#Recycled Carbon Fiber research

Explore tagged Tumblr posts

Text

Researchers use carbon nanotube derivatives to strengthen recyclable plastics

Reducing the environmental impact caused by plastics can be addressed through different strategies, such as the manufacture of more durable plastics or recycling. In general, there are two main types of plastics. The first is thermoplastics, which can be melted and molded to form other objects, although their mechanical properties weaken if they are melted several times. And the second, thermosets, do not melt at high temperatures, since the chains of the polymers that form them are intertwined by chemical bonds. Thermoset plastics have advantageous properties compared to thermoplastics. They tend to have a higher resistance to impact and mechanical stress, although they are also more brittle. Epoxy resin, silicone or melamine are examples of thermoset plastics, commonly used in construction. To make these plastics stronger, engineers add reinforcement materials such as carbon fibers. They are already used to manufacture objects such as motorcycle helmets or sports equipment, which are very durable although they cannot be easily recycled.

Read more.

#Materials Science#Science#Carbon nanotubes#Nanotechnology#Carbon#Nanotubes#Plastics#Polymers#Recycling#Strength of materials

24 notes

·

View notes

Text

Nepal-based startup Shah Hemp Inno-Ventures (SHIV) is a unique social enterprise transforming wild-grown hemp, bamboo and other natural resources into a catalyst for fair employment, economic growth and climate-change mitigation. Guided by a mission to harness local resources for global impact, SHIV also cultivates relationships with local communities to ensure a positive impact and above-standard working conditions for its employees — who essentially turn local ‘weeds’ into everything from hemp bags, backpacks, paper, soaps, hemp seed oil and hempcrete to bamboo mats and furniture. We spoke with Chief Operations Officer Nivedita Bansal to learn more about how the organization combines sustainable farming, waste management, and community empowerment to build a more environmentally sustainable and socially equitable future.

According to Cambridge University researcher Darshill Shah, “Hemp can capture atmospheric carbon twice as effectively as forests while providing carbon-negative biomaterials for architects and designers.” A hectare of hemp can absorb 8-15 tonnes of CO2. In comparison, forests only capture 2-6 tonnes, depending on the type of trees and region.

SHIV’s product line essentially turns waste into products, but how do you manage your own waste?

NB: Our primary business model is in fact based on managing waste: Wild hemp is seen as a nuisance to local farmers and is usually just chopped away and burned. Hemp fibers are fully compostable, making most of the materials we don’t use for manufacturing indeed compost. Our facility is zero waste; and we recycle, upcycle or reuse all the inorganic waste — such as bag straps, zippers, utility attachments and other similar materials utilized during manufacturing. By communicating with local municipality, neighboring communities and universities and sharing our methodology — especially our hempcrete building techniques — we serve as activists for these sustainable practices.

7 notes

·

View notes

Text

Formula 1 2026 Engine Regulation Changes - TEXT BLOCK

I wrote up this explanation of each of the engine regulation changes for my WIFE and it's good enough I wanted to share it here.

Formula 1 2026 Engine Regulation Changes:

1: **New fuel must be 100% carbon free fuel, part of the FIA's plan for "net zero carbon" F1 racing by 2030.** ARAMCO is leading the research into the new carbon-neutral fuel. The goal is to be able to reuse municipal waste, food waste, or even gas pulled from the atmosphere to fuel cars. As of now it's being tested only in Formula racing, but the goal is to slowly release this fuel for road use as well across the world. Right now the F1 cars run on E10 (90% gasoline, 10% renewable ethanol). F1 and the FIA are the best people to lead this project because they know that full electric cars are not attainable for most people in the world and so replacing fuel with a carbon-neutral fuel (carbon is pulled from the environment to make the fuel, and the same amount is emitted by the engine. This essentially maintains the carbon equilibrium.) Formula 2 and Formula 3 are already running on a fuel mix comprised with 55% of this new biofuel. F1 is really driving sustainable practices. They are the first motorsport to use FSC (Forest Sustainability Council) certified tires, McLaren is releasing their new carbon fiber recycling (first industrial scale use), all of F1's DHL delivery trucks for European races run on 100% biofuel as of last year, all 10 teams have received the FIA's 3-star environmental accreditation.

2: **Increased electric power in the cars** - as of right now its 75% engine/25% electric power. The goal is 50%/50% by increasing the MGU-K unit from 120 kW to a 350 kW generator - this is what Verstappen is worried about as there isn’t an equivalent increase in battery size meaning the current ~30 second max boost from the electric motors will be reduced to ~10 seconds with the larger motor and same battery size. Drivers will have to downshift during straights to charge the battery more often, hopefully leading to closer racing as people won’t be able to just fly off using the electric motors.

3: **No more MGU-H** (this will help people like Stake or other small teams) - this was primarily driven by the fact that we have 2 new engine producers in 2026: Audi and Honda are joining the field and will need time to develop engines to catch up with teams like Ferrari and Red Bull. The issue is the MGU-H almost completely solved turbo lag (if you notice in your car, the turbo doesnt spool up until a certain RPM, the MGU-H spools the turbo from the time of acceleration, allowing for all waste exhaust to be used for charging the battery instead of wasting some spooling the turbo). This may lead to the return of Schumacher level throttle control to keep the turbo spooled during cornering. It’s going to be a learning curve for the racers who have only ever raced with an anti-lag system like the MGU-H.

4: **Reduced fuel allowance** - cars burn through around 100 kg of fuel per race, in 2026 this will be limited to 70 kg. The new engines ARE more efficient so it should equal out to the same power for less fuel.

The FIA is also pushing teams towards focusing less on raw engine power and more on aerodynamics and drag reduction to improve engine efficiency. Essentially, this is a test bed for the future of all high end racing by developing incredibly efficient powerful engines with a smaller form factor and better

15 notes

·

View notes

Text

towwn: ready to *spring* into action this earth month? sustainable fitness gear not only boosts personal health goals, it’s way healthier for the planet. so step/jog/run away from the nylon, polyester, traditional cotton + virgin synthetics, and get with the eco-program with these earth-friendly workout brands.

@losanoofficial these comfy clothes move from barre class to the couch + back. materials are bpa-free recycled or natural fabrics with a reduced co2 footprint.

@champion the legacy sports apparel brand’s new “eco future” collection features 100% certified organic cotton + recycled polyester, meeting gots + oeko-tex standards. sustainable initiatives include worker rights, water treatment + chemical safety.

@pearlizumiofficial/ this biking gear brand is committed to 98% eco-friendly materials and aims to eliminate single-use plastics and virgin forest fibers by 2025 + reduced emissions. promoting cycling as a means of transport, positive environmental change is part of their mission.

