#Rotary Screen Printing Machine Parts

Text

How Do You Take Care of Your Printed Clothes

Hello, in this blog we will discuss how to master the art of caring for your clothes.

DO YOU KNOW BY DOING PROPER CARE OF YOUR GARMENT, YOU CAN BE A SUSTAINABILITY CHAMPION?

The most important part of sustainable movement is how to care for your clothes. The washing machine has entered every household In last one decade. The fast fashion has made the concept of mass production a success. Unfortunately, mass production directly affects the quality of fabrics, textiles & other processes like sourcing, dyeing, washing, etc.

Welcome to the Ultimate Guide on how to care for your printed garments! We all love our printed clothes, but maintaining their vibrant colors and designs can be a challenge. At Wildmoss, we understand the importance of preserving the quality and longevity of your printed garments. That's why our team of experts has compiled their knowledge and experience into this ultimate guide, so you can enjoy your favorite prints for years to come.

Hand washing clothes isn't merely an antiquated practice, but a viable laundry solution, especially for delicate items. A direct & indirect impact on the environment. This simple guide applies to all the other loving clothes in your wardrobe.

First of all- WHY BLOCK PRINTED FABRICS NEED SEPARATE WASHING CARE?

The garments made from Natural materials and processed in traditional technologies often benefit from hand washing preventing potential damage that could arise from machine washing. The block printing technique Is a labour intensive process That gives unique patterns with each impression. The fabrics which are printed through hand block printing technique do have lesser penetration of colour as compared to The screen printed or rotary printed. These fabrics require as much special attention in washing, as much carefully the fabric has been printed.

For Know More Click Here

0 notes

Text

Types of Textile Machinery Used in Textile Industries

The textile industry, a cornerstone of contemporary production, is predicated heavily on advanced equipment to produce fabrics and different textile products. As the era evolves, so does the range and class of textile equipment. Understanding these machines is crucial for all and sundry worries inside the industry. In this weblog, we will discover the varieties of fabric machinery utilised in fabric industries, that specialise in their roles and features, and how they contribute to the production method.

Introduction to Textile Machinery

Textile machinery encompasses a wide range of devices used to method raw fibres into completed merchandise. These machines perform numerous functions, from spinning and weaving to dyeing and finishing. Each system performs a vital role in ensuring the high-quality and performance of textile production.

Spinning Machines

1. Spinning Frames:

Spinning frames draw yarn out of uncooked fibres by twisting them, the fibres being cotton or wool. There are several grades in this technique: carding, drawing and roving. Spinning frames come in various forms; namely the ring spinning and rotor spinning, each having its advantages.

2. Open-End Spinning Machines:

These machines are recognised for his or her potential to course of yarn’s production at high pace and in giant portions successfully. These vary from the conventional spinning frames in a way that eliminate the use of roving; thus, making the process more efficient.

Weaving Machines

1. Power Looms:

Power loom is a mechanical weaving machine used for shedding and beats the warp and weft yarns to form material. They have in large part substituted handlooms mainly on the basis of velocity as they supply constant first-rate materials.

2. Rapier Looms:

Rapier looms are modern weaving units that are acknowledged for their flexibility. They are versatile for an extensive variety of yarn sorts and material patterns that make them suitable for complicated fabrics.

3. Air-Jet Looms:

These looms use air to propel the weft yarn through the warp shed, allowing for quicker and more green weaving. Air-jet looms are particularly appropriate for lightweight fabrics and excessive-velocity production.

Knitting Machines

1. Circular Knitting Machines:

Circular knitting machines create tubular fabric with the aid of knitting yarn in a non-stop round movement. They are commonly used for generating seamless garments, socks, and other hosiery products.

2. Flat Knitting Machines:

These machines knit fabrics in a flat form and are used for growing items like sweaters, scarves, and different flat-knit clothes. Flat knitting machines provide more flexibility in design and sample variations.

Dyeing and Printing Machines

1. Jet Dyeing Machines:

Jet dyeing machines are used to dye fabric in a closed system, wherein the dye liquor is circulated at excessive pressure. This method ensures uniform dyeing and is appropriate for diverse material types.

2. Rotary Screen Printing Machines:

Rotary display printing machines follow styles to material by forcing dye via a cylindrical display screen. They are recognised for his or her performance and ability to provide elaborate designs on a large scale.

Finishing Machines

1. Stenter Machines:

Stenter machines stretch and dry fabrics, ensuring they meet the desired dimensions and satisfactory requirements. This system improves the fabric’s texture, appearance, and stability.

2. Calendering Machines:

Calendering machines consist of heated rollers that press and easy fabric, enhancing their end and lustre. They are often used for fabric like cotton, polyester, and blends.

