#Pvc Cable Duct

Explore tagged Tumblr posts

Text

#Wiring Duct#PVC Channel#Solid Cable Duct#PVC Wiring Channels#Cable Ducts#Cable Duct Cutter#Wiring Ducts Narrow Slot#Wiring Ducts Wide Slot#Wiring Ducts Un-Slotted#Cable Trunking Wide Slot#Cable Trunking Narrow Slot#Cable Tray Wide Slot#Cable Tray Narrow Slot

1 note

·

View note

Text

The Power of Flexibility: The Remarkable Benefits of Installing Flexible Bollard Lane Dividers

In today's fast-paced world, traffic management has become a critical concern for cities and municipalities. One innovative solution gaining popularity is the installation of Flexible Bollard lane dividers Auckland NZ. These sturdy and adaptable barriers offer a range of benefits that go beyond simple traffic control. In this article, we'll explore the remarkable advantages of incorporating flexible bollard lane dividers into urban infrastructure, from increased safety to enhanced urban aesthetics.

Enhancing Safety and Accident Prevention

The foremost benefit of flexible bollard lane dividers lies in their ability to enhance road safety. These dividers create a clear visual separation between lanes, reducing the chances of accidental lane changes and resulting collisions. Thanks to their flexible design, bollard dividers absorb impact forces, minimizing vehicle damage and protecting drivers and passengers from severe injuries. In high-risk areas prone to accidents, such as sharp curves or intersections, these dividers act as a reliable physical barrier, preventing vehicles from straying into opposing traffic lanes. You can use Utility Markers Christchurch for marking.

Improving Pedestrian Safety

Flexible bollard lane dividers not only prioritize the safety of motorists but also benefit pedestrians. By demarcating dedicated pedestrian areas, such as crosswalks or sidewalks, these dividers help establish a safer environment for those on foot. This delineation enhances pedestrian visibility and encourages drivers to remain within their designated lanes, reducing the likelihood of accidents involving pedestrians. Consequently, communities can enjoy improved walkability, encouraging healthier lifestyles and a greater sense of security for their residents.

Efficient Traffic Management

When it comes to traffic management, flexibility is key. Traditional lane dividers, such as concrete barriers, can hinder road maintenance, emergency response, and event planning. In contrast, flexible bollard lane dividers can be easily removed and reinstalled, providing unparalleled versatility. You can order Pvc Cable Duct New Zealand in bulk from our website.

They allow for efficient traffic flow adjustments, facilitating road repairs, event setups, or emergency access when needed. This flexibility ensures minimal disruptions and maximizes the capacity of road networks, leading to smoother traffic patterns and reduced congestion.

Enhancing Urban Aesthetics

Beyond their practical advantages, flexible bollard lane dividers contribute to enhancing the visual appeal of urban landscapes. With their sleek design and customizable options, these dividers seamlessly integrate with the existing architecture, adding a touch of modernity to city streets.

0 notes

Text

High-Performance Fiber Optic Cables for the FTTH Access Network Application

With the continuous development of FTTH (Fiber-to-the-Home) network construction, there will be more and more new varieties of fiber optic cables for the FTTH access network application. This article will discuss the three types of fiber optic cables for FTTH in detail.

Fiber Optic Cables for FTTH Access Network

FTTH is an access network architecture that allows deploying xPON technology to provide high speeds of Internet access downstream (from the network to the end-user) and upstream (from the user to the network) over optical fiber from the operator’s switching equipment to an individual home. The main fiber optic cables implemented to build up the FTTH access network are the FTTH feeder cable, FTTH distribution cable, and FTTH drop cable.

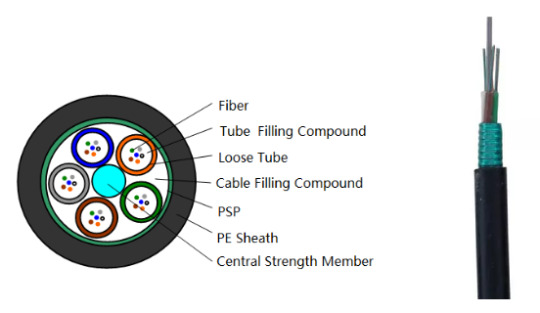

FTTH Feeder Cable

FTTH feeder cable, such as stranded loose tube light-armored cable connects the central office/hut to the fiber distribution hub (FDH). It is ideal for duct and aerial installations. This cable has good mechanical and temperature performance, high hydrolysis resistance, high strength loose tube, good crush resistance and flexibility, high tensile strength ensured by steel wire, and good moisture-proof ensured by PSP (steel tape).

Stranded loose tube light-armored cable construction is that 250um fibers are positioned in a loose tube which is made of high modulus plastic and filled with a water-resistant filling compound; A steel wire, sometimes sheathed with polyethylene (PE) for cable with high fiber count, locates in the center of core as a metallic strength member; Tubes are stranded around the strength member into a compact and circular cable core; The PSP is longitudinally applied over the cable core which is filled with the filling compound to protect it from water ingress; The cable is completed with a PE sheath.

