#Polymer Bearing Market

Explore tagged Tumblr posts

Text

The Polymer Bearing Market: Trends, Drivers, and Future Outlook

The polymer bearing market is experiencing significant growth due to its extensive application in various industries and the advantages it offers over traditional metal bearings. This article delves into the key trends, drivers, and future prospects of the polymer bearing market, highlighting why these bearings are becoming a preferred choice in multiple sectors.

Advantages of Polymer Bearings

Polymer bearings, made from materials such as PTFE, PEEK, and nylon, provide several benefits that make them attractive to different industries:

1. Corrosion Resistance: Unlike metal bearings, polymer bearings are highly resistant to corrosion, making them suitable for use in harsh environments, including chemical processing and marine applications.

2. Lightweight: Polymers are lighter than metals, which can significantly reduce the weight of machinery and equipment, leading to energy savings and improved efficiency.

3. Low Friction and Wear: These bearings exhibit low friction coefficients and excellent wear resistance, contributing to longer service life and reduced maintenance costs.

4. Self-Lubricating Properties: Many polymer bearings are self-lubricating, eliminating the need for additional lubrication and reducing maintenance requirements.

Key Market Drivers

Several factors are driving the growth of the polymer bearing market:

1. Growing Demand in Automotive Industry: The automotive industry is one of the largest consumers of polymer bearings. These bearings are used in various applications, including steering systems, seats, and transmission systems. The demand for lightweight and durable components in electric vehicles is further propelling the market growth.

2. Expansion of Industrial Machinery: The increasing use of industrial machinery in manufacturing and production processes is boosting the demand for polymer bearings. Their ability to operate efficiently under extreme conditions makes them ideal for heavy-duty applications.

3. Rising Focus on Sustainable Solutions: The shift towards environmentally friendly and sustainable manufacturing practices is encouraging the adoption of polymer bearings. Their long service life and reduced need for lubrication align with the goals of reducing environmental impact and operational costs.

4. Technological Advancements: Continuous research and development efforts are leading to the introduction of advanced polymer materials with enhanced properties. Innovations in polymer science are resulting in bearings that can withstand higher loads and temperatures, further expanding their application range.

Challenges and Restraints

Despite the numerous advantages, the polymer bearing market faces certain challenges:

1. High Initial Costs: The cost of high-performance polymers can be higher than traditional materials, leading to increased initial investment. However, the long-term benefits often outweigh the initial expenses.

2. Limited Load-Bearing Capacity: While advancements are being made, polymer bearings generally have lower load-bearing capacities compared to metal bearings. This limitation can restrict their use in certain heavy-load applications.

3. Temperature Sensitivity: Some polymer bearings may not perform well under extremely high temperatures. Selecting the appropriate polymer material for specific applications is crucial to overcoming this challenge.

Regional Insights

The polymer bearing market is witnessing significant growth across various regions:

1. North America: The presence of major automotive manufacturers and the growing industrial sector are driving the demand for polymer bearings in this region. The focus on reducing vehicle weight and improving fuel efficiency is further supporting market growth.

2. Europe: Europe is another prominent market for polymer bearings, with a strong emphasis on sustainability and energy efficiency. The region's advanced manufacturing capabilities and stringent environmental regulations are fostering the adoption of polymer bearings.

Asia-Pacific: The Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization and urbanization. The increasing production of automobiles, coupled with the expansion of the manufacturing sector, is creating substantial opportunities for the polymer bearing market.

Request for a sample of the report browse through- https://univdatos.com/get-a-free-sample-form-php/?product_id=28029

Future Outlook

The future of the polymer bearing market looks promising, with several trends shaping its growth trajectory:

1. Integration with IoT and Smart Technologies: The integration of polymer bearings with Internet of Things (IoT) technologies is expected to enhance their performance and monitoring capabilities. Smart bearings that can provide real-time data on their condition and performance will revolutionize maintenance practices.

2. Development of High-Performance Polymers: Ongoing research into high-performance polymers will lead to the development of bearings with improved load-bearing capacities and temperature resistance. These advancements will expand the range of applications for polymer bearings.

