#Polyurea floor coatings

Explore tagged Tumblr posts

Text

Concrete Coating Products - Valence Coatings

What are protective ceramic coatings for concrete?

Protective ceramic coatings for concrete are specialized materials designed to protect concrete surfaces from damage, enhance durability, and improve performance. These coatings typically consist of advanced ceramics, silicate compounds, or nano-ceramic particles suspended in a binder or resin. They create a durable, impervious layer on the concrete surface, providing various protective benefits.

Benefits of Ceramic Coatings for Concrete:

Chemical Resistance: Protects concrete from damage caused by exposure to chemicals, acids, alkalis, and other corrosive substances.

Waterproofing: Creates a hydrophobic layer that prevents water infiltration, reducing issues like freeze-thaw damage or waterborne staining.

Abrasion Resistance: Enhances durability by making the surface more resistant to wear, scratches, and impacts.

UV Resistance: Protects against sun damage and prevents the surface from discoloration or degradation due to prolonged UV exposure.

Thermal Resistance: Some coatings offer high thermal resistance, making them suitable for environments with extreme temperature fluctuations.

Ease of Cleaning: Provides a smooth, non-stick surface that resists dirt, oil, and other contaminants, simplifying maintenance.

Aesthetic Enhancement: Available in various finishes (glossy, matte, or tinted), these coatings can enhance the appearance of the concrete.

Applications:

Industrial Flooring: Used in factories, warehouses, and workshops for durability and chemical resistance.

Residential and Commercial Spaces: Protects decorative concrete in garages, patios, or driveways.

Infrastructure: Used in bridges, tunnels, and parking structures to protect against environmental exposure.

Water Containment Areas: Applied in pools, tanks, and wastewater treatment plants to prevent leaks and chemical degradation.

Common Types:

Epoxy Ceramic Coatings: Combine epoxy resins with ceramic particles for enhanced durability and chemical resistance.

Silicate-based Coatings: Penetrate the concrete surface, forming a durable bond that improves resistance to water and chemicals.

Nano-ceramic Coatings: Utilize nanotechnology to create ultra-thin, highly protective layers with exceptional hydrophobic and thermal properties.

Would you like to know about specific products, application methods, or maintenance tips for ceramic coatings?

#residential floor coating company#showroom floor coating near me#polyasaprtic coat distributor#concrete coating companies#commercial polyurea floor coatings#epoxy floor coating distributor

0 notes

Text

Polyurea Garage Floor Coating

Why Choose Polyurea For Your Garage Floor: Reasons To Consider

When it comes to flooring options for your garage, durability and protection are paramount. Among the various materials available, polyurea stands out as an exceptional choice. This article explores why Polyurea Garage Floor Coating is becoming increasingly popular for garage flooring.

Exceptional Durability

Polyurea is renowned for its remarkable strength and durability. It can withstand heavy impacts, making it ideal for a garage where tools, equipment, and vehicles are frequently used.

Unlike traditional epoxy, which can chip or crack under stress, polyurea forms a flexible bond that can handle daily wear and tear rigors without losing its integrity.

Fast Curing Time

One of the standout features of polyurea is its fast curing time. While traditional epoxy coatings can take days to cure fully, polyurea can be used in as little as 24 hours.

This means less downtime for your garage and a quicker return to regular activities. If you’re eager to get your garage back in action, polyurea is the way to go.

Resistance to Chemicals and Stains

Garages are often prone to spills from oil, antifreeze, and various chemicals. Polyurea’s inherent resistance to these substances makes it an excellent choice for flooring.

Unlike other materials that may absorb stains or become discolored, polyurea creates a barrier that repels spills, making it easier to clean and maintain.

Flexibility In Application

Polyurea can be applied in various conditions, including extreme temperatures, making it versatile for different environments.

This flexibility allows homeowners to have their garage floors coated even in less-than-ideal weather conditions without sacrificing the quality of the finish.

Aesthetic Appeal

In addition to its functional benefits, Polyurea Garage Floor Coating can enhance the aesthetic appeal of your garage. Available in a range of colors and finishes, it can complement the overall design of your home.

With options for metallics and decorative flakes, you can achieve a polished look that transforms your garage from a utilitarian space into a stylish home extension.

