#Rotary Steerable System Industry

Explore tagged Tumblr posts

Link

#market research future#rotary steerable system market#rotary steerable system#rotary steerable systems#rotary steerable industry

0 notes

Text

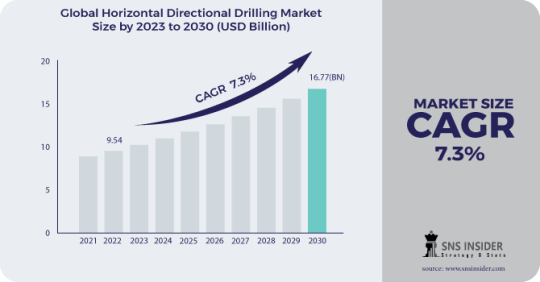

Horizontal Directional Drilling Market Analysis and Forecast 2031: Exploring Size, Share, and Scope Trends

The Horizontal Directional Drilling research report provides a quick analysis of market value, volume, return, factors, opportunity, competition, and current strategic behaviour. This includes forecasting demand, detailed explanations of assumptions and methodologies, as well as historical data and forecasts. This study examines the financial market environment to assess competition in local and global markets. The survey highlights the growth potential of the Horizontal Directional Drillingindustry over the forecast period.

Ask For Sample Report Here @ https://www.snsinsider.com/sample-request/1099

The report includes data on strategic alliances, new product launches, projects, transactions, collaborations, key market players, and drivers, constraints and opportunities. It provides the tools you need to assess the Horizontal Directional Drilling market for companies, customers, buyers, sellers, service providers, and distributors.

Market Segmentation

By Technique

Conventional

Rotary Steerable System

By Parts

Rigs

Pipes

Bits

Reamers

Others

By Application

On-shore

Off-shore

By End User

Oil and Gas Excavation

Utility

Telecommunication

By Company

American Augers, Inc.

Ditch Witch

Ellingson Companies

Vermeer Corporation

The Toro Company

Baker Hughes Incorporate

Halliburton Company

Schlumberger Limited

Weatherford International National Oilwell Varco, Inc.

Nabors Industries, Ltd.

The Application Management Services (AMS) market is divided into three categories: type, provider and application, allowing you to more accurately assess the size, climate, growth and development of the market. Charts, diagrams and records are used to represent the segments. Horizontal Directional Drillingmarket research also provides insights into the target market's product category and is based on a variety of organizational objectives such as product segmentation, production volume, product definition, and requirements, etc.

The market study thoroughly investigates the scope of the target market. Market innovation that has been stable in the past and is expected to stabilize again in the future is the subject of this study. Industry structure, definition, product characteristics, market penetration and maturity analysis are all included in the Horizontal Directional Drilling market report. Market size and growth rate are also analysed for forecast periods.

Regional Analysis

The report covers industry rankings and reported interpretations using regional surveys. Use of both primary and secondary sources to calculate market revenue for large industry organizations. Therefore, this study contains several important features. This Horizontal Directional Drillingmarket study explores the many factors that influence the growth of a region, including the financial, cultural, social, technical and political conditions of the region. This chapter describes the regional and global globalization of various term exchanges. Similarly, this study provides a reliable amount of country-by-country research and analysis of regional market share.

Buy This Report Here @ https://www.snsinsider.com/checkout/1099

Competitive Outlook

The size of the sector is also determined by the characteristics of the major players in the sector, according to the report. Major capabilities of major industry players are studied using secondary as well as primary sources and their revenue in the market is calculated in this study. This market research examines the top-down tactics of large companies. This section of the report provides contact details for the major vendors in the Horizontal Directional Drillingindustry. The survey also explores the market competition, market prices and channel characteristics among the major players.

2 notes

·

View notes

Text

0 notes

Text

STALLASSIST™ SOFTWARE

DETECT, MITIGATE, AND RECOVER FROM DOWNHOLE STALLS

95% of operators experience motor/rotary steerable system (RSS) stalls downhole. Frequent stalls can result in premature bit and BHA failures that lead to unplanned trips, tools lost in hole, sidetracks or cement plugs – and in some cases plugging and abandoning a well if the mitigation efforts are unsuccessful. H&P StallAssist™ software was designed not only to detect downhole stalls, but to mitigate and help recover from them. By increasing bit and BHA reliability this technology can help decrease sidetracks or lost in hole occurrences and increase motor and bit longevity, translating into more footage drilled per BHA and reduced time to target.

HOW DOES IT WORK?

FEATURES

ADVANTAGES

OUTCOME

As pressure is reaching the stall rating, the system continually and simultaneously evaluates several factors; pressure, the speed in which the pressure is rising and motor specifications

Dynamic, real-time calculations prevent the motor from ever seeing the strain of pressure that is outside motor limitations

Detects and actions a stall much faster than a human can feasibly do, stopping significant wear from excessive force on elastomer and mechanical motor components

Within in just a couple of seconds of detection, StallAssist immediately and automatically executes the full sequence to react to a stall

Consistent and immediate action. Without StallAssist software, a driller would have to action each step in the process; See steps 1-7 above. The driller can now focus on the full spectrum of drilling operation activities

Helps eliminate delayed or inconsistent reactions that put additional strain on the motor, reducing premature BHA failure and associated replacement costs

Configured based on operators operational preferences and practices. As an example, pumps can be slowed or stopped after stall detection

Allows for quicker recovery of electrical and mechanical systems

Quickly resume operations, reducing downtime

Unlike other industry offering, StallAssist is a software-based system

No downhole tools are required

Avoid additional risk and cost associated with downhole tools

StallAssist software detects and mitigates stalls during both rotating and sliding activity

Not dependent on drilling method

Confidence throughout the drilling process

After 2 years of testing StallAssist™ software: No Stall Undetected. No False Detections.

CONTACT US

For more information on how our StallAssist™ software can help you achieve better drilling outcomes, contact an H&P sales representative today or contact us through our website at helmerichpayne.com/contact. It’s time to follow through on your drilling performance potential.

