#Positive Photoresist

Explore tagged Tumblr posts

Text

Microposit S1800 G2 Series Photoresists for Advanced IC Device Fabrication

Discover Microposit S1800 G2 Series Photoresists at A-Gas Electronic Materials. These positive photoresists, using a toxicologically safe casting solvent, are ideal for advanced IC device fabrication and maintaining linewidth control on reflective substrates.

#Microposit S1800 G2 Series Photoresists#positive photoresist systems#advanced IC device fabrication#toxicologically safe casting solvent#A-GAS#A-GAS Electronic Materials

0 notes

Text

0 notes

Text

The Evolving Landscape of the Photoresist & Photoresist Ancillaries Market: Trends, Challenges, and Future Prospects

The Photoresist & Photoresist Ancillaries Market was valued at USD 3.9 billion in 2023 and will surpass USD 5.4 billion by 2030; growing at a CAGR of 4.8% during 2024 - 2030. The photoresist and photoresist ancillaries market has witnessed significant growth and transformation over the past decade, driven primarily by advancements in semiconductor manufacturing, the proliferation of consumer electronics, and the rising demand for advanced packaging solutions. As we move further into the era of digital transformation and smart technologies, understanding the dynamics of this market becomes crucial for stakeholders across the supply chain.

Understanding Photoresist and Photoresist Ancillaries

Photoresists are light-sensitive materials used in photolithography and photoengraving processes, critical in the manufacturing of semiconductor devices. These materials are applied to a substrate, exposed to light through a mask, and then developed to create a patterned coating. The accuracy and quality of these patterns are vital for the functionality of semiconductor components.

Photoresist ancillaries, on the other hand, include various chemicals and materials that support the photolithography process. These include anti-reflective coatings, developers, edge bead removers, and adhesion promoters. While photoresists are the central component in lithography, ancillaries play a crucial role in enhancing the efficiency and precision of the process.

Get a Sample Report: https://intentmarketresearch.com/request-sample/photoresist-photoresist-ancillaries-market-3641.html

Market Drivers and Growth Trends

Booming Semiconductor Industry: The semiconductor industry’s rapid growth, fueled by the increasing demand for electronic devices, has been a significant driver for the photoresist market. The continuous scaling down of semiconductor devices requires more sophisticated photolithography processes, thereby increasing the demand for high-performance photoresists and ancillaries.

Technological Advancements: The shift towards advanced packaging technologies, such as 3D ICs, fan-out wafer-level packaging, and system-in-package (SiP), has created new opportunities for the photoresist market. These technologies require precise patterning and etching, driving the need for specialized photoresists.

Rise of Automotive Electronics: The automotive industry’s transition towards electric and autonomous vehicles is another significant factor contributing to the market’s growth. The increasing integration of advanced electronics in vehicles demands higher semiconductor production, thereby boosting the photoresist market.

Expanding Applications in Displays: Photoresists are also critical in the production of flat panel displays (FPDs), particularly in OLED and LCD technologies. As the demand for high-resolution displays in smartphones, TVs, and other devices increases, so does the demand for photoresists.

Challenges in the Market

Despite the positive growth trajectory, the photoresist and photoresist ancillaries market faces several challenges:

Environmental and Health Concerns: The chemicals used in photoresists and ancillaries are often toxic and pose environmental and health risks. Regulatory pressures to minimize the use of hazardous materials are compelling manufacturers to innovate and develop eco-friendly alternatives, which can be costly and time-consuming.

Supply Chain Disruptions: The semiconductor industry has been grappling with supply chain disruptions, particularly in the wake of the COVID-19 pandemic. These disruptions have affected the availability of raw materials for photoresists, leading to production delays and increased costs.

Technological Complexity: As semiconductor devices become smaller and more complex, the requirements for photoresists become more stringent. Developing new materials that can meet these demands is challenging and requires significant investment in research and development.

Future Prospects and Opportunities

The future of the photoresist and photoresist ancillaries market looks promising, with several key trends expected to shape its trajectory:

Innovation in Eco-Friendly Photoresists: The growing emphasis on sustainability is likely to drive innovation in environmentally friendly photoresists. Biodegradable photoresists and those based on non-toxic solvents are expected to gain traction in the coming years.

Growth in EUV Lithography: Extreme Ultraviolet (EUV) lithography is emerging as a critical technology for advanced semiconductor manufacturing. The adoption of EUV is expected to create new opportunities for photoresist manufacturers, as EUV requires specialized photoresists that can withstand shorter wavelengths of light.

Expanding Applications in Emerging Technologies: The rise of new technologies such as 5G, IoT, and AI will drive further demand for semiconductors, and by extension, for photoresists. As these technologies mature, the need for more sophisticated and reliable semiconductor components will continue to fuel market growth.

Regional Growth in Asia-Pacific: The Asia-Pacific region, particularly countries like China, Japan, and South Korea, is expected to lead the market in terms of growth. The region’s strong semiconductor manufacturing base, coupled with government initiatives to boost local production, will drive demand for photoresists.

Get an insights of Customization: https://intentmarketresearch.com/ask-for-customization/photoresist-photoresist-ancillaries-market-3641.htmlv

Conclusion

The photoresist and photoresist ancillaries market is poised for significant growth, driven by the continuous advancements in semiconductor technology and the rising demand for electronics across various industries. While the market faces challenges, particularly in terms of environmental concerns and supply chain disruptions, the opportunities for innovation and expansion are vast. Stakeholders who can navigate these challenges and capitalize on emerging trends will be well-positioned to thrive in this dynamic market.

