#Propylene Market

Explore tagged Tumblr posts

Text

Propylene Prices, News, Trend, Graph, Chart, Monitor and Forecast

The global propylene market plays a crucial role in the petrochemical industry, influencing a wide range of downstream products such as polypropylene, acrylonitrile, propylene oxide, and cumene. Over the past few years, propylene prices have experienced significant fluctuations due to various economic, geopolitical, and supply chain factors. The market dynamics are primarily driven by crude oil prices, production capacities, demand from end-use industries, and global trade policies. As an essential feedstock in the chemical sector, propylene prices are closely tied to refinery operations, cracker margins, and global energy trends. The demand for propylene is largely dictated by the growth of industries such as packaging, automotive, construction, and textiles, where polypropylene and other derivatives are extensively used.

One of the primary influences on propylene pricing is the cost of crude oil and natural gas, as both are key sources of propylene production through steam cracking and fluid catalytic cracking (FCC). Crude oil price fluctuations directly impact the cost of production, making the propylene market highly sensitive to energy market trends. The geopolitical landscape, including conflicts in oil-producing regions and OPEC+ production policies, further contributes to price volatility. Additionally, the global economic environment, including inflation rates, interest rates, and industrial output, plays a significant role in shaping the pricing trends of propylene. During periods of economic growth, demand for consumer goods and infrastructure development surges, leading to higher consumption of propylene derivatives, which in turn drives prices upward.

Get Real time Prices for Propylene: https://www.chemanalyst.com/Pricing-data/propylene-51

The supply side of the propylene market is influenced by production capacities, refinery operations, and unplanned shutdowns. Many countries with large petrochemical hubs, such as the United States, China, and the Middle East, continuously invest in expanding their production capacities to meet the rising demand. However, supply chain disruptions caused by factors such as extreme weather events, transportation bottlenecks, or regulatory restrictions can lead to short-term price spikes. The shift toward sustainability and the increasing focus on bio-based and recycled propylene also impact market dynamics, as companies invest in greener alternatives to reduce their carbon footprint. Regulations regarding emissions and plastic waste management further shape the production strategies of key players in the market.

The Asia-Pacific region remains a dominant force in the propylene market, driven by strong industrial growth, rising consumer demand, and expanding manufacturing capacities. China, in particular, plays a significant role in global propylene pricing due to its massive refining and petrochemical sector. The country's strategic investments in integrated refinery-petrochemical complexes ensure a steady supply of propylene, impacting regional and global price trends. Other Asian countries such as India, South Korea, and Japan also contribute to the dynamic pricing landscape, with demand from packaging, automotive, and construction industries driving consumption. The region's reliance on imported crude oil makes it susceptible to external market shocks, further adding to the price volatility.

North America is another key player in the propylene market, with the United States leading the production due to its abundant shale gas reserves. The rise of propane dehydrogenation (PDH) plants has significantly altered the supply structure, making the region more self-sufficient in propylene production. The advantage of low-cost feedstocks from shale gas has provided a competitive edge to North American producers, helping them expand their footprint in the global market. However, weather-related disruptions such as hurricanes affecting Gulf Coast refineries can lead to supply constraints and price spikes. The region's strong demand for polypropylene in packaging, automotive components, and consumer goods continues to support propylene price stability, despite occasional fluctuations due to external factors.

In Europe, the propylene market is influenced by refinery operations, energy policies, and regulatory frameworks. The region's emphasis on sustainability and circular economy initiatives has led to increased investments in bio-based and recycled propylene. However, high energy costs and dependence on imported crude oil pose challenges for European producers, making the market susceptible to price fluctuations. The ongoing transition toward greener alternatives, coupled with stringent environmental regulations, affects the operational strategies of refineries and petrochemical plants. Additionally, trade relations with key suppliers such as the Middle East and Russia impact supply security and pricing trends in the region.

The Middle East, known for its abundant hydrocarbon resources, is a major supplier of propylene and its derivatives to global markets. Countries such as Saudi Arabia, the UAE, and Iran benefit from low production costs and integrated refining-petrochemical complexes, allowing them to maintain competitive pricing. The region's strategic focus on expanding petrochemical capacities to diversify away from crude oil exports has bolstered its position in the global propylene market. However, geopolitical tensions and trade sanctions can create supply disruptions, leading to price fluctuations. The region's growing investments in downstream industries, including polypropylene production, further shape market dynamics.

Latin America and Africa also contribute to the global propylene market, albeit at a smaller scale compared to other regions. Brazil, Mexico, and Argentina have notable petrochemical industries that influence regional pricing trends. However, economic instability, regulatory challenges, and limited refining capacities often impact supply consistency. In Africa, emerging industrialization and infrastructure development are driving demand for propylene-based products, though supply constraints and logistical challenges remain key concerns for market participants. Both regions have potential for growth, especially with increasing foreign investments in refining and petrochemical projects.

The future outlook for propylene prices remains closely tied to energy market trends, technological advancements, and sustainability initiatives. The growing adoption of propane dehydrogenation technology is expected to enhance supply security and stabilize prices in key markets. Additionally, the increasing emphasis on circular economy principles and recycling initiatives will play a role in shaping production strategies. As industries continue to shift toward sustainable materials and bio-based alternatives, the propylene market is likely to witness structural transformations. While short-term price fluctuations are inevitable due to geopolitical and economic uncertainties, the long-term trajectory is expected to align with global industrial growth and evolving consumer preferences.

Market participants, including producers, traders, and end-users, must closely monitor key factors such as crude oil prices, supply chain dynamics, and regulatory developments to make informed decisions. The integration of digital technologies and data analytics in supply chain management is also expected to enhance market efficiency, reducing the impact of unexpected disruptions. With the continued expansion of production capacities and the rise of sustainable alternatives, the global propylene market is poised for dynamic changes, offering opportunities for stakeholders across the value chain.