3. Expansion into New Industries: The unique properties of polymer bearings will drive their adoption in emerging industries such as renewable energy, healthcare, and electronics. Their versatility and performance benefits will open up new opportunities for market growth.

In conclusion, the polymer bearing market is poised for substantial growth, driven by the demand for lightweight, durable, and sustainable solutions across various industries. While challenges remain, continuous technological advancements and the exploration of new applications will ensure a bright future for polymer bearings.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

0 notes

Text

The global Polymer Bearing Market is expected to grow at a significant rate of around 4% during the forecast period.

0 notes

Text

Pristyn Care: Innovations in ACL Surgery: The Development and Use of Synthetic Ligaments

Anterior cruciate injuries are one of the most common but most crippling sports-related injuries caused to athletes from amateur to professional levels. It limits the knee joint from unstable activities for rotating and forward movements. The injury of the ACL can reduce the mobility of joints, causing chronic pain, and deteriorating the quality of life drastically.

In most of the cases, it necessitates surgery. New developments, techniques of production, and ways to use synthetic ligaments nowadays represent a true revolution in orthopedic medicine. All the novelties in treatment were taken into consideration by Pristyn Care in its work to innovate the Pristyn healthcare services, and as soon as the patients began to take the benefit of the most advanced options for ACL repair through minimally invasive interventions, the expanded benefits of minimally invasive techniques began to be evident clearer.

Importance of ACL Reconstruction

The ACL plays a very important part in the stability and movement of the knee joint; basically, activities such as walking, running, and jumping are regulated. These micro-injuries, if not halted in the growth phase, can grow into serious knee instability. The individual is put at risk of further injuries and a high probability of degenerative, destructive joint conditions of the osteoarthritic type. It is estimated that about 200,000 reconstructions of the ACL are carried out annually across the globe, and the question of finding and applying an integral treatment suddenly becomes urgent.

Most notably, the introduction of artificial ligaments entirely changed the idea of ACL reconstruction; it was the arrival on the market of a durable commercial analog of traditional grafts. In most cases, the period of recovery was elongated by the occurrence of pain in the donor area and the need to recover two traumatized areas and to use transplant tissue taken from the body of the patient. Contemporary solutions, backed by state-of-the-art equipment and the teams of surgeons in the Pristin Care facilities, have brought initiation of repair of an ACL tear to a new level—the maximum quality of life that individuals devastated by such an injury can hope for.

Synthetic ligaments. What exactly are synthetic

Some of the commonly used and developed synthetic implants are the synthetic ligaments used in orthopedic surgery. More precisely, they are artificially created biomaterials used in cases of a technique for replacing damaged natural ligaments. The synthetic ligaments are not autografts, allografts, or autografts harvested from the body of the patient but, on the contrary, they are biocompatible polymers in origin.

The various available options of synthetic ligaments and benefits brought by it include good quality, which is consistent; unlimited supply; and no morbidity at the donor site. The extraction of autografts can be a bit frightening to the patient, and most of the time, more time for recovery is needed. Other than that, synthetic ligaments minimize the time used during the surgery because grafting is not necessary.

That is why advanced synthetic ligaments are increasingly being used as a substitute for grafting, since, in some places, the availability of appropriate and right donor grafts is very limited. This, therefore, enhances the access and timeliness of the surgeries for anybody in need of ACL.

Where Technological Innovations Impact Development on Synthetic Ligaments

The development of an artificial ligament, and more so that of an artificial fiber, is an extremely interdisciplinary field of materials science and engineering, aiming to produce fibers with properties analogous to natural ligaments. If performed on a human knee, that material should be strong, flexible, and durable enough to bear the dynamic stresses. Modern ones are made using advanced polymers, usually polyethylene terephthalate, and polyurethanes for their qualities of strength and elasticity.

This is particularly the case since such developments are specifically targeted at the improvement in the integration of such material with human tissue, the further reduction of risks for tissue rejection, as well as the enhancement of the healing process itself. Particularly, "Pristyn Care" is engaged in doing the given research process further enhancing the boundary of what is possible to be done with synthetic ligament technology. Focusing on knee biomechanics allows developers to adapt how a ligament's structure is formed to recreate natural motion while at the same time reducing complications and inducing new methods of natural and efficient ways of healing.