#Photoresist Materials#Photomask Materials#Photoresist Compounds#Photolithographic Coatings#Photoresist Solvents

0 notes

Text

My one objection to this is that I would be pretty surprised if any CPUs were not both light and shadow CPUs. I'm not an expert in computer architecture, but my experience with fabricating transistors in a lab course is that positive and negative photoresist are often both used in different steps even in the same process for producing a single transistor. Otherwise very true though, computers are magical thinking crystals.

The problem with writing a fantasy story where they have computers that are powered by magic is that computers are already magic.

Seriously. Moreso than any other subject I know, computers are the ultimate bell-curve, where people who don't know much about how they work and people who know a lot about how they work both agree: they're magic.

Like, do you know how we make computers? We etch intricate patterns in crystals. Using light. The shape of the drawings determines how they work.

Seriously, that's how they're made. We grow super-pure crystals, cut them into wafers, cover them with acid, then shine a light on them through a mask to activate or deactivate the acid, etching away some of the silicon surface. It's called photolithography.

Only we've since decided light is "too big" and we've moved up to using x-rays, which are smaller. This lets us fit smaller drawings on our crystals!

The best part is that because some processes use light to harden the photoresist layer and some processes use light to break it down, it means some computers are made of light (because the parts of the crystal that got light on them remained behind) and some parts are made of shadow (because the parts that got light were washed away.)

Do you have a Light CPU or a Shadow CPU? You'll probably never know. This is industrial secret stuff.

And because we're making them with light, we can make them tiny and we can make lots at once. Like, I found a reference once that said that MOSFETs (a type of electrical switch) is the single thing Humanity has made the most of over our entire time on this planet.

How many have we made, exactly? It's estimated that between 1960 and 2018, we made about 13 SEXTILLION of them.

That's 13,000,000,000,000,000,000,000.

If every human alive (all 8 billion of us) lived to 70 and devoted our whole lives to making them, never sleeping, just making MOSFETs, we'd have to make 736 a second to make 13 sextillion MOSFETs.

Computers are magic. And we're very good at being wizards.

6K notes

·

View notes

Text

The Photoresist Chemicals market is projected to grow from USD 3,375.86 million in 2024 to USD 4,360.18 million by 2032, reflecting a compound annual growth rate (CAGR) of 3.25%.The photoresist chemicals market is undergoing a significant transformation, driven by the burgeoning demands of the semiconductor and electronics industries. Photoresist chemicals are light-sensitive materials used in photolithography and photoengraving processes to form a patterned coating on a surface. These chemicals play a critical role in the manufacturing of printed circuit boards (PCBs), microelectromechanical systems (MEMS), and integrated circuits (ICs), making them indispensable to modern technology.

Browse the full report at https://www.credenceresearch.com/report/photoresist-chemicals-market

Market Dynamics

The photoresist chemicals market is expected to witness robust growth in the coming years. Several factors contribute to this positive outlook:

1. Advancements in Semiconductor Technology: The continuous miniaturization of electronic devices necessitates more sophisticated and precise photolithography techniques. Photoresist chemicals are crucial in defining the intricate patterns on semiconductor wafers, enabling the production of smaller and more powerful chips.

2. Rising Demand for Consumer Electronics: The proliferation of smartphones, tablets, wearable devices, and other consumer electronics has led to increased production of semiconductors, thereby boosting the demand for photoresist chemicals.

3. Growth of the Automotive Industry: The automotive sector's shift towards electric and autonomous vehicles is driving the need for advanced electronic components, which rely heavily on photoresist chemicals for their manufacturing.

4. Expansion of the Internet of Things (IoT): The IoT ecosystem's growth is spurring the development of numerous connected devices, all of which require semiconductors produced using photoresist chemicals.

Types of Photoresist Chemicals

Photoresist chemicals are broadly categorized into three types based on their properties and applications:

1. Positive Photoresists: These chemicals become soluble when exposed to light, allowing the exposed areas to be washed away, leaving a patterned coating. They are preferred for their high resolution and precision in semiconductor manufacturing.

2. Negative Photoresists: These chemicals become insoluble when exposed to light, causing the unexposed areas to be washed away. They are typically used in applications requiring thick photoresist layers, such as MEMS fabrication.

3. DNQ-based Photoresists: Diazonaphthoquinone (DNQ)-based photoresists are widely used in the production of PCBs and ICs. They offer excellent resolution and are compatible with various etching processes.

Regional Insights

The photoresist chemicals market is globally segmented into North America, Europe, Asia-Pacific, and the rest of the world. Among these regions, Asia-Pacific dominates the market, driven by the presence of major semiconductor manufacturing hubs in countries like China, Japan, South Korea, and Taiwan. The region's strong electronics manufacturing infrastructure and significant investments in semiconductor fabs contribute to its market leadership.

North America is another key market, with the United States being home to several leading semiconductor companies and research institutions. The region's focus on technological innovation and R&D activities fuels the demand for advanced photoresist chemicals.

Europe is also witnessing growth in the photoresist chemicals market, supported by the automotive industry's expansion and the increasing adoption of IoT devices. Countries like Germany and France are at the forefront of this growth, with strong semiconductor manufacturing capabilities.

Competitive Landscape

The photoresist chemicals market is highly competitive, with several key players vying for market share. Some of the prominent companies include:

1. Tokyo Ohka Kogyo Co., Ltd.: A leading manufacturer of photoresist chemicals, known for its innovative solutions and extensive product portfolio. 2. JSR Corporation: Specializes in high-performance photoresists used in semiconductor manufacturing. 3. Dow Chemical Company: Offers a range of advanced photoresist materials for various applications. 4. Fujifilm Holdings Corporation: Provides cutting-edge photoresist chemicals and has a strong presence in the global market. 5. Sumitomo Chemical Co., Ltd.: Known for its high-quality photoresist products used in electronics manufacturing.