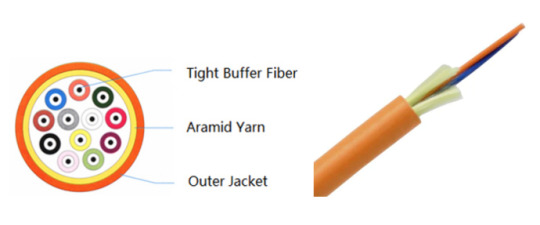

FTTH Distribution Cable

FTTH distribution cable connects the FDH to the fiber access termination (FAT). FTTH distribution cable, such as indoor distribution cable uses φ900um tight buffer fibers as an optical communication medium and aramid yarn strength member. It is compliant with a PVC or LSZH jacket. Generally, FTTH distribution cable is available in fiber counts ranging from 2 to 144 fibers. It has excellent stripping performance of tight buffer fiber, good tensile strength, and small size. FTTH distribution cable is used in indoor /outdoor and backbone cable distribution in building applications.

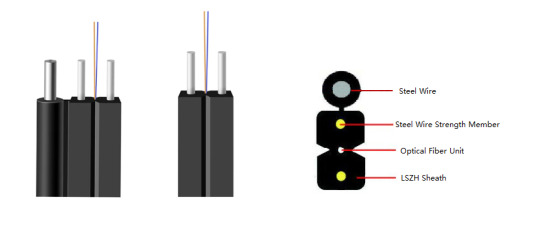

FTTH Drop Cable

FTTH drop cable is used between the fiber terminal and the building or home. It is ideal for aerial, direct buried, and ducted installations. FTTH drop cable has good crush resistance ensured by parallel strength member, good tensile strength ensured by single steel wire, low smoke, small diameter, zero halogen sheath, simple structure, lightweight, and high practicability.

FTTH drop cable construction is that the optical fiber unit is positioned in the center. Two parallel steel wire strength members are placed at the two sides; A steel wire as the additional strength member is also applied. The cable is completed with an LSZH sheath.

Things to Consider When Choosing Fiber Optic Cables for FTTH Access Network

When choosing the three fiber optic cables for the FTTH access network, there are some general elements that you should pay attention to that influence the method of cable deployment.

Type of FTTH Architecture: The FTTH architecture implemented will influence the data rate and the optical power budget, which will affect the choice of fiber optic cable for the FTTH access network.

Fiber Type of Existing Network: If an existing network is expanded, you must add hardware that can integrate seamlessly with the existing infrastructure.

Installation Environment: No matter the indoor or outdoor applications, there are always different environments where the cable will be installed. For instance, in rugged spaces where your cable may suffer damage, such as basements or in conduits sharing space with electrical or other wirings, you may choose a rugged sheathed cable that is flexible and crush resistant.

Conclusion

FTTH allows a fiber optic cable to be laid from the provider’s equipment directly to the user’s home. Choosing the correct fiber optic cables for FTTH access networks will directly affect network reliability, operational flexibility, and the economics of FTTH deployment.

Sun Telecom specializes in providing one-stop total fiber optic solutions for all fiber optic application industries worldwide. Contact us if you have any needs.

#suntelecom#fiberoptic#telecommunications#fttx#telecomengineering#cabling#osp#fiberopticcable#catv#telecomconsult

3 notes

·

View notes

Text

Building and Construction Tapes Market: Regional Growth Trends

The Building and Construction Tapes Market is expanding due to the increasing demand for effective bonding, sealing, and insulation solutions in the construction industry. These tapes play a vital role in enhancing durability, efficiency, and aesthetics across residential, commercial, and industrial projects.

Read Complete Report Details of Building and Construction Tapes Market: https://www.snsinsider.com/reports/building-and-construction-tapes-market-2890

Market Segmentation

By Product

Masking Tapes

Commonly used for temporary protection during painting or finishing.

Features: Easy removal without residue, versatility.

Double-Sided Tapes

Ideal for bonding materials without visible fasteners.

Features: Strong adhesion, aesthetics, durability.

Duct Tapes

Multi-purpose tapes for sealing, repairing, and waterproofing.

Features: High strength, moisture resistance.

Others

Specialty tapes like electrical, reflective, or safety tapes.

By Backing Material

Paper

Lightweight and easy to tear.

Applications: Masking and general-purpose uses.

Foil

Offers high resistance to heat and moisture.

Applications: HVAC and roofing.

Polypropylene (PP)

Flexible, lightweight, and cost-effective.

Applications: Packaging and bonding.

Polyethylene (PE)

High durability and weather resistance.

Applications: Outdoor and heavy-duty tasks.

Foam

Provides cushioning and soundproofing.

Applications: Glazing and insulation.

Polyvinyl Chloride (PVC)

Known for toughness and weather resistance.

Applications: Electrical and plumbing.

PET (Polyethylene Terephthalate)

High tensile strength and thermal stability.

Applications: Specialty bonding.

Others

Includes materials like fabric and rubber-based tapes.

By Application

Building Envelope

Tapes for air sealing and water protection.

Flooring

Used for carpet and tile installation.

Windows and Roofing

Tapes for glazing, sealing, and waterproofing.

Doors, Walls & Ceilings

For bonding, insulation, and soundproofing.

HVAC and Electrical

Tapes used for duct sealing and cable management.

Others

Applications like protection and repair.

By Function

Glazing

Tapes for securing and sealing glass panels.

Bonding

Adhesive tapes replacing mechanical fasteners.

Soundproofing and Insulation

Tapes with acoustic and thermal insulation properties.

