#Qualitycontrol

Explore tagged Tumblr posts

Text

What Is a Desktop Appraisal and How Does It Work?

As technology continues to transform the real estate and mortgage industry, many traditional processes are being reimagined for efficiency and convenience. One such innovation is the desktop appraisal - a modern alternative to the conventional home appraisal method. For homeowners, buyers and lenders, understanding what a desktop appraisal is and how it works can offer clarity and potentially faster, cost-effective options for property valuation.

Understanding the Basics: What Is a Desktop Appraisal?

A desktop appraisal is a type of real estate valuation where the appraiser evaluates a property's value remotely - without ever setting foot on the premises. Instead of visiting the property in person, the appraiser relies on available digital data sources, such as:

Tax assessments

Multiple Listing Service (MLS) data

Public property records

Floor plans

Aerial or satellite imagery

Renovation permits and building records

By analyzing these records from their office, appraisers can generate a professional opinion of value. Desktop appraisals have become more prominent in recent years, especially during periods when in-person inspections are impractical or unnecessary, such as during the COVID-19 pandemic.

How Does a Desktop Appraisal Differ from Other Appraisal Types?

There are a few different types of appraisals in real estate and each serves a unique purpose:

Traditional Appraisals: The appraiser visits the property in person, inspects the interior and exterior and creates a comprehensive report based on direct observation and comparable sales.

Hybrid Appraisals: A third party (not the appraiser) collects on-site property data, including photos and measurements. The appraiser then reviews the collected data remotely and completes the appraisal.

Desktop Appraisals: The appraiser performs the entire valuation remotely, using only publicly available or third-party data. There is no physical inspection at all.

While a traditional appraisal is the gold standard for accuracy, desktop appraisals are gaining traction for being faster and more scalable, especially in low-risk or high-volume scenarios.

When Are Desktop Appraisals Used?

Desktop appraisals aren’t suitable for every transaction. However, they are an excellent option under the right circumstances. Common uses include:

Mortgage pre-approvals or purchase transactions

Home equity loans or home equity lines of credit (HELOCs)

Portfolio evaluations for banks and investors

Tax appeal support

Insurance valuation purposes

Market analysis for sellers determining listing prices

According to Fannie Mae guidelines, desktop appraisals are typically only allowed for purchase transactions and may come with property-type and loan-to-value (LTV) restrictions.

Advantages of Desktop Appraisals

Faster Turnaround Time: Without the need for scheduling on-site visits, a desktop appraisal can often be completed in a matter of days - sometimes even hours - compared to the one to three weeks it may take for a full appraisal.

Cost-Effective: Desktop appraisals are typically less expensive than traditional ones, with costs often ranging between $75 to $200, compared to $300 to $500 or more for full appraisals.

Less Intrusive: Since no one needs to visit the home, desktop appraisals are more convenient for homeowners who may not want the hassle of coordinating an in-person inspection.

Reduced Bias: With no physical interaction, the likelihood of subjective bias due to a home's appearance, location or occupant decreases.

Scalability for Lenders: Lenders with large loan portfolios can quickly obtain valuations across multiple properties, making this an efficient solution for bulk transactions.

Limitations and Risks of Desktop Appraisals

Limited Data Accuracy: If the data sources are outdated, inaccurate or incomplete, the final appraisal may not reflect the property's true market value.

Not Universally Accepted: Many lenders and loan products still require traditional appraisals. Desktop appraisals may not meet FHA, VA or USDA lending guidelines.

Not Suitable for Complex Properties: Homes with unusual features, major upgrades or located in volatile markets may require more detailed, in-person evaluation.

Regulatory Compliance: Appraisers must ensure that their desktop appraisal complies with USPAP (Uniform Standards of Professional Appraisal Practice), including proper disclosures, data verification and scope of work documentation.

Desktop Appraisal Forms and Tools

To conduct a desktop appraisal, professionals typically use specific appraisal forms. The most common is Form 1004 Desktop, a variant of the Uniform Residential Appraisal Report. In some cases, a Form 70D may be used when fewer reporting requirements apply.

Appraisers may also rely on automated systems such as:

Fannie Mae's Desktop Underwriter® (DU)

Freddie Mac's Loan Product Advisor®

These systems assist underwriters in evaluating credit risk and qualifying borrowers efficiently, using data such as credit scores, income, assets and appraisal results.

Who Can Perform Desktop Appraisals?

Licensed or certified appraisers are the only professionals authorized to perform a desktop appraisal. However, appraiser trainees can complete them under direct supervision, making it a good training tool.

Importantly, the appraiser should have prior experience in the subject’s market area to ensure accurate interpretations of local market conditions.

How to Prepare for a Desktop Appraisal

If you’re involved in a transaction where a desktop appraisal might be used, here are a few steps to ensure a smooth process:

Provide Updated Property Information: Share recent renovation details, photos or available floor plans.

Ensure Public Records Are Correct: Verify that tax records and MLS listings accurately reflect the property’s square footage, lot size, and features.

Be Aware of Eligibility Requirements: Understand that not all properties qualify for desktop appraisals.

Understand the Timeline: While faster than traditional appraisals, the timeline still depends on data availability and the appraiser's schedule.

The Future of Desktop Appraisals

As digital solutions continue to reshape real estate, desktop appraisals are expected to play a larger role, particularly in:

Pandemic or disaster response situations

High-volume markets

Remote property evaluations

Green-lighting fast closings in competitive markets

Government-sponsored enterprises (GSEs) like Fannie Mae and Freddie Mac have already tested the risk performance of desktop appraisals and found them comparable to traditional ones in certain scenarios. As tools and datasets become more robust, expect desktop appraisals to become even more common in mortgage lending.

