#Rocketdyne

Explore tagged Tumblr posts

Text

When North American Rockwell builds a spacecraft, North American Rockwell builds a spacecraft.

#vintage advertising#north american rockwell#nasa#apollo#spacecraft#apollo command module#apollo service module#saturn rocket#rockets#lunar module#moon landing#the 60s#engineering#rocketdyne

62 notes

·

View notes

Photo

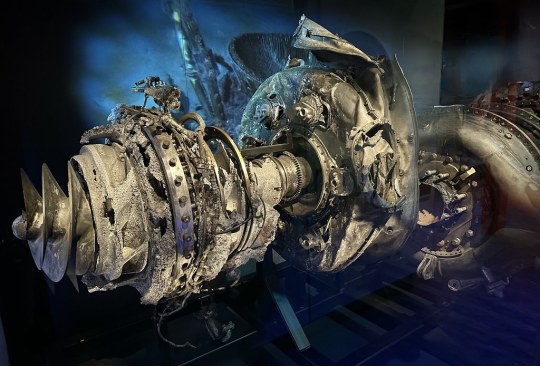

Saturn V F-1 Rocket Engine Remains from Apollo 11 by jurvetson https://flic.kr/p/2omF4H4

28 notes

·

View notes

Text

SSME Shuttle Engine2

Cliff Steenhoff on Flickr

0 notes

Text

Deming and Rocketdyne

Sometime in late January of 1987, almost one year to the day after the Space Shuttle Orbiter Challenger was destroyed as it ascended to orbit, I was assigned by the temp agency I was using at the time to begin work on the Space Shuttle Main Engine team at Rockwell International’s Rocketdyne Division in Woodland Hills, CA. Prior to that fateful date I had, with one exception, never worked at a…

View On WordPress

#14-points#Challenger#Control#Deming#management#Philosophy#Rocketdyne#Rockwell International#Space Shuttle#SSME#Total Quality Management#TQM

0 notes

Text

youtube

0 notes

Text

"This image depicts a Boeing worker installing an F-1 engine on the Saturn V S-IC flight stage at the Michoud Assembly Facility (MAF). The Saturn IB and Saturn V first stages were manufactured at the MAF, located 24 kilometers (approximately 15 miles) east of downtown New Orleans, Louisiana. The prime contractors, Chrysler and Boeing, jointly occupied the MAF. The basic manufacturing building boasted 43 acres under one roof. By 1964, NASA added a separate engineering and office building, vertical assembly building, and test stage building."

Date: November 1967

NASA ID: 6760478

#Rocketdyne F-1#F-1#Rocket Engine#S-IC#Saturn V#Rocket#NASA#Apollo Program#Construction#Michoud Assembly Facility#New Orleans#Louisiana#November#1967#my post

58 notes

·

View notes

Text

The F-104, affectionately known by the Canadian Air Force as “the lawn dart.”

Pointy! This thing had the lift-over-drag ratio of a brick, btw, but it looks super awesome.

#F-104#the NF-104 had a Rocketdyne AR2-3 rocket engine with hydrogen peroxide as an oxidizer#there’s one mounted on a stick near where I work it’s aggressively cool-looking

22K notes

·

View notes

Text

0 notes

Text

Actualizaciones para Todos los motores agregados a la etapa central del cohete lunar Artemis II de la NASA

El cohete más poderoso del mundo El 25 de septiembre de 2023, ingenieros y técnicos de la NASA, Aerojet Rocketdyne y Boeing completaron la instalación de los cuatro motores RS-25 en el escenario central del cohete del Sistema de Lanzamiento Espacial (SLS) de la NASA. Esta es una etapa importante en el desarrollo del SLS, que es el cohete más poderoso del mundo. Los motores RS-25 son motores de…

View On WordPress

0 notes

Text

ALT: This video shows blades of grass moving in the wind on a beautiful day at NASA’s Michoud Assembly Facility in New Orleans. In the background, we see the 212-foot-core stage for the powerful SLS (Space Launch System) rocket used for Artemis I. The camera ascends, revealing the core stage next to a shimmering body of water as technicians lead it towards NASA’s Pegasus barge. Credit: NASA

The SLS (Space Launch System) Core Stage by Numbers

Technicians with NASA and SLS core stage lead contractor Boeing, along with RS-25 engines lead contractor Aerojet Rocketdyne, an L3Harris Technologies company, are nearing a major milestone for the Artemis II mission. The SLS (Space Launch System) rocket’s core stage for Artemis II is fully assembled and will soon be shipped via barge from NASA’s Michoud Assembly Facility in New Orleans to the agency’s Kennedy Space Center in Florida. Once there, it will be prepped for stacking and launch activities.

Get to know the core stage – by the numbers.

