#Repairing Aluminum Boat

Explore tagged Tumblr posts

Text

Everything You Need to Know About Buying HTS-528 Brazing Rods

When it comes to achieving strong, durable joints in metalworking projects, selecting the right brazing rod is crucial. Among the various options available, the HTS-528 brazing rod stands out as a popular choice for both professionals and DIY enthusiasts. In this article, we will explore why the HTS-528 is a preferred choice, how to buy it, and the benefits it offers.

What is HTS-528 Brazing Rod?

HTS-528 is a high-performance brazing rod designed for welding and brazing applications. Unlike traditional brazing rods, HTS-528 does not require flux, which simplifies the process and reduces preparation time. It is known for its excellent bonding capabilities, making it suitable for joining a variety of metals, including aluminum, steel, and stainless steel.

Key Features of HTS-528 Brazing Rods

Flux-Free Application: One of the standout features of HTS-528 brazing rods is that they do not require the use of flux. This not only simplifies the brazing process but also minimizes the clean-up required after the job is completed.

Versatility: It works well on a variety of metals to Buy HTS-528 brazing rods. This brazing rod offers a dependable way to make sturdy, long-lasting joints whether you're working with steel, copper, or aluminum.

High Strength and Durability: The HTS-528 brazing rod delivers high tensile strength and excellent resistance to wear and corrosion. This makes it ideal for applications where joint integrity is critical.

Ease of Use: With its flux-free nature, the HTS-528 brazing rod is user-friendly, making it accessible for both experienced professionals and those new to brazing.

How to Buy HTS-528 Brazing Rod

When purchasing HTS-528 brazing rods, there are several factors to consider to ensure you get the best product for your needs:

Source: Look for reputable suppliers or manufacturers who specialize in welding and brazing materials. Reliable sources will provide high-quality HTS-528 rods and may offer additional resources or support.

Packaging and Quantity: HTS-528 brazing rods come in various packaging options. Consider how much material you need for your project and choose a packaging size that suits your requirements.

Price: While cost is an important factor, it’s essential to balance it with quality. Opt for competitive pricing but avoid the cheapest options if they compromise on quality.

Specifications: Verify the specifications of the HTS-528 brazing rods to ensure they meet the requirements of your project. This includes checking the diameter and length of the rods.

Reviews and Recommendations: Reading reviews and seeking recommendations from industry professionals can help you gauge the effectiveness and reliability of the brazing rods you’re considering.

Benefits of Using HTS-528 Brazing Rods

Improved Efficiency: The absence of flux means you can complete your brazing projects more quickly and efficiently, saving you time and effort.

Cleaner Work Environment: Since HTS-528 doesn’t require flux, you will have less residue and fewer contaminants to clean up, leading to a cleaner workspace.

Enhanced Joint Quality: The HTS-528 brazing rod provides a strong, high-quality joint that can withstand significant stress and wear, enhancing the longevity of your repairs or constructions.

Versatile Applications: Its ability to work with different metals makes HTS-528 a versatile choice for various projects, from automotive repairs to industrial applications.

Whether you are a seasoned professional or a hobbyist, HTS-528 provides a reliable solution for creating strong durable joints without the hassle of flux. By understanding its features, benefits, and the best practices to Buy HTS 528 brazing rods can make an informed decision and achieve excellent results in your brazing tasks. It can significantly impact the success and efficiency of your metalworking projects.

#Buy HTS-528 Brazing Rod#HTS-528 Brazing Rod#Boat Repair with HTS 2000#Aluminum Repair Brazing Rod#Aluminum Brazing Rods Online#Aluminum brazing rod#Brazing and welding rods#cast aluminum repair#die cast aluminum repair

0 notes

Text

Metal Welding Services in Miami: What to Know

Metal Welding Services in Miami: What to Know

If you’re searching for top-notch metal welding services near me in Miami, finding a professional and reliable service provider is key. Miami’s booming construction, automotive, and marine industries demand high-quality welding solutions for various projects. Let’s explore what makes metal welding services in Miami stand out and what you should look for when selecting a provider.

What Are Metal Welding Services?

Metal welding involves joining two or more metal parts through heat, pressure, or both. Welding is an essential process in industries like construction, automotive, manufacturing, and shipbuilding. Miami is home to a range of experienced welding professionals who cater to diverse project needs, including:

Structural welding: For buildings and bridges.

Automotive welding: For vehicle repairs and customization.

Marine welding: Specializing in ships and boats.

Custom metal fabrication: Tailored designs for unique projects.

Why Choose Professional Metal Welding Services in Miami?

Miami is a hub for skilled welders offering precision, durability, and expertise. Here are some key benefits of choosing local welding services:

Expertise in Various Techniques: Certified professionals in Miami use advanced techniques such as TIG, MIG, and stick welding for high-quality results.

Access to High-Quality Materials: Miami welding shops have access to durable metals like aluminum, stainless steel, and carbon steel.

Compliance with Local Regulations: Professionals ensure projects adhere to Miami’s building and safety codes.

Fast Turnaround Times: Local services minimize delays, ensuring your project is completed on time.

Types of Metal Welding Services Offered in Miami

Whether you’re working on a large-scale construction project or need small repairs, Miami’s welding professionals provide a range of services:

Residential Welding: Gates, fences, and railings.

Commercial Welding: Storefronts, signs, and structural supports.

Industrial Welding: Heavy machinery, pipelines, and tanks.

Repair Services: Fixing broken metal parts for boats, vehicles, or equipment.

How to Find the Best Metal Welding Services Near You

Finding the right welding service in Miami can be overwhelming. Here are some tips to help you choose the best provider:

Check for Certifications: Look for welders certified by organizations like the American Welding Society (AWS).

Read Reviews and Testimonials: Online reviews on platforms like Google and Yelp can give insights into the quality of service.

Compare Pricing: Request quotes from multiple providers to ensure competitive pricing without compromising quality.

Ask About Experience: Providers with extensive experience in your specific project type are likely to deliver better results.

Inspect Their Equipment: Modern, well-maintained equipment indicates a commitment to quality.

Top-Rated Welding Companies in Miami

Here are some highly recommended welding services in Miami to consider:

Miami Welding & Fabrication: Specializing in custom designs and structural welding.

South Florida Marine Welding: Experts in marine welding and aluminum fabrication.

Elite Welding Services: Known for precision welding and on-site services.

Benefits of Choosing Local Welding Services

Opting for a local welding service in Miami comes with several advantages:

Quick Response Times: Local businesses can provide on-site services faster.

Knowledge of Miami’s Environment: Welders understand the impact of Miami’s humid climate on metal structures.

Supporting Local Economy: Working with local providers strengthens the community.

Common Metals Used in Welding Projects

Miami welding services work with a variety of metals depending on the project requirements. Common metals include:

Aluminum: Lightweight and corrosion-resistant, ideal for marine and automotive projects.

Stainless Steel: Strong and resistant to rust, perfect for construction and decorative purposes.

Carbon Steel: Durable and cost-effective, suitable for heavy-duty industrial applications.

Copper: Used for electrical and plumbing applications.

How Much Do Metal Welding Services Cost in Miami?

The cost of metal welding services in Miami varies based on factors like:

Type of Project: Custom designs or large-scale industrial jobs may cost more.

Materials Used: Exotic metals like titanium are more expensive.

Complexity of Work: Intricate designs or repairs require more time and expertise.

On average, welding services in Miami range from $75 to $150 per hour, but it’s best to request a detailed quote for accurate pricing.

Tips for Maintaining Welded Metal Structures

To ensure the longevity of your welded metal structures, follow these maintenance tips:

Regular Inspections: Check for signs of wear, rust, or cracks.

Cleaning: Use appropriate cleaners to remove dirt and prevent corrosion.

Apply Protective Coatings: Paint or galvanize metal surfaces to enhance durability.

Avoid Overloading: Prevent excessive stress on welded joints.

Why Miami’s Climate Matters for Welding Projects

Miami’s coastal location and humid climate can affect metal structures over time. Professional welders in Miami understand these challenges and take necessary precautions, such as:

Using corrosion-resistant materials.