Embroidery Machines

Computerized Embroidery Machines:

These machines are used to create intricate embroidery designs on fabrics. With the aid of computer software, they can produce detailed and consistent patterns, making them essential for high-quality embroidery work.

Textile Testing and Quality Control Machines

1. Tensile Testing Machines:

Tensile testing machines measure the strength and elasticity of fabrics, ensuring they meet industry standards. They play a crucial role in quality control and product development.

2. Color Fastness Testing Machines:

These machines assess the colour fastness of dyed fabrics by subjecting them to various conditions, such as washing, light exposure, and rubbing. This ensures the durability and longevity of the fabric’s colour.

Generally, textile industry uses a broad category of equipment in the conversion process from textile material to the final product. All machines ranging from spinning and weaving to dyeing and finishing are very important in the process. It is worthwhile to study the functions as well as the capacities of these machines for anyone that is involved in the textile business.

It has been a well-known fact at Weavetech organisation that accurate textile machinery guarantees good fabric production. The awareness of the most recent innovations and the wide spectrum of machinery guarantees that clients get the most appropriate items and services.

It is critical for any textile factory to ensure that they acquire the right textile factory machine that will make their production to be more efficient and of high quality as well as be versatile in use. Whether you operate within spinning, weaving, knitting, and finishing categories, it is very important that you are able to get the right equipment so as to also be able to compete in the complex textile market.

Read More:- Types of Textile Machinery Used in Textile Industries

0 notes

Video

undefined

tumblr

Lead edge feeder colors Flexo printer slotter rotary die cutter machine

This equipment can complete multiple processes such as multi-color printing, creasing, slotting, trimming, corner cutting, die cutting, and punching of cardboard at one time. The equipment adopts lead edge adsorption paper feeding, the host and fan frequency converter control the start and stop, the main touch screen and side touch screen adopts the PLC programming system to control the various parts , and realize the human-machine interface to control the operation of each part .

0 notes

Text

How Does A Heat Transfer Press Work? What Are The Advantages And Disadvantages?

The goal of a heat transfer press is to transfer a graphic or pattern from one substrate to another. In most situations, this entails transferring designs from a particular transfer paper to fabric, paper, plastic, or ceramic material. A heat transfer press, as the name suggests, achieves this goal by combining heat and pressure.

The heat transfer paper is an important part of this process. Almost any large contribution can be transferred to the desired substrate by printing on heat transfer paper with a basic inkjet printer. Because no particular printer is required, the beginning cost for a heat transfer-based firm is considerably reduced.

There are numerous heat transfer press machine alternatives available today. The majority of these are still flatbed or clamshell in configuration, however rotary heat presses are becoming increasingly widespread as they are easier to automate. To that aim, heat transfer press machines that are both automated and manually controlled are offered. A semi-automated solution is also available. Heat transfer press machines with automated functions are, predictably, more expensive.

Heat transfer presses have proven to be quite popular among small-business owners looking to create bespoke t-shirt firms. Small heat press machines may now be purchased for less than $200 and include digital temperature readouts and timers. A normal inkjet printer can be used to print on heat transfer paper.

The development of heat transfer press technology, which has a very low technical and financial barrier to entry, has resulted in a spate of enterprises offering custom-designed goods in the last few of years.

Heat transfer press advantages and disadvantages

To evaluate the merits of heat transfer press technology, compare it to other technologies developed for similar purposes, such as screen printing and sublimation printing. What are the advantages and disadvantages of the heat transfer press in comparison to the alternatives?

Advantages

Design variety and resolution are excellent.

Heat transfer printing has made the process of designing unique products exceedingly simple. Any digital design can be implanted in a variety of fabrics, ceramics, and other materials by simply printing it on heat transfer paper. There is no longer any need to limit the number of colours in the design or to undertake several printing passes, which was a major constraint of traditional screen printing.

Disadvantages

Fabric feels thick.

The ink does not become a part of the cloth as a result of heat transfer pressing. Instead, a complete layer of heat transfer paper is placed on top of the fabric, considerably increasing the weight, flexibility, and breath ableness of the garment. When printing huge graphics, a t-shirt or any other article of clothing can become extremely uncomfortable.

Heat transfer press for sale comes when it is in demand so user may come any time at the time of sale just like heat transfer vinyl in Atlanta are more in use. For more details visit to our website.

0 notes

Text

What equipment is needed to make organic fertilizer into granules?

Bio-organic fertilizers are mainly derived from plants and animals. They are applied to the soil to provide carbonaceous substances whose basic function is plant nutrition. After processing, toxic and harmful substances are eliminated, and a large number of beneficial substances are contained. Why should organic fertilizer be made into granules?

