#Profinet Encoders Distributors

Explore tagged Tumblr posts

Text

Choosing the Right Profinet Encoder: Characteristics and Best Practices

Profinet Encoder

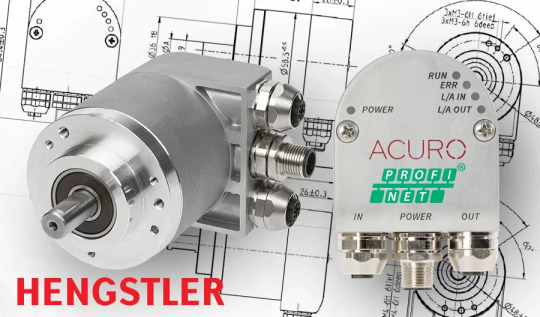

Multitier encoders with fieldbus, outright encoders collection MEM-Bus, best quality hengstler profinet encoders profile Specifications V4.1 version 3.162 related to Profidrives, demands of the Application Courses 3 and 4, RT Actual Time and IRT Isochronous Real Time Transmission Mode, common telegrams 81, 82, 83, 84, the customer telegram 860, encoders actual time diagnostic function makes sure the gadget state consistent monitoring, MEM-Bus encoders, multitier version with 29-bit resolution, Different mechanical versions are offered. The electric link is provided by 3 M12 adapters, the stout aluminium instance guarantees a high defence level. The building technology allows for high acceleration and rate worth’s and gives the transducer a long life.

Profinet Encoder Characteristics:

Fieldbus user interface: Profinet

Encoder Account V4.1 Variation 3.162

Application courses 3–4

Transmission settings (RT and IRT)

Conventional telegrams 81, 82, 83, and 84

Customer telegram 860

Aluminium situation

Defence level: IP67; shaft side: IP65

Resolution: 29 little bit

PROFINET-ready outright encoders function separately and are non-reactive.

Network frameworks are commonly subject to regular modifications, e.g., in the case of new robotics with constant changes of tools or expansions during procedures. PROFINET-ready outright encoders, Design A58HE (blind hollow birthed) and Version A58SE (shaft), are developed for harsh factory and plant atmospheres.

Conveniently designed right into a wide array of applications, these encoders plug straight right into a connect with marginal requirements and work in different setups, consisting of bus, ring, and star setups that can proceed interaction in the event of a line break.

As absolute encoders, they keep absolute position information even after a power loss, assisting in quick system healing at start-up without the requirement for system re-homing. Prepared for Market 4.0 and the Industrial Internet of Things, data exchange between the Model A58HE, Setting A58SE, and other applications has no influence on the control loophole.

These encoders are non-reactive and can function independently from the PLC or master, moving information through network entrances to various other automation networks and sites, as well as the cloud for analysis.

Encoders with Profane Communications

Encoder Products Company showcased its brand-new Design A58HE and Version A58SE, which are multi-turn, Ethernet-ready outright encoders made for rough manufacturing facilities and plant environments. Along with Ether pet cat Deterministic Interaction, the versions A58HE and A58SE now supply PROFINET communication procedures as well.

These encoders are especially suited to applications where fieldbus connectivity is needed and the encoder has to maintain absolute placement information after power-off occasions. The Model A58HE is a 58 mm encoder in a blind hollow-birthed construction, and the Model A58SE is a 58 mm shaft encoder readily available with either a securing flange or synch flange, in both compact and sturdy arrangements. The portable version is the most compact Ether feline or PROFINET-capable encoder readily available.

“Both the A58HE and A58SE encoders are easily made into a wide variety of applications," claims Sarah Walter, electric designer and EPC Technical Applications Manager. "And with the new heavy-duty design and the new small model—which is one of the most compact devices available on the market—they are unbelievably flexible mechanically. What actually sets our encoders apart, however, is their high accuracy. These absolutes will provide you with accurate activity comments whenever.

Conclusion

Sr. Indus Electro Systems Pvt. Ltd.: The non-reactive and independent operation of these encoders, coupled with their capability to deal with network portals, facilitates efficient information exchange within the network and also extends to cloud-based evaluation. As shown by Encoder Products Company's A58HE and A58SE designs, these encoders satisfy the demands of different applications, offering portable and sturdy configurations to accommodate diverse mechanical demands.