Cable Management

Tapes for organizing and securing electrical wiring.

Protection

For surface protection during construction.

By Distribution

Direct Sales

Sales directly to contractors, builders, or end users.

Third-Party

Via distributors, retailers, or e-commerce platforms.

By End Use

Commercial

Office buildings, shopping malls, and institutions.

Industrial

Factories, warehouses, and specialized facilities.

Residential

Houses, apartments, and other living spaces.

By Region

North America

High demand due to renovation and green building trends.

Europe

Focus on energy-efficient and sustainable construction.

Asia-Pacific

Booming construction sector due to urbanization and infrastructure development.

Latin America

Growth driven by increasing investments in housing and commercial projects.

Middle East & Africa

Expansion of commercial and industrial infrastructure.

Market Trends and Opportunities

Sustainability Focus: Growing adoption of eco-friendly tapes using recyclable or biodegradable materials.

Advanced Adhesives: Development of high-strength and weather-resistant adhesive formulations.

Smart Tapes: Incorporation of sensors or functional coatings for advanced applications.

Customization: Tailored tapes to meet specific construction needs.

Market Outlook

The Building and Construction Tapes Market is expected to grow steadily through 2031, driven by urbanization, infrastructure investments, and the push for sustainable construction practices. With innovations in materials and adhesive technologies, the market is poised to offer enhanced performance and versatility across applications.

About Us:

SNS Insider is a global leader in market research and consulting, shaping the future of the industry. Our mission is to empower clients with the insights they need to thrive in dynamic environments. Utilizing advanced methodologies such as surveys, video interviews, and focus groups, we provide up-to-date, accurate market intelligence and consumer insights, ensuring you make confident, informed decisions.

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

0 notes

Text

Strength Meets Stability: Upgrade Your Duct System with HDPE Spacers

In the world of infrastructure and utility management, the efficiency and longevity of duct systems are crucial. These systems, responsible for housing essential cables and pipelines, need to be built with precision, durability, and cost-efficiency in mind. One material that is redefining the standards of duct system construction is High-Density Polyethylene (HDPE). In particular, HDPE spacers are gaining popularity due to their unique combination of strength, flexibility, and affordability. This article explores why HDPE spacers are becoming the go-to choice for upgrading duct systems, discusses their benefits, and provides insights into pricing, suppliers, and installation procedures.

The Evolution of Duct Spacers

Traditionally, duct systems have relied on materials like steel, concrete, and PVC for support and stability. However, these materials have several limitations, such as susceptibility to corrosion, high weight, and difficulty in handling and installation. HDPE duct spacers have emerged as a superior alternative, offering a range of benefits that address these challenges. Made from high-density polyethylene, a thermoplastic polymer known for its high strength-to-density ratio, HDPE duct spacers provide excellent resistance to chemicals, moisture, and mechanical stress. This evolution in material choice is driving a transformation in how duct systems are designed and maintained.

Why Choose HDPE Spacers?

The decision to upgrade a duct system with HDPE spacers is often motivated by several compelling advantages. Firstly, HDPE duct spacers offer unmatched durability. Unlike traditional materials, HDPE does not corrode, rust, or degrade easily over time. This makes it an ideal choice for environments where the duct system is exposed to harsh weather conditions or corrosive elements.

Secondly, HDPE spacers are incredibly lightweight compared to their metal or concrete counterparts. This lightweight nature significantly reduces transportation and handling costs, making HDPE duct spacer installation more cost-effective. Additionally, their flexibility allows for easy manipulation during installation, reducing labor time and effort.

Another critical benefit is the material's strength. HDPE spacers are designed to withstand significant loads and pressure, providing robust support for duct systems. This strength, combined with flexibility, ensures that HDPE spacers can absorb and dissipate stress, preventing damage to the ducts and ensuring long-term stability.

Finally, HDPE spacers are environmentally friendly. They are often made from recycled materials and can be recycled at the end of their lifespan, reducing the environmental impact associated with duct system maintenance and upgrades.

Pricing Dynamics

One of the key considerations when choosing materials for duct systems is cost. HDPE duct spacer price can vary depending on several factors, including the size and complexity of the spacer, the supplier, and the quantity ordered. Generally, HDPE spacers are competitively priced compared to traditional materials like metal and concrete, especially when considering their durability and low maintenance requirements.

The cost savings are not just limited to the initial purchase price. HDPE spacers’ lightweight nature reduces transportation costs, and their ease of installation can lower labor costs. Furthermore, their longevity means reduced replacement and repair costs over time. When factoring in these aspects, the overall cost-effectiveness of HDPE spacers becomes evident, making them a wise investment for any duct system upgrade.

Finding the Right Suppliers of HDPE Spacer

Selecting the right HDPE duct spacer supplier is crucial to ensure you receive high-quality materials that meet your specific needs. A reputable supplier will offer a range of HDPE spacers in different sizes and configurations to accommodate various duct system designs. They will also provide detailed product specifications, including load-bearing capacities, material composition, and compliance with industry standards.

When evaluating HDPE duct spacer suppliers, consider their experience in the industry, customer reviews, and the breadth of their product offerings. Some suppliers may also offer customization options, allowing you to order spacers tailored to your project's unique requirements. Additionally, look for suppliers who provide technical support and guidance on installation procedures to ensure the success of your duct system upgrade.

