#Refrigerated enclosure)

Explore tagged Tumblr posts

Photo

Racks - Modern Wine Cellar Example of a minimalist wine cellar design with storage racks

0 notes

Text

Overlord had been busy. He'd put in a rather expensive custom order, converting a part of his private room into a... habitat of sorts. He still didn't trust Meredith so he'd installed a sturdy plasteel wall, fitted with a door he could enter from. Since Meredith's last escapades he'd also putted fine weave mesh wire over all of the vents in this room. The enclosure lay to one side of the large berthroom Overlord called his own, tucked away neatly.

Inside was what appeared by all rights to be a large dollhouse, albeit fitted out with running water and electricity, heated, even featuring a tiny working bath and refrigerator stocked with human food.

Attached was a small garden and greenhouse, lit from above with large LED grow lights and stocked with soil, seeds and all manner of tools.

The garden however was already laid out and planted, full grown trees encircling a small pond. Nearby was a bench, soft blanket rather thoughtfully settled over it.

The house iteself featured a few key rooms that were self contained and closed off from prying optics. The living areas were left open however, kitchen and lounge room, outdoor area. That way Overlord could watch his little pet with ease.

Overlord was so proud to show off his pet's new home to her. He was utterly giddy with excitement.

"Merry-kins!" He called in a sing song tone, near skipping towards the pitiful little plasteel cube that had served as her prison when Overlord was away. He'd kept the new addition to the room behind a curtain visibly bouncing with excitement as he leaned down and carefully plucked her from the cube.

"I have a surprise for youuuuu." He flung the curtain back, revealing the new installation, opening the plasteel door and carefully setting Meredith down just in front of the front balcony.

Overlord beamed at her, so excited.

@athenafire

32 notes

·

View notes

Text

Powder Coated Metal: The Ultimate Finish for Durability and Style in the UK

In the bustling world of manufacturing and fabrication across the UK, the demand for durable, aesthetically pleasing, and environmentally conscious finishes is ever-growing. This is where powder coated metal truly shines, offering a superior alternative to traditional liquid paints for a vast array of applications. From architectural elements to everyday household items, the distinct advantages of powder coating make it a preferred choice for professionals and consumers alike.

What Makes Powder Coated Metal Stand Out?

At its heart, powder coating is a dry finishing process where finely ground particles of pigment and resin are applied to a metal surface. Unlike wet paint, it contains no solvents, making it a much greener option. The magic happens through an electrostatic process: the powder particles are electrically charged and sprayed onto a grounded metal component. This charge causes the powder to cling to the surface, creating a remarkably even and uniform layer.

Once applied, the coated metal then enters a curing oven. Here, heat triggers the powder to melt, flow out, and form a continuous, robust film. This crucial curing stage results in a bond far stronger than that of typical liquid paints, creating a finish that is not only beautiful but also incredibly resilient.

Unrivalled Durability and Protection

One of the most compelling reasons for the widespread adoption of powder coated metal is its exceptional durability. This cured finish creates a tough, protective barrier that offers superior resistance against:

Chipping, scratching, and abrasion: It stands up to daily wear and tear much better than conventional paint.

Fading: Particularly with polyester powders, powder coatings offer excellent UV resistance, ensuring colours remain vibrant even with prolonged exposure to sunlight, crucial for outdoor applications in the varied UK climate.

Corrosion and rust: The thick, continuous layer provides an effective shield against moisture, chemicals, and the elements, significantly extending the lifespan of the underlying metal. This makes it ideal for items exposed to the often damp UK weather.

This inherent toughness means that powder coated metal often requires less maintenance and fewer touch-ups over its lifespan, which can typically range from 5 to 20 years or more, depending on the specific powder type, application quality, and environmental conditions.

Aesthetics and Environmental Advantages

Beyond its strength, powder coated metal delivers on aesthetics. It offers an almost limitless palette of colours, gloss levels (from matte to high gloss), and textures (smooth, wrinkled, hammered, metallic). This versatility allows for incredible design flexibility, ensuring a perfect finish for any project.

From an environmental standpoint, powder coating is a clear winner. Being solvent-free, it releases minimal or zero Volatile Organic Compounds (VOCs) into the atmosphere, making it a safer process for both workers and the environment. Furthermore, any overspray can often be collected and reused, significantly reducing waste compared to liquid paint applications.

Common Applications in the UK

You’ll find powder coated metal everywhere, from industrial settings to your own home:

Architectural: Window frames, doors, railings, building facades, and outdoor signage benefit from its weather resistance and long-lasting appeal.

Automotive: Wheels, chassis components, and various vehicle parts are powder coated for protection against corrosion and wear.

Domestic: Appliances like washing machines and refrigerators, as well as garden furniture and barbecues, rely on powder coating for their durability and attractive finish.

Industrial: Machinery, tools, and electrical enclosures frequently use powder coating for robust protection in demanding environments.

While the initial setup for powder coating can be more involved than traditional painting, the long-term benefits in terms of durability, reduced maintenance, and environmental responsibility make powder coated metal a smart and sustainable choice for a premium finish.

2 notes

·

View notes

Text

Fencing became a primary mode of seizure of [...] land and resources for the benefit of individual ranching enterprises in the West. [...] Estimates are that 100,000 bovine animals roamed Texas by 1830. Three decades later, on the eve of the Civil War, that number had increased to an estimated 3.5-5 million. [...] In the boom years of the 1870s and 1880s, the cattle barons enjoyed “near hegemony” over western [...] lands by declaring a simple right of sovereignty. [...] Thus, part and parcel of the American colonial project was this type of land acquisition - the process of turning the public domain into private property [...]. As the railroads began to extend and connect to rural outposts in the Plains states, entrepreneurs in the new cow towns such as Abilene, Kansas, sought out Texas livestock trails [...]. The most-well-known of the western cattle trails ran from Texas northward to the state of Kansas [...]. From 1867 until 1871, the 1,000-mile-long Chisholm Trail was the main livestock trail from Texas, a trail that ran from San Antonio [...] through Oklahoma and ended at Abilene. [...] They collectively drove 600,000-700,000 [cows] north from Texas during 1871 alone, all eventually bound for abattoirs in St. Louis and Chicago. [...]

