#Rectangular Stainless Steel Pipes

Text

Thanks to the aforementioned reasons, the Indian steel industry is reaping profits. For more engaging content on steel and steel pipes, stay in touch with the best stainless steel pipes manufacturer at https://sigmapipes.com/.

2 notes

·

View notes

Text

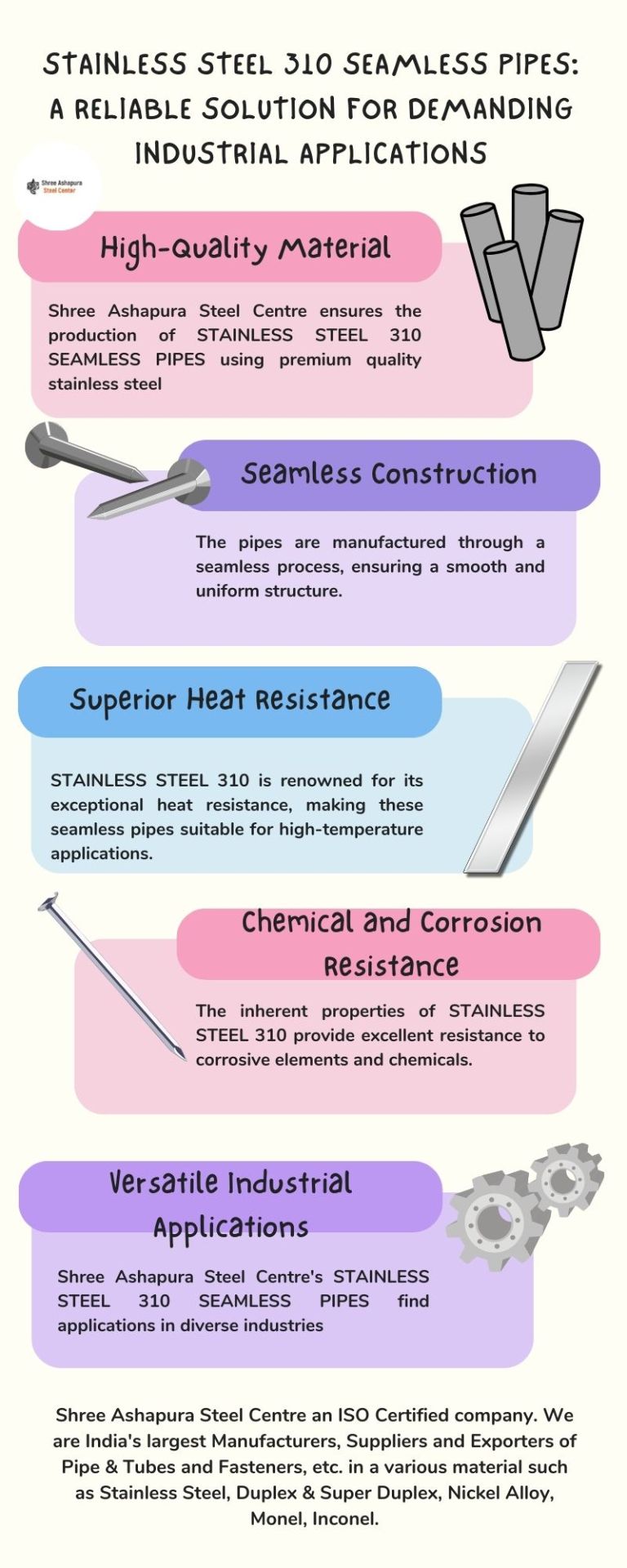

Shree Ashapura Steel Centre an ISO Certified company. We are India's largest Manufacturers, Suppliers and Exporters of Pipe & Tubes and Fasteners, etc. in a various material such as Stainless Steel, Duplex & Super Duplex, Nickel Alloy, Monel, Inconel.

#Stainless Steel 310 Seamless Pipe Manufacturer#DIN 1.4841 Seamless Tube#ASME SA312 SS 310 Polished Pipe#UNS S31000 Seamless Pipe Supplier#ASTM A312 TP310 Pipe#Stainless Steel 310 ERW pipe Stockiest#ss 310 tube#310 stainless steel square tubing#DIN 1.4539 Seamless Tube#ASME SA673 SS 904L Polished Pipe Manufacturer#UNS N08904 Seamless Pipe Supplier#ASTM A312 tp 904L Welded Pipe#DIN 1.4539 Rectangular Pipe#Stainless Steel 904L Seamless Tube Stockiest

0 notes

Text

Best Stainless Steel Pipes Manufacturer in India

Bright Steel Centre is one of India's largest Stainless steel pipes Manufacturers in India. We have played an important role in the expansion and development of the Indian market and quality exports. We manufacture ASTM A312 Stainless Steel Pipe in a variety of sizes, shapes, and specifications to meet the needs of our valued customers. Stainless steel pipes have a high corrosion resistance and are becoming increasingly cost-effective. Our Supplied SS Pipes are well-known for their dependability and quality all over the world.

Bright Steel Centre is a leading Stainless Steel Pipes manufacturer in India. Seamless / ERW / Welded / Fabricated / LSAW Pipes are among the various types of stainless steel pipes available. They are also available in a variety of shapes and sizes, including Round, Square, Rectangular, Hydraulic, and many others. We are also an aluminium sheet Manufacturer In India, Ss pipes manufacturer.

Product source: Manufacturers of stainless steel pipes.

2 notes

·

View notes

Text

Reliable manufacture of ASTM A333 Grade 6 Steel Pipe.

What is ASTM A333 Grade 6 Steel Pipe?

Astm A333 Grade 6 Pipe is a type of carbon steel pipe specifically crafted for use in low temperature environments. Renowned for its toughness, impact strength and high strength characteristics it finds applications across industries like oil and gas petrochemicals and power generation.

2. What are the standard specifications ?

Sizes Range : Nominal Pipe Size 1/2" to 48 “ O.D.

DIMENSION : 1/2” NB to 36” NB

Wall Thickness : 2.0mm-14 mm.

Outer Dimensions: 19.05mm-114.3mm

ASTM A333 Grade 6 Pipe: SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules.

Specifications: ASTM A/ASME SA 179 | ASTM A/ASME SA 192, ASTM A/ASME SA 210 Gr. 1, C | BS 3059 | DIN 2391

Thickness: 50mm to 7.00mm, customized OD

Class: Seamless / ERW / Welded / Fabricated / CDW

GR P9 Pipes Form: Round, Rectangular, Square Pipes/Tubes, Hydraulic etc

Length: Single Random, Double Random & Required Length, Custom Size — 12 Meter lengths

Coatings: 3PE/3LPE, FBE, Galvanized, Varnished, CRA or stainless clad and lined

Finishing Surface: PE (Plain End), BE (Beveled Ends)

Effective Temperature Service : 500°F to -50°F

Chemicals Composition: Carbon, Phosphorus, Nickel, Silicon, Sulphur, Manganese.