Get Real time Prices for Propylene: https://www.chemanalyst.com/Pricing-data/propylene-51

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Propylene#Propylene Price#Propylene Prices#Propylene Pricing#India#united kingdom#united states#Germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

Mono Propylene Glycol Market: Exploring Global Growth Trends, Demand Drivers, and Emerging Opportunities

The mono propylene glycol market has witnessed significant expansion, driven by its diverse applications across multiple industries. As a versatile chemical compound, mono propylene glycol is widely utilized in industries such as cosmetics, pharmaceuticals, food and beverages, and automotive. Its growing demand is fueled by increasing awareness of sustainable production practices and rising consumer preferences for safe and environmentally friendly products. The chemical's ability to serve as a humectant, solvent, and heat transfer fluid makes it indispensable in both industrial and consumer applications.

Key Factors Driving Market Demand The market's growth is significantly influenced by advancements in industrial sectors like construction, automotive, and food processing. Mono propylene glycol's utility in antifreeze and coolant formulations continues to be a major driver, especially as global temperatures fluctuate, increasing demand for temperature-regulating solutions. Additionally, its application in personal care products is expanding due to its non-toxic and skin-friendly properties. Regulatory support for its use in food-grade and pharmaceutical-grade products further boosts its acceptance across markets.

Regional Trends and Market Expansion North America and Europe hold substantial shares of the mono propylene glycol market due to well-established industrial bases and stringent quality standards. Meanwhile, Asia-Pacific is emerging as a key region for market growth, propelled by rapid industrialization, increasing investments in infrastructure, and expanding consumer markets. Countries like China and India, with their growing automotive and construction industries, are creating immense opportunities for manufacturers to capitalize on. Moreover, the region’s rising focus on sustainable production aligns with global trends in reducing the environmental impact of chemical processes.

Sustainability and Eco-Friendly Trends One of the most critical trends shaping the mono propylene glycol market is the growing emphasis on sustainability. Consumers and industries alike are seeking products derived from renewable sources to minimize their ecological footprint. This has led to innovations in bio-based mono propylene glycol production, offering a greener alternative to conventional petrochemical-derived options. The integration of circular economy principles in chemical manufacturing further supports the development of sustainable supply chains, benefiting manufacturers and end-users.

Technological Advancements and Market Challenges Technological innovations are playing a pivotal role in shaping the future of the mono propylene glycol market. Enhanced manufacturing processes, improved product formulations, and increased focus on R&D have led to better performance and cost-efficiency. However, the market faces challenges, including fluctuating raw material prices and competition from substitute products. Manufacturers are addressing these hurdles by investing in advanced production techniques and diversifying their product portfolios to maintain competitiveness.

Future Outlook and Opportunities The mono propylene glycol market is poised for steady growth in the coming years, with emerging opportunities in bio-based products and expanding applications in pharmaceutical and food-grade segments. As industries adopt more sustainable practices and innovative solutions, mono propylene glycol is set to remain a critical component in addressing global challenges related to efficiency and environmental impact. Companies focusing on partnerships, innovation, and eco-friendly initiatives are likely to gain a competitive edge in this evolving market.

1 note

·

View note

Text

Propylene Glycol Market size was valued at US$ 4.51 Bn. in 2023 and transportation is one of the dominating segments reviewed in our report and dominating the Global Polypropylene Market.

0 notes

Text

Exploring the FEP Heat Shrink Medical Tubing Market: Growth, Applications, and Future Prospects

The FEP (Fluorinated Ethylene Propylene) Heat Shrink Medical Tubing market is experiencing robust growth, spurred by innovations in healthcare, a shift toward minimally invasive devices, and the need for safe, biocompatible materials. FEP tubing is valued for its chemical resistance, flexibility, and transparency, which make it ideal for various applications within the medical industry. FEP Heat Shrink Medical Tubing Market is estimated to be USD 145 million in 2024, and it is projected to reach USD 208 million by 2029 at a CAGR of 7.4%.

Key Features of FEP Tubing

FEP is a fluoropolymer known for its exceptional durability under challenging conditions. When heat-shrunk, FEP tubing conforms to underlying components, adding a protective layer around medical devices. Key properties include:

Biocompatibility: Minimizes the risk of reactions, ensuring safe interaction with human tissue.

Chemical and Thermal Stability: Essential for protecting sensitive components against chemical exposure and high temperatures.

Transparency and Smoothness: Allows medical professionals to monitor fluids within the device while also ensuring easy device insertion.

Key Applications

FEP heat shrink tubing is indispensable across various medical applications:

Catheters: Acts as a durable, smooth protective layer that navigates the body’s complex pathways while shielding sensitive inner wiring.

Endoscopic Instruments: Offers protection from chemical exposure and maintains structural integrity through sterilization cycles.

Electrosurgical Devices: Adds a layer of safety by insulating electrically conductive parts.

Encapsulation for Wires and Sensors: Safeguards sensors in monitoring equipment, especially those exposed to harsh environments.

Market Growth Drivers

Several factors drive the demand for FEP heat shrink tubing:

Rising Demand for Non-invasive Procedures: As minimally invasive methods become the norm, demand for high-quality, durable tubing has risen.

Medical Device Innovations: FEP tubing supports next-generation devices by enabling flexible, strong material integration.

Adherence to Global Standards: FEP tubing’s compliance with strict international health standards boosts its usage in the healthcare sector.

Healthcare Expansion in Emerging Markets: Increased global access to healthcare is driving demand for high-quality medical equipment.

Market Challenges

While FEP tubing holds a strong market position, it faces challenges. Competing materials like PTFE offer similar benefits, so careful material selection is essential for manufacturers. Additionally, FEP is a costly material due to its specialized manufacturing process, which can impact product pricing.