Equipment required for the production of granular organic fertilizer:One. Hopper automatic transmission: 1. Belt transmission. 2. Automatic feeding. 3. Avoid sticking to the wall.Two. Vertical grinder: 1. Manganese steel blade. 2. Not afraid of damage. 3. Large output.Three. Drum screening machine: 1. Plus seal. 2. Bring a beater. 3. Not stick to the wall

Four. Organic fertilizer granulator machine: Common organic fertilizer granulators on the market include: npk fertilizer granulator, rotary drum granulator, disc granulator machine, new organic fertilizer granulator, new two-in-one organic fertilizer granulator, flat die granulator, ring die granulator, all kinds of granulators have their own production characteristics, and the fertilizer granulator machine price vary.

Five. Cooler: 1. It can greatly increase the cooling speed, ease the labor intensity and improve the efficiency. 2. Further remove part of the water and reduce the temperature of fertilizer granules. 3. The equipment has compact structure, high cooling efficiency, reliable performance and strong adaptability.Six. Automatic packaging machine: 1. The machine adopts a new type of fully intelligent control instrument, which automatically corrects the deviation and reports the deviation, and the fault comes from the diagnosis. 2. The parts in contact with the material are all made of 304 stainless steel, which has a long service life. 3. A printer interface is reserved, which can print production data such as packaging quantity and total weight. 4. The control box adopts sealed form, which is suitable for extreme dust environment. The tightening parts are made of stainless steel for long service life.

0 notes

Link

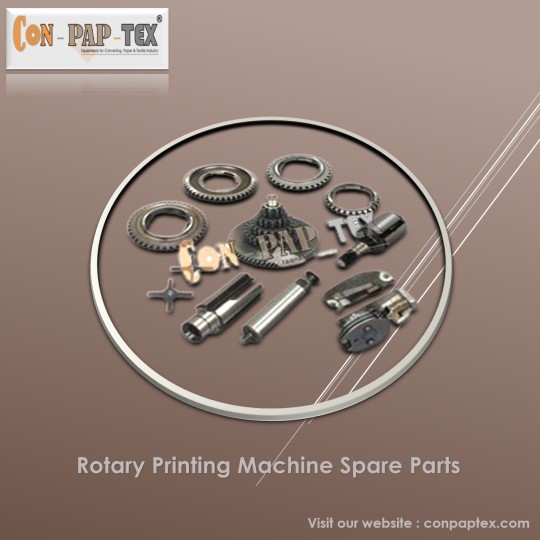

Con-Pap-Tex is a Company Promoted by Experts Technocrats having more than 25 Years of Experience in Rotary Printing Machine, and Rotary Printing Machine Part. Spare Parts for Rotary Printing Machine Like Printing Unit Lifting Bevel Box, Hand Wheel, Screen drive Gear Shaft, Screen Drive gear, Fork Assembly, Muff Coupling, Eccentric Type, Bearing, Rollers MS etc.

#Spare Parts for Rotary Printing Machine#Rotary Printing Machine Part#Textile Machinery Parts#Rotary Printing Machine Spare Parts#Rotary Screen Printing Machine Parts

1 note

·

View note

Link

We “CON-PAP-TEX” are leading manufacturer, exporter and supplier of Rotary Spares, Spare Parts for Rotary Screen Printing Machine. Spares for Rotary Screen Printing Machine Like Printing Unit Lifting Bevel Box, Hand Wheel, Screen drive Gear Shaft, Screen Drive gear, Fork Assembly, Muff Coupling, Eccentric Type, Bearing, Rollers MS etc. Also, we are leading manufacturer of Rubber Roller, Slitter Rewinding Machine, Web Guiding System and more.

0 notes

Link

Leading manufacturer of Stenter Machine Spare Parts like Chain Link, Bottom Parts, Stenter Machine Pin Bar, Stenter Clip, textile machinery in India. A Textile Machinery Spare Parts Manufacturer, Stenter Machine, Jigger Machine, Rotary Screen Printing Machine, Mechanical Cloth Guiders, Folding Machine, Gear Sets, Nylon Gear Cuppling & Sleeve, Rubber Roller, Stenter Clip, Stenter Machine Pin Bar etc. Stenter Clips of Any Make like Artos, Dhall, Harish, Yamuna, Hi-Tech, S.M., Stenmech Lucy , Bharat Eng., Monfort, Montex, Swastik, Bruckner, Babros, Ambika, Famatex, etc. Chain Link & Bottom Parts (Pin Block, Loop Chain) of Any Make Stenter Machine. Pin Bars - Any make like Artos, Harish, Supra, Montex etc. Shaft (Main Drive, Driven Horizontal Shaft, etc.) Over Feed (Rubber Pulley Assembly, Drum Pulley Assembly, Post Pin Brush Assembly, Three Finger Uncurrler Assembly).