Applying protective coatings to combat rust.

Ensuring proper welding techniques to withstand environmental stressors.

Conclusion

When searching for metal welding services near me in Miami, it’s important to choose a provider with expertise, modern equipment, and a proven track record. Whether you need custom fabrication, industrial repairs, or marine welding, Miami’s professionals offer reliable solutions to meet your needs. By selecting a trusted local welding service, you can ensure your project is completed efficiently and to the highest standard.

2 notes

·

View notes

Text

-ˋˏ ꒰ 🐚 ꒱ ── the odysseus : a character study ( death by boating accident tw ).

the 35 ft white sailboat parked at the valparaiso marina is made out of lightweight aluminum, teak wood and fiberglass. it’s small enough that a one-man operation is not too physically strenuous, but the boat itself is showing it’s age and previous neglect : the hull is crusted with barnacles. the steel railings are starting to rust. the upper deck creaks with each step, and if rohan is docked at the marina instead of on the water it’s likely because he’s replacing rotting boards, ropes, and corroded parts inside the motor. netting hangs from the side, disappearing into the dark water of the marina below.

the odysseus was originally built in the late 1980s. rohan impulsively bought it five years ago off the coast of vancouver while on bereavement leave after the death of his mother and sister. when he bought it the boat was practically unusable, and because of that it was cheap. equipped with nothing but lots of extra time and a desperate need to distract himself from the crushing reality of his grief ( and the guilt of not returning home for the funerals ) rohan spent half a year teaching himself the basics of boat repair instead of dealing with his own problems : he replaced the sails, stripped the plumbing, gutted the interior until he was able to take it out for the first time.

a set of horizontal doors open to a ladder that leads below-deck. his living space is uncomfortably small, especially for a grown man : a kitchenette with a stovetop, a seating area that’s become a makeshift workbench, an archway that opens onto a bed. rohan is at least tidy, if not particularly organized. empty surface area is artfully cluttered with different equipment he’s tinkering with, half-finished composition notebooks full of numbers, books he’s in the middle of reading. sticky notes dangle from cupboards with coordinates and irrelevant and months-old reminders like call dad and make dentist appointment, all of which are incomplete and entirely forgotten about ( or avoided. )

once the boat was in working order, it was only a matter of time before he quit the research position he worked so hard to get and travelled down the west coast a free unemployed man. while he was traveling he started to collect an arsenal of makeshift camera equipment and, thus, unique footage of different kinds of sea life. rohan considers himself more as a documentarian than a scientist. because he never studied marine biology, he doesn’t feel comfortable as a voice in any scientific communities, but he still frames all of his work through the lens of education rather than entertainment. his goal is to showcase the beauty of the ocean, but also to document animal behaviours so they can be studied in better detail by people who have a better idea about what they’re looking at. rohan understands just how fragile alive things are, and how fast some of them are disappearing, and he’s determined to document them before that happens.

during this time he got a lot of random, unstructured footage, which he started gathering into a portfolio collected on youtube and tiktok. he refuses to be on camera, so the platforms themselves didn’t draw in money or attention, but it allowed him to showcase what it was he wanted to do to people who mattered ( and gave him some extra funds to cover the expenses of being alive. ) rohan was able to start applying for grants and contracts, and his reputation within academic circles quickly shifted from up and coming climate scientist to nomadic oceanic videographer ; most of his contracts are to film and edit together raw footage into informational videos for conservation groups or educational institutions.

beside the ladder are a twin set of metal lockers for storage : spare oxygen tanks and his scuba equipment, gas canisters, first aid, flares. an apocalyptic preparation kit for the worst case scenarios. a calendar swings precariously attached to the teak wood wall above, persistently falling off the wall with the ebb and flow of the waves, marking important deadlines. the calendar is carefully plotted out, days crossed out and circled in red ink. it’s easy to lose track of time when you spend days on the ocean at a time.

when he’s in between grants or contracts rohan has free reign to track and study whatever he’s passionate about in the moment. during these periods he usually studies the seasonal ecosystems just off the coast of valparaiso, with his topic of interest changing depending on the time of year and the animals that are nearby. the reefs off the beaches aren’t particularly deep so he usually doesn’t bother with heavy tanks or equipment ; rohan was effectively born freediving── diving without tanks and heavy equipment── in the kelp forests just off the coast of falmouth, so he doesn’t rely on equipment as much. when he invites people out diving with him, it’s usually within sight of the beaches and the marina.

every few weeks he takes longer excursions further out into the pacific. these are generally for a specific purpose or to track and get footage of a specific animal on request── migrating whales, hammerhead sharks around the seamounts, sea turtles── and he will spend multiple days at a time out on the water without coming back into port. he doesn’t bring people out on multi-day trips like this ; he does these alone, because he doesn’t like the idea of being stuck with anyone with no escape for an extended period of time, and because if something happens, he wants to be sure that he’s the only one put at risk. these are usually the times where he digs out all of his actual diving gear because the water is deeper and he wants to be down there for longer, though he will still freedive just for fun.

the decor inside the boat is sparse and impersonal; everything serves a functional purpose rather than aesthetic purpose. there’s one exception. tucked in a back corner, half-hidden by the safety equipment piled in front of them, old photos are taped to an elegantly decorated box : an older woman holding a giant spider crab, that same woman and a younger verison of her smiling and waving towards the camera, a family standing in front of a wild, overgrown garden near the sea. unfortunately the movement of the waves don’t allow for trinkets that aren’t tied down, so inside the box sit the sentimental items that rohan can’t bring himself to get rid of, such as the shark tooth his sister gave hi when he was 7 or the collection of seashells from falmouth he used to keep on the windowsill of his college dorm. the most recently addition is a basket of dead things, used to make a makeshift offerenda luna insisted upon after finding a shedded crab skin their first dive together. rohan wears the key to the box around his neck, still carrying the secrets him and his sisters used to hide inside it when they were kids.

rohan’s obsession with the ocean is bordering on religious. it’s in part a regression, coming from an attempt to reconnect with his childhood, aka the fond memories he has with a family he won’t see again. it became very obvious once the accident happened how little rohan actually cared about the conferences and research labs, and he was able to remember the reason why he went into ocean sciences in the first place── not for prestige or money or to save the world, but because he was raised by people who loved the ocean and it’s part of his dna.

the odysseus is where his self-inflicted isolation started. although he’s well aware of the dangers of diving alone, he’s more likely to sacrifice his personal safety for the serenity of being the only human for miles or for the efficiency of knowing he can complete his work on his own. it’s easier to pour all of his energy outside of himself and into something that he thinks is productive and helpful ; and because the things he does are productive and helpful, rohan doesn’t have to stop, pause, process everything that happened in the last half-decade. it’s likely that he not stumbled into the opportunity he may have been forced into working through some of these issues, but for now, if the sea decides to take him and reunite him with the people he's lost, then he will happily go with it.

#rohan kaur : musings#rohan kaur : character study#valpohqinspo#death tw#tw death#by boating accident#not him tho#obviously

9 notes

·

View notes

Text

Aluminum Boat Maintenance Q&A: Expert Insights

As an aluminum boat owner, you know that proper maintenance is key to ensuring your vessel's longevity and performance on the water. However, with the unique properties of aluminum, there are specific considerations to keep in mind. In this comprehensive Q&A, we'll tap into expert insights to address some of the most common questions and concerns regarding aluminum boat maintenance.

Cleaning and Protecting the Hull

How should I clean the aluminum hull of my boat? According to experts, the best way to clean aluminum boat hull is to use a dedicated aluminum boat hull cleaner or a mild soap and water solution. Avoid harsh chemicals or abrasive cleaners, as they can damage the aluminum's protective oxide layer. Regular cleaning helps prevent the buildup of salt, dirt, and other contaminants that can lead to corrosion. Experts recommend using a soft brush or cloth to gently scrub the hull, paying extra attention to areas where dirt and grime tend to accumulate, such as around hardware and fittings. Rinse thoroughly with fresh water after cleaning to remove any residual soap or cleaner.What's the best way to protect the aluminum hull from corrosion? Applying a high-quality aluminum boat wax or sealant is crucial for protecting the hull from corrosion. These products create a barrier against moisture, salt, and other corrosive elements, while also enhancing the boat's appearance. Experts recommend waxing or sealing the hull at least once a year, or more frequently if you use your boat in harsh conditions. When selecting a wax or sealant, look for products specifically formulated for aluminum boats. These products often contain additives that help inhibit corrosion and provide additional protection against UV rays and other environmental factors.