Future Market Directions

Advances in medical technologies suggest a bright future for FEP tubing. Emerging trends include:

New Material Blends: Manufacturers are experimenting with FEP hybrids for enhanced performance.

Wearable Medical Devices: As healthcare becomes increasingly wearable, the need for flexible, durable materials like FEP is set to grow.

Eco-conscious Production: With environmental sustainability in focus, manufacturers are also exploring greener production practices.

Download PDF Brochure :

The FEP heat shrink medical tubing market is poised for expansion, especially as healthcare devices continue to evolve. Its properties make FEP tubing a valuable asset to medical innovation, and manufacturers that focus on both quality and sustainability will likely see success in this competitive landscape. For those in the industry, staying updated on FEP advancements can provide an edge in developing next-gen medical devices that balance functionality, safety, and efficiency.

#FEP heat shrink medical tubing#biocompatible tubing#minimally invasive devices#catheter tubing#medical device innovations#healthcare market growth#fluorinated ethylene propylene tubing

0 notes

Text

Global Propane Dehydrogenation to Propylene Market, Market Size, Market Share, Key Players | BIS Research

Thermoset plastics, known for their excellent mechanical strength, chemical resistance, and durability, have long been integral in industries like automotive, aerospace, electronics, and construction. However, their primary drawback has been that, once cured, they are difficult to recycle. This has posed a significant environmental challenge, as traditional thermosets end up in landfills, contributing to plastic waste.

The global propane dehydrogenation (PDH) to propylene market is projected to reach $22,721.2 million by 2031 from $10,314.6 million in 2022, growing at a CAGR of 9.2% during the forecast period 2022-2031.

Propane Dehydrogenation to Propylene Overview

Thermosets are polymers that, when cured through heat or chemical reactions, become rigid and maintain their shape permanently.

The very feature that makes thermosets desirable for applications requiring durability is also what makes them difficult to recycle. Traditional thermoset plastics cannot be reshaped or reprocessed once cured because the cross-linked molecular structure prevents them from being melted down.

Applications for Propane Dehydrogenation to Propylene Market

1 Automotive and Aerospace: These industries rely heavily on thermoset composites for lightweight, high-strength materials that improve fuel efficiency and performance.

2 Electronics: Thermoset plastics are commonly used in electronic components due to their excellent insulating properties.

3 Construction: Thermosets are used in construction materials such as adhesives, coatings, and insulation.

Market Segmentation

1 By End Users

2 By Technology

3 By Derivative

4 By Region

Download the report and get more information @ Propane Dehydrogenation to Propylene Market

Major Key Players

LyondellBasell Industries Holdings B.V.

Borealis AG

Williams

INEOS Group Limited

GAIL (India) Limited

Jinneng Science and Technology Company Limited

Dow Chemical Company

Koch Industries, Inc.

And many others

Download the sample page click here @ Propane Dehydrogenation to Propylene Market

Demand – Drivers and Limitations

Following are the demand drivers for the global Propane Dehydrogenation to Propylene market:

• Advancement in Thermoset Recycling Technologies Globally • Regulations Promoting Plastic Recycling in Various Countries • Investments and Collaboration in Plastic Recycling Industry

The following are the challenges for the global Propane Dehydrogenation to Propylene market:

• Complex Process of Thermoset Recycling • Lack of Proper Infrastructure for Hard-to-Recycle Products

Recent Developments in Propane Dehydrogenation (PDH) to Propylene Market

• In March 2022, KBR and ExxonMobil Catalysts and Licensing collaborated on the advancements of propane dehydrogenation (PDH) technology. Under the collaboration, ExxonMobil's proprietary catalyst technology would be combined with KBR's proprietary K-PRO PDH technology to convert propane into propylene.

•In January 2022, Hyosung Chemical started the production of propylene by PDH technology for the production of polypropylene units. Before the start-up of this plant, the polypropylene units were dependent on imported propylene.

Conclusion

The propane dehydrogenation (PDH) market for propylene production is positioned for significant growth, driven by the rising demand for propylene across various industries, including packaging, automotive, construction, and textiles.

Overall, the PDH market is poised for expansion, supported by the growing demand for propylene in emerging economies, continued advancements in PDH technology, and a global push towards more energy-efficient and cost-effective chemical processes

0 notes

Text

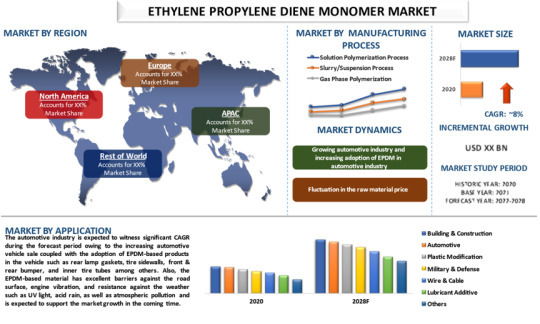

Ethylene Propylene Diene Monomer (EPDM) Market: Current Analysis and Forecast (2022-2028)

According to a new report published by UnivDatos Markets Insights, the Ethylene Propylene Diene Monomer (EPDM) Market is expected to grow at a CAGR of around 8% from 2022-2028. The analysis has been segmented into Manufacturing Process (Solution Polymerization Process, Slurry/Suspension Process, and Gas Phase Polymerization); Application (Building & Construction, Automotive, Plastic Modification, Military & Defense, Wire & Cable, Lubricant Additive, and Others); Region/Country.

The Ethylene Propylene Diene Monomer (EPDM) market report has been aggregated by collecting informative data on various dynamics such as market drivers, restraints, and opportunities. This innovative report makes use of several analyses to get a closer outlook on the Ethylene Propylene Diene Monomer (EPDM) market. The Ethylene Propylene Diene Monomer (EPDM) market report offers a detailed analysis of the latest industry developments and trending factors in the market that are influencing the market growth. Furthermore, this statistical market research repository examines and estimates the Ethylene Propylene Diene Monomer (EPDM) market at the global and regional levels.