@mate_the_label/ stylish tees, gots-certified stretch leggings + more effortlessly cool gear are made in body-inclusive sizes using organic cotton, recycled polyester + linen and non-toxic dyes.

@pact all items are crafted with organic cotton + carbon neutral, recycled materials. tees, tanks, joggers + hoodies are all sustainability certified, while fair trade partnerships + ethical production includes the “give back box” program to encourage recycling of clothes and packaging.

@patagonia committed to both eco responsibility + animal welfare, patagonia promises goods are made safely, fairly & humanely while reducing emissions + conducting research on microplastics.

@wolven wolven combines sultry design with sustainability via recycled fabric + practices that combat ocean pollution + deforestation, as well as carbon-offsetting partnerships. eco-packaging emphasizes reusability, while a community-driven mission merges ethical style with activism for a greener planet.

@tentree made from sustainable cotton + recycled polyester, the bluesign-certified co. ensures ethical sourcing + thoughtful craftsmanship. plus, every purchase helps plant 10 trees to support reforestation.

7 notes

·

View notes

Text

Sustainable Fashion: A Guide to Ethical Choices Sustainable Fashion: A Guide to Ethical Choices

In today's world, conscious consumerism is on the rise. People are increasingly aware of the impact their choices have on the environment and society. This shift has also extended to the fashion industry, leading to a growing demand for sustainable and ethical clothing.

What is Sustainable Fashion?

Sustainable fashion refers to clothing and accessories that are produced in a way that minimizes environmental impact and ensures fair labor practices. It encompasses everything from the choice of materials to the manufacturing processes and the overall lifecycle of a garment.

Why is Sustainable Fashion Important?

Environmental Impact: The fashion industry is one of the world's largest polluters. By choosing sustainable options, you can help reduce waste, conserve resources, and minimize carbon emissions.

Ethical Considerations: Sustainable fashion ensures that workers are treated fairly and that the production process does not exploit people or the planet.

Quality and Durability: Sustainable garments are often made with higher quality materials and better construction techniques, ensuring they last longer and reduce waste.

How to Choose Sustainable Fashion:

Research Brands: Look for brands that prioritize sustainability in their practices. Many brands now have certifications or labels that indicate their commitment to ethical and environmentally friendly production.

Consider Materials: Opt for natural fibers like organic cotton, linen, and bamboo, which are renewable and biodegradable. Avoid synthetic fabrics like polyester, which are derived from fossil fuels and can release harmful chemicals during production.

Check for Fair Trade Certifications: Fair Trade labels guarantee that the products were made under fair working conditions and that workers received a living wage.

Buy Less, Wear More: Invest in high-quality, timeless pieces that you can wear for years to come. Reduce impulse purchases and focus on building a sustainable wardrobe.

Support Secondhand and Vintage: Give pre-loved clothing a new life by shopping at thrift stores, consignment shops, or online marketplace

Sustainable Fashion Tips:

Wash Clothes Less Frequently: Excessive washing can contribute to the degradation of fabrics and release microplastics into the water.

Air Dry Clothes: Avoid using a dryer, which can shrink or damage garments and consume a lot of energy.

Repair and Mend: Instead of discarding damaged clothes, learn to repair or mend them to extend their lifespan.

Donate or Recycle: When you're ready to part with old clothes, donate them to charity or recycle them. Many clothing retailers now have recycling programs.

By making conscious choices and supporting sustainable fashion brands, you can contribute to a more ethical and environmentally friendly fashion industry. Together, we can create a future where style and sustainability go hand in hand.

2 notes

·

View notes

Text

Toilet paper

I recently read some articles that state that many of the top US brands of toilet tissue contain no recycled content and are made with wood fiber from Canada’s boreal forests. Boreal forests cover vast expanses in Canada, Alaska, and Russia and are crucial to our planet, as they store 30% to 40% of land-based carbon. These forests make up one of the world’s last remaining stretches of true wilderness and are filled with centuries-old conifers and birches. Each year, industrial logging operations clearcut approximately one million acres of intact forest, feeding demand for Canada’s wood products—of which the United States is the largest purchaser. Much of this logging goes to make toilet paper, paper towels, and facial tissues that consumers use once and then just throw away. Several of the typical brands of toilet paper in the US have no recycled content and are made with virgin forest fiber from the boreal forests.

There are many reasons to reconsider the brand of toilet paper you use. Boreal forests are important for our planet’s future. Toilet paper made with recycled content has one-third the carbon footprint of toilet paper made from virgin wood fiber from trees. Some companies offer these products made from more sustainable plants. Also, there are several types of bleaching processes used to manufacture toilet paper, paper towels, and facial tissues, and some of the processes are more harmful to the environment than others. The Natural Resources Defense Council (NRDC) has researched various brands in the US and has developed a report that uses several factors to evaluate the sustainability of various US brands of toilet paper, paper towels, and facial tissue. The report is titled “The Issue with Tissue” https://www.nrdc.org/bio/ashley-jordan/2022-tissue-scorecard-tps-future-lies-sustainability and was last updated in 2022. I believe the report covers only US brands, but I hope non-US readers can use the information in the NRDC report to find information to evaluate your local brands. One other thing – evaluate your own habits. Are you using more toilet paper, facial tissue, or paper towels than required for each use?

17 notes

·

View notes

Text

MATERIAL RESEARCH

Looking into regenerative/recycled/recyclable/environmentally-friendly materials.

Repreve: Recycled PET bottle fabric

“We transform plastic bottles into certifiable, traceable, high-performance yarn … REPREVE® is made with less carbon, using non-toxic products. It reduces global warming potential compared to conventional virgin polyester. We empower brands and consumers to take a positive step … Our collaboration with Oerlikon Barmag on the eAFK EvoCooler technology has reduced the energy required to texture our yarn. REPREVE® SmartDye™ and WaterWise™, both proprietary innovations, have reduced the amount of water and energy used in the dye process.” - https://repreve.com/discover-repreve

Econyl: Recycled fishing net and nylon fabric

“Fishing nets, together with other nylon waste, are regenerated into ECONYL® nylon. … As well as being a solution on waste, ECONYL® regenerated nylon is also better when it comes to climate change. It reduces the global warming impact of nylon by up to 90% compared with the material from oil.” Also recycled into the material: old carpets, pre-consumer waste, and textile scraps. - https://www.econyl.com/the-process/

Agraloop Biofibre: created from agriculture/food waste

“The Agraloop™ refines natural fibers derived from agricultural crops into textile-grade fiber called Agraloop™ BioFibre™. A NEW Natural Fibermindfully sourced for circularity. With our specialized wet processing technique, cellulose fiber from stems and leaves are purified into soft fiber bundles ready to spin into yarns. The Agraloop processes left-overs from various food and medicine crops including, oilseed hemp/flax, CBD hemp, banana, and pineapple.” - https://circularsystems.com/agraloop

Pinayarn: Fabric made from pineapple waste

“Piñayarn® by Ananas Anam is an innovative and low impact yarn, made from waste pineapple leaves. Piñayarn offers a 100% plant-based, recyclable, and biodegradable textile solution for a world otherwise dominated by petroleum-based textiles and resource intense virgin fibres.” - https://www.ananas-anam.com/pinayarn/

Recycled Cotton

“Recycled cotton can be generally defined as converting cotton fabric into cotton fiber that can be reused in textile products. Recycled cotton is also commonly referred to as regenerated cotton, reclaimed cotton, or shoddy. Recycled content includes recycled raw material, as well as used, reconditioned, and re-manufactured components.