On the whole, the Profinet Encoder series stands out for its adaptability, reliability, and high performance, making it a beneficial component in the developing landscape of industrial automation.

#profinet encoders#Profinet Encoders Distributors#cable assemblies#maxon distributors india#harting han connectors#hengstler encoders

0 notes

Text

A Human-Machine Interface: What Is It and How Does It Operate?

Human-Machine Interfaces from best Weidmuller power supplies create a usable interface that helps a person establish a communication system with a device. We can explain this more straightforwardly by saying it is simply an input/output device. The information is input here. The person operating the machine inputs it into the machine. The machine outputs the commands based on the data fed into it. On the other hand, the machine may also input the information from its sensors or hardware, which is then outputted on the HMI for the machine operator to decipher and ultimately make out.

Next, combined with programmable logic controllers or PLC, machine sensors record and put forward the information as inputted and received. HMIs are often utilised in industrial settings because of the particular input/output relationship they carry with them. In this sector, an HMI is very frequently used to decipher, see, and control the following information:

Production Time

Production Trends

Visual Data

Temperature Control

Human-Machine Interface and Its Benefits

Human Machine Interfaces, or HMI, from us as one of the best cable assemblies in India, has become part and parcel of machine designs in the industrial sector primarily because of the number of benefits it offers its users. First, the increased visibility of these interfaces makes data centralisation easy to read and ensures that vital notifications or production changes are never missed. This interface's enhanced efficiency results in accurate, real-time data generation that is particularly useful in such a high-paced environment. Here are some other benefits of Human Machine Interface and they are:

Reduction in Cost

Improved Usability

Improved Management of Time

Areas of Application of HMI

We find the maximum utilisation of Human Machine Interface from Hengstler counters supplies in the industrial settings as this sector needs to communicate with and control the machines accurately. This sector requires this kind of control so that industrial processing can be maintained at the optimal level, proper control over the final finished product can be maintained, and the overall safety of the process can be taken care of. To be specific, the industries that use HMIs include:

Manufacturing

Recycling and Waste Management

Oil and Gas

Energy and Power

Food and Beverage

We Give a New Meaning to the Word “Efficiency”

We, SR Indus Electro System, one of the best Weidmuller Distributors in India, are the single source provider equipped with the latest Human-machine Interface technology. It is capable of meeting complex processes of machines and systems. Weidmuller HMI provides efficient integration to your automation systems. They are optimised to meet specific human-machine interfaces. Through our UV66-BAS-4-RES-W easy multi-touch panels, it becomes easier to monitor and control the machines and systems. Moreover, the u-view multi-touch panels from Weidmuller offer perfect image quality and are fit for use in the industrial environment devoid of any restrictions. Additionally, we provide profinet encoders.

Our HMI is very efficient performance-wise, as its image quality is unparalleled. Besides the image quality, its powerful processors make working with u-view multi-touch panels smooth and enjoyable. The compatibility rate of u-view multi-touch panels allows them to be used in various applications. This becomes possible because we use world-class web technology based on HTML5. Hengstler encoders presents robust motor feedback encoders tailored for demanding applications, compatible with both brushless servo and stepper motors. Leveraging Acuro drive technology, dynamic servo drives transition into a fully digital realm for the first time. Even under harsh operating conditions, such as those encountered within motor housings, reliability remains uncompromised. Proudly brought to you by Sr Indus Electro Systems.

#hengstler encoders#weidmuller power supplies#cable assemblies#harting han connectors#electronic components supplier#profinet encoders

0 notes

Text

Choosing Hengstler Counters for Your Industrial Automation Needs

Hengstler's was formed in 1846 in Johannes Hengstler's workshop, initially producing gongs for clocks up until 1912, when they started to make precision-transformed components as well. Eager to increase their organization, in 1926 Hengstler bought the Efunda Company, which produced counting devices and machines. Despite the economic crisis at the end of the 1920s, the company survived and continued to be an industrial success in the years that followed.