Market Overview

Ethylene Propylene Diene Monomer (EPDM) is a synthetic material obtained from natural gas and thermal cracking petroleum products such as naphtha. EPDM is widely used in low-slope buildings, automotive applications, and construction applications due to their longer durability and superior resistance to environmental factors such as UV, ozone, and other weather condition. In recent times, the EPDM witnessed significant demand due to its increasing demand from the automotive industry, manufacturing & construction industry attributed to its lower cost, higher moldability, and longer durability. Also, the EPDM could be used as an alternative to silicon rubber and could also be incorporated in the hose, O-ring, accumulator bladder, diaphragms, and connectors for wire & cables among many other applications on the account of their higher resistance towards tearing, abrasive, solvent, and temperature.

Factors such as technological advancement coupled with the growing number of industries and manufacturing units along with the new product launches in the market are some of the prominent factors that are positively influencing the market growth globally.

Some of the major players operating in the market include DowDuPont Inc., Exxon Mobil Corporation, Lion Elastomers, Johns Manville, SK Global Chemical Co. Ltd, Lanxess AG, Mitsui Chemical Inc., PetroChina Company Limited, Kumho Polychem, and Versalis S.p.A.

COVID-19 Impact

The recent covid-19 pandemic has disrupted the world and has brought a state of shock to the global economy. The global pandemic has impacted the manufacturing industry along with supply chain disruption, regulatory and policy changes, labor reliance, working capital management, and liquidity & solvency management. The Ethylene Propylene Diene Monomer (EPDM) market has been significantly affected during these times owing to the gap between supply and demand.

The global Ethylene Propylene Diene Monomer (EPDM) market report is studied thoroughly with several aspects that would help stakeholders in making their decisions more curated.

Based on application, the market is segmented into building & construction, automotive, plastic modification, military & defense, wire & cable, lubricant additive, and others. The automotive industry is expected to witness significant CAGR during the forecast period owing to the increasing automotive vehicle sale coupled with the adoption of EPDM-based products in the vehicle such as rear lamp gaskets, tire sidewalls, front & rear bumper, and inner tire tubes among others. Also, the EPDM-based material has excellent barriers against the road surface, engine vibration, and resistance against the weather such as UV light, acid rain, as well as atmospheric pollution and is expected to support the market growth in the coming time.

Based on the manufacturing process, the market is segmented into solution polymerization process, slurry/suspension process, and gas phase polymerization. The solution polymerization segment is expected to witness significant growth during the forecast period due to the higher concentration and lower required amount for the optimized performance. Additionally, solution polymerization is used to manufacture both crystalline and amorphous polymer grades and is expected to support market growth.

Ethylene Propylene Diene Monomer (EPDM) Market Geographical Segmentation Includes:

North America (United States, Canada, and Rest of North America)

Europe (Germany, United Kingdom, Spain, Italy, France, and the Rest of Europe)

Asia-Pacific (China, Japan, India, and the Rest of Asia-Pacific)

Rest of the World

Asia-Pacific is anticipated to grow at a substantial CAGR during the forecast period. This is mainly due to the rapid industrialization and growing automotive industries along with the electronic & electrical industry, consumer goods industry, and medical sector in the region. Also, the ongoing infrastructural projects and increasing disposable income of the individual are expected to support market growth in the coming time. Furthermore, EPDM has also been used as a substitute for thermoplastic olefins and thermoplastic vulcanizate in the manufacturing industry. Also, the lower cost of the raw material coupled with the lower cost of production associated with the lower labor cost propels the market for the EPDM. Moreover, the growing research & development activities, increasing investment, and technological investment are expected to derive the market in the coming time. For instance, in March 2022, Arlanxeo a Netherland-based firm announced to increase in its production capacity by 15% for its EPDM plant based in Changzhou, China.

The major players targeting the market include:

DowDuPont Inc.

Exxon Mobil Corporation

Lion Elastomers

Johns Manville

SK Global Chemical Co. Ltd

Lanxess AG

Mitsui Chemical Inc.

PetroChina Company Limited

Kumho Polychem

Versalis S.p.A.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=31683

Competitive Landscape

The degree of competition among prominent global companies has been elaborated by analyzing several leading key players operating worldwide. The specialist team of research analysts sheds light on various traits such as global market competition, market share, most recent industry advancements, innovative product launches, partnerships, mergers, or acquisitions by leading companies in the Ethylene Propylene Diene Monomer (EPDM) market. The major players have been analyzed by using research methodologies for getting insight views on global competition.

Key questions resolved through this analytical market research report include:

• What are the latest trends, new patterns, and technological advancements in the Ethylene Propylene Diene Monomer (EPDM) market?

• Which factors are influencing the Ethylene Propylene Diene Monomer (EPDM) market over the forecast period?

• What are the global challenges, threats, and risks in the Ethylene Propylene Diene Monomer (EPDM) market?

• Which factors are propelling and restraining the Ethylene Propylene Diene Monomer (EPDM) market?

• What are the demanding global regions of the Ethylene Propylene Diene Monomer (EPDM) market?

• What will be the global market size in the upcoming years?

• What are the crucial market acquisition strategies and policies applied by global companies?

We understand the requirement of different businesses, regions, and countries, we offer customized reports as per your requirements of business nature and geography. Please let us know If you have any custom needs.

Browse Related Newsletter from UnivDatos Market Insights

Titanium Dioxide Market - SWOT Analysis [2023-2028]

Recycled Carbon Fiber Market - SWOT Analysis [2023-2028]

About Us:

UnivDatos Market Insights: Your Partner in Data-Driven Market Strategies. Unlock growth opportunities and make smart decisions with our expert research and insights.