Final Thoughts

Desktop appraisals are a sign of the digital transformation sweeping across the real estate industry. They offer speed, cost savings and convenience- but they aren’t a one-size-fits-all solution. By understanding how they work, when they’re used, and what their strengths and limitations are, both lenders and borrowers can make informed decisions about property valuation.

At Suntel Global, we specialize in staying ahead of industry trends. Whether you're processing a mortgage, managing real estate portfolios or just exploring modern valuation tools, our expert team is here to support your goals with data-backed insights and scalable solutions.

#SuntelGlobal#suntelglobal#appraisalqcreviewservices#appraisalqcreview#appraisalreview#MortgageLending#AppraisalQC#mortgageprocessing#Outsourcing#residentialappraisalexperts#QualityControl#UnderwritingSupport#trustedappraisalsolutions#appraisalcompliance#valuationreview#appraisalaudit#ResidentialAppraisal#RealEstateSupport#RiskManagement#appraisalreport#homebuyingtips#MortgageSupport#MedicalBilling#TechSolutions#propertyvaluation#USA#UnitedStates#America

2 notes

·

View notes

Text

Boost your product quality and avoid costly errors! Our latest blog post reveals how Pre-Production Inspection (PPI) is your secret weapon for unlocking efficiency and ensuring flawless manufacturing from the start. Don't miss out on these essential insights!

Read more: https://www.the-inspection-company.com/blogs/unlocking-efficiency-pre-production-inspection-quality-manufacturing

2 notes

·

View notes

Text

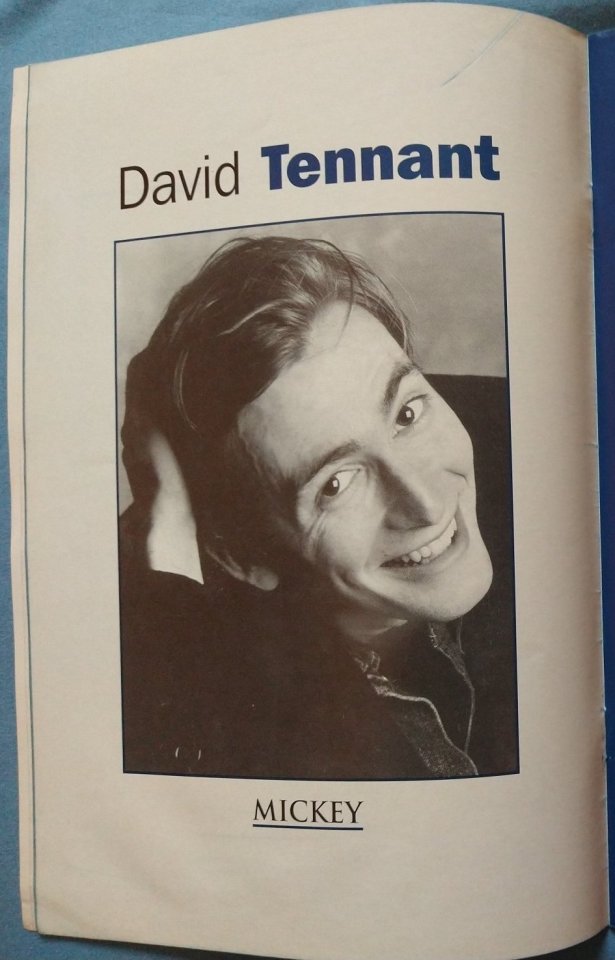

Update: new info about David Tennant's elusive 1996 short film Quality Control!

I've got a few new updates to add to this post I did a while back about a short film David Tennant did in 1996 called Quality Control. If you haven't yet read my first post about this short film, you can read it at the link I posted above. And then come on back!

Firstly, Quality Control was broadcast many more times than I thought it was! I thought it was only broadcast four times between 1996 and 1998, so imagine my surprise when I did some digging and found it had actually broadcast eleven times between 1996 and 1999. Oops!

But by far the biggest update I have on this short is that recently I've discovered why it was made...and by whom!

But first, the updated broadcast list:

BROADCAST DATES:

1996:

4 Jan 1996 - 1:55pm - Channel 4

10 Jun 1996 - 1:55pm - Channel 4

9 Dec 1996 - 2pm - Channel 4

10 Dec 1996 - 1:30pm - Regional S4C

1997:

18 Jun 1997 - 10:45am - Regional S4C

25 Jun 1997 - 10:45am - Channel 4 & Regional S4C

1998:

8 Feb 1998 - 3:30pm - Channel 4

26 Oct 1998 - 1:30pm - Channel 4

6 Nov 1998 - 1:30pm - Regional S4C

1999:

18 Jun 1999 - 1:30pm - Channel 4

29 Jun 1999 - 1:30p - Regional S4C

Of course now that I've found these, I'm aware there may be other broadcast dates I have yet missed. If so, I didn't find any past 2000. But I reserve the right to be mistaken, ha!

Now here's the bigger update: the why, and the who!