Future Outlook

The future of the photoresist chemicals market looks promising, with continuous advancements in semiconductor technology and the growing adoption of electronic devices. Innovations in photolithography techniques, such as extreme ultraviolet (EUV) lithography, are expected to drive the demand for more sophisticated photoresist chemicals.

Moreover, the increasing focus on sustainability and environmental regulations is pushing manufacturers to develop eco-friendly photoresist solutions. This trend is likely to create new opportunities for companies that can offer green alternatives without compromising performance.

Key Player Analysis

FUJIFILM Corporation

TOKYO OHKA KOGYO CO., LTD.

I. DuPont de Nemours

JSR Corporation

Dow

Mitsui Chemicals America Inc

LG Chem

Shin-Etsu Chemical Co., Ltd.

TOK America

Honsou Chemical Industry

Segments:

Based on Product Type:

Positive

Negative

Based on Spectral Line Size:

G-line

I-line

KrF (Krypton Fluoride)

ArF immersion (Argon Fluoride Immersion)

ArF dry (Argon Fluoride Dry)

Based on End Use Applications:

Microelectronics

Sand carving

Fabrication of printed circuit boards

Based on the Geography:

North America

US

Canada

Mexico

Europe

Germany

France

UK

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/photoresist-chemicals-market

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

Photoresist Cleaners Market Analysis 2023 Dynamics, Players, Type, Applications, Trends, Regional Segmented, Outlook & Forecast till 2033

The competitive analysis of the Photoresist Cleaners Market offers a comprehensive examination of key market players. It encompasses detailed company profiles, insights into revenue distribution, innovations within their product portfolios, regional market presence, strategic development plans, pricing strategies, identified target markets, and immediate future initiatives of industry leaders. This section serves as a valuable resource for readers to understand the driving forces behind competition and what strategies can set them apart in capturing new target markets.

Market projections and forecasts are underpinned by extensive primary research, further validated through precise secondary research specific to the Photoresist Cleaners Market. Our research analysts have dedicated substantial time and effort to curate essential industry insights from key industry participants, including Original Equipment Manufacturers (OEMs), top-tier suppliers, distributors, and relevant government entities.

Photoresist Cleaners Market Benefits

Photoresist Cleaners research reports provide critical insights for strategic decision-making. They help businesses understand market trends, customer preferences, and competitive landscapes. By analyzing data on market size, growth potential, and consumer behavior, companies can identify new opportunities and mitigate risks. These reports also guide product development, pricing strategies, and marketing campaigns, ensuring alignment with current market demands. Furthermore, market research reports enhance forecasting accuracy and help in benchmarking performance against competitors. Ultimately, they inform investment decisions, optimize resource allocation, and foster innovation, contributing to sustained business growth and a competitive edge.

Key Report Highlights:

Key Market Participants: The report delves into the major stakeholders in the market, encompassing market players, suppliers of raw materials and equipment, end-users, traders, distributors, and more.

Comprehensive Company Profiles: Detailed company profiles are provided, offering insights into various aspects including production capacity, pricing, revenue, costs, gross margin, sales volume, sales revenue, consumption patterns, growth rates, import-export dynamics, supply chains, future strategic plans, and technological advancements. This comprehensive analysis draws from a dataset spanning 12 years and includes forecasts.

Market Growth Drivers: The report extensively examines the factors contributing to market growth, with a specific focus on elucidating the diverse categories of end-users within the market.

Data Segmentation: The data and information are presented in a structured manner, allowing for easy access by market player, geographical region, product type, application, and more. Furthermore, the report can be tailored to accommodate specific research requirements.

SWOT Analysis: A SWOT analysis of the market is included, offering an insightful evaluation of its Strengths, Weaknesses, Opportunities, and Threats.

Expert Insights: Concluding the report, it features insights and opinions from industry experts, providing valuable perspectives on the market landscape.

Receive the FREE Sample Report of Photoresist Cleaners Market Research Insights @ https://stringentdatalytics.com/sample-request/photoresist-cleaners-market/9526/

Market Segmentations:

Global Photoresist Cleaners Market: By Company • Dongjin Semichem • DuPont • Merck KGaA (Versum Materials) • ENF Tech • Tokyo Ohka Kogyo • Nagase Chemtex Corporation • LG Chem • Entegris • Sanfu Chemical • LTC • Fujifilm • Mitsubishi Gas Chemical • Jiangyin Jianghua • Technic Inc • Anji Micro • Solexir Global Photoresist Cleaners Market: By Type • Positive Photoresist (PR) Strippers • Negative Photoresist (PR) Strippers Global Photoresist Cleaners Market: By Application • Wafer Processing • LCD/OLED

Regional Analysis of Global Photoresist Cleaners Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Photoresist Cleaners market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase Photoresist Cleaners Market Research Report @ https://stringentdatalytics.com/purchase/photoresist-cleaners-market/9526/

Report includes Competitor's Landscape:

➊ Major trends and growth projections by region and country ➋ Key winning strategies followed by the competitors ➌ Who are the key competitors in this industry? ➍ What shall be the potential of this industry over the forecast tenure? ➎ What are the factors propelling the demand for the Photoresist Cleaners? ➏ What are the opportunities that shall aid in significant proliferation of the market growth? ➐ What are the regional and country wise regulations that shall either hamper or boost the demand for Photoresist Cleaners? ➑ How has the covid-19 impacted the growth of the market? ➒ Has the supply chain disruption caused changes in the entire value chain?

Why to Purchase Photoresist Cleaners Market Report?

