#Rapier Loom Machine Manufacturers

Explore tagged Tumblr posts

Text

Understanding the Benefits of Rapier Loom Machines Over Other Loom Types

Rapier loom machines are revolutionizing the textile industry with superior performance and efficiency. Compared to traditional looms, they offer unparalleled versatility, enabling the weaving of a wide range of fabrics, from lightweight to heavy, with precision. Rapier looms ensure minimal yarn wastage, faster production speeds, and excellent fabric quality. Their ability to weave intricate designs makes them ideal for producing high-value textiles. Dashmesh Jacquard, a trusted name in the textile machinery sector, provides cutting-edge rapier looms known for their durability and advanced technology. These machines are energy-efficient, easy to operate, and designed to meet the evolving demands of modern textile manufacturing.

Read More: Understanding the Benefits of Rapier Loom Machines Over Other Loom Types

#Rapier Loom Machine Manufacturers#Best Rapier Loom Machine Manufacturers#Top Rapier Loom Machine Manufacturers#Rapier Loom Machine Manufacturers in india#Best Rapier Loom Machine Manufacturers in india#Top Rapier Loom Machine Manufacturers in india

0 notes

Text

Achieve exceptional fabric quality with Paramount Looms. Our machines deliver consistent results and superior performance.

#fabricquality #textiles #weaving #powerloom #surat

#fabricquality#textiles#weaving#powerloom#surat#power loom manufacturer in surat#power loom manufacturer in india#rapier loom machine manufacturer in surat#rapier loom machine manufacturer gujarat#air jet loom manufacturer in gujarat#air jet loom manufacturer in surat#jacqaurd machine manufacturer in india#yarn weaving machine manufacturer in india#water jet loom machine manufacturer in gujarat#power loom manufacturer in gujarat

1 note

·

View note

Text

Discover the various types of textile machinery used in the industry. Learn about weaving, spinning, dyeing, and finishing machines that enhance efficiency and quality in textile production. Generally, textile industry uses a broad category of equipment in the conversion process from textile material to the final product. All machines ranging from spinning and weaving to dyeing and finishing are very important in the process.

0 notes

Text

Premier electronic jacquard manufacturers in Panipat, delivering top-quality textile machinery to enhance your weaving processes and production efficiency.

#electronic jacquard manufacturers india#Electronic Jacquard#Rapier Loom Machine#Rapier Loom Machine Price#Rapier Loom#Farming Equipment India#power loom machine#power loom#cost of power loom

0 notes

Text

Madaan Jacquard, based in Panipat, is a trusted name among jacquard manufacturers and suppliers. Explore our range of high-quality jacquard machines and discover competitive prices in India. We're your go-to source for all things jacquard.

#Madaan Jacquard Panipat#Jacquard Manufacturers in Panipat#Jacquard Suppliers in Panipat#Jacquard Machine Price in India#Agriculture Implements Manufacturer in India#Disc Harrow Manufacturers in India#Electronic Jacquard Manufacturers India#Rapier Looms Manufacturers in India#Electronic Jacquard Manufacturers in Panipat#Powerloom Manufacturers in India#Rotary Tiller Manufacturers in India#Rotavator Manufacturers in India#Electronic Jacquard in Bangalore

0 notes

Text

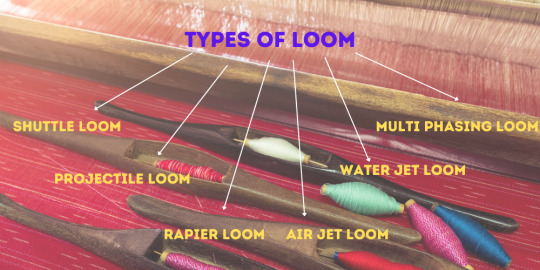

“Discover: Types of Loom in Textile Manufacturing”

Loom? What are They? What Do They Manufacture?

Looms is the weaving machine which converts the yarn into a fabric. There is no history of when looms were discovered but one thing is clear that it was before the birth of Jesus christ. There are 2 types of looms: Shuttle Looms and Shuttleless Looms. Below we are going to learn about various types of looms. The end result of this machine is fabric and wholesalers and retailers buy t-shirts in bulk made out of those fabric.

