#Pp Non Woven Geotextile

Explore tagged Tumblr posts

Text

Finding Geotextile Fabric Manufacturers in India?

Shankar Pack is one of the largest PP Geotextiles manufacturers in India. We provide high-strength polypropylene is widely used to filter, stabilize, reinforce, separate, drain, and isolate soils in geotextile manufacturers categories of civil construction applications, our products are quality tested on various parameters to ensure compliance with international industrial standards.

#pp woven geotextiles#pp non woven geotextile#plastic polyethylene sheeting#geotextile manufacturers#non woven geotextile suppliers#non woven geotextile fabric manufacturers#geotextile fabric suppliers#woven geotextile manufacturers in india#geotextile fabric manufacturers in india#geotextile fabric manufacturers in gujarat

0 notes

Text

What Are the Benefits of Using Non-Woven Fabric?

The non-woven fabrics are materials that are produced by thermal, mechanical and chemical processes. These are engineered fabrics that are used in various industrial and consumer products, by itself or with other materials. It is hygroscopic, UV resistant and flame retardant.

The non-woven fabrics have various benefits, including minimising solid wastes, and landfills and releasing no pollutants in the air and soil. In this blog, we will look into the various benefits of using non-woven fabrics that make them more practical and versatile than other traditional fabrics.

What is Non Woven Fabrics?

The non woven fabric is an engineered material manufactured from different fibers. These materials need not be converted to fibres into yarn, as the fibre yarns are bonded together due to inherent friction from one fibre to another.

Benefits of Using Non Woven Fabrics

Light Weight: The pp non-woven fabrics are the primary raw material for production. Its specific gravity is only 0.09, which is ⅗ of cotton. It is super-soft and pleasant to touch.

Softness: Its softness makes it ideal for non woven fabric bags. The bags are soft and comfy.

Eco-friendly: The reason why geotextile fabric manufacturers in Gujarat are in demand for its non-woven fabrics is its eco-friendly nature. This makes it applicable in different industries. With the rising concerns over environmental consciousness and sustainability, woven materials have gained immense popularity.

Air-Permeable: The non woven bags are made of fiber that exhibits excellent air permeability. This makes it easy to clean and maintain.

Non-Toxic and Non-irritant: The non woven bag material is non-toxic, non-irritant, odourless and stable. The manufacturers use food-grade materials, which makes it ideal for industries like pharmaceutical, personal care, cosmetics and other products.

Water Resistant: The non woven fabric manufacturer in India caters to different industries that need water-repellent materials. The non woven materials are made of polypropylene chips and are non-absorbent and water resistant properties. This makes the end-product exhibit excellent breathabilty and porous.

Excellent Physical Properties: As the material is made of PP spinning directly into the mesh and thermally bonded, it gives the products exceptional strength than other fibre materials.

Uses of Non Woven Fabric

The Non Woven Fabric is Used in a Variety of Applications, Such as:

Medical: The non-woven fabrics have gained a lot of popularity, especially during the pandemic. It is widely used in the manufacturing of various medical products like gloves, masks, surgical drapes, plastic, medical packaging, cleanroom wipes, disposal face masks and more.

Health & Hygiene: The spunboud non woven material has brought an evolution in the hygiene industry. It is used in producing various hygiene products like sanitary pads, diapers, make-up wipes, nail wipes, facial pads, and other products.

Geotextile and Construction: The PP cover manufacturers provide non-woven geotextiles that are used in various applications in the construction and engineering industry. It is primarily used for drainage systems, separation, canal construction, filtration, landfill lining and others.

Household: We are surrounded by non woven geotextiles. It is a part of everyday lives, ranging from water and air filters, household wipes, floor wipes, coffee filter material and much more. Shankar Packaging Ltd. is a prominent filtration fabric manufacturer. We offer a range of filtration materials in 100% multifilament, monofilament spun and other combinations.

Conclusion

Woven fabrics are used in different industrial sectors and play a pivotal role in the technical industry globally. Its soil stability, tear and puncture resistance, UV resistance, breathability, excellent weather ability and tensile strength make it a versatile material. Shankar Packaging Ltd. is a leading geotextile manufacturer and supplier in India.

We offer a comprehensive range of technical textiles, indu-tech, geo-tech, agro-tech and pack-tech products to clients across the globe. Our geotextile is also ideal for geo tubes and geo bags. At SPL, we provide technical textiles in 3 different yarns viz PES multifilament, PP tape yarns and PPMF. To know more about geotextiles and other products, contact us.

#non woven fabric#non woven fabric bags#geotextile fabric manufacturers in Gujarat#non woven bags#non woven bag material#non woven fabric manufacturer in India#spunboud non woven material#PP cover manufacturers#filter material

0 notes

Text

SAMI Layer Pavement Fabrics: Boost Road Durability

SAMI Layer Pavement Fabrics: Boost Road Durability

Introduction:

In the ever-evolving landscape of road construction, innovations like SAMI layer pavement fabrics are transforming the way we approach durability and longevity in infrastructure. This blog post explores the key benefits and applications of SAMI layer fabrics, shedding light on how they play a crucial role in enhancing the resilience of our roads.

Understanding SAMI Layer Pavement Fabrics:

How SAMI Layer Fabrics Boost Road Durability

SAMI layer pavement fabrics strengthen the road in multiple ways:

Crack Prevention

Acting as a barrier, the SAMI fabric inhibits cracks from appearing and spreading across the road surface. This adds years to the pavement life. The bonded fabric intercepts cracks at the surface level preventing downward propagation into the base layers.

Enhanced Structural Stability

The integration of the high-modulus SAMI layer evenly distributes traffic loads over a broader pavement area. This reduces concentrated stresses and deformations leading to pavement failures. The outcome is improved stability and strength.

All-Weather Reliability

SAMI fabrics are engineered using polymers like polyester, polyethylene or glass fibers that can withstand diverse environmental conditions from freezing winters to scorching summers. This makes roads more reliable through changing seasons.

Extended Lifespan

The collective impact of crack prevention, load distribution and weather resistance provided by SAMI layers is a significantly extended road lifespan. The surface maintains integrity for longer periods without requiring repairs and rehab.

Sustainable Construction

Applications of SAMI Layer Pavement Fabrics

Some prominent applications that highlight the benefits of SAMI layers include:

Road Rehabilitation

Applying SAMI fabrics provide an economical overlay solution for rehabilitating aged, damaged road surfaces. The fabric strengthens the existing base while providing a new wearing course.

New Road Construction

Integrating a SAMI layer into new road construction leads to more crack-resistant, durable surfacing that extends the period between overlays.

Preventing Reflective Cracking

SAMI layers serve as effective crack retarders at the interface of old and new pavement sections. This addresses reflective cracking, a common issue in road overlays.

Bridge Deck Protection

In conclusion:

SAMI layer pavement fabrics are a game-changer in the realm of road construction, offering a sustainable and effective solution for enhancing the durability of our infrastructure. As we pave the way to the future, these innovative fabrics prove to be an indispensable asset in creating roads that can withstand the test of time.

#geotextile#pavement#non woven fabrics#woven mesh fabric#pp woven bags#woven#woven fabric manufacturers#fabrics

0 notes

Text

Non-woven geotextiles are an important category of geosynthetics used across a wide range of infrastructure and construction applications. This guide provides a deep dive into what non-wovens are, their types, key properties, manufacturing processes, installation methods, advantages, applications, and more.

Introduction to Non-Woven Geotextiles

Geotextiles refer to permeable, polymeric textile materials used in contact with soil or rock in civil engineering applications. They can be woven or non-woven.

Non-woven geotextiles are made by bonding polymeric fibers together through processes like needle punching, heat bonding or resin bonding. The random arrangement of fibres produces a strong, porous and flexible material.

Geotextiles that are non-woven are better than those that are woven. They are better at filtering, draining, and cushioning, and are easier to install. In addition, they are more budget-friendly. These characteristics make non-wovens ideal for many functions like filtration, drainage, separation, and reinforcement.