Tensile Strength : 65000 psi (Longitudinal) ,415 (Transverse)

Yield Strength : 35000 psi (Longitudinal) ,240 (Transverse)

3. Applications of A333 steel pipe

These pipes are usually used in low temperature as it has the strength to bear upto -50 degree fahrenheit.Moreover in oil and gas industries,Chemical plants,Power generation etc.

4. What are benefits of using A333 steel pipes?

A333 pipes are more durable than any other pipes in market,they are cost effective than ASTM A106 and A252.

5. How can we maintain these pipes?

i. Insulating pipes properly.

ii. Cleaning internally and externally.

iii. Monitoring systems

Conclusion: As a result these pipes are low temperature services

0 notes

Text

Supplier of Stainless Steel Flat Bar in Karnataka

Arisa Impex is a leading Supplier of Stainless Steel Flat Bar in Karnataka.

Our Manufacturing Unit is in Ahmedabad, Gujarat, India.

Arisa Impex is a Manufacturer, Exporter, and Supplier of Stainless Steel Products, including Stainless Steel Round Bars, Wires, Rods, Sheets, Coils, Pipes, Flat Bars, Square Bars, Hexagonal Bars, Angles, Flanges, and Alloy Steel.

A Stainless Steel Flat Bar is a rectangular or square section of stainless steel with a flat surface. It is used in various applications requiring strength, durability, and corrosion resistance.

We are selling high-grade quality series such as 200, 300, and 400.

Features:

Corrosion Resistance: Resists rust and corrosion in various environments.

Durability: High tensile strength and toughness for long-lasting performance.

Versatility: Available in various sizes and grades to meet different needs.

Smooth Finish: Offers a clean and smooth surface for aesthetic and functional purposes.

Machinability: Easy to cut, weld, and fabricate for diverse applications.

Work Process:

Melting: Stainless steel is melted in a furnace.

Casting: The molten steel is cast into ingots or billets.

Hot Rolling: We heat and roll ingots or billets into flat bar shapes.

Cooling: We cool and solidify the hot-rolled bars.

Surface Finishing: We finish the bars through processes such as polishing or grinding to achieve the desired surface quality.

Specification:

Stainless Steel Flat Bar Grades: 202, 304, 304L, 304H, 316, 316L, 316H, 316Ti, 321, 309, 310, 347, 400 Series Etc.

Size: 20mm to 100mm

Thickness: 5mm to 50mm

Length: 2 meters – 6 meters ( 8 feet to 20 feet)

Heat Treatment: Solution Annealed

Tolerances: H12, H11, K11, K12, H10, H8, H9, H13, K10, K9

Packing: standard packing

Specifications: EN 10272, EN 10088-3 Grade 304/ 304L, 316/ 316L

Finishes: Cold Drawn, Turned, Bright Drawn, Polished, Rough Turned, Centreless Ground, Bright, Annealed, Smooth Turned, Peeled, Grinding, Black

Arisa Impex is a Supplier of Stainless Steel Flat Bar in Karnataka including locations like Bangalore, Mysore, Hubballi-Dharwad, Kalaburagi, Mangalore, Belagavi, Davanagere, Bellary, Vijayapura, Shimoga, Tumkur, Raichur, Bidar, Udupi, Hospet, Gadag-Betageri, Robertsonpet, Hassan, Bhadravati, Chitradurga, Kolar, Mandya, Chikmagalur, Gangavati, Bagalkot, Ranebennuru, Arsikere, Chakradharpur.

Feel free to contact us for more information and inquiries.

View Product: Click Here

Read the full article

0 notes

Text

Alloy Tubes Manufacturer Things to Know Before You Buy

WE'VE GOT THE CAPABILITY TO MAKE WELDED OR ALLOY TUBING IN SQ., RECTANGULAR, FLAT SIDED OVAL, ELLIPTICAL AND A NUMBER OF OTHER CUSTOM MADE STYLES IN A NUMBER OF MATERIALS.

CORROSION RESISTANCE: MANUFACTURER OF STAINLESS STEEL TUBES AND PIPES IS NATURALLY RESISTANT TO SEVERAL SORTS OF CORROSION ON ACCOUNT OF ITS TRICKY, OXIDIZED OUTER LAYER. AS IT IS PRODUCED FROM VARIOUS UNIQUE ALLOYS, IT COULD POSSIBLY ARISE TO TOUGH AILMENTS.

POWERFUL NEED FOR ALLOY TUBING SIGNIFIES THAT THESE MANUFACTURERS MAY WELL NEED TO HAVE TO INVEST IN NEW PRODUCTS AND SERVICES TO HELP KEEP UP WITH DESIRE AND TURN THIS TREND INTO A POSSIBILITY FOR EXPANSION.

A BIG PRESENCE IN THE FACILITY GENERATION FIELD IN THE MANUFACTURING AND EXPORTER OF SEAMLESS TUBES SUPPLIES A TRUSTED AND DEPENDABLE MERCHANDISE THAT WILL FACE UP TO ESSENTIALLY THE MOST DEMANDING APPS.

FOR QUALITY THREADS OF THE HIGHEST INTERCONTINENTAL STANDARDS, FOR EXAMPLE API OR GOST, WE FEATURE OUR TCG THREAD CUTTING DEVICE AND RMG COUPLING THREADING EQUIPMENT INSIDE OUR PRODUCTS ASSORTMENT. OUR MACHINES PROVIDE HIGH-HIGH-QUALITY FINISHED MERCHANDISE – HOWEVER, TYPICAL CHECKS ARE INDISPENSABLE TO GUARANTEE THE PROPER EXCELLENT OF CUT THREADS. THUS, WE OFFER AN AUTONOMOUS OPTICAL INLINE MEASUREMENT PROCEDURE FOR ANALYZING THREADS AND SEALING LIPS ON OCTG TUBES.

OFFERED OUR EXTENSIVE INVENTORY OF MATERIALS, AND EACH DAY PROFITS QUANTITY OF IN EXCESS OF 100 TONES, WE WOULD GIVE YOU THE TOP COSTS, EVEN REDUCE THE DIRECT MANUFACTURING UNIT RATES.

THE ROTARY EXPANDER CAN BE A EXCLUSIVE FORM OF CROSS-ROLLING MILL WITH CONICAL, AXIALLY ADJUSTABLE ROLLS. THE NICKEL ALLOY TUBES ARE EXPANDED MANUFACTURER OF STAINLESS STEEL TUBES AND PIPES BY ROLLING THEM IN EXCESS OF A PLUG.

