#Railway Parts India

Explore tagged Tumblr posts

Text

0 notes

Text

Discover the latest innovations in railway parts manufacturing in India, including high-performance materials, 3D printing, automation, green manufacturing, and more. Learn how these advancements are shaping the future of India's railways for enhanced efficiency, safety, and sustainability.

0 notes

Text

The Ultimate Guide to Choosing a Reliable Railway Parts Manufacturer in India

In the fast-paced world of transportation, the railway sector remains a critical backbone of economic development. Ensuring the smooth operation of this sector requires high-quality parts and components. Selecting a reliable railway parts manufacturer in India is essential for maintaining efficiency and safety. This guide will walk you through the crucial aspects to consider when making this important choice, with a special focus on Happy Forging Ltd. (HFL), a leading name in the industry.

Understanding the Importance of Quality Railway Parts

Railway parts are subjected to extreme conditions, including high speeds, heavy loads, and varying environmental factors. This immense stress and wear necessitate components that are robust, durable, and precisely engineered. Every part, from the smallest bolt to the largest axle, plays a critical role in ensuring the smooth and safe operation of trains.

Key Components and Their Roles

Axles: Axles bear the weight of the train and transmit power from the engine to the wheels. They must be exceptionally strong and precisely manufactured to avoid failures that could lead to derailments or other serious accidents.

Wheels: Wheels endure constant contact with the rails, requiring materials that can withstand wear and maintain structural integrity over long distances. Their design affects the train's stability and smoothness of travel.

Brake Systems: Reliable brakes are crucial for controlling the train's speed and ensuring safe stopping. High-quality brake components prevent overheating and ensure consistent performance under various conditions.

Bearings: Bearings reduce friction between moving parts, allowing smooth rotation of wheels and other components. High-quality bearings minimize wear and tear, contributing to the longevity and efficiency of the train.

The Necessity of High Standards

Choosing a railway parts manufacturer in India that adheres to stringent quality standards is vital for several reasons:

Safety: Inferior parts increase the risk of malfunctions that can lead to accidents, posing dangers to passengers and cargo. High-quality parts are engineered to meet safety standards, significantly reducing these risks.

Reliability: Trains operate on tight schedules, and any failure in components can lead to delays and operational disruptions. Reliable parts ensure consistent performance and minimize the likelihood of breakdowns.

Cost-Efficiency: While high-quality parts may have a higher upfront cost, they reduce long-term maintenance expenses. Durable components mean fewer replacements and repairs, saving money over the train's lifespan.

Key Factors to Consider When Choosing a Railway Parts Manufacturer

1. Industry Experience and Reputation

Experience and reputation are strong indicators of reliability. A manufacturer with a long-standing presence in the industry, like Happy Forging Ltd., has likely honed its processes and established robust quality control measures.

Track Record: Investigate the manufacturer’s history. HFL, for instance, has been a trusted name in the railway parts sector for decades.

Client Testimonials and Reviews: Look for feedback from other businesses to gauge the manufacturer’s reliability and service quality.

2. Quality Standards and Certifications

Quality certifications are a testament to a manufacturer's commitment to excellence. Ensure that the railway parts manufacturer in India you choose complies with international and national standards.

ISO Certification: Check if the manufacturer is ISO certified, which ensures they meet rigorous quality management criteria.

Industry-Specific Certifications: For railway parts, certifications like IRIS (International Railway Industry Standard) are crucial.

3. Range of Products and Customization Options

A reliable manufacturer should offer a wide range of products and the ability to customize parts to meet specific requirements.

Product Portfolio: Examine the variety of parts the manufacturer produces. HFL offers an extensive range of railway components.

Customization Services: The ability to produce custom parts is crucial for meeting unique specifications and needs.

4. Supply Chain and Delivery Reliability

Timely delivery is essential to avoid disruptions in operations. Evaluate the manufacturer’s supply chain efficiency and their ability to deliver parts on schedule.

Logistics and Distribution Network: A well-established network ensures timely delivery.

Lead Time: Assess the manufacturer’s lead time and their capacity to handle urgent orders.

6. Customer Support and Service

Excellent customer service is vital for resolving issues quickly and ensuring a smooth collaboration.

After-Sales Support: Ensure the manufacturer provides robust after-sales support and services.

Communication: Effective communication channels are essential for addressing concerns and queries promptly.

Why Choose Happy Forging Ltd. (HFL)?

Happy Forging Ltd. (HFL) exemplifies the qualities of a top-tier railway parts manufacturer in India. With decades of experience, HFL has built a reputation for excellence and reliability. The company is committed to delivering high-quality railway and auto parts that meet stringent industry standards.

Comprehensive Quality Assurance

HFL adheres to rigorous quality control processes. The company is ISO certified and follows industry-specific standards to ensure every part meets the highest quality benchmarks.

Extensive Product Range

HFL offers a wide range of railway parts, from axles and wheels to brake systems and bearings. They also provide customization options to meet specific requirements, making them a versatile auto parts manufacturer in India.

Reliable Supply Chain

With a robust logistics and distribution network, HFL ensures timely delivery of parts. Their efficient supply chain management minimizes lead time and ensures that clients receive their orders without delay.