Download the full product literature from here: https://www.helmerichpayne.com/media/product-literature/StallAssist-FactSheet.pdf.

#helmerichandpayne#drillingtechnology#rigcontractoroilandgas#drillingautomation#drillingrigcontractoroilandgas

0 notes

Text

Optimizing Wellbore Operations_ Strategies for Efficient Drilling and Completion by Oilfield Professionals like Javier Daniel Salcido (1)

Javier Daniel Salcido Odessa Texas

Optimizing Wellbore Operations: Strategies for Efficient Drilling and Completion by Oilfield Professionals like Javier Daniel Salcido

In the highly competitive field of oil and gas, optimizing wellbore operations is critical to enhancing efficiency, reducing costs, and maximizing productivity. Efficient drilling and completion processes not only influence operational success but also impact the overall economics of oilfield projects. As the industry evolves with advancing technologies and increasing demands, adopting effective strategies for wellbore operations becomes paramount. This blog delves into key strategies for optimizing drilling and completion processes to achieve operational excellence and economic viability, ensuring that companies remain at the forefront of industry advancements.

Strategic wellbore optimization helps oil and gas companies stay competitive by improving operational efficiency and resource recovery. Through innovative technologies and best practices, companies can streamline their operations, reduce downtime, and enhance overall performance. The following sections outline essential strategies to achieve these goals, focusing on technological advancements, effective practices, and comprehensive maintenance approaches.

Implementing Advanced Drilling Technologies

The integration of advanced drilling technologies is essential for optimizing wellbore operations. Modern drilling technologies, such as rotary steerable systems (RSS) and managed pressure drilling (MPD), offer significant improvements in accuracy, efficiency, and safety. By adopting these technologies, industry professionals like Javier Daniel Salcido enhance drilling precision, reduce non-productive time, and navigate complex geological formations more effectively.

Rotary steerable systems enable precise control of the wellbore trajectory, allowing for accurate directional drilling and improved reservoir contact. Managed pressure drilling, on the other hand, provides better control over wellbore pressure, reducing the risk of kicks and blowouts. Implementing these advanced technologies helps streamline the drilling process, minimize operational risks, and improve overall well performance. Moreover, continuous advancements in drilling technologies offer opportunities for innovation and further optimization.

Leveraging Real-Time Data and Analytics

Real-time data and analytics play a crucial role in optimizing wellbore operations. By utilizing data acquisition systems and analytics tools, oilfield professionals such as Javier Daniel Salcido monitor drilling parameters, assess well conditions, and make informed decisions promptly. Real-time data enables better control over the drilling process, allowing for rapid adjustments to optimize performance and mitigate potential issues.

Implementing advanced data analytics also helps in predicting and addressing potential challenges before they escalate. Predictive maintenance and real-time monitoring of equipment can identify anomalies and prevent failures, reducing downtime and operational costs. Leveraging these data-driven insights enhances operational efficiency and supports informed decision-making throughout the drilling and completion phases. Furthermore, integrating machine learning algorithms with real-time data can lead to even more accurate forecasts and optimized operations.

Enhancing Completion Techniques

Optimizing wellbore operations extends beyond drilling to include completion techniques. Effective completion strategies are vital for maximizing well productivity and ensuring long-term performance. Techniques such as hydraulic fracturing, multistage completions, and intelligent completions contribute to enhancing reservoir access and improving overall well performance.

Hydraulic fracturing, or fracking, involves injecting fluids into the wellbore to create fractures in the reservoir rock, facilitating the flow of hydrocarbons. Industry professionals including Javier Daniel Salcido convey that multistage completions allow for the stimulation of multiple zones within a well, increasing reservoir contact and production rates. Intelligent completions use advanced sensors and control systems to monitor and manage well performance in real-time. Employing these completion techniques optimizes wellbore operations and maximizes resource recovery. Additionally, integrating new technologies into completion processes can further enhance efficiency and effectiveness.

Adopting Efficient Drilling Practices

Efficient drilling practices are crucial for reducing operational costs and enhancing wellbore performance. Techniques such as optimized drilling parameters, effective use of drilling fluids, and efficient bit selection contribute to improving drilling efficiency and minimizing non-productive time.

Optimizing drilling parameters, such as weight on bit and rotary speed, helps balance drilling performance and equipment wear. Using appropriate drilling fluids reduces friction, cools the bit, and removes cuttings from the wellbore. Selecting the right bit type for specific geological conditions enhances drilling efficiency and extends bit life. By adopting these practices, oilfield professionals like Javier Daniel Salcido achieve more efficient drilling operations and lower overall costs. Additionally, employing automated drilling systems and advanced simulation tools can further refine drilling practices and enhance overall performance.

Ensuring Rig and Equipment Maintenance

Regular maintenance of rigs and equipment is essential for maintaining operational efficiency and preventing unexpected downtime. Implementing a comprehensive maintenance program helps ensure that all equipment is in optimal working condition and reduces the risk of failures during drilling and completion operations.

Scheduled inspections, preventive maintenance, and timely repairs are key components of an effective maintenance program. By addressing potential issues before they become critical, operators can avoid costly delays and maintain consistent performance. Investing in maintenance not only prolongs equipment lifespan but also enhances overall operational efficiency and safety. Additionally, adopting predictive maintenance technologies and digital twins can further improve maintenance strategies and ensure continuous operational excellence.

Fostering Collaboration and Training

Fostering collaboration and investing in training are critical for optimizing wellbore operations. Effective communication and teamwork among drilling and completion teams ensure that all aspects of the operation are aligned and managed efficiently. Additionally, ongoing training and skill development help ensure that personnel are knowledgeable about the latest technologies and best practices.

