#Railway Test Systems Manufacturer

Explore tagged Tumblr posts

Text

The effectiveness of your Railway Test Systems strategy depends on your choice of track maintenance equipment. This choice could have a significant impact on how well your plan functions in the long run.

#Railway Test Systems#Key Elements of Railway Testing#Railway Maintenance Equipment#Railway Test Procedures#Types of railway test systems#Railway Test Systems Price#Railway Test Systems Suppliers#Railway Test Systems Manufacturer#Railway Test Systems Price in India

0 notes

Text

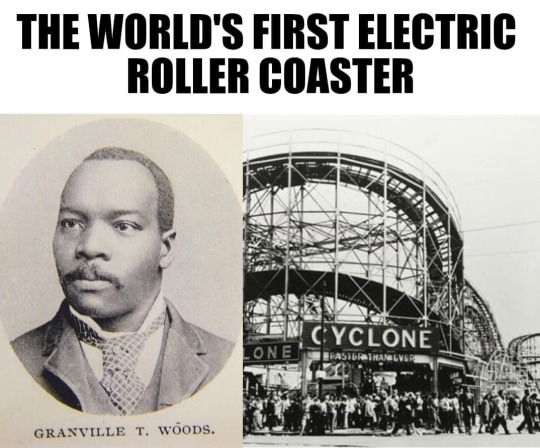

THE WORLD'S FIRST ELECTRIC ROLLER COASTER

Granville T. Woods (April 23, 1856 – January 30, 1910) introduced the “Figure Eight,” the world's first electric roller coaster, in 1892 at Coney Island Amusement Park in New York. Woods patented the invention in 1893, and in 1901, he sold it to General Electric.

Woods was an American inventor who held more than 50 patents in the United States. He was the first African American mechanical and electrical engineer after the Civil War. Self-taught, he concentrated most of his work on trains and streetcars.

In 1884, Woods received his first patent, for a steam boiler furnace, and in 1885, Woods patented an apparatus that was a combination of a telephone and a telegraph. The device, which he called "telegraphony", would allow a telegraph station to send voice and telegraph messages through Morse code over a single wire. He sold the rights to this device to the American Bell Telephone Company.

In 1887, he patented the Synchronous Multiplex Railway Telegraph, which allowed communications between train stations from moving trains by creating a magnetic field around a coiled wire under the train. Woods caught smallpox prior to patenting the technology, and Lucius Phelps patented it in 1884. In 1887, Woods used notes, sketches, and a working model of the invention to secure the patent. The invention was so successful that Woods began the Woods Electric Company in Cincinnati, Ohio, to market and sell his patents. However, the company quickly became devoted to invention creation until it was dissolved in 1893.

Woods often had difficulties in enjoying his success as other inventors made claims to his devices. Thomas Edison later filed a claim to the ownership of this patent, stating that he had first created a similar telegraph and that he was entitled to the patent for the device. Woods was twice successful in defending himself, proving that there were no other devices upon which he could have depended or relied upon to make his device. After Thomas Edison's second defeat, he decided to offer Granville Woods a position with the Edison Company, but Woods declined.

In 1888, Woods manufactured a system of overhead electric conducting lines for railroads modeled after the system pioneered by Charles van Depoele, a famed inventor who had by then installed his electric railway system in thirteen United States cities.

Following the Great Blizzard of 1888, New York City Mayor Hugh J. Grant declared that all wires, many of which powered the above-ground rail system, had to be removed and buried, emphasizing the need for an underground system. Woods's patent built upon previous third rail systems, which were used for light rails, and increased the power for use on underground trains. His system relied on wire brushes to make connections with metallic terminal heads without exposing wires by installing electrical contactor rails. Once the train car had passed over, the wires were no longer live, reducing the risk of injury. It was successfully tested in February 1892 in Coney Island on the Figure Eight Roller Coaster.

In 1896, Woods created a system for controlling electrical lights in theaters, known as the "safety dimmer", which was economical, safe, and efficient, saving 40% of electricity use.

Woods is also sometimes credited with the invention of the air brake for trains in 1904; however, George Westinghouse patented the air brake almost 40 years prior, making Woods's contribution an improvement to the invention.

Woods died of a cerebral hemorrhage at Harlem Hospital in New York City on January 30, 1910, having sold a number of his devices to such companies as Westinghouse, General Electric, and American Engineering. Until 1975, his resting place was an unmarked grave, but historian M.A. Harris helped raise funds, persuading several of the corporations that used Woods's inventions to donate money to purchase a headstone. It was erected at St. Michael's Cemetery in Elmhurst, Queens.

LEGACY

▪Baltimore City Community College established the Granville T. Woods scholarship in memory of the inventor.

��In 2004, the New York City Transit Authority organized an exhibition on Woods that utilized bus and train depots and an issue of four million MetroCards commemorating the inventor's achievements in pioneering the third rail.

▪In 2006, Woods was inducted into the National Inventors Hall of Fame.

▪In April 2008, the corner of Stillwell and Mermaid Avenues in Coney Island was named Granville T. Woods Way.

510 notes

·

View notes

Text

THE WORLD'S FIRST ELECTRIC ROLLER COASTER

Granville T. Woods (April 23, 1856 – January 30, 1910) introduced the “Figure Eight,” the world's first electric roller coaster, in 1892 at Coney Island Amusement Park in New York. Woods patented the invention in 1893, and in 1901, he sold it to General Electric.

Woods was an American inventor who held more than 50 patents in the United States. He was the first African American mechanical and electrical engineer after the Civil War. Self-taught, he concentrated most of his work on trains and streetcars.

In 1884, Woods received his first patent, for a steam boiler furnace, and in 1885, Woods patented an apparatus that was a combination of a telephone and a telegraph. The device, which he called "telegraphony", would allow a telegraph station to send voice and telegraph messages through Morse code over a single wire. He sold the rights to this device to the American Bell Telephone Company.

In 1887, he patented the Synchronous Multiplex Railway Telegraph, which allowed communications between train stations from moving trains by creating a magnetic field around a coiled wire under the train. Woods caught smallpox prior to patenting the technology, and Lucius Phelps patented it in 1884. In 1887, Woods used notes, sketches, and a working model of the invention to secure the patent. The invention was so successful that Woods began the Woods Electric Company in Cincinnati, Ohio, to market and sell his patents. However, the company quickly became devoted to invention creation until it was dissolved in 1893.

Woods often had difficulties in enjoying his success as other inventors made claims to his devices. Thomas Edison later filed a claim to the ownership of this patent, stating that he had first created a similar telegraph and that he was entitled to the patent for the device. Woods was twice successful in defending himself, proving that there were no other devices upon which he could have depended or relied upon to make his device. After Thomas Edison's second defeat, he decided to offer Granville Woods a position with the Edison Company, but Woods declined.

In 1888, Woods manufactured a system of overhead electric conducting lines for railroads modeled after the system pioneered by Charles van Depoele, a famed inventor who had by then installed his electric railway system in thirteen United States cities.

Following the Great Blizzard of 1888, New York City Mayor Hugh J. Grant declared that all wires, many of which powered the above-ground rail system, had to be removed and buried, emphasizing the need for an underground system. Woods's patent built upon previous third rail systems, which were used for light rails, and increased the power for use on underground trains. His system relied on wire brushes to make connections with metallic terminal heads without exposing wires by installing electrical contactor rails. Once the train car had passed over, the wires were no longer live, reducing the risk of injury. It was successfully tested in February 1892 in Coney Island on the Figure Eight Roller Coaster.