Low Maintenance Requirements

Once applied, polyurea flooring requires minimal maintenance. Routine cleaning with a mop and mild detergent is usually sufficient to keep it looking pristine. This ease of upkeep is a significant advantage for busy homeowners who may not have the time to dedicate to extensive floor care.

Enhanced Safety Features

Polyurea can be mixed with anti-slip additives, enhancing the safety of your garage floor.

This is particularly beneficial in areas prone to spills or wet conditions, reducing the risk of slips and falls. This safety feature can provide peace of mind for families with children or pets.

Environmentally Friendly Options

Many polyurea products are now available in environmentally friendly formulations, reducing the planet's impact while still providing outstanding performance. Choosing a green option allows homeowners to invest in sustainable materials without compromising on quality.

Conclusion

Polyurea presents a compelling case when considering a flooring solution for your garage. Its durability, quick curing time, chemical resistance, and aesthetic flexibility make it an ideal choice for functional and visual appeal.

With low maintenance requirements and enhanced safety features, polyurea is not just an investment in your garage—it’s an investment in peace of mind and lasting quality.

Polyurea should be at the top of your list if you want to upgrade your Garage Floor.

#Garage floor coating#Epoxy garage floor#Polyaspartic floor coating#Polyurea garage floor coating#Resin Garage floor

1 note

·

View note

Text

Platinum Flooring LLC

Address:

88 Walnut St, Belmont, MA 02478 USA

Phone:

(617) 505-9232

Website:

Description:

Platinum Flooring LLC, Belmont MA, 617-505-9232, is a family owned business and we bring over 20 years of professional experience in floor remodeling! We are trusted by our community! From garages and basements to school gyms, restaurants, and laundromats, we specialize in remodeling a wide array of spaces. We provide our customers with high-quality industrial-grade epoxy, polyaspartic, polyurea, and metallic flooring solutions, ensuring you maximize your investment. We also offer an efficient 1-day start-to-finish service! Proudly serving all of Massachusetts and neighboring states including New Hampshire, Connecticut, and Rhode Island.

Business email:

Business hours:

M-F from 8am-7pm,

Sat 12pm-5pm, Sun-closed

Social links:

https://www.linkedin.com/in/adam-reese-65067432a/

https://www.instagram.com/platinumflooringbelmont/

#epoxy floors#polyurea floor coating#metallic epoxy floor#epoxy garage floor#polyaspartic floor coating#garage floor epoxy#marble epoxy floor#polyaspartic garage floor coating#polyurea garage floor coating#polyurea coating#metallic epoxy garage floor#epoxy flooring#polyaspartic flooring#polyurea flooring#epoxy garage flooring#polyaspartic coating

1 note

·

View note

Text

PU Flooring Solution

Polyurethane (PU) Flooring is designed to exhibit a high cross-linking density, contentious polyurethane systems that are non-toxic, non-hazardous, and highly chemical-resistant and can now be installed more efficiently and effectively.

PU are typically designed for Pharmaceuticals, Hospitals, Laboratories, Spinning Mills, Textiles & Garments, Food Processing & Beverage, Schools, Offices, Storage Area, Commercial & Residential floors in demanding conditions. PU systems have been extremely reliable in adverse conditions. PU coatings are usually added to concrete floors to provide a permanent, smooth, a resistance performance. It has long durability and can sustain huge loads. Most buildings need appropriately maintained floors hence making PU floors an ideal choice. Some of the time industrial flooring also measure the creatively expend all necessary need of the manufacturer.

Nowadays PU flooring service is growing to the international level which is much value for the real life. People who want to take those kinds of service. PU flooring has the most power deciding the PU floor need to consider easy to clean and point loading traffic from more equipment before doing the heavy pallet trolleys and forklift water with a proxy place.

websites: https://perfectsolutionbd.net

Mail :[email protected]

#polyurea coatings#polyurethane#epoxy flooring#flooring services#pu flooring#Pu floor solution in dubai#pu floor solution in india#pu floor solution in thailand#pu floor solution in Malaysia#pu floor solution in china