#Stenter Machine Spare Parts#Textile Machinery#Stenter Machine#Textile Machinery Spare Parts Manufacturer#Jigger Machine#Rotary Screen Printing Machine#Mechanical Cloth Guiders#Folding Machine#Textile Machine Manufacturer#Textile Machine price#Textile Machinery Spare Parts#Textile Machinery Industry#Textile Machinery in India

0 notes

Link

Spares Textile Processing Machinery, Textile Machinery Spare Parts Manufacturer India, Stenter Machine, Jigger Machine, Rotary Screen Printing Machine. Universal (Multi Repeat) Bridge Assembly Drive & Pump Side for 640,820,914. Single Repeat Bridge Assembly Drive & Pump Side for 640,820,914. Universal Screen Setting Assembly (RH / LH). Screen Setting Assembly (RH / LH). Screen Guide Bearing Bracket. Screen Guide Bearing & Pin. Stenter Machine Spare Parts like, Stenter Clips, Chain Link Bottom Parts, Pin Block, Loop Chain, Pin Bars, Gear Box Parts, Shaft, Over Feed and Chain Wheels. Cloth Guider Spare Parts, Bracket left & right, Base Plate Alluminium Left, Base Plate Alluminium Right, Tope Fiber Roller Laminated complete, and Fiber Roller Laminated only. Healed Frames and Healed Frame Accessories. Reeds, Heralds and Drop Pins. Spinning Weaving Machinery Spare Parts.

https://youtu.be/NqBr-6efPf8

#Stenter Machine#Textile Machinery Spare Parts#Textile Machinery#Textile Machine price#Textile Machine spare parts#Textile Machine Manufacturer#Jigger Machine#Rotary Screen Printing Machine#Textile Machinery Spare Parts Manufacturer India#Spares Textile Processing Machinery#Spinning Weaving Machinery Spare Parts#Stenter Machine Spare Parts#Cloth Guider Spare Parts#Folding Machine Spare Parts

0 notes

Link

All type of Parts of Rotary Printing Machine Manufacturer, all types of Textile Machinery Spare Parts, Rotary Screen Printing Machine with longer durability. We are leading manufacturer, exporter and supplier of Spare Parts for Rotary Printing Machine international standard from last 25 years from India. Spares for Rotary Screen Printing Machine Like Printing Unit Lifting Bevel Box, Hand Wheel, Screen drive Gear Shaft, Screen Drive gear, Fork Assembly, Muff Coupling, Eccentric Type, Bearing, Rollers MS etc.

#Spare Parts For Rotary Printing Machine#Textile Machinery#Textile Machinery spare parts#Rotary Screen Printing Machine#Rotary Screen Printing Machines#Parts of Rotary Printing Machine#Parts of Rotary Printing Machines#Textile Machinerys#Textile Machinery parts

0 notes

Text

We are a leading manufacturer, exporter, and supplier of Spare Parts for Rotary Printing Machine international standards for the last 25 years from India. Spares for Rotary Screen Printing Machine Like Printing Unit Lifting Bevel Box, Hand Wheel, Screen drive Gear Shaft, Screen Drive gear, Fork Assembly, Muff Coupling, Eccentric Type, Bearing, Rollers MS, etc. For more information:

Website: conpaptex.com

Email: [email protected]

Contact Us: +91-7940085305

2 notes

·

View notes

Text

9) Group Task-1960′s

Image sourced: http://www.thepeoplehistory.com/1960s.html

Following on from the first part of the critical thinking lecture, as a group we looked into the influencing factors that impacted fashion in the 1960’s.

The invention of laser cutting machines, development of screen-printing machines, and the invention of tights were created during this time period.

The Vietnam war, Martin Luther King’s famous speech and his assassination, LSD becoming illegal in the USA, the moon landing, and the start of the gay rights movement were amongst the most impactful invents during the 60′s.

Some of the most prominent social changes of the sixties are The Beatles, Woodstock Festival, Breakfast at Tiffany’s, Andy Warhol, Op Art, Audrey Hepburn, rebellion, and a growth in the hippie lifestyle.

Fashion changes that came from the different contributing factors of the 1960’s include hippie fashion which was ignited after the Vietnam War, Twiggy and Mary Quant who were catalyst for the mod trend and shorter hemlines, Ralf Lauren, and Yves Saint Laurent.