Purchasing a market research report provides valuable, reliable insights that are often beyond a company's in-house capabilities. These reports deliver comprehensive data on market trends, customer behaviors, competitive analysis, and industry forecasts, saving time and resources on extensive data collection and analysis. They offer expert perspectives and methodologies, ensuring credible, up-to-date information. By accessing tailored, actionable intelligence, businesses can make informed decisions, reduce uncertainty, and identify opportunities for growth. Additionally, these reports enhance strategic planning, risk management, and competitive positioning, making them a crucial investment for companies seeking to stay ahead in their industry and drive innovation. Customization of the Report:

This report can be customized to meet the client’s requirements. Please connect with our sales team ([email protected] ), who will ensure that you get a report that suits your needs. You can also get in touch with our executives on +1 346 666 6655 to share your research requirements.

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels:

Linkedin | Facebook | Twitter | YouTube

0 notes

Text

Photoresist Chemicals Market Strategies: Competitive Intelligence and Market Positioning

Photoresist chemicals are a crucial component in the field of semiconductor and microelectronics manufacturing. These chemicals play a pivotal role in the photolithography process, enabling the precise transfer of intricate circuit patterns onto semiconductor wafers. The term "photoresist" refers to a light-sensitive material that undergoes chemical changes when exposed to ultraviolet (UV) light, allowing for the selective etching or deposition of materials on the wafer's surface.

The photoresist chemicals market has witnessed significant growth and evolution in recent years, largely driven by the rapid advancements in technology and the increasing demand for smaller, more powerful electronic devices. This market's primary focus is the semiconductor industry, where photoresists are essential for creating the intricate patterns that form the basis of integrated circuits, microprocessors, memory chips, and other electronic components.

As technology continues to advance, the demand for smaller and more densely packed electronic components has surged. This trend necessitates the development of advanced photoresist chemicals capable of achieving higher resolution and finer details during the photolithography process. Moreover, the emergence of new applications like advanced packaging, 3D integration, and organic electronics has expanded the scope of the photoresist chemicals market beyond traditional semiconductor manufacturing.

The photoresist chemicals market is highly competitive, with major players constantly innovating and investing in research and development to meet the evolving demands of the semiconductor industry. Companies are striving to develop photoresist materials that offer higher sensitivity, improved resolution, and better environmental sustainability. Additionally, there is a growing emphasis on developing EUV (extreme ultraviolet) photoresists to enable the production of smaller and more powerful semiconductor devices.

In terms of photoresist chemicals market trends, sustainability and environmental considerations have become increasingly important. Manufacturers are focusing on developing eco-friendly photoresist chemicals that reduce the environmental impact of the semiconductor manufacturing process. Furthermore, the globalization of the semiconductor industry has led to increased demand for photoresist chemicals in emerging markets, contributing to the market's overall growth.

In conclusion, the photoresist chemicals market plays a pivotal role in the semiconductor and microelectronics industry. It encompasses the development and production of light-sensitive materials critical for photolithography processes, enabling the fabrication of advanced electronic components. As technology continues to advance, the market is expected to witness further growth and innovation, driven by the need for higher-resolution patterning and environmental sustainability in semiconductor manufacturing.

#Photoresist Chemicals Market#Photoresist Chemicals Market Growth#Photoresist Chemicals Market Trends

0 notes

Text

Silicon Back-End Process Episode 7: Wafer-Level Packaging

After summarising conventional package assembly, this article will be the first of two on wafer-level packaging, the other main semiconductor packaging type. Photolithography, sputtering, electroplating, photoresist (PR) stripping, and metal etching — the five core WLP processes — will be covered.

Fully intact wafer packaging

WLP precedes wafer dicing. In fan-in and fan-out wafer-level chip scale packaging (WLCSP), the wafer is intact throughout the process. WLP includes redistribution layer (RDL), flip chip, and through-silicon via1 (TSV) packaging, even though only part of their operations are done before the wafer is diced. Electroplating metal and pattern vary by package2. They all package similarly, as shown below.

After testing, wafers are dielectrically coated as needed. Photolithography exposes the chip pad again after dielectric layer testing.

A metal layer is sputtered on the wafer3. This metal layer helps the electroplated metal layer adhere and blocks metal chemical growth by blocking diffusion. It transfers electrons during electroplating and applies photoresist to create a layer while photolithography designs.

Electroplating coats metal thickly. After electroplating, PR stripping and etching remove thin metal layers. Wafers are electroplated with desired metal layers. This layout wires fan-in WLCSP, redistributes RDL pads, and bumps flip chip packaging. The following sections will examine each step.

Photolithography: Sketching Masked Wafer Pattern

Photolithography combines stone (litho) and drawing (graphy). Photolithography involves applying a photoresist to the wafer and selectively exposing it to light through a mask with a desired design. The light-exposed parts create the pattern. Process sequence is in Figure 2.

Photolithography is used in WLP to pattern dielectric, photoresist pattern electroplated, and etch diffusion layers for metal wiring.

Compare photolithography to photography to understand it.

Figure 3 illustrates how sunlight photographs an object, scene, or person. Photolithography uses a light source to transfer mask designs to an exposure instrument. Finally, film in a camera is like photolithography wafer photoresist.

Figure 4 shows three wafer photoresist application methods. Spin coating, film laminating, and spray coating. Soft baking removes solvents after photoresist application to keep the viscous photoresist on the wafer and thick.

Spin coating spreads viscous photoresist from the centre of a spinning wafer to the edges due to centrifugal force (Figure 5). The wafer photoresist is uniformly thick. If spin speed is low and viscosity is high, photoresist is thick. Thinly apply if viscosity is low and spin speed is high.