Contact us:

UnivDatos Market Insights (UMI)

Email: [email protected]

Web: https://univdatos.com

LinkedIn: www.linkedin.com/company/univ-datos-market-insight/

Ph: +91 7838604911

0 notes

Text

Propylene Oxide Market Size, Analysis and Forecast 2031

0 notes

Text

The propylene oxide market in India is experiencing robust growth, primarily driven by several key factors. Firstly, the escalating demand for polyurethane, a versatile polymer derived from propylene oxide, serves as a prominent driver.

#India Propylene Oxide Market Report#India Propylene Oxide Market Report 2024#India Propylene Oxide Market Report 2032#India Propylene Oxide Market 2024#India Propylene Oxide Market 2032

0 notes

Text

Propylene Oxide Market Dynamics: A Comprehensive Overview

Introduction Propylene oxide is an organic compound with the chemical formula C3H6O. It is a colorless volatile liquid that is miscible with water, most common organic solvents and has a faint ethereal odor. C3H6O is an epoxide, meaning it contains an oxide group bonded to two carbon atoms forming a three-membered cyclic ether. It is formed through the oxidation of propylene. Production of Propylene Oxide Industrially, propylene oxide is produced on a large scale through the chlorohydrin process or hydroperoxide process. In the chlorohydrin process, propylene is oxidized with chlorine in the presence of a chloride catalyst to form propylene chlorohydrin which is then hydrolyzed to yield C3H6O and hydrochloric acid. This process allows for greater selectivity in product formation. The hydroperoxide process involves three steps - first hydroperoxide is formed by oxidizing propylene with an oxygen containing gas like air or oxygen over a silver catalyst. This is followed by decomposition of hydroperoxide to form C3H6O and water. The final step recovers and purifies the C3H6O product. This process affords higher atom efficiency and lower energy consumption. Properties and Applications Due to its versatile functionality of forming additional bonds through ring opening, C3H6O has a wide range of applications. It is mainly used for producing polyether polyols which are building blocks for polyurethane products like rigid and flexible foams for insulation and cushioning. C3H6O is also used to produce propylene glycols that are commonly used as heat transfer fluids and manufacturing solvents. As an intermediate chemical, C3H6O is converted to propylene glycol ethers which are used in industrial and automotive antifreeze formulations as well as paints, coatings and cleaning agents due to their good solvent properties. Epoxy resins formed from reacting C3H6O with epichlorohydrin are used to produce protective and durable coatings, adhesives, composites and encapsulation of electronics. C3H6O acts as a intermediate in producing other chemical compounds like propylene glycol monomethyl ether and propylene glycol monomethyl ether acetate which are solvents for inks, coatings and electronics packaging. It can also react with amines to form amine oxide surfactants that are used in personal care, home care and industrial cleaning products. Health and Environmental Effects While C3H6O is useful industrially, it also poses certain health risks. It is a volatile flammable liquid and contact with eyes and skin can cause irritation. Inhalation may cause respiratory issues. Studies have shown it to be possibly carcinogenic to humans and its vapors are harmful if inhaled in large quantities. Organizations like the EPA have classified C3H6O as a hazardous air pollutant and possible human carcinogen. Manufacturing sites emitting this chemical are subject to regulations regarding its release into the environment. Proper handling and storage in a well-ventilated area along with use of protective equipment is important when working with propylene oxide. Spills contaminating soil and water need remediation to minimize environmental damage. Conclusion In summary, C3H6O is a versatile chemical building block found in many industrial and commercial products. While serving important applications, its adverse health effects require careful production and usage practices, transportation, storage and disposal according to safety guidelines. Ongoing research explores safer production technologies for this valuable oxirane compound supporting many modern industries. With proper risk management measures, propylene oxide will continue meeting manufacturing needs sustainably.

0 notes

Text

Global Ethylene Propylene Diene Monomer Market is expected to grow at a significant rate of around 8% during the forecast period.

0 notes

Text

Propylene Glycol Prices, News, Trend, Graph, Chart, Monitor and Forecast

Propylene Glycol is a versatile chemical compound widely used across various industries, including pharmaceuticals, food and beverage, cosmetics, and industrial applications. Its price trends are influenced by multiple factors such as raw material costs, supply chain disruptions, production capacities, and market demand. Over recent years, the propylene glycol market has witnessed significant fluctuations, driven by changes in crude oil prices, economic conditions, and regulatory policies. Understanding the pricing dynamics of this essential chemical is crucial for manufacturers, distributors, and end users looking to optimize procurement strategies and reduce operational costs.

The pricing of propylene glycol is closely linked to the cost of its primary raw material, propylene oxide, which is derived from petrochemical sources. Any fluctuations in crude oil prices directly impact the cost of propylene oxide, leading to price variations in propylene glycol. In times of high crude oil prices, production costs tend to rise, resulting in higher market prices. Conversely, when crude oil prices decline, there is usually a reduction in the cost of raw materials, which can lead to lower propylene glycol prices. Additionally, geopolitical tensions, trade restrictions, and supply chain disruptions can create volatility in raw material supply, further influencing market prices.

Get Real time Prices for Propylene Glycol: https://www.chemanalyst.com/Pricing-data/propylene-glycol-1095

Another critical factor affecting propylene glycol prices is global supply and demand dynamics. The growing demand from the pharmaceutical and food industries has contributed to steady price increases in recent years. Propylene glycol is widely used as a solvent, humectant, and stabilizer in numerous applications, making it an essential ingredient in various consumer and industrial products. The increasing consumption of packaged foods, personal care products, and pharmaceuticals has fueled demand, thereby exerting upward pressure on prices. Additionally, as industries prioritize sustainability, the market for bio-based propylene glycol has expanded, introducing another variable in pricing structures. While bio-based alternatives often come at a premium due to higher production costs, they cater to the rising consumer preference for environmentally friendly products.