Exceptional Customer Service

HFL is dedicated to providing excellent customer support. Their after-sales service team is always ready to assist with any issues or concerns, ensuring a smooth and hassle-free experience for their clients.

The Role of an Auto Parts Manufacturer in Railway Parts Production

While the primary focus here is on railway parts, it's worth noting that many manufacturers also produce auto parts. The technological and quality control processes used in manufacturing auto parts can significantly benefit railway parts production.

Shared Technological Advancements

Technological advancements in the auto industry often translate to improvements in railway parts manufacturing. Techniques like precision forging, CNC machining, and advanced material science are common to both sectors.

Cross-Industry Expertise

A manufacturer with expertise in both railway and auto parts can leverage cross-industry knowledge to enhance product quality and innovation. HFL, as an auto parts manufacturer in India, brings this dual expertise to the table, ensuring superior products for both sectors.

Conclusion

Choosing a reliable railway parts manufacturer in India is crucial for maintaining the efficiency and safety of railway operations. Factors such as industry experience, quality standards, technological capabilities, product range, supply chain reliability, and customer support are essential considerations. Happy Forging Ltd. (HFL) stands out as a leading manufacturer, excelling in all these aspects.

By trusting HFL, you ensure that your railway components are of the highest quality, delivered on time, and backed by excellent customer service. Whether you need standard parts or customized solutions, HFL is the go-to choice for reliable and top-quality railway part

#steering knuckles manufacturer#forging#railway parts manufacturer in india#steel forging services in india

0 notes

Text

The market of railway parts manufacturers in India

Industry Overview

India has the fourth-largest railway network in the world, just behind the US, Russia, and China.

This huge market requires a constant supply of spare parts and components.

Advanced composite component manufacturers such as Rockman AC are supplying the most advanced railway components.

The railway parts manufacturers in India are growing rapidly to meet this demand.

Growth factors

The growth of the railway parts manufacturing industry is driven by

The government's focus is on infrastructure development.

Increasing demand for railway as a mode of transportation.

Quality of components supplied by the third-party manufacturers.

Key components manufactured with advanced composites

Several body components and parts are manufactured with advanced composites:

Composite car bodies are now very common, especially in high-speed trains.

Composite interior panels are lighter and more durable.

Bogies get extra strength and rigidity with advanced composites.

Composite braking components are lighter, heat resistant, and durable.

Composite doors and windows are energy efficient, corrosion resistant, and durable.

For more information on railway parts manufacturers in India visit: https://rockmanac.com/

0 notes

Text

Sujan Industries stands out as a premier railway parts manufacturer in India, offering a diverse range of railcar components, rubber springs, rubber pads, and more.

0 notes

Text

LancerFab is a reliable manufacturer and supplier of railway parts in India. With rich experience in manufacturing railway products that are critical to the sustenance and development of the railways, we offer Indian railway parts and Indian railway metro parts to the railway sector in the country.

#metal fabrication#sheet metal fabrication#railway equipment manufacturers#railway parts manufacturer#metro rail & railway parts manufacturer#metro rail parts manufacturer#railway parts manufacturer of India#metro rail and railway parts supplier

0 notes

Text

Top 20 BL Live-action of 2024

20. Love Is a Poison - This series made my wish to see Hama Shogo in a BL come true. I loved his character in Koisenu Futari (2022) and wanted more of his character’s interaction with Takahashi Issei’s character. Also, the series leaned into the surreal with the squealing, sparkling succulents. While the legal drama part of the series was light, it was the first time I was invested in the character’s careers since Beloved Enemy (2017) [which is going to have a Thai remake/adaptation]. I absolutely enjoyed the dynamics of a neo-super-darling seme paired with a devoted, kuudere uke. But, I wish there were fewer flashback/compilation scenes.

19. Unknown - I never thought Priest’s Da Ge will become something like this. I am impressed by the meticulous cultivation that source material underwent. That little carp really crossed the gate to become a dragon. The Unknown managed to tone down the golden finger bits and keep things realistic to an extent, fit the whole business venture arc neatly into Taiwan’s SME-heavy capitalism. It fleshed out Le ge, and his relationship with both his underlings and his junior and made him interesting. It gave me one of my favorite mob characters in a BL – an ex-gangster with his blacked-out tattoos running a street food stall. In line with Taiwanese tradition, this series not only employed high BL literacy but also dedicated time to educate. (more on it here)

18. Cosmetic Playlover - I was hesitant to watch this show since I had enjoyed the first few volumes of manga and lost interest in later volumes. I knew they were going to censor the hell out of the first volume. While I am still bitter about that fact, I still enjoyed the series.

17. Love is Better the Second Time Around - this had some of my favorite moments from a BL - two-faced seme employing all sorts of methods to seduce and ensnare the uke, return of the alone-at-the-railway-station trope, seme using helpless, feverish face and acting coquettish (some seriously charming gap moe), teasing a seme's seme (this one did it better than At 25:00 in Akasaka which fumbled it by choice) and kishōtenketsu - 4 part traditional East Asian narrative structure (which appeared in many series this year and the last) with family negotiation aiming at adoption reversal. (I wanted seme to recommend uke in his place to his native household - that way they can also get married, if and when it gets legalized.)