COLD DRAWN STAINLESS STEEL SEAMLESS TUBE ORDINARILY INCORPORATES A SHINIER GLIMPSE WITHOUT WELD LINES INCREASING THE AESTHETICS WITH THE SOLUTIONS DURING WHICH IT'S INCLUDED.

THE CERAMIC COATING CHARACTERISTICS MINIMAL THERMAL CONDUCTIVITY PLUS INTENSE HARDNESS. IT FUNCTIONS LIKE A HEAT AND HAVE ON DEFENSE SHIELD AND FOR A PASSIVE SEPARATING LAYER THAT SUBSTANTIALLY EXTENDS THE PROVIDER LIFE OF THE PIERCER PLUGS, LEADING TO DECREASED TOOLING PRICES AND ENHANCED PRODUCTIVITY OF YOUR RESPECTIVE PLANT.

THROUGH ITS PENNSYLVANIA PRODUCTION FACILITY, SALEM TUBE, KRYSTAL GLOBAL ENGINEERING LIMITED. MUMBAI, TUBACEX AMERICA IS A NUMBER ONE MANUFACTURER OF HIGHER PRECISION STAINLESS METAL AND NICKEL ALLOY MORE INFO TUBES. THE TRUTH IS, AS A LEADING TUBING MANUFACTURER, TUBACEX THE USA OFFERS THE MARKETPLACE’S BIGGEST PORTFOLIO OF SIGNIFICANT-EFFICIENCY TUBING AND CORROSION-RESISTANT NICKEL ALLOYS, IN ADDITION TO A DEDICATION TO QUICK DIRECT INSTANCES AND CRISIS TASKS.

THEIR 500 PERSONNEL PROVIDE HIGHER-HIGH QUALITY GOODS FOR YOUR AUTOMOTIVE AND POWER SECTORS AS WELL AS CUSTOMIZED INDUSTRIAL OPTIONS FOR CONSTRUCTION AND HYDRAULIC TUBES MANUFACTURER UNITS.

COUNTRYWIDE ALLOY TUBE PROCESSING (NTP) IS STARTED AROUND THE BASIC PRINCIPLE OF CONSTRUCTING ENTERPRISE SIMPLE FOR OUR SHOPPERS. FROM SHORT GUIDE MOMENTS TO HELP WITH PROTOTYPE STRUCTURE AND DRAWINGS, NTP IS YOUR ONE PARTICULAR-CEASE SOLUTION FOR YOUR MONEL ALLOY TUBE REDUCING AND SHEET METALLIC DEMANDS.

OUR LATEST COST FOR SS 304 STAINLESS STEEL SEAMLESS PIPES IS RS. 250/KG, SS 316L STAINLESS STEEL SEAMLESS TUBES IS RS. 305/KG, SEAMLESS BRIGHT ANNEALED TUBES IS RS. 410/KG AND SEAMLES PIPES IS RS. SEVENTY THREE/KG. THE PRICE FOR STAINLESS METAL SEAMLESS TUBES AND CARBON METAL SEAMLESS TUBES HAS IMPROVED NOT LONG AGO BECAUSE OF SHORTAGE OF RESOURCES, GREATER UNCOOKED PRODUCT COSTS AND EXPORTER CONSTRAINTS FOR MANUFACTURER OF STAINLESS STEEL TUBES AND PIPES. THE IMPORT RESTRICTIONS ARE ON ACCOUNT OF STEEL TOP QUALITY REGULATE GET, UNDER WHICH NICKEL ALLOY TUBES IS OFTEN IMPORTED INTO INDIA ONLY FROM BIS (BUREAU OF INDIAN STANDARDS) AUTHORIZED FACTORIES.

FIND OUT HOW OUR STYLE AND DESIGN TEAM STARTED OUT WITH A NORMAL MOULD FOUNDATION TO PRODUCE A SEMI-CUSTOM CLAMSHELL WITH SEVERAL FEATURES IN A FAST AND PRICE-EFFICIENT METHOD.

To know more about:

#nickel alloy tubes#stainless steel nickel alloy tubes#seamless steel nickel alloy tubes#top nickel alloy tubes in Mumbai#best nickel alloy tubes in Mumbai#top manufacturer of nickel alloy tubes#best manufacturer of nickel alloy tubes in Mumbai#nickel alloy tubes manufacturer in Mumbai#nickel alloy tubes in india#nickel alloy tubes in Mumbai#nickel alloy tubes in Vadodara#nickel alloy 200 in Mumbai#nickel alloy in Mumbai#nickel 2200#nickel 2201

0 notes

Text

Building the Future: India’s Top Stainless Steel Tubing and Piping Manufacturers.

India has hooked itself up as a first-rate player within the stainless-steel region, producing great tubes and pipes for a worldwide marketplace. With a diverse variety of producers specialising in various goods, the use of a support sector that requires accuracy, sturdiness, and dependability. Kamal Steels is a key player among these producers, offering a diverse variety of stainless steel tubing and pipe solutions adapted to specific industrial requirements.

Seamless Steel Tubing: Unmatched Quality

India's seamless metallic tubing manufacturers, including Kamal Steels, are known for producing tubes with splendid strength and best ability. These seamless tubes are critical in sectors like oil and gasoline, cars, and construction, where high-strain conditions require robust materials. Seamless tubes provide better dependability and lifespan in essential packages due to the fact that they take away welds.

Complete Stainless Steel Pipe Solutions

India's stainless-steel pipe producers provide a huge range of pipes to meet a number of commercial desires. SS 304 pipes, with their remarkable corrosion resistance, are a bendy choice for an extensive variety of applications. SS 316 and SS 316L pipes, which are extra proof against chlorides and acids, are acceptable for marine and chemical processing programs. Manufacturers assure that these pipes satisfy excessive specs, making them a dependable solution for tough packages.

Specialised Tubing for Precision Applications

Kamal Steels and other outstanding producers in India excel at making specialised chrome steel tubes for unique programs. Stainless steel condenser tubes and warmth exchanger tubes are crucial in thermal management structures because they offer powerful heat transmission while also being long-lasting. Power generation and business heating rely heavily on stainless-steel boiler tubes, which could endure excessive temperatures and pressures.

Expansive Product Range

India's stainless steel tube and pipe producers produce a huge range of objects, such as:

Stainless Steel Square Pipe: These adaptable pipes are ideal for structural and architectural applications, as they offer both strength and aesthetic appeal.

Stainless metallic perforated pipes: used in filtering and screening programs, combine sturdiness with powerful overall performance.