In 1896, Woods created a system for controlling electrical lights in theaters, known as the "safety dimmer", which was economical, safe, and efficient, saving 40% of electricity use.

Woods is also sometimes credited with the invention of the air brake for trains in 1904; however, George Westinghouse patented the air brake almost 40 years prior, making Woods's contribution an improvement to the invention.

Woods died of a cerebral hemorrhage at Harlem Hospital in New York City on January 30, 1910, having sold a number of his devices to such companies as Westinghouse, General Electric, and American Engineering. Until 1975, his resting place was an unmarked grave, but historian M.A. Harris helped raise funds, persuading several of the corporations that used Woods's inventions to donate money to purchase a headstone. It was erected at St. Michael's Cemetery in Elmhurst, Queens.

LEGACY

▪Baltimore City Community College established the Granville T. Woods scholarship in memory of the inventor.

▪In 2004, the New York City Transit Authority organized an exhibition on Woods that utilized bus and train depots and an issue of four million MetroCards commemorating the inventor's achievements in pioneering the third rail.

▪In 2006, Woods was inducted into the National Inventors Hall of Fame.

▪In April 2008, the corner of Stillwell and Mermaid Avenues in Coney Island was named Granville T. Woods Way.

#granville t woods#black inventor#invented#world's first#electric roller coaster#1893#read about him#read about his invention#reading is fundamental#knowledge is power#black history

123 notes

·

View notes

Text

Ensuring Reliability and Safety: The Importance of Quality Traction Converters and Connectors in Railways

Introduction

The modern railway industry is evolving at a rapid pace, with advancements in technology playing a crucial role in enhancing efficiency, sustainability, and safety. Among the many components that contribute to the seamless functioning of a railway system, traction converters and connectors stand out as vital elements. This blog explores the significance of quality railway traction converter manufacturer and railway traction connector manufacturer in ensuring the reliability and safety of railway operations, with a specific focus on manufacturers in this domain.

Railway Traction Converters: The Powerhouses of Rail Mobility

Railway traction converters manufacturers play a pivotal role in the electrification of trains. These devices are responsible for converting electrical power from the grid into the appropriate form for the efficient and controlled movement of trains. As the demand for electrified rail systems grows, the role of railway traction converters manufacturers becomes increasingly critical.

Advancements in Traction Converter Technology

Leading manufacturers in the field of railway traction converters are at the forefront of innovation. They constantly strive to develop converters that are not only more efficient but also environmentally friendly. The integration of cutting-edge technologies, such as regenerative braking systems and advanced power electronics, contributes to the reduction of energy consumption and environmental impact.

Reliability Challenges and Solutions

Ensuring the reliability of traction converters is paramount for the uninterrupted operation of rail services. Manufacturers invest significantly in research and development to address challenges related to overheating, voltage fluctuations, and system failures. Robust testing procedures and quality assurance measures are implemented to guarantee the reliability of these critical components.

Railway Traction Connectors: Linking Efficiency and Safety

Railway traction connectors play a crucial role in ensuring the seamless transmission of power between various components of the rail system. These connectors serve as the interface between the traction converter and the train, facilitating the efficient transfer of electrical energy for propulsion.

Key Considerations in Connector Design

Manufacturers specializing in railway traction connectors prioritize several key considerations in their design and production processes. These include factors such as durability, weather resistance, and ease of maintenance. The harsh operating conditions that railways often face, including exposure to extreme weather and mechanical stress, necessitate connectors that can withstand such challenges without compromising performance.

Innovations in Connector Technology

In response to the evolving needs of the railway industry, manufacturers are continually innovating their connector designs. The integration of smart technologies, such as sensor-equipped connectors capable of real-time monitoring, enhances the safety and reliability of railway operations. These innovations contribute to the prevention of malfunctions and enable proactive maintenance measures.

Post Insulator for Railways: Ensuring Electrical Isolation and Safety

Post insulators for railways are critical components in railway electrification systems, providing electrical insulation and preventing current leakage. They play a crucial role in ensuring the safety of both passengers and railway personnel.

Importance of Quality Insulators

Railway electrification systems are subject to high voltage, and the quality of post insulators is paramount in maintaining electrical isolation. High-quality insulators prevent flashovers and electrical breakdowns, reducing the risk of accidents and disruptions. Manufacturers specializing in post insulators for railways adhere to stringent quality standards to meet the safety requirements of modern rail systems.

Challenges in Insulator Performance

The performance of post insulators can be affected by various factors, including environmental conditions, pollution, and mechanical stress. Manufacturers address these challenges through the use of advanced materials and coatings that enhance insulator resistance to environmental factors. Ongoing research and development efforts focus on improving the longevity and reliability of post insulators.

Choosing the Right Manufacturers: A Key to Reliability and Safety

Selecting reliable and experienced manufacturers is crucial for railway operators looking to ensure the longevity and safety of their electrified rail systems. Whether it is traction converters, connectors, or post insulators, the expertise and commitment of manufacturers significantly impact the performance of these components.

Key Criteria for Manufacturer Selection

Railway operators should consider several key criteria when choosing traction converter, connector, and post insulator manufacturers. These include a proven track record, adherence to industry standards, the use of advanced technologies, and a commitment to continuous improvement. Collaborating with reputable manufacturers enhances the likelihood of deploying systems that meet or exceed safety and reliability expectations.

Conclusion

In conclusion, the reliability and safety of railway systems depend heavily on the quality of traction converters, connectors, and post insulators. Manufacturers in these domains play a critical role in advancing technology to meet the evolving needs of the railway industry. As electrification becomes more prevalent, ensuring the highest standards in the design, production, and maintenance of these components is essential for the seamless, efficient, and safe operation of rail networks worldwide.

#Post Insulator For Railways#Railway Traction Converter Manufacturers#India#Railway Traction Connectors Manufacturers#railway#third rail#locomotive#tram#metro#railway engine

7 notes

·

View notes

Text

Best-Quality Bolts: Your Trusted Manufacturer

Introduction

Bolts are something fasteners applied in most industries, serving securely to connect in construction, manufacturing, and engineering. As a reputable manufacturer, stockist, supplier, and exporter of high-class bolts, we serve multiple sectors across the globe with our top-notch fastener solutions. At Ananka Group, we stress durability, reliability, and precision to ensure that our bolts meet global standards and specific requirements of the customers.

Bolts are essential for connecting two or more components together. We, at Ananka Group, boast our manufacturing process of using superior machinery, quality material, and innovative techniques in manufacturing bolts. Our Bolts meet international standards in the form of ASTM, ISO, DIN, and BS.

Key Feature of Bolts

Precision Engineering: Accuracy in dimension for perfect fitting.

Material Durability: High-grade metals and alloys.

Corrosion Resistance: Specific coatings to withstand aggressive environments.

Customized: Supplied in lengths, diameters, various sizes, forms, specifications, and grades.

Bolts Applications & Uses

Bolts are very versatile and are used within various industries:

Construction Industry: Structural assemblies, bridges, buildings

Automotive Sector: Manufacturing of vehicles and heavy machinery

Oil & Gas Industry: Pipelines, refineries, and offshore platforms

Aerospace Industry: Usage within aircraft assemblies and parts

Marine Applications: Withstand saline corrosion.

Power Plants: To protect vital machinery and infrastructure.

Railways: Used in laying and renovation of tracks.

Best Selling Varieties of Bolts

We have an extensive variety of bolts to suit different needs. Some of our top varieties include:

Hex Bolts: Suitable for construction and mechanical work.

Carriage Bolts: Most often used in applications where wood is bonded to another piece of wood.