The newest technologies will save artificial knee ligaments from being inferior or just equal to the traditional knee-ligament grafts and most of the time, they will be far above benchmark levels by such a huge amount, marking a huge leap in ACL reconstruction technology.

How Pristyn Care is Changing the Way ACLs are Reconstructed

Pristyn Care leads from the front in the adaptation and innovation of methods for synthetic ligaments in the reconstruction of ACLs. There is a deep commitment to the assimilation of the latest in medical innovations with the aid of advanced technology that supports conducting such complex procedures in ultra-modern surgical facilities. With patient safety and surgical efficacy set to be a priority, the surgical centers of Pristyn Care can perform every ACL surgery under the best of conditions. Moreover, Pristyn Care is actively involved in partnering with advanced medical researchers and bioengineers to further enhance effectiveness and safety in the use of synthetic ligaments.

Reviews of ACL surgery operations under the aegis of Pristyn Care state that the medical staff were professional, the facilities were modern, and generally, surgeries were performed with good outcomes. All these statements refer not to new medical technologies but to the high rates of patient satisfaction and trust.

Advantages of Synthetic Ligaments in ACL Reconstruction

Using synthetic ligaments in ACL reconstruction has one major benefit which is the elimination of donor site morbidity. Unlike conventional techniques that include removing body tissue from a patient, these issues can be avoided by using synthetic ligaments. Therefore, it is widely recognized as an effective approach that lessens the chances of postoperative infection and pain reduction along with a quicker & easier recovery process. Pristyn Care reviews indicate that patients have highly ranked this method because they recover within a short time and experience minimal postoperative discomfort.

Pristyn healthcare reviews indicate that Pristyn Care’s use of synthetic ligament in ACL surgery has yielded outstanding results, which have enabled patients to make fast comebacks for sports and their normal duties.

In Pristyn Care reviews, people talk about how much they are satisfied with the minimal interruption to their lives, and the quickness with which they recovered. Good testimonials through Pristyn Healthcare reviews emphasize how advanced surgical practices and individualized treatments offered by Pristyn Care are geared towards providing high-quality health services resulting in the best outcomes.

Identify the Challenging Issues and Consider

The utilization of synthetic materials in surgical procedures presents both opportunities and challenges. Although these materials can enhance the recovery process due to their design to integrate with tissue without triggering an immune response, their long-term durability remains a concern. Pristyn Care reviews often highlight the rigorous monitoring of synthetic-tendon integration, particularly under the continuous stress imposed by daily activities. This is an area of active research within Pristyn healthcare reviews, focusing on enhancing the material's ability to withstand long-term use without compromising safety.

Additionally, regulatory and ethical factors about these techniques are vital. In addition, all synthetic materials used are strictly regulated by Pristyn Care for maximum safety. This commitment to safety standards is reflected in Pristyn healthcare reviews where the rigorous clinical trials and medical & ethical constraints are highly acknowledged. These materials undergo stringent safety checks before their approval for use so that they conform with the highest possible safety standards hence maintaining the reputation of Pristyn Care as a provider of safe, innovative, and effective Pristyn health care solutions.

Patient Success Stories and Case Studies

Against this backdrop, many life-changing benefits make patients at Pristyn feel that their ACL is rebuilt with synthetic ligaments. This is not on paper, but one watches how a patient describes getting back to sports activity after months of surgery and says great recovery is credited to great care. Another case in point reflects a patient who almost felt no pain with rapid rehabilitation due to advanced surgical techniques at Pristyn Care. These stories strengthen the good reviews about high satisfaction rates and successful surgical outcomes on Pristyn healthcare platforms.