In the 1960’s screen printing was completely modernised and used alongside a rotary machine for mass production of which helped drive the up-and-coming pop culture. Andy Warhol created pop art which is a very well-known style of art today. Warhol used bright and bold colours to glamorise the the fun and liveliness of the sixties. Screen printing has also enabled the fashion industry to be able to mass print textiles for colourfully printed garments.

The Woodstock Festival was popularised in the 60′s and promoted a sense of community and togetherness, love and peace, rebelling against capitalism and society, and protesting the ongoing Vietnam War. The impact Woodstock had on the fashion Industry was huge, with women no longer wanting to be restricted in their clothes and opted for a more loose fitting approach with free flowing garment styles and long hemlines- clothing was either recycled, thrifted or handmade.

1 note

·

View note

Text

PART DECORATION FOR PLASTIC INJECTION MOLDING

Many plastic injection molded parts need to have some form of decoration applied to them after being manufactured. Possible reasons for decorating or marking parts include identification, tracking, branding, notices, warnings, instructions, as a product attribute, or otherwise. There are some standard methods of decorating plastic parts, and each has certain advantages and considerations, depending on the part application, the decorating purpose, and the resin being used.

PAD PRINTING

Historically, one of the more popular methods for decorating plastic parts has been with pad printing. There are three different types of pad printing machines: open inkwell, closed ink cup, and rotary gravure, which is used for printing 360 degrees on a part. Machines have a printing plate or a cliché, which commonly are made out of steel for durability. The artwork to be printed onto the parts is etched into the printing plate.

As the name suggests, the machines have transfer pads that come in a few different shapes and that are made out of silicone rubber with various hardness or shore levels. Pad life ranges from 10,000 to 100,000 cycles with an average of about 50,000.

The process consists of the pad picking up ink in the etched image on the cliché and placing it onto the part. Pad printing uses a type of solvent-based ink specifically designed for this purpose. This type of decoration also requires the fabrication of nesting fixtures to hold the parts in place during the printing process.

HEAT TRANSFER

A newer and usually more effective method of part decoration is thermal or heat transfer. With this process, the image is printed on a polyester film, which is coated with an adhesive so the image will stick to the part. Rolls of this film with the digitally printed images are placed on the printing machine’s reels, which index forward to print successive parts. Fixtures to hold parts are used here, as they are in pad printing. Additionally, a silicone decorating head or pad applies heat and pressure to print the transfer image onto the part.

Some advantages of heat transfer include the ability to create an image with four colors plus white in as high as 1200 dpi. In addition, there is no drying or curing time with decorating plastic parts, as there is with pad printing. Further, heat transfer decorations generally are tougher than pad printing and can be dishwasher safe.

HOT STAMP

Another common technique used to decorate plastic injection molded parts is hot stamping. A hot stamp machine transfers an image with pre-dried ink to a part with a die, again using heat and pressure and a fixture to hold the part, as with the previous methods.

One main advantage of hot stamping is the ability to apply a metallic foil or embossing to a plastic part. If you’re reading this article on a desktop computer, chances are the monitor in front of you has a logo that has been hot stamped on it. It also is a relatively clean process, compared to the wet ink used in pad printing.

LASER MARKING

Another method for decorating injection molded parts is by utilizing a laser marking system. This approach includes laser marking, laser engraving, and laser etching. Laser marking (or foaming) changes the color of the part where the text or graphic is, while the surface stays relatively unchanged. Alternatively, laser engraving removes some of the surface material, whereas laser etching melts the surface resin and creates a raised mark.

Of course, laser marking, engraving and etching all require a laser decorating machine. Additionally, fixtures to hold the parts usually are required, as with other decorating methods, although some fixtureless laser decorating systems have been developed. Some advantages of laser decorating include less wear and tear on the decorating equipment, it’s a precise and repeatable process, and it provides the ability to decorate some hard-to-reach part areas. Due to these benefits, industries like medical, automotive and aerospace often utilize the process.

IN-MOLD DECORATION

The method of in-mold decoration involves placing a pre-printed plastic film or appliqué in an injection mold before the part is molded, and the graphic then adheres to the part after it forms in the mold’s cavity. In-mold decoration requires a uniquely designed and built plastic injection mold and a carrier film feeder. The film can be manually placed into the mold between each cycle, but that greatly increases the manufacturing time and labor costs associated with the parts. However, even with a feeder, parts requiring in-mold decoration generally tend to be more expensive than other decorated parts, due to the specialized design, tooling and manufacturing required.

INKJET DECORATION

Inkjet printing on plastics is a relatively newer process, and it involves digitally printing a graphic onto a part. The system essentially is the same as inkjet printers for paper, with which most of us are familiar, although it uses a different type of ink. These machines typically use either conventional or LED lamps, and the process eliminates labels, films, printing plates, clichés or screens, as required with other decorating methods, although they do require a printhead and ink. Historically, this kind of decorating is somewhat slower and more costly than other forms, although advances are being made.