Stainless Steel Sanitary Tube: Used inside the meals and beverage sectors. These have applications in the pharmaceutical, and dairy sectors, these tubes provide sanitary and easy-to-use answers.

Stainless Steel Coil Tubes: These flexible tubes are perfect for instrumentation and warmth in alternate packages.

Stainless Steel Mechanical Tubes: These tubes are ideal for a variety of mechanical programs due to their extra strength and dimensional correctness.

Stainless metallic capillary tubes, recognised for their accuracy and tiny diameter, are essential in scientific and scientific equipment.

Stainless Steel Rectangular Tubes: These tubes are perfect for structural and architectural programs, supplying power and a sleek appearance.

Stainless Steel Corrugated Tubes: These tubes, which enhance flexibility and power, are best for fluid transportation and business applications.

Stainless Steel Precision Tubing: These tubes are made with high precision and tight tolerances to meet the needs of particular programs.

Stainless metallic U tubes are used in heat exchangers and condensers to enhance thermal switch performance.

Stainless Steel Instrumentation Tube: These tubes are critical additives for instrumentation and management structures, supplying reliable overall performance in critical packages.

Keeping up with International Standards

Top producers, such as Kamal Steels, respect strict international standards, including ASTM A213 for seamless stainless steel tubes. This devotion assures that their goods satisfy the highest quality standards, offering consumers dependable and high-performing solutions. Detailed information about SS pipe weight and other characteristics enables clients to make educated selections, ensuring they receive the finest product for their requirements.

Building the Future: India’s Top Stainless Steel Tubing and Piping Manufacturers.

India's stainless steel tubing and piping producers, driven by industry leaders such as Kamal Steels, continue to develop and offer high-quality products to fulfil the changing demands of diverse sectors. Their dedication to quality and diverse product offerings cement their position as worldwide leaders in stainless steel manufacturing. Whether you want conventional or specialised stainless steel products, these suppliers provide the dependability and performance needed for industrial success.

0 notes

Text

Rectangular Mild Steel Pipes and Their Applications

Rectangular steel pipes are a type of mild steel variant pipe that has a rectangular cross-section. These pipes are widely used in construction, engineering, and industrial applications due to their strength, durability, and cost-effectiveness. They are often preferred over other materials due to their high resistance to corrosion and good thermal conductivity. They come in a variety of sizes and thicknesses to meet the specific requirements of different applications. They are commonly used in the construction of structures such as bridges, buildings, and highways, as well as in the manufacturing of furniture, railings, and scaffolding.

Due to their versatility and durability, these pipes are a popular choice for many industries. They are also easy to transport and install, making them a convenient option for construction projects of all sizes. Today, Sigma Pipes will be discussing in detail the benefits as well as the applications of these stainless steel pipes.

Source Link

0 notes

Text

Stainless Steel Lean Duplex 2304 Tubes Suppliers

Introduction

In industries that demand materials with high strength, excellent corrosion resistance, and cost-effectiveness, stainless steel Lean Duplex 2304 tubes are an ideal choice. These tubes are extensively used in sectors such as chemical processing, oil and gas, and marine applications. Universe Metal & Alloys, a leading manufacturer in India, specializes in producing high-quality Lean Duplex 2304 tubes, renowned for their exceptional mechanical properties and reliability.

Description

Lean Duplex 2304 is a nitrogen-enhanced duplex stainless steel that combines the favorable properties of both austenitic and ferritic steel grades. This unique composition results in a material with superior strength and excellent resistance to various forms of corrosion, while being more economical than traditional duplex stainless steels. Universe Metal & Alloys manufactures Lean Duplex 2304 tubes using advanced technology and stringent quality control measures, ensuring they meet the highest industry standards.

These tubes are designed to provide high tensile strength, outstanding resistance to stress corrosion cracking, and excellent resistance to pitting and crevice corrosion. The dual-phase microstructure of Lean Duplex 2304 enhances toughness and durability, making these tubes suitable for a wide range of demanding applications.

Benefits

Choosing stainless steel Lean Duplex 2304 tubes from Universe Metal & Alloys offers numerous advantages:

Superior Corrosion Resistance: Lean Duplex 2304 tubes exhibit excellent resistance to chloride-induced stress corrosion cracking, pitting, and crevice corrosion, making them ideal for use in corrosive environments.

High Strength: The dual-phase microstructure of Lean Duplex 2304 provides high tensile and yield strength, allowing for reduced wall thickness and weight savings in various applications.

Improved Toughness and Ductility: These tubes offer a good balance of toughness and ductility, ensuring reliable performance in demanding conditions.

Cost-Effective: Lean Duplex 2304 is a more economical alternative to traditional duplex stainless steels, offering similar performance at a lower cost.

Versatility: Lean Duplex 2304 tubes can be used in various applications, including chemical processing, oil and gas, marine, and power generation industries.

Specification

Specification of Stainless Steel Lean Duplex 2304 Tubes

Pipe Standard

AISI, DIN, EN, GB, JIS, ASTM, ASME

Seamless Pipe Outer Diameter

6.00 MM OD up - 250 MM OD, Sizes up to 12 Inch NB

Welded Tubes sizes

5.0 MM - 1219.2 MM

EFW Tubes size

5.0 MM to 1219.2 MM

Pipe Thickness

0.3MM to 50 MM

Size

3.35 - 101.6 MM OD, 15 - 150 NB Inch

Size

6.35 - 152 MM outer diameter

wall thickness

0.020 inch to 0.220inch

Schedule

Schedule 5, 10, 40, 80, 80S, 160, XXS, XS Duplex 2205 Pipe Supplier

Finish

Annealedand Pickled, Polished, Mirror finish, Bright and Annealed, MF, NO.1, NO.4, 2B, BA, HL, 8K, etc

Form

Straight Tubes, Round, Rectangular, Hydraulic, Square, Coiled, U Shape, Hollow etc.

Pipe Length

Single Random, Double Random, Standard & Cut length

End

Plain End, Beveled End, Treaded Pipe.

Tubes Types

Alloy 2205 Seamless, ERW, EFW, Welded, Fabricated, CDW, DOM, CEW Tubes

Pipe Marking

All Tubes are marked as follows: Supplier or Manufacturer’s Name, Grade, Standard, OD, Thickness, Length, Heat No. (Or according to the customer’s request.)

Application

Boiler, Heatexchanger, Oil Tube, Gas Tube and Fluid Tube

Conclusion

Universe Metal & Alloys has established itself as a premier manufacturer of stainless steel Lean Duplex 2304 tubes in India. Their unwavering dedication to quality, innovation, and customer satisfaction has earned them a trusted reputation across various industries that require high-performance materials.