Conclusion

ACL injuries are mostly known as anterior cruciate ligament injuries and they are common and severe, especially in high-impact sports or activities that involve the knee joint heavily. These injuries negatively affect performance, so it requires a well-planned recovery plan to safely go back to what one was doing before. One main surgical procedure through which the normal functions of the knee can be restored is known as ACL reconstruction. The Return to Play (RTP) protocols post-surgery should be focused on total recuperation, prevention of future traumas, and restoration of peak levels of performance. For Pristyn Care, emphasis has been put on RTP post-ACL reconstruction to achieve full patient recovery and enable them to regain their best level of performance. In Pristyn care reviews, there is usually mention of how effective its customized RTP protocols are because these protocols help in preventing reinjuries. Further, Pristyn Healthcare reviews also hail the individualistic approach taken during the rehabilitation period which has significantly improved the success rates for ACL surgeries conducted at Pristyn Care.

#pristyn care#pristyn care reviews#pristyn healthcare#pristyn healthcare reviews#pristyn care lybrate#pristyn care company

3 notes

·

View notes

Text

Automotive Bearing Market Advancements in Technology and Materials Driving Future Innovations in Vehicle Performance and Efficiency

The automotive bearing market has seen significant developments over the past few years, driven by advancements in technology, increasing demand for fuel efficiency, and the shift toward electric vehicles (EVs). Bearings, crucial components in reducing friction and ensuring smooth rotation in automotive parts, play an integral role in the performance, durability, and efficiency of vehicles. These developments are reshaping the landscape of the automotive industry, with innovative bearing solutions emerging in response to growing consumer and regulatory demands for sustainability, energy efficiency, and reduced emissions.

Technological Advancements

One of the key developments in the automotive bearing market is the continuous advancement of bearing technology. Manufacturers are investing heavily in research and development to create more efficient, durable, and lightweight bearings that can withstand the harsh conditions of modern vehicles. The rise of electric vehicles has further accelerated this trend, as EVs demand highly efficient bearings that can support the higher torque loads and faster speeds associated with electric drivetrains.

Advanced materials, such as ceramic and polymer bearings, have gained popularity due to their light weight, resistance to corrosion, and ability to handle extreme temperatures. These materials are ideal for high-performance applications in both traditional and electric vehicles, leading to a rise in their adoption across the industry.

Shift Towards Electric Vehicles (EVs)

The rapid growth of electric vehicles has significantly impacted the automotive bearing market. Bearings for electric drivetrains are becoming more specialized, requiring manufacturers to design products that can handle the unique demands of electric motors, which operate differently from conventional internal combustion engines. For example, electric vehicle motors tend to have a higher rotational speed and torque, requiring bearings that can offer better performance in these conditions.

Additionally, the growing demand for electric vehicles has led to an increased need for energy-efficient bearings that reduce power losses and enhance the vehicle's overall energy performance. Bearing manufacturers are focusing on creating products that minimize friction and wear, which can significantly improve the efficiency of electric vehicles.

Market Trends and Challenges

One of the major trends in the automotive bearing market is the increasing focus on sustainability. With rising environmental concerns and stricter emission regulations, automotive manufacturers are under pressure to adopt more eco-friendly solutions. As a result, bearings that reduce friction, improve fuel efficiency, and extend the lifespan of vehicles are in high demand. Manufacturers are also exploring recyclable and biodegradable materials to reduce their environmental impact.

However, despite these advancements, the market faces several challenges. The rising cost of raw materials, including high-performance metals and advanced polymers, is putting pressure on manufacturers. Additionally, the complexity of designing bearings that meet the diverse needs of both conventional and electric vehicles adds to the development costs. Competition in the market is also intensifying as new players enter the bearing manufacturing space, making it more difficult for established brands to maintain their market share.

Future Outlook

Looking ahead, the automotive bearing market is expected to continue its growth, driven by the rise of electric vehicles, technological advancements, and the ongoing push for sustainability. As automakers increasingly adopt electric drivetrains, the demand for specialized bearings will rise, presenting opportunities for manufacturers to innovate and capitalize on new trends. Furthermore, as consumers become more environmentally conscious, the demand for energy-efficient and long-lasting bearings will continue to grow.