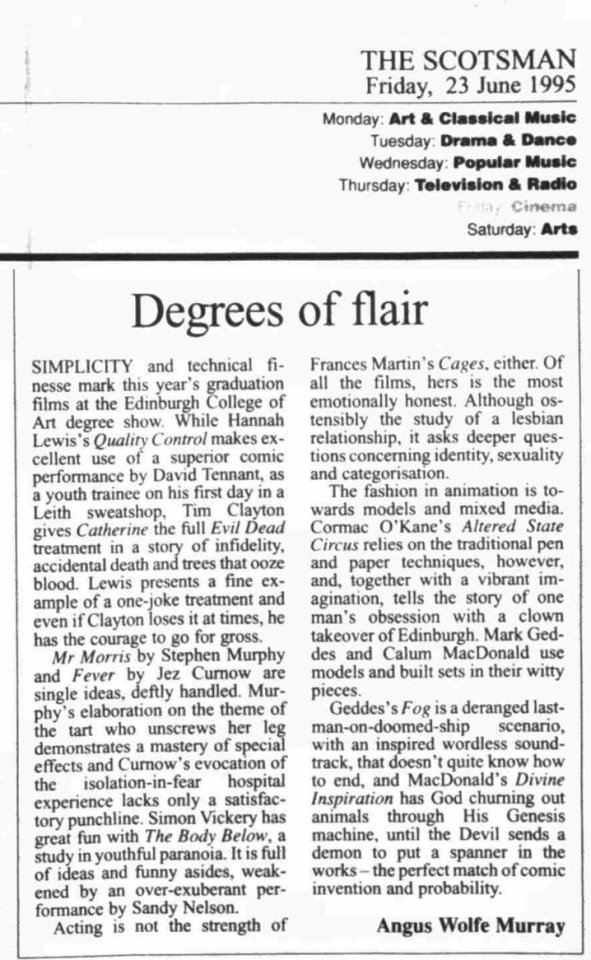

Published 23 June 1995 in The Scotsman, here's the article that broke it wide open for me, and its relevant quote:

"Simplicity and technical finesse marked this year's graduation films at the Edinburgh College of Art degree show. While Hannah Lewis's Quality Control makes excellent use of a superior comic performance by David Tennant as a youth trainee on his first day in a Leith sweatshop…"

WOW, right?

But this new information leads to all sorts of other questions. If this short was initially part of a degree course, how did it make the leap to broadcast? Was it in one of the short film UK production schemes happening at the time which were helping new film creatives launch their ideas: i.e., First Reels, Tartan Shorts, New Found Land?

I'm not sure. At first blush, Quality Control doesn't seem to have been included in a larger broadcast of shorts like Bite and Spaces had been (Bite was shown on the program Don't Look Down on STV, and Spaces was shown on STV as a part of First Reels.) In its broadcast listings, Quality Control is always listed on its own.

The description the article gives on the short is also very interesting. The article says David played a youth trainee on his first day in a Leith sweatshop. But reviews and blurbs of the short's plot in newspapers say he was a job trainee who becomes a quality controller/inspector at a skateboard factory. It seems to me that a sweatshop and a skateboard factory are two very different places, but are they? Was that changed somehow between its showing at the College of Art degree show, or was it just the article writer's bad description?

Blurbs about Quality Control from various newspapers

And just who is Hannah Lewis, its creator? Well my money's on producer Hannah Lewis, who's worked with Morag McKinnon and Colin McLaren. They all met at the Edinburgh College of Art, and had made three shorts together by 1999 (one of which, 'Home', won a BAFTA!) But if she is the right Hannah Lewis, Quality Control isn't listed anywhere on her IMDb. So while I can't be sure she's the short's creator, the time is right, and the place is right. A lot of the dots sure do line up!

Now we know why it was done - and who did it - can we find it? Is it archived somewhere? I haven't found it so far if it is - at least it's not archived at the Moving Image Archive in Glasgow, or at the British Film Institute. But I've yet to check to see if the Edinburgh College of Art may have it.

As far as all the other questions this raises - like how did David get involved with the project (since he was living in London at the time) and if he knew someone who knew someone who...ya know? Pfffft. Your guess is as good as mine! It's one more "I dunno" to add to the pile.

In conclusion, we may be as close as we've ever been to finding out more about David's elusive 1996 short, Quality Control.

I'll keep on searching!

23 notes

·

View notes

Text

AI-powered #computervision systems are transforming how we ensure product quality in manufacturing! They don’t just spot flaws—they prevent them from ever reaching the consumer. What do you think about how #AI is reshaping industries? Drop a comment below!

👉🌐 https://www.pranathiss.com/our-products 👉📧 [email protected] 👉📲 +1 732 333 3037

#MachineLearning#ComputerVision#Manufacturing#QualityControl#Automation#Innovation#TechTrends#FutureOfWork

6 notes

·

View notes

Text

Industrial Batch Ovens: Everything You Need to Know About Their Mechanisms and Operation 🔥

Industrial batch ovens are crucial in modern manufacturing, offering flexible and controlled heating solutions for industries such as aerospace, automotive, food, and pharmaceuticals. Ideal for batch processes like curing, drying, aging, and sterilizing, these ovens provide precise control over temperature, time, and airflow, making them adaptable for diverse production needs.

Ready to optimize your manufacturing process? 🔥 Contact us today to find the perfect industrial batch oven for your needs!

Industrial Batch Ovens: Everything You Need to Know About Their Mechanisms and Operation - Quora

2 notes

·

View notes

Text

【Costco’s Brand Secret: They Even Monitor the Size of Cashews!】

Think Costco is just about bulk products at low prices? Guess what—they’re so meticulous they even control the size of their cashews and the number of peels on canned peaches! This isn’t a joke; it’s part of Costco’s genius in balancing quality and affordability. Today, let’s uncover how Costco’s obsession with details and cost-saving tricks turned them into a retail powerhouse! ✨

Kirkland Private Label: Quality, Not Cheapness

Kirkland isn’t your average low-cost brand—it’s the ultimate combination of “low price and high quality.” Every cashew has to be the same size, and every canned peach needs a precise number of peels. Yep, even your canned fruit gets the luxury treatment at Costco!