---

Infrastructural and technological developments at towns such as Abilene [...] at the termini of the cattle trails also represent a singularly important carceral phenomenon of the nineteenth-century United States innovations in transportation, specifically, the “cattle car” (and by 1869, the refrigerated car that hauled dead animal carcasses) [...].

It was primarily British companies that played a major role in developing the transcontinental railroad in the 1870s and 1880s - the foreign “cattle barons” - and who eventually also shipped refrigerated cow carcasses to Britain in ocean steamers. [...]

Railroad development actually included an array of ancillary infrastructural developments [...] - railroad stations with telegraph facilities, supervisory personnel, and company-owned [...] stockyards. [...] The first twenty-car shipment of cows from Abilene to Chicago was in September of 1867. [...] This north-south cattle complex expanded in the 1870s, as the demand for beef, tallow, and hides greatly expanded amid postwar [conditions].

---

Concomitantly, one of the most significant instruments [...] was the revolutionary invention of wire fencing, which facilitated the enclosure of [...] land for private use. [...] Netz argues for the critical importance [...] [of] the case of barbed wire [in] the violent enclosure [...] during colonization of the American West. [J.G.] patented barbed wire in 1874 and opened a small manufacturing plant in DeKalb, Illinois, for its production, with large-scale production and sale eventually located to [...] Massachusetts. More than 350 barbed wire patents were issued between 1875 and 1890, although it was the [J.G.] patent that came to monopolize the market (and indeed, is the fence still in use today). [...] One rather infamous early adopter in the Texas Panhandle [...] fenced in over 3 million acres of public range with illegal fences while others followed suit [...]. Also in the Texas Panhandle, [a] Scottish-backed [...] ranch pursued its own 3 million acre fencing project, operating on a grant from the state with an estimated 6,000 miles of fence. [...] Such [...] activities led to what has been called the “Fence Cutting Wars” [...]. Estimates are that up to 7.3 million acres of [...] land was fraudulently expropriated by cattle companies in this way [...].

---

All text above by: Karen M. Morin. "Bovine Lives and the Making of a Nineteenth Century American Carceral Archipelago". In: Carceral Logics: Human Incarceration and Animal Captivity edited by Lori Gruen and Justin Marceau, pages 261-275, 2022. Online publication date April 2022. DOI: doi dot org slash 10.1017/9781108919210.018 [Bold emphasis and some paragraph breaks/contractions added by me. Presented here for commentary, teaching, criticism purposes.]

#going through old stuff about railroads as tentacles of imperial extraction#tidalectics#multispecies#ecologies#geographic imaginaries#ecology

46 notes

·

View notes

Text

The Monument - HASO on AO3

Chapter 7: Devouring.

“I like this one.” Julian grinned, squatting down in front of the largest tank.

“That’s moon.” Jae said, following Julian’s lead and kneeling beside him as they stared at the massive snake slinking around the enclosure. “She’s like, almost ten years old or something.”

“Can I hold her?”

Jae blinked in surprise, a jolt running through his skin at the question. Jade’s parents… probably wouldn’t like that. He remembered reading something about not handling them frequently… but he hadn’t taken any of them out since week one. Besides, Julian had proven himself to be good with animals. He said he liked lizards… if they washed hands beforehand it should be fine, right?

“You’re not scared?” He asked, perhaps hoping to discourage Julian’s curiosity about the giant black snake. “She might be nonvenomous, but she can still bite.”

“I’ve been bit by worse.” Julian said casually, ignoring Jae’s bewilderment at such a statement. His eyes glittered with excitement as he watched the snake through the glass, likely looking to find her head within her masses of giant coils.

“What else has bit you?” He asked, incredulous.

Julian rolled his eyes. “Cats, dogs, horses, other snakes. A whole bunch of stuff.”

“I, uh, I guess you can touch her. If you wash your hands first.”

“Of course.”

There was a small metal sink installed in the room already, which made it easy to quickly wash their hands before Jae carefully pushed the sliding glass door open. “Well… here you go.” He muttered, waving a hand for Julian to reach in.

“Hey, girl.” He whispered excitedly, brushing his fingers over the dark scales. He flinched backwards as she moved under his hand, an anxious giggle bubbling up from his chest as he leaned in again, cupping his hand over her body. “Oh, you are beautiful.”

“You like snakes.” Jae mumbled, almost in shock over Julian’s pure joy.

“I’ve seen this snake at the Smith’s reptile house before, but I’ve never seen her this close. She’s amazing.”

“They’ve never invited you over to see the animals? You guys are neighbors.”

Julian shrugged, leaning back as he closed the glass door himself, wiping his hand on his jeans. “We don’t really talk much. I was friends with Jade, and I know them, but it’s not like me and Mr. Smith share beers on the weekends.”

’We did.’ Jae thought absently.

They got to work after that, preparing and feeding each snake or spider it’s own meal one by one. The rats and chinchillas were easy enough, fed daily with simple meals from a bag. The spiders were fed live crickets which was more difficult sure, but today was especially taxing since the snakes were being fed too.

Snakes didn’t get fed every day. The… ’meals’ they ate were massive compared to their body size. Thanks to that they only needed to be fed once every two weeks.

“The snake food is in the fridge.” Jae instructed, pointing to a small silver refrigerator under the sink counter. “It’s…they’re mice. Big mice.”

“I know what snakes eat.” Julian said simply as he opened the fridge door. “Do I need gloves to touch them?”

“Uuh- I mean they’re clean. But I wore them last time.” He watched as Julian contemplated it momentarily, before grabbing a pair of blue nitrile gloves from the counter, and removing the white styrofoam box from the cooler. “Bring it here.” He instructed, taking a pair of clean metal tongs and reaching into the box, pulling out one of the mice by it’s middle and gently setting it in the snake’s enclosure.

Julian watched with great interest as the snake, one of the king snakes, investigated its meal. Its tongue slipping quickly in and out of its mouth. “Don’t they get bored, eating something that’s already dead?”

“Do you?” Jae asked, side-eyeing him as Julian chuckled, the two looking back at the snake in interest as it struck the mouse, beginning its slow methodical devouring.

#art#ltmfp#webtoon#digital art#artists on tumblr#fanfic#fanfiction#original fanfiction#ao3#archive of our own#haso#humans are space orcs#humans are space australians

6 notes

·

View notes

Text

How to experience soda induced existential terror.

Have a large amount of ADHD.

Have a preferred cup, ideally with a straw.