For more information or to place an order, contact Universe Metal & Alloys at [email protected] or call +91-22-66363360 / 66393788.

0 notes

Text

Top Stainless Steel PipesManufacturer in India

Bright Steel Centre is one of India's largest stainless steel pipes Manufacturers in India. We have played an important role in the expansion and development of the Indian market and quality exports. We manufacture ASTM A312 Stainless Steel Pipe in a variety of sizes, shapes, and specifications to meet the needs of our valued customers. Stainless steel pipes have a high corrosion resistance and are becoming increasingly cost-effective. Our Supplied SS Pipes are well-known for their dependability and quality all over the world.

Bright Steel Centre is a leading Stainless Steel Pipes manufacturer in India. Seamless / ERW / Welded / Fabricated / LSAW Pipes are among the various types of stainless steel pipes available. They are also available in a variety of shapes and sizes, including Round, Square, Rectangular, Hydraulic, and many others. We are also an aluminium sheet Manufacturer In India, Ss pipes manufacturer.

Product source: Manufacturers of stainless steel pipes.

2 notes

·

View notes

Text

Stainless Steel 316L Seamless Tubes Suppliers In Mumbai

Stainless Steel 316L Seamless Tubes are a high-performance material widely utilized in various industrial applications due to their superior corrosion resistance and strength. These tubes are manufactured from a low-carbon variant of Stainless Steel 316, which enhances their weldability and reduces the risk of carbide precipitation. The seamless manufacturing process ensures that the tubes are free from welds and joints, providing consistent quality and enhanced mechanical properties.

What is a Seamless Tube?

A seamless tube is a type of pipe that is produced without any welding or joints. It is made by drawing a solid billet of metal through a die or using a rotary piercing process to form a hollow tube. This process eliminates the need for welding and results in a tube with uniform thickness and superior strength. Seamless tubes are known for their ability to withstand high pressures and temperatures, making them ideal for critical applications.

Benefits of Stainless Steel 316L Seamless Tubes

Enhanced Corrosion Resistance: The addition of molybdenum in 316L provides excellent resistance to chloride-induced corrosion, making these tubes suitable for use in harsh and corrosive environments.

Low Carbon Content: The low carbon content reduces the risk of carbide precipitation during welding, enhancing the tube’s overall integrity and reducing the risk of intergranular corrosion.

High Strength and Durability: The seamless construction ensures that the tubes have uniform strength and durability, making them ideal for applications requiring high pressure and stress.

Weldability: Stainless Steel 316L offers good weldability, making it easier to fabricate and install in various applications.

Temperature Resistance: These tubes maintain their mechanical properties at elevated temperatures, making them suitable for high-temperature applications.

Aesthetic Appeal: The smooth surface finish of seamless tubes adds to their aesthetic appeal, making them suitable for architectural and decorative applications.

Stainless Steel 316L Tubes Standard Specifications

Specifications ASTM A213 / ASME SA213

Outside Diameter 1/8″ OD TO 2″OD 3MM OD TO 38 MM OD

Thickness 1MM TO 3 MM 0.028 TO 0.156 IN, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS

Size 1/2″ NB – 24″ NB

Type Seamless / Capillary Tubes

Form Round Tubes, Square Tubes, Rectangular Tubes.

Length Single Random, Double Random & Required Length

End Plain End, Beveled End, Treaded

Finish Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

Introduction to Stainless Steel 316L Seamless Tubes

Stainless Steel 316L Seamless Tubes are a high-performance material widely utilized in various industrial applications due to their superior corrosion resistance and strength. These tubes are manufactured from a low-carbon variant of Stainless Steel 316, which enhances their weldability and reduces the risk of carbide precipitation. The seamless manufacturing process ensures that the tubes are free from welds and joints, providing consistent quality and enhanced mechanical properties.

What is a Seamless Tube?

A seamless tube is a type of pipe that is produced without any welding or joints. It is made by drawing a solid billet of metal through a die or using a rotary piercing process to form a hollow tube. This process eliminates the need for welding and results in a tube with uniform thickness and superior strength. Seamless tubes are known for their ability to withstand high pressures and temperatures, making them ideal for critical applications.

Benefits of Stainless Steel 316L Seamless Tubes

Enhanced Corrosion Resistance: The addition of molybdenum in 316L provides excellent resistance to chloride-induced corrosion, making these tubes suitable for use in harsh and corrosive environments.

Low Carbon Content: The low carbon content reduces the risk of carbide precipitation during welding, enhancing the tube’s overall integrity and reducing the risk of intergranular corrosion.

High Strength and Durability: The seamless construction ensures that the tubes have uniform strength and durability, making them ideal for applications requiring high pressure and stress.

Weldability: Stainless Steel 316L offers good weldability, making it easier to fabricate and install in various applications.

Temperature Resistance: These tubes maintain their mechanical properties at elevated temperatures, making them suitable for high-temperature applications.

Aesthetic Appeal: The smooth surface finish of seamless tubes adds to their aesthetic appeal, making them suitable for architectural and decorative applications.

Industry Use of Stainless Steel 316L Seamless Tubes

Chemical Processing: Used for handling corrosive chemicals and aggressive environments due to its superior resistance to chemical corrosion.

Marine Environments: Ideal for marine applications, including shipbuilding and offshore structures, due to its resistance to saltwater corrosion.

Food and Beverage Industry: Commonly used in food processing and beverage production equipment for its sanitary properties and ease of cleaning.

Pharmaceutical Industry: Employed in pharmaceutical manufacturing for its resistance to contamination and ease of sterilization.

Oil and Gas Industry: Utilized in the extraction and processing of oil and gas due to its strength and resistance to corrosive substances.

Heat Exchangers: Used in heat exchangers for its ability to withstand high temperatures and corrosive environments.

Architectural Applications: Suitable for architectural and structural applications where both strength and aesthetics are important.

Conclusion

Stainless Steel 316L Seamless Tubes offer a combination of exceptional corrosion resistance, strength, and durability, making them an excellent choice for a wide range of industrial applications. Their seamless construction ensures consistent quality and performance, while their low carbon content enhances weldability and reduces the risk of corrosion. Metinox Piping provides high-quality 316L seamless tubes that meet international standards and specifications, ensuring reliability and efficiency in various applications

For more details

Email: [email protected]

Contact: 70212 61928

If any enquiries please contact us our support team will connect you as soon as possible

0 notes

Text

Different Types of Pipes & Tubes and Their Uses

Introduction

Nova Steel Corporation is one of the leading Pipes and Tubes Manufacturers in India. Pipes and tubes are essential components in various industries, from construction to plumbing. Understanding the different types and their uses can help you choose the right material for your specific needs. This guide will cover the most common types of pipes and tubes, their materials, and their applications.