Where else can you feel like a fruit connoisseur while shopping for canned peaches? 🍑

Membership Program: A Psychological Masterstroke

"Want to shop here? Pay a membership fee first!" That’s Costco’s clever strategy. Their membership program creates an exclusive VIP feeling, and once you join, you’ll think twice before leaving. After all, if you’ve already paid for membership, might as well shop until it’s worth it, right? 💸

Minimal Product Selection, Minimal Advertising: Less is More

Costco’s philosophy is simple: offer fewer products, but make every item count. No need for aggressive marketing—one free sample session can do the trick. Who could say no to buying after enjoying a slice of pizza or a sip of wine? 🍕🍷

And those large bulk packages? Sure, you’re spending more upfront, but the lower unit cost makes it a smart buy. Suddenly, everyone feels like a wholesale expert: “Buying in bulk just makes sense!” 😎

Local Adaptation: From Rice to Organic Groceries

Costco knows how to win over local markets by tailoring their offerings. In Asia, they stock up on rice and seafood; in Europe, it’s all about organic products. No matter where they go, Costco finds a way to thrive. 🌍

Supply Chain Mastery: Running Lean and Passing the Savings

Costco works directly with manufacturers, cutting out middlemen and slashing distribution costs. No fancy shelves or elaborate displays—just stacks of products in a warehouse. It’s simple and efficient.

This lean operation lets Costco pass the savings directly to you. Brutally straightforward? Absolutely! But it’s why you get more value for your money. 🤝

Making Frugality a Lifestyle

Costco’s success isn’t just about bulk purchases or low prices—it’s a reflection of their obsession with quality. They’ve shown us that affordable goods can also be premium, and if a store cares enough to monitor the size of your cashews, why wouldn’t you trust them?

So, the next time you visit Costco, grab a Kirkland cashew jar or a can of peaches—and don’t forget to enjoy a few free coffee samples along the way. Saving money can be fun, and Costco has made it an art! 🎉

Costco: Meticulous to the max, unbeatable on value! 💪

resourse:https://www.expbravo.com/9918/costco-2.html,https://www.epochtimes.com/b5/24/5/11/n14246352.htm,https://www.daybuy.tw/costco/32992/,https://udn.com/news/story/120915/8173436

6 notes

·

View notes

Text

Save Big on GI Flanges-Get Lowest Prices with Udhhyog

In today's competitive industrial landscape, procurement efficiency is essential, especially when it comes to sourcing critical components like GI flanges. If you're looking for GI flanges at the lowest price, Udhhyog is here to help you save big while ensuring you receive top-quality products.

Understanding GI Flanges

Galvanized Iron (GI) flanges are essential components in piping systems, providing a reliable connection between pipes and fittings. They are favored for their corrosion resistance, which makes them ideal for various applications, including plumbing, water supply, and industrial processes. GI flanges are available in different types, such as slip-on, weld neck, and blind flanges, each serving specific purposes.

Why Choose Udhhyog for Your GI Flanges?

At Udhhyog, we understand the needs of Micro, Small, and Medium Enterprises (MSMEs) across India. We are dedicated to providing high-quality GI flanges at the lowest prices without compromising on quality. Here are a few reasons why Udhhyog stands out as your go-to supplier:

Quality Assurance: Our GI flanges are manufactured to meet international standards, ensuring durability and reliability in your applications. We prioritize quality to provide you with products that stand the test of time.

Competitive Pricing: We leverage our industry expertise and efficient supply chain management to offer the lowest prices for GI flanges in the market. With Udhhyog, you can procure the best without breaking the bank.

Wide Selection: Whether you need slip-on flanges, blind flanges, or any other type, Udhhyog has a comprehensive range of GI flanges to meet your specific requirements.

Fast Delivery: We understand that time is of the essence in your projects. Our streamlined logistics ensure that your orders are delivered promptly, allowing you to keep your operations running smoothly.

Flexible Credit Options: To support MSMEs, we offer a 45-day credit period, helping you manage cash flow effectively while ensuring you have access to the materials you need.

Applications of GI Flanges

GI flanges are commonly used in various industries, including:

Construction: For joining pipes in building projects.

Water Treatment: Ensuring secure connections in water supply systems.

Chemical Processing: Used in pipelines that transport chemicals and other fluids.

HVAC Systems: Connecting ducts and ensuring efficient airflow.

How to Order GI Flanges from Udhhyog

Ordering your GI flanges from Udhhyog is a seamless process. Simply visit our website and browse our range of products. You can easily find GI flanges at the lowest prices by following these steps:

Select Your Product: Choose the type and size of GI flanges you need.

Add to Cart: Once you've made your selection, add the items to your cart.

Checkout: Complete your purchase using our secure payment options.

Delivery: Sit back and relax as we process your order and deliver it to your doorstep.

#GFlanges#GIFlanges#Flanges#FlangeManufacturing#PipingSolutions#IndustrialSupplies#PipeFittings#LowestPrices#AffordableFlanges#SaveBig#CostEffective#BudgetFriendly#Industry-Specific Hashtags#Construction#WaterSupply#ChemicalProcessing#HVAC#IndustrialEquipment#Udhhyog#Engineering#Manufacturing#QualityControl#MSME#SupplyChain

5 notes

·

View notes

Text

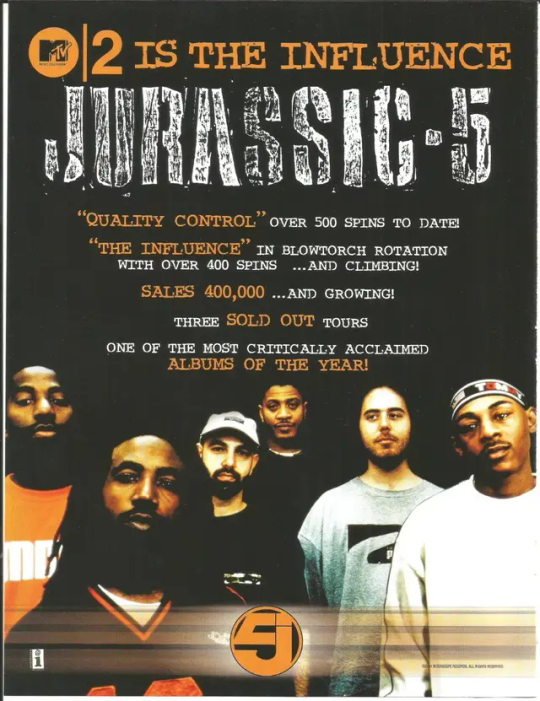

Quality Control, 2000

2 notes

·

View notes

Text

Kanban in action! Visualize your workflow, identify bottlenecks, and improve continuously. 🔍💡

Visit http://vabro.com and try for free!!!!