Learn About Shuttle Looms

This is the most primitive loom in the history of loom. In this machine there is a shuttle which contains bobbins and around bobbins there are yarn wounded. In this weaving machine the shuttle travels from one corner to the other and hence the fabric is made. The speed of this machine is 110-225 ppm [Picks Per Minute]. It is quite noisy and inefficient.

Fabric Weaving Without a Shuttle in the Loom Is It Possible?

Projectile Loom

Projectile loom is a shuttleless loom, in this looms instead of a shuttle projectile are there. Projectiles are made out of stainless steel and hence it was light weight. As the projectile lightweight this saves lots of energy and increases the efficiency of the machine. This loom speed was 300 ppm. The weaving takes place when the projectile goes across the width of the loom with the yarn.

Rapier Loom

This loom is also shuttleless. In this loom the weft is carried by a rapier which is a long rod like structure. Many kinds of fabric could be made using this loom and it is highly efficient. The range of GSM things loom could weave is 20-850 GSM. From home fabric to industrial fabric can be made using this loom. There are 4 types of rapier loom in the market.

Single Rigid Rapier Loom

Double Rigid Rapier Loom

Double Flexible Rapier Loom

Telescopic Rapier Loom

Air-Jet Loom

In this loom the yarn is transferred from the force of air, it does not have any shuttle. This loom is highly efficient and versatile. This loom does not make noise because it does not have many moving parts. As the moving parts are less then the floor space requirement and maintenance is low. The weft travels with the help of air pressure and once it reaches the shedding area interlacement takes place. This machine can be used in manufacturing Denim fabric, polyester dress material and cotton shirting fabric.

Water Jet Loom

Water pressure is used in this loom to transfer weft from one end to the other. It is a shuttleless loom machine. The speed of this machine is 600 ppm. This machine is highly efficient but we can use yarn which is hydrophobic, like polyester, polyamides etc. Hydrophilic yarn can not be used.

#textile#manufacturing#textiles#yarn#clothing#dyeing#knitting#business#fiber art#pattern#fabric#fiber#cotton#linen#wool#tshirt#weaving#small business#entrepreneur#india#made in india#trade#wholesale t shirts#wholesalers

8 notes

·

View notes

Text

SFJ100 Type Drying Cylinder Sizing Machine

Scope of application: The working process of this series of sizing machines is to sizing the warp threads processed by the slitting machine, then drying them, and finally winding them into woven shafts. It is suitable for the sizing of chemical fiber filaments, and can be used as a pre-weaving equipment for shuttleless looms such as water jet, air jet, rapier, and projectile.

0 notes

Text

Carbon Fabric

8 characteristics of��Carbon fiber material

I. Small density, light weight:

It is about 1/5 of copper and 3/5 of aluminum alloy, greatly reducing the product.

II. Good chemical resistance:

Substituting metal avoids corrosion and extends life.

III. Fatigue resistance, long service life:

No permanent deformation, greatly improving the safety and stability of product components.

IV. High strength, high modulus:

About 1.3 times of copper, 3.7 times of aluminum alloy, improve product strength, rigidity and other mechanical properties.

V. Low coefficient of thermal expansion:

It will not affect the use of products due to thermal expansion and cold contraction image products.

VI. Good electrical conductivity:

Excellent electrical conductivity in composite materials.

VII. Energy absorption and shock absorption:

It has excellent damping function to vibration, thus reducing vibration and noise.

VIII. Self-lubricating, wear resistance:

Make full use of self-lubricity to improve product smoothness and reduce component wear.

ABOUT US

We were founded in September 2015 and located in Zhijiang Industrial Park, Haining, Zhejiang, is a large scientific and technical enterprise focusing on scientific research, product development, production, sales and service in the area of fiberglass-based. Carbon Fabric Suppliers and Carbon Fabric Company. The glass fiber products and glass fiber composite material we produce are widely used and can be used in electric appliances, electronics, transportation, chemical engineering, architectural engineering, heat insulation, sound absorption, fire prevention and environmental protection, and other high-tech fields. We use 4.6-meter automatic warping machines, 3.4-meter air-jet looms and 4.6-meter wide high-grade rapier looms, suitable for PTFE, PVA, PVC, PU, and silicone coating. Our main products are fiberglass cloth, fiberglass mesh, waterproof building material, special building material, bakeware, BBQ accessories, and sealing strip. Our products are sold to more than 30 provinces at home and several countries and regions in North America, South America, Europe, Mid East, Southeast Asia, Oceania, Africa, and so on. We will be committed to becoming a professional fiberglass products company with China's competitive advantage and complete industry chain and forming a superior fiberglass composite material manufacturing enterprise.