Anchor Bolts: For fixing structures to concrete.

Eye Bolts: Best for lifting or rigging purposes.

U-Bolts: Most commonly used for securing pipes or rods.

Flange Bolts for automotive and machinery applications.

J-Bolts for structural functions and foundations

Why Choose Us?

Quality Assurance: Stringent quality tests at every manufacturing stage

Global Supply: Consistent supply to more than 50 countries

Custom Solutions: Tailor-made bolts according to specific requirements

Competitive Pricing: Premium products at economical prices

Expert Support: Dedicated team to assist with product selection and technical queries

Conclusion

Bolts are the most important component that helps a structure or system withstand and function properly. With devotion to excellence, Ananka Group is a reliable partner for all industries across the globe. The quality bolts along with exceptional services make us the preferred choice of clients worldwide.

FAQ

Q1. What are the materials used for manufacturing bolts?

We use high-grade materials such as stainless steel, carbon steel, alloy steel, and exotics like Inconel and Monel.

Q2. Is it possible to customize bolts for special applications?

Yes, we can offer special fasteners according to the specific dimensions, material, and coating requirements.

Q3. What types of industries do you supply bolts to?

We cater to construction, automotive, aerospace, oil & gas, marine, and power generation sectors.

Q4: How long does it take you to deliver ordered products internationally?

We ensure timely delivery. Delivery time depends on order quantity and destination.

0 notes

Text

Ambica Cables: Leading the Way in FRLS Cable Manufacturer

In today’s fast-paced world, safety in electrical systems has become paramount. Fires, electrical failures, and the emission of toxic fumes can cause devastating consequences, making it essential to use high-quality, fire-safe electrical cables. This is where FRLS cables manufacturers come into play. Among the leading manufacturers of FRLS cables, Ambica Cables stands out for its commitment to quality, safety, and performance.

What are FRLS Cables?

FRLS cables are specially designed to prevent the spread of fire and minimize the amount of smoke generated in the event of a fire. These cables are often used in public spaces, residential buildings, industrial complexes, and anywhere fire safety is a critical concern. The unique characteristics of FRLS cables include:

Fire Retardancy: The cable’s insulation is designed to withstand fire, preventing the spread of flames along the length of the cable.

Low Smoke Emission: In the event of a fire, FRLS cables emit significantly lower levels of smoke compared to conventional cables, ensuring better visibility and reducing the risks of asphyxiation.

Low Toxicity: FRLS cables are made with materials that release minimal toxic gases when exposed to fire, making them safer for occupants and first responders.

Why Choose Ambica Cables for FRLS Cables?

Ambica Cables, a trusted name in the cable manufacturing industry, has built a reputation for producing high-performance FRLS cables that meet global safety standards. Here’s why Ambica Cables is the preferred choice for FRLS cables:

1. Commitment to Quality

Ambica Cables is known for its unwavering commitment to quality. The company uses the finest raw materials and state-of-the-art manufacturing processes to ensure that each FRLS cable meets or exceeds international safety and performance standards. From raw materials to finished products, every cable is rigorously tested for fire resistance, smoke emission levels, and mechanical strength.

2. Advanced Manufacturing Technology

To meet the growing demands for safety in modern infrastructure, Ambica Cables employs cutting-edge technology in its manufacturing processes. With the use of high-quality polymers, fire-resistant coatings, and specialized insulation materials, Ambica ensures that its FRLS cables offer superior protection and reliability. The company’s in-house R&D team is dedicated to innovating and improving its products to stay ahead of industry trends and safety requirements.

3. Wide Range of FRLS Cables

Ambica Cables offers a comprehensive range of FRLS cables, including power cables, control cables, flexible cables, and more. These cables are designed for use in various applications, such as:

Residential Buildings: Ensuring the safety of homes and apartment complexes by preventing fire hazards.

Commercial & Industrial Installations: Ideal for high-traffic areas like shopping malls, hospitals, schools, and manufacturing units.

Transport Systems: Essential for underground railway systems, airports, and tunnels where fire safety and visibility are critical.

4. Stringent Testing & Certification

To guarantee the highest standards of safety and quality, Ambica Cables undergoes stringent testing procedures, including fire resistance tests, smoke density tests, and toxicity tests. The company’s FRLS cables are certified by reputed international and national standards bodies, such as ISI (Indian Standards Institute), UL (Underwriters Laboratories), and IEC (International Electrotechnical Commission).

5. Eco-Friendly Approach

In today’s environmentally-conscious world, Ambica Cables recognizes the importance of sustainability. Ambica’s FRLS cables are designed to be eco-friendly, using non-toxic, recyclable materials that reduce environmental impact. The company is committed to reducing its carbon footprint and ensuring that its production methods are as environmentally responsible as possible.

6. Custom Solutions & Exceptional Service

Ambica Cables understands that every project is unique and requires customized solutions. Whether it’s a large-scale industrial installation or a specialized residential project, the company offers tailored FRLS cable solutions to meet specific customer needs. Furthermore, Ambica’s customer service team is always ready to provide expert guidance, ensuring smooth project execution from start to finish.

The Importance of FRLS Cables in Fire Safety

FRLS cables play an essential role in modern fire safety systems. In the event of a fire, the safety of building occupants and emergency responders depends not only on the speed of evacuation but also on the safety of the building’s infrastructure. FRLS cables significantly reduce the risks associated with electrical fires, making them crucial in the following ways:

Preventing Fire Spread: FRLS cables help prevent the spread of fire throughout a building, especially in areas with a high concentration of electrical wiring.

Improving Visibility: With low smoke emission, these cables provide clearer evacuation routes, improving the chances of safe evacuation during emergencies.

Reducing Toxic Hazards: Traditional cables can emit harmful gases in the event of a fire, increasing the danger. FRLS cables, however, are designed to minimize these risks, helping to ensure a safer environment for everyone.

Conclusion: Ambica Cables – A Trusted Partner for Fire Safety

Ambica Cables has firmly established itself as one of the leading manufacturers of FRLS cables, offering products that combine innovation, safety, and reliability. With a focus on delivering high-quality, fire-retardant solutions, Ambica continues to meet the evolving needs of industries that prioritize fire safety and risk management.

By choosing Ambica Cables for your FRLS cable needs, you’re investing in safety, quality, and peace of mind. Whether it’s for residential, commercial, or industrial projects, Ambica Cables’ FRLS offerings ensure that your electrical systems are safer, more reliable, and more fire-resistant.

Visit:- https://www.ambicacables.com/

1 note

·

View note

Text

HVAC Units Been Tested Before Shipment

The principal component in any HVAC unit is its compressor. The performance of this compressor is regulated by a VFD. The VFD helps in reducing its power consumption. Not only this, it helps in avoiding the wear and tear of equipment, thereby reducing the need for maintenance. By checking, analysing and then varying the input power, the Power PCB and Control PCB control the output from the VFD to always suit the load conditions optimally.

Why HVAC testing?

An HVAC normally handles heavy loads in large areas often with frequent footfalls such as commercial complexes, malls, airports, railway and metro stations. As such, their compressors along with their VFDs should perform at peak level always. It is therefore essential to test the VFD before checking the other components of the HVAC.

Tests performed on HVAC Power PCB

Some of the major tests performed on the HVAC are:

Isolation test: Each component of the HVAC is tested by isolating it from the rest of the system. This ensures the component works as designed under varying load conditions without impacting the performance of the other components in the process. With each component performing as required, the HVAC system as a whole function accordingly.