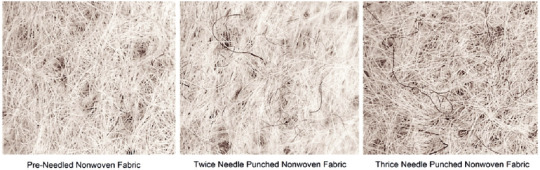

Needle Punched Non-Woven Geotextiles

Needle-punched non-wovens are a major type of non-woven geotextile produced by mechanically orienting and entangling fibers. Hundreds of fine needles repeatedly penetrate a fibre web to tangle the fibres into a strong, porous and stable fabric.

Compared to other non-wovens, needle-punched variants have high permeability and drainage capacity along with good puncture resistance. This makes them ideal for filtration and drainage applications.

Types of Needle-Punched Non-Woven Geotextiles

Needle-punched non-wovens can be categorized into three main types based on weight and fiber thickness:

Lightweight Needle Punched Wovens

Made from fine fibres and low fiber weights between 20-100 gsm. Mainly used in applications that do not require high strength.

Medium Weight Needle Punched Non Wovens

Heavier fibers and medium basis weights of 100-250 gsm. Provides moderate strength for functions like separation.

Heavyweight Needle Punched Non-Wovens

Very coarse, thick fibres and high basis weights above 250 gsm. Imparts maximum strength for reinforcement uses.

Selections depend on the target function. Non-woven fabrics can be categorized into lightweight and heavyweight variants.

Key Functions and Applications of Non-Woven Geotextiles

Non-woven geotextiles perform various functions that make them indispensable for major infrastructure and construction projects:

Filtration Applications

The porous structure allows water to pass through while blocking soil particles. This filtration ability is useful in:

Roadway drainage systems

Retaining walls

Landfill drainage

Water treatment plants

Drainage Applications

Nonwovens have high water flow rates in the principal direction. This makes them excellent for drainage purposes like:

Landfill drainage layers

Sports field drainage

Retaining wall and slope drainage

Separation Applications

The fabric physically separates dissimilar materials. Key applications include:

Roadway base and subbase separation

Railroad bed separation

Foundations separation

https://www.aakarperiwal.com/blogs/wp-content/uploads/2023/09/geotextile-500x500-3.webp

Reinforcement Applications

Non-wovens provide reinforcement for additional strength when wrapped around soil. Uses include:

Embankments over soft soils

Retaining walls with stacked blocks

Slopes requiring improved bearing capacity

Erosion Control Applications

The fabric acts as a permeable layer to protect against wind and water erosion while allowing water passage. Some uses are:

Covering slopes along railways and highways

Coastal embankments erosion control

Riverbanks and canal protection

Transportation Applications

Within road construction, non-wovens assist with filtration, separation, drainage and stabilization. Common applications:

Separation between sub-base and subgrade

Filtration in edge drains alongside pavements

Soil stabilization for improved load-bearing

Construction Applications

Foundations and walls drainage

Vapor barriers in concrete slabs

Flooring reinforcement and crack prevention

This demonstrates the versatility of non-woven geotextiles across diverse functions in C&I projects. Their adaptive properties drive widespread adoption.

Key Properties of Non-Woven Geotextiles

Non-woven geotextiles exhibit unique properties derived from their material composition, manufacturing method and overall structure:

Raw Materials

Most non-wovens use polypropylene as the raw material which is cost-effective and provides required properties. High-end variants use polyester or a polypropylene-polyester blend.

Basis Weight

Basis weight is the mass per unit area measured in g/m2. Heavier basis weights produce stronger fabrics with higher puncture resistance. Typical range is from 20 g/m2 to 300 g/m2.

Thickness

Thickness depends on fiber density and varies from 1mm to 15mm. Affects permeability, cushioning ability and separation effectiveness.

Hydraulic Properties

Non-wovens have high water permeability (normal to the plane) and adequate transmissivity. Allows swift drainage while blocking soil passage.

Mechanical Properties

Tensile strength, tear strength, puncture resistance and burst strength are key mechanical properties. Non woven selection depends on the required load capacity.

Endurance Properties

Long-term resistance against environmental exposure, chemicals, microbes and mechanical stresses comes under endurance properties. Requires proper polymer choice.

These characteristics directly impact the effectiveness and lifespan of the non-woven geotextile for its intended function.

Overview of Manufacturing Processes

Non-woven geotextile production involves specialized processes to achieve the desired fiber arrangement and properties:

Web Formation

The first step is creating a uniform web of fibres laid out in overlapping, random orientations using air, mechanical or wet-laid techniques.

Web Bonding

The fiber web undergoes thermal, chemical or mechanical bonding. This interlocks the fibres to impart strength, stability and thickness.

Finishing

Additional treatments enhance properties - for instance, calendering uses heated rollers to achieve smoothness. Fabric edges are trimmed to create rolls.

Testing and Inspection

Extensive testing under certified labs evaluates parameters like strength, permeability, opening size etc. This ensures compliance with specifications.

Keeping manufacturing consistent and monitoring variabilities is vital for non-woven quality assurance. Automation allows scalable production with minimal defects.

Design and Installation Factors for Non-Woven Geotextiles

Proper design, handling and deployment of non-wovens ensures successful project outcomes:

Site Preparation

The installation site must be graded uniformly and cleared of debris/rocks to avoid damage. Burial depth is determined. Subsurface drainage may be added.

Installation Techniques

Non wovens can be unrolled on site and placed loose or tense. Joints are sewn or bonded. Additional layers can be installed to enhance functioning. Fixings like sandbags or pegs may be used.

Seams and Overlaps

Adjoining rolls are overlapped for continuity. End overlaps depend on joint strength. Edges can be sewn, welded, glued or kept loose. Key consideration for soil retention uses.

Design Factors

Careful specifications of geotextile properties like strength, permeability, and opening size based on engineering requirements and testing. Survivability and performance lifetime also key.

Following recommended practices for non-woven deployment optimizes field performance and prevents failures.

Key Benefits and Advantages of Using Non-Woven Geotextiles

Non-woven geotextiles offer numerous benefits that make them advantageous over traditional materials:

Cost-Effectiveness

Made from polypropylene, non-wovens are an affordable alternative to CMP pipe drains or graded aggregates for drainage. Limited overlap joints also reduce the quantity required.

Rapid Drainage Performance

The high porosity provides greater flow capacity compared to sand filters or gravel layers. Useful in applications like retaining walls.

Good Puncture and Burst Resistance

The entangled fibrous structure provides better resistance against punctures during installation compared to woven geotextiles.

Ease of Installation

Flexible, lightweight non-wovens are simpler to install in field conditions compared to rigid materials. No special equipment needed.

Enhanced Properties

Specialized manufacturing processes like calendering and bonding create improved non-wovens with the right balance of filtration, separation, cushioning and strength.

Wider Widths

The ability to produce up to 5m wide rolls compared to just 1m for wovens leads to faster deployment with fewer joints.

These advantages have positioned non-wovens as a material of choice for major construction activities and geotechnical engineering applications.

Applications and Case Studies Demonstrating Non-Woven Geotextiles in Action

Non-woven geotextiles have delivered value across many real-world projects:

Landfill Construction - Needle-punched non-wovens used in leachate collection systems increased design life while reducing clogging through superior filtration compared to gravel layers.

Retaining Wall Drainage - Heat-bonded non-wovens used as wall wraps maintained water drainage and prevented soil washout, keeping 100km of critical rail walls safely stabilized through extreme weather.

Riverbank Protection - Durable non-woven wraps applied on embankments prevented erosion along highly flood-prone rivers through monsoons. Filtered runoff while retaining soil stability.

Roadway Improvement - Calendered non-wovens beneath motorway overpasses provided vital reinforcement to stabilize compressible soil while facilitating drainage and preventing pumping.

Coastal Reinforcement - Wide-width non-wovens encasing sandy coastal cliffs added shear strength and tensile reinforcement. Protected against collapse from rising sea levels and storm surges.

This demonstrates how non-wovens of different compositions can be adapted for specialized needs in infrastructure projects where performance and longevity are critical.