Dealing with Dents and Scratches

How can I repair minor dents in my aluminum boat? For small dents, you can often use specialized aluminum dent repair tools or techniques, like suction cups, to gently massage the metal back into shape. However, for larger or more severe dents, you may need to seek professional assistance from a reputable boat repair shop or mobile fiberglass repair service near you. Aluminum Boat Hull Repair: Unraveling the CostsWhat's the best way to remove scratches from an aluminum boat? Depending on the depth and severity of the scratches, you can try using a fine-grit sandpaper or aluminum polish to buff them out. For deeper scratches, you may need to consider professional assistance, as they may require more extensive repair work, such as welding or patching. When addressing scratches yourself, start with the finest grit sandpaper or aluminum polish, and work your way up to coarser grits if necessary. Be sure to follow the manufacturer's instructions and take care not to over-sand or create additional scratches or swirl marks.

Corrosion and Electrolysis Prevention

How can I identify and address corrosion on my aluminum boat? Corrosion often manifests as pitting, discoloration, or flaking on the aluminum surface. To address it, you'll need to remove the affected areas, either by sanding or using a chemical treatment, and then apply a protective coating or paint. In severe cases, you may need to seek professional assistance for more extensive repairs or even partial replacement of corroded components. Identifying corrosion early is key to preventing it from spreading and causing more significant damage.What causes electrolysis in aluminum boats, and how can I prevent it? Electrolysis is a form of corrosion caused by electrical currents passing through the aluminum and the surrounding water. It can be prevented by ensuring proper bonding and grounding of your boat's electrical systems, as well as by using sacrificial anodes or zincs to protect the aluminum from galvanic corrosion. Restoring Aluminum Boats: Addressing Frequent Concerns

Leak and Hole Repairs

How can I repair a small hole or leak in my aluminum boat? For minor leaks or holes, you can often use a marine-grade epoxy or aluminum patching compound to seal the affected area. However, for larger holes or more extensive damage, you may need to seek professional assistance for welding or patching services.Can aluminum boats be repaired if they have significant hull damage? Yes, in many cases, even severe hull damage can be repaired on aluminum boats. Reputable boat repair shops and mobile fiberglass repair services can often perform welding, patching, or even partial hull replacement to restore the structural integrity of your vessel.By following these expert insights and addressing common concerns, you can keep your aluminum boat in top condition and enjoy many years of safe and enjoyable adventures on the water. Remember, proper maintenance is key to preserving the longevity and value of your aluminum vessel.

3 notes

·

View notes

Note

How long does a circumnavigation take start to finish? Are you going by yourself? What kind of boat do you have?

It depends… on your purpose, your boat, your crew, your route, and def the weather. If you’re looking to set a record, you’ll need to make the circuit in 42 days or less. If you’re looking to tick a box on your bucket list, you could make the middle lat route in 4 to 6 months, again, depending on stuff.

Beyond that, the timeline is up to you. Most I know who weren’t constrained by time have spent a year plus on an initial trip around the globe. Subsequent circumnavigations - very common - that include deviations off the primary routes to new places and long stays in places that capture your heart mean you could spend years at sea. Often those who spend years making the big circle do it in seasonal segments, making trips home to see family and handling other obligations. Some get off the dock and never want to come back unless it’s for repairs and to provision. Regardless of how the next couple of years play out, we plan to spend 2 years, perhaps a bit longer, on the initial circuit.

Once upon a time my plans included a mostly solo circumnavigation, with friends and family joining me for long passages and segments as their time permitted. Today it’s a different story. What the crew makeup looks like is yet to be determined, but for a variety of reasons we will likely hire a professional couple as a First Mate/Engineer and Stew/Deckhand.

Plans for the boat are being drawn as we speak. She will be a one-off aluminum hulled expedition sailboat designed for long periods off the dock. More on her later, if anyone is interested, and we finalize details.

7 notes

·

View notes

Text

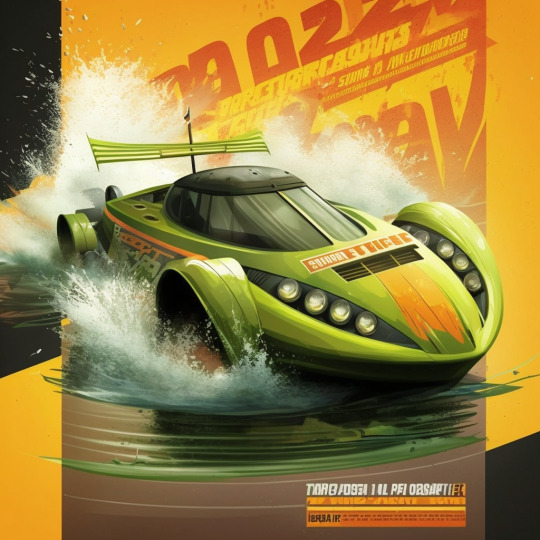

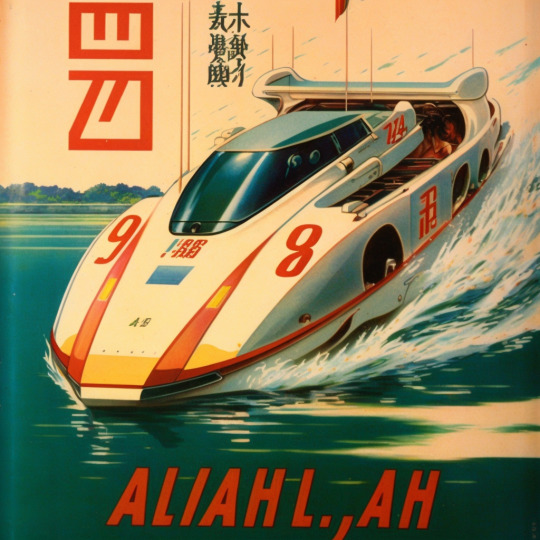

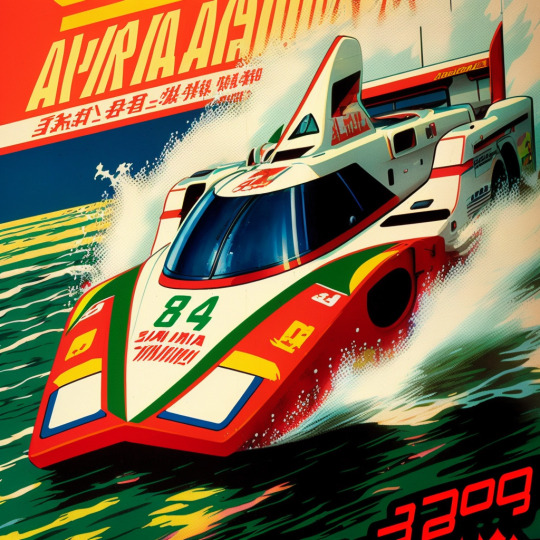

Top row: Magazine article and poster from the Splash Grand Prix Middle row: Magazine cover and poster from the California Amphibious Racing Circuit Bottom row: Posters for the Japan Amphibious Endurance Tournament

With the rising popularity in amphibious cars, it only made natural sense to try and push them to their limits, to see just how fast they could go over both land and sea. As a result, several amphibious racing circuits arose all around the world. We've got some advertising material here, as well as some details and descriptions about some vehicles from three of those circuits.