1 note

·

View note

Text

Seamless Protection: Exploring the Polyurea Coatings Market

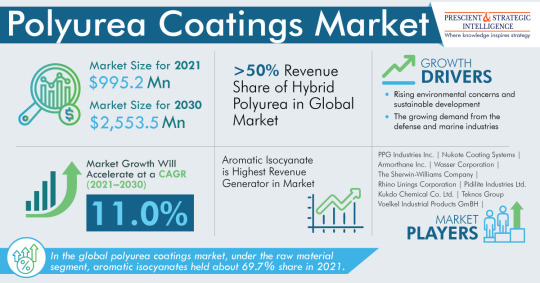

The size of the polyurea coatings market was USD 995.2 million in the recent past, and it will power at a rate of 11% and reach a value of USD 2,553.5 million by 2030, according to P&S Intelligence.

The automotive and transportation sector had the second-largest share, of about 26%. Polyurea coatings are used on the exteriors of vehicles, such as two-wheelers and trucks. They are usually seen on the chassis, driveshafts, gearboxes, and engines, as they provide good resistance to the exterior thermal and physical pressure.

To receive free sample pages of this report@ https://www.psmarketresearch.com/market-analysis/polyurea-coatings-market/report-sample

Consequently, polyurea coatings are becoming popular among automakers. China, Germany and Japan are the top three passenger vehicle producers. Consequently, polyurea coatings’ applications have advanced greatly in these countries. Volkswagen, Mercedes, Audi, Porsche, Opel, and BMW are all part of Germany's extremely competitive automobile industry. This industry generates about USD 468.5 billion, which accounts to about 20% of the total revenue of the German industry. Aromatic isocyanates are formulated with the use of benzene and toluene as raw materials. Methylenediphenyl disocyanate and Toulenedisocyanate are two of the most-common aromatic isocyanates used in the construction industry. The weather of Europe and North America is favorable for the use of aromatic polyurea coatings, which are less expensive than aliphatic substitutions. Aromatic isocyanates are used as a basecoat, meaning they are the first layer applied to any surface. Consequently, they are widely used in vehicles, that is the reason aromatic polyurea coatings market size will grow rapidly. The requirement for polyurea coating will surge in the APAC with a rate of 11.9% in the years to come. The high-pace monetary growth and substantial investment by private and government companies in numerous sectors, such as maritime, manufacturing, automotive, and construction, are driving the regional demand for industrial coatings. It is because of the increasing ecological concerns and requirement for sustainable expansion, polyurea coatings had a major place in the coatings sector, garnering high investment in R&D.

#Polyurea coatings#Protective coatings#Industrial applications#Corrosion resistance#Waterproofing solutions#Abrasion resistance#Coating technology#Surface protection#Infrastructure maintenance#Automotive coatings#Flooring solutions#Market trends#Seamless coatings#Chemical resistance#Environmental durability#Spray-on coatings#Application versatility#Market growth#Coating innovation#Future of polyurea coatings.

0 notes

Link

Your garage is a multipurpose space serving various functions, including storage, a workshop, and a recreational area. With constant foot traffic, vehicle movement, and exposure to harmful substances such as oil and gas, your garage floor can be susceptible to wear and tear. However, with a high-quality polyurea garage floor coating, you can ensure that your garage floor remains durable and resistant to damage for years.

0 notes

Text

Polyurea vs. Polyaspartic Concrete Coatings - Which Is Best For You?

View On WordPress

0 notes

Text

Can I paint polyurethane paint over epoxy enamel?

Yes, it is possible to paint polyurethane paint over epoxy enamel, but it is important to take certain precautions to ensure a successful outcome. Here are some important factors to keep in mind:

Surface Preparation

The epoxy floor must be completely clean and free of any contaminants such as dirt, grease, or oils.

It is important to remove any loose or peeling paint by sanding or using a paint stripper.

After sanding or stripping, make sure to thoroughly clean the surface to remove any dust or debris.

Priming

To ensure good adhesion, apply a suitable primer designed for use with both epoxy and polyurethane paints.

This will provide a proper base for the polyurethane paint to adhere to and improve the overall durability and finish of the final coating.

Application

When applying the polyurethane paint, follow the manufacturer's instructions for mixing, application, and drying times.