16. Living with Him – The reason why this series is on this list is pretty unique. I never understood Japanese focus and fetish of nape (the way navel is in south India) before this series. The camera managed to capture the uke's neck, especially when he had his head bent slightly, in a stunning manner. Overall, the camera language was very intimate without being bawdy, perfectly suitable for the domestic setting of this BL. I loved the series more than I did the manga.

15. Century of Love - Gave me Hindi serial style BL complete with a red cloth enveloping the main couple during their fated encounter. It is a lakorn, so that's to be expected. I felt that the pair's romance progressed at an uncharacteristically fast pace given the initial resistance. (In other words, I wanted their romance to progress slowly, like over 400 episodes.) I thoroughly enjoyed the characters including the villains.

14. Healing Thingyan – this BL from Myanmar is no longer available at SKY Production’s YouTube channel. I had a good time watching this BL set in a village in the context of New Year where friends become lovers after much hesitation and an interrupted confession from the year before. My heart was pounding when the couple poured water over the left side because that's where their hearts are at. Also, the religious restriction (I am a little weak to this trope) to physical intimacy as a tactic to skip kiss scene - I would have been irked if it wasn't for the execution - the couple standing under arching bamboo, wearing sarong and acting all sweet. It is set in 2019. Later, I came to know that allegedly (I would appreciate if someone can help me gain more clarity on this matter), SKY production could be a proxy of 7th Sense Creation, an entertainment company cofounded by Kin Thiri Thet, daughter of Senior General Min Aung Hlaing (Commander-in-Chief of Myanmar’s armed forces and Acting President against whom the Prosecutor of the International Criminal Court has filed an application for an arrest warrant, alleging his involvement in crimes against humanity targeting the Rohingya population. (source))

13. The Time of Fever - I'm not very sure if this one can be considered a complete story in itself but even if not, it is immensely satisfying. Age-blind casting shouldn't have worked so well but it did.

12. Gray Shelter - this one made me feel as though I read a nice short story or a novel. It was viscous like honey, the way such types of Korean BL novels (like Picked Up In Winter) tend to be. It had a very masculine vibe with underlying unease of depending and being depended on.

11. Hitochigai kara Hajimaru Koi mo Aru aka Love Can Sometimes Start with the Wrong Person [fansubs available at Drama Otaku] - substitute lover trope but this time the substitute is two-faced. Everyone has their own agenda but this love is a zero-sum game. (I wanted 3p ending though – not possible since one actor is playing both the twins). I loved all the scheming and all those little lies. This one had explicit use of BL terms like seme and uke by a main character.

10. Perfect Propose - workplace that brings workers to tears, corporate slave uke who decides to quit (without starting a job hunt 😔) and an untethered seme who grows hydroponics tomatoes in their balcony. It is adapted from a single volume manga and not a novel, yet it uses every minute it's got to make you feel ALL THAT.

9. High School Return of a Gangster - I was sad that they meant it as a bromance and worried for the future of BL creation in South Korea since it was Number Three Pictures, the company that created popular BL Unintentional Love Story and The Time of Fever, by its own admission struggling financially with limited recovery of production costs (more on this here). When I started watching, I couldn't care any less about their intentions. It was an absolute delight. I was still immersed in the exhilaration of Aavesham (2024) and had wished to see such things in the context of a BL. And this one delivered. I was shipping the underboss with his main lackey (they have history between them and reminded me of the relationship between Ranga and Ambaan) at one point and the next moment, shipping him with his foxy classmate. The series toned down the bully-loves-bullied aspect in the novel, and humanized and contextualized the main bully with his life in the underbelly of the economy, so much so that I felt bad when the bullies were prosecuted (what will happen to Hong Jae-min's sister😟) while gangsters and the rich who hire them went scot-free in the live action. The face-slapping part left a bitter taste in my mouth with the secretary facing the brunt (and the misogyny embedded in the socio-economic fabric that breeds such hatred) while the father isn't retaliated against enough. I read and enjoyed the novel, but face-slapping was even more makjang. It is tough to get accepted in live action form as it is, in South Korea, since the gangster is middle-aged and it is only towards the end of the novel that the characters are finally out of high school, unlike in Mr. Mitsuya's Planned Feeding [fansubs by @isaksbestpillow] with a significant age gap but both are adults and are in a Japanese BL. Gong (공, Korean for seme) (a suspected psychopath, raised under constant surveillance by his father) consciously falls in love with the middle-aged su (수, Korean for uke) inhabiting the body of a high schooler, going as far as visiting his previous residence and pursuing him as one would an old person.

8. My Damn Business - From the first episode, this one had me hooked. Week after week, I was eagerly waiting for those 8 minute long episodes. It acknowledged the manhwa side of BL and hinted at their iconic smut pages (in a way New Employee live action couldn't). It executed stalking horse trope, with Park Min-jae (R. I. P) playing the stalking horse, in a manner that had me giddy with excitement. I also appreciate GND STUDIO for casting darker-skinned actors – in this one and in Fake Buddies. GND studio also has decent BL literacy as is evident from the above-mentioned series. In the third episode, Fake Buddies used the East Asian tradition of representing gay and lesbian relationships through rose (from barazoku (薔薇族)) and lily (from yurizoku (百合族)) respectively to hint at the BL and GL couple.