To stay competitive, bearing manufacturers will need to focus on developing innovative solutions that meet the evolving needs of the automotive industry. Whether through the use of advanced materials, smart technology, or improved manufacturing processes, the future of the automotive bearing market looks promising, with significant potential for growth and innovation.

0 notes

Text

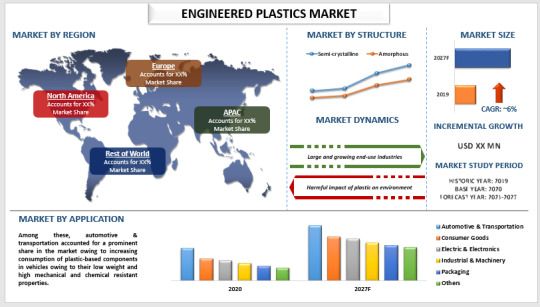

The Engineering Plastics Market is projected to grow from USD 122855 million in 2024 to an estimated USD 212671 million by 2032, with a compound annual growth rate (CAGR) of 7.1% from 2024 to 2032.Engineering plastics have emerged as the backbone of various industries, providing versatile solutions that outperform traditional materials such as metals and ceramics. These high-performance polymers are specifically designed for applications requiring superior mechanical, thermal, and chemical properties. With a growing demand from sectors like automotive, electronics, construction, and healthcare, the global engineering plastics market is set for robust growth.

Browse the full report https://www.credenceresearch.com/report/engineering-plastics-market

Market Overview

The global engineering plastics market is projected to grow significantly in the coming years, driven by technological advancements and increasing applications across industries. According to recent market reports, the market is expected to reach a value of over $150 billion by 2030, growing at a compound annual growth rate (CAGR) of approximately 6-7% during the forecast period. Key players like BASF, DowDuPont, SABIC, and LG Chem dominate the market, leveraging their extensive R&D capabilities to develop innovative and sustainable solutions.

Key Types of Engineering Plastics

Engineering plastics are broadly classified into several types, each tailored for specific applications. Some of the most commonly used categories include:

1. Polyamides (PA): Also known as nylon, these materials are widely used in automotive components, textiles, and industrial machinery due to their excellent strength, abrasion resistance, and thermal stability. 2. Polycarbonates (PC): Renowned for their transparency and impact resistance, polycarbonates are essential in manufacturing electronic displays, automotive headlamps, and medical devices. 3. Polyoxymethylene (POM): Commonly known as acetal, this plastic is used in precision parts like gears, bearings, and fasteners due to its high rigidity and dimensional stability. 4. Acrylonitrile Butadiene Styrene (ABS): Known for its toughness and ease of processing, ABS finds applications in consumer electronics, toys, and automotive interiors. 5. Thermoplastic Polyesters (PET, PBT): These are widely used in electrical components and packaging, owing to their excellent chemical resistance and thermal properties.

Market Drivers

1. Rising Demand from the Automotive Sector: Engineering plastics are replacing traditional materials in the automotive industry to reduce vehicle weight and improve fuel efficiency. Components such as fuel systems, interior trims, and under-the-hood applications are increasingly using high-performance plastics.

2. Growth in Electronics and Electrical Industry: With the proliferation of smart devices and advanced electronics, the demand for lightweight, durable, and heat-resistant materials has surged. Polycarbonates and ABS are critical in manufacturing casings, connectors, and display screens.

3. Focus on Sustainability: Engineering plastics are increasingly being recycled and reused to align with global sustainability goals. This shift toward eco-friendly solutions is fostering innovation and adoption in multiple industries.

4. Expanding Infrastructure and Construction Activities: The construction sector’s need for durable, lightweight, and corrosion-resistant materials is driving the demand for engineering plastics in pipes, panels, and insulation systems.

Challenges in the Market

Despite its promising growth, the engineering plastics market faces challenges such as volatile raw material prices and stringent environmental regulations. The reliance on petrochemical derivatives makes these materials vulnerable to fluctuations in crude oil prices. Additionally, the disposal and recycling of engineering plastics pose environmental concerns that industries are working to address.