Apply the paint in thin, even coats, and allow adequate drying time between coats.

It is also important to ensure proper ventilation to avoid any issues with fumes.

Curing

After the final coat is applied, allow the polyurethane paint to cure fully before using the floor.

This can take several days, depending on the manufacturer's instructions and the conditions in the space.

If you're looking to paint your epoxy floor and want to ensure a successful outcome, consider using Dr. CIPY's range of coating solutions. With their high-quality products and expert guidance, you can be confident in achieving a durable and attractive finish on your floor. Don't compromise on quality - trust Dr. CIPY for all your coating needs.

#Polyurea Coatings#Polysulphide Sealants#PU Flooring#Industrial Epoxy Flooring#Epoxy Flooring#Epoxy Floor Coatings#Epoxy Flooring Cost#Polyurethane Paint#Epoxy Flooring Coating

0 notes

Text

EPOXYSHİNE - DRAGON+ (2)

Welcome to our blog post dedicated to transforming your garage into a durable and stylish space with garage floor flakes. Whether you're looking to improve the functionality of your garage or simply enhance its aesthetic appeal, understanding the options available can make a significant difference. Garage flooring has come a long way, offering a range of solutions from basic concrete to advanced coatings that are both resilient and visually appealing.

Garage Floor Flakes

When considering options for enhancing your garage space, garage floor flakes offer a practical and aesthetically pleasing solution. These small pieces of colored materials are designed to be mixed into floor coatings, creating a textured finish that not only looks great but also provides additional durability.

One of the main advantages of using garage floor flakes is their ability to hide imperfections in the concrete surface. They can effectively camouflage stains, cracks, and chips that are often found in older garage floors. This means a cleaner and more appealing look without the need for costly surface repairs.

Additionally, garage floor flakes contribute to the slip resistance of your flooring. The texture created by the flakes makes it safer to walk on, reducing the risk of slips and falls, especially when the floor is wet or oily. This safety aspect, combined with the visual appeal, makes garage floor flakes a popular choice for many homeowners.

Garage Flooring

When considering your garage, the flooring is often an overlooked aspect that plays a crucial role in the overall functionality and appearance of the space. Choosing the right garage flooring can enhance durability, aesthetics, and ease of maintenance. Common options include epoxy coatings, tiles, and interlocking mats, each with its own set of advantages.

One of the most popular choices for garage flooring is epoxy, known for its resilience and ability to withstand heavy loads. An epoxy coating can transform a dull concrete surface into a vibrant, high-gloss finish that not only looks great but also resists staining, chemicals, and impact. Additionally, it can be customized with decorative garage floor flakes for a unique look that hides imperfections and provides extra texture.

In addition to epoxy, tiles and vinyl can also be effective alternatives. Garage tiles are easy to install and replace, making them a flexible choice for those who might want to change their garage flooring in the future. Vinyl options offer a softer feel underfoot and come in a variety of designs that can mimic other materials. Ultimately, the best choice of garage flooring will depend on your specific needs, preferences,

Floor Coating

When it comes to enhancing the appearance and durability of your garage, floor coating is an essential element to consider. This process involves applying a protective layer over the garage floor, which not only improves its aesthetic appeal but also provides a robust defense against stains, spills, and wear and tear. By investing in high-quality floor coating, homeowners can ensure their garage remains a functional and attractive space for years to come.

Various types of floor coatings are available in the market, including epoxy, polyurethane, and polyurea options. Among these, epoxy coatings are particularly popular due to their exceptional strength and resistance to chemicals. Moreover, the variety of colors and finishes available allows for endless customization, enabling homeowners to create a garage environment that suits their personal style and needs.

In addition to aesthetic benefits, an effective floor coating can significantly increase the longevity of your garage flooring. It creates a barrier that prevents moisture and dirt from penetrating the surface, thus minimizing the damage that could occur over time. Ultimately, whether you use your garage for parking, storage, or as a workshop, investing in the right floor coating can transform the space, making it more durable and visually appealing.

Garage Floor Coating

When it comes to choosing the right solution for your garage floor, garage floor coating offers an innovative way to protect and enhance the aesthetic of your space. Unlike traditional flooring, which can deteriorate over time due to spills, stains, and wear, a high-quality coating creates a resilient layer that withstands the rigors of everyday use.