7. Boku to Boku ga Sukina Kare to, Kimi to aka Me, Him, and You [fansubs available at Drama Otaku]- Honestly, I didn't expect to be this impressed by this one going in. I had such low expectations. I absolutely love the pairing between Higashi Keisuke and Hiroki Iijima, much more than Higashi Keisuke and Nakajima Sota in Ossan no Pants ga Nandatte Ii Janai ka! [fansubs by @isaksbestpillow] and Hiroki Iijima and Inukai Atsuhiro in Our Dining Table. The series played with my heartstrings a lot. I fondly remember several of the scenes and all the emotions they evoked in me. At the end, there was a longing for something, maybe some more time with those characters, especially the model and his uncle.

6. Pit Babe (2023) - omegaverse with enigma - Japan has like 1 manga but through PitBabe I discovered that enigma has become a popular secondary gender in Thai BL space. I love buff uke and I got one paired with a two-faced, loyal loser seme in this one. Super pretty villain, Tony, had me wishing for him to be an omega (I love megalomaniac omegas). I also enjoyed reading the book – every time it rained, that silent phone call, Babe's jealousy towards omegas, the suspense and the pregnancy scare.

5. Love Sea - MAME lifted me out of a BL slump with this one. I also enjoyed the GL pair a lot - there is nothing I like more than performative cuteness/winsomeness (കൊഞ്ചൽ konjal, aegyo, sajiao, kawaii) and benevolent sexism weaponized and employed for emotional manipulation. High EQ manipulators are so rare, my favourite type of yandere (especially when paired perfectly with someone who gets swept up in the moment easily, like Techno). I wonder why MAME doesn't write Janus-faced men that way too. And the men who perform winsomeness such as Tongrak, Kengkla and Tharn, when they do so, have motivations that aren’t Machiavellian enough.

4. Heavens x Candy - OP Pictures is bringing to screens BL that are otherwise tough to get made. This one explored otaku culture, loneliness, family and love through fan pilgrimages, cute and horrifying family dynamics, adult entertainment avenues and love hotels with those transparent walls of bathrooms. It healed my heart after the blow dealt by I Became the Main Role of a BL Drama.

3. Love Syndrome: The Beginning – I didn't expect this but I'm glad to have received it. I want more but now that the director, F Nontapat Sriwichai, has passed away, I don't expect anything anymore. If only his legacy would inspire someone with the ability and mettle. I prefer meriba endings over happy endings. So, when Love Syndrome III was the first to get an adaptation, I was drawn into Yeonim’s universe. The movie focuses on Gear and Night’s relationship and spends relatively less time on Day and Itt. Yet, it is not hesitant to portray the beginning of their relationships, especially the eroticized violence and the morbid conditioning (調教), showcasing exceptional BL literacy.

2. Kubi (2023) – [Fan-subs] I must praise the excellent production quality before anything else. It is about multiple legendary figures in Japanese history such as Oda Nobunaga, Araki Murashige, Akechi Mitsuhide, Mori Ranmaru and Yasuke. The movie has historically accurate ending with specifics changed to fit the narrative. It is based on Honno-ji Incident and Battle of Yamazaki. Those who died then, dies in the movie too but who killed who and why are fictional. (meta here)

1. Takumi-kun Series 6: Nagai Nagai Monogatari no Hajimari no Asa (2023) – this one and Kubi came out last year but I got the chance to watch them only this year. Thanks to fan subs by @furritsubs. I read and re-read those chapters from the novel and I'm still basking in the magic of Shinobu Gotoh's storytelling. First time since Unni R's story and screenplay for Charlie (2015), I got immersed in a love story where the couple barely even interact and the romance unfolds in a thriller-like fashion. While a lot of character motivation gets lost on the way in this live action, most important of them were impossible to miss when snow fluttered around in a bottle, when a delirious Takumi sought Gii in a crowded stairway landing and when Yoshizawa jumped out to stop Takabayashi from hurting. (ongoing meta series here)

-

Here are the top 20 of 2024: live-action BL that I watched and enjoyed this year. I haven't watched everything that came out this year (I'm saving up some for the upcoming year) and did revisit a lot of older stuff (not listed) when there was nothing enjoyable to watch. This year, I realized that I am able to tolerate, if not enjoy, when I'm not too familiar with the content it is adapted from with some exceptions. I don't treat BL like fables or life lessons. I don't bother with moral validation from the choice of media I consume either. But there are certain real-world killjoys in media that may affect my enjoyment, like what happened with The Sign. Please feel free to ask for content warnings.