Industry Trends and Ongoing Innovations in Non-Woven Geotextiles

Several interesting trends, developments and innovations are shaping the non-woven geotextiles sector:

High Growth Potential - The non-wovens market is projected to grow steadily at 6% CAGR driven by major public infrastructure investments and demand from emerging economies.

Raw Material Advances - Enhanced polymers like high-density polypropylene and high-modulus polyester are creating improved non-wovens with greater functionality.

Manufacturing Improvements - Process enhancements and new techniques are allowing more fine-tuned manipulation of fiber properties during production.

Multifunctional Products - Combining non-wovens with drainage nets or reinforcing grids creates single products that provide filtration, separation and reinforcement together.

Application R&D - Ongoing research into novel uses for non-wovens like landfill caps, nuclear waste containment and offshore geotextiles to drive adoption across new domains.

Conclusion

Non-woven geotextiles have become an indispensable resource for civil engineering and infrastructure applications where their high permeability, strength, and versatility can enhance project outcomes and lifespan.

As materials and manufacturing continue evolving, non-wovens are poised to meet more specialized demands. With a thorough understanding of their capabilities, civil engineers can apply these adaptable fabrics for a sustainable future.

0 notes

Text

Top 10 Non-Woven Materials: Uses & Benefits

Non-woven materials are revolutionizing industries with their durability, cost-effectiveness, and eco-friendly nature. Here’s a quick look at the top 10 non-woven materials, their uses, and the benefits they offer:

1. Polypropylene (PP) Non-Woven Fabric

Uses: Shopping bags, surgical masks, and packaging.

Benefits: Lightweight, durable, and recyclable.

2. Polyester (PET) Non-Woven Fabric

Uses: Automotive interiors, filtration systems, and furniture.

Benefits: High strength, water resistance, and long-lasting.

3. Spunlace Non-Woven Fabric

Uses: Wet wipes, hygiene products, and cleaning cloths.

Benefits: Soft, highly absorbent, and strong.

4. Meltblown Non-Woven Fabric

Uses: Medical masks, air filters, and oil absorbents.

Benefits: Superior filtration and fine fiber structure.

5. Geotextile Non-Woven Fabric

Uses: Road construction, drainage, and soil stabilization.

Benefits: Robust, UV-resistant, and enhances soil strength.

6. Viscose Non-Woven Fabric

Uses: Diapers, wound dressings, and personal care products.

Benefits: Skin-friendly, biodegradable, and highly absorbent.

7. Biodegradable Non-Woven Fabric

Uses: Grocery bags, compostable packaging, and agricultural covers.

Benefits: Environmentally sustainable and decomposable.

8. Needle-Punched Non-Woven Fabric

Uses: Carpets, blankets, and soundproofing.

Benefits: Flexible, durable, and versatile.

9. Spunbond Non-Woven Fabric

Uses: Disposable gowns, agricultural sheets, and carry bags.

Benefits: Lightweight, breathable, and economical.

10. Laminated Non-Woven Fabric

Uses: Waterproof bags, protective clothing, and promotional products.

Benefits: Moisture-resistant and highly durable.

Conclusion

Non-woven materials offer tailored solutions for industries ranging from healthcare to agriculture. With a focus on sustainability and innovation, they are driving a greener and more efficient future.

https://favouritehub.com/top-10-non-woven-materials-uses-benefits/

0 notes

Text

A Beginner’s Guide to PP Spunbond Nonwoven Fabric Properties

In the realm of textiles, nonwoven fabrics have become increasingly popular due to their versatility and unique properties. Among the various types of nonwoven fabrics, PP spunbond nonwoven fabric stands out for its impressive characteristics and wide range of applications. This guide aims to provide beginners with an understanding of the properties of PP spunbond nonwoven fabric, its production process, and its uses.

Understanding Nonwoven Fabric

To fully appreciate PP spunbond nonwoven fabric, it’s essential to grasp the concept of nonwoven fabric itself. Non woven fabric are materials made from fibers that are bonded together through various methods, excluding traditional weaving or knitting techniques. This production method allows for a fabric that is both lightweight and durable, making it ideal for numerous applications across different industries.

Characteristics of Nonwoven Fabric

One of the most notable characteristics of nonwoven fabric is its flexibility. This property allows manufacturers to create fabrics that can be tailored to meet specific needs. Nonwoven fabrics can be produced in various weights, thicknesses, and textures, offering a broad spectrum of options for manufacturers and end-users alike. Furthermore, the production process can incorporate additional treatments, enhancing properties like water resistance, flame retardancy, and UV stability.

The Role of PP in Nonwoven Fabric

Polypropylene (PP) is a thermoplastic polymer widely used in the production of nonwoven fabrics. As a nonwoven fabric manufacturer, utilizing PP provides several advantages. First, PP is lightweight and has a low density, contributing to the overall lightness of the finished product. Second, it offers excellent chemical resistance, making it suitable for applications where exposure to various substances is expected. Lastly, PP spunbond nonwoven fabric exhibits good tensile strength and durability, which are crucial for ensuring that the fabric can withstand everyday wear and tear.

Properties of PP Spunbond Nonwoven Fabric

When exploring PP spunbond nonwoven fabric, several properties set it apart from other textiles. Here are some of the key attributes:

1. High Strength

One of the primary reasons for the popularity of PP spunbond nonwoven fabric is its high strength. The process of spinning the fibers and bonding them together creates a robust structure that can endure significant stress and strain. This property is particularly valuable in applications like geotextiles and agricultural coverings, where durability is paramount.

2. Breathability

PP spunbond nonwoven fabric is also known for its breathability. The fabric structure allows air to circulate freely, which is beneficial in applications like hygiene products and medical textiles. This breathability helps to keep moisture away from the skin, reducing the risk of skin irritation and infections.

3. Lightweight Nature

The lightweight nature of PP spunbond nonwoven fabric is another significant advantage. This property makes it easy to handle and transport, reducing shipping costs and simplifying manufacturing processes. It also contributes to the comfort of the final product, whether it’s a disposable garment or an industrial filter.

4. Cost-Effectiveness

From a manufacturing perspective, PP spunbond nonwoven fabric is cost-effective. The production process is efficient, allowing for large quantities of fabric to be produced in a relatively short time. Additionally, the raw materials used in creating PP are often less expensive than those for woven fabrics, resulting in lower production costs.

5. Chemical Resistance

As mentioned earlier, one of the advantages of using polypropylene is its excellent chemical resistance. PP spunbond nonwoven fabric can withstand exposure to various chemicals without degrading, making it suitable for medical and industrial applications where contact with chemicals is common.

6. Versatility

PP spunbond nonwoven fabric is incredibly versatile, allowing for a wide range of applications. From disposable medical gowns and face masks to agricultural fabrics and automotive interiors, the possibilities are nearly endless. This versatility makes it a popular choice among Non woven fabric manufacturer, as they can cater to different markets and customer needs.

Production Process of PP Spunbond Nonwoven Fabric

To fully understand the properties of PP spunbond nonwoven fabric, it's essential to explore its production process. The process involves several key steps:

1. Polymer Extrusion

The first step in creating PP spunbond nonwoven fabric is polymer extrusion. In this process, polypropylene pellets are heated until they melt and are then extruded through a spinneret. The spinneret has multiple holes, creating long continuous filaments of polypropylene.

2. Spinning

After extrusion, the filaments are cooled and drawn to enhance their strength. The drawn filaments are then laid out in a random or oriented manner on a conveyor belt. This step is crucial as it determines the final properties of the nonwoven fabric.

3. Bonding

The next step involves bonding the laid fibers together to form a cohesive fabric. This can be achieved through various methods, including thermal, chemical, or mechanical bonding. In the case of PP spunbond nonwoven fabric, thermal bonding is commonly used, where heat is applied to the fabric to fuse the fibers together.

4. Finishing

Once the fabric is bonded, it may undergo finishing processes to enhance its properties. This can include treatments for water repellency, antimicrobial properties, or dyeing. These finishes allow manufacturers to tailor the fabric to specific applications and customer preferences.