Throughout the 1950s, Hengstler bought a plastic shot melding machine that permitted them to establish an entire host of innovative originalities, such as the advanced counter device, the 'System 400', which was launched in 1957 and ended up being a worldwide success. Diversifying their profile better, they created a variety of analogue products for tape-recording the visibility or lack of employees, called 'Flexitimes' which sold all over Europe, eventually replacing them with electronic variations throughout the 1980s.

At the leading edge of innovation, they produced the initial modular rotary encoders with opto-ASIC modern technology throughout 1993, and their encoder portfolio was boosted further with a variety of procurements. Hengstler eventually entered the FORTIVE Team in 2016, a focused industrial growth company driving innovation in the locations of field instrumentation, transportation, and noticing and automation control.

To date, the Hengstler brand name is considered one of the globe's leading producers of industrial control elements, including a huge array of electronic and analog counters and rotary encoders that can be found in many industrial applications worldwide.

Simply a few of the considerable variety of Hengstler products we stock at Sr Indus Electro Systems Pvt Ltd:

Encoders

Counters

Couplings

Hengstler Counters Benefits

Accurate Counting: Hengstler counters distributors supply exact and accurate counting of occasions, ensuring reputable data collection and surveillance.

Digital Numerical Display: The counters include a digital numerical display, supplying clear and easy-to-read information, enhancing exposure, and minimizing the chances of mistakes.

Versatility: These counters are functional and can be used across diverse sectors for counting different sorts of occasions or processes.

Profinet Interface: Some Hengstler Counters come geared up with a Profinet interface, allowing smooth integration into industrial networks and enhancing connection and control.

Durability: Hengstler is known for making durable and long-lasting products. The counters are developed to stand up to tough industrial settings, guaranteeing resilient performance.

Certified for Safe Use: Hengstler Counters are certified for safe use in numerous industries, meeting market criteria and regulations.

Harrower Resolvers and Dynapar Encoders Solutions: Specific Hengstler Counters are integrated with Harrower Resolvers and Dynapar Encoders, offering added performances and services for specific applications.

Expert Technical Support: Hengstler offers expert technical support, making certain that customers receive assistance and advice when needed, adding to the reliable procedure of the counters.

Features and Benefits

Various front panel sizes

Front panel measurements are 55mm x 28mm.

Plug-in screw incurable link

Running temperature levels vary between -10 °C and 50 °C. How to Hengstler Encoder Repair

Our Hengstler encoder repair can be put on a variety of models, including the HD, ICURO, and HS arrays.

Typical problems and issues can include incorrect outcomes, fluid access, entrapped dirt bits, and alignment modifications caused by resonances or outside shock.

Utilizing our specialist screening and fixing hub, your Hengstler encoder repair service starts with a full assessment, permitting us to create a total recap of any concerns discovered.

Our engineers can work efficiently at any time with remarkable turn-around times. Our standard service can take between 4 and 5 days, with faster turn-around of less than 24 hours for business-essential circumstances.

If our team cannot accomplish your encoder repair service, a suitable replacement can be sourced for a really competitive rate via our global procurement network.

Conclusion

At Sr. Indus Electro Systems Pvt Ltd., we proudly stock a vast array of Hengstler products, consisting of encoders, counters, combinings, and more. Our partnership enables us to provide accurate counting, digital mathematical displays, and functional services to varied sectors.

The Hengstler counters, recognized for their durability and safety and security certifications, have actually ended up being important components in different industrial applications. Our team provides expert technical support, making Hengstler a trusted choice for services around the world.

For Hengstler encoder repair work, our specialized services resolve usual problems such as incorrect results, liquid access, and placement modifications. Our effective repair centre offers quick turnarounds, ensuring minimal downtime for essential operations.

Fundamentally, Hengstler's tradition as a leading distributor of industrial control elements proceeds, driven by technology, integrity, and a commitment to satisfying the evolving requirements of markets worldwide.

0 notes

Text

Profinet Encoders Products Company in India

Sr. Indus Electro Systems Pvt. Ltd. is one of the best profinet encoders distributors and suppliers in India. We offer best quality hengstler profinet encoders. These encoders are well regarded for their superior quality and provide state-of-the-art functionality and dependability, guaranteeing excellent performance in a variety of industrial applications. Our dedicated team strives to empower businesses by providing precision-engineered encoders that enhance operational efficiency, accuracy, and productivity across diverse sectors.

0 notes