#Vabro#Agile#Kanban#Lean#ProjectManagement#Kaizen#LeanManufacturing#ContinuousImprovement#TaiichiOhno#ProcessImprovement#QualityControl

2 notes

·

View notes

Text

Ultimate Guide to PCB Testing Methods: Ensuring Quality and Reliability in Your Circuits

In the electronics sector, Printed Circuit Boards (PCBs) are the life-lines of virtually all gadgets that are in use in the modern society. From humble home appliances to gigantic industrial equipment, PCBs are the skeletal framework of hardware organization and connection of circuit elements. It is vital to guarantee the quality and dependability of these fundamental parts – thus enters PCB testing methods. It is our hope that this extensive hand will help identify the most suitable test strategies for PCB testing, why these techniques matter, and how to maximize your circuits’ functionality.

Introduction

Firstly, an increase in the capability of different electronic devices leads to higher necessary requirements to the PCBs used in their production. Performing tests on the PCBs is an essential step in the manufacturing process done to confirm that a given board performs as a unit to the expected levels. This guide aims at explaining various techniques of PCB testing with a view of having a better understanding on how to achieve quality and reliability on the circuits.

Why PCB Testing is Crucial

PCB Testing When it comes to the potential defects on PCBs, there are shorts, opens, and some component placements. They can cause device failure, decline in performance level, and sometimes also pose safety issues. Through high-quality testing regimes, it becomes easier to address problems before they reach the customer, and thus manufacturers will have reliable and efficient products. Key reasons for PCB testing include:

Detecting Manufacturing Defects: Solder bridges, missing and placed in wrong position components, all can be detected in the initial stages easily.

Ensuring Functionality: Ensuring that the PCB does what is wanted and needed when it is in use, and under several conditions.

Quality Assurance: Ensuring that the business meets industry standards, and what clients require of them.

Cost Efficiency: Decreasing the likelihood of rework and recall by identifying possible defects before they get to the customer.

Types of PCB Testing Methods

These are the types of PCB Testing Methods:

Visual Inspection

Technique one as also referred to as the VI or visual inspection is the simplest and basic type of testing done on PCBs. The technique entails inspecting the board with naked eyes for some of the common faults including solder bridges, missing parts, and misalignment issues.

Automated Optical Inspection (AOI)

AOI employs cameras and software algorithms to check PCBs for defects and performs the inspections singly. This method of inspection is far more efficient than the manual inspection and simultaneously versatile enough to identify numerous problems.

X-ray Inspection

Some functions which include examination of features of BPCs that could not be easily inspected include solder joints under components through x-ray inspection. It is especially effective in inspecting defects in BGA (Ball Grid Array) and other various packages as well.

In-Circuit Testing (ICT)

ICT entails applying different voltage across the PCB to checks on the electrical characteristics of the needy part and connections. The use of this method is highly recommended for the identification of functional problems and verification of the circuit’s goodness.

Functional Testing (FCT)

Functional testing evaluates the effectiveness of the PCB pointing to the fact that it can be tested when placed in use. This method enables the certification of that the PCB works as expected under actual environment.

Flying Probe Testing

In flying probe testing, the probes are moved around to test the electrical properties of the created PCB. Lower to medium volume production runs can be made easily by using this technique; hence it is advantageous in this regard.

Boundary Scan Testing

Boundary scan testing also called as JTAG testing extends test circuitry into all the components for testing the connections between them. Although, this method is very efficient for identifying connection problems and faults.

Burn-In Testing

Burn-in testing puts the PCB in a state of operational stress for a long time to capture early-life failures. This aspect makes the method reliable for the long term since it is likely to identify problems that may occur when the equipment is in use for a long time.

Detailed Analysis of Each Testing Method works

These are the detailed analysis of each testing method works:

Visual Inspection

Pros:

Simple and low-cost

Determined to be a system for the reporting of noticeable defects as soon as they are observed.

Cons:

Time-consuming for complex boards

Limited to visible defects

Automated Optical Inspection (AOI)

Pros:

Fast and accurate

Is capable of detecting various kinds of defects.

Non-destructive

Cons:

High initial setup cost

May need to have better settings optimized for specific boards.

X-ray Inspection

Pros:

Examines hidden features

Ideal for complex packages

Cons:

Expensive equipment

Requires skilled operators

In-Circuit Testing (ICT)

Pros:

Thorough electrical testing

High fault coverage

Cons:

Requires custom fixtures

Not for all the boards or servers that you wish to build.

Functional Testing (FCT)

Pros:

Ensures real-world performance

Detects system-level issues

Cons:

Time-consuming

The mathematical test object can involve complex arrangements of test configurations.

Flying Probe Testing

Pros:

Flexible and adaptable

Cost-effective for small batches

Cons:

Slower than ICT for big volumes

Applicable only when the board is specially designed

Boundary Scan Testing

Pros:

Interconnections have high fault coverage.

Said; No need to have physical access to the test points

Cons:

Requires boundary scan-enabled components

Complex setup

Burn-In Testing

Pros:

Identifies early-life failures

Ensures long-term reliability

Cons:

Time-consuming and costly

Perhaps stressful to the board

Choosing the Right Testing Method

The choice of the appropriate method of PCB testing can be influenced by several factors such as the level of complexity of the PCB and the numbers of boards to be tested as well as the actual costs of the testing process and other features. Consider the following when choosing a testing method:

Board Complexity: Great board densities or component placement can be a determinant as to whether one needs AOI or X-ray inspection.