Short Circuit Test: A component will not turn on in spite of receiving the requisite power supply – this is attributed to either a short circuit in the line from the supply to the PCB or within the PCB itself. A non-functional component leads to a defective HVAC equipment causing improper usage which can further aggravate the problem and can have a cascading impact on the other components.

Current and Voltage Calibration/Measurement: Each component must receive the current and voltage as rated for it. The source power from the power supply must reach the component to match the rated. Any impedance causing it must be rectified to ensure proper functioning. It must be calibrated and measured.

IGBT/MOSFET Gate drive test: The switching of the HVAC must be proper. This is ensured by conducting the IGBT/MOSFET Gate drive test on the PCB. The power is calibrated and measured using an oscilloscope.

HVAC performance suiting the varying requirements is ensured by controlling its Variable Frequency Drive (VFD). The functionality of the VFD’s Control PCB must be thoroughly tested.

Tests performed on HVAC Control PCB

The Control PCB, which connects to the VFD’s main circuit via the gate drive board, is tested to ensure that its logic controls the VFD such that the VFD performs as desired.

Towards this end, the following tests are performed:

Write FLASH Memory/EPROM data test to ensure the data and commands are stored properly in the main board

Communication test between the external equipment and operator interface components, and the VFD

Analog Input/output Calibration/Measurement of the main circuit parameters such as temperature, current and voltage

Testing the performance of other components

Besides the VFD, other components also need to be tested to ensure that the HVAC performs as desired. Components such as the thermostat, condenser coil and evaporator coil need to be tested before shipment.

Why Automated Test Equipment (ATE)?

The time taken to test the many parameters in an HVAC is greatly reduced by using an ATE. Besides an ATE provides efficiency and ease of use.

The use of an ATE makes it possible to customise the sequence of tests. The equipment used can be customised as per the requirements. Often the operation of HVAC is very complex with diverse sets of operating environments. Proper testing of the functionality of the HVAC is required which is provided by the ATE.

At MELSS, we have been understanding the industry’s requirements for more than 25 years, and provide some of the best-in-class ATEs.

To know more about automated test equipment manufacturers

0 notes

Text

Revolutionizing Ground Stabilization: A Complete Guide to Polyester Geogrids

Introduction: Understanding the Foundation of Modern Construction

In the ever-evolving world of construction and civil engineering, innovative materials continue to reshape how we approach ground stabilization and reinforcement projects. Among these groundbreaking solutions, polyester geogrids have emerged as a game-changing technology, offering unprecedented strength, durability, and cost-effectiveness. As more construction professionals seek reliable polyester geogrid suppliers and manufacturers, understanding the intricacies of this material becomes increasingly crucial.

The Evolution of Geosynthetics: From Concept to Reality

The development of polyester geogrids represents a significant milestone in geosynthetic technology. These high-performance materials, created through sophisticated manufacturing processes, have revolutionized soil reinforcement applications. Leading polyester geogrid manufacturers have continuously refined their production techniques, resulting in products that offer superior tensile strength, minimal elongation under load, and exceptional chemical resistance.

Technical Excellence: What Sets Polyester Geogrids Apart

Polyester geogrids stand out due to their unique structural composition. Manufactured using high-tenacity polyester yarns, these materials undergo specialized coating processes that enhance their durability and performance. Quality polyester geogrid suppliers ensure their products meet rigorous international standards, providing materials that maintain their structural integrity even under extreme conditions.

Applications of Polyester Geogrids in Construction

Polyester geogrids are used in a wide range of construction and civil engineering applications. One of the most common uses is in road construction, where geogrids are used to reinforce the base and sub-base layers. By distributing the load evenly, polyester geogrids reduce the risk of road deformation and rutting, which can occur due to heavy traffic loads over time.

In addition to road construction, polyester geogrids are also used in the stabilization of slopes and embankments. By reinforcing the soil and preventing erosion, geogrids help to maintain the structural integrity of slopes, even in areas with high rainfall or unstable soil conditions. This makes them an essential tool for preventing landslides and other forms of slope failure.

Retaining walls are another common application for polyester geogrids. When used in conjunction with retaining wall systems, geogrids help to strengthen the soil behind the wall, reducing the pressure on the wall itself and increasing its overall stability. This is particularly important in areas where retaining walls must support large loads or where the soil is prone to shifting.

Construction Sectors

The versatility of polyester geogrids makes them indispensable in various construction applications:

Retaining wall reinforcement

Road base stabilization

Railway track bed improvement

Slope stabilization

Foundation reinforcement

Embankment support

Best Practices in Geogrid Installation

Successful implementation of geogrid solutions relies heavily on proper installation techniques. Professional Polyester geogrid installation begins with thorough site preparation and follows specific guidelines:

Surface Preparation

Remove all vegetation and debris

Grade and compact the surface

Ensure proper drainage

Layout and Positioning

Unroll the geogrid in the specified direction

Maintain proper overlap between adjacent rolls

Secure temporary anchoring as needed

Fill Placement

Place fill material carefully to avoid damage

Maintain minimum cover requirements

Compact in specified lifts

Quality Considerations for Procurement

When selecting a Polyester geogrid supplier, several factors deserve careful consideration:

Manufacturing certifications and quality control processes

Product testing documentation

Technical support capabilities

Installation guidance and training

Warranty terms and conditions

Environmental Impact and Sustainability

Modern polyester geogrid manufacturers increasingly focus on sustainable production methods. These initiatives include:

Reduced energy consumption in manufacturing

Use of recycled materials where possible

Minimized waste production

Extended product lifecycle considerations

Cost-Benefit Analysis

While initial material costs from polyester geogrid suppliers may seem significant, the long-term benefits often justify the investment:

Reduced maintenance requirements

Extended infrastructure lifespan

Lower labor costs during installation

Decreased material usage in construction

Future Trends and Innovations

The polyester geogrid industry continues to evolve, with manufacturers investing in:

Advanced coating technologies

Enhanced UV resistance

Improved load distribution capabilities

Smart monitoring integration

The Importance of Polyester Geogrid Suppliers

As the demand for polyester geogrids has surged, the role of polyester geogrid suppliers has become increasingly critical. These suppliers are responsible for ensuring that construction companies have access to high-quality, reliable geogrids that meet specific project requirements. A reputable polyester geogrid supplier will not only provide products but also offer technical guidance and support, helping engineers and project managers choose the right type of geogrid for their particular needs.

Quality is paramount when it comes to polyester geogrids. Inferior materials or poorly manufactured geogrids can compromise the stability and safety of a project, leading to costly repairs and potential hazards down the line. Reputable suppliers work closely with polyester geogrid manufacturers to ensure that the products they distribute meet stringent industry standards. Additionally, they often maintain a stock of various types and sizes of geogrids, ensuring that contractors can easily find what they need without facing delays.

Conclusion

As construction challenges become more complex, the role of high-quality polyester geogrids becomes increasingly vital. Choosing the right Polyester geogrid manufacturer and following proper installation protocols ensures optimal project outcomes and long-term performance.

Frequently Asked Questions (FAQs)

What is the typical lifespan of polyester geogrids in soil reinforcement applications?

Polyester geogrids, when properly installed and maintained, typically have a design life of 75-120 years. However, this can vary depending on soil conditions, environmental factors, and the specific grade of geogrid used. Regular monitoring and proper installation are crucial for achieving maximum longevity.

How do temperature fluctuations affect polyester geogrid performance?

Polyester geogrids maintain their structural integrity across a wide temperature range (-30°C to +60°C). Unlike some alternative materials, they exhibit minimal creep under sustained loads and maintain their dimensional stability even during significant temperature variations. However, extreme conditions should be discussed with your supplier for specific recommendations.