One of the benefits of a garage floor coating is its ability to be customized to fit your needs. Various options, such as epoxy and polyaspartic coatings, can provide different levels of durability, gloss, and color. This allows homeowners to select a finish that not only meets their practical needs but also reflects their personal style.

Installation of a garage floor coating is typically a straightforward process, but it is essential to ensure proper preparation and application. A well-prepared surface will maximize the adhesion of the coating and significantly extend its lifespan. Therefore, it’s advisable to either follow proper guidelines for DIY projects or consult with professionals who specialize in flooring solutions.

437 notes

·

View notes

Text

Future-Proof Your Property: The Incredible Benefits of Polyurea Coatings

Ready to experience the polyurea magic?

From industrial floors that can withstand heavy machinery to boat hulls that brave the toughest storms, polyurea has got you covered. It’s time to say goodbye to surface worries and hello to long-lasting protection.

What makes polyurea so special?

Tough as nails: It can handle anything from heavy impacts to harsh chemicals without flinching. Imagine your floors, truck bed, or roof repair being virtually indestructible!

Lightning-fast results: Polyurea is your new best friend. It dries super quickly, so you can get back to enjoying your newly protected surfaces in no time.

read more............. Polyurea

2 notes

·

View notes

Text

Commercial Protective Coatings - Valence coatings

What materials are used in protective coatings?

Protective coatings are used to safeguard surfaces from corrosion, wear, chemicals, and other environmental factors. The materials used in protective coatings depend on the specific application and the type of protection required. Common materials include:

1. Epoxy Resins

Properties: Excellent adhesion, chemical resistance, and durability.

Applications: Industrial environments, marine coatings, and pipelines.

2. Polyurethane

Properties: High flexibility, impact resistance, and UV stability.

Applications: Automotive finishes, floors, and exterior building surfaces.

3. Zinc

Properties: Sacrificial corrosion protection, preventing rust by corroding in place of the base metal.

Applications: Galvanizing steel, bridges, and marine structures.

4. Acrylics

Properties: Quick drying, good weather resistance, and gloss retention.

Applications: Architectural coatings, automotive topcoats, and decorative finishes.

5. Silicones

Properties: High heat resistance and water repellency.

Applications: High-temperature equipment, chimneys, and exhaust systems.

6. Alkyds

Properties: Good weather resistance, flexibility, and ease of application.

Applications: General-purpose metal protection, structural steel, and machinery.

7. Polyurea

Properties: Rapid curing, abrasion resistance, and waterproofing.

Applications: Bridges, roofing, and tanks.

8. Ceramic Coatings

Properties: High thermal resistance, wear resistance, and chemical stability.

Applications: High-temperature machinery, aerospace components, and exhaust systems.

9. Fluoropolymers

Properties: Excellent chemical resistance, low friction, and high durability.

Applications: Chemical tanks, pipelines, and exterior architectural coatings.

10. Powder Coatings

Properties: Environmentally friendly (no solvents), durable, and resistant to chipping.

Applications: Appliances, furniture, and automotive parts.

Each material provides specific benefits, making them suitable for different environments and protective requirements.

#Garage Floor Coatings Mn#Protective Coating For Concrete#Protective Coating Solutions#Epoxy Flooring Companies#Commercial Protective Coatings#Branded Concrete Coatings#Polyurea Coatings Suppliers#Concrete Coatings Mn#Concrete Coatings Minnesota

0 notes

Text

Concrete Floor Coating Market Size, Share, and Competitive Landscape

Rising Construction Activities and Demand for Durable Flooring Solutions Drive Growth in the Concrete Floor Coating Market.

The Concrete Floor Coating Marketsizewas valued at USD 4.75 Billion in 2023. It is estimated to hit USD 7.61 Billion by 2032 and grow at a CAGR of 5.4% over the forecast period of 2024-2032.

The Concrete Floor Coating Market is experiencing significant growth, driven by increasing demand for durable, protective, and aesthetically appealing flooring solutions across industrial, commercial, and residential applications. Concrete floor coatings enhance surface strength, resistance to chemicals and abrasions, and provide decorative finishes, making them essential for warehouses, factories, garages, retail spaces, and institutional buildings. With growing investments in infrastructure, construction, and renovation projects, the market is poised for continued expansion.