The Splash Grand Prix was started in 1947 by a group of New England amphibious automobile enthusiasts who wanted to see just how fast their boat-cars could go. The result was the Splash Grand Prix, a 5-lap race around a course that takes place on equal amounts land and sea. While not as fast as some of the other circuits, it's been described as more high intensity, shorter-range event, with the winding spaghetti-like roads of the New England area being the perfect challenge for drivers to navigate. The event is a very friendly and humble affair, with people bringing their tents, grills, and coolers in a huge picnic/cookoff style event that culminates into watching the big race. Cars are usually modified or custom-built roadsters, though there have been a few modern-style entries (but nothing too flashy, as there are strict component and weight requirements). The red car in the article to the left is the Hammnicar III, built by John M. Hammond the Fourth in 1982, as a tribute to the then-lost Hammnicar I, and the seldom-seen Hammnicar II. It was used in the Splash Grand Prix in the 1982, 1983, and 1984 seasons, winning the first two, but by 1984, it was out of date. The Hammnicar II was based off of a VW Superbeetle, not unlike the Catfish, but was designed as a tandem-control vehicle, powered by a Chevrolet Corvair Turbo 180 hp turbo motor, rather than the original Volkswagen flat 4. It competed in the super-modified 200 hp class, and was able to achieve speeds on the water of up to 40 knots, while able to do 120 mph on land.

On the other side of the country, we'll find the California Amphibious Racing Circuit. Founded in 1954, you'll find that this event is the polar opposite of the Splash Grand Prix. Loud, bombastic cars with sleek designs and souped-up engines are the stars of the show, and sponsorships litter the sides of the cars like a NASCAR vehicle. Everyone and their grandmother is trying to sell you something at the CARC, and the atmosphere is intoxicatingly overwhelming. The race is televised across the country, with millions tuning in to see these amphibious beasts rip across the sand and surf at speeds that can reach over 130 mph! In 2003, Thompson Hydrosports, a well-known homologation manufacturer, finally decided to dip it's toes into building it's own entry into the 2004 California Circuit season, building the Thompson Tornado (the vehicle on the magazine to the left), powered by the homologation 350 Chevrolet, machined to produce 500 horsepower. The vehicle itself was built from fiberglass and aluminum, and had a top speed on the water of 90 knots, while on land it could achieve 160 mph. The Tornado would become infamous once it entered production in the next year, for being super fast, agile, but most importantly, dangerous. of the 52 built, including the 2 prototypes, 31 of them were damaged beyond repair, or lost in accidents, with a total of 8 fatal accidents killing one or both of the crew. The most notable of the accidents being of the 41st production vehicle, driven by Robert Hall, and James Williams as Navigator, was lost in an 87 knot roll, the vehicle disintegrating around the crew, with nothing of the wreck being recovered, other than two of the wheels.

Crossing the pond, you'll find the Japan Amphibious Endurance Tournament, an affair squarely in the middle of the SGP and the CARC in terms of flashiness. While a little late to the party in 1970, it is nonetheless a beloved event enjoyed by racing enthusiasts across the globe, with events being televised across the world. While CARC vehicles are built for speed, JAET vehicles are built for endurance, boasting innovative designs meant to be efficient and comfortable while still being powerful. Being an endurance tournament, the track usually spans the entire length of Japan in both land and sea, meaning the races can sometimes take over 2 days to fully complete. Pit stops are placed at key points in the race (usually in the transitions between ground and water), but some legs of the race can result in the drivers going for over 8 hours straight! The car featured in the leftmost advertisement is the 1999 ALIAH, developed by the Japanese Hydronautics Committee in 1998. A non-government entity, like the FIA, the JHC built the ALIAH as a successor to Project Kikka, an unbuilt prototype for a 200 mph on road racer, and a 100 knot superboat. ALIAH was built to succeed in nearly as many areas, using a folding wheel mechanism, to allow all 6 wheels to be hidden away to allow for higher speeds on the water. The actual ALIAH travelled up to 185 mph on land, and 83 knots on the water. During testing, however, the vehicle had an engine fire, from it's twin Toyota 1GZ-FE V12 engines, that produced 800 hp each, to the rear 4 wheels, or the hydrojets at the back. Posthumously, the gearbox was found to be at fault, though the EFS (Engine Fire Suppressants) were used, and saved the boat. This Magazine cover shows the post-fire repairs, missing aerodynamic panels, and allowing the internals to be seen. The ALIAH was used to demonstrate the CLASS VI racing series, and CLASS VI is still ongoing, though the current dominant force as of the 2023 season are turbine-electric hybrids, allowing for intense acceleration on land, and intense acceleration on ground. The ALIAH is on display in Karuizawa, at the JHC's headquarters/museum for hydro-racing. It is on display in situ post testing, with the fire damage still visible in places, though repairs had been made after the fire, which are also visible.

#Splash Grand Prix#California Amphibious Racing Circuit#Japan Amphibious Endurance Tournament#Fictional Events#ai generated images#human written context#unreality#unfiction

2 notes

·

View notes

Text

Ok, let me make something clear:

Plastic cases are not the problem.

On a quality modern sewing machine, one that is sold through a dealership, there's a solid metal framework inside the machine. The plastic cover comes off, and the motor, shafts, etc are all connected to a metal (usually steel or cast aluminum) framework. In the old days, this framework was part of the shell of the machine.

This is good.

It means that it's easier to remove lint and debris, easier to access any electronic parts, and easier to check and set the timing of the machine, the hook/needle clearance, and the feed timing. It's easier to reach areas that need to be lubricated. It also makes it way easier to replace any parts that get damaged or worn out.

However, the machines you see on the shelf at w@lmart have plastic cases, but no internal framework. Service techs can open up the plastic casing, but the guts of the machine are attached to the back half of the case.

This is bad.

These are machines that won't last long. That's why they're so cheap! I think the intention is to make a disposable sewing machine for people who want to make a couple of projects and then set it in a closet for 20 years, or just throw it away. Some of those machines have a metal-tipped PLASTIC HOOK instead of a metal hook and it makes me cry.

Unfortunately, that's not how such machines are marketed. If you like to sew, if you're making things to sell, if you're a quilter or a cosplayer or a fashion designer, you might mistakenly buy one of these disposable machines and then wonder why it's a total piece of crap.

Also, the two examples given in photos are a hand-crank machine (not electric) and a modern machine with the Singer logo. The Singer Sewing Machine company no longer exists. The name was sold to a big conglomerate and exploited today to make people believe they're buying a "real" singer. I have a whole separate rant about that.

There are still hand crank machines today, in fact I own a Harris hand-crank model from the 1920s that I acquired for a Steampunk project. It does sew, but I'm faster with a needle and thread in my hand. It is all-metal and weighs enough to be a boat anchor. I can't lift it by myself anymore. It may actually be heavier than my 6 needle professional embroidery machine.

And the truth is that the machine doesn't have to be physically heavy to be a good solid workhorse of a machine. The outer casing just needs to protect the important bits inside, such as the metal framework that holds all the machine bits in place.

How do I know? I'm a sewing machine repair tech, educator, and enthusiast. I've been working for a sewing machine dealership for over 20 years.

Do you think the people who design modern sewing machines in plastic cases ever feel insignificant because of it? knowing that they're making machines with the lifespan of a dog when they could (if they'd been born a few generations earlier) be making machines with the lifespan of a Galapagos tortoise?

28K notes

·

View notes

Text

Aluminum Welding Rods Near Me: Your Guide to Quality Welding Supplies

Welding is an essential skill in various industries, from automotive to construction and fabrication. One of the most crucial components in welding is choosing the right rods, especially when working with aluminum. If you are searching for Aluminum Welding Rods Near Me, ensuring you purchase from reputable Welding Shops Near Me | MapleWeld is essential for getting the best quality and performance.

Why Choose Aluminum Welding Rods?

Aluminum welding rods are widely used due to their lightweight properties and excellent corrosion resistance. Whether you are working on automotive repairs, marine applications, or structural welding, aluminum rods offer superior weld strength and durability.

Benefits of Aluminum Welding Rods:

Lightweight & Strong – Aluminum rods provide excellent tensile strength without adding excess weight.

Corrosion Resistance – Perfect for outdoor and marine applications where exposure to moisture is high.