#japanese bl#thai bl#taiwanese bl#korean bl#bl drama#bl series#Takumi-kun Series 6: Nagai Nagai Monogatari no Hajimari no Asa#Kubi#heavens x candy#Love Syndrome The Beginning#my damn business#love sea the series#Boku to Boku ga Sukina Kare to#Kimi to#pit babe the series#perfect propose#Hitochigai kara Hajimaru Koi mo Aru#high school return of a gangster#the time of fever#Healing Thingyan#gray shelter#century of love#living with him#Love is Better the Second Time Around#cosmetic playlover#unknown the series#love is a poison#love is like a poison#doku koi#takumi kun 6

35 notes

·

View notes

Text

Pamban bridge, Raneshwaram, Tamilnadu, India: Pamban Bridge is a railway bridge that connects the town of Mandapam in mainland India with Rameswaram on Pamban Island. Opened on 24 February 1914, it was India's first sea bridge, and was the longest sea bridge in India until the opening of the Bandra-Worli Sea Link in 2010. The rail bridge is, for the most part, a conventional bridge resting on concrete piers but has a double-leaf bascule section midway, which can be raised to let ships and barges pass through. Wikipedia

118 notes

·

View notes

Text

Pamban bridge Tamilnadu, India: Pamban Bridge is a railway bridge that connects the town of Mandapam in mainland India with Rameswaram on Pamban Island. Opened on 24 February 1914, it was India's first sea bridge, and was the longest sea bridge in India until the opening of the Bandra-Worli Sea Link in 2010. The rail bridge is, for the most part, a conventional bridge resting on concrete piers but has a double-leaf bascule section midway, which can be raised to let ships and barges pass through. Wikipedia

95 notes

·

View notes

Note

I am sliding into your inbox to ask you about historically multicultural australia 👀 what’s one fact/event/etc no one’s asked about yet that you think makes a good story?

I have a million and one ideas for things that no one has asked about that i think are terribly underrated. But I'll roll with a definitely not unknown, but definitely brushed over, simple answer of the topic of "afghan cameleers" in Australia.

While theyre often called "Afghan" in Australian history, they actually came from a variety of countries throughout the Middle East and south Asia. They were predomanently Muslim men, some bringing their families, although other religious minorities did also exist.

The Cameleers, (and their camels) were first brought over to Australia in 1838, although in no form of high numbers until 1858 when they were involved in the Bourke and Wills exploration of the east coast states. As a British colony, there were various high level people in Australia who were aware (from interactions with India and the Middle East primarily) of the benefits of camels in dealing with desert climates.

For over 50 years, camel trains became the primary form of transporting pastoral goods across much of the rural parts of Australia, at the hands of very experienced Cameleers. As a result of this, there was historically a number of towns which became known as "little Asia"s, "little Afghanistan"s or "Ghantowns".

Many of these men are coming to be recognised in modern times as fundamental actors in Australia's modern history. They also married Aboriginal, Chinese, or European women, and often, despite racial and cultural descrimination, became well respected members of local towns, playing important roles in their developments. Many of the men continued to travel back and forth from their home-countries, conducting business on an international scale. At the peak of employment, it is believed that 2000-4000 cameleers were employed in Australia, however recording of this immigration at this time is limited, and it is possible the numbers may have been higher.

However, when Australia introduced the Immigration Restriction Act 1901 (otherwise known as the "White Australia Policy"), many of these men found they were unable to become naturalised citizens of the newly-federated country, and thus unable to return to the communities (and families) that had become their homes. The remaining "afghan" communities dwindled after this. With the increase of railway access to Australia, the need for skilled cameleers died out, and the once valued workers became subject to a lack of employment, and increasing government and community persecution. Much of the men that remained into this time chose to return to their home-countries.

However, some communities remained. The town of Marree in South Australia is the location of the first Mosque in Australia, and is recognised as the longest surviving "Ghan-town" community, and the location of many descendant families. These workers, and their descendants, are also responsible for the construction of Australia's oldest permanent mosque, the Central Adelaide Mosque.

In recent times Australia is beginning to acknowledge important role these men made in the country's modern history, although they are subject to limited discussion, research, and archaeological recognition. And there is still a way to go, especially in making sure that the surviving archaeological sites relating to these communities and workers aren't lost.

#this was such a fun ask#even if it took me forever to get to it#If anyone wants actual references lmk#or just info in general#i wrote most of it from memory so I'll have to go find where my files are saved#but somewhere i have books and journal articles and stuff saved#the benefits of writing a thesis on multicultural heritage#i swear i have sources on everything#in a disorganised file#somewhere#history#Australia#mice answers things#archaeology#they let a mouse do archaeology?

51 notes

·

View notes

Text

A devastating rail crash that left almost 300 people dead has refocused international attention on the importance of railways in the lives of Indians.

Indeed, to many Western observers, images of men and women crammed into overcrowded cars serve as a metaphor for modern India. Take, for example, a report by German newspaper Der Spiegel on India’s population surpassing China’s. Published just weeks before the accident in Odisha province on June 2, the now much-criticized cartoon depicted a shabby Indian train crammed with passengers rushing past a streamlined Chinese train with only two people in it.

Where does this enduring image in the West of Indian railways – and of India – come from? As a scholar of Indian history and author of 2015 book “Tracks of Change: Railways and Everyday Life in Colonial India,” I believe the answers lie in the gigantic infrastructure projects of the 19th century – forged at the intersection of colonial dictates and capitalist demands.