Applications of PP Spunbond Nonwoven Fabric

PP spunbond nonwoven fabric finds use in a wide variety of applications, thanks to its unique properties. Here are some common applications:

1. Medical Textiles

In the medical field, PP spunbond nonwoven fabric is used to create surgical gowns, masks, and drapes. Its breathability and strength make it ideal for disposable medical products, helping to maintain hygiene and reduce the risk of infection.

2. Hygiene Products

This type of nonwoven fabric is also widely used in hygiene products such as diapers, feminine hygiene products, and adult incontinence products. The fabric's soft texture and moisture-wicking properties enhance comfort and performance.

3. Agriculture

In agriculture, PP spunbond nonwoven fabric serves as mulch films, crop covers, and weed control fabrics. Its durability and UV resistance make it suitable for protecting crops and promoting healthy growth.

4. Construction

The construction industry utilizes PP spunbond nonwoven fabric in geotextiles, providing drainage and soil stabilization. Its high strength and resistance to chemicals make it an excellent choice for various construction applications.

Conclusion

In summary, PP spunbond nonwoven fabric offers a unique combination of properties that make it an essential material in various industries. Its strength, breathability, lightweight nature, and cost-effectiveness are key attributes that appeal to manufacturers and end-users alike. As the demand for nonwoven fabrics continues to grow, understanding the properties of Non woven fabric spunbond will help beginners appreciate its significance in the modern textile landscape. Whether you're considering purchasing nonwoven fabric or exploring its applications, this beginner's guide provides a solid foundation for understanding this remarkable material. Frequently Asked Questions (FAQs)

Where is PP spunbond nonwoven fabric used? It is used in a variety of applications, including healthcare (surgical gowns and masks), agriculture (crop covers and mulch), geotextiles (soil stabilization), hygiene products (diapers), and packaging (shopping bags). Is PP spunbond nonwoven fabric recyclable? Yes, PP spunbond nonwoven fabric can be recycled, depending on the local recycling facilities. Many manufacturers are now producing fabrics from recycled materials, promoting sustainability.

Can PP spunbond nonwoven fabric be printed on? Yes, PP spunbond nonwoven fabric can be printed on using various techniques, including screen printing and digital printing. This makes it suitable for branding and promotional items.

0 notes

Text

PP Spunbond Nonwoven Fabric: A Comprehensive Guide

Introduction to PP Spunbond Nonwoven Fabric

PP (Polypropylene) spunbond nonwoven fabric is a versatile and widely used material in various industries due to its unique properties and cost-effectiveness. The term "spunbond" refers to a specific manufacturing process that creates nonwoven fabrics from thermoplastic polymers like polypropylene. Unlike traditional woven fabrics, where threads are interlaced, Spunbond nonwoven fabric is made by bonding long fibers through mechanical, thermal, or chemical means. This process gives it superior strength and durability, making it an essential material in medical, agricultural, and industrial applications.

What is Spunbond Nonwoven Fabric?

Spunbond nonwoven fabric is created through a process where thermoplastic polymers, typically polypropylene, are melted and extruded through fine nozzles to form continuous filaments. These filaments are then laid onto a conveyor belt in a random web-like pattern. The bonding process involves either thermal or chemical bonding to create a strong, durable sheet of fabric. The result is a lightweight, breathable, and flexible material that offers excellent strength, moisture resistance, and softness.

Properties of PP Spunbond Nonwoven Fabric

PP spunbond nonwoven fabric stands out due to its exceptional properties, making it highly suitable for various applications. First, it is lightweight, which makes it easy to handle and cost-effective in terms of transportation and storage. Additionally, the material is breathable, allowing air to pass through while still providing adequate protection from particles and liquids. Its high tensile strength ensures that it can withstand rigorous use in demanding environments, while its resistance to chemicals and UV radiation further extends its range of applications.

Applications of Spunbond Nonwoven Fabric

Spunbond nonwoven fabric is widely used across many industries due to its versatility. In the medical field, it is commonly used to make surgical gowns, masks, and disposable drapes due to its barrier properties and sterilization capabilities. In agriculture, spunbond nonwoven fabric serves as crop covers, helping to protect plants from frost, insects, and extreme weather conditions while allowing sunlight and moisture to penetrate. Furthermore, the fabric finds use in the automotive industry for insulation and soundproofing components. It is also a key material in the production of hygiene products, such as diapers and sanitary napkins, owing to its softness and absorbent qualities.

Manufacturing Process of Spunbond Nonwoven Fabric

The process of manufacturing spunbond nonwoven fabric involves several key stages. First, polypropylene resin is fed into an extruder, where it is heated and melted. The molten polymer is then forced through a spinneret with fine holes, which produces continuous filaments. These filaments are stretched and cooled before being deposited onto a moving conveyor in a random pattern. The web of filaments is then Spun bonded non woven fabric together using heat, pressure, or chemicals to form a solid fabric. The final product can be treated with additional coatings or additives to enhance specific properties, such as water repellency or flame resistance.

Differences Between Spunbond and Other Nonwoven Fabrics

Spunbond nonwoven fabric differs from other types of nonwoven fabrics, such as meltblown and needlepunch, primarily in terms of its manufacturing process and properties. Meltblown nonwoven fabrics, for example, have finer fibers and are often used for filtration applications, such as face masks and air filters. In contrast, spunbond nonwoven fabric has thicker fibers and is generally used for structural and protective applications. Needlepunch nonwoven fabrics, on the other hand, are produced by mechanically entangling fibers, resulting in a thicker and more textured fabric, often used in carpets and geotextiles.

Advantages of Using PP Spunbond Nonwoven Fabric

One of the main advantages of PP spunbond nonwoven fabric is its cost-effectiveness. The production process is relatively simple, and the raw material (polypropylene) is inexpensive. This makes spunbond nonwoven fabric an affordable option for manufacturers in various industries. Additionally, the fabric's strength and durability ensure that it can be used in a wide range of demanding applications, from medical supplies to industrial materials. The material is also environmentally friendly, as it is 100% recyclable and can be reused multiple times without losing its properties.

Environmental Impact and Sustainability of Spunbond Nonwoven Fabric

While Non woven spunbond fabric is made from polypropylene, a synthetic polymer derived from petroleum, it is still considered a more sustainable option compared to other materials. This is because the production process uses less energy and water, and the fabric itself is recyclable. Moreover, the long lifespan of PP spunbond nonwoven fabric means that it does not need to be replaced frequently, reducing the amount of waste generated. Additionally, advances in technology have led to the development of biodegradable versions of spunbond nonwoven fabric, which break down more quickly in the environment.

Customization and Enhancements of Spunbond Nonwoven Fabric

One of the key benefits of using spunbond nonwoven fabric is the ability to customize it to meet specific needs. Manufacturers can alter the thickness, weight, and texture of the fabric to suit different applications. For instance, spunbond nonwoven fabric can be made thicker and more durable for use in construction and industrial settings, or it can be made softer and more breathable for medical and hygiene products. Additionally, the fabric can be treated with various additives, such as fire retardants, antimicrobial agents, or hydrophobic coatings, to enhance its performance in specific environments.

Challenges and Future Developments in Spunbond Nonwoven Fabric

While PP spunbond nonwoven fabric offers many advantages, there are also some challenges to consider. One of the main challenges is the environmental impact of polypropylene, as it is derived from non-renewable resources. However, ongoing research and development efforts are focused on finding alternative materials and improving the biodegradability of nonwoven fabrics. Additionally, advancements in manufacturing technology are expected to further enhance the properties of spunbond nonwoven fabric, making it even more versatile and sustainable in the future.

Conclusion: The Growing Demand for Spunbond Nonwoven Fabric

The demand for spunbond nonwoven fabric is expected to continue growing, driven by its wide range of applications and its cost-effectiveness. Industries such as healthcare, agriculture, and construction are increasingly relying on this material for its strength, durability, and versatility. As manufacturers continue to innovate and improve the properties of spunbond nonwoven fabric, it will likely play an even greater role in addressing global challenges, from sustainability to healthcare. Whether it's protecting crops, preventing infection, or enhancing industrial processes, spunbond nonwoven fabric is a critical material in modern society.