To generate solder bumps in wafer-level packages like flip chip, a photoresist layer of 30 to 100 μm thickness is required. Although a single spin coating is difficult to produce the right thickness. Some situations need lots of photoresist and soft baking. Lamination starts the film at the desired thickness, making it effective for thick photoresists. Processing without wafer waste is cheaper. However, rough wafer surfaces can hinder film adhesion, causing flaws. Spray coating uniformly thickens photoresist on rough wafers.

After coating and mild baking, photoresist is lit. The wafer’s photoresist receives the pattern from light through the mask. To remove a positive photoresist that weakens with light, the mask must have holes. A negative photoresist that hardens when exposed to light requires holes in the mask. Mask aligners4 or steppers5 are used for WLP photolithography.

Developer solution dissolves photolithography-weakened photoresist. Figure 6 shows that puddle development pours the developer onto the wafer’s centre so it spins slowly, tank development immerses multiple wafers, and spray development sprays the developer. Figure 7 is a puddle chamber. After puddle development, photolithography patterns photoresist.

Films Sputtering: Wafer Thin

By physical vapour deposition6, sputtering creates a thin metal sheet on a wafer. Under bump metallurgy is the metal layer on flip chip wafers underneath the bumps. Two or three metal film layers consist of an adhesive layer, a current carrying layer that supplies electrons during electroplating, and a diffusion barrier with solder wettability7 to prevent compounds from forming between the plating layer and metal.

Titanium acts as the adhesion layer, copper as the current carrying layer, and nickel as the diffusion barrier. UBM affects flip chip package quality and dependability. Aramid and WLCSP metal wiring layers have adhesive and current-carrying layers to promote adhesion.

Argon gas becomes plasma8 and hits a target with the same composition as the metal on which positive argon ions will be deposited (Figure 8). Collisions deposit metal particles on the wafer from the target. The direction of metal particles in sputtering is constant. Trench or vertical connection access (via) plates can affect flat plates, even though they are uniformly thick. Uneven shapes can thin the wall’s parallel to metal deposition surface below the plate’s floor.

Bonding Metal Layers Electroplating

Electroplating deposits wafer metal ions from electrolyte solution. A reduction reaction with exogenous electrons does this. Electroplating coats WLP wire and electrical bumps with thick metal. Figure 9 shows how the anode oxidises a metal to create an ion and release electrons to the external circuit. Metal ions oxidised at the anode or in solution receive electrons and reduce to metal.

The cathode plate becomes a wafer with WLP electroplating. The anode plate uses an insoluble electrode like platinum and metal to be plated. Metal ions are dissolved and dispersed from the anode plate to maintain solution ion concentration. A wafer-plated insoluble electrode needs periodic metal ion replenishment to maintain ion concentration. The cathode and anode electrochemical reactions are shown in Figure 10.

The wafer’s side faces down and the anode is below the solution when electroplated. Solution flows towards the wafer and hits it hard, electroplating. Photoresist patterns on the wafer to be plated can now contact the solution. Electrons from electroplating equipment at the wafer’s edge encounter metal ions in the solution at patterned areas. Patterns mix with metal ions in the solution to reduce and create metal wiring or bumps.

Photoresist Removal: PR Stripping and Metal Etching

After using photoresist, PR stripping must remove it. PR stripping uses a chemical stripper to develop puddles, tanks, or sprays. The sputtering coating must be removed because electroplating creates metal wiring or lumps. The wafer will short circuit if the metal film is not removed. Acid-based wet etching dissolves metal coatings. As wafer metal patterns become finer, puddle development and PR stripping become more popular.

0 notes

Text

0 notes

Text

Photoresist Chemicals Market Size, Share, Demand, Growth & Trends by 2032

The market for photoresist chemicals is expanding due to the inherent properties of photoresist chemicals and the lack of any viable substitutes. Between 2022 and 2032, overall demand for photoresist chemicals is expected to expand at a CAGR of 3.6%, totaling roughly US$ 4,537.2 Million. Photoresist chemicals are used in the fabrication of µm- and sub-µm structures, prominently in the micro-electronics industry. These are speciality chemical which changes its chemical structure when exposed to ultraviolet (UV) light, this unique property makes them ideal for photolithography and photoengraving processes which in turn are commonly used in semiconductor manufacturing industry.

Get a Sample Copy of Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-2334 Henceforth, photoresist chemicals are considered as an essential component for making high-performance circuit boards and semiconductor chips. Various chemical are used for this purpose, to achieve the desired properties, such as, poly methyl methacrylate (PMMA), poly methyl glutarimide (PMGI), phenol formaldehyde resin (DNQ), SU-8 and OSTE polymers. Further, there are two basic classification of photoresists, positive and negative, both works on different principals, but cater to similar needs. However, with increasing smaller geometry designs in micro-electronics industry, positives are becoming more popular, as they offer process controllability. With inevitable features offered by Photoresist chemicals and absence of any other feasible alternatives, market for photoresist chemical is ever growing Photoresist Chemicals Market: Drivers and Restraints The global photoresist chemicals market is projected to grow at a moderate growth rate as the demand for micro-electronics continue to steadily grow, amid rising demand from electronic products in developing nations, and increasing penetrations of IoT across the globe. Furthermore, rising demand for dynamic display technology is expected to be another prominent factor fuelling growth in photoresists chemicals market. Excessive R&D in the photoresist chemicals and its end use industry, is expected to drive innovations, further shaping newer demand arenas, and fuelling more revenues in the global photoresist chemicals market. Photoresist chemicals are prominently made from crude oil; thus rising prices of crude oil is expected to increase costs, this coupled with continued pricing pressure from end use industries, shall affect margins in the market. Furthermore rising environmental concerns regarding derogatory effects of these chemicals is also expected to affect the market in long term.