Drink exclusively non-carbonated beverages from cup mentioned in 2.

Purchase a large container of soda to be consumed with a specific meal.

Put left over soda in refrigerator.

Live life as normal for a few days.

Go to kitchen to refill empty water cup(2).

Remember soda.

Put soda in cup.

Return soda back into refrigerator and immediately forget soda exists anywhere within your home.

Return yourself and cup of "normal drink" to your usual spot in your enclosure.

Take a sip.

Experience a sudden WRONG TEXTURE! for no goddamned reason!

Bonus points: Make a post on your favorite hellsite about how your drink betrayed you and made reality feel suddenly unpredictable and incorrect on a fundamental level, only to absentmindedly pick up your cup from where it always sits and bring it up to your unsuspecting mouth, having obviously completely forgotten that the DRINK HAS WRONG TEXTURE! just happened even if you were just writing about it and experience it again!

4 notes

·

View notes

Text

Two refrigerators found in a dumpster enclosure.

#dumpster#dump#dumpster dive#throwing away money#freegan#kids toys#brand name#dumpster diving#free stuff#brand new#refrigerators#electronics#home goods#appliances

3 notes

·

View notes

Text

Heat Pump Noise Levels: What to Know Before Buying Understanding the Importance of Sound Ratings in Choosing the Right System

When planning to upgrade or install a heating and cooling solution, one often-overlooked factor is the noise produced by the unit. While performance, energy efficiency, and long-term costs usually dominate discussions, heat pump noise levels play a crucial role in ensuring year-round comfort, both indoors and outdoors. Homeowners, especially those in quiet neighborhoods or urban areas with space constraints, need to consider how sound levels could affect day-to-day life. Before committing to a system, learning what causes operational noise, how to interpret decibel ratings, and which units offer quieter performance can lead to a more satisfying investment.

Understanding How Heat Pumps Work and Why They Produce Noise

A heat pump operates by transferring heat from one place to another—either from the outside in for heating or inside out for cooling. During this process, components like the compressor, fan, and refrigerant lines are at work. Each of these parts contributes to operational sound. Most noise is generated by the compressor cycling on and off, the fan spinning at different speeds, and the movement of refrigerant through copper lines.

Older systems or poorly installed units tend to generate more noise due to vibration, component wear, or lack of noise-reduction features. However, advancements in design and engineering have significantly improved sound ratings in modern systems. Quiet operation is now a competitive advantage in the heating and cooling market, with many manufacturers prioritizing noise control in their newest models.

Why Noise Level Matters in Residential Settings

Low noise levels contribute to a better quality of life. A heat pump that produces excessive sound can disrupt daily routines, especially during the night or early morning hours. Children’s bedrooms, home offices, and outdoor seating areas should remain undisturbed. This becomes even more essential in compact residential environments, such as townhouses or homes with neighbors in close proximity.

Excessive noise may also violate local noise ordinances, potentially resulting in fines or mandatory modifications. Understanding a system’s sound output in decibels (dB) helps ensure compliance and prevents unnecessary neighborhood disputes.

Decoding Decibels: How Loud Is Too Loud?

Decibel ratings are the industry standard for measuring heat pump noise. A whisper registers around 30 dB, while normal conversation averages 60 dB. Modern, high-efficiency heat pumps typically operate within the 40 to 60 dB range, with ultra-quiet models falling below 50 dB.

It's important to examine both indoor and outdoor unit ratings. Outdoor compressors are often the louder component, especially during startup or defrost cycles. Look for systems that feature noise-dampening technology like sound blankets, insulated compressor compartments, and variable-speed fans that reduce sharp noise changes.

Factors That Influence Heat Pump Noise Levels

Several variables contribute to the overall sound level of a heat pump system. These include:

Compressor Type: Scroll compressors are generally quieter than reciprocating models. Inverter-driven compressors adjust their speed to meet demand, avoiding the loud on/off cycling of traditional units.

Fan Design: Blade shape, motor quality, and rotation speed impact how much air is moved and how quietly it's done.

Cabinet Construction: Sturdier enclosures with vibration-absorbing materials limit mechanical noise and rattling.

Installation Quality: Improper mounting or loose connections can create excessive vibration and amplify sound. Proper insulation and leveling are critical.

Proximity to Living Spaces: Units placed near windows or outdoor patios will seem louder, even if the actual decibel output is within acceptable ranges.

Choosing a Low-Noise Heat Pump Model

When selecting a heat pump, prioritize models that are Energy Star-rated and feature certified sound ratings from organizations like the Air-Conditioning, Heating, and Refrigeration Institute (AHRI). Quiet models often advertise specific technologies like dual-stage compressors or acoustic insulation. Look for terms like "low-noise operation," "quiet mode," or "variable speed" in product specifications.

Consulting professional installers about the quietest models available can help identify systems that perform effectively without creating unnecessary disturbance. Additionally, it’s wise to check product reviews and noise comparisons to understand how each model performs in real-life settings.

Ideal Installation Tips to Minimize Noise

Even the quietest heat pump can become noisy if installed incorrectly. Here are some best practices to reduce unwanted noise:

Choose the Right Location: Avoid placing the outdoor unit near bedroom windows, under balconies, or in narrow passageways where sound can echo.

Install Anti-Vibration Pads: These pads absorb mechanical vibration and reduce noise transmission through the walls or floor.

Use Acoustic Barriers: Fencing, shrubbery, or purpose-built sound barriers can deflect and absorb noise without restricting airflow.

Maintain Adequate Clearance: Proper airflow prevents strain on the fan and compressor, reducing the risk of operational noise spikes.

Ensure Routine Maintenance: Dirty filters, loose parts, or worn components can cause an otherwise quiet system to grow louder over time.

Comparing Heat Pump Models Based on Noise Ratings

Shopping for a heat pump should involve comparing multiple models, especially in terms of sound performance. Specifications typically list two noise levels: one for indoor units and one for outdoor. Always compare these ratings side-by-side and factor in the real-world implications of decibel differences. A drop of 10 dB might not seem like much numerically, but it equates to a perceived halving of noise to the human ear.

Look beyond marketing terms and request technical documentation or spec sheets to see real noise data. Systems designed for noise-sensitive environments, such as hospitals or schools, usually meet higher acoustic standards and make excellent residential options.