HDPE Spacer Installation: Tips and Best Practices

The installation of HDPE duct spacers is straightforward, but there are several best practices to ensure optimal performance and longevity. First, it's essential to prepare the duct trench properly. The trench should be free of debris and adequately compacted to provide a stable foundation for the spacers and ducts.

During HDPE duct spacer installation, spacers should be placed at regular intervals to distribute the load evenly and prevent sagging or displacement of the ducts. It’s also crucial to secure the spacers properly to prevent them from shifting during backfilling. HDPE spacers are designed to interlock or clip together, simplifying the installation process and ensuring a stable and secure arrangement.

Furthermore, while HDPE spacers are resistant to most chemicals and environmental factors, it's important to follow the manufacturer's guidelines regarding exposure to extreme temperatures or specific chemicals that could affect the material’s integrity. Adhering to these best practices will maximize the benefits of HDPE spacers, ensuring a robust and long-lasting duct system.

Conclusion

Upgrading duct systems with HDPE spacers is a smart choice for anyone looking to enhance the durability, stability, and cost-efficiency of their infrastructure. The unique properties of HDPE, including its strength, flexibility, and resistance to environmental stressors, make it an ideal material for duct system components. As more industries recognize the benefits of HDPE duct spacers, their adoption is likely to increase, setting a new standard for duct system construction and maintenance.

Whether you’re planning a new installation or upgrading an existing system, considering HDPE duct spacers could provide the strength and stability you need, combined with the peace of mind that comes from choosing a reliable, cost-effective solution. With the right supplier and adherence to best practices during installation, HDPE spacers can significantly improve the performance and longevity of your duct systems, ensuring they meet the demands of today and tomorrow.

Frequently Asked Questions

1. What are the primary advantages of using HDPE duct spacers over traditional materials? HDPE duct spacers offer several advantages, including superior durability, resistance to corrosion and chemical exposure, lightweight for easy handling and installation, and cost-effectiveness due to lower transportation and maintenance costs. Additionally, HDPE spacers are environmentally friendly, often made from recycled materials, and can be recycled at the end of their lifespan.

2. How does the HDPE duct spacer price compare to other materials like metal or concrete? The price of HDPE duct spacers is generally competitive with traditional materials. While the upfront cost may be similar or slightly higher, the overall cost-effectiveness of HDPE spacers becomes apparent when considering reduced transportation costs, easier installation, and lower maintenance and replacement costs over time. HDPE spacers' long-term durability can result in significant cost savings compared to metal or concrete alternatives.

3. Can HDPE duct spacers be used in all types of duct systems? Yes, HDPE duct spacers are versatile and can be used in various duct systems, including those for electrical, telecommunications, and water pipelines. Their flexibility and strength make them suitable for both underground and above-ground installations, and they can be customized to fit specific system requirements.

0 notes

Text

Upgrade Your Connectivity with High-Quality SDI Cables for Unmatched Performance

Achieve top-notch performance with our premium SDI cables. Featuring 0.6/1kV plain annealed stranded copper, XLPE X90 insulation, and a durable PVC 5V90 sheath, these cables ensure reliable connectivity. Perfect for buildings and industrial plants, they can be installed indoors, outdoors, or in underground ducts. Trust World Wire Cables for a seamless, high-quality connection. For more information, visit us at: https://www.wwcables.com.au/products/sdi.html.

0 notes

Text

Wallpaper of the day, Tower HVAC

Having a dry column was a lifesaver for the tower part, we can see how the main duct running along the ceiling of the Sky deck through the structure of the tower and going vertically connects to this dry column at different levels

Where for example in the Officers quarters that we have here settable unitary solutions fulfill AC for each cabin, likewise moisture capture is achieved using unitary solutions

But in all using the dry column we have a solution for both HVAC and crucially air exchange by connecting to the IN/OUT component of the Sky Deck

What about the cables that also run inside that dry column, proper insulation using several layers encased in their own PVC conduit

Another lifesaver for this project, the repeaters, the ability to put that pressure back in the ducts at different laps of the layout

I am confident that CAES will come to constitute the backbone of air conditioning, oxygen enrichment and CO2 capture aboard the future spaceships that BCS is also about

That is whatever their size may be, and already considering hyperscale carriers environment maintenance using massive amounts of antibacterial helium mix in closed cycles