Browse Full Report: https://www.futuremarketinsights.com/reports/photoresist-chemicals-market Photoresist Chemicals Market: Region Wise Outlook The global photoresist chemicals market is segmented into the seven key regions: North America, Latin America, Western Europe, and Eastern Europe, Asia Pacific Excluding Japan (APEJ), Japan and Middle East and Africa (MEA). APEJ and Japan together leads the Global Photoresist Chemicals Market in terms of demand, followed by North America and Western Europe. Furthermore, owing to rapidly rising electronics industry in India and China, the APEJ region is anticipated to remain its dominance and grew steadily over the forecast period. Along with, rising economies of Latin America, demand for microelectronics is expected to significantly rise in the region, translating into rising demand for photoresist chemicals. In terms of production, photoresist market has been a forte of Japan and Korea based companies, and with many new upcoming companies in the region, competition in the APEJ market is expected to further intensify. Photoresist Chemicals Market: Key Players

The Dow Chemical Company

Fujifilm Electronic Materials Co. Ltd

Tokyo Ohka Kogyo Co. Ltd.

E.I. DuPont de Nemours

Mitsui Chemicals America Inc

JSR Corporation

LG Chem

Shin-Etsu Chemical

TOK America

Honsou Chemical Industry

Key Segments Covered in the Photoresist Chemicals Industry Analysis

By Product Type:

Positive

Negative

By Spectral Line Size:

g-line

i-line

KrF

ArF Immersion

ArF Dry

By End Use Application:

Microelectronics

Sand Carving

Fabrication of Printed Circuit Boards

Others

By Region:

North America

Latin America

Europe

Asia Pacific

Middle East & Africa

0 notes

Text

The Impact of Advanced Photoresists on Semiconductor Efficiency

Discover how advanced photoresists enhance semiconductor efficiency with higher resolution, improved sensitivity, and greater process stability. Learn about the benefits for performance, cost savings, and environmental impact. Contact A-Gas Electronic Materials for expert guidance and solutions.

#advanced photoresists#semiconductor efficiency#photolithography#positive photoresists#negative photoresists#EUV lithography#semiconductor manufacturing#high-resolution photoresists#energy efficiency#A-Gas Electronic Materials#UK#semiconductor innovation#photoresist technology#electronic devices

0 notes

Text

About Positive Photoresist Material

The photoresist developer can dissolve the portion of the photoresist exposed to light in a positive photoresist. Following that, the developer solution washes away the exposed resist, leaving only windows of the underlying material visible. Positive photoresists can maintain their size and pattern because the photoresist developer solvent does not permeate the areas that have not been exposed to UV light. Positive Photoresist Material has a chemical structure that allows portions exposed to light to develop quicker than sections that are not. Phenol-formaldehyde novolak resins are used to make positive photoresists.

0 notes

Text

Who am I as an Artist? Moving Forward

There are so many different methods of printmaking, each with their own character and charms. Linocut prints producing patchy and carefree prints, etching specialising in tone and monoprints creating one-of-a-kind pieces each time. I am personally most inspired by screen printing, also known as silkscreen printing. Screen printing is a form of printing using a screen made of stretched fabric and a frame1. The artist creates a stencil by applying glue, film/paper or photoresist to the areas of the screen that they don’t want printed, then smears ink through the untouched parts of the screen to create a print. This method is primarily used on paper and fabric; however, it is possible to print on other materials such as wood and metal if using specific inks. Screen printing is wildly popular due to its ability to print bright and even colours regardless of the surface2. Screen printing works similarly to a reduction print, creating multidimensional art using layers rather than tone and shading. It is also praised for its ability to produce identical prints in little to no time, making it a key method in the mass production for the likes of posters. Screen printing started being used in the 1920’s for advertisements, even though the method dates all the way back to 221 AD China3, and was being used by artists only 10 years later. By the 1950’s, screen printing had become a widely appreciated media amongst artists. During the 1960’s, screen printing boomed in popularity after pop artists such as Andy Warhol and Keith Harring used it for their designs4. Screen printing was the prime medium for the pop art movement because of the ease at which you could create colourful block shapes and patterns, as well its ability to mass produce designs. Screen printing has a long and diverse history, but not one that is going to end anytime soon. The method is still wildly popular today amongst printmakers, with its charming characteristic and accessibility maintaining its popularity as strong as ever.

Ben Rider

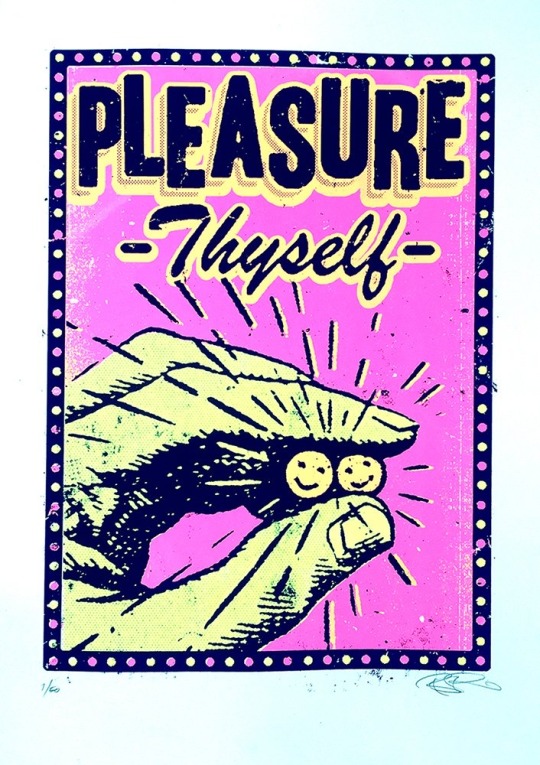

Ben Rider is an illustrator and prink maker based in London. Rider is known for his messy neon prints with punk undertones. His work is created using a screen print to bring his illustrations alive, usually in a psychedelic pop art style. One of my favourite pieces of his would be ‘Pleasure Thyself.