Collaborative efforts between teams can lead to innovative solutions and improved problem-solving. Regular training programs keep staff updated on new technologies, safety protocols, and industry standards. By prioritizing collaboration and training, operators can enhance their team’s capabilities and drive overall operational success. Furthermore, promoting a culture of continuous learning and knowledge sharing within the organization can lead to sustained improvements and innovations in wellbore operations.

Optimizing wellbore operations through efficient drilling and completion strategies is essential for achieving success in the oil and gas industry as underscored by industry professionals such as Javier Daniel Salcido. By implementing advanced drilling technologies, leveraging real-time data, enhancing completion techniques, adopting efficient practices, ensuring rigorous maintenance, and fostering collaboration, operators can significantly improve their wellbore operations.

These strategies not only enhance operational efficiency but also contribute to better resource recovery and cost management. As the industry continues to evolve, staying abreast of the latest advancements and best practices is crucial for maintaining a competitive edge and achieving long-term success in oilfield operations. Embracing these strategies ensures that companies remain agile, innovative, and capable of meeting the demands of an ever-changing market.

0 notes

Text

North America Geosteering Technology Market Growing Demands, Supply and Business Outlook till 2027

“The geosteering technology market in North America is expected to grow from US$ 4,988.03 million in 2019 to US$ 8,597.20 million by 2027; it is estimated to grow at a CAGR of 11.0 % from 2020 to 2027.”

The report discusses many vital industry facets that influence the “North America Geosteering Technology Market” industry acutely which includes an extensive study of competitive edge, latest advancements, region-wise industry environment, contemporary market, and emerging trends, leading market contenders, and the current tendency of the end-user. The report also oversees market size, market share, growth rate, revenue, and CAGR reported previously along with its forecast estimation.

To Get a Sample PDF Copy:

https://www.businessmarketinsights.com/sample/TIPRE00015438

North America Geosteering Technology includes Market Analysis Report Top Companies:

· Cougar Drilling Solution Inc.

· Emerson Paradigm Holding LLC

· Exlog

· Geonaft

· Geotech Logging Services LLC

· Halliburton Energy Services, Inc.

· HMG Software LLC

· ROGII Inc.

· Schlumberger Limited

· Terracosm Software, LLC

North America Geosteering Technology Market Split by Product Type and Applications:

This report segments the North America Geosteering Technology Market on the basis of Types are:

· Logging While Drilling (LWD)

· Measurement-While-Drilling (MWD)

· Rotary Steerable Systems (RSS)

· Drive Systems

· Others

On the basis of Application, the North America Geosteering Technology Market is segmented into:

· Petroleum Development

· Natural Gas Transportation

· Others

Market Analysis and Status: North America Geosteering Technology Market:

-Since the COVID-19 virus outbreak in December 2019, the ailment has spread to just about 100 nations around the world with the World Health Organization pronouncing it a general health crisis. The worldwide effects of the coronavirus infection 2019 (COVID-19) are as of now beginning to be felt, and will significantly influence the North America Geosteering Technology Market.

-COVID-19 can influence the worldwide economy in three fundamental manners: by straightforwardly influencing creation and request, by supply chain and market interruption, and by its financial effect on firms and financial markets.

Scope of the Report:

The research report on the North America Geosteering Technology Market is a comprehensive publication that aims to identify the financial outlook of the market. For the same reason, it offers a detailed understanding of the competitive landscape. It studies some of the leading players, their management styles, their research and development statuses, and their expansion strategies. The report also includes product portfolios and the list of products in the pipeline. It includes a thorough explanation of the cutting-edging technologies and investments being made to upgrade the existing ones.

Click here to buy this report:

https://www.businessmarketinsights.com/buy/single/TIPRE00015438

Influence of the North America Geosteering Technology Market Report:

-Comprehensive assessment of all opportunities and risks in the North America Geosteering Technology market.

-North America Geosteering Technology market recent innovations and major events.

-Detailed study of business strategies for the growth of the North America Geosteering Technology market-leading players.

-Conclusive study about the growth plot of the North America Geosteering Technology market for forthcoming years.

-In-depth understanding of North America Geosteering Technology market-particular drivers, constraints, and major micro markets.

-Favourable impression of vital technological and market latest trends striking the North America Geosteering Technology market.

Finally, the North America Geosteering Technology Market Report is the authoritative source for market research that can dramatically accelerate your business. The report shows economic conditions such as major locales, item values, profits, limits, generation, supply, requirements, market development rates, and numbers.

Customization of the Report: This report can be customized as per your needs for additional data for up to 3 companies or countries or 40 analyst hours.

About Us:

Business Market Insights is a market research platform that provides subscription services for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductors; Aerospace & Defense; Automotive & Transportation; Energy & Power; Healthcare; Manufacturing & Construction; Food & Beverages; Chemicals & Materials; and Technology, Media, & Telecommunications.

Contact us:

If you have any questions about this report or would like further information, please contact us:

Contact person: Sameer Joshi

Phone: +16467917070

Email: [email protected]

0 notes

Text

13 Innovations in Directional Drilling Technology

In recent years, directional drilling technology has revolutionised the oil and gas industry. Directional drilling enables operators to drill horizontally and accurately target a desired subsurface area. As such, directional drilling is becoming increasingly popular for cost-effective exploration in costly and hard-to-reach locations. There are various innovations in directional drilling Sydney technology that have improved the efficiency, accuracy, and safety of operations.

Robotic Drill Bits

Robotic drill bits have improved the accuracy and speed of directional drilling operations. These automated systems are able to drill with greater precision than manual systems, allowing for more efficient and cost-effective exploration.

Downhole Motors

Downhole motors allow operators to change direction while drilling without having to pull out the drill string. This technology allows for faster, more precise drilling and reduces costs associated with pulling up the bit every time a direction change is needed.

Real-Time Drilling Monitoring

This technology utilises sensors and monitoring systems that relay data about the drilling process back to operators in real time, allowing them to make changes as needed. This enables operators to be more responsive to downhole problems, save time, and optimise drilling performance.