---

A carrier of freight, not people

Railways remain the backbone of passenger traffic in India, transporting some 23 million people daily. In the pre-pandemic 2018-19 financial year, 7.7 billion passenger journeys in India. [...] Yet, when first planned in the 1840s, India’s railways were intended to primarily transport freight and livestock, not people. Indians were thought unlikely to become railway passengers by directors of the English East India Co., a merchant monopoly that gradually annexed and administered large parts of India under U.K. crown control. [...] However, early colonial railway policy was driven by pervasive Orientalist imaginings of a people rendered immobile by poverty, living in isolated villages [...]. The trope interlocked with colonial thinking that railways would foster greater industrialization which in turn would further a capitalist economy. They also aligned with the practical needs of a colonial trading monopoly which needed raw materials for English industries, such as cotton, to be moved swiftly and efficiently from India’s interiors to port towns [...].

---

Despite the doubters, the new Indian railways attracted an increasing number of passengers. The half-million passengers recorded in 1854 when tracks became operational increased to 26 million in 1875. By 1900, annual passenger figures stood at 175 million and then almost trebled to 520 million by 1919-20. By the time of the partition of India in 1947 it had risen to more than 1 billion passenger journeys annually. Indeed, images of overcrowded trains came to epitomize the upheaval of partition, with the rail system used to carry swaths of uprooted peoples across the soon-to-be Pakistan-India border. Third-class passengers, overwhelmingly Indians, comprised almost 90% of this traffic. These escalating figures did not, however, generate a lowering of fares. Nor did they result in any substantial improvements in the conditions of [...] travel. [...]

---

The generally British railway managers seemed disinclined to remedy systematic overcrowding, which included transporting passengers in wagons meant for livestock. Rather, they insisted that such overcrowding was caused by the peculiar habits and inclinations of Indian passengers: their alleged [...] inclination to follow one another “like sheep” into crowded carriages. These attributes were soon rendered into a more public narrative, especially among Western mindsets. Journalist H. Sutherland Stark, writing for the industry publication Indian State Railways Magazine in 1929, stated that though “unversed” in railway administration and traffic control, he knew railway facilities were not the problem. Rather, Indian passengers lacked the mental preparedness, “self-possession” and “method” necessary to travel like “sane human beings.” Stark suggested passenger education as a solution to the perceived problem, making railway travel a tool for “self-composure and mass orderliness.” [...]

---

More than a century later, this depiction endures, though, ironically, it now serves as a foil to understanding contemporary India. In a piece published in The New York Times on March 12, 2005, the author lauded the then-new Delhi metro, emphasizing that it had “none of the chaotic squalor of hawkers and beggars that characterizes mainline railroads in India, nor do desperate travelers hang from the sides of the trains.” As the debate rages on whether safety has taken a back seat to “glossy modernization projects” in India – early analyses suggest signaling failure might have caused June 2, 2023, accident – railways continue to represent India’s history.

In the heyday of empire, they were deemed the technology through which Britain would drag India into capitalist modernity. In 1947, they became a leitmotif for the trauma of the partition that accompanied the independence of India and Pakistan. As the coverage of Odisha accident reminds us, it continues to be a metaphor in the West for evaluating contemporary India.

---

Headline, image, caption, and all text above by: Ritika Prasa. “Overcrowded trains serve as metaphor for India in Western eyes -- but they are a relic of colonialism and capitalism.” The Conversation. 9 June 2023. [Bold emphasis and some paragraph breaks/contractions added by me.]

159 notes

·

View notes

Text

0 notes

Note

What are they doing?

They're express engines. They're discussing the state of the railway (gossiping)

but fun thing, there are only 4 A4s here

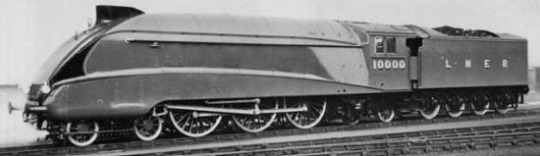

far right isn't an A4, it's Hush Hush

yep, the LNER's rebuilt white elephant. By all acounts I've found, post rebuild she was just a non-standard A4. Although it is worth noting Gresley was considing rebuild the A4s with the boiler fit to no.10000, so he was impressed with that at part of the rebuild at least.

heading left, we have Golden Eagle

Empire of India (my beloved)

Golden Shuttle, who was later renamed Dwight D. Eisenhower and Preserved

and Dominion of New Zealand

#Hazel Asks#Ask Hazel#Hazel Q&A#LNER#London North Eastern Railway#LNER A4#LNER W1#4-6-2#4-6-4#A4 Pacific

36 notes

·

View notes

Text

Railway Parts Manufacturer in India: A Detailed Analysis

Introduction to Railway Parts Manufacturing Industry in India

The railway parts manufacturing industry in India plays a crucial role in supporting the country's vast railway network. India has one of the largest rail networks in the world, making the demand for railway parts consistently high. This industry includes the production of components such as wheels, axles, bearings, and various other essential parts needed to keep trains running smoothly and safely.

The railway sector in India is driven by both the Indian Railways and various private players, ensuring a steady flow of orders for manufacturers. Companies in this sector range from small-scale industries to large, established firms, all contributing to the robust supply chain necessary for the operation and maintenance of the railway network.

Importance of Railway Parts Manufacturing

Railway parts manufacturing is essential for several reasons:

Safety: High-quality parts ensure the safety of trains, passengers, and goods. Faulty components can lead to accidents, causing loss of life and property.