Can polyester geogrids be used in environments with high chemical exposure?

Polyester geogrids demonstrate excellent resistance to most naturally occurring soil chemicals and conditions. However, they should be carefully evaluated for use in highly alkaline environments (pH > 9) or areas with high organic content. Reputable manufacturers can provide chemical resistance data and guidance for specific applications.

What are the key factors to consider when determining the appropriate geogrid strength for a project?

The selection of appropriate geogrid strength depends on several factors:

Design loads and safety factors

Soil conditions and characteristics

Project requirements and specifications

Installation conditions and methods

Long-term performance requirements Professional engineering analysis is recommended for optimal product selection.

0 notes

Text

Interactive Kiosk Market - Structure, Size, Trends, Analysis and Outlook 2022-2030

Interactive Kiosk Industry Overview

The global interactive kiosk market size was valued at USD 28.45 billion in 2021 and is projected to expand at a compound annual growth rate (CAGR) of 7.1% from 2022 to 2030.

Due to the high development in payment and security technologies, the market has witnessed rapid growth over the past few years. Many of the self-service kiosk manufacturers will continue to extract these technologies’ maximum potential and are expected to include them as an indispensable component of their product offering. Interactive kiosks help prevent long queues at public places, such as inquiry counters at railway stations, banks, and malls and check-in counters at airports. At places, such as hospitals and government offices, they help reduce the paperwork associated with visitor data collection and enhance visitors’ experiences.

Gather more insights about the market drivers, restrains and growth of the Interactive Kiosk Market

An increase in product adoption in the BFSI and retail segments is expected to be a major growth driver for the market. Some of the major manufacturers are already working on developing and integrating Artificial Intelligence (AI)-based technology in interactive kiosks. For instance, ViaTouch Media has introduced AI-based kiosks, which enable shoppers to examine the products before making a purchase. As products are removed from the retailer’s shelf, a video screen above displays product information to the customer. The growing problems due to the outbreak of COVID-19 have increased the adoption of self-checkout kiosks to avoid human interaction. As self-checkout kiosks ensure social distancing in stores, they pave the way for a little human interaction.

Looking forward to driving the adoption of and advantages offered by interactive kiosks to customers, the vendors operating in the market have launched various advanced solutions and technologies in response to the COVID-19 pandemic. The COVID-19 pandemic has doubled the R&D spending and innovation by the vendors. For instance, kiosk systems with temperature sensors, Personal Protective Equipment (PPE)-dispensing kiosks, smart kiosks that collect swab samples for COVID-19 tests, and mobile testing kiosks are some of the latest solutions launched by the vendors operating in the market. The vendors are expected to continue focusing on product innovation and development to gain a significant share in the years to come.

Interactive Kiosk Market Segmentation

Grand View Research has segmented the global interactive kiosk market report on the basis of component, type, end use, and region:

Component Outlook (Revenue, USD Million, 2017 - 2030)

Hardware

Display

Printer

Others

Software

Windows

Android

Linux

Others (iOS, Others)

Service

Integration & Deployment

Managed Services

Type Outlook (Revenue, USD Million, 2017 - 2030)

Automated Teller Machines (ATMs)

Retail Self-Checkout Kiosks

Self-Service Kiosks

Vending Kiosks

End Use Outlook (Revenue, USD Million, 2017 - 2030)

BFSI

Retail

Food & Beverage

Healthcare

Government

Travel & Tourism

Others

Regional Outlook (Revenue, USD Million, 2017 - 2030)

North America

US

Canada

Europe

UK

Germany

France

Asia Pacific

China

India

Japan

Singapore

Thailand

Indonesia

Malaysia

Vietnam

Australia

Latin America

Brazil

Middle East & Africa (MEA)

Browse through Grand View Research's Next Generation Technologies Industry Research Reports.

The global hybrid printing technologies market size was estimated at USD 4.59 billion in 2023 and is projected to grow at a CAGR of 12.3% from 2024 to 2030.

The global 4D printing market size was estimated at USD 156.8 million in 2023 and is anticipated to grow at a CAGR of 35.8% from 2024 to 2030.

Key Companies & Market Share Insights

The market is characterized by the presence of a few players accounting for significant industry share. New product launches and technology partnerships are some of the major strategies adopted by key companies to strengthen their market position. Key industry players are also heavily investing in research & development projects and focusing on establishing production infrastructure to develop and offer differentiated and cost-effective self-service solutions. The Meridian, Advanced Kiosk, and Kiosk Information System have a strong market presence due to the availability of a strong R&D department and production facilities. The companies mainly focus on product innovation and effective distribution through a strong network of partners in multiple countries, such as the U.S., Germany, India, and Brazil. Some of the key players in the global interactive kiosk market include:

NCR Corp.

Diebold Nixdorf AG

ZEBRA Technologies Corp.

Advanced Kiosks

Embross Group

GRGBanking

IER SAS

Order a free sample PDF of the Interactive Kiosk Market Intelligence Study, published by Grand View Research.

0 notes

Text

Turkey to Launch Dynamic Tests of Its First High-Speed Electric Train in 2025

Turkey is preparing to begin dynamic tests of its first high-speed electric train in 2025, this is reported by the railway transport news portal Railway Supply.

Photo, video: Daily Sabah Minister of Transport and Infrastructure, Abdulkadir Uraloğlu, announced that this significant event is scheduled for the fourth quarter of next year. Talgo and CAF: Is a Merger Possible? Before that, the train will undergo static tests at the facilities of Turkish Railway Vehicles Industries Inc. (TURASAŞ). The project is being carried out in collaboration with the Rail Transport Technologies Institute of TCDD and the Turkish Scientific and Technological Research Council (TÜBİTAK). The design of the high-speed electric train is expected to be completed by the end of 2024, after which the prototype construction will begin. The Minister emphasized that key components will be developed and manufactured domestically using national resources, reaffirming the country's commitment to technological independence. The new train will consist of eight cars, capable of reaching speeds of up to 225 km/h, with a total passenger capacity of 584, including special accommodations for passengers with disabilities. This initiative aims to improve transport accessibility for all categories of citizens. The development of the new high-speed electric train is based on the national Sakarya electric train, which was launched into service in 2023. As part of the program to expand the train fleet, the former Minister of Transport, Adil Karaismailoğlu, announced that by 2025, the number of Sakarya trains will increase to 15 units, and by 2030, to 56. Turkey is making confident strides towards expanding its domestic railway production and integrating modern technologies into the country’s transportation system. The introduction of national high-speed trains will significantly enhance infrastructure and reduce travel times between major cities. Photo, video: Daily Sabah Rail business, industry, and railway technology news from Railway Supply that you might have missed: New Nightjet Trains: Comfortable Night Routes from Vienna and Munich to Rome Read the full article

0 notes

Text

Interactive Kiosk Market, 2030: Growth Share and Future Trends

The global interactive kiosk market size was valued at USD 28.45 billion in 2021 and is projected to expand at a compound annual growth rate (CAGR) of 7.1% from 2022 to 2030.

Due to the high development in payment and security technologies, the market has witnessed rapid growth over the past few years. Many of the self-service kiosk manufacturers will continue to extract these technologies’ maximum potential and are expected to include them as an indispensable component of their product offering. Interactive kiosks help prevent long queues at public places, such as inquiry counters at railway stations, banks, and malls and check-in counters at airports. At places, such as hospitals and government offices, they help reduce the paperwork associated with visitor data collection and enhance visitors’ experiences.