Torque and Drag Technology

Torque and drag technology uses sensors that measure the torque, weight on bit (WOB), hookload, and other parameters of a drill string during operation for better control over the drilling process. This helps operators avoid stuck pipe issues and increase both safety and speed of operations.

Automated Drilling Systems

Automated systems with digital sensors improve accuracy by giving real-time feedback on downhole conditions while providing advanced risk management capabilities during operations. This allows greater control over parameters like torque and weight on bit, enabling operators to minimise damage to equipment and maximise wellbore success rates.

Integrated Drilling Solutions

Integrated drilling solutions that combine data from surface and downhole sensors can provide operators with a more comprehensive view of the drilling process. This helps to reduce non-productive time and manage risk by providing insight into potential problems before they become major issues.

Dynamic Underbalanced Drilling

Dynamic underbalanced drilling (DUBD) is a technique used in directional drilling that utilises low pressure gas to minimise formation damage. DUBD allows for improved wellbore stability, reduced material costs, and superior reservoir access.

Rotary Steerable Systems

Rotary steerable systems are drill bits that enable precise steering while drilling in hard rock formations. They consist of an array of adjustable blades or teeth that allow the drill bit to continuously redirect its course without making frequent stops for adjustments. This allows operators to maximise speed and accuracy of drilling operations.

Programmable Power Tongs

Programmable power tongs help automate pipe handling tasks during directional drilling, increasing safety and reducing human error associated with manual labour. These robotic systems are designed to increase torque and tension while minimising physical strain on the operator.

Smart Completion Tools

Smart completion tools can be used in combination with directional drilling technology to improve wellbore integrity, reduce downhole problems, and enhance production performance. This includes tools like intelligent valves and sensors that give real-time feedback on downhole conditions.

High Pressure/High Temperature Drilling Fluids

High pressure/high temperature (HPHT) drilling fluids are specially formulated to minimise risk and keep wellbores stable at extreme depths. This helps reduce the risk of downhole blowouts and malfunctioning equipment due to high-pressure, high-temperature environments.

High Angle Drilling

High angle drilling enables operators to drill horizontally at greater angles than traditional directional drilling methods. This technique allows for improved reservoir access and increased production rates while saving costs associated with long horizontal wells.

Horizontal Managed Pressure Drilling

Managed pressure drilling (MPD) is a specialised process that utilises backpressure control technology during the drilling process. This enables operators to maintain optimal formation pressures throughout the entire wellbore, reducing potential risks associated with over-pressurization.

Overall, directional drilling technology is an important tool for cost-effective exploration and production operations in challenging locations. With a variety of specialised tools and techniques, operators can improve accuracy and reduce operational risks associated with complex drilling operations.

0 notes

Text

Rotary Steerable System Industry- Insight, Size, Growth, Trends, Demand, Key Player profile and Regional Outlook by 2030

The rotary steerable systems market is projected to progress with ~7.01% CAGR from 2020 to 2027.

Taste the market data and market information presented through more than 100 market data tables and figures spread in 150 numbers of pages of the project report. Avail of the in-depth table of content & market synopsis on “Global Rotary Steerable Systems market Information from 2020 to 2027."

A rotary steerable system is a form of drilling technology used in directional drilling operations; these systems employ specialized downhole equipment to replace conventional directional tools such as mud motors. Rotary steerable systemsare mainly deployed when drilling horizontal, directional, or extended-reach wells.

The rotary steerable systems market in North America is estimated to account for the highest share of the rotary steerable systems market. The region is one of the largest markets for oil & gas production. The rise of oil and gas investments and rising discoveries of oil and gas fields such as the North Sea drilling project will drive the growth of the regional market.

Get a FREE Sample@ https://www.marketresearchfuture.com/sample_request/10603

The global rotary steerable systems market is classified based on type, application, and region. By type, the global market has been segmented into push the bit and point the bit.

The push the bit is expected to hold the larger share in the global market during the forecast period. Push-the-bit tools have pads on the outside surface of the tool, which press against the wellbore, thereby eventually causing the bit to press on the opposite side, causing a direction change.

By application, the global market has been segmented into onshore and offshore. The onshore application segment is expected to hold a larger share of the global market.

By region, the rotary steerable system marketis segmented into Europe, Asia-Pacific, North America, the Middle East & Africa, and South America. North America dominates the rotary steerable systems market.The increased demand for energy in the region because of the growing population and rising per capita disposable income is expected to drive the regional market during the forecast period.

Access Report @ https://www.marketresearchfuture.com/reports/rotary-steerable-system-market-10603

The important players operating in the global rotary steerable systems marketare Baker Hughes, a GE Company LLC (US), Halliburton (US), National Oilwell Varco (US), Schlumberger Limited (US), Weatherford (US), APS Technology Inc. (US), Double Barell RSS (US), Nabors Industries Ltd (US), Gyrodata Incorporated (US), Leam Drilling Systems LLC (US), Target Energy Inc. (US) and Huisman Equipment B.V. (Netherlands).

This research report provides insights into various levels of analysis, such as industry analysis and market share analysis for the leading industry competitors, along with their profiles. It also helps in studying the target segments by providing views on the emerging and high-growth segments. The market data comprises the necessary assessment of the competitive scenarios and strategies in the global rotary steerable systems market, including high-growth regions and/or countries and political and economic environments. The project report further provides both historical market values and pricing & cost analysis.