High Thermal Conductivity – Ensures faster and more efficient heat dissipation during welding.

Ease of Use – Suitable for beginners and professionals alike.

When purchasing Aluminum Welding Rods Near Me, always opt for a trusted supplier like Welding Shops Near Me | MapleWeld to guarantee quality materials.

How to Select the Right Aluminum Welding Rods?

When choosing aluminum welding rods, consider factors such as alloy composition, thickness, and intended use.

Key Factors to Consider:

Alloy Type – Common aluminum welding rods include ER4045, ER5356, and ER1100. Each alloy type has specific properties suitable for different applications.

Diameter – Selecting the correct rod diameter ensures proper weld penetration and strength.

Welding Process – Whether you are using TIG or MIG welding, the right rod type is crucial.

Welding Position – Some aluminum rods work better in vertical, overhead, or horizontal positions.

For expert guidance, visiting Welding Shops Near Me | MapleWeld can help you find the perfect match for your welding needs.

Where to Buy Aluminum Welding Rods?

Finding a reliable supplier is key to ensuring your welding projects succeed. The best places to buy Aluminum Welding Rods Near Me include local welding supply stores, online retailers, and specialized welding shops like MapleWeld.

Why Choose MapleWeld?

High-Quality Products – MapleWeld stocks premium-grade aluminum welding rods.

Wide Selection – A variety of sizes and alloy types to suit your welding needs.

Expert Advice – Knowledgeable staff to help you choose the best rods for your project.

Convenient Locations – Easy access to Welding Shops Near Me | MapleWeld ensures you get what you need quickly.

Tips for Successful Aluminum Welding

Aluminum welding requires precision and technique to achieve strong and clean welds. Here are some essential tips:

Preparation & Setup:

Clean the Surface – Remove any oxidation or dirt from the aluminum before welding.

Choose the Right Rods – Use high-quality rods from Welding Shops Near Me | MapleWeld.

Adjust Your Settings – Ensure proper amperage and heat control for optimal results.

Use a Shielding Gas – Argon gas is recommended for TIG welding aluminum.

Welding Techniques:

Maintain a consistent torch angle.

Use steady and controlled movements.

Avoid excessive heat to prevent warping.

Apply post-weld treatments for better finish and strength.

By following these techniques and sourcing quality rods from Aluminum Welding Rods Near Me, you can achieve professional-grade welds.

Common Applications of Aluminum Welding Rods

Aluminum welding rods are used in various industries and projects, including:

Automotive Repairs – Fixing vehicle frames, radiators, and fuel tanks.

Aerospace Engineering – Lightweight yet strong components for aircraft manufacturing.

Marine Construction – Building and repairing boats, docks, and marine structures.

Fabrication & Manufacturing – Custom metal fabrication projects requiring durability.

Household Repairs – Fixing aluminum gates, fences, and furniture.

For all these applications, having a reliable supplier like Welding Shops Near Me | MapleWeld ensures you get the best quality welding rods.

Why MapleWeld Stands Out?

If you're searching for Aluminum Welding Rods Near Me, MapleWeld is the go-to choice for welders in Canada. Here’s why:

Extensive Product Range – From aluminum rods to welding accessories, MapleWeld has it all.

Competitive Prices – Affordable rates without compromising quality.

Trusted by Professionals – Used by expert welders across industries.

Fast Shipping & Availability – Convenient options to get welding supplies quickly.

Visit Welding Shops Near Me | MapleWeld to explore their complete range of welding products.

Final Thoughts:

Selecting the right Aluminum Welding Rods Near Me is crucial for achieving high-quality welds. Investing in premium welding rods from Welding Shops Near Me | MapleWeld ensures durability, strength, and excellent results in every project.

Whether you’re a beginner or an expert welder, using the right materials and techniques will significantly impact the outcome. So, don’t compromise on quality—trust MapleWeld for all your aluminum welding needs.

Start your welding journey today with the best aluminum welding rods in Canada!

#welding accessories in canada#welding#welding supply in canada#canada supply#mapleweld supply in canada

0 notes

Text

Effective Maintenance Tips for Aluminium Boat:

Regular maintenance not only enhances its performance but also extends its lifespan, saving you costly repairs in the future. From cleaning techniques to corrosion prevention and ensuring your outboard engine brackets are well-maintained, knowing how to care for your aluminum boat effectively is key to enjoying smooth sailing every time. Visit:- https://sabaylok.com/blogs/22193/Effective-Maintenance-Tips-for-Aluminium-Boat

#aluminum boat designers in canada#39 express cruiser#center console sport fishing boats#welded aluminum boat kit#aluminum sport fishing boats#two level interior boats

0 notes

Text

#Aluminum Boat Repair with hts 2000#Brazing rod for thread repair#Buy HTS 2000 Brazing Rods#Buy HTS-528 Brazing Rod#Fuel Tank Repair Brazing Rods#Gas Welding Repair Using HTS 2000#HTS 2000 Aluminum Repair#HTS 2000 brazing rod#HTS-528 Brazing Rod#Boat Repair with HTS 2000#hts 2000 for aluminium boat repair

0 notes

Text

Shore Station Boat Lifts: Innovative Features for Easy Boating

Boating is a beloved pastime for many, offering serenity, adventure, and a connection to nature. However, maintaining a boat is a large task, and proper storage can lead to costly repairs and reduced longevity. Enter Shore Station boat lifts: the ultimate solution to protect your investment and make boating easier and more enjoyable. These lifts combine advanced technology with user-friendly features to provide unmatched convenience and functionality.

Why Choose a Shore Station Boat Lift?

Shore Station boat lifts have long been a trusted name in the boating industry. Their reputation is built on durability, reliability, and a commitment to innovation. These lifts are engineered to keep your boat safe, prevent hull damage, and make launching and storing your boat a breeze. Whether you’re a seasoned sailor or a weekend enthusiast, a Shore Station lift offers practical benefits that make every outing more enjoyable.

Key Innovative Features of Shore Station Boat Lifts

Durable construction materials

Shore Station lifts are built to withstand harsh marine environments. Using marine-grade aluminum and galvanized steel, these lifts resist corrosion, even in saltwater conditions. The sturdy design ensures long-term reliability, protecting your boat season after season.

Hydraulic technology for smooth operation

One of the standout features of Shore Station boat lifts is their advanced hydraulic technology. This system allows for smooth and efficient lifting and lowering of your boat. With the press of a button, you can safely store your boat above water level, keeping it free from algae, barnacles, and other aquatic nuisances.

Easy-to-use control systems

Modern Shore Station lifts come equipped with intuitive control systems. Many models feature wireless remotes and smartphone integration, allowing you to operate your lift from the dock or your boat. The simplicity of these controls makes it accessible even for those new to boating technology.

Innovative canopy systems

Protecting your boat from the elements is crucial, and Shore Station’s innovative canopy systems do just that. These canopies provide full coverage, shielding your boat from UV rays, rain, and debris. Made from high-quality, weather-resistant materials, they ensure your boat remains clean and ready for use.

Integrated safety features

Safety is a top priority for Shore Station. Features like automatic shut-offs, emergency release systems, and overload protection are standard. These additions not only protect your boat but also give you peace of mind during operation.

Environmentally friendly design

Shore Station boat lifts are designed with the environment in mind. The hydraulic systems use biodegradable fluid, minimizing environmental impact. Additionally, the lifts are energy-efficient, requiring minimal power to operate.

Customizable options

Every boater has unique needs, and Shore Station recognizes this by offering a range of customizable options. From different weight capacities to specialized accessories like solar panels and motor stops, you can tailor your lift to fit your specific requirements.

Fast installation and portability

Shore Station boat lifts are known for their straightforward installation process. Many models are portable, allowing you to reposition or remove the lift with ease. This feature is especially useful for those who move between docking locations or need to adjust their setup based on water levels.

Weather-resistant electrical systems

The electrical components of Shore Station lifts are designed to endure exposure to water and extreme weather conditions. These weather-resistant systems reduce the risk of malfunctions, ensuring your lift operates reliably year-round.