Gather more insights about the market drivers, restrains and growth of the Interactive Kiosk Market

An increase in product adoption in the BFSI and retail segments is expected to be a major growth driver for the market. Some of the major manufacturers are already working on developing and integrating Artificial Intelligence (AI)-based technology in interactive kiosks. For instance, ViaTouch Media has introduced AI-based kiosks, which enable shoppers to examine the products before making a purchase. As products are removed from the retailer’s shelf, a video screen above displays product information to the customer. The growing problems due to the outbreak of COVID-19 have increased the adoption of self-checkout kiosks to avoid human interaction. As self-checkout kiosks ensure social distancing in stores, they pave the way for a little human interaction.

Looking forward to driving the adoption of and advantages offered by interactive kiosks to customers, the vendors operating in the market have launched various advanced solutions and technologies in response to the COVID-19 pandemic. The COVID-19 pandemic has doubled the R&D spending and innovation by the vendors. For instance, kiosk systems with temperature sensors, Personal Protective Equipment (PPE)-dispensing kiosks, smart kiosks that collect swab samples for COVID-19 tests, and mobile testing kiosks are some of the latest solutions launched by the vendors operating in the market. The vendors are expected to continue focusing on product innovation and development to gain a significant share in the years to come.

Interactive Kiosk Market Segmentation

Grand View Research has segmented the global interactive kiosk market report on the basis of component, type, end use, and region:

Component Outlook (Revenue, USD Million, 2017 - 2030)

• Hardware

o Display

o Printer

o Others

• Software

o Windows

o Android

o Linux

o Others (iOS, Others)

• Service

o Integration & Deployment

o Managed Services

Type Outlook (Revenue, USD Million, 2017 - 2030)

• Automated Teller Machines (ATMs)

• Retail Self-Checkout Kiosks

• Self-Service Kiosks

• Vending Kiosks

End Use Outlook (Revenue, USD Million, 2017 - 2030)

• BFSI

• Retail

• Food & Beverage

• Healthcare

• Government

• Travel & Tourism

• Others

Regional Outlook (Revenue, USD Million, 2017 - 2030)

• North America

o U.S.

o Canada

• Europe

o U.K.

o Germany

o France

• Asia Pacific

o China

o India

o Japan

o Singapore

o Thailand

o Indonesia

o Malaysia

o Vietnam

o Australia

• Latin America

o Brazil

• Middle East & Africa (MEA)

Browse through Grand View Research's Next Generation Technologies Industry Research Reports.

• The global hybrid printing technologies market size was estimated at USD 4.59 billion in 2023 and is projected to grow at a CAGR of 12.3% from 2024 to 2030.

• The global 4D printing market size was estimated at USD 156.8 million in 2023 and is anticipated to grow at a CAGR of 35.8% from 2024 to 2030.

Key Companies & Market Share Insights

The market is characterized by the presence of a few players accounting for significant industry share. New product launches and technology partnerships are some of the major strategies adopted by key companies to strengthen their market position. Key industry players are also heavily investing in research & development projects and focusing on establishing production infrastructure to develop and offer differentiated and cost-effective self-service solutions. The Meridian, Advanced Kiosk, and Kiosk Information System have a strong market presence due to the availability of a strong R&D department and production facilities. The companies mainly focus on product innovation and effective distribution through a strong network of partners in multiple countries, such as the U.S., Germany, India, and Brazil. Some of the key players in the global interactive kiosk market include:

• NCR Corp.

• Diebold Nixdorf AG

• ZEBRA Technologies Corp.

• Advanced Kiosks

• Embross Group

• GRGBanking

• IER SAS

Order a free sample PDF of the Interactive Kiosk Market Intelligence Study, published by Grand View Research.

#Interactive Kiosk Market#Interactive Kiosk Industry#Interactive Kiosk Market size#Interactive Kiosk Market share#Interactive Kiosk Market analysis

0 notes

Text

What Industries Is Precision Machining Applicable To?

Precision machining is applicable to a wide range of industries including, but not limited to automotive, aerospace, biomedical, petrochemical, energy, environmental protection, etc. due to its high accuracy, quality and flexibility.

Aerospace The aerospace sector places extremely high demands on the precision, strength and weight of parts and assemblies. Precision machining technology is used in the manufacturing of engine components, turbine blades, turbine disks, aeronautical instruments, propulsion systems, satellite parts and structural components such as hulls, wings and empennage. These parts require extremely high geometric accuracy, surface quality and material properties to ensure the performance, safety and reliability of the aerocraft. (Ultra-precision machining technology is used in the manufacturing of precision engine parts, aerospace structural components, guidance and control elements, etc., which is widely used in satellite manufacturing, automatic spacecraft rendezvous and docking, satellite guidance and control, etc.)

Biomedical Ultra-precision machining technology is used in the manufacturing of diagnostic devices, medical devices, medical equipment parts, surgical instruments, artificial human implants such as artificial joints, bone plates, spinal screws, cardiac stents, etc. in which medical devices are manufactured with stringent requirements for precision and quality to ensure their safety and effectiveness in clinical use. These devices require precise dimensions and shapes, as well as smooth surfaces to minimise human rejection and increase biocompatibility.

Automobile

Automobiles are made up of thousands of precision parts, and the fineness of these parts directly affects their performance and safety. In automotive manufacturing, precision machining technology is used to produce key components such as engine parts, braking systems, steering systems, transmission components, suspension systems parts, precision instruments and body electronics. CNC Precision Machining can help manufacturers produce more accurate, safe and durable automotive parts. High precision machining not only improves the performance and reliability of automobiles, but also promotes the automation and intelligent development of the automotive industry.

Petrochemical, Energy and Environmental Protection

Ultra-precision machining technology is used in the manufacturing of gases, liquids and solid tanks, wind and solar power generation heavy machinery equipment, electrical equipment and nuclear reactor components, etc., in addition to the manufacturing of environmental protection equipment, metrology equipment and so on.

Electronic Device

Modern electronic products such as smartphones, computers, and wearable devices rely on precision machining technology for many of their internal key components. For example, mobile phone housings, chip packages, miniature sensors and circuit boards all require high precision machining technology to ensure product performance and stability.

Optics and Photoelectricity

Optical instruments such as microscopes, telescopes, astronomical telescopes, camera lenses, optical lens, fibre optic communication devices, laser components, etc. require precision machining technology in their manufacturing process to ensure the accuracy and surface quality of optical components. Small errors in these components can have a significant impact on imaging quality.

Semiconductor

The semiconductor industry also has a high demand for precision machining technology. The production, packaging and testing of semiconductor wafers requires the use of high-precision equipment and processes to ensure product quality and performance.

Railway

In the field of rail transportation, such as high-speed trains, underground vehicles and other rail vehicles above the precision electronic equipment shell of custom and structural components, such as the manufacturing and processing, need to be supported by precision machining technology.

To summarize, precision machining technology plays a vital role in modern industry, covering multiple fields from high-tech products to daily necessities. The application areas of precision machining technology will continue to expand as technology continues to advance and demand continues to increase.

#design#autos#business#cnc machining#prototyping#precision machining#prototype#prototype machining#rapid prototyping#machining parts#cnc precision machining#precisionmanufacturing#high precision#5 axis machining#cnc parts company#cnc parts factory#cnc machining center

1 note

·

View note

Text

Railway Component Manufacturers in India: Aceforge Leading the Way

India's railway network, one of the largest in the world, relies on a vast array of high-quality components to ensure safe, efficient, and reliable operations. At the heart of this industry are the manufacturers who produce these critical components, and Aceforge Pvt Ltd is at the forefront of this domain. As a leading railway component manufacturer in India, Aceforge plays a pivotal role in supporting the nation’s rail infrastructure with its top-notch products and expertise.