Seasonal demand variations also play a role in price fluctuations. During winter months, demand for propylene glycol surges due to its extensive use in antifreeze and de-icing applications. This seasonal spike in consumption can lead to temporary price hikes, particularly when supply is tight. On the other hand, during off-peak seasons, demand tends to stabilize, potentially leading to price corrections. Market participants closely monitor these trends to optimize their purchasing decisions and inventory management strategies.

Regional market conditions significantly impact pricing trends. North America, Europe, and Asia-Pacific are the key markets for propylene glycol, with varying price dynamics in each region. In North America, the presence of major chemical manufacturers and stable raw material supply often lead to competitive pricing. The U.S. market, in particular, benefits from domestic production capacities that help mitigate extreme price fluctuations. In Europe, stringent environmental regulations and fluctuating energy costs contribute to price variability. Additionally, the shift towards sustainable production methods and the increasing adoption of bio-based propylene glycol impact market pricing in the region. Asia-Pacific, being a major manufacturing hub, experiences significant price volatility due to fluctuations in feedstock availability, regulatory changes, and shifting demand patterns in key economies such as China and India.

Trade policies, tariffs, and logistical challenges also influence global propylene glycol prices. Changes in import-export regulations can impact supply chains, affecting the overall cost of production and distribution. Supply chain disruptions, such as those witnessed during the COVID-19 pandemic, have highlighted the vulnerabilities of global trade and logistics. Shipping delays, container shortages, and port congestion have contributed to price spikes in various regions. Companies that rely on global supply chains must navigate these challenges by securing alternative sourcing options and optimizing logistics strategies.

Environmental regulations and sustainability initiatives are reshaping the propylene glycol market landscape. Many governments and regulatory bodies are implementing stricter emission norms and encouraging the use of eco-friendly alternatives. This shift has prompted chemical manufacturers to explore bio-based production methods, which often involve higher costs but align with sustainability goals. As a result, bio-based propylene glycol is gaining traction, influencing overall market pricing. Consumers and industries seeking greener solutions are willing to pay a premium for sustainable products, thereby altering traditional price dynamics.

The role of technological advancements in propylene glycol production cannot be overlooked. Innovations in manufacturing processes have enabled greater efficiency, cost reduction, and improved product quality. Advanced catalysts, optimized reaction conditions, and alternative feedstocks are being explored to enhance production sustainability. These developments have the potential to impact market prices by reducing reliance on traditional petrochemical sources and increasing the availability of cost-effective alternatives.

Economic conditions and macroeconomic factors also play a crucial role in determining propylene glycol prices. Inflation, currency fluctuations, interest rates, and overall economic growth influence purchasing power and industrial activity. During economic downturns, reduced industrial output and lower consumer spending can lead to decreased demand, causing price declines. Conversely, periods of economic growth drive higher consumption across industries, supporting price stability or even increases.

Future price trends for propylene glycol will likely be shaped by ongoing shifts in supply chain strategies, sustainability initiatives, and market demand. As industries adapt to changing consumer preferences and regulatory landscapes, pricing structures may continue to evolve. Market participants must stay informed about global developments, technological advancements, and emerging trends to make well-informed procurement and investment decisions. By closely monitoring price movements, industry players can mitigate risks, optimize production planning, and enhance competitiveness in the global market.

In conclusion, the propylene glycol market is highly dynamic, with prices influenced by multiple interconnected factors. Raw material costs, supply-demand dynamics, regional market conditions, environmental regulations, and economic trends all contribute to price fluctuations. As industries continue to innovate and adapt to changing market conditions, the pricing landscape for propylene glycol will remain subject to shifts driven by technological advancements, sustainability initiatives, and global economic developments. Staying informed about these factors is essential for businesses seeking to navigate the complexities of the propylene glycol market and make strategic decisions for future growth.

Get Real time Prices for Propylene Glycol: https://www.chemanalyst.com/Pricing-data/propylene-glycol-1095

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Propylene Glycol#Propylene Glycol Price#Propylene Glycol Pricing#India#united kingdom#united states#Germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

Growth of Propylene Oxide Market Quantitative and Qualitative Analysis | Industry Challenges and Forecast till 2036

Research Nester has released a report titled “Propylene oxide Market: – Global Demand Analysis & Opportunity Outlook 2036” which also includes some of the prominent market analyzing parameters such as industry growth drivers, restraints, supply and demand risk, market attractiveness, year-on-year (Y-O-Y) growth comparisons, market share comparisons, BPS analysis, SWOT analysis and Porter’s five force model.

The global propylene oxide market has shown significant growth on account of increasing application of propylene oxide as a chemical intermediate. Backed by this factor, the propylene oxide market is estimated to witness significant growth in the coming years. In 2019, the market accounted for a market value of USD 13875.7 million and is estimated to grow by a CAGR of 5% over the forecast period of 2023-2035. A significant trend in the propylene oxide market has been the development and commercialization of new production technologies, which not only reduces the production of by-products but also does not use any chlorine-based chemistry.

Request Report Sample@

https://www.researchnester.com/sample-request-2804

Regionally, the global propylene oxide market is segmented into North America, Asia Pacific, Europe, Latin America, and Middle East & Africa region. Among the market in these regions, the Asia Pacific propylene oxide market is estimated to witness highest growth throughout the forecast period. The region is home to some of the fastest-growing economies of the world, including China, India, Bangladesh, and others. The evolution of construction, automotive, food & beverage and other industries has further strengthened the overall economic growth of the region, which is further anticipated to create lucrative opportunities for the new entrants in the market.

The Europe propylene oxide market is expected to touch a value of USD 4199.5 by 2035 by growing at a CAGR of 2.8 percent over the forecast period. Propylene oxide has gained popularity in the European market owing to its growing adoption in end-use industries such as construction & manufacturing, automobiles, consumer electronics, and packaging. Germany is the largest as well as the fastest-growing country in Europe propylene oxide market. The rapidly growing construction sector in the country on account of population growth, demographic changes, and favorable environment has influenced the market growth. The building & construction industry is one of Europe’s main consumer of propylene oxide.