Benefits of Using a Shore Station Boat Lift

Investing in a Shore Station boat lift goes beyond convenience. It offers numerous benefits that enhance your boating experience:

Boat longevity - Keeping your boat out of the water prevents hull damage, extending its lifespan.

Time-saving - Launching and docking become quicker and more efficient, giving you more time on the water.

Improved resale value - A well-maintained boat retains its value better, and using a lift helps achieve this.

Enhanced safety - Secure storage reduces the risk of accidents or damage caused by changing water levels or storms.

Year-round protection - With Shore Station’s robust design, your boat remains safe through all seasons.

Shore Station Accessories to Enhance Your Experience

To complement their lifts, Shore Station offers a range of accessories that add functionality and convenience:

Solar-powered charging systems - Use sustainable solar power to keep your lift’s battery charged.

LED lighting kits - Illuminate your dock and lift for nighttime boating adventures.

Boat guides and bumpers - Ensure smooth docking and protect your boat from scratches or dents.

Motorized winches - Automate the lifting process further for effortless operation.

These accessories enhance the overall usability of the lift, making it a must-have for any serious boater.

Tips for Maintaining Your Shore Station Boat Lift

While Shore Station lifts are built for durability, regular maintenance ensures optimal performance:

Inspect the lift regularly - Check for signs of wear, such as frayed cables or rusted components.

Clean the lift - Rinse the lift with fresh water to remove salt and debris, especially in saltwater environments.

Lubricate moving parts - Apply marine-grade lubricants to keep the moving parts functioning smoothly.

Check electrical systems - Regularly test the motor and electrical components to avoid surprises.

Protect the hydraulic system - Replace hydraulic fluid as needed and look for any leaks.

Following these maintenance tips will keep your lift in top condition, ensuring reliable operation for years to come.

Why Shore Station Boat Lifts Stand Out

In the crowded market of boat lifts, Shore Station remains a leader due to its commitment to innovation and quality. Their products are designed with the user in mind, blending cutting-edge technology with practical features. Whether you’re a recreational boater or a seasoned mariner, Shore Station boat lifts provide the tools you need to simplify your boating experience. A Shore Station boat lift is more than just a storage solution; it’s a game-changer for any boater. Its innovative features, durable construction, and user-friendly design make it a valuable investment. From protecting your boat against damage to offering unparalleled convenience, these lifts enhance every aspect of the boating lifestyle. Serv-a-Dock is the best option if you are looking for shore station boat lifts in Lake Minnetonka. Contact them via email or by calling 952-443-2811.

0 notes

Text

Essential Guide to Fuel Tank Fittings and Gas Caps for Optimal Performance

Fuel tank fittings are essential for the efficient and safe operation of any fuel tank system, whether for vehicles, boats, or industrial equipment. These fittings connect different components, helping maintain fuel flow and prevent leaks. Quality fittings are vital for commercial and recreational applications to secure the entire fuel system.

Types of Fuel Tank Fittings

Fill Neck Fittings: These connect the fuel fill neck to the tank, allowing fuel to enter without spillage. They must be durable and fuel-resistant to ensure reliability.

Vent Fittings: Vent fittings prevent pressure buildup in the fuel tank by allowing excess vapors to escape. Proper venting is crucial for safety and efficient fuel flow.

Return Line Fittings: Found in systems with fuel pumps, these fittings return unused fuel from the engine to the tank, reducing pressure and overheating risks.

Drain Fittings: Essential for maintenance, drain fittings allow fuel drainage for cleaning or repairs.

Why a Good Gas Cap Matters

Gas cap do more than cover the fuel tank. They prevent fuel evaporation, minimize dirt and contaminants, and reduce pressure buildup. CapsNeck’s high-quality gas caps fit securely, protecting fuel integrity and contributing to environmental responsibility by reducing harmful emissions.

Key Features to Look For

Material Durability: Fuel tank fittings and gas caps are exposed to fuel, moisture, and heat, so quality materials like stainless steel or aluminum are best.

Compatibility: Ensure fittings and gas caps are compatible with your tank type to avoid leaks or malfunctions.

Sealing Mechanism: Secure seals are essential in gas caps to prevent fuel evaporation and contamination.

Maintenance Tips

Regular Inspections: Check fittings and caps regularly for signs of wear or corrosion.

Replace When Needed: Worn-out or damaged fittings and caps can lead to costly leaks. Replace them promptly.

CapsNeck provides a range of high-quality fuel tank fittings and gas caps designed for durability, compatibility, and safety. Enhance your fuel system's performance and protect your investment by choosing CapsNeck for all your fuel tank part needs. For more visit https://www.capsnecks.com

0 notes

Text

How Do You Repair and Protect the Bottom of Your Boat?

The bottom of your boat is constantly exposed to harsh elements, from saltwater and marine life to debris and impacts. Over time, this exposure can cause wear and tear, leading to damage such as cracks, chips, and hull degradation. Repairing and protecting the bottom of your boat is essential not only for its longevity but also for its performance and safety on the water. Here’s a guide to help you understand how to repair and protect your boat’s hull to keep it in top condition.

1. Inspect the Hull Regularly

The first step in maintaining the bottom of your boat is regular inspection. A thorough check will help you catch small issues before they become major problems. Look for:

Scrapes, gouges, or deep scratches.

Cracks, especially around seams and joints.

Faded or peeling paint or gel coat.

Growth of marine life (barnacles, algae, etc.).

Any signs of corrosion (especially on metal parts like trim tabs or outdrives).

After inspecting, make a note of any areas that require attention and prioritize repairs based on severity.

2. Clean the Bottom of Your Boat

Before you can repair or protect the hull, it’s essential to clean it thoroughly. Regular cleaning will remove dirt, salt buildup, and marine growth that can damage the bottom over time. Use a marine-grade cleaner that is safe for your boat’s material (fiberglass, aluminum, or wood) to scrub the hull. If you notice barnacles or other hard growths, use a scraper to gently remove them. Be careful not to scratch or damage the surface.

For boats that are kept in saltwater, cleaning the hull after each outing will help prevent the buildup of corrosive salt deposits.

3. Repairing Damage to the Hull

If you find cracks, chips, or gouges in the hull, timely repair is crucial to prevent further damage. Here's how to handle common repairs:

Minor Scratches and Chips:

For small cosmetic damage, you can typically use a boat-specific gel coat repair kit. Clean the area first, then apply the gel coat according to the manufacturer’s instructions. Sand it smooth once it dries and buff it to restore the shine.

Cracks or Larger Gouges:

For deeper cracks or gouges that expose the fiberglass beneath the surface, you will need a more substantial repair. First, clean the damaged area and allow it to dry thoroughly. For fiberglass boats, mix a fiberglass resin and hardener, apply it to the crack or gouge, and then smooth it out with a putty knife. Once it has cured, sand the surface smooth and apply a layer of gel coat to match the surrounding hull. If you’re not familiar with fiberglass repair, it might be wise to hire a professional for larger damage.

Hull Leaks:

If the boat has developed a leak, it’s crucial to pinpoint its source and repair it immediately. Leaks in the bottom of the hull can be caused by damaged fiberglass, corroded seams, or failing seals. Small leaks can be patched with marine sealant or epoxy resin, but more severe damage may require professional repair or re-lamination.

4. Applying Bottom Paint for Protection

To protect the hull from future damage and deterioration, applying bottom paint is a key step. Bottom paint helps prevent the growth of marine organisms like algae and barnacles, which can damage the hull and reduce performance. It also creates a protective barrier against the harsh elements of the water.

Steps to Apply Bottom Paint:

Clean the hull thoroughly: Before applying bottom paint, ensure the hull is free of dirt, oil, or any old paint.

Sand the surface: Lightly sand the hull to create a rough surface for better paint adhesion.

Choose the right type of bottom paint: There are different types of bottom paint, including antifouling paints that prevent marine growth and hard paints for boats that are frequently in dry dock. Make sure to select the appropriate paint based on the type of boat, your location, and how often you use your boat.