Types of Pipes

Metal Pipes

Metal pipes are known for their strength and durability, making them suitable for a wide range of applications.

Steel Pipes

Steel pipes are commonly used in construction and industrial settings due to their high strength and resistance to pressure. They are ideal for transporting water, gas, and oil. Steel pipes come in various forms, including galvanized, Carbon Steel Pipes, and stainless steel, each with specific advantages. Galvanized steel pipes, for example, are coated with zinc to prevent rusting, making them suitable for outdoor and underground use. We are also Large Diameter Pipe Manufacturers in India.

Copper Pipes

Copper pipes are widely used in plumbing for residential and commercial buildings. They are resistant to corrosion and have a long lifespan. Copper pipes are also highly conductive, making them suitable for both hot and cold water supply. Additionally, they are recyclable and have a lower environmental impact compared to some other materials.

PVC Pipes

PVC (Polyvinyl Chloride) pipes are used extensively in residential plumbing and drainage systems. They are resistant to chemical corrosion and have a smooth interior surface that reduces friction and improves water flow. PVC pipes are also versatile and can be used for both above-ground and underground installations. We are also one of the best S355 Pipes Manufacturers in India.

Types of Tubes

Steel Tubes

Steel tubes are similar to steel pipes but are typically used in structural applications. They are available in various shapes, including round, square, and rectangular, and are used in construction, automotive, and manufacturing industries. Steel tubes offer high strength and durability, making them ideal for supporting heavy loads and withstanding harsh conditions.

Aluminum Tubes

Aluminum tubes are lightweight and corrosion-resistant, making them suitable for aerospace, automotive, and marine applications. They have excellent thermal conductivity and are often used in heat exchangers and refrigeration systems. Aluminum tubes are also easy to fabricate and can be extruded into various shapes and sizes. We are also High Nickel Alloy Pipes & Tubes Manufacturers.

Copper Tubes

Copper tubes are used in a wide range of applications due to their excellent thermal and electrical conductivity. They are commonly used in HVAC (Heating, Ventilation, and Air Conditioning) systems, refrigeration, and plumbing. Copper tubes are also antimicrobial, making them a good choice for water supply systems where hygiene is a concern.

Uses of Pipes and Tubes

Residential Applications

In residential settings, pipes and tubes are used for plumbing, heating, and cooling systems. Copper and PEX pipes are commonly used for water supply, while PVC pipes are used for drainage and sewage systems. Steel and copper tubes are used in HVAC systems to transfer heat and coolant.

Industrial Applications

In industrial applications, pipes and tubes are used for transporting liquids and gases, as well as in structural and mechanical systems. Steel pipes are used for transporting oil and gas, while PVC and concrete pipes are used in chemical and wastewater treatment plants. Steel and aluminum tubes are used by Pipes and Tubes Manufacturers and use this equipment and machinery due to their strength and durability.

Construction Applications

In construction, pipes and tubes are used for both structural and utility purposes. Steel pipes are used for scaffolding and as supports for buildings and bridges. Concrete pipes are used for stormwater and sewage systems. Aluminum and steel tubes are used in the construction of buildings, bridges, and other infrastructure projects.

Understanding the different types of pipes and tubes and their uses is crucial for selecting the right material for your project. Each type has its unique properties and applications, making them suitable for specific tasks. By considering the material, strength, durability, and application, you can ensure the success and longevity of your plumbing, construction, or industrial project.

For More Details:

Website: novasteelcorporation.com

Product: Pipes and Tubes Suppliers

Other Product: Duplex Steel Pipes Manufacturers

0 notes

Text

Best Stainless Steel Pipe Exporters in Nigeria: Why Midland Alloys Inc. Stands Out

Introduction: The Growing Demand for Stainless Steel Pipes in Nigeria

Nigeria's industrial landscape is experiencing a surge in demand for high-quality stainless steel pipes. As the country continues to invest in infrastructure development, modernize its manufacturing sector, and expand its oil and gas operations, the need for durable, corrosion-resistant, and versatile piping solutions has become increasingly crucial.

Midland Alloys Inc., a leading exporter of stainless steel pipes, has emerged as a trusted partner for Nigerian businesses seeking reliable and innovative piping solutions. With a strong focus on quality, customer service, and tailored offerings, Midland Alloys Inc. has established itself as a premier provider of stainless steel pipes in the Nigerian market.

Best Stainless Steel Pipe Exporters in Nigeria

Why Choose Midland Alloys Inc. for Stainless Steel Pipes?

Unmatched Quality Assurance

At the heart of Midland Alloys Inc.'s success is its unwavering commitment to quality. The company's state-of-the-art manufacturing facilities are equipped with the latest technology and staffed by a team of experienced professionals who meticulously oversee every stage of the production process.

Midland Alloys Inc. adheres to the highest international standards, including ISO, ASME, and ASTM certifications, ensuring that its stainless steel pipes meet or exceed the most stringent quality requirements.

Wide Range of Products

Midland Alloys Inc. offers a comprehensive portfolio of stainless steel pipe products to cater to the diverse needs of Nigerian industries. From seamless and welded pipes to square, rectangular, and large-diameter options, the company's product range is designed to cover a wide spectrum of applications, including chemical processing, oil and gas, power generation, and more.

Custom Solutions for Diverse Needs

Recognizing that every project is unique, Midland Alloys Inc. prides itself on its ability to provide tailored solutions to its Nigerian clients. The company's team of technical experts works closely with customers to understand their specific requirements and develop customized pipe configurations that meet their exact specifications.

Best Stainless Steel Pipe Fittings Exporters in Nigeria

The Benefits of Stainless Steel Pipes from Midland Alloys Inc.

Durability and Longevity

Stainless steel pipes from Midland Alloys Inc. are renowned for their exceptional durability and long-lasting performance. Crafted from high-quality alloy materials and manufactured with precision, these pipes are designed to withstand the rigors of demanding industrial environments, ensuring a prolonged service life for Nigerian businesses.

Corrosion Resistance

One of the key advantages of Midland Alloys Inc.'s stainless steel pipes is their superior corrosion resistance. The company's pipes are engineered to resist a wide range of chemical agents, environmental factors, and harsh operating conditions, making them an ideal choice for applications in the oil and gas, chemical, and marine industries.

Cost-Effectiveness

While quality and performance are paramount, Midland Alloys Inc. also recognizes the importance of cost-effectiveness for its Nigerian clients. By leveraging its global supply chain, advanced manufacturing capabilities, and operational efficiencies, the company is able to offer its stainless steel pipes at competitive prices, delivering exceptional value to its customers.