SCREEN PRINTING

Most people are familiar with screen printing in the context of t-shirts, and this also can be referred to as silk screening. Screen printing can be used for parts with flat or cylindrical surfaces but is not recommended for parts with complex curves and shapes. One advantage of screen printing is that it can print metallic graphics onto parts, which some other methods cannot do. Although providing the option of printing with multiple colors, a separate screen is needed for each separate hue, which increases cost and decorating time. The surface to be decorated needs to be prepared prior to printing, too.

PAINTING

When injection molding a part cannot achieve the desired texture, finish or color, painting the parts sometimes is utilized as a secondary operation. This approach can include spray painting and powder coating. As most injection molders do not perform painting as a finishing operation, the parts will need to go to a secondary provider, which often results in increased costs.

PLATING

When looking for a metal finish on an injection molded part, hard chrome plating and electroless nickel plating are two commonly used options. Plating offers a decorative finish, and it provides a certain level of corrosion protection. One item to note is that any surface imperfections on the part can affect the look of the plating, so consideration needs to be given there. Additionally, few molders also perform plating services, so those two suppliers will need to coordinate their work. There also are some design and material considerations that must be taken into account.

CONCLUSION

There are many different methods of decorating a plastic injection molded part, and each has its own unique advantages and disadvantages, depending on the requirements of the project. When developing a new product with components that may need to be decorated in some way, attention should be given to the part design, the polymer being used, the decorating purpose, the part application, the governing regulations, and the cost considerations. If we can answer any questions, don’t hesitate to reach out to us.

--

Ash Brown // VP, Business Development

1 note

·

View note

Text

Virtuscope Cyberdeck Build

New Post has been published on https://planet-geek.com/2022/08/22/stuff-n-bother/virtuscope-cyberdeck-build/

Virtuscope Cyberdeck Build

Somewhere in the 2nd year of the pandemic, I stumbled across a posting on Hackster.io about a design for a ‘Cyberdeck’.

A what now?

For those who don’t know, the term Cyberdeck was coined by William Gibson (the inventor of the terms “Cyberpunk” and “Cyberspace” by the way) to describe a piece of computing equipment used to to jack into the net in the future. These fictional machines were basically the hot rods of the grunge tech and hacker scene, able to do anything from simple education stuff all the way to allowing a talented hacker to penetrate the most well protected systems out in cyberspace. They were fast, personalized tech that marked the owner as someone serious about hacking.

BootDSC’s Original Cyberdeck Design

I’ll admit, I’ve read everything by William Gibson, Neal Stephenson (you know, the guy who actually invented the term ‘metaverse’?), Bruce Sterling, and Philip K Dick. In particular, Gibson’s portrayal of Ono-Sendai decks that could jack into and surf cyberspace are well wedged in my psyche. The idea of building and customizing my own ‘deck was too good a concept to pass up, so I took the plunge.

The Printer

There are basically 3 major components to a build like this. The case, the keyboard, and the computer. While it’s possible to build your own keyboard and computer, I wasn’t ready for all that, so I used off the shelf parts for that. The case, however, I’d manufacture myself.

The first phase of this was to get my 3d printer up and running again. I’d been doing a bunch of printing, learning the ropes as it were on how to use TinkerCAD and Cura to take a shape and turn it into a Real Live Thing. I built a healthy respect for people who operated industrial equipment. 3d printing isn’t a push a button, get an object system. It requires constant tinkering, adjusting, repair, and fiddling to keep it all working, and there’s a million small ‘tricks’ you learn in the process to keep a 3d printer running smoothly. It’s a good feeling when you can get your system dialed into the point where you can just power it up, prep the surface, and say “PRINT THIS”, and it works.

Some smooth first layer porn.

My printer (a Creality CR10) had been acting twitchy for a while. I’ve used it for a couple projects in the past, but nothing serious in the last year or two. The problem(s) turned out to be a combination of bad bed levelling, bad bed prep, and a completely horked print nozzle. Once I got those straightened out, I was printing clean, flat prints without any fiddling. I was ready!

The Design

I have to give full credit to BootDSC and the full on Virtuscope design on Thingiverse. This was my first exposure to decks, and I immediately went “I WANT ONE”. Fortunately, the Cyberdeck Cafe website had an entire build page that details all the parts needed. I set up my printer and started printing components, dove into Amazon and various websites to order the parts needed.

Printing the frame, hinges, panels, and other components took about a week. In that time, some of my components had started to arrive, most importantly the Raspberry Pi 4 that was to be the heart of the system, as well as a Geekworm X728 LIPO battery/power module. Screen, keyboard, and other componentry arrived over the next few days.