Regular Maintenance to Keep Noise Levels Low

Routine upkeep ensures that a heat pump continues to operate quietly. Tasks such as cleaning coils, checking fan alignment, tightening connections, and replacing worn parts reduce unnecessary sound. Scheduling seasonal inspections ensures that problems are identified and corrected before they escalate into louder, more costly issues.

Neglecting regular maintenance not only increases noise but can also shorten the system’s lifespan and raise energy costs. Staying proactive about servicing keeps performance and noise levels optimized.

Making an Informed Decision Based on Sound and Performance

Noise may not be the first factor that comes to mind when evaluating a heat pump, but it quickly becomes a priority once the system is in use. Balancing quiet operation with energy efficiency, heating capacity, and long-term value ensures satisfaction and comfort.

With thoughtful research and proper installation, it's entirely possible to enjoy the benefits of a high-performance heat pump system without sacrificing peace and quiet at home. Being informed about noise ratings and acoustic design features empowers buyers to make smarter, more confident choices—ones that keep both the household and the neighborhood content.

0 notes

Text

Best Beverage Coolers for 2025 – Stylish & Compact – Elite Man Cave

Explore the best beverage coolers for 2025. Stylish and compact options for homeowners and wine enthusiasts. Shop KingsBottle’s exclusive collection today!

#beverage cooler#under counter wine fridge#golf simulator enclosure#retractable golf simulator screen#golf simulator flooring#golf flooring#bbo poker tables#poker tables for sale#beverage refrigerator#wine and beverage cooler

0 notes

Text

Can A Heat Pump Replace Both Your AC And Water Heater?

Homeowners have traditionally relied on distinct appliances for cooling, space heating, and water heating — such as air conditioners, geysers, and room heaters — resulting in clutter, elevated electricity costs, and regular maintenance. Nowadays, heat pump systems present a more intelligent solution. These compact, all-in-one units deliver cooling, heating, and hot water through a single, energy-efficient system. They minimize appliance clutter, reduce operating expenses, and simplify installation, making them perfect for households that prioritize space and efficiency. In this blog, we will delve into what heat pumps are, how they operate, their cost and energy advantages, practical uses, and why they are rapidly becoming the future of modern home comfort.

How do heat pumps work?

Heat pumps use advanced refrigeration and hydraulic systems to provide both air and water heating capabilities. In cooling mode, they extract heat from the indoor air and expel it outside, operating similarly to a standard air conditioner. In heating mode, they reverse this process — drawing heat from the outdoor air and transferring it inside. For water heating, the system channels hot refrigerant through a coil in a buffer tank to heat water for everyday use. Depending on the configuration, heat pumps can prioritize either air or water heating, or manage both at the same time. With minimal space requirements, they effectively address multiple comfort needs within a single unit.

The benefits they provide

· Space-efficient design

A key advantage of heat pumps is their ability to save space. Rather than needing separate units for cooling, heating, and water, you have a single system that handles everything. This significantly minimizes clutter, particularly in smaller homes or apartments. With just one outdoor unit and a combined indoor water tank, there’s less necessity for wall-mounted water heaters in every bathroom or additional piping throughout the residence. These systems streamline utility configurations and free up balconies, utility areas, and rooftops — providing a cleaner, more minimalist arrangement ideal for contemporary living.

· Exceptional energy efficiency

Heat pumps are engineered for optimal performance with minimal energy consumption. With their impressive Coefficient of Performance (COP), they can provide three to five times more heating or cooling energy than the electricity they utilize. By employing a shared refrigeration cycle, the system can effortlessly switch between heating or cooling for both space and water based on demand, maximizing output without raising consumption. Inverter-driven models enhance efficiency further by adjusting compressor speed in real-time. This results in fewer energy surges and a consistently balanced load, all contributing to reduced energy bills and a smaller environmental impact.

· Financial savings and simplified maintenance

In addition to energy savings, heat pumps provide long-term financial advantages. By replacing multiple devices, you streamline equipment and eliminate redundant components like compressors, fans, and control boards. This not only lowers installation costs, but also reduces ongoing maintenance expenses. Maintenance becomes more straightforward and less frequent, as you only need to service one system instead of three. In many households, the savings from decreased electricity usage alone can recoup the initial investment within a few years.

Potential limitations

· Upfront cost: The initial investment is higher than that of a single air conditioner or geyser, but savings can offset this.

· Complex installation: Installation should be performed by certified professionals.

· Noise: Outdoor units can produce noise; opt for models that operate below 50 dB or consider noise-reducing enclosures.

Despite these factors, many homeowners discover that the advantages significantly outweigh the installation hurdles.

Performance comparison with separate systems

Heat pump systems exceed the performance of traditional setups while offering added advantages in efficiency, space optimization, and simplified maintenance. Here’s how they compare.

· Cooling: Matches the efficiency of a standard air conditioner

· Heating: Delivers reliable heating through a reversible heat pump cycle

· Hot Water: Dedicated hot water output, just like a geyser or boiler

· Space usage: One compact unit replaces multiple appliances

· Energy efficiency: Higher efficiency with minimal energy consumption

· Maintenance: Fewer components mean easier, less frequent service

· Installation cost: One-time, unified installation instead of multiple setups

Heat pump systems perform as well as separate ACs and geysers, while offering added benefits in space savings, efficiency, and convenience.

Considerations before you buy

Before purchasing, consider these key factors to ensure your heat pump system performs efficiently and fits your requirements.

· System sizing: It is essential to match the combined load, including room-area BTU and hot water requirements.

· Installation space: The outdoor unit requires proper airflow, while tanks need access to water and electricity.

· Climatic range: The system should be rated to handle the coldest temperatures expected in your area.

· Temperature prioritization: Some models prioritize hot water, which should correspond with household usage patterns.

· Local support: Verify the availability of technicians who are trained in heat pump solutions.

Well-sized and properly configured systems provide seamless performance throughout the year with minimal disruption.

Indeed — a modern heat pump system can effectively replace both your air conditioner and water heater, providing a unified solution for comprehensive home comfort. They are a space-efficient, cost-effective, reliable solution that offer year-round heating, cooling, and hot water. For those aiming to future-proof their spaces without compromising comfort or efficiency, heat pump systems represent the ideal choice. If you’re considering a heat pump in Bangalore, Vindsol offers reliable domestic models tailored for the local weather. These systems efficiently replace both air conditioners and geysers, with compact design and strong service support across the city.