Fresh and ready for another journey in space

Thank you for having followed

0 notes

Text

how to open isulatation form cable

how to remove insulation from cable

how to air seal electrical outlets

how to open an outside plug socket

how to connect insulated flexible duct

cam lock power connectors

duct seal electrical box

how to drop cable from attic

diy waterproof electrical box

power cord for dryer install

in wall power cord and cable kit,

air seal electrical boxes,

gas appliance connector,

how to connect polyethylene gas pipe,

how to open pvc trunking,

safely cap off electrical wire,

what to do with unused electrical wires,

how to open outdoor electrical box,

not able to plug into outlet,

how to plug into safety outlet,

patch electrical outlet drywall,

how to plug into a tamper resistant outlet,

adj pow-r bar link 6 outlet power strip,

add cable outlet to room,

how to insert wires into back of outlet,

how to install a cable pass through wall plate,

tucking wires into electrical box,

how to cap unused electrical wires,

what are the holes for on electrical plugs,

how to put electric socket outside,

using outlet to strip wire,

how to safely cap off electrical wires,

how to seal electrical outlets,

how to disconnect power outlet,

how to disconnect power cord from garbage disposal,

how to disconnect plug socket,

how to close an electrical outlet,

how to install power cable for dryer,

best way to fold wires into electrical box,

how to strip uf-b cable,

how to strip uf electrical wire,

how to cap off old electrical wires,

how to take wires out of outlet

easy way to open isulatation form cable,

how to air seal electrical outlets,

how to remove insulation from cable,

easy way to remove wire insulation,

easy way to strip cable,

safely cap off electrical wire,

how to pass electrical wire through wall,

best way to fold wires into electrical box,

do it yourself insulation,

diy ac duct replacement,

diy air conditioner replacement part 3,

diy connectors,

how to remove ac quick connector smoke detector,

fully insulated quick-disconnect terminals,

cable semiconductor layer removal tool,

what to do with unused electrical wires,

how to open and close air vents,

how to take off gauges hvac,

how to take cover off mrcool mini split,

using outlet to strip wire,

cable insulation removal tool,

what to do with old phone jack outlet,

remove insulation from attic,

how to seal electrical wires,

how to terminate teck cable,

cap off unused electrical wires,

how do tamper resistant outlets work,

use of cable ties,

what are the holes for on electrical plugs,

how to safely cap off electrical wires,

how to remove wire insulation without cutting wire,

how to isolate electrical wires,

how to test cable insulation,

how to open a cable seal,

zip tie electrical connectors,

zif connector locking bar,

how to disconnect power outlet,

how to insert wires into back of outlet,

how to strip teck cable,

how to take ac out of wall,

easiest way to strip cable,

how to strip an electrical wire

0 notes

Text

Flat Submersible cable

Siechem introduced that "Siechem 3 core flat cables for submersible pump motors.

Submersible cables perform under rough and tough field conditions. In house PVC compounds are formulated to meet the demanding operating conditions.

These cables can be used in duct, conduit, or aerial wiring for electric power in houses, buildings, flats, apartments, hospital, factories and also used with UPS, inverter, battery, control panels etc,.

To know more about Siechem's wires and cables visit: www.siechem.com

#cricketer damodaran rohit#cricketer rohit damodaran#damodaran rohit#rohit damodaran#siechem#siechem technology#wires and cables

0 notes

Text

Flat submersible cable

Siechem introduced that "Siechem 3 core flat submersible cable" reviewed by Rohit damodaran.

Submersible cables perform under rough and tough field conditions. In house PVC compounds are formulated to meet the demanding operating conditions.

These cables can be used in duct, conduit, buildings, flats, apartments, hospitals, factories and also used with UPS, inverter, battery, control panels etc,.

To know more about Siechem's wires and cables visit: www.siechem.com

#cricketer rohit damodaran#damodaran rohit#damodaran rohit cricketer#siechem#rohit damodaran#siechem technology#wires and cables

0 notes

Text

Wire Management Tips for a Clean Audio Visual Setup

An audio visual setup is the heart of any home theater or professional presentation space. Whether you are design audio visual solutions for a home or office, wire management is a crucial but often overlooked aspect. Untidy wires can clutter the overall aesthetic and potentially cause technical issues down the line. In this blog, we will discuss various tips and tricks to neatly organize wires for a clean and professional looking audio visual design.

Understanding the Problem

When setting up an audio visual system, most of the focus goes into choosing the right equipment, speakers, projector etc. However, it is easy to neglect the wires that connect all these components. A tangled mess of wires behind or around the AV gear can spoil the overall design and user experience. It becomes difficult to troubleshoot or replace components when wires are haphazardly bundled together. Excess wire lengths are also undesirable as they add to the clutter. Poorly managed wires can potentially damage expensive equipment if pulled accidentally. It is therefore important to take some time and carefully plan the wire routing from the beginning of an audio visual setup.

Planning is Key

Before starting the physical wiring process, take a few minutes to map out routes on paper. Consider all components, their locations and ports/connections required. Look for shortest and most concealed routes between devices. Mark any planned wire runs on walls or ceilings to identify ideal pathways. Make sure there is sufficient access for adding/removing components later on. Determine total wire lengths needed to minimize excess. This upfront planning will save a lot of trouble during and after installation. It also future proofs the system for easy modifications or expansions down the line.

Wire Concealment

Once the routes are mapped, focus on hiding wires from visible areas as much as possible. For in-wall or behind-furniture runs, consider installing small PVC conduits or wire ways. Surface mounted trunking is another clean option for routing along walls, behind TVs etc. Ensure all wall/ceiling pathways are properly fire rated based on building codes if penetrating structural surfaces. For open equipment racks, consider customized ducting/trunking solutions to neatly channel all wires to/from devices. Proper trunking conceals clutter and makes adding new connections easy later on.

Wire Management Accessories

There are several handy accessories available to help manage and organize excess wire lengths neatly:

Cable Ties: Reusable nylon ties are a simple way to bundle together related cable runs. Avoid over-tightening.

Cable Wraps: Self-adhesive Velcro wraps come in different sizes for grouping small or large bundles.

Wire Looms: Flexible braided or woven sleeves neatly contain multiple cables within.

Cable Combs: Plastic or rubber combs create spaced channels to dress cables running along walls or shelves.