Production Volume: Applications that are characterized by high volumes can be easily facilitated by ICT while the low to medium volume applications may require flying probe testing.

Budget: Both manual inspection and AOI are favorable for various production volumes, while X-ray and ICT are more expensive at the beginning.

Specific Requirements: There are two types of the test, namely Functional Test and Burn-In Test that should be made so as to attain the long term reliability in applications that are critical.

Best Practices for PCB Testing

Using the best techniques in testing PCBs increases the quality and reliability of the circuits that you are working on. Here are some key practices to follow:

Early Testing: It is recommended to carry out the tests when the product is still in its design and manufacturing phase so that problems can be noted earlier before they reach a very catastrophic level.

Automate Where Possible: Use method such as automation to reduce the time and improve on the quality of the testing.

Regular Calibration: It is necessary to check if all the testing equipment used for calibration are accurate.

Comprehensive Coverage: This way, you will be able to ensure that there are no defects that are not tested as the best testing approach combines all types of testing methods.

Document Everything: Ensure that you keep records of the tests performed, the results obtained, as well as any measures taken to correct the breaches.

Common Challenges and How to Overcome Them

These are the common challenges and how to overcome them:

False Positives/Negatives

Automated testing methods maybe good some times, they give you the results that are either positive or negative and this will lead to unnecessary rework or more alarming leaving critical defects unfound. In order to avoid this, make sure that testing algorithms and testing equipment are updated and fine-tuned from time to time.

Component Access

Some of the testing techniques involve handling parts of the circuit and with high density board this can be very difficult. Some of the ways in which testbench implementation can be avoided are as follows Boundary scan testing and X-ray inspection.

High Costs

Some form of testing such as X-ray and ICT testing is often very costly. The effectiveness must come with reasonable prices; try to combine some of the mentioned approaches to cover all the aspects without spending too much money.

Future Trends in PCB Testing

About the future, it can be stated that its trends will be in fact linked to the tendencies in technologies and expectations towards ever higher quality and quantity of tested PCBs. Key trends to watch include:

AI and Machine Learning: Using of intelligence algorithms and machine learning in testing algorithms to enhance the efficiency and the minimization of false negative or false positives.

IoT and Smart Manufacturing: Higher testing flexibility and opportunities for the continuous test process supervision.

Advanced Imaging Techniques: The need for better techniques that would enhance the detection of defects within a printed circuit.

Environmental Stress Testing: More focus in the testing of PCBs under different environmental pressures in order to improve on its longevity.

Conclusion

Quality and reliability of packaged circuits have to be maintained to contribute positively in any electronic equipment. This paper seeks to explain the common testing techniques for PCB so that PCB manufacturers are able to test and see if they are free from defects and if they are functional. This ultimate guide will give you a full insight on the available options in PCB testing that will enable you make the best decision that will give you perfect circuits.

The aim is to help you understand how to attain the best quality of PCBs, what methods are worth following, and what trends drive future improvements, thus contributing to the quality of the final electronic products and, consequently, consumer satisfaction.

#PCBTesting#Electronics#CircuitBoard#QualityControl#Engineering#Technology#Manufacturing#IndustrialDesign#Tech#Innovation

2 notes

·

View notes

Text

Published in Nature Photonics, the UCLA study describes the new focal-plane array, which involves fitting 283,500 nanoantennas in a space smaller than the size of a typical sesame seed. The array is capable of providing spatial amplitude and phase distributions, as well as an imaged object’s temporal and spectral data directly, thereby bypassing the need for raster scanning. The team also utilized a machine learning-trained neural network to enhance the resolution of the captured images in real time.

3 notes

·

View notes

Text

SELECTIVE SOLDER 🔬🔥🔧

Selectively soldering components to printed circuit board (PCBs), while avoiding heat-sensitive parts - ensuring that only the desired areas are soldered, minimizing potential damage to the components and making high quality finished boards!

#adafruit#electronics#selective#solder#selectivesolder#pcb#opensource#opensourcehardware#manufacturing#factory#electronicsproduction#qualitycontrol#heatsensitive#componentprotection#circuitboards#innovation#precisionengineering#techmanufacturing

14 notes

·

View notes

Text

David Tennant's Obscure Short Films: 1996's Quality Control

I'm back for a short(er) little David Tennant in Obscure Performances post today. Let's have a teeny-tiny chat about another rarity of David's, shall we? - a short film he did in 1996 called Quality Control. And when I say this is a rarity, believe me….it's a rarity.