Best Stainless Steel Pipe Exporters in Singapore

Our Commitment to Customer Satisfaction

Exceptional Customer Service

At Midland Alloys Inc., customer satisfaction is the driving force behind everything the company does. The company's dedicated team of sales and technical professionals are committed to providing personalized attention and responsive support to each and every client, ensuring a seamless and hassle-free experience.

Timely Deliveries

Midland Alloys Inc. understands the importance of timely deliveries in the Nigerian market, where project deadlines and supply chain efficiency are critical. The company's robust logistics network and streamlined order fulfillment processes ensure that its stainless steel pipes are delivered to clients on schedule, minimizing delays and disruptions.

Comprehensive After-Sales Support

Midland Alloys Inc.'s commitment to customer satisfaction extends beyond the initial sale. The company's after-sales support team is available to assist Nigerian clients with installation guidance, maintenance advice, and any other post-purchase needs, ensuring the long-term performance and reliability of its stainless steel pipe products.

Case Studies: Success Stories from Our Nigerian Clients

Midland Alloys Inc. Helps Oil and Gas Company Overcome Corrosion Challenges

A leading oil and gas company in Nigeria was facing persistent corrosion issues with its existing piping system, leading to frequent breakdowns and costly downtime. The company turned to Midland Alloys Inc. for a solution and was impressed by the company's technical expertise and customized approach.

Midland Alloys Inc. conducted a thorough assessment of the company's requirements and recommended a specialized grade of stainless steel pipes that could withstand the harsh operating conditions. The installation of these pipes resulted in a significant reduction in corrosion-related incidents, improved system reliability, and enhanced operational efficiency for the oil and gas company.

Best Stainless Steel Pipe Exporters in Poland

Midland Alloys Inc. Supports Expansion of Chemical Processing Facility

A major chemical processing company in Nigeria was undertaking a major expansion of its production facilities and needed a reliable supplier of stainless steel pipes that could meet its stringent quality and delivery requirements. Midland Alloys Inc. was selected as the preferred partner, thanks to its proven track record, extensive product range, and commitment to customer satisfaction.

Midland Alloys Inc. worked closely with the chemical company to design and deliver a customized piping solution that seamlessly integrated with the new production lines. The timely and efficient delivery of the pipes, coupled with Midland Alloys Inc.'s comprehensive after-sales support, ensured a smooth and successful expansion project for the client.

How to Partner with Midland Alloys Inc. for Your Stainless Steel Needs

Partnering with Midland Alloys Inc. for your stainless steel pipe requirements in Nigeria is a straightforward process. Simply reach out to the company's sales team, who will be happy to provide you with a detailed product catalog, pricing information, and technical specifications. (Mobile No.: +91-9820238369 | E-mail: [email protected] | www. midlandalloys.com)

The team will then work closely with you to understand your specific needs and develop a tailored solution that meets your requirements. From there, Midland Alloys Inc. will handle the entire order fulfillment process, from production to delivery, ensuring a seamless and hassle-free experience.

Conclusion: Your Trusted Partner in Stainless Steel Pipe Exportation

As Nigeria's industrial landscape continues to evolve, the demand for high-quality stainless steel pipes has never been greater. Midland Alloys Inc. has firmly established itself as the premier exporter of these essential products, offering Nigerian businesses a winning combination of unparalleled quality, diverse product offerings, and exceptional customer service.

By partnering with Midland Alloys Inc., Nigerian companies can unlock the full potential of stainless steel pipes, benefiting from their durability, corrosion resistance, and cost-effectiveness. With a proven track record of success and a steadfast commitment to customer satisfaction, Midland Alloys Inc. is the trusted choice for all your stainless steel pipe needs in Nigeria.

#midlandalloysinc#manufacturer#supplier#exporter#stockiest#metal#stainless steel pipe#stainless steel

0 notes

Text

Stainless Steel Pipe and Tube in Gujarat

Arisa Impex is a Supplier of Stainless Steel Pipe and Tube in Gujarat.

Arisa Impex is a Manufacturer, Exporter, and Supplier of Stainless Steel Products like Stainless Steel Round bar, Wire, Rods, Sheets, Coils, Pipe, Flat Bar, Square Bar, Hexagonal Bar, Angle, Flanges, and Alloy Steel.

Our headquartered in Ahmedabad, Gujarat, India.

Available in various grades, sizes, and thicknesses, our pipes are designed for high-pressure applications and can be customized to suit your specifications.

We manufacture both welded and seamless tubes, ideal for structural, mechanical, and fluid transportation applications. Our tubes come in round, square, and rectangular shapes.

We also provide specialized stainless steel products, including custom fittings, flanges, and bends, ensuring a comprehensive solution for your project.

We source stainless steel from reputable suppliers, ensuring all materials meet stringent quality standards.

Our experienced engineers collaborate with clients to create tailored solutions that meet their specific needs.

Arisa Impex is a Supplier of Stainless Steel Pipe and Tube in Gujarat including locations like

Ahmedabad, Amreli, Bharuch, Bhavnagar, Bhuj, Dwarka, Gandhinagar, Godhra, Jamnagar, Junagadh, Kandla, Khambhat, Kheda, Mahesana, Morbi, Nadiad, Navsari, Okha, Palanpur, Patan, Porbandar, Rajkot, Surat, Surendranagar, Valsad, Veraval.

For more information about our product catalog, please feel free to reach out to us through the provided contact details.

Read the full article

0 notes

Text

Alloy Tubes Manufacturer Things To Know Before You Buy

Alloy 20 is a nickel-chromium-molybdenum alloy initially created for applications involving sulfuric acid. It has a very high corrosion resistance. It is considered a “super” stainless steel because of its pitting and chloride ion corrosion resistance. Alloy 20 is widely used in chemical, food processing, pharmaceutical, and the plastic industries

WE'VE GOT THE CAPABILITY TO MAKE WELDED OR ALLOY TUBING IN SQ., RECTANGULAR, FLAT SIDED OVAL, ELLIPTICAL AND A NUMBER OF OTHER CUSTOM MADE STYLES IN A NUMBER OF MATERIALS.

CORROSION RESISTANCE: MANUFACTURER OF STAINLESS STEEL TUBES AND PIPES IS NATURALLY RESISTANT TO SEVERAL SORTS OF CORROSION ON ACCOUNT OF ITS TRICKY, OXIDIZED OUTER LAYER. AS IT IS PRODUCED FROM VARIOUS UNIQUE ALLOYS, IT COULD POSSIBLY ARISE TO TOUGH AILMENTS.