FAQs about Spunbond Nonwoven Fabric

1. What is spunbond nonwoven fabric used for?

Spunbond nonwoven fabric is used in a variety of applications, including medical supplies (surgical gowns, masks), agriculture (crop covers), automotive components, hygiene products (diapers, sanitary napkins), and industrial materials.

2. Is PP spunbond nonwoven fabric recyclable?

Yes, PP spunbond nonwoven fabric is 100% recyclable, making it an environmentally friendly option. Additionally, some manufacturers are developing biodegradable versions to further reduce environmental impact.

3. How is spunbond nonwoven fabric made?

Spunbond nonwoven fabric is made by melting polypropylene polymer and extruding it through fine nozzles to form continuous filaments. These filaments are then laid randomly and bonded together using heat or chemicals to create a strong, durable fabric.

0 notes

Text

PP Fibrillated Yarn: Enhancing Durability in End Products

In the world of textiles and materials, durability is a key factor that manufacturers and consumers alike consider when choosing products. One innovative material that has gained popularity for its strength and versatility is PP Fibrillated Yarn Price. This specialized yarn is increasingly used across various industries, enhancing the durability of end products and offering numerous benefits. In this blog, we will explore what PP fibrillated yarn is, its properties, applications, and how it contributes to creating long-lasting products.

What is PP Fibrillated Yarn?

PP fibrillated yarn is made from polypropylene, a thermoplastic polymer known for its excellent strength-to-weight ratio. The term "fibrillated" refers to the process by which the yarn is extruded and then split into PP Fibrillated Yarn Suppliers filaments, creating a network of interconnected strands. This unique structure not only provides enhanced strength but also increases the surface area of the yarn, allowing for improved adhesion in various applications.

Key Properties of PP Fibrillated Yarn

Strength: One of the standout features of PP fibrillated yarn is its remarkable tensile strength. This makes it suitable for applications where durability is essential.

Lightweight: Despite its strength, PP fibrillated yarn is lightweight, which helps reduce the overall weight of products without compromising their integrity.

Chemical Resistance: Polypropylene exhibits resistance to many chemicals, making PP fibrillated yarn suitable for use in challenging environments.

Moisture Resistance: The yarn does not absorb water, which helps prevent mold and mildew, further enhancing its durability.

UV Stability: PP fibrillated yarn can be treated to resist degradation from ultraviolet (UV) light, extending the lifespan of products exposed to sunlight.

Applications of PP Fibrillated Yarn

PP fibrillated yarn is used across various sectors due to its unique properties. Here are some common applications where this material shines:

1. Geotextiles

In civil engineering and construction, PP fibrillated yarn is widely used in geotextiles for applications such as soil stabilization, erosion control, and drainage systems. Its strength and moisture resistance make it ideal for reinforcing soil structures and preventing erosion, thus enhancing the durability of infrastructure projects.

2. Agriculture

In agricultural applications, PP fibrillated yarn is utilized for making nets and ropes. These products are used for securing crops, shading plants, and creating barriers against pests. The durability of the yarn ensures that these agricultural tools withstand harsh weather conditions, leading to better crop yields and reduced costs associated with replacements.

3. Non-Woven Fabrics

PP fibrillated yarn is a popular choice in the production of non-woven fabrics. These fabrics are widely used in hygiene products, such as diapers and sanitary pads, as well as in medical applications like surgical masks. The durability and moisture resistance of PP fibrillated yarn enhance the longevity and effectiveness of these products, providing consumers with reliable options.

4. Industrial Applications

In various industrial settings, PP fibrillated yarn is used for making durable packaging materials, tarpaulins, and conveyor belts. Its strength and lightweight properties make it an ideal choice for applications where performance and longevity are critical. Manufacturers benefit from reduced replacement costs due to the enhanced durability of products made with this yarn.

5. Sports and Leisure

PP fibrillated yarn is also used in sports nets, ropes, and other recreational equipment. The durability and resistance to environmental factors ensure that sports gear can withstand rigorous use over time. Whether it's fishing nets or sports field fencing, products made from PP fibrillated yarn provide reliable performance.

Enhancing Durability in End Products

The unique structure and properties of PP fibrillated yarn contribute significantly to enhancing the durability of end products. Here’s how:

1. Improved Adhesion

The fibrillated structure increases the surface area of the yarn, allowing for better adhesion when used in composite materials. This is particularly important in applications where multiple layers or materials are bonded together. Stronger adhesion means greater durability and a longer lifespan for the final product.

2. Resistance to Environmental Factors

PP fibrillated yarn’s resistance to moisture, chemicals, and UV light helps protect products from environmental degradation. For instance, outdoor furniture made with PP fibrillated yarn will last longer, retaining its appearance and structural integrity despite exposure to sun and rain.

3. Lightweight and Strong

The combination of being lightweight and strong allows manufacturers to create products that are easy to handle and transport without compromising durability. This is particularly beneficial in industries like shipping and logistics, where weight can significantly affect costs.

4. Cost-Effectiveness

Investing in products made with PP fibrillated yarn can be cost-effective in the long run. Although the initial investment may be higher than traditional materials, the reduced need for replacements and maintenance, combined with the enhanced performance, leads to savings over time.

Choosing the Right PP Fibrillated Yarn

When selecting PP fibrillated yarn for specific applications, it’s essential to consider factors such as tensile strength, thickness, and UV resistance. Different projects may require different specifications, and working with reputable suppliers who can provide quality assurance is crucial.

Tips for Selection:

Understand the Application: Identify the specific requirements of the end product and choose a yarn that meets those needs.

Consult with Experts: Engage with manufacturers or suppliers who can guide you in selecting the right type of PP fibrillated yarn based on your project.

Test Samples: Whenever possible, request samples to test the performance of the yarn in real-world conditions before making a bulk purchase.

Conclusion

PP fibrillated yarn has emerged as a game-changer in various industries, providing enhanced durability and versatility in end products. Its unique properties, including strength, lightweight nature, and resistance to Fibrillated Polypropylene Yarn factors, make it an ideal choice for applications ranging from construction and agriculture to textiles and sports gear.

As businesses continue to seek durable solutions that can withstand the rigors of daily use, PP fibrillated yarn stands out as a reliable option. By investing in this innovative material, manufacturers can enhance the longevity of their products, ultimately leading to cost savings and improved customer satisfaction. Whether you are in construction, agriculture, or any industry that values durability, considering PP fibrillated yarn may be one of the best decisions for your product development strategy.

Frequently Asked Questions (FAQs):

1. What is PP fibrillated yarn, and how does Singhal Industries utilize it in their products? PP fibrillated yarn is a type of yarn made from polypropylene that features a unique fibrillated structure, enhancing its strength and durability. Singhal Industries uses this innovative material in various applications, including geotextiles, agricultural nets, and non-woven fabrics, ensuring high-quality and long-lasting products.

2. How does Singhal Industries ensure the durability of their products made from PP fibrillated yarn? Singhal Industries ensures durability by selecting high-quality PP fibrillated yarn that offers excellent tensile strength, moisture resistance, and UV stability. This attention to material quality, combined with advanced manufacturing processes, allows them to create products that withstand environmental challenges and provide reliable performance over time.

3. Why should businesses choose Singhal Industries for their PP fibrillated yarn needs? Businesses should choose Singhal Industries for their PP fibrillated yarn needs due to the company’s commitment to quality and innovation. With a focus on enhancing product durability and performance, Singhal Industries provides a wide range of solutions tailored to meet specific industry requirements, ensuring customer satisfaction and cost-effectiveness.

0 notes

Text

PP Spunbond Nonwoven Fabric: Versatility, Benefits, and Applications

Polypropylene (PP) spunbond nonwoven fabric is a versatile and widely used material in various industries due to its unique properties and benefits. This type of Non Woven Cloth Manufacturer is produced through a specialized process that combines polypropylene fibers into a strong, durable fabric without weaving or knitting. This article explores the characteristics, advantages, applications, and frequently asked questions (FAQs) about PP spunbond nonwoven fabric.

What is PP Spunbond Nonwoven Fabric?