Expertise in Railway Component Manufacturing

Aceforge has established itself as a key player in the railway sector by specializing in the production of a wide range of components essential for the smooth functioning of trains and rail systems. Their expertise spans across multiple categories, including mechanical, electrical, and safety components, all of which are manufactured with the highest standards of quality and precision.

Diverse Product Range

Aceforge’s product portfolio is extensive, catering to the diverse needs of the railway industry. Some of the critical components they manufacture include:

Bogie Components: Aceforge produces robust bogie frames, axle boxes, and suspension systems that are vital for the stability and smooth movement of trains on tracks.

Coupling and Draft Gear: High-strength couplers and draft gears designed by Aceforge ensure secure and reliable connections between railway cars, enhancing safety during operations.

Brake Systems: The company manufactures a range of braking components, such as brake shoes, discs, and cylinders, that are crucial for the effective control and stopping of trains.

Track Components: Aceforge also provides components like fishplates, tie bars, and rail clips that are essential for maintaining the integrity and alignment of railway tracks.

Electrical Components: From wiring harnesses to signaling equipment, Aceforge supplies the electrical components necessary for the operation and safety of modern trains.

Commitment to Quality and Innovation

Aceforge’s commitment to quality is unwavering. Each component is subjected to rigorous testing and quality control measures to ensure it meets the stringent standards required by the railway industry. The company’s dedication to innovation is evident in its continuous investment in research and development, allowing them to introduce new and improved components that meet the evolving needs of the railway sector.

Sustainable Manufacturing Practices

Recognizing the importance of sustainability, Aceforge integrates eco-friendly practices into their manufacturing processes. This includes reducing energy consumption, minimizing waste, and using environmentally responsible materials. Their commitment to sustainability not only helps protect the environment but also aligns with global trends towards greener and more efficient rail transportation.

Strategic Partnerships and Global Presence

Aceforge’s success is bolstered by its strategic partnerships with key stakeholders in the railway industry. These collaborations allow them to stay ahead of industry trends, adopt best practices, and meet the specific requirements of their clients. Additionally, their global reach ensures that Aceforge’s high-quality railway components are used not only in India but also in international markets.

Conclusion

As one of the leading railway component manufacturers in India, Aceforge Pvt Ltd is synonymous with quality, innovation, and reliability. Their comprehensive product range, commitment to excellence, and sustainable practices make them a trusted partner for railway operators and manufacturers across the country and beyond.

For any railway company looking to enhance the performance and safety of their operations, Aceforge stands ready to provide world-class components that meet the highest industry standards. With Aceforge, the future of railway transportation is on the right track.

0 notes

Text

Railway Parts India: Leading Manufacturers and Suppliers

Railway Parts India: Leading Manufacturers and Suppliers

Railway parts encompass a wide range of components and equipment used in the construction, maintenance, and operation of railway systems. These parts are critical for ensuring the efficient and safe functioning of trains and railway networks. Deccan Engineering Works takes pride in being a trusted and leading manufacturer and supplier of high-quality railway parts India. With years of industry experience and expertise, we are dedicated to delivering exceptional products that meet the stringent requirements and standards of the railway sector.

Our extensive product range covers various railway parts, including:

Rails and Sleepers:

♦ We offer a wide selection of rails and sleepers that are designed to withstand heavy loads and provide a smooth and stable track foundation.

Rolling Stock Components:

♦From bogies and wheels to brake systems and couplers, our rolling stock components are engineered for optimal performance and reliability.

Electrical and Power Supply Equipment:

♦ Our range includes transformers, switchgears, and other electrical equipment that ensure a reliable power supply for railway networks.

Track Maintenance Tools:

♦We offer a comprehensive range of track maintenance tools, such as rail trolleys, rail grinders, and welding machines, to facilitate efficient track maintenance and repair.

Railway Parts Suppliers

♦ As a trusted railway parts suppliers, we have established strong partnerships with renowned manufacturers worldwide. This enables us to source and supply a diverse range of high-quality products to our clients. Our dedicated procurement team ensures that we maintain a vast inventory of railway parts, meeting the varied needs of our customers.

Choosing us as your preferred supplier of railway parts offers compelling reasons:

1. Uncompromising Quality: Our unwavering commitment to quality ensures that our railway parts meet the highest industry standards. We subject our products to rigorous testing and inspection processes, guaranteeing superior performance and reliability.

2. Rich Expertise and Experience: With a team of highly skilled engineers and technicians, we bring a wealth of expertise and experience to every project. Our dedicated professionals strive for excellence in all aspects, including design, of Railway Parts Manufacturers.

3. Tailored Customization: We understand that each railway project has unique requirements. Therefore, we offer customization options to tailor our products to your specific needs. This ensures seamless integration and optimal performance within your railway system.

4. Punctual Delivery: We recognize the criticality of project timelines. Through streamlined manufacturing processes and efficient supply chain management, we prioritize timely project completion. You can rely on us to deliver your railway parts within the agreed-upon deadlines.

When it comes to railway parts, Deccan Engineering Works is your reliable partner. Contact us today to discuss your requirements and let our team provide you with the best solutions for your railway projects.

Quality Assurance:

We adhere to stringent quality control measures throughout the manufacturing process to ensure that our machined parts and components meet the highest quality standards. Our team of experienced engineers and inspectors conducts rigorous inspections and tests to guarantee the reliability and performance of our products.

Advanced Technology:

Equipped with advanced CNC machines, computer-aided design (CAD) software, and other cutting-edge tools, we have the capability to handle complex machining requirements. Our commitment to technological advancement enables us to stay ahead of the curve and provide innovative solutions to our clients.

Skilled Workforce:

At Deccan Engineering Works, we have a team of highly skilled and experienced professionals who are passionate about their craft. Our engineers and technicians possess in-depth knowledge of machining techniques and are dedicated to delivering excellence in every project.

Competitive Pricing:

We believe in offering competitive pricing without compromising on the quality of our products. Our efficient production processes, streamlined operations, and strategic partnerships enable us to provide cost-effective solutions that add value to your business.

Customization Options:

We understand that every customer has unique requirements.That's why we offer tailored solutions and customization options to meet your specific needs. Whether it's a one-off prototype or large-scale production run,we work closely with our clients to provide personalised services and deliver superior results.

Quick Link

Home

About Us

Our Services

Infrastructure

Contact Us

Capabilities

CNC Machining

4 Axis Machining

5 Axis Machining

Mechanical Assembly

High Precision Machining

Industries

Oil & Gas Parts

Railway Parts

Pump Parts

Hydraulic Parts

Pneumetic Parts

Get In Touch

Plot No. F-39, Deccan Engineering Works, MIDC Satpur, Nashik- 422007 Maharashtra, India

+91 9657039991

(0253) 6646234

#cnc machining suppliers#cnc milling india#cnc milling manufacturers#precision manufacturing india#cnc milling suppliers#cnc turning jobwork services#precision parts manufacturing india#cnc machining manufacturers#cnc turning india#cnc machining india

0 notes

Text

Railway Parts Manufacturer in India: A Detailed Analysis

Introduction to Railway Parts Manufacturing Industry in India

The railway parts manufacturing industry in India plays a crucial role in supporting the country's vast railway network. India has one of the largest rail networks in the world, making the demand for railway parts consistently high. This industry includes the production of components such as wheels, axles, bearings, and various other essential parts needed to keep trains running smoothly and safely.