POWERFUL NEED FOR ALLOY TUBING SIGNIFIES THAT THESE MANUFACTURERS MAY WELL NEED TO HAVE TO INVEST IN NEW PRODUCTS AND SERVICES TO HELP KEEP UP WITH DESIRE AND TURN THIS TREND INTO A POSSIBILITY FOR EXPANSION.

A BIG PRESENCE IN THE FACILITY GENERATION FIELD IN THE MANUFACTURING AND EXPORTER OF SEAMLESS TUBES SUPPLIES A TRUSTED AND DEPENDABLE MERCHANDISE THAT WILL FACE UP TO ESSENTIALLY THE MOST DEMANDING APPS.

FOR QUALITY THREADS OF THE HIGHEST INTERCONTINENTAL STANDARDS, FOR EXAMPLE API OR GOST, WE FEATURE OUR TCG THREAD CUTTING DEVICE AND RMG COUPLING THREADING EQUIPMENT INSIDE OUR PRODUCTS ASSORTMENT. OUR MACHINES PROVIDE HIGH-HIGH-QUALITY FINISHED MERCHANDISE – HOWEVER, TYPICAL CHECKS ARE INDISPENSABLE TO GUARANTEE THE PROPER EXCELLENT OF CUT THREADS. THUS, WE OFFER AN AUTONOMOUS OPTICAL INLINE MEASUREMENT PROCEDURE FOR ANALYZING THREADS AND SEALING LIPS ON OCTG TUBES.

OFFERED OUR EXTENSIVE INVENTORY OF MATERIALS, AND EACH DAY PROFITS QUANTITY OF IN EXCESS OF 100 TONES, WE WOULD GIVE YOU THE TOP COSTS, EVEN REDUCE THE DIRECT MANUFACTURING UNIT RATES.

THE ROTARY EXPANDER CAN BE A EXCLUSIVE FORM OF CROSS-ROLLING MILL WITH CONICAL, AXIALLY ADJUSTABLE ROLLS. THE NICKEL ALLOY TUBES ARE EXPANDED MANUFACTURER OF STAINLESS STEEL TUBES AND PIPES BY ROLLING THEM IN EXCESS OF A PLUG.

COLD DRAWN STAINLESS STEEL SEAMLESS TUBE ORDINARILY INCORPORATES A SHINIER GLIMPSE WITHOUT WELD LINES INCREASING THE AESTHETICS WITH THE SOLUTIONS DURING WHICH IT'S INCLUDED.

THE CERAMIC COATING CHARACTERISTICS MINIMAL THERMAL CONDUCTIVITY PLUS INTENSE HARDNESS. IT FUNCTIONS LIKE A HEAT AND HAVE ON DEFENSE SHIELD AND FOR A PASSIVE SEPARATING LAYER THAT SUBSTANTIALLY EXTENDS THE PROVIDER LIFE OF THE PIERCER PLUGS, LEADING TO DECREASED TOOLING PRICES AND ENHANCED PRODUCTIVITY OF YOUR RESPECTIVE PLANT.

THROUGH ITS PENNSYLVANIA PRODUCTION FACILITY, SALEM TUBE, KRYSTAL GLOBAL ENGINEERING LIMITED. MUMBAI, TUBACEX AMERICA IS A NUMBER ONE MANUFACTURER OF HIGHER PRECISION STAINLESS METAL AND NICKEL ALLOY MORE INFO TUBES. THE TRUTH IS, AS A LEADING TUBING MANUFACTURER, TUBACEX THE USA OFFERS THE MARKETPLACE’S BIGGEST PORTFOLIO OF SIGNIFICANT-EFFICIENCY TUBING AND CORROSION-RESISTANT NICKEL ALLOYS, IN ADDITION TO A DEDICATION TO QUICK DIRECT INSTANCES AND CRISIS TASKS.

THEIR 500 PERSONNEL PROVIDE HIGHER-HIGH QUALITY GOODS FOR YOUR AUTOMOTIVE AND POWER SECTORS AS WELL AS CUSTOMIZED INDUSTRIAL OPTIONS FOR CONSTRUCTION AND HYDRAULIC TUBES MANUFACTURER UNITS.

COUNTRYWIDE ALLOY TUBE PROCESSING (NTP) IS STARTED AROUND THE BASIC PRINCIPLE OF CONSTRUCTING ENTERPRISE SIMPLE FOR OUR SHOPPERS. FROM SHORT GUIDE MOMENTS TO HELP WITH PROTOTYPE STRUCTURE AND DRAWINGS, NTP IS YOUR ONE PARTICULAR-CEASE SOLUTION FOR YOUR MONEL ALLOY TUBE REDUCING AND SHEET METALLIC DEMANDS.

OUR LATEST COST FOR SS 304 STAINLESS STEEL SEAMLESS PIPES IS RS. 250/KG, SS 316L STAINLESS STEEL SEAMLESS TUBES IS RS. 305/KG, SEAMLESS BRIGHT ANNEALED TUBES IS RS. 410/KG AND SEAMLES PIPES IS RS. SEVENTY THREE/KG. THE PRICE FOR STAINLESS METAL SEAMLESS TUBES AND CARBON METAL SEAMLESS TUBES HAS IMPROVED NOT LONG AGO BECAUSE OF SHORTAGE OF RESOURCES, GREATER UNCOOKED PRODUCT COSTS AND EXPORTER CONSTRAINTS FOR MANUFACTURER OF STAINLESS STEEL TUBES AND PIPES. THE IMPORT RESTRICTIONS ARE ON ACCOUNT OF STEEL TOP QUALITY REGULATE GET, UNDER WHICH NICKEL ALLOY TUBES IS OFTEN IMPORTED INTO INDIA ONLY FROM BIS (BUREAU OF INDIAN STANDARDS) AUTHORIZED FACTORIES.

FIND OUT HOW OUR STYLE AND DESIGN TEAM STARTED OUT WITH A NORMAL MOULD FOUNDATION TO PRODUCE A SEMI-CUSTOM CLAMSHELL WITH SEVERAL FEATURES IN A FAST AND PRICE-EFFICIENT METHOD.

To know more about:

#nickel alloy tubes#stainless steel nickel alloy tubes#seamless steel nickel alloy tubes#top nickel alloy tubes in Mumbai#best nickel alloy tubes in Mumbai#top manufacturer of nickel alloy tubes#best manufacturer of nickel alloy tubes in Mumbai#nickel alloy tubes manufacturer in Mumbai#nickel alloy tubes in india#nickel alloy tubes in Mumbai#nickel alloy tubes in Vadodara#nickel alloy 200 in Mumbai#nickel alloy in Mumbai#nickel 2200#nickel 2201

0 notes