Efficiency: Well-manufactured parts help in the smooth operation of trains, reducing downtime and delays. This efficiency is critical for both passenger and freight services.

Economic Impact: The railway industry is a significant contributor to the Indian economy. The manufacturing of railway parts provides employment to thousands and supports numerous ancillary industries.

Innovation and Growth: Continuous innovation in railway parts manufacturing leads to improved performance and new technologies, contributing to the overall growth of the railways.

However, the industry faces challenges such as fluctuating raw material prices and the need for constant technological upgrades to meet global standards.

Manufacturing Capabilities and Technologies

India's railway parts manufacturing sector boasts a wide range of capabilities and uses advanced technologies to meet the needs of modern railways:

Precision Engineering: Companies use state-of-the-art machinery to produce components with high precision. This ensures that parts meet strict quality standards.

Automation: Many manufacturers employ automated processes to enhance production speed and reduce human error. This includes the use of robotics and computer-controlled machinery.

Material Science: Advanced materials like high-strength alloys and composites are used to manufacture durable and lightweight parts, improving the performance and lifespan of railway components.

Quality Control: Rigorous quality control measures, including non-destructive testing and computerized inspection systems, ensure that only the best parts reach the market.

Despite these advancements, some manufacturers struggle with the high cost of technology adoption and maintaining skilled labor.

Market Trends and Growth Opportunities

The railway parts manufacturing industry in India is evolving with several key trends and opportunities:

Government Initiatives: The Indian government has launched various initiatives, such as "Make in India," to boost local manufacturing. This provides significant opportunities for railway parts manufacturers to expand their operations.

Global Market: Indian manufacturers are increasingly exporting railway parts to international markets, taking advantage of competitive pricing and quality.

Technological Advancements: The adoption of new technologies like 3D printing and IoT (Internet of Things) is creating new opportunities for innovation and efficiency in manufacturing processes.

Sustainability: There is a growing focus on sustainable manufacturing practices, with companies investing in eco-friendly materials and processes.

However, the industry must navigate challenges such as stiff global competition and the need for continuous investment in research and development to stay ahead

Challenges Facing the Industry

Technological Advancements

Staying abreast of technological advancements is crucial for forgings companies in India to maintain competitiveness. Investments in research and development are essential to meet evolving safety and efficiency standards in railway operations.

Infrastructure and Logistics

Logistical challenges can impact the timely delivery of railway components. Improved infrastructure and streamlined logistics processes are necessary to support the industry's growth aspirations.

Government Initiatives and Policies

Make in India Initiative

The Indian government's Make in India initiative has provided a significant impetus to the manufacturing sector, including railway parts manufacturing. Incentives and policies aimed at promoting domestic production have encouraged investments in modernizing manufacturing facilities and adopting sustainable practices.

Regulatory Framework

Adherence to stringent regulatory standards is paramount in the railway industry. Manufacturers must comply with safety and quality regulations set by authorities to ensure the reliability and durability of railway components.

Future Outlook

Emerging Technologies

The adoption of digital technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) is poised to revolutionize the railway parts manufacturing landscape. Predictive maintenance and real-time monitoring solutions will enhance operational efficiencies and reduce downtime.

Sustainable Practices

There is a growing emphasis on sustainability in manufacturing processes. Companies are increasingly adopting eco-friendly practices and materials to minimize their environmental footprint while meeting the demands of a greener future.

Conclusion In conclusion, the railway parts manufacturer in India industry is poised for robust growth driven by technological advancements, export opportunities, and government support. Companies like Bharat Forge Limited, Ramkrishna Forgings Limited, and Happy Forging continue to innovate and excel in producing high-quality components that support the safe and efficient functioning of railway networks globally.

#forging#forging services in india#steel forging services in india#technology#railway parts manufacturing#forgings companies in India

0 notes

Text

The Sign of Four: The Strange Story of Jonathan Small (Part One of Two)

I will split this in two parts as I've got a lot to cover here.

CW for discussions of nasty prison conditions.

The depth of the Thames is about 6.5 metres at low tide in Woolwich, near to the Plumstead Marshes as they were then. However, the river has strong currents and very little visibility, so it would be a risky operation even with 2024 diving technology for some rather small objects.

The rupee originally was a silver coin dating back to ancient times in India, becoming something of a standard currency during the Mughal period. The East India Company introduced paper rupees and while there was an attempt by the British to move their territory to the pound sterling, they soon gave up, minting their own rupees with the British monarch's head on. The currency was also non-decimal. India retained the currency post-independence and went decimal as well.

Mangrove trees are very common in equatorial coastline regions - they can remove salt from the water, which would kill many other trees.

Prisoners set to the Andaman Islands penal colony were forced to work nine to ten hours a day to construct the new settlement, while in chains. Cuts from poisonous plants and friction ulcers from the chains would often get infected, resulting in death.

The convict huts on Ross Island were two-storey affairs, with the bottom as a kitchen and took area, the prisoners sleeping on the upper floor. Designed this way as an anti-malaria measure, they however leaked and the prisoners themselves were constantly damp from the rainfall, offering them little protection from the mosquitoes in any event.