Future Outlook

The engineering plastics market is poised for significant advancements, with R&D efforts focusing on developing bio-based alternatives and enhancing performance characteristics. Innovations in polymer blends and composites will further expand their application scope. Additionally, collaborations between manufacturers and end-users will pave the way for customized solutions tailored to specific industrial needs.

Key Player Analysis:

Ascend Performance Materials

Chevron Phillips Chemical Company LLC

Daicel Corporation

Eastman Chemical Company

Evonik Industries AG

Ginar Technology Co., Ltd.

Grand Pacific Petrochemical Corporation

Mitsubishi Engineering-Plastics Corporation

Ngai Hong Kong Company Ltd.

Nylon Corporation of America (NYCOA)

Piper Plastics Corp.

Polyplastics Co., Ltd.

Ravago

Teknor Apex

Trinseo LLC

Wittenburg Group

Segmentation:

By type,

Acrylonitrile Butadiene Styrene

Polyamide

Polycarbonate

Thermoplastic Polyester

Polyacetal

Fluoropolymer

Others

By end-use industries,

Automotive & Transportation

Consumer Appliances

Electrical & Electronics

Industrial & Machinery

Packaging

Others

Based on Region:

North America

U.S.

Canada

Mexico

Europe

Germany

France

U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

Browse the full report https://www.credenceresearch.com/report/engineering-plastics-market

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

Carbon-Filled PTFE Thrust Pad: Best Choice for Durability by Goa Polymer

When it comes to high-performance components in industries requiring low friction, high durability, and robust load-bearing properties, Carbon-Filled PTFE Thrust Pads have become a top choice. Goa Polymer, a leading name in the manufacturing and supply of thrust pads, brings innovation, expertise, and industry-leading standards to this vital component. In this article, we’ll explore why these pads are essential, their core features, and why Goa Polymer’s Carbon-Filled PTFE Thrust Pads stand out as the best in the market.

What is a Carbon-Filled PTFE Thrust Pad?

A Carbon-Filled PTFE Thrust Pad combines the smooth, low-friction characteristics of PTFE (Polytetrafluoroethylene) with the added strength and durability of carbon fillers. This blend is ideal for applications requiring resistance to wear and stability under heavy loads, as carbon enhances the material’s hardness, making it more resilient under challenging conditions.

With increasing demands in industrial applications, these thrust pads serve a critical role in minimizing friction between rotating components, thus prolonging equipment life and reducing maintenance requirements. Goa Polymer leverages cutting-edge technology to produce best-in-class Carbon-Filled PTFE Thrust Pads, making them a preferred choice across various sectors, from automotive to chemical manufacturing.

Key Advantages of Goa Polymer’s Carbon-Filled PTFE Thrust Pads

Superior Load-Bearing Capacity:- Goa Polymer’s Carbon-Filled PTFE Thrust Pads are designed to handle heavy loads effectively. The carbon filling amplifies the pad’s ability to support significant weights, making it a valuable asset in industries where load endurance is crucial.

Exceptional Wear Resistance:- Goa Polymer’s Carbon-Filled PTFE pads exhibit excellent wear resistance. By integrating high-grade carbon, these thrust pads provide prolonged performance even under constant friction, drastically reducing replacement frequency and costs.

Minimal Friction for Optimal Efficiency:- The PTFE in these thrust pads offers ultra-low friction, enhancing efficiency in applications like pumps and compressors. This characteristic is essential for applications demanding high-speed rotation, as it minimizes energy loss due to heat generation.

Enhanced Stability Under High Temperatures:- Goa Polymer’s Carbon-Filled PTFE Thrust Pads excel in high-temperature settings, maintaining stability and performance under thermal stress, making them ideal for heavy machinery and high-heat applications.

Resistance to Corrosion and Chemical Exposure:- PTFE itself is inherently resistant to many chemicals, and the carbon enhancement only adds to this property. Industries such as chemical manufacturing find Goa Polymer’s Carbon-Filled PTFE Thrust Pads invaluable due to their resilience against corrosive substances.