PP spunbond nonwoven fabric is made from polypropylene fibers that are spun and bonded together through a process of spinning, heating, and bonding. The result is a fabric that is neither woven nor knitted but still offers a range of benefits and applications.

The manufacturing process involves melting polypropylene pellets and extruding them through spinnerets to form continuous filaments. These filaments are then laid out in a web and bonded together using heat, pressure, or adhesive. The result is a fabric that is strong, lightweight, and has a variety of uses across different industries.

Properties of PP Spunbond Nonwoven Fabric

PP spunbond nonwoven fabric has several distinctive properties that make it suitable for various applications:

Durability: The spunbond process creates a fabric with excellent strength and durability. The fibers are bonded together in a way that provides resistance to tearing and abrasion.

Lightweight: PP spunbond fabric is lightweight, which makes it easy to handle, transport, and use in various applications.

Breathability: The fabric has good breathability, allowing air and moisture to pass through. This makes it suitable for applications where ventilation is important.

Water Resistance: PP spunbond nonwoven fabric is resistant to water, making it useful in applications where moisture resistance is required.

Chemical Resistance: The polypropylene fibers provide resistance to many chemicals, which is beneficial in industrial and medical applications.

Cost-Effectiveness: The production process of PP spunbond nonwoven fabric is cost-effective, making it a budget-friendly option for many uses.

Eco-Friendly: Polypropylene is a recyclable material, and nonwoven fabrics made from it can often be recycled or repurposed, contributing to sustainability.

Versatility: PP spunbond fabric can be manufactured in various weights, thicknesses, and colors, making it adaptable to a wide range of applications.

Applications of PP Spunbond Nonwoven Fabric

The Non Woven Textile Manufacturers is used in numerous industries due to its versatile properties. Some common applications include:

Medical and Healthcare: In the medical field, PP spunbond nonwoven fabric is used for surgical gowns, masks, and other disposable medical items. Its breathability, strength, and resistance to fluids make it ideal for these applications.

Agriculture: In agriculture, PP spunbond fabric is used for crop covers, weed barriers, and protective covers. It helps regulate temperature, control weeds, and protect plants from pests and harsh weather.

Construction: In construction, PP spunbond nonwoven fabric is used as a geotextile material in road construction, erosion control, and drainage systems. Its strength and filtration properties help improve soil stability and prevent erosion.

Packaging: The fabric is used in packaging applications, such as in the production of shopping bags, protective covers, and wrapping materials. Its durability and lightweight nature make it a practical choice for these uses.

Home Textiles: PP spunbond fabric is used in various home textile products, including mattress covers, curtains, and upholstery. Its versatility and ease of maintenance make it suitable for these applications.

Automotive: In the automotive industry, PP spunbond nonwoven fabric is used for interior car upholstery, sound insulation, and filtration systems. Its durability and performance characteristics make it ideal for automotive applications.

Hygiene Products: The fabric is used in the production of hygiene products such as diapers, feminine hygiene products, and adult incontinence products. Its softness, absorbency, and comfort are key attributes for these applications.

Industrial Uses: PP spunbond nonwoven fabric is also used in various industrial applications, including filter media, protective clothing, and various components requiring durable, lightweight materials.

Benefits of PP Spunbond Nonwoven Fabric

PP spunbond nonwoven fabric offers numerous benefits across different applications:

High Strength: The spunbond process produces a fabric with high tensile strength and durability, making it suitable for demanding applications.

Cost-Effective: The efficient manufacturing process makes PP spunbond nonwoven fabric a cost-effective material, providing good performance at an affordable price.

Breathability: The fabric’s breathability makes it comfortable for use in medical and hygiene products, as well as in agricultural and industrial applications.

Water and Chemical Resistance: The fabric’s resistance to water and chemicals enhances its utility in various environments, including medical, agricultural, and industrial settings.

Versatility: The ability to produce PP spunbond fabric in different weights, colors, and specifications allows for a wide range of applications, from medical supplies to construction materials.

Eco-Friendly Options: While polypropylene is a synthetic material, efforts are made to improve the recyclability and environmental impact of PP spunbond nonwoven fabric, contributing to more sustainable practices.

Ease of Fabrication: PP spunbond fabric can be easily cut, sewn, and shaped, allowing for straightforward fabrication into various products and applications.

Conclusion

PP spunbond nonwoven fabric is a versatile and durable material that offers a range of benefits across various industries. Its properties, including high strength, lightweight nature, and resistance to water and chemicals, make it suitable for applications in medical supplies, agriculture, construction, and more. As an affordable and adaptable fabric, Non Woven Fabric Manufacturing continues to be a valuable choice for many industrial and commercial needs. Whether you are involved in manufacturing, agriculture, or any other industry that requires high-performance materials, PP spunbond nonwoven fabric provides a reliable and effective solution.

FAQs About PP Spunbond Nonwoven Fabric

1. What is the difference between spunbond and other nonwoven fabrics?

Spunbond nonwoven fabric is made by spinning continuous fibers and bonding them together using heat and pressure. This process results in a fabric with high strength and durability. Other nonwoven fabrics, such as meltblown or needlepunched, use different methods for bonding fibers and may have different properties and applications.

2. Is PP spunbond nonwoven fabric environmentally friendly?

PP spunbond nonwoven fabric is made from polypropylene, a recyclable material. However, the environmental impact of the fabric depends on how it is disposed of and whether it is recycled. Efforts are being made to improve the sustainability of nonwoven fabrics, including increasing recycling options and using eco-friendly additives.

3. Can PP spunbond nonwoven fabric be used for outdoor applications?

Yes, PP spunbond nonwoven fabric can be used for outdoor applications, such as agricultural covers and geotextiles. Its resistance to water and weathering makes it suitable for various outdoor uses.

4. How do you clean and maintain PP spunbond nonwoven fabric?

PP spunbond fabric is relatively low maintenance. It can be cleaned with mild detergents and water. For specific applications, such as medical or hygiene products, follow the manufacturer’s recommendations for cleaning and maintenance.

5. What are the typical weights and thicknesses of PP spunbond nonwoven fabric?

PP spunbond nonwoven fabric is available in a range of weights and thicknesses, typically from 10 to 200 grams per square meter (gsm). The choice of weight and thickness depends on the intended application and performance requirements.

0 notes

Text

PP Spunbond Nonwoven Fabric: Versatile, Durable, Eco-Friendly Solutions

In the world of modern manufacturing and packaging, materials that offer versatility, durability, and environmental sustainability are highly valued. PP (Polypropylene) Spunbond Nonwoven Fabric stands out as a key player in meeting these criteria, serving a wide range of applications across various industries. At Singhal Industries, we specialize in manufacturing high-quality PP Spunbond Nonwoven Fabric that meets stringent standards of performance and eco-friendliness.

What is PP Spunbond Nonwoven Fabric?

PP Spunbond Nonwoven Fabric is a type of nonwoven material made from thermoplastic polymer polypropylene. Unlike traditional woven fabrics, which are created by weaving or knitting yarns together, nonwoven fabrics are manufactured by bonding fibers together through various processes. PP Spunbond Exporter in Ahmedabad is produced by spinning and bonding polypropylene fibers together to form a strong and durable web.

Key Characteristics of PP Spunbond Nonwoven Fabric

1. Versatility:

PP Spunbond Nonwoven Fabric is incredibly versatile and finds applications in diverse industries such as agriculture, medical, automotive, construction, and packaging.

It can be engineered to have different properties like water resistance, breathability, and strength, making it suitable for a wide range of end uses.

2. Durability:

Known for its strength and durability, PP Spunbond Nonwoven Fabric offers excellent tear and tensile strength, making it ideal for applications where robust performance is essential.

It withstands harsh environmental conditions, including exposure to chemicals and UV radiation, without compromising its integrity.

3. Eco-Friendliness:

As environmental sustainability becomes increasingly important, PP Spunbond Nonwoven Fabric stands out for its eco-friendly characteristics.

It is recyclable and can be manufactured using recycled polypropylene materials, reducing overall environmental impact.