5Print Club London. (n.d.). Pleasure Thyself by Ben Rider. [online] Available at: https://printclublondon.com/shop/pleasure-thyself/ [Accessed 13 Mar. 2021].

This print includes a hand holding to smiley faces, as well as the name of the piece, ‘Pleasure Thyself’. This print is fairly simple; however, I feel as though there's a lot of depth to it. At first glance, it simply seems to be a print about looking after yourself and your mental health. The description of the piece states, ‘In these strange days it's good to be reminded to just be kind to ourselves too!’. I feel as though there could also be a comparison drawn between this piece and drug culture. The hand seems to be holding two smiley faces, which at first reminded me of pills. The slogan of, ‘Pleasure Thyself’ could also relate to the act of getting high or taking an upper. I feel as though the colour pallet helps strengthen this analysis. The piece includes bright pink and yellow, creating a psychedelic feeling. There are also a bunch of lines coming out of the faces, making them the main focus point of the piece. I feel that this also adds emphasis to the pill like shapes. However, some may say that these lines were included to replicate a sun. It could also be argued that this print was inspired by addiction. Many people fall into a dark hole and use drugs as a form of escapism, using the euphoric feeling of being under the influence as a stimulant during hard times. Over all, I feel that this piece was created with this double entendre in mind. It could simply be enjoyed as a print about looking after yourself and staying positive, but on the other hand, could also be viewed as a piece inspired by drug culture. With many of Rider’s pieces having a sense of social commentary to them, I don’t doubt that this was his intentions.

Steven Wilson

Steven Wilson is an artist, designer and animator based in Brighton. Born in London, Wilson currently works for his own self-titled business alongside Pedro Cardoso. The company works in both analogue and digital methods to create unique and colourful pieces of art. Steven Wilson has found a great deal of success since launching his company in 2001, creating work for big names such as: Nike, The Oscars, Virgin and the New York Times, amongst many others.6

7 STEVENWILSONSTUDIO. (n.d.). Krunk Melt. [online] Available at: https://www.stevenwilsonstudio.com/prints/krunk-melt [Accessed 13 Mar. 2021].

‘Krunk Melts’ is a screen print, made using 3 layers, by Steven Wilson. It includes a bear, with a rather unpleased look on its face, melting away. I really liked this print because of the bright colours and unusual subject matter. Many of Steven Wilson’s work has a huge pop art style to it, and you can definitely see the correlation in this piece. The print uses a lot of bright colours, creating a cartoon style. The bear is outlined with a dark blue rather than a black, softening the piece all together. I feel that this makes the print feel a lot more comforting, compared to creating a stark contrast between the bright colours and a solid black outline. However, this carefree style is contradicted with the expression on the bear’s face. It has a very disapproving look on its face, as opposed to the stereotypical cheery smile cartoons are often given. This changed the feeling of the piece completely. The look on the bear’s face, along with the fact that it is melting, created a more sombre feeling to the print. This is strengthened with the fact that the bear itself is blue, a colour often used to convey sadness. I really liked the contrast this created. The use of bright colours in a piece that feels rather negative confuses the viewer. The art that, at first, seemed so cherry and carefree now has a sense of melancholy that was not initially obvious. I feel that this depth, mixed with the simplicity of the design, created a really interesting and effective print. After closely inspecting the piece, you are almost left not knowing how to feel about it, highlighting how powerful an image it is.

Andy Warhol

Andy Warhol was an American artist who explored a huge selection of media such as: painting, printing and sculpture as well as photography and film. Warhol was best known for his screen prints that explored the relationship between advertisement and celebrity culture. His art boosted him to fame during the 60’s, leading to him being considered a leading artist of the pop art movement with pieces such as, ‘Campbell’s Soup Cans’ and ‘Shot Mrilyns’. 8

9Revolver Gallery. (n.d.). Giant Panda 295 by Andy Warhol. [online] Available at: https://revolverwarholgallery.com/portfolio/warhol-giant-panda/ [Accessed 13 Mar. 2021].

Giant Panda 295 is a screen print done by Andy Warhol in 1983. The piece was done as a commission by Ron and Freyda Feldman, and was one of ten pieces created inspired by endangered animals. The print included a red panda with a thin blue outline and pink and yellow details. I really liked this piece as I felt it was instantly obvious why it was created. The red and yellow together somewhat mimics a fire, creating a sense of danger and anxiety. The use of a blue outline really helps the piece stand out more, especially against the red. This choice was especially effective in the eyes of the panda. There isn't really much detail, however I feel that this colour choice makes them look a lot more unnatural. The blue against the red really helps the eyes stand out. I feel that this was done to make the view feel like the panda is looking right at them, almost as if the panda is shaming you for not helping. This small detail, along with the intense colour pallet creates a sense of urgency, almost pushing you to help the cause. I think that this was a highly successful piece, managing to capture so much emotion in such a simple print. Even without looking into the background of the piece, you can hazard a good guess as to why it was created. Proving just how powerful a print this is, highlighting Warhol’s talent as a whole.

Screen printing inspires me for many reasons, and I feel that the more artists I research that explore the medium, the more passionate I feel about it. I really love that every artist that uses screen printing does it in their own way, with every artist’s work looking wildly different from each other's. Yet, the use of bright colours and layers ties them all together. I think throughout my journey as a printmaker, I want to experiment with screen printing more, taking into consideration how I can use both colour and layering to enhance my work.