Pre-consumer: includes scraps created by yarn and fabric by-products

Post-consumer: includes garments, upholstery, towels, household items to be repurposed

The largest volume of recycled cotton sources is produced through pre-consumer waste, such as cutting scraps. Post-consumer waste is more difficult to sort through due to various color shades, fabric blends, and it is generally a more labor-intensive process.” - https://cottonworks.com/en/topics/sustainability/cotton-sustainability/recycled-cotton/

Mylium: Mycelium-based leather

“At Mylium we treasure fungi that grow in a thread-like network, called mycelium. Mycelium grows by extending and branching its tips in search of nutrients. The threads hook strongly together and are pressed to form a uniform sheet.” -https://www.mylium.nl/technology/

Hemp fabric

“One of the most eco-friendly aspects of hemp is that it uses very little water, about 1/20th of the amount of water it takes to grow cotton and can often be rain-fed. Hemp can grow in almost all soil conditions, and unlike cotton (which depletes the soil of nutrients) hemp’s deep-reaching roots preserve the topsoil and subsoil. Hemp plants grow densely as well, leaving no room for weeds and competing plants and is less vulnerable to insects, which means little to no use of pesticides.” Hemp fabric is also biodegradable, and depending on where it is sourced from- largely produced by sustainable practices. - https://wearethefabricstore.com/au/sustainability/gots-organic-hemp

Lyocell and Modal: fibres made from sustainable wood

“TENCEL™ Lyocell and Modal fibers help to maintain the environmental balance by being integrated into nature’s cycle. The fibers originate from the renewable raw material wood, created by photosynthesis. The certified biobased fibers are manufactured using an environmentally responsible production process. The fibers are certified as [100%] compostable and biodegradable, and thus can fully revert back to nature.” - https://www.tencel.com/b2b/sustainability

An interesting article on the incredible role of mycelium and waste management...

4 notes

·

View notes

Text

How Science and Technology Are Changing Ice Hockey

It's time to examine how science and technology transform ice hockey. Hockey is thrilling, and technology assists in many ways to make it more fun. For instance, rinks are being constructed to handle the demands of professional hockey, while sensors and carbon composite sticks are helping to make the game safer.

Most hockey sticks up until around ten years ago were made of wood. Those wooden sticks often broke or cracked. Players would thus keep other posts on the bench. Manufacturers eventually released composite bats.

A carbon fiber hockey stick is referred to as a composite stick. It is more flexible and lower in weight. These hockey sticks are also sturdier and more robust than their forerunners.

In a mold, the materials are heated and compacted during production. While fiberglass contributes to strength, carbon fibers have an excellent tolerance for heat. They may be mixed with other materials, such as thermoplastic Aramid, which helps shield the stick from deterioration.

Although a more recent technology, carbon composite sticks have already started to change the sport. Goalies like Sergei Bobrovsky have already begun using them. This season, 24 NHL goalies have converted to composites.

Thanks to sensors, a new ice hockey age is about to begin. Thanks to technology, more metrics and insights can be given to coaches and players. It will also assist authorities in making the best decisions.

The NHL is using wearable technology to enhance player training and safety. To detect player biomechanics and other motions on the rink, sensors are included in pucks, helmets, and skates.

They also use infrared cameras to keep tabs on players, pucks, and jerseys. Both movement and distance detection may be added to these cameras.

The speed and direction of a puck or disc are detected by a new hockey goal created using technology. This intelligent goal may be modified to operate in many modes and compute phases utilizing several sensors.

The Shockbox is another cutting-edge piece of technology; it is a helmet sensor that transmits the hit count to a smartphone. This technology may be discrete and operated by groups of people.

It's challenging to build a rink that can withstand the demands of professional hockey. There are several considerations. You will need to be ready to do the task, from illumination to the correct quantity of snow.

The most effective method for doing this is water recycling. Each year, this helps to save hundreds of thousands of gallons of water. Long-term savings are another benefit.

An NHL rink is an ice surface 200 feet long and 85 feet broad. It has a four-centimeter thickness. It has a one-inch-thick coating of crystal-clear water on top.

According to the National Ice Hockey Association, approximately 20,000 impact-related injuries are reported annually in the country. These include PCL or LCL tears, meniscus tears, and kneecap dislocations.

The frequency of ice hockey injuries among US adult players has been the subject of many studies. Concussions have received some of the research's attention. In hockey, concussions, which are a kind of severe brain damage, often occur. They usually happen when a player falls and hits his head on a hard surface. A well-fitted helmet is necessary to avoid a concussion.

In a different research, concussions among NHL enforcers were analyzed. They claimed that concussions were the cause of 15% of their injuries. A concussion may include headaches, light sensitivity, nausea, and vomiting.

Additionally, the researchers discovered that among a group of guys between the ages of 26 and 35, there was a significant rise in impact-related injuries. The bank was not statistically significant when compared to younger age groups.

The construction of a professional hockey rink is one of the most impressive engineering achievements. You may create a rink ideal for the activity by combining water, transparent layers, and the necessary components. Fortunately, basketball teams sometimes share venues with professional hockey teams.

5 notes

·

View notes

Text

Thermoplastic Composites Market Industry Outlook By Forecast Period 2032

The latest study released on the Global Thermoplastic Composites Market by Straits Research, Research evaluates market size, trend, and forecast to 2032. The Thermoplastic Composites Market consider covers noteworthy inquire about information and proofs to be a convenient asset record for directors, investigators, industry specialists and other key people to have ready-to-access and self-analysed study to help understand market trends, growth drivers, openings and up and coming challenges and approximately the competitors.