Apply paint in layers: Use a roller or brush to apply the first coat of paint. Allow it to dry, and then apply a second coat. Follow the manufacturer’s instructions for drying times and the number of coats needed.

5. Protecting Against Corrosion

Corrosion, especially in metal components of the boat like the propeller, drive shaft, and trim tabs, is a common issue for boats in saltwater environments. Regularly inspect metal parts for signs of rust or corrosion and take steps to prevent it.

Use corrosion inhibitors: Apply marine corrosion inhibitors to metal parts, especially those below the waterline. These products help protect against saltwater exposure.

Consider sacrificial anodes: Install sacrificial anodes (zinc or aluminum) on the boat’s metal components. These anodes corrode instead of your boat’s more valuable metal parts, protecting them from rust and degradation.

Regular cleaning and maintenance: Rinse metal parts with fresh water after every use to remove salt deposits that can accelerate corrosion.

6. Maintain Your Boat’s Trailer and Lift

If you use a trailer or lift system to transport your boat, don’t forget to maintain the equipment that keeps your boat above water when it’s not in use. Check the trailer for any rust, wear on the rollers, or faulty brakes. Inspect the lift system for signs of wear or damage and make necessary repairs before putting the boat back in the water.

7. Consider Professional Help for Complex Issues

While many boat owners can handle basic cleaning, maintenance, and small repairs, some hull issues may require professional expertise. If you’re dealing with extensive damage, complex repairs, or if you simply want peace of mind, hiring a professional boat repair technician can ensure the job is done correctly.

Conclusion Proper care and maintenance of the bottom of your boat are essential to keeping it in good condition and maximizing its lifespan. Regular inspections, cleaning, and repairs will protect the hull from wear, marine growth, and environmental damage. By applying bottom paint, addressing minor repairs promptly, and taking steps to prevent corrosion, you can enjoy a safe and smooth ride for years to come. Whether you’re handling repairs yourself or enlisting the help of a professional, taking the time to care for your boat’s bottom is an investment in its long-term performance and durability.

0 notes

Text

Aluminum Boat Buyer's Guide: Addressing Common Queries

Purchasing an aluminum boat can be both an exciting and overwhelming experience, particularly for first-time buyers. With a vast array of options available, it's perfectly natural to have questions and concerns about making the right choice. This comprehensive guide is designed to address common queries about buying an aluminum boat, helping you navigate the process with confidence and ease.

Choosing the Right Size and Type

Your intended use will heavily influence your decision regarding the size and type of aluminum boat you should purchase. Consider how many passengers you plan to accommodate and the activities you envision enjoying on the water.

What Types of Aluminum Boats Are Available?

Aluminum boats come in various configurations, including Jon boats, bass boats, fishing boats, pontoon boats, and even larger vessels like cruisers and yachts. Each type is tailored for specific purposes such as fishing, water sports, or leisurely cruising. For instance, Jon boats are celebrated for their versatility and affordability, making them suitable for fishing, hunting, or other recreational activities. Bass boats are specifically designed for bass fishing and feature amenities like live wells, rod holders, and ample tackle storage.

Determining the Right Size for Your Needs

When selecting the appropriate size for your aluminum boat, consider how many people will typically be on board, the gear you’ll need to bring along, and the waters you plan to navigate. Generally speaking, larger boats provide more stability and capacity but can be more challenging to transport and maneuver. If you primarily fish with one or two companions, a 16- to 18-foot aluminum fishing boat may be ideal. However, if you anticipate having more passengers or venturing into rougher waters, a pontoon boat or a larger center console model might be more suitable.

Evaluating Quality and Construction

When investing in an aluminum boat, it’s critical to ensure that you're purchasing a well-constructed and durable vessel. Understanding different construction methods and materials can significantly impact your decision-making process.

What Should I Look for in Terms of Aluminum Boat Construction Quality?

Look for boats with fully welded hulls; these are typically more robust and less prone to leaks compared to riveted or seamed designs. Pay attention to the thickness of the aluminum used in construction; thicker gauges are generally more durable and resistant to dents and impacts. Reputable manufacturers often utilize marine-grade aluminum alloys like 5052 or 5086, which offer superior corrosion resistance and strength compared to standard aluminum.It's important to remember that even well-constructed aluminum boats may require maintenance over time. For instance, if you notice any damage or weakening in the transom area of your boat, consider looking into transom repair options or even aluminum boat transom replacement if necessary.

Are There Any Reputable Aluminum Boat Manufacturers I Should Consider?

Several well-known manufacturers produce high-quality aluminum boats worth considering. Brands like Tracker, Lowe, Crestliner, Starcraft, and Xpress have established themselves as reliable options in the market. Be sure to compare features and pricing among these reputable brands. Additionally, don't overlook regional manufacturers or custom builders who may cater to specific needs or preferences.

Factoring in Costs and Budgeting

Before making a purchase decision regarding an aluminum boat, it's essential to factor in all associated costs to ensure you stay within your budget.

What Are the Typical Costs Involved in Purchasing an Aluminum Boat?

When budgeting for your new aluminum boat purchase, remember that there are costs beyond just the price of the vessel itself. You'll need to account for registration fees, trailer expenses (if applicable), safety equipment costs, as well as any accessories or upgrades you might want. It's also vital to budget for ongoing maintenance costs, storage fees, fuel expenses, and insurance premiums. These additional costs can add up quickly; therefore, having a realistic understanding of your total investment is crucial.

Are There Any Financing Options Available for Aluminum Boat Purchases?

Many dealerships and manufacturers offer financing options that can make purchasing an aluminum boat more manageable financially. Be sure to compare interest rates and terms from various lenders to find the best deal that suits your financial situation. Some lenders may also provide special financing promotions or incentives that could save you money.

Assessing Dealer Reputation and Support

Ensuring that you receive proper support after your purchase is crucial for long-term satisfaction with your aluminum boat.

How Can I Evaluate the Reputation of an Aluminum Boat Dealer?

To assess a dealer's reputation effectively, check online reviews from previous customers, ask for recommendations from fellow boaters, and inquire about the dealer's experience with aluminum boats specifically. A reputable dealer should be knowledgeable about their products and transparent regarding pricing and services offered.

What Kind of Support Should a Dealer Provide After the Sale?

A good dealer should offer ongoing support that includes maintenance services as well as assistance with registration and licensing processes. They should also provide guidance on proper care techniques for your new boat while suggesting accessories that enhance your experience on the water. Many dealers offer warranty programs or extended service plans that provide peace of mind by protecting your investment over time.

Considering Resale Value and Longevity

Before making a long-term decision about purchasing an aluminum boat, it’s important to assess its potential resale value as well as its longevity.

How Does Resale Value Compare Between Aluminum Boats and Other Materials?

Aluminum boats generally hold their value well due to their durability and low maintenance requirements compared to other materials like fiberglass. However, resale value can vary based on factors such as age, condition, brand reputation, and market demand. Well-maintained aluminum boats from reputable manufacturers often command higher resale prices than fiberglass counterparts of similar age.

What Is the Typical Lifespan of an Aluminum Boat with Proper Maintenance?

With proper care and maintenance practices in place—such as regular cleaning, waxing, inspections—an aluminum boat can last for decades! Aluminum's inherent resistance to corrosion allows it to withstand harsh marine environments better than many other materials available today.For detailed information on maintaining your aluminum boat in top condition over its lifespan, check out our guide on Transom Repair: Mastering Fixes.

Accessories and Customization Options

Depending on how you intend to use your new vessel—and your personal preferences—consider various accessories that can enhance both functionality and appearance.

What Are Some Popular Accessories for Aluminum Boats?

Standard accessories often include:

Bimini tops or canopies for shade

Rod holders specifically designed for fishing

Depth finders

Trolling motors

Custom graphics or wraps

These additions not only improve your overall experience on the water but also allow you to tailor your vessel according to specific needs—whether you're an avid angler looking for enhanced fishing capabilities or someone who enjoys leisurely cruising with friends.

Can Aluminum Boats Be Customized After Purchase?