The global propylene oxide market is segmented on the basis of production process into chlorohydrin process, styrene monomer process, hydrogen peroxide process, TBA co-product process, and cumene-based process. Among these, is it anticipated that the chlorohydrin (CPHO) process will account for a market value of about USD 4920.6 million by 2020. CHPO is the oldest process used in the production of propylene oxide and held the largest market share in 2019.

Request for customization @

https://www.researchnester.com/customized-reports-2804

Increasing Use Of Propylene Oxide As A Chemical Intermediate to Drive the Market Growth

Increased demand for propylene oxide for the production of chemical intermediates such as for the polyurethane and solvent industries, is a key factor expected to drive the growth of the market over the forecast period. The rapidly growing healthcare sector is also expected to create lucrative opportunities for the global propylene oxide market. Propylene oxide is used for low-temperature sterilization of medical devices, bandages, and various other pharmaceutical products. It also functions as an essential chemical intermediate for the manufacture of propylene glycol, which is widely used in the chemical, food & beverage, pharmaceutical and cosmetics industries. Over the forecasted period, this factor is expected to drive the growth of the global demand for propylene oxide.

However, the possible carcinogenicity associated with the application of propylene oxide along with the environmental liability associated with the chlorohydrin process for the production of propylene oxideis expected to serve as a restraining factor in the growth of propylene oxide market during the forecast period.

This report also provides the existing competitive scenario of some of the key players of the propylene oxide market which includes company profiling of Dow, Balchem Inc (NASDAQ: BCPC), BASF SE (ETR: BAS), Ashland (NYSE: ASH); Alfa Aesar, Thermo Fisher Scientific.; Sumitomo Chemical Co, Ltd. (TYO: 4005), Huntsman International LLC (NYSE: HUN), Lyondellbasell Industries Holdings B.V. (NYSE: LYB), Eastman Chemical Company (NYSE: EMN) among other prominent players.

The profiling enfolds key information of the companies which comprises of business overview, products and services, key financials and recent news and developments. Conclusively, the report titled “Propylene Oxide Market– Global Demand Analysis & Opportunity Outlook 2036”, analyses the overall propylene oxide industry to help new entrants to understand the details of the market. In addition to that, this report also guides existing players looking for expansion and major investors looking for investment in the global propylene oxide market in the near future.

Access Full Report, here@

https://www.researchnester.com/reports/propylene-oxide-market/2804

About Research Nester-

Research Nester is a leading service provider for strategic market research and consulting. We aim to provide unbiased, unparalleled market insights and industry analysis to help industries, conglomerates and executives to take wise decisions for their future marketing strategy, expansion and investment etc. We believe every business can expand to its new horizon, provided a right guidance at a right time is available through strategic minds. Our out of box thinking helps our clients to take wise decision in order to avoid future uncertainties.

Contact for more Info:

AJ Daniel

Email: [email protected]

U.S. Phone: +1 646 586 9123

U.K. Phone: +44 203 608 5919

0 notes

Text

Sustainable Practices in the Propylene Oxide Market: Environmental Implications

Propylene Oxide: A Versatile Chemical Used Widely in Various Industries Production and Uses of Propylene Oxide Propylene oxide is primarily produced through a chemical process called chlorohydrin process where propylene is reacted with chlorine and water in the presence of a catalyst. This commercial process results in an approximate yield of 90% of propylene oxide. Propylene oxide production began back in the 1950s and has grown significantly over the past few decades with increasing applications across various industries. On an average, over 10 million metric tons of propylene oxide is produced globally every year to meet the growing demand. Main applications of propylene oxide include production of polyether polyols, which are further used to manufacture polyurethane flexible and rigid foams. These foams find applications as insulation in buildings as well as packaging, furniture, bedding, and automotive industries. Propylene oxide is also used to produce propylene glycols that are deployed as antifreeze and deicing fluids as well as solvents in food, pharmaceuticals and various other industries. Other notable applications of propylene oxide include production of specialty chemicals like glycol ethers used as solvents and surfactants. Global Demand and Key Markets Presently, Asia Pacific region accounts for over 50% of global propylene oxide production led by China. Other major producers include Europe and North America. The propylene oxide market is forecast to grow at over 4% annually driven by the expanding construction as well as automotive industries in developing countries and the need for insulating materials as well as car seats made from polyurethane foam. The polyurethane flexible foams produced using propylene oxide find widespread applications in bedding, furniture, automotive seating and insulation in buildings across all geographies. The polyurethane rigid foams are extensively used in construction projects for thermal and acoustic insulation. Future growth in infrastructure and real estate markets in Asian countries like India and construction growth in Africa and Middle East is expected to drive demand for insulating polyurethane foams and propylene oxide in turn. Fluctuating Raw Material Prices The prices of propylene oxide are closely linked to that of propylene, which is the main raw material. Over the past year, propylene prices have witnessed volatility due to supply disruptions and rising energy prices impacting global propylene oxide market. Any fluctuations in oil and natural gas prices from where propylene is derived further impact the prices. Presently, propylene prices and hence propylene oxide prices are on an upward trend driven by tight supply of propylene following repairs in refineries and outages at cracker units. Environmental Regulations Like several chemical commodities, propylene oxide production and operations are also regulated for environmental reasons given its hazardous nature during production. Manufacturers have to adhere to standards pertaining to air pollution control equipment at production facilities and strict disposal guidelines for any propylene oxide waste generated. Some regions and standards organizations are also promoting transition towards more sustainable production methods. In summary, propylene oxide is a critical petrochemical supporting major manufacturing sectors globally through its diverse applications especially in polyurethane products. While raw material price trends remain an important factor, the increasing uses of propylene oxide based chemicals coupled with downstream industry growth ensure steady future prospects for this multimillion ton chemical market. Adherence to environmental standards during production will also be a key aspect for sustainability.