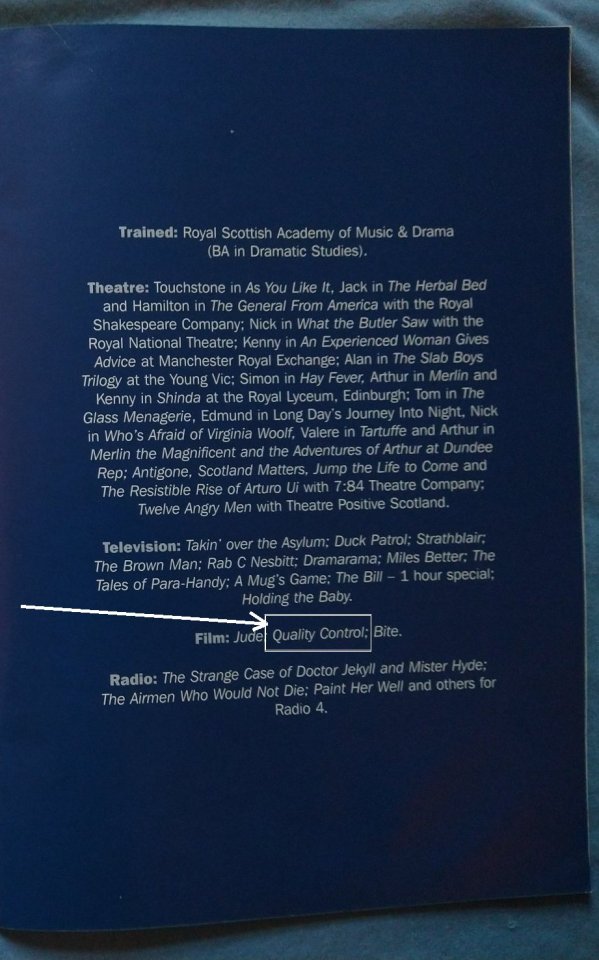

I've at least been able to confirm David acted in this short film, for he mentions it as a film credit in two places: the 1996 programme for The Herbal Bed, and the 1997 programme for Hurly Burly - as evidenced by this cast listing of his from my Hurly Burly programme:

Quality Control has very little to no presence on the Internet, and there are only a few mentions of its existence. The first one I've been able to track which attributed the short to David was from a "David Tennant Fact Of The Day" post from May 2012.

The second mention is from the British Film Institute (BFI). If you study this notation, you'll notice another interesting detail: unlike many other works, the BFI does NOT hold any film or video materials relating to Quality Control. So they don't have a copy!

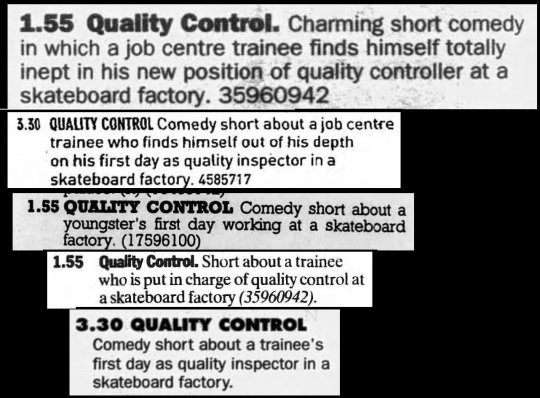

The BFI describes the film as a "comedy in which a job centre trainee finds himself totally inept in his new position of quality controller at a skateboard factory." But I hoped I might find a few other clues from another contemporary source: newspapers. So that's where I went!

All of the descriptions said Quality Control was a 20-minute short comedy - but I also learned it was the trainee's first day on the job, too. One can also assume (and I certainly do) David plays the role of the trainee. Here are some various listings I found:

What's very interesting, though, is something the BFI doesn't list: Quality Control was also re-broadcast two years later in 1998! The 'Fact of The Day' I mentioned earlier clued me into that detail, and that tidbit was invaluable in my search for mentions of the short. Why? Because this one's a real tough one to search. David's never mentioned in any printed synopsis, and seriously…just try to do a search using only the words, "Quality Control." It's an utter nightmare!

But knowing what I knew, I was able to add to the information the 'Fact Of The Day' had provided. Quality Control originally aired at 1:55p on 10 Jun 1996 on BBC Channel 4. In 1998, Channel 4 aired it two more times: on 8 Feb 1998 at 3:30p, and at 1:30p on 26 Oct 1998. It was also repeated regionally on S4C at 1:30p on 6 Nov 1998.

Its repetition in 1998 has intrigued me. It implies the BBC kept a copy of the short from 1996 to its re-air dates in 1998. The BFI listing for the short says it doesn't have a copy in its archives, but unless the BBC has subsequently erased it, a copy of that short might still exist. Somewhere. I'd love to find it, as it's one of the few things David did during that time I haven't seen. So we have no screenshots. But we know he did it. And who knows if the BBC has it in their archive.

But you know, maybe someone's got it recorded somewhere on an old Betamax tape.

34 notes

·

View notes

Text

The Role of Biofilm Inspection in Food and Beverage Industry Safety

Biofilm, a slimy layer of microorganisms, poses significant challenges in the food and beverage industry. These microorganisms adhere to surfaces, forming resilient colonies that can contaminate products, compromise hygiene, and lead to costly recalls. Effective biofilm inspection services are thus crucial for maintaining high safety standards in this sector.

The presence of biofilm can be particularly problematic in processing environments where moisture and nutrients provide an ideal breeding ground. Regular and thorough biofilm inspection services help identify these hidden threats before they escalate. Utilizing advanced technologies, such as Bioscan LTD's Biodtex LAMP, ensures accurate detection of biofilm even in hard-to-reach areas, safeguarding product integrity and consumer health.

Vessel crack test inspection services play a vital role in this context. Cracks and crevices in processing equipment are prime locations for biofilm formation. By conducting regular vessel crack test inspection services, companies can detect structural weaknesses that may harbor biofilm, allowing for timely maintenance and cleaning. This proactive approach not only prevents contamination but also extends the lifespan of the equipment, ensuring smoother operations and reduced downtime.

Tank inspection services are equally essential. Tanks used for storage and fermentation in the food and beverage industry are susceptible to biofilm accumulation. Implementing routine tank inspection services helps in identifying biofilm presence and ensuring thorough cleaning procedures. This is critical for maintaining the purity and quality of the products, preventing spoilage, and adhering to stringent industry regulations.

In conclusion, maintaining food and beverage safety is paramount, and effective biofilm inspection services, vessel crack test inspection services, and tank inspection services are integral to this process. By leveraging cutting-edge technology and regular inspections, companies can mitigate risks, uphold quality standards, and ensure the safety of their products. For reliable and comprehensive inspection solutions, Bioscan LTD stands as a trusted partner in the industry.

For more information, visit Bioscan LTD.