The global thermoplastic composites market size was valued at USD 16.02 billion in 2021. It is expected to reach USD 27.55 billion by 2030, growing at a CAGR of 6.21% during the forecast period (2022-2030).

Thermoplastic composites have low density, better insulation, environmental resistance, and better mechanical properties, and they may be chemically unstable in terms of physical characteristics. Additionally, they are recyclable, heat-weldable, and thermoformable. Thermoplastic composites are widely used in many end-use industries, including aerospace & defense, construction, automotive, healthcare, and others, because of their superior physicochemical properties.

Some of the key players profiled in the study are:

BASF SE

Celanese Corporation

DSM

Dupont

Hanwha

Lanxess

Mitsubishi Chemical Advanced Materials

PPG Industries

SABIC

Solvay SA.

Get Free Sample Report PDF @ https://straitsresearch.com/report/thermoplastic-composites-market/request-sample

The titled segments and sub-section of the market are illuminated below:

By Fiber Type

Glass

Carbon

Mineral

Others

By Product Type

Glass Mat Thermoplastics Composites

Advanced Thermoplastic Composites

By Resin Type

Polyamides

Polypropylene

Polyether ether ketone

Hybrid

Others

By Application Type

Oil & Gas

Aerospace & Defense

Marine

Construction

Military

Others

Get Detailed Segmentation @ https://straitsresearch.com/report/thermoplastic-composites-market/segmentation

Geographically, the detailed analysis of consumption, revenue, market share, and growth rate of the following regions:

• The Middle East and Africa (South Africa, Saudi Arabia, UAE, Israel, Egypt, etc.)

• North America (United States, Mexico & Canada)

• South America (Brazil, Venezuela, Argentina, Ecuador, Peru, Colombia, etc.)

• Europe (Turkey, Spain, Turkey, Netherlands Denmark, Belgium, Switzerland, Germany, Russia UK, Italy, France, etc.)

• Asia-Pacific (Taiwan, Hong Kong, Singapore, Vietnam, China, Malaysia, Japan, Philippines, Korea, Thailand, India, Indonesia, and Australia).

Objectives of the Report:

•To carefully analyze and forecast the size of the Thermoplastic Composites Market by value and volume.

• To estimate the market shares of major segments of the Thermoplastic Composites Market

• To showcase the development of the Thermoplastic Composites Market in different parts of the world.

• To analyze and study micro-markets in terms of their contributions to the Thermoplastic Composites Market, their prospects, and individual growth trends.

• To offer precise and useful details about factors affecting the growth of the Thermoplastic Composites Market

• To provide a meticulous assessment of crucial business strategies used by leading companies operating in the Thermoplastic Composites Market, which include research and development, collaborations, agreements, partnerships, acquisitions, mergers, new developments, and product launches.

Key questions answered:

• How feasible is Thermoplastic Composites Market for long-term investment?

• What are influencing factors driving the demand for Thermoplastic Composites Market near future?

• What is the impact analysis of various factors in the Global Thermoplastic Composites Market growth?

• What are the recent trends in the regional market and how successful they are?

Buy Thermoplastic Composites Market Research Report @ https://straitsresearch.com/buy-now/thermoplastic-composites-market

Region Included are: Global, North America, Europe, APAC, South America, Middle East & Africa, LATAM.

Country Level Break-Up: United States, Canada, Mexico, Brazil, Argentina, Colombia, Chile, South Africa, Nigeria, Tunisia, Morocco, Germany, United Kingdom (UK), the Netherlands, Spain, Italy, Belgium, Austria, Turkey, Russia, France, Poland, Israel, United Arab Emirates, Qatar, Saudi Arabia, China, Japan, Taiwan, South Korea, Singapore, India, Australia and New Zealand etc.

At long last, Thermoplastic Composites Market is a important source of direction for people and companies.

Thanks for reading this article; you can also get region wise report version like Global, North America, Europe, APAC, South America, Middle East & Africa, LAMEA) and Forecasts, 2024-2032

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Thermoplastic Composites Market Market#Thermoplastic Composites Market Market Share#Thermoplastic Composites Market Market Size#Thermoplastic Composites Market Market Research#Thermoplastic Composites Market Industry#What is Thermoplastic Composites Market?

0 notes

Text

Adipic Acid Market : Technology Advancements, Industry Insights, Trends And Forecast 2033

The adipic acid global market report 2024 from The Business Research Company provides comprehensive market statistics, including global market size, regional shares, competitor market share, detailed segments, trends, and opportunities. This report offers an in-depth analysis of current and future industry scenarios, delivering a complete perspective for thriving in the industrial automation software market.

Adipic Acid Market, 2024 report by The Business Research Company offers comprehensive insights into the current state of the market and highlights future growth opportunities.

Market Size -

The adipic acid market size has grown strongly in recent years. It will grow from $6.73 billion in 2023 to $7.11 billion in 2024 at a compound annual growth rate (CAGR) of 5.7%. The growth in the historic period can be attributed to demand for nylon, the synthetic fiber boom, world wars and synthetic materials, globalization and trade, and electronics and consumer goods.

The adipic acid market size is expected to see strong growth in the next few years. It will grow to $9.0 billion in 2028 at a compound annual growth rate (CAGR) of 6.1%. The growth in the forecast period can be attributed to textile industry growth, consumer behavior and preferences, infrastructure development, automotive fuel efficiency standards and climate change mitigation efforts. Major trends in the forecast period include biotechnological production, sustainable feedstocks, integration with carbon capture, decarbonization and renewable energy integration, and advanced analytical and monitoring tools.

Order your report now for swift delivery @

The Business Research Company's reports encompass a wide range of information, including:

1. Market Size (Historic and Forecast): Analysis of the market's historical performance and projections for future growth.

2. Drivers: Examination of the key factors propelling market growth.

3. Trends: Identification of emerging trends and patterns shaping the market landscape.

4. Key Segments: Breakdown of the market into its primary segments and their respective performance.

5. Focus Regions and Geographies: Insight into the most critical regions and geographical areas influencing the market.

6. Macro Economic Factors: Assessment of broader economic elements impacting the market.

Market Drivers -

The increasing automobile industry is expected to propel the growth of the adipic acid market going forward. The automobile industry refers to the collection of companies and activities involved in designing, developing, manufacturing, marketing, and selling motor vehicles. The automobile industry is increasing due to demand for personal mobility, economic growth, and urbanization. Adipic acid plays a significant role in enhancing the performance, durability, and aesthetics of automotive components and materials by contributing to the efficiency and safety of automobiles. For instance, in April 2024, according to the Society of Motor Manufacturers and Traders, a UK-based influential trade association, the number of vehicles on UK roads reached 41.4 million in 2023, with car ownership increasing by 1.6% to 35.7 million. Therefore, the increasing automobile industry is driving the growth of the adipic acid market.