Resource : Read More

0 notes

Text

Is the Generac 48kW Generator the Right Backup Power Solution for Your Home or Business?

About

In today’s world, where power outages can disrupt homes and businesses, having a reliable backup generator is essential. The Generac 48kW generator stands out as a top-tier solution for large homes, commercial properties, and facilities requiring uninterrupted power. In this blog, we’ll explore its features, benefits, installation process, and why it’s a smart investment for long-term power security.

Why Choose the Generac 48kW Generator?

1. Powerful & Reliable Performance

The Generac 48kW generator is designed to handle heavy electrical loads, making it ideal for:

Large residential properties with high power demands

Small to medium-sized businesses

Hospitals, data centers, and other critical facilities

With 48,000 watts of power, it can seamlessly support HVAC systems, refrigerators, medical equipment, and essential electronics during an outage.

2. Advanced Automatic Transfer Switch (ATS)

One of the standout features of the Generac 48kW generator is its automatic transfer switch (ATS), which detects power loss within seconds and starts the generator automatically. This ensures:

No manual intervention required

Instant power restoration (typically within 10-30 seconds)

Protection against surges and electrical damage

3. Quiet & Efficient Operation

Despite its high power output, the Generac 48kW generator operates quietly, thanks to:

Advanced sound-dampening technology

Efficient engine design that reduces noise levels

Compliance with local noise ordinances

4. Durable & Low-Maintenance Design

Generac generators are built to last, featuring:

A robust steel enclosure for weather resistance

Self-diagnostic systems that alert you to maintenance needs

Long-lasting engines with extended service intervals

5. Smart Technology Integration

The Generac 48kW generator can be monitored remotely via:

Mobile app notifications for real-time status updates

Wi-Fi-enabled controllers for easy maintenance tracking

Automatic weekly self-tests to ensure readiness

Installation & Maintenance

Professional Installation Recommended

Due to its size and power capacity, the Generac 48kW generator should be installed by certified professionals. Key installation considerations include:

Proper placement (at least 5 feet from structures for ventilation)

Compliance with local electrical and fuel codes

Connection to natural gas or propane fuel sources

Routine Maintenance Tips

To ensure longevity, follow these maintenance steps:

Monthly testing (automatic self-tests are built-in)

Annual professional inspections (oil changes, filter replacements)

Battery checks to prevent startup failures

Cost & ROI of a Generac 48kW Generator

While the Generac 48kW generator is an investment, its benefits justify the cost:

Prevents financial losses from power disruptions (especially for businesses)

Increases property value with a premium backup power system

Reduces insurance premiums in some cases due to enhanced safety

Conclusion: Is the Generac 48kW Generator Worth It?

For homeowners and businesses that demand uninterrupted power, the Generac 48kW generator is a top choice. With its high capacity, automatic operation, smart monitoring, and durability, it provides peace of mind during outages. Whether you’re safeguarding a luxury home or a critical commercial facility, this generator ensures that life—and business—goes on without interruption.

Ready to invest in a Generac 48kW generator? Contact a certified dealer today to discuss installation and financing options!

0 notes

Text

GBM Industries – Haryana’s Leading Manufacturer of Powder Coating Plants

Founded in 1984 in Bahadurgarh, Haryana, GBM Industries has emerged as a frontrunner in the design and manufacturing of industrial ovens and surface finishing equipment. As an ISO 9001:2015 certified company, GBM stands for quality, innovation, and commitment to customer satisfaction.

With a strong presence in both Indian and international markets, GBM Industries specializes in custom-built powder coating plant solutions that meet the high demands of automotive, appliance, architectural, and general engineering industries. Built with advanced engineering, GBM’s powder coating systems are designed to deliver durability, cost-efficiency, and environmental friendliness—making them the go-to choice for high-performance applications in 2025 and beyond.

What is a Powder Coating Plant?

A powder coating plant is a complete system engineered to apply dry powder onto metal or conductive surfaces using electrostatic spray guns. The coated surface is then cured in an oven, producing a hard, smooth, and durable finish. Compared to traditional wet painting methods, powder coating is more efficient, environmentally safe, and long-lasting.

Why GBM Industries Leads the Powder Coating Industry

1. Trusted Legacy and Industry Experience

With nearly two decades of excellence, GBM Industries brings unmatched expertise to surface finishing systems. Their in-depth knowledge of industrial ovens and coating processes ensures every project is executed with precision, efficiency, and quality control.

2. Custom-Tailored Solutions

No two businesses are alike. GBM understands that each industry has unique coating needs, which is why they offer custom powder coating plant designs to fit space, production capacity, and technical specifications—whether it’s a batch-type plant for small-scale production or a fully automated conveyor-based system for continuous operations.

3. ISO-Certified Manufacturing Excellence

As an ISO 9001:2015 certified company, GBM adheres to strict quality management systems. Each plant is thoroughly tested to ensure flawless performance, safety, and long service life, even under demanding industrial environments.

Key Features of GBM Powder Coating Plants

GBM Industries integrates the latest advancements in automation and energy efficiency, offering features such as:

Electrostatic Spray Guns (manual or automatic)

High-Efficiency Curing Ovens (electric, diesel, or gas fired)

Powder Recovery Booths for reduced wastage

Modular Pretreatment Systems with multi-tank setup

Overhead or Floor-Mounted Conveyor Systems

Advanced Control Panels with PLC/SCADA options

Environment-Friendly Operation with zero-VOC emissions

These systems are engineered to offer high throughput, minimal maintenance, and consistent coating qualit

Specification of GBM Powder Coating Plants

Coating Booth: MS/SS construction with cyclone-type recovery system

Spray Gun Type: Electrostatic (Manual / Automatic)

Curing Oven: Electric, Diesel, or Gas-fired – temperature up to 250°C+

Conveyor Type: I-Beam, Power & Free, Overhead, or Floor Conveyor

Pretreatment Line: 5 to 9 tank process with optional hot phosphating

Control System: Smart automation with PLC / SCADA-based control

Coating Thickness: 60–120 microns (standard)

Industries Served by GBM’s Powder Coating Plants

GBM’s powder coating plants are widely used across various sectors, including:

Automotive & Auto Parts – Wheels, bumpers, chassis, accessories

Home Appliances – Refrigerators, air conditioners, kitchen equipment

Architectural & Building Materials – Doors, windows, grills, railings

Electrical & Electronics – Distribution boards, control panels, enclosures

General Engineering & Hardware – Tools, storage units, office furniture

Each solution is designed for uniform finish, corrosion resistance, and long-term durability.