Cable Managers: Open/closed track systems provide organized pathways and drops for wire runs behind/under AV racks.

Adhesive Cable Clips: Discreet one-sided clips securely mount individual cables onto surfaces like walls or undersides of tables/furniture.

The above products help reduce clutter, label runs clearly and allow for stress-free cable routing and management. Investing in good quality wire organization tools pays off greatly in terms of aesthetics and serviceability.

Distribution Boxes

For large setups spanning multiple rooms, consider installing centralized distribution boxes to neatly terminate and route all system wires. These metal enclosures consolidate power, audio/video cables and network lines before they branch off individually to endpoint devices. Well-designed distribution boxes with removable covers and pre-defined bays for punch downs simplify future changes and additions to the system infrastructure tremendously. Certified installation by professionals also ensures maximum lifespan and reliability of a distributed AV system.

Labeling System

No matter how perfectly the wires are routed, without a clear labeling system it becomes impossible to identify cables later on. Use permanent cable labels, shrink tube markers or tie-wraps with printed identification to label every wire at both ends. The labeling should logically match electronic schematics/documentation of the system. Consider color-coding related circuits for quick identification. Keep an as-installed system wiring diagram updated with all cable callouts for future reference during maintenance or troubleshooting. Proper labeling is especially important in commercial/institutional audio visual setups that may involve multiple technicians over time.

Tips for Specific Scenarios

Home Theater - For home theater wiring, conceal runs behind walls, furniture, crown molding etc as feasible based on construction. Use cable Combs/managers neatly along baseboards.

Conference Rooms - Surface mount wiring in plenum rated trunking neatly along edges. Termination strips keep flexible.

Classrooms - Install centralized under-floor wiring distribution boxes. Neatly bundle drops to wall plates/projectors using cable wraps.

Offices - Mount equipment/speakers on modular wiring channels suspended from ceiling. Neatly sleeve cables end to end.

Conclusion

To summarize, taking some time for careful planning and proper wire management techniques can make a big difference in the overall aesthetics and functionality of an audio visual system. Clean, organized and clearly labeled wires ensure reliable operation as well as a high-end finished look. Following the best practices discussed can help create a professional grade AV setup either for home or commercial purposes.

0 notes

Text

How PVC ducts can save you money on energy bills

Are you tired of high energy bills eating away at your hard-earned cash? Look no further than Pvc Cable Duct Auckland! Not only are they affordable and easy to install, but they can drastically reduce your monthly energy expenses. In this blog post, we'll explore the benefits of using PVC ducts for ventilation and how it can help you save money in the long run. Keep reading to learn more about this cost-effective solution that will keep both your wallet and home happy.

Advantages of Using a PVC Duct

PVC ducts can save you money on energy bills by providing an insulation barrier against heat transfer. By keeping the air inside the ducts cooler, your air conditioner won't have to work as hard to maintain a comfortable temperature in your home. This can lead to lower energy bills and extend the life of your air conditioner. Foe quotes on Horticulture markers Auckland, contact us today.

In addition, PVC ducts are less likely to develop mold or mildew growth than other types of ductwork. Mold and mildew can cause a musty smell in your home and can also trigger allergies and respiratory problems. PVC ducts are easy to clean and maintain, so you can keep your home healthy and smelling fresh.

PVC ducts are very durable and can last for many years with proper maintenance. This means that you won't have to replace your ductwork as often as you would if you used another material, which can save you money in the long run.

Insulation for Your Home

PVC ducts are an excellent insulation material for your home. They are made of a durable, lightweight material that is easy to install and maintain. PVC ducts have a high R-value, meaning they are very effective at insulating your home from heat and cold. This can help you save money on your energy bills by keeping your home more comfortable year-round.

How PVC Ducts Save Money on Energy Bills

PVC ducts are an excellent way to save money on energy bills. By using PVC ducts, you can reduce the amount of heat that is lost through your ductwork. This will help to keep your home more comfortable and reduce your energy costs. In addition, PVC ducts are less likely to leak than other types of ductwork, which can also lead to savings on your energy bills. Contact us to order Packaging Tube Auckland.

Types of PVC Ducts

There are many different types of PVC ducts available on the market. But, which type is best for you and your home? Here's a breakdown of the most common types of PVC ducts to help you make an informed decision:

• Rigid PVC Ducts: These are the most commonly used type of PVC ducts. They're strong, durable, and easy to install. Plus, they're affordable and can be used in a variety of applications.

• Flexible PVC Ducts: As the name suggests, these ducts are flexible, making them ideal for tight spaces. They're also lightweight and easy to install. However, they're not as strong as rigid PVC ducts and can be more expensive.

• Semi-Rigid PVC Ducts: These offer the best of both worlds – they're stronger than flexible PVC ducts but more flexible than rigid PVC ducts. They're also easy to install and work well in a variety of applications. However, they can be more expensive than both rigid and flexible PVC ducts. For Horticulture markers Auckland, contact us now!

Installation and Maintenance Tips

PVC ducts are a great way to save money on your energy bills. Here are some tips for installation and maintenance:

1. Make sure that the PVC ducts are installed properly. If they are not, they will not be as effective in saving you money on your energy bills.