Market Trends -

Major companies operating in the adipic acid market are focusing on developing innovative products, such as Eco-Friendly Nylon 66, to gain a competitive edge in the market. Eco-friendly Nylon 66 refers to a type of nylon material produced using environmentally sustainable methods and incorporating recycled or bio-based components. For instance, in August 2022, Toray Industries Inc., a Japan-based textile industry company, launched 100% Bio-Based Adipic Acid, a raw material for nylon 66 (polyamide 66), from sugars derived from inedible biomass. This innovative solution, 100% bio-based adipic acid, offers significant potential for reducing carbon emissions and environmental impact while maintaining the performance and quality standards required by industries, driving sustainable development, and meeting the increasing demand for eco-friendly products.

The adipic acid market covered in this report is segmented –

1) By Raw Material: Cyclohexanol, Cyclohexanone

2) By Sales Channel: Direct Sale, Indirect Sale

3) By Application: Nylon 6, 6 Fiber, Nylon 6, 6 Resin, Polyurethanes, Adipate Esters

4) By End Use Industry: Automotive, Electrical And Electronics, Packaging And Consumer Products, Building And Construction, Textile, Other End-Use Industries

Get an inside scoop of the adipic acid market, Request now for Sample Report @

Regional Insights -

Asia-Pacific was the largest region in the adipic acid market in 2023. The regions covered in the adipic acid market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

Key Companies -

Major companies operating in the adipic acid market are <b>PetroChina Company Limited, Invista, BASF SE, Sumitomo Chemical Company Limited, Asahi Kasei Corporation, Evonik Industries Aktiengesellschaft, Du Pont de Nemours Inc., LANXESS Aktiengesellschaft, Huntsman Corporation, Solvay Société Anonyme, UBE Corporation, Ascend Performance Materials Operations LLC, Shenan Shenma Nylon Chemical Co. Ltd., Radici Partecipazioni SpA, Fibrant BV, DOMO Chemicals GmbH, Finoric LLC, Alfa Chemical Co. Ltd., Wego Chemical Group Inc., Graham Chemical Corporation, KeenBolden LLC, Otto Chemie Pvt. Ltd., Tangshan Zhonghao Chemical Co. Ltd., BioAmber Inc.</b>

Table of Contents

1. Executive Summary

2. Adipic Acid Market Report Structure

3. Adipic Acid Market Trends And Strategies

4. Adipic Acid Market – Macro Economic Scenario

5. Adipic Acid Market Size And Growth

…..

27. Adipic Acid Market Competitor Landscape And Company Profiles

28. Key Mergers And Acquisitions

29. Future Outlook and Potential Analysis

30. Appendix

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

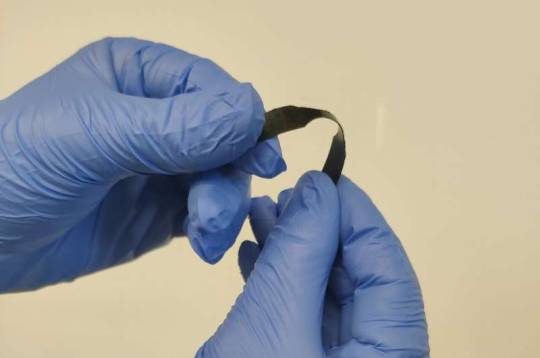

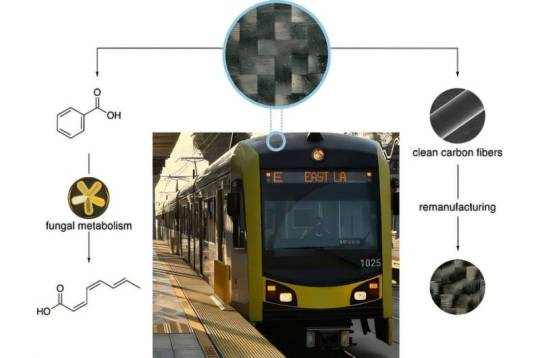

New method successfully recycles carbon fiber composite into reusable materials

USC researchers have developed a new process to upcycle the composite materials appearing in automobile panels and light rail vehicles, addressing a current environmental challenge in the transportation and energy sectors. The study recently appeared in the Journal of the American Chemical Society. "I wasn't sure if it was possible to fully recycle composite materials," said Travis Williams, professor of chemistry at the USC Dornsife College of Letters, Arts and Sciences. "As wonderful as these materials are for making energy-efficient vehicles, the problem with composites is we don't have a practical route to recycle them, so the materials end up in landfills." The chemistry demonstrated in the study, a partnership among Williams and professors Steven Nutt of the M.C. Gill Composites Center at the USC Viterbi School of Engineering, Clay C.C. Wang of the USC Alfred E. Mann School of Pharmacy and Pharmaceutical Sciences and Berl Oakley of the University of Kansas, is a new approach that shows that composite materials can be recovered and recycled in a manner that preserves the integrity of the materials.

Read more.

#Materials Science#Science#Carbon fiber#Fibers#Composites#Carbon#Recycling#Waste#Fungi#Polymers#University of Southern California

16 notes

·

View notes

Text

Bambrew’s range of eco-friendly packaging alternatives

Bambrew, an Indian startup specializing in sustainable packaging, is making strides in the fight against single-use plastics by offering a range of 'eco-friendly' alternatives, says Vaibhav Anant, founder & CEO. The company provides packaging solutions made from renewable, biodegradable materials such as bamboo, seaweed, banana fiber, and agro-waste. According to Anant, these materials are fully compostable and serve as viable alternatives for businesses seeking to reduce their environmental footprint.

“Our solutions are governed by four core principles of sustainability—eco-friendliness, functionality, cost-efficiency, and scalability. These guiding principles enable us to deliver packaging options that are not only environmentally responsible but also commercially viable for businesses of all sizes,” Anant says.

Bambrew offers a range of packaging alternatives, including mailer bags, flexible pouches, rigid boxes, and custom solutions, all designed to meet the functional needs of various sectors while remaining scalable. It has developed solutions for industries such as FMCG, CPG, fresh fruits and vegetables (F&V), food and beverages (F&B), and e-commerce and retail packaging.

Notable clients include Amazon, Nykaa, Hindustan Unilever, Mahindra Logistics, and Tata 1mg.

Material-Agnostic Company

Anant explains that Bambrew is a material-agnostic company, meaning it develops solutions using various materials, all adhering to the four core principles of sustainability as mentioned earlier.