Absolutely! One of the advantages of owning an aluminum boat is its high degree of customizability. Many owners choose to modify their vessels over time by changing seating arrangements or adding new electronics such as audio systems. It's essential to work with experienced professionals when making modifications so that you don’t compromise structural integrity during upgrades.

Choosing the Right Dealer

When purchasing an aluminum boat, selecting the right dealer can significantly impact your overall satisfaction with both the buying process itself as well as future support after purchase.

Should I Prioritize Local Dealers or Consider Options Further Away?

While local dealers offer convenience along with support services post-purchase—such as maintenance—you might find better pricing or selection by exploring options further away from home base. Many dealers will assist with delivery arrangements if needed; therefore keeping an open mind during your search is beneficial!

Are There Advantages to Buying from a Dealer Specializing in Aluminum Boats?

Dealers who specialize in selling aluminum vessels possess extensive knowledge about these types of boats which proves invaluable when choosing models suited specifically towards individual needs while understanding maintenance requirements thoroughly too! Additionally they often maintain strong relationships with manufacturers allowing them access parts specific only towards certain brands making repairs easier down-the-line!

How Important Is It To Have A Dealer With A Dedicated Service Department?

Having access through a dealer possessing dedicated service departments can greatly enhance long-term ownership satisfaction especially if planning on keeping said vessel over many years! Skilled technicians familiarized within this field ensure proper maintenance & repairs take place extending lifespan while preserving value throughout ownership journey!By addressing these common questions regarding purchasing an aluminum boat—alongside considering various factors outlined within this guide—you'll be equipped with knowledge necessary towards making informed decisions tailored specifically towards meeting personal boating aspirations! Researching thoroughly coupled alongside asking pertinent questions ensures finding just right vessel providing enjoyment throughout countless adventures spent upon water!

0 notes

Text

Reliable Protection: Discover Our Durable Metal Carports!

When it comes to safeguarding your vehicles and outdoor equipment, finding the right shelter is essential. Metal carports have emerged as a popular solution for homeowners seeking reliable protection against the elements. With their durability, versatility, and cost-effectiveness, metal carports are not just an investment in your property, but also in the longevity of your vehicles. In this article, we’ll explore the benefits of metal carports, the different types available, and why they are the ideal choice for your storage needs.

The Benefits of Metal Carports

1. Durability and Strength

One of the primary advantages of metal carports is their exceptional durability. Constructed from high-quality steel or aluminum, these structures can withstand harsh weather conditions, including heavy rain, snow, hail, and strong winds. Unlike wooden carports that can rot, warp, or be infested with pests, metal carports provide long-lasting protection without the risk of deterioration. This durability ensures that your vehicles remain safe and secure year-round, reducing the need for frequent repairs or replacements.

2. Cost-Effectiveness

Metal carports are often more cost-effective than traditional garages. They are quicker and easier to install, which reduces labor costs. Additionally, metal structures require minimal maintenance compared to wood, which can require regular treatments and repairs to maintain its condition. Over time, the savings on maintenance and replacement costs can add up, making metal carports a smart financial choice for homeowners.

3. Versatile Designs

Metal carports come in a variety of designs, sizes, and colors, allowing you to choose a structure that fits your specific needs and aesthetic preferences. Whether you have a single car, multiple vehicles, or even an RV or boat, there is a metal carport to suit your requirements. You can customize your carport with options such as side panels, doors, and additional storage space, ensuring that your shelter is both functional and visually appealing.

4. Quick Installation

Another advantage of metal carports is their quick and straightforward installation process. Most metal carports come in pre-engineered kits that can be easily assembled, often within a few hours. This means you can have your carport up and ready to use in no time, providing immediate protection for your vehicles. Additionally, the installation can often be done without the need for a concrete foundation, further simplifying the process.

5. Eco-Friendly Option

For environmentally conscious homeowners, metal carports offer an eco-friendly storage solution. Metal is recyclable, meaning that at the end of its life cycle, your carport can be repurposed, reducing waste. Furthermore, many manufacturers use environmentally friendly coatings and finishes that minimize harmful emissions during production. By choosing a metal carport, you are making a sustainable choice for your property.

Types of Metal Carports

When considering a metal carport, it’s essential to understand the different types available:

1. Standard Carports

Standard carports are open structures with a roof supported by metal posts. They provide excellent protection from rain and sun while allowing for easy access. Standard carports are ideal for those who want a simple, functional shelter for their vehicles without the extra features of enclosed options.

2. Enclosed Carports

Enclosed carports provide additional protection by featuring walls and doors, offering a secure environment for your vehicles. These carports are perfect for those looking to protect their cars from theft, vandalism, or severe weather conditions. Enclosed carports can also serve as additional storage space for tools, equipment, or other items.

3. RV Carports

If you own a recreational vehicle (RV), a dedicated RV carport is a smart investment. These structures are taller and wider than standard carports, providing ample space for your RV while ensuring it remains protected from the elements. RV carports can also be designed with extra height to accommodate larger vehicles.

4. Custom Carports

For those with unique requirements, custom carports offer the flexibility to design a shelter that meets your specific needs. You can choose the size, shape, color, and features that best fit your property and vehicle storage needs. Custom carports can blend seamlessly with your home’s architecture, enhancing your property’s overall aesthetic.

Why Choose Our Metal Carports?

At [Your Company Name], we pride ourselves on offering high-quality metal carports that meet the needs of every customer. Our carports are designed with durability and functionality in mind, ensuring you get the best protection for your investment. Here are a few reasons why our metal carports stand out:

Quality Materials: We use only the highest quality steel and aluminum, ensuring our carports can withstand the test of time.

Customization Options: Our range of customization options means you can create a carport that perfectly fits your requirements.

Exceptional Customer Service: Our team is dedicated to helping you find the right carport and providing support throughout the buying process.

Affordable Pricing: We believe that quality protection should be accessible, which is why we offer competitive pricing on all our metal carports.

Conclusion

Investing in a metal carport is a smart decision for any homeowner looking to protect their vehicles and outdoor equipment. With their durability, cost-effectiveness, and versatile designs, metal carports provide reliable protection against the elements. Whether you choose a standard carport or a custom design, you can rest assured that your investment will serve you well for years to come. Discover the difference a durable metal carport can make—contact us today to learn more about our offerings and find the perfect solution for your property!

0 notes

Text

The Future of Cleanliness: Laser Cleaning Technology on Aluminum Surfaces

Aluminum is a popular material, known for being light and resistant to rust. It is used in many areas, but it is important to keep it clean to maintain its good appearance and function. In this guide we will explore how laser technology is changing the way we clean aluminium. This method is great for jobs like removing paint and making aluminum engines shine again. Let's find out how laser technology makes cleaning easier and better.

Why should you clean aluminum surfaces?

Stop Corrosion: Aluminum can rust when exposed to things like air and water. Regular cleaning removes harmful substances that can cause rust. This helps the aluminum last longer and stay strong.

Look Better: Whether in cars or buildings, aluminum looks best when it's clean and shiny. Laser cleaning provides a perfect, spotless finish that restores its original beauty.

Remove Paint Easily: If you need to remove paint from aluminum without damaging it, laser technology is the way forward. This is really useful when you need to refurbish or repair aluminum parts.

Why choose laser technology for cleaning aluminium?

Precise and Careful: Laser cleaning allows you to target specific areas without damaging the rest of the material. This is especially important for detailed aluminum parts.

Gentle and environmentally friendly: In contrast to harsh cleaning methods, lasers are gentle and do not damage the surface. Plus, they're better for the environment because they don't use harsh chemicals or create waste.

Fast and Productive: Laser cleaning is fast, which means less waiting time and more action. This is a big plus for jobs where you need to clean quickly.

Where Laser Cleaning Really Shines With Aluminum:

The automotive industry: Perfect for cleaning parts of cars, such as engines and outer panels. Building and Construction: Great for making aluminum parts of buildings, like windows and walls, look like new again. Boat and Shipyard: Keeps boat parts clean, ensuring they work well and are safe. Production : Removes unwanted substances from aluminum parts, ensuring they are precisely manufactured.

0 notes