand Sensing#valtitude#SAP SCM#APO modeling#forecasting tool#SAP#Usability#Analytics#IBP Demand#IBP Inventory#IBP Supply#S&OP Workshop#demand planning workshop#Demand Planning for S&OP Workshop#demand planning workshop in India

0 notes

Text

Take advantage of the automated modeling strategies

First Order Exponential Smoothing Models or Constant Model

Moving Average Models

Linear Regression Models and MLR Models

Second Order Exponential Smoothing with Trend

Holt-Winters Models

To know More, Visit Us:

#Valtitude#Demand Planning#S&OP Forecasting Consulting#Supply Chain Management Software#IBP#Supply Chain Optimization#SAP SCM#APO modeling#forecasting tool#Forecasting Consulting#Demand Modeling#Demand Sensing#valtitude#S&OP Workshop#demand planning workshop#Demand Planning for S&OP Workshop#demand planning workshop in India

0 notes

Text

Who Should Attend Inventory Optimiztion

Production Planners

Supply Chain Analysts

Director of Supply Chain

Director of Value Chain

Analysts in the Supply Chain

Inventory Planners

Operations Planners

Financial Analysts

Director of Logistics

Director of Customer Service

To know More, Visit Us:

#Valtitude#Demand Planning#S&OP Forecasting Consulting#Supply Chain Management Software#IBP#Supply Chain Optimization#SAP SCM#APO modeling#forecasting tool#SAP#Usability#Analytics#IBP Demand#IBP Inventory#IBP Supply#Forecasting Consulting#Demand Modeling#Demand Sensing#valtitude#S&OP Workshop#demand planning workshop#Demand Planning for S&OP Workshop#demand planning workshop in India

0 notes