0 notes

Text

Rotary Steerable System Market Technologies, Demands and Global Trends

Rotary Steerable System Market

Rotary Steerable System Market is expected to be valued at USD 3.6 Billion, with a CAGR of 7.01% Forecast by 2027

$3.6 Billion

Market Size

7.01%

CAGR

North America

Dominating Region

2022-2027

Forecast Period

Segmentation

By TypePush The BitPoint The Bit

By ApplicationOnshoreOffshore

Key Players

Baker Hughes

a GE Company LLC (US)

Halliburton (US)

National Oilwell Varco (US)

Schlumberger Limited (US)

Weatherford (US)

APS Technology Inc. (US)

Double Barell RSS (US)

Nabors Industries Ltd (US)

Gyrodata Incorporated (US)

Leam Drilling Systems LLC (US)

Target Energy Inc. (US

Drivers

Increased Investment in the Offshore Drilling Sector

Rising Energy Demand

Recent Advancements and Technological Growth

0 notes

Text

Directional Drilling Services Market Industry Insights and Opportunity Analysis, 2018-2026

Directional drilling refers to a process of drilling a well with a preferred deviation to reach the target location. This type of drilling is done for placing the wellbore precisely to get maximum recovery both on land and offshore regions. The main aim of this type of drilling is to cover large areas by the use of the single rig. Maturing and aging onshore oilfields has paved paths to increasing directional drilling in the onshore regions supported by offshore exploration and production activities in deep and ultra-deep regions over the past few decades. This is further backed by augmenting horizontal drilling services to maximize the productivity of the oil and gas well.

Global Directional Drilling Services Market Taxonomy

On the basis type, the global directional drilling services market is segmented as:

Conventional

Rotary Steerable System (RSS)

On the basis of service, the global directional drilling services market is segmented as:

Measurement While Drilling (MWD) and Survey

Logging While Drilling (LWD)

Turbo-Drills

RSS

Motors

Request Copy Of This Business Report: https://www.coherentmarketinsights.com/market-insight/directional-drilling-services-market-870

Major Keyplayers: Halliburton Company, Weatherford International Plc., Schlumberger Limited, Nabors Industries Ltd., National Oilwell Varco, Cathedral Energy Services Ltd., Baker Hughes Incorporated, General Electric Oil & Gas, and Jindal Drilling & Industries Limited.

About Us:

Coherent Market Insights is a global market intelligence and consulting organization that provides syndicated research reports, customized research reports, and consulting services. We are known for our actionable insights and authentic reports in various domains including aerospace and defense, agriculture, food and beverages, automotive, chemicals and materials, and virtually all domains and an exhaustive list of sub-domains under the sun. We create value for clients through our highly reliable and accurate reports. We are also committed in playing a leading role in offering insights in various sectors post-COVID-19 and continue to deliver measurable, sustainable results for our clients.

Contact:

Coherent Market Insights 1001 4th Ave, #3200 Seattle, WA 98154, U.S. Email: [email protected] United States of America: +1-206-701-6702 United Kingdom: +44-020-8133-4027 Japan: +050-5539-1737 India: +91-848-285-0837

0 notes

Link

#market research future#rotary steerable system market#rotary steerable system#rotary steerable systems#rotary steerable industry

0 notes

Text

Directional Drilling Market to Reach USD11.43 Billion by 2027

Increasing oilfield exploration and growing number of oil well discoveries to drive the demand for Global Directional Drilling Market in the forecast period.

According to the TechSci Research report, “Directional Drilling Market - Global Industry Size, Share, Trends, Competition, Opportunity and Forecast, 2017-2027”, the Global directional drilling market was valued at USD8.10 billion in 2021 and is forecast to grow at a CAGR of 5.71% to reach USD11.43 billion by 2027. Increasing oilfield exploration activities for discovering new shale reserves and surging demand for energy are driving the growth of the global directional drilling market. Low installation costs and faster installation backed by high oil prices lead to the increased demand for drilling process which has high efficiency and productivity, which is driving the demand for global directional drilling market.

When compared with traditional drilling, directional drilling is cheaper as it requires less operators, hence there is saving in manpower. In addition, less dirt is displaced through directional drilling, therefore less dirt needs to be restored. Horizontal directional drilling does not require backhoe and other heavy equipment rentals which further reduces the overall cost of operation.

Browse 215 market Figures spread through 252 Pages and an in-depth TOC on "Global Directional Drilling Market”.

https://www.techsciresearch.com/report/directional-drilling-market/4569.html

Global directional drilling market is segmented into type, component, service, technology, application, field development type, company, and regional distribution. Based on application, the market can be segmented into onshore and offshore. The demand for offshore projects is continuously increasing owing to the vast untapped reserves being used by developing deep-water projects. Consequently, the application of directional drilling in offshore projects is expected to grow at a CAGR of 6.22% in the forecast period. The offshore oil and gas contracts increased by approximately 6% in November 2021, with a total of 210 contracts compared to 198 contracts in the previous month.

In terms of field development type, the market can be segregated into greenfield and brownfield. The greenfield development projects in the global directional drilling market are expected to grow at a CAGR of 6.17% in the forecast period as they aim to develop new oil and gas fields. Countries all over the world are investing in oil & natural gas industry with a primary emphasis on greenfield projects. Middle Eastern countries such as Qatar, the UAE, and Saudi Arabia aim to ramp up gas production to meet rising regional demand, fueling the development of greenfield projects.

Leading players operating in the global directional drilling market include:

Halliburton Co.

Schlumberger Limited

Scientific Drilling International

Loam Drilling Systems, Inc.

NOV Inc.

Baker Hughes Holdings LLC

Weatherford International plc

Jindal Drilling & Industries Limited

Cathedral Energy Services Ltd

Nabors Industries Ltd.

Gyrodata Incorporated

The global directional drilling market is consolidated with few players accounting for approx. 70% of the market. Schlumberger Limited, followed by Halliburton Co., led the global directional drilling market in 2021. Schlumberger Limited is an oilfield services company, offering drilling and measurement in which it provides services related to mud logging for directional drilling.

While Halliburton Co. is the world’s largest provider of products and services for the energy industry. On November 16, 2021, the company released iCruise X Intelligent Rotary Steerable System, a drilling platform with advanced technology.

Download Sample Report @ https://www.techsciresearch.com/sample-report.aspx?cid=4569

Customers can also request for 10% free customization on this report.