Key Players in the Market

The global Concrete Floor Coating market is highly competitive, with major industry players focusing on innovation, product durability, and eco-friendly formulations. Key companies include:

Tennant Coatings (Tennant Ecoat)

Vanguard Concrete Coating (Vanguard Polyurea Coating)

BASF SE (MasterTop 1327)

Trucrete Surfacing Systems (Trucrete Epoxy Flooring)

PPG Pittsburgh Paints (Pittsburgh Paints & Stains Epoxy Floor Coating)

North American Coating Solution (NACS Epoxy Coating)

Sherwin-Williams Company, (Sherwin-Williams Epoxy Floor Coating)

Elite Crete Systems (Elite Crete Polyurethane Coating)

Pratt & Lambert (Pratt & Lambert Epoxy Coating)

Florock (Florock FloroCrete)

These companies are investing in advanced coatings technology, sustainable materials, and high-performance protective coatings to meet the growing global demand.

Future Scope and Emerging Trends

The Concrete Floor Coating Market is set to expand significantly with the rise in industrialization, urbanization, and infrastructure development. The growing preference for epoxy, polyurethane, and polyaspartic coatings is fueling market demand due to their superior durability, chemical resistance, and ease of maintenance. Eco-friendly, low-VOC (volatile organic compound) coatings are gaining traction as regulatory bodies push for sustainable construction solutions. Additionally, advancements in nanotechnology and self-healing coatings are opening new possibilities for enhanced performance and longevity. The increasing adoption of polished concrete floors in commercial spaces and retail outlets is also contributing to market growth.

Key Market Highlights:

✅ Growing Industrial and Commercial Construction: Increased use of protective floor coatings in warehouses, factories, and logistics centers. ✅ Rising Demand for Decorative Coatings: Expanding use of colored, textured, and high-gloss finishes in residential and commercial buildings. ✅ Shift Toward Eco-Friendly Solutions: Development of low-VOC, water-based, and UV-resistant coatings to meet sustainability goals. ✅ Advancements in High-Performance Coatings: Introduction of self-healing and nanotechnology-enhanced coatings for extended durability. ✅ Expansion in Renovation and Restoration Projects: Growing adoption of floor coatings in old structures to enhance durability and aesthetics.

Conclusion

The Concrete Floor Coating Market is witnessing rapid expansion, driven by advancements in durability, aesthetics, and environmentally friendly solutions. With continued growth in construction, industrial flooring, and commercial renovations, companies that invest in innovation, sustainability, and high-performance coatings will gain a competitive edge in the market.

Read Full Report: https://www.snsinsider.com/reports/concrete-floor-coating-market-3908

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Concrete Floor Coating Market#Concrete Floor Coating Market Size#Concrete Floor Coating Market Share#Concrete Floor Coating Market Report#Concrete Floor Coating Market Forecast

0 notes

Text

Polyurea Garage Floor Coatings Ann Arbor

Supreme Creations Floor Coatings specializes in providing durable and stylish flooring solutions, including epoxy and polyaspartic coating systems. Their professional installations come with a 20-year warranty, ensuring long-lasting quality and peace of mind. They cater to various spaces such as basements, garages, exterior concrete areas, and commercial settings, enhancing both the aesthetics and functionality of floors. For more information or to schedule an installation, you can contact them at (313) 808-2453. https://scfloorcoatings.com/services/garage-floor-coating/

0 notes

Text

Enhance Your Home with Stylish and Long-Lasting Epoxy Flooring in Apple Valley

If you’re looking for a flooring solution that is durable, stylish, and long-lasting, polyaspartic floor coating from Johnson may be the perfect choice for you. Whether for residential garages, commercial spaces, or industrial applications, polyaspartic coatings provide an unmatched combination of strength and aesthetic appeal. At Johnson, our expert team ensures a professional application process that guarantees high-quality results. Read on to learn how polyaspartic floor coating melbourne can completely transform your floors in Melbourne.

What is Polyaspartic Floor Coating?