Word count- 1.487

1 Tate (2017). Screenprint – Art Term | Tate. [online] Tate. Available at: https://www.tate.org.uk/art/art-terms/s/screenprint [Accessed 13 Mar. 2021].

2Customplanet.co.uk. (2020). What is Screen Printing? A Step-by-Step Guide to Silk Screen Printing. [online] Available at: https://www.customplanet.co.uk/what-is-screen-printing-step-by-step-i50 [Accessed 13 Mar. 2021].

3www.leicesterprintworkshop.com. (n.d.). A brief history of screenprinting - Leicester Print Workshop. [online] Available at: http://www.leicesterprintworkshop.com/printmaking/screenprinting/a_brief_history_of_screenprinting/#:~:text=A%20brief%20history%20of%20screenprinting.%20Screenprinting%20originated%20in [Accessed 13 Mar. 2021].

4My Modern Met. (2018). 8 Print Artists That Will Inspire You to Try Silk Screen Printing at Home. [online] Available at: https://mymodernmet.com/silk-screen-printing-artists/ [Accessed 13 Mar. 2021].

6STEVENWILSONSTUDIO. (n.d.). About. [online] Available at: https://www.stevenwilsonstudio.com/about [Accessed 13 Mar. 2021].

8Tate (2019). Andy Warhol 1928-1987 | Tate. [online] Tate. Available at: https://www.tate.org.uk/art/artists/andy-warhol-2121 [Accessed 13 Mar. 2021].

2 notes

·

View notes

Link

The global Photoresist Chemicals market will reach xxx Million USD in 2017 and CAGR xx% 2011-2017. The report begins from overview of Industry Chain structure, and describes industry environment, then analyses market size and forecast of Photoresist Chemicals by product, region and application, in addition, this report introduces market competition situation among the vendors and company profile, besides, market price analysis and value chain features are covered in this report.

0 notes

Text

Skinny Movie Deposition For Lift Off: Critical Basic principles

Skinny Movie Coatings are at times applied to entire surfaces of substrates, "wall to wall" so to converse, in a ongoing unbroken movie. But numerous situations the ultimate variety of no matter what specific content is currently being used is patterned so that it is coated in selected distinct parts and bare in other folks. There are two principal approaches to reach this outcome: 1. Subtractive, or Etch Back system - the overall area is coated, and then choose parts are taken off, leaving the ideal sample. The pattern generating step ordinarily entails some sort of bodily masking agent and then an suitable type of etching to take out what need to be taken off and not damage something else. 2. Additive, or Carry Off procedure - the sample creating action, which once more will generally contain some sort of actual physical masking agent, will come first. This is adopted by the coating procedure, which is comparable to using a stencil. Only the ideal sample will get applied by way of the openings in the mask on to the precise substrate. The excessive finishes up on top of the mask and is taken off when the mask is lifted off. This type of Carry Off Slim Movie Deposition course of action will be the subject of this write-up. A main consideration for deciding on a Actual physical Vapor Deposition (PVD) course of action for Carry Off is the pattern specification. If the pattern proportions and tolerances are comparatively large, a physical mask such as a slender sheet metal stencil can do the job and the process can be effectively any form. But for smaller dimensions, sharper line resolution, and tighter tolerances, the mask will most likely have to be photoresist. To accomplish thoroughly clean traces, this photoresist is generally uncovered and created to generate a destructive slope, an "overhanging" edge so that the deposition can be shadowed beneath it leaving a little gap between the edge of the coated line and the photoresist protection. There are also unique twin layer photoresists for this purpose, providing a step overhang instead of a slope. And to just take authentic edge of the capability so afforded, which can give fantastic final results in micron or lesser proportions, the deposition vapor stream should have a very long imply absolutely free path and impinge on the masked substrate perpendicular to its floor. The previous needs lower chamber pressure, typically down below 10-four torr. And the latter commonly requires a fairly lengthy throw - the length from supply to substrate. When you loved this informative article and you would like to receive more details relating to Alta definizione 2020 i implore you to visit the website. For both of these motives, Thermal Evaporation is typically the PVD method of selection. The resource is normally located in the heart of the base of a vertical cylindrical chamber. The substrate holder (usually named tooling) is a dome rotating about a vertical axis centered above the resource at a standard distance of eighteen inches or more. The dome is frequently curved, a portion of a sphere with some radius of curvature. For Elevate Off, this radius of curvature ought to be equal to the toss distance, which is the supply to substrate (dome) length. If the source ended up a genuine mathematical level resource, it would consequently be positioned at the centre of an imaginary sphere of radius R, with the real dome remaining the topmost part of claimed sphere. With process pressure normally in the ten-5 to ten-6 torr selection, the suggest no cost route - the regular distance an evaporated atom or molecule will vacation in a straight line prior to colliding with an additional gas atom or molecule - will be at minimum equivalent to R. And with the vapor particles all touring in straight strains to all factors on the dome, every a person is on a immediate radial line and will strike the surface of the dome perpendicular to the plane that would be tangent to the floor at that stage. This condition provides perpendicular incidence on the curved dome surface area, which is needed for best pattern precision - a vapor stream coming in at an angle will not deposit particularly in the center of the photoresist (mask) opening as was supposed. But substrates are virtually generally flat, which is a deviation from this excellent curved floor and thus a deviation from totally perpendicular incidence. A fantastic rule of thumb for superior precision Elevate Off patterns is to hold this angular mistake, the deviation from perpendicular vapor stream impingement on the substrate, to fewer than five levels. And, for substrates these kinds of as semiconductor wafers in typical tooling domes, the vapor stream is perpendicular at the centre of the wafer (zero angular error) and will increase toward the edges, with the utmost error becoming dependent on the wafer diameter in relation to the throw distance.

1 note

·

View note