“Due to increasing adoption of directional drilling in the region, North America is the dominant region in the Global Directional Drilling Market accounting for a share of 30.45% in 2021. North America is emerging as the largest market for onshore applications of directional drilling due to the surge in shale gas production in the United States and intervention activities in its shale basin regions. Horizontal wells drilled into tight oil and shale gas deposits continue to account for a growing share of crude oil and natural gas production in the United States and therefore are becoming a profitable market for directional drilling companies.” said Mr. Karan Chechi, Research Director with TechSci Research, a research based global management consulting firm.

“Directional Drilling Market - Global Industry Size, Share, Trends, Competition, Opportunity and Forecast, 2017-2027, Segmented By Type (Conventional System, Rotary Steerable System), By Component (Drilling Tool Rental, Rig Rental, OCTG Rental, Consumables, Others), By Service (Drilling, Logging-While-Drilling, Measurement-While-Drilling & Survey), By Technology (Wellbore Positioning, Side Tracking, Well Planning, Others), By Application (Onshore v/s Offshore), By Offshore Application (Shallow, Deep, Ultra-deep), By Field Development Type (Greenfield Vs Brownfield), By Region” has evaluated the future growth potential of global directional drilling market and provided statistics & information on market size, shares, structure and future market growth. The report intends to provide cutting-edge market intelligence and help decision makers take sound investment decisions. Besides, the report also identifies and analyzes the emerging trends along with essential drivers, challenges, and opportunities in the of global directional drilling market.

Press Release : https://www.techsciresearch.com/news/6893-directional-drilling-market.html

Contact

Mr. Ken Mathews

708 Third Avenue,

Manhattan, NY,

New York – 10017

Tel: +1-646-360-1656

Email: [email protected]

Web: https://www.techsciresearch.com

0 notes

Text

Directional Drilling Services Market: Trends, Market Size, and Forecasts up to 2030

The report on the global directional drilling services market provides qualitative and quantitative analysis for the period from 2017 to 2025. The report predicts the global directional drilling services market to grow with a CAGR of 4.9% over the forecast period from 2019-2025. The study on directional drilling services market covers the analysis of the leading geographies such as North America, Europe, Asia-Pacific, and RoW for the period of 2017 to 2025. The report on directional drilling services market is a comprehensive study and presentation of drivers, restraints, opportunities, demand factors, market size, forecasts, and trends in the global directional drilling services market over the period of 2017 to 2025. Moreover, the report is a collective presentation of primary and secondary research findings.

Request to Fill The Form To get Sample Copy of This Report: https://www.sdki.jp/sample-request-104588 Porter's five forces model in the report provides insights into the competitive rivalry, supplier and buyer positions in the market and opportunities for the new entrants in the global directional drilling services market over the period of 2017 to 2025. Further, IGR- Growth Matrix gave in the report brings an insight into the investment areas that existing or new market players can consider. Report Findings 1) Drivers • Rise in energy demand due to shale gas development • Increasing urbanization and industrialization • Increasing advancement in drilling technologies 2) Restraints • Rising focus on renewable energy 3) Opportunities • Discovery of new oilfields Research Methodology A) Primary Research Our primary research involves extensive interviews and analysis of the opinions provided by the primary respondents. The primary research starts with identifying and approaching the primary respondents, the primary respondents are approached include 1. Key Opinion Leaders associated with Infinium Global Research 2. Internal and External subject matter experts 3. Professionals and participants from the industry Our primary research respondents typically include 1. Executives working with leading companies in the market under review 2. Product/brand/marketing managers 3. CXO level executives 4. Regional/zonal/ country managers 5. Vice President level executives. B) Secondary Research Secondary research involves extensive exploring through the secondary sources of information available in both the public domain and paid sources. At Infinium Global Research, each research study is based on over 500 hours of secondary research accompanied by primary research. The information obtained through the secondary sources is validated through the crosscheck on various data sources. The secondary sources of the data typically include 1. Company reports and publications 2. Government/institutional publications 3. Trade and associations journals 4. Databases such as WTO, OECD, World Bank, and among others. 5. Websites and publications by research agencies Segment Covered The global directional drilling services market is segmented on the basis of type, service, and application. The Global Directional Drilling Services Market by Type • Conventional • Rotary Steerable System The Global Directional Drilling Services Market by Service • Logging-while-Drilling (LWD) • Rotary Steerable System (RSS) • Measurement While Drilling (MWD) and Survey • Drag Analysis • Well Bore Positioning • Other Services The Global Directional Drilling Services Market by Application • Onshore • Offshore Company Profiles The companies covered in the report include • Weatherford International plc • Cathedral Energy Services Ltd. • Schlumberger Limited • National Oilwell Varco, Inc. • Halliburton Company • Baker Hughes Co. • Jindal Drilling and Industries Limited • Gyrodata Inc. • Leam Drilling Systems, LLC • Scientific Drilling International Inc. • Other companies What does this report deliver? 1. Comprehensive analysis of the global as well as regional markets of the directional drilling services market. 2. Complete coverage of all the segments in the directional drilling services market to analyze the trends, developments in the global market and forecast of market size up to 2025. 3. Comprehensive analysis of the companies operating in the global directional drilling services market. The company profile includes analysis of product portfolio, revenue, SWOT analysis and latest developments of the company. 4. IGR- Growth Matrix presents an analysis of the product segments and geographies that market players should focus to invest, consolidate, expand and/or diversify.

The dynamic nature of business environment in the current global economy is raising the need amongst business professionals to update themselves with current situations in the market. To cater such needs, Shibuya Data Count provides market research reports to various business professionals across different industry verticals, such as healthcare & pharmaceutical, IT & telecom, chemicals and advanced materials, consumer goods & food, energy & power, manufacturing & construction, industrial automation & equipment and agriculture & allied activities amongst others.