Ague is an obsolete term for malaria; adults experience chills and fever in cycles.

The British would conduct experiments with quinine as a malaria treatment by force-feeding it to the prisoners. This caused severe side effects.

The British would make use of locals as warders, who wore sashes and carried canes. I'd imagine they could probably be quite brutal.

Pershoe is a small town on the River Avon near Worcester. It has a railway station with an hourly service to London, taking just under two hours today.

"Chapel-going" in this context means that the people attended a non-conformist church i.e. not one part of the Church of England.

"Taking the Queen's/King's shilling" was a historical term for joining the armed forces - for the army this was officially voluntary, but sailors could be forcibly recruited, being known as "press-ganged" until 1815. You would be given the shilling upon initial enlistment or tricked into taking it via it being slipped into your opaque beer. You would return the shilling on your formal attestation and then receive a bounty which could be pretty substantial in terms of the average wage, although a good amount of that would then be spent on your uniform. Some enlisted, deserted and then reenlisted multiple times to get multiple payments. The practice officially stopped in 1879, but the slang term remains.

The 3rd Buffs refers to the latter 3rd Battalion, Buffs (East Kent Regiment), a militia battalion that existed from 1760 to 1953, although it effectively was finished in 1919. However, in reality, they did not go to India to deal with the rebellion, instead staying in Great Britain to cover for the regular regiments who did.

The British never formally adopted the Prussian "goose step" instead going for the similar, but less high-kicking, slow march.

The musket would possibly have been the muzzle-loaded Enfield P53, a mass-produced weapon developed at the Royal Small Arms Factory in Enfield. It was itself was the trigger of the Indian Rebellion in 1857 due to the grease used in the cartridges. They would also be heavily used in the American Civil War on both sides, especially the Confederate one as they smuggled a lot of them, with only the Springfield Model 1861 being more widely used. As a result, they are highly sought after by re-enactors. The British used them until 1867, when they switched to the breech-loading Snider-Enfield, many of the P53s being converted.

The crocodile would likely have been a gharial, which mainly eat fish. Hunting and loss of habitat has reduced their numbers massively, with the species considered "Critically Endangered" by the IUCN.

"Coolie" is a term today considered offensive that was used to describe low-wage Indian or Chinese labourers who were sent around the world, basically to replace emancipated slaves. Indentured labourers, basically - something the US banned (except as a riminal punishment) along with slavery in 1865. In theory they were volunteers on a contract with rights and wages, however abuses were rife. Indentured labour would finally be banned in British colonies in 1917.

Indigo is a natural dark blue dye extracted from plants of the Indigofera genus; India produced a lot of it. Today, the dye (which makes blue jeans blue) is mostly produced synthetically.

I have covered the "Indian Mutiny" as the British called it here in my post on "The Crooked Man".

The Agra Fort dates back to 1530 and at 94 acres, it was pretty huge by any standards. Today, much of it is open to tourists (foreigners pay 650 rupees, Indians 50), although there are parts that remain in use by the Indian Army and are not for public access.

"Rajah" meaning king, referred to the many local Hindu monarchs in the Indian subcontinent; there were also Maharajahs or "great kings", who the British promoted loyal rajahs to the rank of. The Muslim equivalent was Nawab. However, a variety of other terms existed. The East India Company and the Raj that succeeded them used these local rulers to rule about a half their territory and a third of the population indirectly, albeit under quite a bit of influence from colonial officials. These rulers were vassals to the British monarch; they would collect taxes and enforce justice locally, although many of the states were pretty small (a handful of towns in some cases) and so they contracted this out to the British. As long as they remained loyal, they could get away with nearly anything.

562 of these rulers were present at the time of Indian independence in 1947. Effectively abandoned by the British (Louis Mountbatten, the last Viceroy, sending out contradictory messages), nearly all of them were persuaded to accede to the new India, where the nationalists were not keen on them, with promises they could keep their autonomy if they joined, but if not, India would not help them with any rebellions. Hyderabad, the wealthiest of the states, resisted and was annexed by force. The ruler of Jammu and Kashmir joined India in exchange for support against invading Pakistani forces, resulting in a war. A ceasefire agreement was reached at the beginning of 1949, with India controlling about two-thirds of the territory; the ceasefire line, with minor adjustments after two further wars in 1965 and 1971, would become known as the Line of Control, a dotted line on the map that is the de facto border and one of the tensest disputed frontiers on the planet.

India and Pakistan initially allowed the princely rulers to retain their autonomy, but this ended in 1956. In 1971 and 1972 respectively, their remaining powers and government funding were abolished.

Many of the former rulers ended up in a much humbler position, others retained strong local influence and a lot of wealth. The Nizam of Hyderbad, Mir Osman Ali Khan was allowed to keep his personal wealth and title after the annexation in 1948 - he had been the richest man in the world during his rule and used a 184-carat diamond as a paperweight, at least until he realised its actual value. The current "pretender", Azhmet Jah, has worked as a cameraman and filmmaker in Hollywood, including with Steven Spielberg.

15 notes

·

View notes

Text

Sujan Industries stands out as a premier railway parts manufacturer in India, offering exclusive railcar components, rubber springs, rubber pads, and more.

0 notes