0 notes

Text

0 notes

Text

Rapier gripper head for Picanol Gammax FF rapier loom.

#rapiergripper #gripperhead #gripper #grippers #rapierloom #rapierspareparts #rapiersilksarees

0 notes

Text

Weaving Rapier Loom Machine manufacturers exporters in India http://www.amarjacquard.com +91-98150-00512

Weaving Rapier Loom Machine manufacturers exporters in India http://www.amarjacquard.com +91-98150-00512

0 notes

Text

Rapier Loom Machine Manufacturers

The Rapier loom machine is a weaving loom used in the textile industry. It uses two rapiers on each side to carry the weft threads through the warp threads, making high speed and versatile fabric production possible. It is ideal for weaving complex patterns and a wide range of fabrics. Dasmesh Jacquard is a Rapier Loom Machine Manufacturer in India. Rapier loom is the most commonly used form of shuttleless weaving rapier loom machinery.

#Rapier Loom Machine#Rapier Loom Machine Manufacturers#Top Rapier Loom Machine Manufacturers#Best Rapier Loom Machine Manufacturers#Rapier Loom Machine Manufacturers in India

0 notes

Text

Inspiration for Your Next Weaving Project

Explore stunning projects created with Paramount Looms. As a premier rapier loom machine manufacturer in Surat, we provide the tools to bring your weaving visions to life. Get inspired by our vibrant and diverse fabric patterns.

#power loom manufacturer in surat#power loom manufacturer in india#rapier loom machine manufacturer gujarat#rapier loom machine manufacturer in surat#power loom manufacturer in gujarat

0 notes

Text

How to Avoid Abrasion of Rapier Head and Rapier Belt of Rapier Loom?

Rapier looms are reliable partners in the tricky dance of textile production, bringing together creative ideas and the ability to make a wide range of fabrics. The rapier head and rapier belt are very important parts of these tools because they move the weft yarn quickly and accurately through the warp. However, like many mechanical surprises, rapier looms need to be carefully watched over and maintained to make sure they keep working well. One of the biggest problems that loom workers have to deal with is the chance that the rapier head and belt will get worn down. Because of friction and wear, abrasion can cause expensive repairs, downtime, and damaged fabric first-class. So, it will be very important for companies that make fabrics to take precautions to protect these important parts. In this guide, we’ll look at five important tips that will help manufacturers keep the rapier head and belt on rapier looms from wearing down, so that production doesn’t stop and the best results are achieved.

1. Regular Lubrication:

Proper lubrication is crucial to reduce friction and wear on the moving components of the rapier loom, which include the rapier head and belt. Use extremely good lubricants recommended via the manufacturer and adhere to the required lubrication agenda. Regular software of lubricants will ensure easy operation and decrease the chance of erosion resulting from friction.

2. Monitor Tension Levels:

Maintaining the precise anxiety stages inside the rapier belt is essential for stopping abrasion and prolonging its lifespan. Periodically test the anxiety of the rapier belt and make adjustments as needed to make sure it’s far neither too loose nor too tight. Improper tension can motivate immoderate put on each the belt and the rapier head, leading to premature failure.

3. Cleanliness is Key:

Maintaining the precise anxiety stages inside the rapier belt is essential for stopping abrasion and prolonging its lifespan. Periodically test the anxiety of the rapier belt and make adjustments as needed to make sure it’s far neither too loose nor too tight. Improper tension can motivate immoderate put on each the belt and the rapier head, leading to premature failure.

4. Proper Alignment:

Misalignment of the rapier head and belt can boom friction and result in improved put on and tear. Periodically take a look at the alignment of the rapier head and belt according to the manufacturer’s specifications. Adjustments may be important to make certain that the components are nicely aligned for easy and efficient weaving.