For more information, please contact:

Hina Miyazu

Shibuya Data Count Email: [email protected] Tel: + 81 3 45720790

0 notes

Text

PDC BIT STEERABILITY MODELING AND TESTING FOR PUSH-THE-BIT AND POINT-THE-BIT RSS

The footage drilled with rotary steerable systems (RSS) has increased significantly these last few years, due notably to the highly complex wells drilled today. Moreover, high requirements about borehole quality are needed to optimize drilling performances, running completion tools or increase the quality of formation evaluation. Rotary steerable systems can be classified in two types according to the steering mechanism: point-the-bit and push-the-bit.

Whatever the type of steering mechanism, both tilt and side force are applied on the bit. Although bit tilt is predominant in point-the-bit system, bit side force is the main factor that affects hole deviation in push-the-bit system. There have been many controversies in the scientific and industrial community regarding the deviation mechanisms involved in these two systems.

To react to this controversy, a full-scale drilling bench has been developed to test drill bits in push-the-bit, point-the-bit or hybrid push-point mode. This new facility enables to apply any coupled tilt-side force on the bit to reproduce the RSS mechanisms.

To react to this controversy, a full-scale drilling bench has been developed to test drill bits in push-the-bit, point-the-bit or hybrid push-point mode. Interesting, right? To learn more, visit us here: https://www.helmerichpayne.com/resources/technical-publications/pdc-bit-steerability-modeling-and-testing-for-push-the-bit-and-point-the-bit-rss or you can reach out to us directly here: https://www.helmerichpayne.com/contact.

#rigcontractoroilandgas#drillingtechnology#helmerichandpayne#drillingautomation#drillingrigcontractoroilandgas

0 notes

Text

Responsible Oilfield Practices- Community Engagement and Impact

Javier Salcido Odessa Texas

In the vast and dynamic universe of oil and gas exploration, standing at the vanguard is the field of drilling technologies. These technological advancements, progressing from the rudimentary percussion drilling of yesteryears to the sophisticated techniques of the modern day, have been instrumental in transforming the oilfield landscape. Their contribution extends beyond mere efficiency enhancement, permeating into realms of safety improvements and productivity boosts. The history of drilling technologies thus unfolds as a tale of relentless innovation and progress, a journey marked by an unwavering commitment to advancement. Central to this narrative is the expertise and dedication of industry professionals like Javier Daniel Salcido, who continually push the boundaries of what's possible in this vital sector.

At the heart of modern drilling lies a convergence of sophisticated techniques and state-of-the-art equipment. Directional drilling, a hallmark advancement, enables drilling in non-vertical directions, allowing access to previously inaccessible reservoirs. This technique, coupled with measurement while drilling (MWD) and logging while drilling (LWD) technologies, provides real-time data on the geological formations being traversed, enhancing decision-making and optimizing the extraction process.

Javier Daniel Salcido brings into focus the revolutionary impact of rotary steerable systems in the drilling industry. Traditional drilling methods relied on motors that rotated the entire drill string, a method having its own set of limitations. These older methods fell short in terms of precision, flexibility, and the potential for mechanical stress on equipment. However, the introduction of rotary steerable systems has dramatically enhanced the drilling operations. These advanced systems provide operators with exact control and superior adaptability, enabling precise steering of the drill bit through intricate subsurface formations. This precision significantly minimizes mechanical stress, which in turn extends the lifespan of the equipment. By increasing accuracy and reducing equipment wear, rotary steerable systems have contributed to a marked improvement in the overall efficiency of drilling operations.

Another game-changing innovation in drilling technology is hydraulic fracturing, popularly known as fracking. This technique involves injecting high-pressure fluid into the reservoir to create fractures in the rock formation, allowing trapped hydrocarbons to flow more freely. While controversial due to environmental concerns, fracking has significantly boosted oil and gas production worldwide, unlocking vast reserves previously deemed uneconomical to extract.

In addition, the progression in drilling fluids, often referred to as muds, has been instrumental in boosting drilling efficacy and maintaining wellbore stability. These technically advanced fluids serve multiple critical roles in drilling operations. They provide cooling and lubrication to the drill bit, mitigating the intense heat generated during drilling and reducing wear and tear. Notably, Javier Daniel Salcido has pointed out that these fluids also help transport rock cuttings to the surface, a crucial task for maintaining clear wellbore pathways and enhancing drilling efficiency. Moreover, these fluids are designed to avert formation damage and exert pressure to counterbalance the extreme downhole pressures, thereby ensuring the well's integrity. This intricate balance of pressures is a core aspect of wellbore stability, a field in which Javier Daniel Salcido has demonstrated significant expertise. Thus, the evolution of drilling fluids has not only improved the technical aspects of drilling but also contributed to safer and more effective oil extraction methods.

The integration of automation and robotics has also transformed drilling operations. Automated drilling rigs equipped with artificial intelligence algorithms can analyze vast amounts of data in real-time, making instantaneous adjustments to optimize drilling parameters, thereby increasing accuracy and reducing human error. Robotics, such as autonomous drones and remotely operated vehicles (ROVs), are employed for inspection, maintenance, and intervention tasks in hazardous or hard-to-reach areas, improving safety and operational efficiency.

The evolution of the oil and gas sector has brought about the advent of "smart wells," sophisticatedly embedded with an array of sensors and downhole monitoring systems. These advanced technologies are game changers, providing a continuous stream of valuable data regarding reservoir conditions. The real-time information obtained enables more proactive reservoir management and facilitates precise optimization of production. It acts as an early warning system, highlighting potential issues well in advance, allowing for preemptive action to be taken. This, in turn, paves the way for more efficient extraction of resources, ensuring the sustainability of operations. In this transformative era, professionals such as Javier Daniel Salcido are key to harnessing the full potential of these advancements, leveraging their profound knowledge and extensive experience in the Wireline oilfield services sector.

Moreover, the use of advanced materials in drilling equipment has significantly enhanced durability and performance. Cutting-edge alloys and composites offer superior resistance to corrosive environments, high temperatures, and extreme pressures, prolonging equipment lifespan and reducing maintenance downtime.