The production process of Spunbond non woven fabric manufacturer consumes less energy and water compared to traditional woven fabrics, making it a greener choice.

Applications of PP Spunbond Nonwoven Fabric

PP Spunbond Nonwoven Fabric's versatility makes it indispensable in various industries:

1. Agriculture:

Used in crop protection, greenhouse coverings, and as ground covers due to its permeability to air and water.

2. Medical and Hygiene:

Widely used in surgical gowns, face masks, and medical wipes due to its softness, breathability, and bacteria resistance.

3. Packaging:

Ideal for packaging applications such as tote bags, shopping bags, and promotional bags due to its strength, lightweight nature, and printability.

4. Automotive:

Used in car upholstery, interior trim, and insulation due to its durability, noise reduction properties, and resistance to mold and mildew.

5. Construction:

Used as geotextiles, roofing membranes, and house wrap due to its strength, moisture resistance, and ability to provide thermal insulation.

Why Choose Singhal Industries for PP Spunbond Nonwoven Fabric?

Singhal Industries is a leading manufacturer of PP Spunbond Nonwoven Fabric, offering:

High-Quality Products: We adhere to strict quality control measures to ensure our PP Spunbond Nonwoven Fabric meets international standards.

Customization: We offer customization options in terms of colors, weights, and specifications to meet specific customer requirements.

Sustainability: Our manufacturing processes emphasize sustainability, with a focus on reducing environmental impact through responsible practices.

Reliability: With years of industry experience and a commitment to customer satisfaction, Singhal Industries is a trusted partner for all your nonwoven fabric needs.

Conclusion

PP Spunbond nonwoven Supplier India continues to revolutionize industries with its versatility, durability, and eco-friendly properties. Whether you're looking for packaging solutions, medical textiles, agricultural covers, or automotive components, PP Spunbond Nonwoven Fabric from Singhal Industries offers a reliable and sustainable choice. Contact us today to explore how our innovative nonwoven fabric solutions can benefit your business.

FAQS

What is PP Spunbond Nonwoven Fabric? PP Spunbond Nonwoven Fabric is a type of material made from polypropylene fibers that are spun and bonded together. It is known for its strength, durability, and versatility in various applications.

What are the key benefits of PP Spunbond Nonwoven Fabric? PP Spunbond Nonwoven Fabric offers versatility across industries, durability against wear and tear, and eco-friendly properties as it is recyclable and can be made from recycled materials.

In which industries is PP Spunbond Nonwoven Fabric commonly used? It is used in agriculture for crop protection and ground cover, in medical applications for surgical masks and gowns, in packaging for bags and wraps, in automotive for upholstery and insulation, and in construction for geotextiles and roofing membranes.

How environmentally friendly is PP Spunbond Nonwoven Fabric? PP Spunbond Nonwoven Fabric is considered eco-friendly due to its recyclability and the potential to use recycled materials in its production. Its manufacturing process also consumes less energy and water compared to traditional fabrics.

Why choose PP Spunbond Nonwoven Fabric from Singhal Industries? Singhal Industries offers high-quality PP Spunbond Nonwoven Fabric with customization options, stringent quality control measures, and a commitment to sustainability. Our products meet international standards and are tailored to meet specific customer needs.

0 notes

Text

Is Geotextile Fabric the Same as Landscape Fabric?

Shankar Packaging provides details on Geotextile Fabric vs Landscape Fabric. Geotextile fabric and landscape fabric have similar properties but both are different. Geotextile is used in various construction and engineering applications. For More Information visit our blog!

#geotextile landscape fabric#PP non woven geotextile#non woven or woven geotech fabric#Geotextile Fabric vs Landscape Fabric

0 notes

Text

Selecting the Perfect PP Woven Fabric: A Comprehensive Guide

Description

PP woven fabric is a robust and versatile material made from polypropylene threads, known for its high tensile strength and tear resistance. Widely used in agriculture, construction, and packaging, it excels in heavy-duty applications like crop covers, geotextiles, and bulk bags. Key features include water resistance and UV resistance, with options for lamination or coating to enhance properties for specific uses such as waterproof tarpaulins and protective covers. When selecting PP woven fabric, consider its weight, thickness, strength, and durability to ensure it meets your application needs, providing a cost-effective and reliable solution.

Physical Characteristics

Understanding the physical characteristics of PP woven fabric is essential for selecting the right type for your needs. Here are key factors to consider:

Weight and Thickness

Strength and Durability

Water and Chemical Resistance

UV Resistance

Breathability and Air Permeability

Consider Application

When selecting the perfect PP woven fabric, it’s crucial to consider the specific application to ensure optimal performance and longevity. Here are some key applications:

Agriculture and Horticulture

Construction and Infrastructure

Packaging and Transport

Home and Outdoor Use

Type Of Fabric

Selecting the right PP woven fabric involves understanding its different types:

1. Coated vs. Uncoated:

Coated PP woven fabric offers enhanced protection against moisture, chemicals, and UV rays, ideal for outdoor use. Uncoated PP woven fabric is more breathable and flexible, suitable for indoor or less demanding projects.

2. Laminated vs. Non-Laminated:

Laminated PP woven fabric is reinforced for increased strength, durability, and water resistance, perfect for heavy-duty applications. Non-laminated PP woven fabric is lighter and more cost-effective, suitable for temporary solutions.

3. UV Treated vs. Non-UV Treated:

UV treated PP woven fabric withstands prolonged exposure to sunlight without degradation, crucial for outdoor use. Non-UV treated PP woven fabric is less suitable for prolonged outdoor use without protection.

4. Special Features and Additives:

PP woven fabric may include:

Anti-Slip Properties: Enhances stability and grip, ideal for packaging or flooring.

Anti-Bacterial Treatment: Inhibits bacterial growth, suitable for medical or food packaging.

Flame Retardant Treatment: Reduces flammability, safer for construction or industrial use.

Understanding these types helps you choose the fabric that best suits your project’s requirements, whether it’s durability, weather resistance, or special features.

Choosing the Right Supplier

When selecting the ideal supplier for your PP woven fabric requirements, prioritize factors like adherence to industry quality standards and certifications, supplier reputation and reviews, availability of customization options, and competitive pricing structures. Look for certifications such as ISO 9001 to ensure quality management systems are in place. Investigate supplier reputations through customer reviews and testimonials to gauge satisfaction levels. Opt for suppliers offering customization options to meet your project’s unique needs. While cost is important, ensure it doesn’t compromise quality. Consider partnering with trusted suppliers like Formosa Synthetics Pvt. Ltd. By considering these factors, you can confidently choose a supplier that aligns with your requirements and ensures the success of your PP woven fabric project. For further insights into PP woven fabric types and applications, explore our comprehensive guide.

Conclusion

In conclusion, selecting the perfect PP woven fabric requires thorough consideration of various factors, from its physical characteristics to specific application needs. Understanding the fabric’s weight, strength, and durability ensures it meets project demands, while considering factors like coating, lamination, and UV treatment helps tailor the fabric to environmental conditions. Choosing a reputable supplier like Formosa Synthetics Pvt. Ltd. is essential for quality assurance and competitive pricing. By following this guide, you can confidently select the ideal PP woven fabric for your project, ensuring durability and performance. For further assistance, explore our website or contact us directly.

Read More

#PPWovenFabric#Polypropylene#Agriculture#Construction#Packaging#WaterResistance#UVResistance#FabricTypes#SupplierSelection#QualityManagement#Customization#FormosaSynthetics

0 notes

Text

The Complete Guide to Non-Woven Geotextiles

Introduction to Non Woven Geotextiles

Geotextiles refer to permeable, polymeric textile materials used in contact with soil or rock in civil engineering applications. They can be woven or non woven.

Non woven geotextiles are made by bonding polymeric fibers together through processes like needle punching, heat bonding or resin bonding. The random arrangement of fibers produces a strong, porous and flexible material.

Geotextiles that are non-woven are better than those that are woven. They are better at filtering, draining, and cushioning, and are easier to install. In addition, they are more budget-friendly. These characteristics make non-wovens ideal for many functions like filtration, drainage, separation, and reinforcement.