Polyaspartic floor coatings are a type of advanced protective coating that provides superior durability compared to traditional epoxy coatings. Originally developed for industrial and commercial use, polyaspartic coatings have gained popularity for residential applications due to their fast curing times, high resistance to wear and tear, and aesthetic versatility.

This innovative coating is made from aliphatic polyurea, which offers better UV stability, chemical resistance, and flexibility than standard epoxy coatings. With a quick curing time and excellent adhesion properties, polyaspartic coatings can be applied in a fraction of the time it takes for traditional coatings to dry and set.

Advantages of Polyaspartic Floor Coating

Exceptional Durability

Polyaspartic coatings are highly resistant to impacts, abrasions, and chemicals. This makes them ideal for garages, warehouses, and commercial spaces where floors endure heavy traffic and mechanical loads. Unlike traditional epoxy coatings, polyaspartic coatings maintain their integrity even under extreme conditions.

Fast Installation and Curing

One of the most significant advantages of polyaspartic coatings is their fast curing time. Unlike epoxy, which can take days to fully cure, polyaspartic coatings typically dry within hours. This means you can return to using your space quickly, minimizing downtime and inconvenience.

UV Stability and Color Retention

Exposure to sunlight often causes epoxy coatings to yellow and degrade over time. Polyaspartic coatings, however, offer superior UV resistance, ensuring that your floors retain their original color and finish for years. This makes them an excellent choice for outdoor applications, patios, and spaces with large windows.

Chemical and Stain Resistance

Whether it’s oil spills, harsh cleaning agents, or other chemicals, polyaspartic coatings resist stains and damage. This feature makes them ideal for industrial environments, commercial kitchens, and automotive workshops.

Slip Resistance and Safety

Polyaspartic coatings can be customized with anti-slip additives, making them a safer choice for homes and businesses. Whether in a garage or a commercial facility, you can enjoy peace of mind knowing your floors provide better traction and reduce the risk of slips and falls.

Applications of Polyaspartic Floor Coatings

Residential Spaces

Homeowners in Melbourne are increasingly choosing polyaspartic coatings for their garages, driveways, and patios. With their high durability and easy maintenance, these coatings provide a polished, modern look while protecting the surface from daily wear and tear.

Commercial Establishments

Businesses such as showrooms, retail stores, and office spaces benefit from the sleek and professional finish of polyaspartic coatings. Their fast installation time allows businesses to upgrade their floors with minimal disruption.

Industrial Facilities

Warehouses, manufacturing plants, and automotive service centers require flooring that can withstand heavy machinery, chemicals, and high foot traffic. Polyaspartic coatings offer superior performance in these demanding environments.

Why Choose Johnson for Your Polyaspartic Flooring Needs?

At Johnson, we pride ourselves on providing top-quality polyaspartic floor coatings in Melbourne. Our expert team ensures a seamless and professional application, using industry-leading techniques and materials. With a focus on customer satisfaction, we work closely with clients to customize flooring solutions that meet their specific needs and aesthetic preferences.

Polyaspartic floor coating from Johnson can dramatically enhance the look, durability, and longevity of your floors in Melbourne. Whether for a residential garage, a commercial showroom, or an industrial epoxy flooring dandenong facility, our expert team ensures a flawless application with long-lasting results. Visit JohnsonsFlooring.com.au to learn more about how we can transform your space with polyaspartic floor coatings today!

0 notes

Link

When it comes to coating floors, there are a plethora of options to choose from. But, in recent years, polyaspartic has gained immense popularity among homeowners and commercial property owners. It is a type of floor coating that offers numerous benefits over traditional coatings such as epoxy. In this blog post, we will dive deep into the world of polyaspartic floor coatings, exploring its advantages, disadvantages, application instructions and much more.

0 notes

Text

Polyurea Coating Costs Explained

Polyurea coatings are a durable, long-lasting solution for protecting surfaces in residential, commercial, and industrial settings. Here’s what you need to know: Cost: Typically ranges from $5 to $10 per square foot, including materials and labor. Benefits: 4x stronger than epoxy, UV-resistant, chemical-resistant, and quick curing. Applications: Used for garage floors, pool decks, industrial…

0 notes