The pursuit of environmentally sustainable drilling practices has led to the development of "green" drilling technologies. Innovations in waterless or reduced-water drilling techniques aim to minimize freshwater usage and mitigate environmental impact. Additionally, the integration of renewable energy sources, such as solar or wind power, into drilling operations helps reduce carbon footprint and dependency on traditional energy sources.

Collaboration and knowledge-sharing among industry players have accelerated the pace of technological advancements in drilling. Partnerships between oil companies, service providers, research institutions, and academia have fostered a collaborative environment conducive to innovation, leading to the rapid development and implementation of cutting-edge drilling technologies.

However, despite these technological marvels, challenges persist. Operating in ultra-deepwater or challenging environments demands continuous innovation to overcome technical hurdles. High-pressure, high-temperature (HPHT) reservoirs pose significant engineering challenges, requiring the development of specialized equipment capable of withstanding extreme conditions while maintaining operational efficiency and safety standards.

The industry faces growing pressure to minimize its environmental footprint. Innovations focused on reducing emissions, minimizing waste generation, and implementing efficient water management strategies are imperative to ensure sustainable drilling practices for future generations.

Drilling technologies have undergone a remarkable evolution, from rudimentary methods to highly sophisticated, interconnected systems. The integration of robotics, automation, data analytics, and sustainable practices has propelled the industry into a new era of efficiency, safety, and environmental consciousness. As technological advancements continue to reshape the oil and gas sector, the quest for innovative solutions remains paramount in meeting the world's energy demands while safeguarding our planet's future.

0 notes

Text

Global Geosteering Technology Market Size, Status and Forecast 2021-2027

Market Analysis and Insights: Global Geosteering Technology Market

The global Geosteering Technology market size is projected to reach US$ XX million by 2027, from US$ XX million in 2020, at a CAGR of XX% during 2021-2027.

With industry-standard accuracy in analysis and high data integrity, the report makes a brilliant attempt to unveil key opportunities available in the global Geosteering Technology market to help players in achieving a strong market position. Buyers of the report can access verified and reliable market forecasts, including those for the overall size of the global Geosteering Technology market in terms of revenue.

Download FREE Sample of this Report @ https://www.grandresearchstore.com/report-sample/global-geosteering-technology-2021-2027-566

On the whole, the report proves to be an effective tool that players can use to gain a competitive edge over their competitors and ensure lasting success in the global Geosteering Technology market. All of the findings, data, and information provided in the report are validated and revalidated with the help of trustworthy sources. The analysts who have authored the report took a unique and industry-best research and analysis approach for an in-depth study of the global Geosteering Technology market.

Global Geosteering Technology Scope and Market Size

Geosteering Technology market is segmented by company, region (country), by Type, and by Application. Players, stakeholders, and other participants in the global Geosteering Technology market will be able to gain the upper hand as they use the report as a powerful resource. The segmental analysis focuses on revenue and forecast by Type and by Application in terms of revenue and forecast for the period 2016-2027.

Segment by Type

LWD

MWD

Rotary Steerable Systems (RSS)

Drive Systems

3D Seismic/Gird Model

Others

Segment by Application

Petroleum Development

Natural Gas Transportation

Others

By Region

North America

U.S.

Canada

Europe

Germany

France

U.K.

Italy

Russia

Nordic

Rest of Europe

Asia-Pacific

China

Japan

South Korea

Southeast Asia

India

Australia

Rest of Asia

Latin America

Mexico

Brazil

Rest of Latin America

Middle East & Africa

Turkey

Saudi Arabia

UAE

Rest of MEA

By Company

Cougar Drilling Solutions

Emerson Paradigm Holding LLC

Schlumberger Limited

GeoSteering Technologies

Petrolink

Halliburton

Exlog

Geotech Logging Services LLC

United Oil & Gas Consulting Ltd.

HMG Software

Horizontal Solutions International

Maxwell Dynamics

Terracosm Software

Rogii Inc.

Lloyd's Register Group Services Ltd.

Get the Complete Report & TOC @ https://www.grandresearchstore.com/ict-and-media/global-geosteering-technology-2021-2027-566

Table of content

1 Report Overview 1.1 Study Scope 1.2 Market Analysis by Type 1.2.1 Global Geosteering Technology Market Size Growth Rate by Type: 2016 VS 2021 VS 2027 1.2.2 LWD 1.2.3 MWD 1.2.4 Rotary Steerable Systems (RSS) 1.2.5 Drive Systems 1.2.6 3D Seismic/Gird Model 1.2.7 Others 1.3 Market by Application 1.3.1 Global Geosteering Technology Market Share by Application: 2016 VS 2021 VS 2027 1.3.2 Petroleum Development 1.3.3 Natural Gas Transportation 1.3.4 Others 1.4 Study Objectives 1.5 Years Considered 2 Global Growth Trends 2.1 Global Geosteering Technology Market Perspective (2016-2027) 2.2 Geosteering Technology Growth Trends by Regions 2.2.1 Geosteering Technology Market Size by Regions: 2016 VS 2021 VS 2027 2.2.2 Geosteering Technology Historic Market Share by Regions (2016-2021) 2.2.3 Geosteering Technology Forecasted Market Size by Regions (2022-2027) 2.3 Geosteering Technology Industry Dynamic 2.3.1 Geosteering Technology Market Trends 2.3.2 Geosteering Technology Market Drivers 2.3.3 Geosteering Technology Market Challenges 2.3.4 Geosteering Technology Market Restraints 3 Competition Landscape by Key Players 3.1 Global Top Geosteering Technology Players by Revenue 3.1.1 Global Top Geosteering Technology Players by Revenue (2016-2021) 3.1.2 Global Geo

CONTACT US: 276 5th Avenue, New York , NY 10001,United States International: (+1) 646 781 7170 / +91 8087042414 Follow Us On linkedin :- https://www.linkedin.com/company/grand-research-store/

0 notes