5. Train Operators:

Proper schooling of operators is crucial for the effective operation and upkeep of rapier looms. Ensure that operators are familiar with the device’s operation manual and are trained to become aware of capability problems along with unusual put on or symptoms of damage to the rapier head and belt. Encourage a way of life of proactive preservation to deal with any problems directly and save you from escalating.

6. Implement Routine Inspections:

Establish an agenda for recurring inspections of the rapier head and belt, as well as other crucial components of the loom. During those inspections, look for signs of wear and tear, harm, or capability areas of the subject. Address any troubles directly to save you from worsening and inflicting abrasion or other operational troubles.

7. Invest in High-Quality Components:

Select top-notch rapier heads and bands that are especially made to be strong and durable. Investing in better chemicals may cost more at first, but it will pay off in the long run by lowering the number of times that repairs and replacements are needed due to abrasion and other types of wear.

Stopping the rapier head and rapier belt from wearing down on rapier looms is very important in the fast-paced world of textile making, where every thread counts and efficiency is key. These extras are what keep the weaving process going. They guide the yarns precisely and quickly to make the fabric that decorates our lives. However, if they are not taken care of properly, friction and wear can damage them, leading to costly repairs, downtime, and goods that are not up to par.

By following the seven important tips in this guide, including regular lubrication and stress monitoring, as well as cleanliness, alignment checks, operator training, regular inspections, and spending money on food additives fabric manufacturers can make their rapier looms more resistant to wear and tear. Manufacturers can make sure that their machines run smoothly, last longer, and keep making awesome fabric by putting in place regular maintenance plans and a commitment to greatness.

Ultimately, the quest to stop the rapier head and belt from wearing down on rapier looms isn’t just about protecting tools; it’s about protecting the integrity of the whole production system. It’s about maintaining a high level of quality in every part of the cloth production process, from the weaving room to the finished product. By putting preventative maintenance first and investing in the strength of their equipment, manufacturers can stay ahead of the curve, reduce downtime, and set themselves up for success in an industry that is always changing.

In the weaving process of textiles, each thread and part is very important to the creation of something bigger than itself. By taking care of the rapier’s head and belt, makers help make their craft a seamless tapestry of new ideas, creativity, and fine craftsmanship. Producers can face the challenges of wear with confidence if they work hard, plan ahead, and are dedicated to doing their best. They’ll know they can get through any problem and keep weaving the fabric of their success. Explore the range of services offered by Weavetech to get complete help and professional advice on how to take care of and improve the performance of your rapier looms. From preventative maintenance packages to cutting-edge technology, Weavetech is the company you can trust to make sure your textile making system lasts and works well. Get in touch with us right away to learn more and start your road to seamless weaving excellence.

Read More :- How to Avoid Abrasion of Rapier Head and Rapier Belt of Rapier Loom?

0 notes

Text

#Madaan Jacquard#Jacquard Manufacturers in Panipat#Jacquard Suppliers in Panipat#Jacquard Machine Price in India#Agriculture Implements Manufacturer in India#Disc Harrow Manufacturers in India#Electronic Jacquard Manufacturers India#Rapier Looms Manufacturers in India

1 note

·

View note

Text

About Dongyi Machinery

Shaoxing Dongyi Machinery Co., Ltd. is a professional of machinery and equipment manufacturing and trading enterprises, We have our own production plant and Perfect part supporting enterprise support. our company is located in the historical and cultural city-Shaoxing City, only 40 km away from Xiaoshan International Airport. The company has many years of industry experience, to provide customers with professional grinding solutions and textile weaving solutions.

Our main products include: automatic bearing grinding machine, surface grinding machine, internal grinding machine,external grinding machine, rapier loom, towel rapier loom . according to the technical requirements of customers, we are responsible for equipment installation, commissioning and training, and timely provide spare parts to provide technical services to customers at home and abroad. Company attaches great importance to product quality, has passed the ISO certification.

We always adhere to the "quality first, customer first, quality and win" business purposes. for the better future and create higher value for our customers, so we will improve the product line more meticulously and provide better quality products and services to our customers at home and abroad.

2 notes

·

View notes