Bambrew prioritizes sustainability not only in its products but throughout the entire product development lifecycle, from sourcing and compounding to conversion processes, says Anant. The company works closely with raw material providers and maintains complete control over production with the latest technology machines for in-house manufacturing. It also operates tech-assisted warehousing and logistics to ensure timely delivery to customers.

“By reducing our reliance on fossil fuels through the use of biofuels and solar energy, we are significantly lowering our carbon footprint. Equally important is the well-being of our workers, and we are committed to maintaining a healthy work-life balance. We adhere to an 8-hour shift structure and offer a range of benefits to ensure a supportive and positive work environment, with a strong emphasis on mental health,” Anant states.

The company has its manufacturing facility in Bangalore and collaborates with several contract manufacturing units across India to expand its reach and capabilities.

Rapid Growth

According to Anant, the company has made big progress over the last 12 months, with growth exceeding 8x.

“This momentum has been incredibly encouraging, and we’re excited to continue building on it in the years to come. As the demand for sustainable solutions grows, we’re committed to scaling responsibly and staying focused on our mission,” he says.

New Offerings

Bambrew is actively working towards the continuous development of advanced meta-materials. It has been extensively researching materials such as Biophil, a home-compostable bioplastic alternative, while also exploring other renewable resources. These materials are designed to offer high performance while being environmentally friendly.

In August of this year, the company introduced a new category of rigid boxes that utilize Kappa boards produced from post-consumer recycled fibers. The product features components like non-animal-based glue, recycled paper cladding, plastic-free Biophil lamination, and plant-based inks. Each element of this product is designed to meet Bambrew's environmental goals and contribute to a fully sustainable manufacturing cycle.

“Additionally, we are actively developing alternative solutions for pharmaceutical packaging, as well as advanced barrier films for food packaging within the FMCG sector. While these are only a few examples, all our efforts are directed towards the broader aim of pushing the envelope of what’s possible within the realm of sustainability and delivering solutions that meet the highest standards of quality while supporting a greener, more sustainable transition into the future,” Anant concludes.

0 notes

Text

The car was built by students at Warwick Manufacturing Group (WMG) at the University of Warwick and will run off a byproduct of wastewater from the utilities company Severn Trent Water.

The Waste2Race Le Mans Prototype race car (LMP3) has been built from a selection of spare and unused parts to further its sustainable street cred in a world little-regarded for its sustainability—motorsport.

The car itself will be used to try to break one of several land speed records depending on how it performs, including the fastest standing and flying starts for both a mile and a kilometer. Its creators hope to have the car fully up and running in the next 6 to 12 months.

The parts themselves come from Ginetta, a British specialist builder of racing and sports cars based in Leeds. Among its green bits and bobs are materials made from recycled carbon fiber and a wing mirror made from beetroot waste.

The steering wheel is also 100% natural, while the firm ENRG Motorsport contributed a battery recovered from a crashed road car.

“These sorts of collaborations are a great example of how businesses, universities, and the endless curiosity of our students can break barriers and push the boundaries of what’s possible,” said Head of the Sustainable Materials and Manufacturing Research Group at WMG, Professor Kerry Kirwan.

0 notes

Text

Aerospace Composites Market Size, Share, Growth, Trends and Forecast 2024-2032

North American region has been one of the forerunners in adopting Aerospace Composites due to the vast availability of aircraft manufacturing units and the strong domestic and export markets for the same. Some of the key reasons that have assisted the extensive expansion of Aerospace Composites in the North American region are the presence of a large number of aircraft manufacturing and aviation services provider companies, the vastly growing low-cost carrier and narrowbody aircraft market, and conducive government policies supporting Aerospace Composites technology advancements.

According to the Univdatos Market Insights analysis, growing investments in the air mobility sector will surge in demand for the Global Aerospace Composites market, which will drive the global scenario of the “Global Aerospace Composites Market” report; the global market was valued at USD 26,910.24 million in 2023, growing at a CAGR of 12.53 % during the forecast period from 2024 - 2032.

Request Free Sample Pages with Graphs and Figures Here - https://univdatos.com/get-a-free-sample-form-php/?product_id=67023

Aerospace Composites Market Overview in North America:

North America Aerospace Composites market has held a sizable market share in 2023. One of the key factors attributed to the growth are higher presence of aerospace and composite manufacturers in the region. The region is also home to some of the largest companies producing aircraft as Boeing, Lockheed Martin, Northrop Grumman, etc. The region also has a higher demand for commercial and military aircraft from the regional airlines as well as some of the largest air forces in the world. Many of the recent developments have also been observed in recent years that are anticipated to assist the demand for aerospace composites in the region. For instance, in 2024, Boeing announced the acquisition of Aerospace Composites Malaysia Sdn Bhd (ACM) making it the first company to fully acquire a wholly-owned manufacturing unit in the Southeast Asia region.

Additionally, the region is also the largest exporter of commercial and military jets due to which the demand for aerospace composites in the production of aircraft is further anticipated to grow and help the region to maintain its prominent position in the coming years i.e., 2024-2032.

Additionally, the region is also a pioneer in terms of aircraft research and development that has noticeably assisted in the development and testing of new-age aircraft fuselage material and paved the way for the Aerospace Composites market.

Growing Demand and Industry Trends:

With the growing focus on sustainability in all sectors aerospace manufacturing companies have also aligned their efforts towards recycling the used materials in the aircraft. With the usage of materials from the scrap and damaged composites from the old aircraft, the raw material reduces the overall cost of production.

Additionally, recycling also helps in reducing carbon emission from the aviation industry. Additionally, recycling has also reduced the cost of manufacturing further easing the price shock of the components in the market.

Furthermore, the usage of carbon-composite fibre in military jets to enhance its range and stealth capability is another factor due to which the demand for the particular category has notably grown.

Many of the current-age aircraft as F35, F16, FA-18, Tejas, Eurofighter Typhoon, Dassault Rafale, etc., extensively use carbon composite fiber in aircraft construction in order to improve its manoeuvrability, fuel-efficiency, stealth capability enhancements, etc.

Related Reports-

Advanced Air Mobility Market: Current Analysis and Forecast (2024-2032)

Drone Warfare Market: Current Analysis and Forecast (2024-2032)

Future Prospects and Opportunities:

The Aerospace Composites market is poised for further growth and diversification. Emerging demand for sustainable vehicles and development presents new-age battery technologies, manufacturers, and autonomous driving solutions. Adopting green mobility, digitalization, and advanced technologies will continue to shape the industry's future, driving efficiency gains and environmental sustainability. Additionally, after the COVID-19 pandemic in 2020, a large number of aviation service providers have focused on integrating narrow-body jets that have only one aisle and offer better fuel economy as compared to the other wide-body jets.