Display portion of the lid

Gluing the base panels together

This was my first decent ‘build from scratch’ project, and I learned early on I was missing a lot of build supplies. M3 screws and nuts, bolts, a good rotary tool (I had been using an old Craftsman tool I bought 30 years ago? But it died a horrible death partway through the build. The Ryobi rotary tool is excellent, though it really does sound like a dentist drill while in operation).

Eventually I had all the pieces I needed, and I could get on with the build.

I wanted to make one relatively large change – I wanted to use a touchscreen. The 7″ HDMI display I used has a ‘mouse’ function in it that connects to the Pi via USB cable. The problem though is fitting it into the lid of the deck was problematic. I ended up redesigning the lid to give it more ‘depth’ to allow the driver board and cabling to fit. Probably my first real 3d design project – I also had to redesign the component bay lid to make room for the new larger lid and hinge. Multiple prints later, it all fit together the way I wanted it to.

Bench testing the display and controller and realizing the lid needed to be deeper.

This is one of those projects that will really never end. I’m constantly modifying the design, adding new components, removing others. I found that the power connection setup on the back was really awkward, so I designed and printed a USB-C port to go in the opening. This means the whole thing can be recharged via USBC cable, or just run off a power adapter. Win!

I also ran into a problem with the touchscreen USB cable, which, as it came from the supplier, had a 6′ long cable with a ferrite core on it. I picked up a kit to allow me to truncate the cable and put a new end on it, but it turns out I got the wrong connectors. So I ended up just chopping the cable in half and soldering it into an older USB-A jack. I only need about a foot of cable, so that worked great.

The Final Product

I love how this looks. I love knowing that I built it, and there’s no other one thats just like it.

So what’s next?

There’s still stuff to do though:

The keyboard setup (a Royal Kludge RK61 USBC / Bluetooth keyboard), while fitting perfectly into the case, I find sort of difficult to work with. The ‘modifier’ keys are awkward and easy to get confused, and as it sits now, I can’t run it off USB while in the case. I have to pull it to recharge it and reconnect via USB.

The rear panel needs more love. The system is supposed to support a secondary Wifi interface to allow it to run Aircrack-NG and other tools without taking down the primary interface. I have the parts, but haven’t put it all together.

Finding the final location for the ‘stack’ (CPU and power board) is proving slightly problematic, as I need space for the USB connections and other wiring. Until that’s locked down, I really can’t mount the boards. I may jsut drill and mount them anyway to keep things from banging around.

Still need to get hte lid closures working – this can be done with a magnetic plate, but it seems a little iffy. May come up with something else.

Mouse input. Sigh. I had hoped the touch screen would work for this, but it really doesn’t. The screen is small (7″) and my finger is fat. I may explore using a stylus, but I think I’ll need some sort of trackball or thumbwheel or something.

Viewing angle – this may be the killer for me. For the lid / screen to work well, the viewing angle has to be relatively laid back. To do that, the hinge and cabling need to be very flexible, and finding that space is mighty hard. If I can’t solve the viewing angle problem, this will be likely remain a toy project, and not something I can use seriously.

Conclusions

I LOVED doing this project. It looks cool, I can say “I BUILT THAT” and I can keep tinkering and making it better. The Pi4 is enough horsepower to have fun on it, while still having decent battery life. Once I get the mobility stuff fixed up, I’ll start carting it around more.

1 note

·

View note

Text

Ghee Packaging for Healthy Outcomes From Nichrome

Ghee is the second most consumed dairy product in India and is widely used in Indian cooking. There are a number of factors for the growing ghee market - population growth, rising incomes, easy availability, and a greater appreciation of the health benefits of ghee. It comes as no surprise that the ghee market is forecast to grow at a rate of 15% till 2024.

Uttar Pradesh currently accounts for the majority of the ghee market in India, followed by Rajasthan and Madhya Pradesh. Some of the prominent players in the market are GCMMF (Amul), RCDF, Mother Dairy, Patanjali, SMC Foods etc.

Ghee Packaging from Nichrome

Even though ghee has a long shelf life - it can be stored for 6 to 12 months under the right conditions - proper filling and packaging play an important role. The ghee can turn rancid when exposed to heat, light, air, water vapour and certain metals that cause deterioration.

Nichrome’s technology can be used to package ghee in commonly used ghee packaging materials:

Tin Cans: Most commonly used for bulk packs of 5L and 15L. Coated to prevent rusting.

Glass Bottles: Provide excellent protection to maintain the quality of ghee. Normally used for retail packs of 100g to 500g.