Environmental and Economic Benefits

Powder coating is the future of sustainable surface finishing. GBM’s systems are designed to:

Eliminate VOC emissions

Recycle unused powder through recovery booths

Reduce energy consumption through insulated ovens

Lower operational costs with minimal maintenance

In a world where sustainability and cost-efficiency are key, GBM's powder coating plants tick all the boxes.

Unmatched After-Sales Support

What truly makes GBM Industries the preferred partner is their comprehensive customer support:

On-site installation and commissioning

Technical training for operators

Scheduled maintenance and service

Spare parts supply and upgrades

This dedication ensures smooth operations and long-term ROI for clients.

Conclusion:

In the fast-paced world of industrial manufacturing, choosing the right partner for your surface finishing needs is critical. GBM Industries, with its proven track record, ISO-certified quality, and tailor-made powder coating plant solutions, is not just a manufacturer—it’s a strategic growth partner for your business.

Contact GBM Industries

Location: Bahadurgarh, Haryana, India Website: https://gbmindustries.com/Email: [email protected] Call: +91 9996055996

0 notes

Text

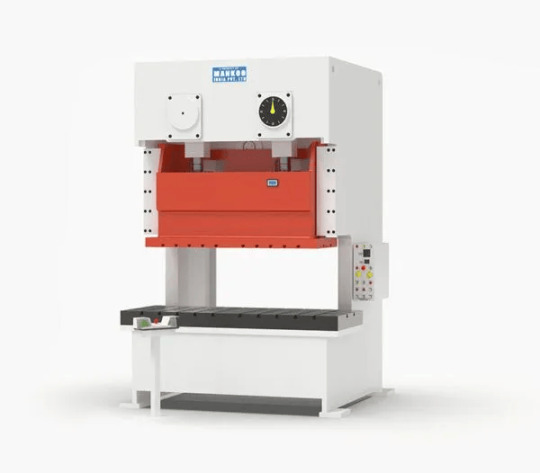

Crafting Heavy Forming with Ease – Mankoo Double Crank Power Press

In the industrial landscape, where precision and power drive productivity, Mankoo Presses stands out as a trusted name in heavy-duty metal forming machinery. Among its flagship innovations, the Double Crank Cross Shaft Press Machine is a high-performance solution designed for demanding applications across the manufacturing sector.

With its rugged build, precise synchronization, and consistent output, this machine symbolizes reliability and efficiency—ideal for operations that involve large dies, thick sheets, and high-tonnage production requirements.

Mankoo Presses – Engineering Excellence Since Inception

Based in Ludhiana, Punjab, Mankoo Presses has carved a niche in the metalworking industry with decades of experience and engineering innovation. Known for delivering heavy-duty presses that combine Indian manufacturing with global standards, Mankoo has become the preferred choice for manufacturers across automotive, appliance, electrical, and construction industries.

At the heart of its product lineup, the Double Crank Cross Shaft Power Press showcases Mankoo’s capability to deliver performance under pressure—literally.

Understanding the Double Crank Cross Shaft Power Press

This advanced machine is designed to handle large dies and high-impact forming operations. Unlike single crank presses, the double crank configuration ensures:

Greater slide stability

Uniform load distribution

A larger working bed

Precise parallelism for die sets

The cross shaft mechanism allows the power to be transmitted across a wide area, reducing deflection and increasing structural rigidity—key for mass production of heavy components.

Where It’s Used: Industrial Applications

Mankoo’s Double Crank Press is trusted by various industries due to its versatile performance:

Automobile Industry: Forming car body panels, engine parts, and chassis components

Appliances Manufacturing: Stamping parts for refrigerators, washing machines, and air conditioners

Electrical Industry: Manufacturing switchgear cabinets, electrical enclosures, and cable trays

Railway & Aerospace: Producing high-strength, structurally sound components

Agricultural Equipment: Forming parts for tractors, ploughs, and mechanical tools

If your production demands volume, accuracy, and durability—this is the machine to count on.

Why Choose Mankoo’s Double Crank Power Press?

1. Superior Build Quality

Mankoo uses high-grade alloy steel and precision machining in the construction of its press bodies, ensuring long-term reliability even in demanding production cycles.

2. High Efficiency

The double crank setup allows for faster operation, better force distribution, and lower vibrations. It handles large dies with less stress on the frame and tooling, enhancing efficiency without compromising safety.

3. Wide Bed & Slide Area

Its large working area supports bigger tooling, enabling the production of oversized components in fewer operations.

4. Safety & Automation Ready

Equipped with:

Pneumatic clutch & brake system

Hydraulic overload protector

Centralized automatic lubrication

Emergency stop controls It also supports automation through feeders, conveyors, and robotic integration—making it future-ready.

5. Custom-Built to Order

Mankoo offers customized models based on client-specific tonnage, stroke length, and die height—ensuring that every machine fits into your workflow perfectly.

Technical Specifications (Typical Range)

Each Mankoo Double Crank Cross Shaft Power Press can be tailored to your needs. Below are standard specification ranges:

Capacity: 250 to 1000 Tons

Stroke Length: 200 mm to 400 mm

Slide Adjustment: 100 mm to 150 mm

Die Height: 500 mm to 800 mm

Bed Area: 2000 x 1000 mm to 3500 x 1500 mm

Motor Power: 15 HP to 75 HP

Stroke per Minute (SPM): 20 to 50

These ranges reflect Mankoo’s ability to customize the press to suit diverse forming operations.

Low Maintenance, Long Life

Mankoo’s machines are engineered for longevity and ease of maintenance:

Centralized auto-lubrication reduces manual upkeep

Slide guides and bearings are built for long life

Quick-access doors make routine inspection hassle-free

Heavy-duty bearings ensure consistent alignment over years of operation

This not only lowers downtime but also reduces operating costs over the long term.

Global Standards, Local Support

Mankoo’s presses are proudly Made in India, with components that meet international quality benchmarks. Beyond domestic dominance, the brand exports to numerous countries, offering a global product with strong local support.