2. Be sure to follow the manufacturer's instructions for installation and maintenance of your PVC ducts.

3. Inspect your PVC ducts regularly to ensure that they are clean and free of debris.

4. When cleaning your PVC ducts, be sure to use a mild soap and water solution. Do not use harsh chemicals or abrasives, as these can damage the PVC material.

0 notes

Text

How To Choose A Suitable Outdoor Cable For Durability And Weather Resistance

Choosing a suitable outdoor cable that offers durability and weather resistance is essential for ensuring reliable connectivity in various outdoor environments. Numerous types of cables are appropriate for outdoor use, as long as they are shielded from direct sunlight or other external factors. This shielding can be achieved by placing the cables in metal conduit, plastic ducting, or, if directly buried, by utilizing steel wire armor.

We’re the leading Finolex Cable Dealers in Kochi, Kerala provides you with the high quality cables and wires to protect your premises.

Here are some key steps to guide you through the process:

Identify the environmental conditions: Determine the specific environmental conditions the cable will be exposed to, such as temperature extremes, moisture levels, UV exposure, and the presence of chemicals or other potentially damaging substances.

Check the cable’s construction materials: Look for cables with materials that can withstand the outdoor environment. Opt for materials like polyethylene (PE) or polyvinyl chloride (PVC) for insulation and jackets, as they provide good resistance to moisture, sunlight, and abrasion. For more demanding environments, consider cables with materials like ethylene propylene rubber (EPR) or cross-linked polyethylene (XLPE) for enhanced durability.

Evaluate the cable’s temperature rating: Make sure that the cable is rated for the temperature conditions outdoors. Cables with a broad temperature tolerance are better suited to ensure they continue to operate effectively in extremely hot and cold climates.

Consider the cable’s water resistance: Opt for cables that offer strong water resistance, like those equipped with water-blocking technology or made from moisture-resistant materials, in order to safeguard the cable’s core from water infiltration and potential damage.

Check for flexibility and strength: Confirm that the cable possesses the necessary flexibility to endure bending and twisting during the installation process, while also exhibiting sufficient strength to withstand potential damage from external factors such as impacts or crushing.

Consider the cable’s installation requirements: Consider the installation procedure and ensure that the selected cable is compatible with the specific installation method, whether it involves direct burial, aerial installation, or placement within conduits.

Consult with professionals: In case you are uncertain about the specific requirements for your project, it is advisable to seek guidance from experienced professionals or cable manufacturers. These experts can offer tailored recommendations that align with your particular needs and the environmental conditions at hand. Tony Enterprises, we’re the best Electrical Industrial Supplier in Kochi, Kerala provides popup box & floor boxes, conduit pipe and accessories, control gears, wires & cables, modular switches, switch gears, protection devices, cable trunking system, and connectors.

0 notes

Text

How To Choose A Suitable Outdoor Cable For Durability And Weather Resistance

Choosing a suitable outdoor cable that offers durability and weather resistance is essential for ensuring reliable connectivity in various outdoor environments. Numerous types of cables are appropriate for outdoor use, as long as they are shielded from direct sunlight or other external factors. This shielding can be achieved by placing the cables in metal conduit, plastic ducting, or, if directly buried, by utilizing steel wire armor.

We’re the leading Finolex Cable Dealers in Kochi, Kerala provides you with the high quality cables and wires to protect your premises.

Here are some key steps to guide you through the process:

Identify the environmental conditions: Determine the specific environmental conditions the cable will be exposed to, such as temperature extremes, moisture levels, UV exposure, and the presence of chemicals or other potentially damaging substances.

Check the cable’s construction materials: Look for cables with materials that can withstand the outdoor environment. Opt for materials like polyethylene (PE) or polyvinyl chloride (PVC) for insulation and jackets, as they provide good resistance to moisture, sunlight, and abrasion. For more demanding environments, consider cables with materials like ethylene propylene rubber (EPR) or cross-linked polyethylene (XLPE) for enhanced durability.

Evaluate the cable’s temperature rating: Make sure that the cable is rated for the temperature conditions outdoors. Cables with a broad temperature tolerance are better suited to ensure they continue to operate effectively in extremely hot and cold climates.

Consider the cable’s water resistance: Opt for cables that offer strong water resistance, like those equipped with water-blocking technology or made from moisture-resistant materials, in order to safeguard the cable’s core from water infiltration and potential damage.

Check for flexibility and strength: Confirm that the cable possesses the necessary flexibility to endure bending and twisting during the installation process, while also exhibiting sufficient strength to withstand potential damage from external factors such as impacts or crushing.

Consider the cable’s installation requirements: Consider the installation procedure and ensure that the selected cable is compatible with the specific installation method, whether it involves direct burial, aerial installation, or placement within conduits.

Consult with professionals: In case you are uncertain about the specific requirements for your project, it is advisable to seek guidance from experienced professionals or cable manufacturers. These experts can offer tailored recommendations that align with your particular needs and the environmental conditions at hand. Tony Enterprises, we’re the best Electrical Industrial Supplier in Kochi, Kerala provides popup box & floor boxes, conduit pipe and accessories, control gears, wires & cables, modular switches, switch gears, protection devices, cable trunking system, and connectors.

0 notes

Text

PVC Tape Roll: The Ultimate Solution for Electrical Insulation and Sealing

In the world of industrial and household applications, the demand for high-quality tapes is undeniable. Among various types of tapes available, PVC Tape Roll stands out as a top choice for its versatility, durability, and cost-effectiveness. Whether it’s used for electrical insulation, sealing, or bundling, PVC Tapes have gained immense popularity due to their superior performance.