#BiofilmInspection#FoodSafety#BeverageSafety#BiofilmDetection#VesselCrackTest#TankInspection#FoodAndBeverageIndustry#IndustrialHygiene#ContaminationPrevention#BioscanLTD#QualityControl#EquipmentMaintenance#FoodProcessingSafety#MicrobialControl

1 note

·

View note

Text

#SurfaceMetrology#PrecisionMeasurement#MetrologyTechnology#ManufacturingAdvancements#QualityControl#Industry4.0#TechnologyInnovation#RoughnessMeasurement#ContourMeasurement#ManufacturingIndustry#Automation#DigitalMeasurement#IndustryTrends#QualityAssurance#MetrologyStandards#EfficiencyImprovement#ManufacturingQuality#FutureTechnology#SurfaceProfiling#SmartManufacturing

2 notes

·

View notes

Text

All About Flange-Udhhyog

Q1: What are the different types of flanges, and how do I choose the right one for my application?

A1: There are several types of flanges, including:

Weld Neck Flanges: Designed for high-pressure applications and welded to the pipe, providing a strong connection.

Slip-On Flanges: Slide over the pipe and are welded both inside and outside, ideal for low-pressure applications.

Blind Flanges: Used to close the end of a piping system, preventing the flow of fluids.

Socket Weld Flanges: For small-diameter pipes, where the pipe is inserted into the flange and welded.

Lap Joint Flanges: Used with a stub end, allowing for easier disassembly.

To choose the right flange, consider the application pressure, temperature, pipe size, and the type of connection required.

Q2: How do flange standards vary by country, and what should I know about them?

A2: Flange standards can vary significantly between countries. For instance:

ANSI (American National Standards Institute): Commonly used in the USA, focusing on pressure ratings and dimensions.

DIN (Deutsches Institut für Normung): Widely used in Europe, specifying metric dimensions and pressure ratings.

JIS (Japanese Industrial Standards): Used in Japan, similar to ANSI but with different specifications.

When selecting flanges, be aware of the applicable standards in your region to ensure compatibility with existing piping systems.

Q3: What materials are commonly used for flanges, and what are their advantages?

A3: Common materials for flanges include:

Mild Steel (MS): Cost-effective and suitable for low-pressure applications.

Stainless Steel: Corrosion-resistant and ideal for high-pressure and high-temperature applications.

Carbon Steel: Offers strength and durability for industrial applications.

Alloy Steel: Used for specialized applications requiring high strength and resistance to wear and corrosion.

The choice of material should be based on the operating environment, pressure, temperature, and the medium being transported.

Q4: How can I prevent leakage in flange connections?

A4: To prevent leakage in flange connections:

Use Quality Gaskets: Select the right gasket material based on the application and ensure proper installation.

Ensure Proper Alignment: Misalignment can lead to leaks; ensure that flanges are correctly aligned before tightening.

Tighten Bolts Uniformly: Follow the manufacturer's specifications for bolt torque to ensure even pressure distribution.

Regular Maintenance: Inspect flanges periodically for wear or damage and replace gaskets as necessary.

Q5: What are the most common applications for MS flanges in various industries?

A5: MS flanges are commonly used in:

Oil and Gas: Connecting pipelines and equipment.

Water Supply: Used in municipal and industrial water systems.

Construction: In various structural applications for strength and support.

Manufacturing: In machinery and equipment to facilitate fluid flow and pressure control.

Q6: How does the price of flanges fluctuate in the current market?

A6: The price of flanges can fluctuate based on several factors:

Material Costs: Increases in raw material prices can lead to higher flange costs.

Supply Chain Issues: Disruptions in manufacturing or transportation can affect availability and pricing.

Market Demand: Increased demand in specific industries can drive prices up.

Regularly monitoring market trends and supplier prices can help you anticipate changes.

Q7: What are the benefits of using stainless steel flanges over mild steel flanges?

A7: Benefits of using stainless steel flanges include:

Corrosion Resistance: Stainless steel can withstand harsh environments, making it suitable for chemical and coastal applications.

Strength and Durability: Offers better strength-to-weight ratios and longevity compared to mild steel.

Aesthetic Appeal: Stainless steel has a polished finish that is visually appealing in exposed applications.

However, stainless steel flanges are typically more expensive than mild steel flanges.

Q8: How do I determine the right flange size for my piping system?

A8: To determine the right flange size:

Measure the Pipe Diameter: Determine the outer diameter of the pipe.

Check Pressure Ratings: Ensure that the flange matches the pressure rating of the piping system.

Refer to Standards: Use ANSI, DIN, or other relevant standards to find the corresponding flange dimensions for your pipe size and pressure requirements.

Q9: What is the significance of flange pressure ratings?

A9: Flange pressure ratings indicate the maximum pressure a flange can withstand at a specified temperature. They are essential for:

Safety: Ensuring that the flange can handle the operational pressures without failing.

Compatibility: Matching flanges with piping and equipment rated for similar pressures prevents leaks and accidents.

Understanding pressure ratings helps in selecting appropriate flanges for your application.

Q10: Are there any recent advancements in flange manufacturing technology?

A10: Recent advancements in flange manufacturing technology include:

3D Printing: Allowing for rapid prototyping and customized designs.

Improved Materials: Development of new alloys that enhance corrosion resistance and strength.

Automation: Use of automated machinery for precision and efficiency in flange production.

Quality Control Technologies: Enhanced inspection techniques using non-destructive testing methods to ensure product integrity.

These advancements contribute to better quality, reduced production times, and cost savings in flange manufacturing.

#Flanges#MSFlanges#FlangeManufacturing#PipingSolutions#IndustrialEquipment#PipingIndustry#FlangeDesign#FlangeStandards#FlangeApplications#MechanicalEngineering#MildSteel#StainlessSteel#CarbonSteel#AlloySteel#OilAndGas#Construction#WaterSupply#Manufacturing#Engineering#ManufacturingInnovation#IndustrialSupply#QualityControl#SafetyFirst#TechAdvancements

5 notes

·

View notes