The railway sector in India is driven by both the Indian Railways and various private players, ensuring a steady flow of orders for manufacturers. Companies in this sector range from small-scale industries to large, established firms, all contributing to the robust supply chain necessary for the operation and maintenance of the railway network.

Importance of Railway Parts Manufacturing

Railway parts manufacturing is essential for several reasons:

Safety: High-quality parts ensure the safety of trains, passengers, and goods. Faulty components can lead to accidents, causing loss of life and property.

Efficiency: Well-manufactured parts help in the smooth operation of trains, reducing downtime and delays. This efficiency is critical for both passenger and freight services.

Economic Impact: The railway industry is a significant contributor to the Indian economy. The manufacturing of railway parts provides employment to thousands and supports numerous ancillary industries.

Innovation and Growth: Continuous innovation in railway parts manufacturing leads to improved performance and new technologies, contributing to the overall growth of the railways.

However, the industry faces challenges such as fluctuating raw material prices and the need for constant technological upgrades to meet global standards.

Manufacturing Capabilities and Technologies

India's railway parts manufacturing sector boasts a wide range of capabilities and uses advanced technologies to meet the needs of modern railways:

Precision Engineering: Companies use state-of-the-art machinery to produce components with high precision. This ensures that parts meet strict quality standards.

Automation: Many manufacturers employ automated processes to enhance production speed and reduce human error. This includes the use of robotics and computer-controlled machinery.

Material Science: Advanced materials like high-strength alloys and composites are used to manufacture durable and lightweight parts, improving the performance and lifespan of railway components.

Quality Control: Rigorous quality control measures, including non-destructive testing and computerized inspection systems, ensure that only the best parts reach the market.

Despite these advancements, some manufacturers struggle with the high cost of technology adoption and maintaining skilled labor.

Market Trends and Growth Opportunities

The railway parts manufacturing industry in India is evolving with several key trends and opportunities:

Government Initiatives: The Indian government has launched various initiatives, such as "Make in India," to boost local manufacturing. This provides significant opportunities for railway parts manufacturers to expand their operations.

Global Market: Indian manufacturers are increasingly exporting railway parts to international markets, taking advantage of competitive pricing and quality.

Technological Advancements: The adoption of new technologies like 3D printing and IoT (Internet of Things) is creating new opportunities for innovation and efficiency in manufacturing processes.

Sustainability: There is a growing focus on sustainable manufacturing practices, with companies investing in eco-friendly materials and processes.

However, the industry must navigate challenges such as stiff global competition and the need for continuous investment in research and development to stay ahead

Challenges Facing the Industry

Technological Advancements

Staying abreast of technological advancements is crucial for forgings companies in India to maintain competitiveness. Investments in research and development are essential to meet evolving safety and efficiency standards in railway operations.

Infrastructure and Logistics

Logistical challenges can impact the timely delivery of railway components. Improved infrastructure and streamlined logistics processes are necessary to support the industry's growth aspirations.

Government Initiatives and Policies

Make in India Initiative

The Indian government's Make in India initiative has provided a significant impetus to the manufacturing sector, including railway parts manufacturing. Incentives and policies aimed at promoting domestic production have encouraged investments in modernizing manufacturing facilities and adopting sustainable practices.

Regulatory Framework

Adherence to stringent regulatory standards is paramount in the railway industry. Manufacturers must comply with safety and quality regulations set by authorities to ensure the reliability and durability of railway components.

Future Outlook

Emerging Technologies

The adoption of digital technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) is poised to revolutionize the railway parts manufacturing landscape. Predictive maintenance and real-time monitoring solutions will enhance operational efficiencies and reduce downtime.

Sustainable Practices

There is a growing emphasis on sustainability in manufacturing processes. Companies are increasingly adopting eco-friendly practices and materials to minimize their environmental footprint while meeting the demands of a greener future.

Conclusion In conclusion, the railway parts manufacturer in India industry is poised for robust growth driven by technological advancements, export opportunities, and government support. Companies like Bharat Forge Limited, Ramkrishna Forgings Limited, and Happy Forging continue to innovate and excel in producing high-quality components that support the safe and efficient functioning of railway networks globally.

#forging#forging services in india#steel forging services in india#technology#railway parts manufacturing#forgings companies in India

0 notes

Text

Heavy Hex Bolts and Nuts Suppliers in Singapore - Sachiya Steel International

Singapore's dynamic industrial landscape demands high-quality fasteners, particularly heavy Hex Bolts and Nuts, to ensure structural integrity and reliability across sectors such as construction, manufacturing, and infrastructure development. Sachiya Steel International Private Limited stands out as India's foremost fastener manufacturer, offering products tailored to meet stringent global standards.

Applications of Heavy Hex Bolts and Nuts

These fasteners find extensive applications across diverse industries due to their reliability and durability:

Construction Industry

Heavy hex bolts and nuts are used in structural steel assemblies, bridges, and high-rise buildings, ensuring stability and safety.

Manufacturing Sector

They are essential in the manufacturing of machinery, equipment, and automotive components, providing strong and secure connections.

Oil & Gas Industry

Offshore platforms, pipelines, and refineries rely on these fasteners for their exceptional strength and resistance to harsh environments.

Infrastructure Development

From roads and railways to public utilities, heavy hex bolts and nuts are crucial in infrastructure projects, offering durability and reliability.

Quality Assurance

Sachiya Steel International places great emphasis on quality. Our fasteners undergo stringent quality checks at each stage of production to meet international standards (ASTM, DIN, BS) and customer specifications. This commitment to quality ensures our products exceed expectations in terms of durability, strength, and corrosion resistance.

Certifications and Compliance

Our quality management systems adhere to stringent quality assurance measures and hold certifications such as ISO 9001:2015. Our products come complete with necessary certifications such as Mill Test Certificates (MTC), Certificates of Origin, and compliance statements, providing assurances of product quality and traceability.

Why Choose Sachiya Steel International?

Expertise in Fastener Manufacturing

Sachiya Steel International is recognized for their expertise and experience in fastener manufacturing, with products tailored specifically for diverse industries such as construction, manufacturing, oil & gas, and infrastructure projects.

Comprehensive Product Range

Our wide range of fasteners consists of heavy hex bolts and nuts in different sizes, materials, and coatings that meet international standards such as ASTM, DIN, and BS to guarantee reliability and performance in challenging applications.

Emphasis on Quality

We place great emphasis on quality, ensuring our fasteners undergo stringent quality controls at each stage of production to meet and exceed customer expectations.

Competitive Pricing and Value

We deliver cost-effective solutions at highly competitive pricing without compromising on quality. Through efficient manufacturing processes combined with strategic sourcing of raw materials, we deliver cost-cutting solutions to our Singapore customers that add efficiency and reliability to their projects. At the same time, we ensure high-quality products that bring added value by contributing directly to project performance and reliability.

Global Reach and Local Support

Sachiya Steel International boasts an unmatched global presence, providing seamless logistics and delivery services directly to Singapore. Furthermore, our customer support team provides prompt service to ensure a positive procurement experience from inquiry to delivery.

Conclusion

Sachiya Steel International stands out as your go-to provider for superior-grade fasteners such as heavy hex bolts and nuts in Singapore. Our expertise in fastener manufacturing, comprehensive product range, emphasis on quality, and customization capabilities make us the preferred choice. With competitive pricing, global reach, and local support, we ensure a seamless procurement experience, delivering high-quality products that meet the stringent requirements of diverse industries.

Read More: Heavy Hex Bolts and Nuts Suppliers in Singapore

0 notes