Semi-rigid Containers: Generally made from HDPE and provide advantages of being lightweight, economical and easy to transport. These containers come in a few types: blow moulded HDPE bottles, jars and cherry cans; and odour-free PET bottles that act as gas barriers.

Flexible Pouches: The most economical approach for ghee packaging. These pouches need to be made using materials with the following characteristics:

- No reaction with ghee

- Easy availability at low cost

- Non-toxic materials

- Should not let the printing ink penetrate into the produce

- Should have good barriers to prevent spoilage

- Should be able to survive the rigours of transportation

Ghee Packaging Solutions from Nichrome

Nichrome is a ghee packing machine manufacturer whose product range has many solutions for the packaging of ghee to match your space, packaging format and budget requirements.

Some of the more popular ones are:

● VFFS Ghee Pouch Packaging Machine

The Filpack Servo SMD is Nichrome’s most popular ghee packaging machine and is a durable, heavy-duty option, with a touch screen HMI panel and PLCs that control operations. It comes with an enclosed SS cabinet for hygienic operation and also occupies less floor space.

The Filpack Servo SMD operates at speeds of 70-85 pouches per minute depending on the package size and can package ghee and other viscous products such as oil, ketchup, fruit pulp, mayonnaise, curry pastes and even products like grease, paint, adhesives etc.

The pouches are in 3 side seal format and quantities range from 50 ml to 1000 ml.

This machine also comes with independent head operation so one can pack two different products and quantities simultaneously.

● Bottle Filling Line

Nichrome’s efficient integrated system for bottle filling and packaging covers a turntable, UV sterilization chamber, automatic liquid filling machine, cap feeding elevator, rotary capping machine, induction sealer, labelling machine, date & batch coding system, and a packing table.

The system is controlled by PLCs and packs a number of viscous products such as ghee, ketchup, chocolate sauce and more. Some of the other applications of this system include a wide variety of food & beverage products such as flavoured milk, soft drinks, energy drinks, water & buttermilk and non-food liquids such as perfumes, oil, shampoos and handwash with SKUs ranging from 100 ml to 20 litres.

● Tin Filling Line

The Tin Filling Line from Nichrome offers sturdy, low maintenance operation with accurate and efficient performance. This line is controlled by PLCs and has a digital LCD touch screen to display settings and safety enclosures with interlocks for rotary parts.

This is a composite friendly line that offers auto lid feeding, placing, and lid seaming. The machinery can be constructed in SS3014, SS316 and MS painted materials with various sterilization and cleaning options available

Conclusion

If you want to take advantage of the rising demand for ghee and the cost-effectiveness of flexible packaging, you should consider Nichrome’s ghee packaging solutions. In addition to offering the latest technology, Nichrome also offers the expertise to customise and manufacture solutions for businesses of all scales.

Nichrome - among the best food packaging machine manufacturers in India - started operations 4 decades ago as a pioneer in milk pouch packaging machines for India’s White Revolution. In the present day, Nichrome’s know-how and capabilities cover the packaging of a wide range of dairy products. Nichrome has a reputation for being a leading integrated packaging solutions provider and oil packing machine manufacturer and is trusted for the superior technology of its automatic packaging machines, manufacturing capabilities, nationwide service support and trenchant problem-solving skills. Nichrome - as a food packaging machine and automatic oil filling machine manufacturer - believes in partnering with customers through the complete lifecycle of the solution, delivering the most effective application-specific solutions.

Nichrome is based out of Pune, India and possesses a service network that spans the world. With a presence in 45 countries and more than 7000 successful installations worldwide, Nichrome is truly a Global Player in its domain.

Visit www.nichrome.com for more information.

#milk pouch packaging machines#oil packing machine manufacturer a#automatic packaging machines#food packaging machine#automatic oil filling machine#integrated packaging solutions#best food packaging machine manufacturers in India#ghee packaging solutions#Tin Filling Line#● Bottle Filling Line

0 notes

Link

We are leading manufacturer, exporter and supplier of Spares for Stormac Stork Rotary Printing Machine Parts. Spares for Rotary Screen Printing Machine Like Printing Unit Lifting Bevel Box, Hand Wheel, Screen drive Gear Shaft, Screen Drive gear, Fork Assembly, Muff Coupling, Eccentric Type, Bearing, Rollers MS etc. Also, we are leading manufacturer of Rubber Roller, Rubber Fillet, Slitter Rewinding Machine, Web Guiding System and more.

#Screen Drive Gear#Screen Drive Gear Shaft#Printing Unit Lifting Bevel Box#Spares For Stormac Stork Rotary Printing Machine Parts#Bearing#Eccentric Type#Muff Coupling#Fork Assembly#Hand Wheel

0 notes