Considering the burgeoning cost of travel per kilometre aviation companies are extensively focusing on adopting light-weight aircraft to minimize their operational cost.

For more information about this report visit- https://univdatos.com/report/aerospace-composites-market/

Conclusion:

In conclusion, the North American Aerospace Composites market reflects a dynamic and evolving landscape supported by government investment, industry collaboration, and technological innovation. As the region continues strengthening its transportation and aviation infrastructure, regulatory frameworks, and strategic partnerships, it is well-positioned to navigate challenges and capitalize on emerging opportunities in the aviation industry.

#Aerospace Composites Market#Aerospace Composites Market Size#Aerospace Composites Market Growth#Aerospace Composites Market Trends#Aerospace Composites Market Analysis

0 notes

Text

Apparel Vendors Based in the USA — Elevating Domestic Manufacturing

Introduction

In recent years, there has been a significant shift in consumer preference towards products that are ethically sourced and made closer to home. This change has spurred a resurgence of domestic manufacturing within the U.S., led by a growing number of apparel manufacturers in the USA committed to producing high-quality, innovative, and sustainable products. As these USA clothing manufacturers step up to redefine what “Made in the USA” stands for, they are not only delivering on quality but also setting new benchmarks for the global fashion industry. In this blog, we’ll explore how clothing manufacturers in America are playing a pivotal role in elevating domestic manufacturing and why partnering with them can be a game-changer for businesses and consumers alike.

1. The Role of Domestic Manufacturing in the USA

Economic Impact

Domestic garment manufacturers in the USA provide a substantial boost to the U.S. economy. By producing locally, these apparel vendors in the USA create jobs, support local suppliers, and contribute to the economic vitality of their communities. This ripple effect extends beyond direct employment in the industry to impact related sectors such as logistics, retail, and research and development. The presence of local production facilities also encourages investments in infrastructure and innovation, thereby strengthening the industrial landscape of the country.

Quality and Innovation

USA apparel manufacturers are known for their commitment to quality and innovation. With stringent standards and a focus on skilled craftsmanship, these clothing vendors supplying to the USA ensure that every garment produced is of exceptional quality. Additionally, the proximity to advanced research centers and the use of state-of-the-art technologies enable these vendors to experiment with new materials, smart textiles, and sustainable production methods, setting new trends in the fashion industry.

2. Key Advantages of Partnering with U.S.-Based Apparel Vendors

Sustainability Practices

Sustainability is a growing concern for both brands and consumers. Sustainable clothing manufacturers in the U.S. are at the forefront of this movement, often leading the way in eco-friendly manufacturing practices. By producing domestically, these apparel manufacturers reduce the carbon footprint associated with shipping and logistics, and their adherence to strict environmental regulations ensures responsible use of resources. Many vendors are also incorporating eco-friendly materials such as organic cotton, recycled polyester, and biodegradable fibers, making them an ideal choice for brands looking to reduce their environmental impact.

Quick Turnaround and Flexibility

One of the key advantages of working with domestic apparel manufacturers in the USA is the speed and flexibility they offer. With production facilities located within the U.S., businesses can benefit from shorter lead times, faster turnaround, and lower transportation costs. This proximity also allows for greater flexibility in production, enabling USA apparel manufacturers to quickly respond to market demands, offer lower minimum order quantities (MOQs), and cater to custom product requirements.

Compliance and Transparency

Domestic clothing manufacturers in America operate under stringent U.S. labor laws, ensuring that workers are treated fairly and manufacturing processes are ethical. This compliance with high labor standards translates into greater transparency and accountability across the supply chain. Brands partnering with these vendors can confidently market their products as being produced under ethical conditions, which resonates strongly with consumers who prioritize social responsibility.

3. Case Study: Successful U.S.-Based Apparel Vendors Leading the Charge

A number of U.S.-based apparel manufacturers have made a name for themselves by combining innovation, sustainability, and quality in their manufacturing processes. Take Pearl Global for instance, a company that has invested heavily in sustainable production technologies and has set benchmarks for ethical manufacturing. By adopting practices such as waterless dyeing, digital printing, and zero-waste initiatives, Pearl Global not only minimizes environmental impact but also maximizes the quality and durability of their products.

Other notable vendors have focused on niche areas like sportswear manufacturers or activewear manufacturers, using cutting-edge fabrics and design techniques that cater to specific consumer needs. Meanwhile, denim manufacturers in the USA are leveraging innovations in textile technology to produce high-quality, durable jeans that are both fashionable and sustainable. Their success stories highlight how U.S. apparel vendors are driving the industry forward while maintaining a commitment to domestic production.

4. Challenges Faced by U.S.-Based Apparel Vendors

High Operational Costs

One of the biggest challenges for USA clothing manufacturers is the high operational cost. The cost of labor, energy, and real estate is significantly higher compared to many other countries, making it difficult to compete on price alone. This challenge is further compounded by the need for constant investment in new technologies to stay competitive in a rapidly evolving market.

Global Competition

U.S. vendors face stiff competition from international manufacturers, particularly those in countries where production costs are lower. This global competition can make it challenging for domestic apparel manufacturers in the USA to offer competitive pricing, especially for larger brands looking to scale their production volumes.

Navigating Supply Chain Disruptions

While domestic production helps mitigate some supply chain risks, garment manufacturers in the USA still need to navigate disruptions such as raw material shortages, logistics challenges, and geopolitical uncertainties. These issues can impact production timelines and increase costs, posing additional hurdles for vendors striving to maintain smooth operations.

5. Why Supporting Domestic Apparel Vendors Matters

Supporting U.S.-based apparel manufacturers goes beyond the economic benefits; it’s about making a positive impact on society and the environment. By choosing domestic manufacturers, brands and consumers contribute to the growth of local economies, the preservation of skilled jobs, and the promotion of ethical manufacturing practices. Moreover, domestic production supports sustainability by reducing the carbon footprint of long-distance shipping and enabling stricter environmental compliance. This support not only drives the resurgence of the domestic manufacturing industry but also encourages a more responsible and conscious approach to fashion.

6. How to Choose the Right U.S - Based Apparel Vendor

Choosing the right apparel vendor is crucial for businesses looking to establish a strong partnership. Factors to consider include:

Certifications and Compliance: Verify if the vendor complies with necessary industry certifications, such as WRAP (Worldwide Responsible Accredited Production) or GOTS (Global Organic Textile Standard), indicating their commitment to ethical and sustainable practices.