0 notes

Text

Detailed Report on Propane Dehydration to Propylene Market | BIS Research

Propane dehydration to propylene is a chemical process in which propane (C₃H₈) is converted into propylene (C₃H₆) by removing hydrogen (H₂) molecules. This process typically occurs through catalytic dehydrogenation, where propane is passed over a catalyst, often chromium, platinum, or vanadium-based, at high temperatures (typically between 500°C and 700°C).

At BIS Research, we focus exclusively on technologies related to precision medicine, medical devices, life sciences, artificial intelligence (AI), machine learning (ML), Internet of Things (IoT), big data, blockchain technology, Propane Dehydration to Propylene Material , advanced materials and chemicals, agriculture and FoodTech, mobility, robotics, and aerospace and defense, among others.

The global propane dehydrogenation (PDH) to propylene market is projected to reach $22,721.2 million by 2031 from $10,314.6 million in 2022, growing at a CAGR of 9.2% during the forecast period 2022-2031.

Propane Dehydration to Propylene Overview

Propane dehydration to propylene, also known as propane dehydrogenation (PDH), is a key industrial process used to convert propane (C₃H₈) into propylene (C₃H₆), an essential building block in the petrochemical industry. Propylene is a vital raw material in the production of polypropylene plastics, acrylonitrile, propylene oxide, and other chemicals.

Chemical Reaction

The primary reaction in propane dehydrogenation is the removal of hydrogen atoms from propane to produce propylene and hydrogen gas:

C3H8→C3H6+H2C₃H₈ \rightarrow C₃H₆ + H₂C3H8→C3H6+H2

This is an endothermic reaction, meaning it requires the input of energy (in the form of heat) to proceed. The reaction typically takes place at high temperatures, generally between 500°C and 700°C, depending on the catalyst and reactor design used.

Catalysts Used in PDH Includes

Chromium Based Catalysts

Platinum Based Catalysts

Vanadium Based Catalysts

Bimetallic Catalysts

Grab a look at the report page click here !

Key factors influencing market growth include

Abundant availability of low cost propane feedstock especially from shale gas

Rapid Industrialization and expanding consumer markets

PDH technology is expected to play an increasingly central role in the global propylene supply chain, offering a more flexible and scalable solution for producers.

The PDH market is poised for long-term growth, supported by favorable economic conditions, strong demand drivers, and continued innovation in process and catalyst technology.

In the automobile industry, the demand for propylene derivatives such as propylene oxide and polypropylene is rising due to the increasing number of electric vehicles that are made from lightweight materials.

Market Segmentation

1 By Technology

CATOFIN

UOP Oleflex

Fluidized Catalytic Dehydrogenation (FCDh)

Steam Active Reforming (STAR)

Based on technology, the propane dehydrogenation (PDH) to propylene market is estimated to be led by the UOP Oleflex segment during the forecast period of 2022-2031.

2 By End Users

Automotive and Transportation

Construction

Packaging

Textile

Electrical and Electronics

Based on end users, the propane dehydrogenation (PDH) to propylene market is estimated to be led by the packaging segment during the forecast period of 2022-2031.

3 By Derivative

Polypropylene

Propylene Oxide

Acrylonitrile

Cumene

Alcohols

Based on derivative, the propane dehydrogenation (PDH) to propylene market is estimated to be led by the polypropylene segment during the forecast period of 2022-2031.

4 By Region

North America - U.S., Canada, and Mexico

Europe - Germany, France, Italy, Spain, Russia, and Rest-of-Europe

China

U.K.

Asia-Pacific and Japan - Japan, India, South Korea, ASEAN, and Rest-of-Asia-Pacific and Japan

In the global propane dehydrogenation (PDH) to propylene market, China and North America are anticipated to gain traction in terms of propane dehydrogenation (PDH) to propylene production, owing to the presence of the world’s largest manufacturers in those regions.

Demand Drivers and Limitations

Growing demand for propylene based products

Increased availability of shale gas

Sustainable and Circular Economy Initiatives

Petrochemical Demand

Fluctuation in Crude Oil Price

Have a look at the free sample click here !

Key Companies

• LyondellBasell Industries Holdings B.V.

• Borealis AG

• INEOS Group Limited

• GAIL (India) Limited

• Dow Chemical Company

• Koch Industries, Inc.

• Formosa Plastics Corporation

• KBR Inc.

Recent Developments in Propane Dehydrogenation (PDH) to Propylene Market

In March 2022, KBR and ExxonMobil Catalysts and Licensing collaborated on the advancements of propane dehydrogenation (PDH) technology. Under the collaboration, ExxonMobil's proprietary catalyst technology would be combined with KBR's proprietary K-PRO PDH technology to convert propane into propylene.

In January 2022, Hyosung Chemical started the production of propylene by PDH technology for the production of polypropylene units. Before the start-up of this plant, the polypropylene units were dependent on imported propylene.

Visit our Next Generation Fuel/ Energy Storage Solutions

Conclusion

The propane dehydration to propylene (PDH) market has experienced significant growth, driven by increasing global demand for propylene, especially for downstream products like polypropylene, acrylonitrile, and propylene oxide.

#Propane Dehydration to Propylene Market#Propane Dehydration to Propylene Report#Propane Dehydration to Propylene Industry

0 notes

Text

https://homment.com/giyIZGSWE8k0NHVzTjqz

The Propylene Oxide Market in 2023 is US$ 25.2 billion, and is expected to reach US$ 39.62 billion by 2031 at a CAGR of 5.80%.

0 notes

Text

https://zekond.com/read-blog/56170_propylene-oxide-market-size-analysis-and-forecast-2031.html

Propylene Oxide Market Size, Analysis and Forecast 2031

0 notes