What makes Mankoo truly dependable is their dedicated after-sales service, including:

On-site commissioning & training

Scheduled maintenance programs

Rapid spare parts delivery

Remote or in-person technical assistance

Finally Boost Your Manufacturing Potential

The Mankoo Double Crank Cross Shaft Power Press is more than a machine—it’s a production powerhouse. Whether you're scaling your operations or seeking to improve output consistency, this press offers the force, form, and functionality your business needs to stay ahead.

By investing in Mankoo’s double crank system, you benefit from:

Higher uptime

Better accuracy

Long-term reliability

Support that grows with your operations

#Power Press machine#Double crank power press#press machine suppliers#power presses in India#Power presses in UAE#Power presses in Russia

0 notes

Text

Growth Prospects OF Shower Enclosure and Cubicles Market till 2033

Global “Shower Enclosure and Cubicles Market” research report is a comprehensive analysis of the current status of the Shower Enclosure and Cubicles industry worldwide. The report categorizes the global Shower Enclosure and Cubicles market by top players/brands, region, type, and end-user. It also examines the competition landscape, market share, growth rate, future trends, market drivers, opportunities, and challenges in the global Shower Enclosure and Cubicles market. The report provides a professional and in-depth study of the industry to help understand its current state and future prospects. What Are The Prominent Key Player Of the Shower Enclosure and Cubicles Market?

Shenzhen Zhuoli Technology Co., Ltd

Philips

Panasonic

Zhongshan Jindao Electric Appliance Co., Ltd

Yidian Holdings (Group)

Wenzhou Pinqi Electric Appliance Co., Ltd

Jiangsu Neweisheng Electromechanical Co.,Ltd

Ningbo Ruier Barbie Medical Equipment Co., Ltd

Shenzhen Fuhengtong Technology Co., Ltd

Guangdong Xiaoxiong Electric Appliance Co., Ltd

Guangzhou Aishi Kaiqi Intelligent Technology Co., Ltd

Royal Booby Company

Time Lab Group

Tecdash

Westinghouse Electric Corporation

Ningbo Tieoni Industrial Co., Ltd

The Primary Objectives in This Report Are:

To determine the size of the total market opportunity of global and key countries

To assess the growth potential for Shower Enclosure and Cubicles

To forecast future growth in each product and end-use market

To assess competitive factors affecting the marketplace

This report also provides key insights about market drivers, restraints, opportunities, new product launches or approvals.

Regional Segment of Shower Enclosure and Cubicles Market:

Geographically, the report includes research on production, consumption, revenue, market share, and growth rate of the following regions:

United States

Europe (Germany, UK, France, Italy, Spain, Russia, Poland)

China

Japan

India

Southeast Asia (Malaysia, Singapore, Philippines, Indonesia, Thailand, Vietnam)

Latin America (Brazil, Mexico, Colombia)

Middle East and Africa (Saudi Arabia, United Arab Emirates, Turkey, Egypt, South Africa, Nigeria)

The global Shower Enclosure and Cubicles Market report answers the following questions:

What are the main drivers of the global Shower Enclosure and Cubicles market? How big will the Shower Enclosure and Cubicles market and growth rate in upcoming years?

What are the major market trends that affecting the growth of the global Shower Enclosure and Cubicles market?

Key trend factors affect market share in the world's top regions?

Who are the most important market participants and what strategies being they pursuing in the global Shower Enclosure and Cubicles market?

What are the market opportunities and threats to which players are exposed in the global Shower Enclosure and Cubicles market?

Which industry trends, drivers and challenges are driving that growth?

Browse More Details On This Report at - https://www.businessresearchinsights.com/market-reports/shower-enclosure-and-cubicles-market-104413

Contact Us:

Business Research Insights

Phone:

US: (+1) 424 253 0807

UK: (+44) 203 239 8187

Email: [email protected]

Web: https://www.businessresearchinsights.com

Other Reports Here:

Graphitization Furnace Market

Merchant Bar Quality Market

Cavity Bandpass Filters Market

Fitness and Yoga Mats Market

Snow Goggles Market

Solar Combiner Boxes Market

Benzocyclobutene (BCB) Resin Market

Biorational Crop Protection (BCP) Market

Hot Air Balloon Ride Market

Knife Sharpener Market

Other Reports Here:

Modular Compressor Station Market

Linux Software Market

Refrigerant Recovery Service Market

Hybrid Cooling Towers Market

AI Camera Market

Impulse Hammer Market

Definite Purpose Contactors Market

White Glove Services Market

Perishable Goods Transportation Market

High Temperature Filter Media Market

0 notes

Text

Understanding the Humidity Chamber – Working Principle and Applications

In scientific research, industrial quality control and product development, accurate environmental control is not just a getting profits - this is a requirement. From drugs to electronics, from textiles to food products, it is important for performance, safety and long life how a material or product behaves under different conditions. It is humble here, but still incredibly important in testing; this Humidity Chamber, a lab testing instrument, comes into play as a game-changer.

At Effective Lab India, we understand the important roles of these chambers to ensure the quality and reliability of your products. Let's look at what a lab humidity chamber is, how it works and its different applications.

What is a Humidity Chamber?

Simply put, a humidity chamber (also known as a climatic chamber or environmental chamber) is a controlled environment testing enclosure designed to maintain specific levels of temperature and, most importantly, humidity. Unlike a standard oven or refrigerator, its primary function is to simulate a wide range of atmospheric conditions so that researchers and manufacturers can inspect and analyse the effect of these conditions on their samples.

It is required to test how a new drug performs in the humid tropical climate, or how an electronic component performs when exposed to moisture. A Stability Chamber provides the correct controlled settings for such a significant examination.

The Science Behind the Stability: Working Principle of a Humidity Chamber

The main principle behind the humidity test chamber is the exact control of two main parameters: One is temperature, and the second is moisture content in the air. Here's a break for how it usually works:

Where Do Humidity Chambers Shine? Key Applications

The versatility of the humidity chambers makes them an inevitable environmental chamber in a wide range of industries:

Why Choose Effective Lab India for Your Humidity Chamber Needs?

At Effective Lab India, we are dedicated to offering state-of-the-art, dependable, and easy-to-use a temperature humidity test chamber that meet the strict needs of modern labs and industries. Our chambers are designed with:

Suppose you want to invest in a high-quality humidity test chamber from Effective Lab India. In that case, it means you are investing in the reliability, performance, safety, and longevity of your products..