Production Capacity and Capabilities: Assess the vendor’s production capacity to ensure they can meet your volume requirements while maintaining high quality.

Track Record and Clientele: Evaluate the vendor’s experience in the industry, the types of products they specialize in, and their ability to handle different types of projects. Look for clothing manufacturers in America who have a proven track record of success and a diverse portfolio of clients.

Customization and Innovation: Consider apparel vendors who offer customization options and who have a history of investing in innovation, particularly if you’re looking for unique product offerings or solutions.

By thoroughly assessing these criteria, brands can find the right apparel vendors in the USA that align with their business goals and values.

7. Conclusion

Apparel vendors in the USA are playing a critical role in elevating domestic manufacturing by focusing on quality, sustainability, and ethical practices. As the demand for locally made products continues to grow, these clothing vendors supplying to the USA are well-positioned to set new standards and lead the industry into a more sustainable and responsible future. By choosing to partner with domestic apparel vendors, brands and consumers alike can contribute to the growth of local economies, support sustainable fashion, and promote the resurgence of high-quality, American-made apparel.

#apparel manufacturers#clothing manufacturers in usa#denim manufacturers#american clothing manufacturers#sustainable clothing manufacturers#denim manufacturers in usa#apparel vendors#usa apparel vendors

0 notes

Text

How Filantro is Shaping the Non-Woven Industry in India

The non-woven fabric industry in India has seen remarkable growth in recent years, with increasing demand across various sectors such as healthcare, agriculture, construction, and packaging. Among the key players driving this growth is Filantro, a company that has positioned itself as one of the leading nonwoven manufacturers in India. Filantro’s commitment to quality, sustainability, and innovation has set new benchmarks for the industry, making it a pioneer in the non-woven fabric market.

In this blog, we’ll explore how Filantro is shaping the future of non-woven manufacturing in India, from its cutting-edge technologies to its sustainability initiatives, and how it continues to meet the growing demands of various industries.

The Rise of Non-Woven Fabrics in India

Before diving into Filantro’s impact, it’s essential to understand the significance of non-woven fabrics in today’s world. Non-woven fabrics are materials made from short or long fibers bonded together through chemical, mechanical, or thermal processes. Unlike traditional woven fabrics, non-woven fabrics do not require weaving or knitting, making them more versatile and cost-effective.

The rise in the use of non-woven fabrics is largely due to their wide range of applications. These fabrics are used in medical products like masks and gowns, hygiene products like diapers and sanitary napkins, and even in agriculture for crop protection. With their lightweight, breathable, and durable properties, non-woven fabrics have become indispensable in numerous industries.

Filantro: Leading Innovation in Non-Woven Manufacturing

As one of the leading non woven manufacturers in India, Filantro has been at the forefront of driving innovation in the industry. The company prides itself on using advanced technologies and eco-friendly practices to produce high-quality non-woven fabrics that meet international standards.

One of Filantro’s core strengths lies in its state-of-the-art manufacturing facilities, which are equipped with the latest machinery and equipment. This allows the company to produce non-woven fabrics in various grades and specifications to cater to the specific needs of different industries. Whether it’s for healthcare, agriculture, or packaging, Filantro ensures that each fabric is produced with the highest level of precision and quality.

Moreover, Filantro continually invests in research and development to stay ahead of industry trends and anticipate the evolving needs of its clients. This focus on innovation has allowed the company to develop new non-woven materials that are stronger, more durable, and more environmentally friendly.

Commitment to Sustainability

In today’s world, sustainability is no longer just an option; it’s a necessity. Filantro understands this and has made significant strides in adopting sustainable manufacturing practices. As one of the responsible non woven manufacturers in India, Filantro uses eco-friendly materials and processes to minimize its environmental impact.

The company’s sustainability efforts include using recycled materials where possible and ensuring that its manufacturing processes produce minimal waste. Additionally, Filantro’s non-woven fabrics are designed to be biodegradable or recyclable, making them an environmentally friendly choice for industries looking to reduce their carbon footprint.

By prioritizing sustainability, Filantro is not only contributing to a greener planet but also setting an example for other non woven manufacturers in India to follow.

Catering to Multiple Industries

One of the reasons behind Filantro’s success is its ability to cater to a diverse range of industries. The versatility of non-woven fabrics makes them suitable for numerous applications, and Filantro has successfully tapped into this demand by offering customized solutions for various sectors.

Healthcare: In the wake of the COVID-19 pandemic, the demand for non-woven fabrics in healthcare has surged. Filantro supplies high-quality non-woven materials for medical products like masks, surgical gowns, and PPE kits. These fabrics are not only breathable but also offer excellent protection against contaminants.

Agriculture: In the agricultural sector, non-woven fabrics are used for crop protection and soil stabilization. Filantro produces durable, UV-resistant fabrics that help farmers increase crop yield and protect plants from harsh environmental conditions.

Packaging: Non-woven fabrics are increasingly being used in packaging solutions due to their lightweight and durable nature. Filantro offers a range of non-woven packaging materials that are both strong and eco-friendly, making them an ideal choice for businesses looking to reduce plastic waste.

Hygiene Products: Non-woven fabrics are a key component in the manufacturing of hygiene products like diapers, sanitary napkins, and wipes. Filantro produces soft, absorbent fabrics that meet the stringent quality standards required for personal hygiene products.

Focus on Quality and Customer Satisfaction

At the heart of Filantro’s success is its unwavering commitment to quality and customer satisfaction. The company has implemented strict quality control measures to ensure that every batch of non-woven fabric meets the highest standards. From the raw materials used to the final product, every step of the manufacturing process is carefully monitored to ensure consistency and reliability.

Moreover, Filantro works closely with its clients to understand their specific needs and offer tailored solutions. Whether a client requires fabrics in specific colors, sizes, or finishes, Filantro’s team of experts ensures that every order is delivered to exact specifications.

This customer-centric approach has earned Filantro a loyal client base, both in India and internationally, solidifying its reputation as a trusted partner in the non-woven fabric industry.

Conclusion

Filantro is more than just a manufacturer; it’s a driving force in the transformation of the non-woven industry in India. By combining innovation, sustainability, and a focus on quality, the company is setting new standards for non woven manufacturers in India. Whether it’s meeting the demands of the healthcare sector, providing eco-friendly packaging solutions, or developing new materials for agriculture, Filantro continues to lead the way.

As the demand for non-woven fabrics grows, Filantro’s commitment to excellence ensures that it will remain at the forefront of the industry, shaping its future for years to come.

This Blog Was Originally Published At: https://filantrofirstofficial.blogspot.com/2024/10/how-filantro-is-shaping-non-woven.html

0 notes