Standing 212 feet tall and measuring 27.6 feet in diameter, the SLS core stage is the largest rocket stage NASA has ever built. Due to its size, the hardware must be shipped aboard NASA’s Pegasus barge.

900 miles

Once loaded, the barge – which was updated to accommodate the giant core stage -- will travel 900 miles to Florida across inland and ocean waterways. Once at Kennedy, teams with our Exploration Ground Systems team will complete checkouts for the core stage prior to stacking preparations.

18 Miles + 500 Sensors

As impressive as the core stage is on the outside, it’s also incredible on the inside. The “brains” of the rocket consist of three flight computers and special avionics systems that tell the rocket what to do. This is linked to 18 miles of cabling and more than 500 sensors and systems to help feed fuel and steer the four RS-25 engines.

8.8 million

Speaking of engines… Our SLS Moon rocket generates approximately 8.8 million pounds of thrust at launch. Two million pounds come from the four powerful RS-25 engines at the base of the core stage, while each of the two solid rocket boosters produces a maximum thrust of 3.6 million pounds. Together, the engines and boosters will help launch a crew of four Artemis astronauts inside NASA’s Orion spacecraft beyond Earth orbit to venture around the Moon.

733,000 Gallons

Achieving the powerful thrust required at launch calls for a large amount of fuel - 733,000 gallons, to be precise. The stage has two huge propellant tanks that hold the super-cooled liquid hydrogen and liquid oxygen that make the rocket “go.” A new liquid hydrogen storage sphere has recently been built at Kennedy, which can store 1.25 million gallons of liquid hydrogen.

Four

The number four doesn’t just apply to the RS-25 engines. It’s also the number of astronauts who will fly inside our Orion spacecraft atop our SLS rocket for the first crewed Artemis mission. When NASA astronauts Reid Wiseman, Christina Koch, and Victor Glover along with CSA astronaut Jeremy Hansen launch, they will be the first astronauts returning to the Moon in more than 50 years.

Make sure to follow us on Tumblr for your regular dose of space!

962 notes

·

View notes

Text

6 December 1963. Air Force test pilot Major Robert W. Smith flew Lockheed F-104A-10-LO Starfighter Aerospace Trainer, 56-0756, to a peak altitude of 120,800 feet. Powered by a General Electric J79-GE-3B turbojet/Rocketdyne LR121 rocket engine.

@ron_eisele via X

60 notes

·

View notes

Video

Linear Aerospike SR-71 Experiment (LASRE) by NASA on The Commons Via Flickr: The NASA SR-71A successfully completed its first cold flow flight as part of the NASA/Rocketdyne/Lockheed Martin Linear Aerospike SR-71 Experiment (LASRE) at NASA's Dryden Flight Research Center (now NASA Armstrong), Edwards, California on March 4, 1998. During a cold flow flight, gaseous helium and liquid nitrogen were cycled through the linear aerospike engine to check the engine's plumbing system for leaks and to check the engine operating characteristics. Cold-flow tests had to be accomplished successfully before firing the rocket engine experiment in flight. The SR-71 flew for one hour and fifty-seven minutes, reaching a maximum speed of Mach 1.58 on this flight. Learn more about the LASRE Project flights in 1997 and 1998 NASA Media Usage Guidelines Credit: NASA/Carla Thomas Image Number: EC98-44440-4 Date: March 4, 1998

21 notes

·

View notes

Text

F-1 Engine Assembly Line in Canoga Park

0 notes

Text

More Than 2 Dozen Jobs!

In my 76 years on this planet, I’ve worked no less than 2 doz jobs, ranging from short order cook, busboy, waiter, restaurant manager, truck driver, forklift driver, butcher, jewelry bench worker, and wiener clerk, to legal secretary, project manager, knowledge manager, and business manager. I retired from Pratt & Whitney Rocketdyne, where I worked on the Space Shuttle Main Engine program for…

View On WordPress

#dignity#Happiness#labor#liquor store#Pratt & Whitney Rocketdyne#Rocketdyne#Space Shuttle Main Engine#SSME#supplemental income#Work

0 notes

Text

"The Saturn I S-IV stage (second stage) for the SA-7 mission being prepared for shipment to Cape Canaveral, Florida. The S-IV stage had six RL-10 engines, which used liquid hydrogen and liquid oxygen as its propellants, arranged in a circle. Each RL-10 engine produced a thrust of 15,000 pounds for a total combined thrust of 90,000 pounds. The SA-7 mission was launched on September 18, 1964 from Cape Canaveral, Florida, and its S-IV stage made the second orbital flight."

Date: January 8, 1964

NASA ID: link

#AS-102#SA-7#Saturn I#Saturn I Block II#Rocket#NASA#Apollo Program#S-IV#Pratt & Whitney Rocketdyne RL-10#RL-10#Douglas#California#January#1964#construction#my post

196 notes

·

View notes