Why Choose a PVC Tape Roll?

A PVC Tape Roll is designed to offer excellent insulation, making it ideal for electrical wiring and protection. Its flexibility and resistance to abrasion, moisture, and chemicals ensure that it can withstand harsh environments. One of the key benefits of using PVC Tapes is their ability to provide a long-lasting solution for various industrial and domestic tasks.

If you're looking for a tape that delivers reliable performance, PVC Tapes with a Silver Shine finish are a perfect option. The Silver Shine not only enhances the aesthetic appeal of the tape but also adds an extra layer of protection. This combination of durability and style makes PVC Tape Roll a preferred choice across industries.

The Importance of Trusted PVC Tape Manufacturers

While there are numerous options for purchasing PVC Tapes, it’s essential to choose the right supplier. Reputable PVC Tape Manufacturers ensure that their products meet industry standards and offer high-performance features like electrical insulation, flame retardancy, and resistance to extreme conditions. Reliable PVC Tape Manufacturers will provide you with quality products that offer maximum value for your investment.

When searching for the best PVC Tape Manufacturers in Delhi, it’s important to consider the manufacturer’s reputation, the quality of their tapes, and their customer service. Delhi, being a hub of manufacturing and trade, hosts some of the most respected PVC Tape Manufacturers in the country. With their advanced manufacturing techniques, PVC Tape Manufacturers in Delhi are known for producing top-notch tapes that serve a variety of purposes.

Versatile Applications of PVC Tapes

PVC Tape Roll is not just limited to electrical insulation. It’s widely used in several industries, including construction, automotive, packaging, and DIY projects. The versatility of PVC Tapes makes them indispensable in these sectors. Here are a few common uses:

1. Electrical Insulation: Thanks to its high dielectric strength, PVC Tape Roll is perfect for insulating electrical wires and cables.

2. Sealing and Bundling: Whether you need to bundle wires or seal ducts, PVC Tapes are a reliable solution.

3. Automotive Industry: In the automotive sector, PVC Tapes are used to wrap wiring harnesses and protect components from corrosion and wear.

4. Decorative Purposes: The Silver Shine finish of certain PVC Tapes adds a decorative touch, making them ideal for aesthetic applications.

Why Opt for PVC Tape Manufacturers in Delhi?

Delhi has long been a hub for manufacturing, and when it comes to PVC Tapes, PVC Tape Manufacturers in Delhi have set the standard. With years of expertise, these manufacturers produce high-quality PVC Tape Rolls that cater to the needs of both industrial and household users. Their tapes are known for their strength, durability, and affordability.

Choosing PVC Tape Manufacturers in Delhi gives you access to a wide range of products that are tested for quality and performance. Their PVC Tapes come in different sizes, colors, and finishes, including the popular Silver Shine, which is highly sought after for its professional look and added protection.

Conclusion

Whether you’re in need of electrical insulation, sealing, or decorative solutions, a PVC Tape Roll with a Silver Shine finish can meet all your requirements. When sourced from reputable PVC Tape Manufacturers, especially PVC Tape Manufacturers in Delhi, you can rest assured that you are getting a product that delivers both quality and value.

#pvc tapes#pvc tape manufacturers in delhi#pvc tape roll#pvc tape manufacturers#PVC tape manufacturers in Delhi

0 notes

Text

Electric Wire & Cable Recycling Adelaide

Do you have any type of Pvc Cable/Wire that you are needing to dispose of?

PVC Cable/Wire is something we buy a lot of at ADELAIDE METAL RECYCLING. PVC, or polyvinyl chloride, is a type of plastic Cable Recycling Adelaide that is used to cover live wires. If you're not sure if your cable or wire is worth anything, read more about the definitions below or get in touch with us to learn more.

High Quality.

One LARGE strand of copper covered in a PVC cable jacket makes up High Grade cable/wire. High quality and grade copper should be present in this copper. In the scrap metal sector, this particular form of cable or wire has a high market value.

Low Grade Low Grade Cable Recycling Adelaide mostly used for ribbon cables, data networks, and telephones.

Here at ADELAIDE METAL RECYCLING we buy a variety of Pvc Cable/Wire. Pvc is a polyvinyl chloride which is a plastic cable Electric Wire Recycling Adelaide used as a jacket for live wires. If you are unsure whether your Cablel/wire is worth something read more about the definitions below, or feel free to contact us to find out more information.

High Grade.

High Grade cable/wire is one LARGE strand of copper coated in a Pvc Cable jacket. This copper Should be a high Quality, and should have a high grade of copper. This type of cable/wire has a high market value in the scrap metal industry.

Low Grade

Low Grade Pvc Cable/Wire is mainly used for data, network, telephone, and ribbon cables ect ..

Loom Wire.

Loom Wire is any wire that comes from a car or construction machinery. This Particular type of wire is a group of Automotive Electric Wire Recycling Adelaide cables or wires which send signals or electricity to many automotive machinery.

Armoured Wire.

Armoured Wire is a wire protected by mechanical damage which makes it a hard wearing power cable. This type of wire is used for electricity mains, underground systems, and cable ducting.

0 notes