Conclusion

Humidity chambers are not just simple equipment but important tools that provide specific information about how products and materials interact with their environment. By mimicking real-world environmental conditions in a controlled setting, they provide valuable information that enables industries to develop more robust, reliable and safe products.

Effective Lab India is a well-known name in the manufacture of laboratory testing equipment. It is one of the leading manufacturers and suppliers of humidity chambers located in Faridabad. To improve the quality of your products and reduce product errors, contact Effective Lab India Today. Our contact phone number is +91 9555515525, and the email address is [email protected].

#Humidity test chamber#humidity chamber#stability chamber#environmental chamber#temperature humidity chamber#humidity chamber manufacturer#humidity chamber supplier#effective lab india#humidity control chamber#Humidity chamber price in india#laboratory humidity chamber#lab humidity chamber

0 notes

Text

RF Filter - RFI EMC Filter

In an era where electronic devices dominate industrial, medical, and commercial applications, maintaining clean and stable power is more critical than ever. Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI) can severely disrupt sensitive equipment, leading to malfunctions, data corruption, and even system failures. This is where RFI EMC Filters come into play—providing essential protection by filtering out unwanted noise and ensuring compliance with global Electromagnetic Compatibility (EMC) standards.

At DMC RF, we specialize in manufacturing high-performance EMI/RFI power line filters, including the RFI EMC Filter 5 to 300 AMP (FCL-66, -660 Series), RFI EMC Filters 25 to 200 AMP (DMC FCL-11, -110, -14, -140, -1 Series), and a wide range of RFI EMC Filter Accessories (FCL-55, -66, -660 Series). Our filters are designed to meet the most stringent industry requirements, ensuring optimal performance and reliability.

Understanding EMI, RFI, and EMC Filters

What is EMI and RFI?

EMI (Electromagnetic Interference): Unwanted disturbances caused by electromagnetic radiation from external sources, affecting electronic circuits.

RFI (Radio Frequency Interference): A subset of EMI, specifically caused by high-frequency signals that disrupt communication and electronic systems.

Why Are EMC Filters Necessary?

Modern electronic devices must comply with EMC regulations (FCC, CISPR, IEC) to ensure they neither emit excessive interference nor are susceptible to external noise. RFI EMC Filters suppress conducted and radiated emissions, protecting both the equipment and surrounding devices from interference.

How Do RFI EMC Filters Work?

These filters use a combination of inductors (chokes), capacitors, and ferrite cores to:

Block high-frequency noise from entering or exiting a device.

Allow clean power to pass through without disruption.

Reduce electromagnetic emissions to meet regulatory standards.

DMC RF’s High-Performance RFI EMC Filters

1. RFI EMC Filter 5 to 300 AMP (FCL-66, -660 Series)

Designed for high-power industrial applications, this series ensures robust noise suppression in demanding environments.

Key Features:

Current Range: 5A to 300A

Voltage Rating: Up to 660V

High Attenuation: Effective noise reduction across a broad frequency spectrum

Rugged Construction: Built to withstand harsh industrial conditions

Compliance: Meets CISPR, EN 55011, and MIL-STD-461 standards

Applications:

✔ Industrial motor drives & servo systems ✔ Medical imaging & diagnostic equipment ✔ Renewable energy inverters & solar power systems ✔ Data centers & telecom infrastructure

2. RFI EMC Filters 25 to 200 AMP (DMC FCL-11, -110, -14, -140, -1 Series)

Ideal for medium-power applications, these filters provide reliable EMI suppression for commercial and industrial equipment.

Key Features:

Current Range: 25A to 200A

High Efficiency: Minimizes conducted and radiated interference

Flexible Mounting Options: Panel or chassis mounting available

Compact Design: Space-saving without compromising performance

Applications:

✔ CNC machines & robotics ✔ Power supplies & UPS systems ✔ HVAC & refrigeration units ✔ Laboratory & test equipment

3. RFI EMC Filter Accessories (FCL-55, -66, -660 Series)

To ensure seamless integration, DMC RF offers a range of compatible accessories, including:

Available Accessories:

Mounting brackets & hardware for secure installation

Shielded enclosures for enhanced EMI protection

Terminal connectors & cable glands

Customizable solutions for specialized applications

Why RFI EMC Filters Are Essential for Your Industry

1. Industrial Automation & Machinery

Prevents interference in PLC systems, servo drives, and robotics.

Ensures smooth operation of CNC machines and conveyor systems.

2. Medical & Healthcare Equipment

Protects sensitive MRI machines, X-ray systems, and patient monitors from noise.

Ensures compliance with medical EMC standards (IEC 60601).

3. Telecommunications & Data Centers

Reduces signal distortion in 5G infrastructure, servers, and networking equipment.

Enhances data integrity and transmission reliability.

4. Renewable Energy Systems

Filters noise from solar inverters, wind turbines, and battery storage systems.

Improves efficiency and lifespan of power electronics.

Choosing the Right RFI EMC Filter

Factors to Consider:

Current & Voltage Ratings – Match the filter to your system’s power requirements.

Attenuation Level – Ensure sufficient noise suppression for your application.

Mounting Style – Panel-mount, chassis-mount, or DIN rail options.

Regulatory Compliance – Check for FCC, CE, CISPR, and UL certifications.

Environmental Conditions – Consider temperature, humidity, and vibration resistance.

Why Choose DMC RF?

✔ Industry-Leading Quality – Rigorously tested for performance & durability. ✔ Wide Range of Options – From 5A to 300A, covering all industrial needs. ✔ Global Compliance – Meets international EMC/EMI standards. ✔ Expert Technical Support – Assistance in selecting the right filter for your application.

In today’s electrically noisy environment, RFI EMC Filters are indispensable for ensuring the reliable operation of sensitive electronic systems. Whether you need a 5A filter for small devices or a 300A industrial-grade solution, DMC RF provides high-performance, compliant, and durable filters tailored to your needs.

By integrating DMC RF’s EMI/RFI power line filters, you can reduce downtime, improve efficiency, and meet global EMC standards with confidence. Contact us now to find the perfect filter solution for your application!

Contact US :

Phone Number : +1(613) 915 5533

Website: https://www.dmcrf.com/emi-rfi-power-line-filters/

1 note

·

View note