Needle Punched Non Woven Geotextiles

Needle punched non wovens are a major type of non woven geotextile produced by mechanically orienting and entangling fibers. Hundreds of fine needles repeatedly penetrate a fiber web to tangle the fibers into a strong, porous and stable fabric.

Types of Needle-Punched Non-Woven Geotextiles

Needle punched non wovens can be categorized into three main types based on weight and fiber thickness:

Lightweight Needle Punched Non Wovens

Made from fine fibers and low fiber weights between 20–100 gsm. Mainly used in applications that do not require high strength.

Medium Weight Needle Punched Non Wovens

Heavier fibers and medium basis weights of 100–250 gsm. Provides moderate strength for functions like separation.

Heavyweight Needle Punched Non Wovens

Very coarse, thick fibers and high basis weights above 250 gsm. Imparts maximum strength for reinforcement uses.

Selections depends on the target function. Non-woven fabrics can be categorized into lightweight and heavyweight variants.

Key Functions and Applications of Non Woven Geotextiles

Non woven geotextiles perform various functions that make them indispensable for major infrastructure and construction projects:

Filtration Applications

The porous structure allows water to pass through while blocking soil particles. This filtration ability is useful in:

Roadway drainage systems

Retaining walls

Landfill drainage

Water treatment plants

Drainage Applications

Non wovens have high water flow rates in the principal direction. This makes them excellent for drainage purposes like:

Landfill drainage layers

Sports field drainage

Retaining wall and slope drainage

Separation Applications

The fabric physically separates dissimilar materials. Key applications include:

Roadway base and subbase separation

Railroad bed separation

Foundations separation

Reinforcement Applications

Non wovens provide reinforcement for additional strength when wrapped around soil. Uses include:

Embankments over soft soils

Retaining walls with stacked blocks

Slopes requiring improved bearing capacity

Erosion Control Applications

The fabric acts as a permeable layer to protect against wind and water erosion while allowing water passage. Some uses are:

Covering slopes along railways and highways

Coastal embankments erosion control

Riverbanks and canals protection

Transportation Applications

Within road construction, non wovens assist with filtration, separation, drainage and stabilization. Common applications:

Separation between sub-base and subgrade

Filtration in edge drains alongside pavements

Soil stabilization for improved load bearing

Construction Applications

Foundations and walls drainage

Vapor barriers in concrete slabs

Flooring reinforcement and crack prevention

This demonstrates the versatility of non woven geotextiles across diverse functions in C&I projects. Their adaptive properties drive widespread adoption.

Key Properties of Non Woven Geotextiles

Non woven geotextiles exhibit unique properties derived from their material composition, manufacturing method and overall structure:

Raw Materials

Most non wovens use polypropylene as the raw material which is cost-effective and provides required properties. High-end variants use polyester or a polypropylene-polyester blend.

Basis Weight

Basis weight is the mass per unit area measured in g/m2. Heavier basis weights produce stronger fabrics with higher puncture resistance. Typical range is from 20 g/m2 to 300 g/m2.

Thickness

Thickness depends on fiber density and varies from 1mm to 15mm. Affects permeability, cushioning ability and separation effectiveness.

Hydraulic Properties

Non wovens have high water permeability (normal to the plane) and adequate transmissivity. Allows swift drainage while blocking soil passage.

Mechanical Properties

Tensile strength, tear strength, puncture resistance and burst strength are key mechanical properties. Non woven selection depends on required load capacity.

Endurance Properties

Long-term resistance against environmental exposure, chemicals, microbes and mechanical stresses comes under endurance properties. Requires proper polymer choice.

These characteristics directly impact the effectiveness and lifespan of the non woven geotextile for its intended function.

Overview of Manufacturing Processes

Non woven geotextile production involves specialized processes to achieve the desired fiber arrangement and properties:

Web Formation

The first step is creating a uniform web of fibers laid out in overlapping, random orientations using air, mechanical or wet-laid techniques.

Web Bonding

The fiber web undergoes thermal, chemical or mechanical bonding. This interlocks the fibers to impart strength, stability and thickness.

Finishing

Additional treatments enhance properties — for instance, calendering uses heated rollers to achieve smoothness. Fabric edges are trimmed to create rolls.

Testing and Inspection

Extensive testing under certified labs evaluates parametes like strength, permeability, opening size etc. This ensures compliance with specifications.

Keeping manufacturing consistent and monitoring variabilities is vital for non woven quality assurance. Automation allows scalable production with minimal defects.

Design and Installation Factors for Non Woven Geotextiles

Site Preparation

The installation site must be graded uniformly and cleared of debris/rocks to avoid damage. Burial depth is determined. Subsurface drainage may be added.

Installation Techniques

Non wovens can be unrolled on site and placed loose or tense. Joints are sewn or bonded. Additional layers can be installed to enhance functioning. Fixings like sandbags or pegs may be used.

Seams and Overlaps

Adjoining rolls are overlapped for continuity. End overlaps depend on joint strength. Edges can be sewn, welded, glued or kept loose. Key consideration for soil retention uses.

Design Factors

Careful specifications of geotextile properties like strength, permeability, and opening size based on engineering requirements and testing. Survivability and performance lifetime also key.

Following recommended practices for non woven deployment optimizes field performance and prevents failures.

Key Benefits and Advantages of Using Non Woven Geotextiles

Non woven geotextiles offer numerous benefits that make them advantageous over traditional materials:

Cost-Effectiveness

Made from polypropylene, non wovens are an affordable alternative to CMP pipe drains or graded aggregates for drainage. Limited overlap joints also reduce quantity required.

Rapid Drainage Performance

The high porosity provides greater flow capacity compared to sand filters or gravel layers. Useful in applications like retaining walls.

Good Puncture and Burst Resistance

The entangled fibrous structure provides better resistance against punctures during installation compared to woven geotextiles.

Ease of Installation

Flexible, lightweight non wovens are simpler to install in field conditions compared to rigid materials. No special equipment needed.

Enhanced Properties

Specialized manufacturing processes like calendering and bonding creates improved non wovens with the right balance of filtration, separation, cushioning and strength.

Wider Widths

Ability to produce up to 5m wide rolls compared to just 1m for wovens leads to faster deployment with fewer joints.

These advantages have positioned non wovens as a material of choice for major construction activities and geotechnical engineering applications.

Applications and Case Studies Demonstrating Non Woven Geotextiles in Action

Non woven geotextiles have delivered value across many real world projects:

Landfill Construction — Needle punched non wovens used in leachate collection systems increased design life while reducing clogging through superior filtration compared to gravel layers.

Retaining Wall Drainage — Heat bonded non wovens used as wall wraps maintained water drainage and prevented soil washout, keeping 100km of critical rail walls safely stabilized through extreme weather.

Riverbank Protection — Durable non woven wraps applied on embankments prevented erosion along highly flood-prone rivers through monsoons. Filtered runoff while retaining soil stability.

Roadway Improvement — Calendered non wovens beneath motorway overpasses provided vital reinforcement to stabilize compressible soil while facilitating drainage and preventing pumping.

Coastal Reinforcement — Wide width non wovens encasing sandy coastal cliffs added shear strength and tensile reinforcement. Protected against collapse from rising sea levels and storm surge.

This demonstrates how non wovens of different compositions can be adapted for specialized needs in infrastructure projects where performance and longevity are critical.

Industry Trends and Ongoing Innovations in Non Woven Geotextiles

High Growth Potential — The non wovens market is projected to grow steadily at 6% CAGR driven by major public infrastructure investments and demand from emerging economies.

Raw Material Advances — Enhanced polymers like high-density polypropylene and high-modulus polyester are creating improved non wovens with greater functionality.

Manufacturing Improvements — Advancements in processing and techniques now enable precise manipulation of fiber properties during production.

Multifunctional Products — Combining non wovens with drainage nets or reinforcing grids creates single products that provide filtration, separation and reinforcement together.

Application R&D — Ongoing research into novel uses for non wovens like landfill caps, nuclear waste containment and offshore geotextiles to drive adoption across new domains.

Conclusion