Why Goa Polymer’s Carbon-Filled PTFE Thrust Pads are the Best Choice

Goa Polymer is committed to producing high-quality thrust pads, focusing on precision, durability, and innovation. Here’s what makes their Carbon-Filled PTFE Thrust Pads an outstanding choice:

Innovative Manufacturing:- Goa Polymer utilizes advanced manufacturing processes to maintain uniformity in material distribution, ensuring consistent quality across each Carbon-Filled PTFE Thrust Pad.

Customisation Options:- Goa Polymer provides customized thrust pads tailored to specific industrial needs. Clients can specify thickness, diameter, and other critical factors to create a perfect fit for their applications.

Stringent Quality Checks:- Every Goa Polymer Carbon-Filled PTFE Thrust Pad undergoes multiple quality checks, assuring the highest standards. This commitment to quality has made Goa Polymer a trusted name in thrust pad manufacturing.

Applications of Carbon-Filled PTFE Thrust Pads

1. Automotive Industry

In automotive applications, where high precision and reliability are crucial, Carbon-Filled PTFE Thrust Pads provide a dependable solution for reducing wear and tear in components that encounter high friction. Goa Polymer’s pads are designed to withstand the rigors of automotive applications, enhancing component longevity and reliability.

2. Industrial Pumps

For industrial pumps, minimizing friction is key to ensuring efficiency. Goa Polymer’s Carbon-Filled PTFE Thrust Pads significantly reduce the friction within pumps, allowing for smoother operation and increased efficiency, making them essential in fluid management systems.

3. Aerospace Engineering

Aerospace components require precision and durability under challenging conditions. Goa Polymer’s Carbon-Filled PTFE Thrust Pads provide the necessary stability, load-bearing strength, and wear resistance required for aerospace applications, contributing to safer and longer-lasting equipment.

4. Chemical Processing Equipment

With excellent resistance to corrosion and a range of chemicals, Goa Polymer’s Carbon-Filled PTFE Thrust Pads are ideal for chemical processing industries. They maintain integrity even in corrosive environments, supporting safe and effective operations.

5. Heavy Machinery

In heavy machinery where thrust pads experience constant friction, Goa Polymer’s Carbon-Filled PTFE Thrust Pads offer durability and performance, reducing downtime and maintenance needs.

The Benefits of Using Carbon-Filled PTFE Thrust Pads from Goa Polymer

Goa Polymer’s Best Carbon-Filled PTFE Thrust Pads are developed with industrial performance and longevity in mind. Here’s why they’re ideal:

Longer Operational Life: Designed for longevity, these thrust pads significantly reduce the need for frequent replacements.

Enhanced Operational Efficiency: The low-friction properties of PTFE reduce wear, optimizing energy use.

Cost-Effective Maintenance: Fewer replacements and lower wear mean a reduced total cost of ownership, saving time and expenses.

Selecting the Best Carbon-Filled PTFE Thrust Pad: Why Goa Polymer?

Finding the best Carbon-Filled PTFE Thrust Pad that matches an application’s unique needs requires careful consideration. Goa Polymer offers technical support to help clients choose the ideal thrust pad, considering factors like load, temperature, and friction requirements. This guidance ensures that businesses get the best value and performance from each thrust pad.

Final Thoughts on Goa Polymer’s Carbon-Filled PTFE Thrust Pads

For industries that prioritize durability, reliability, and performance, Goa Polymer’s Carbon-Filled PTFE Thrust Pads are the best option. These thrust pads, manufactured with advanced technologies and rigorous quality checks, have set a benchmark in the market. Their low friction, high wear resistance, and high-temperature tolerance make them an invaluable component across various sectors, from automotive to heavy machinery.

Choosing the right Carbon-Filled PTFE Thrust Pad is crucial to achieving optimal operational efficiency and reducing long-term maintenance costs. With Goa Polymer’s expertise, commitment to quality, and customization options, you can be assured of receiving thrust pads that meet the highest standards in performance and durability.

For more information on purchasing Goa Polymer’s Carbon-Filled PTFE Thrust Pads, or to get expert guidance on selecting the best option for your applications, reach out to their support team today.

0 notes

Text

Geogrids Market: Growth, Trends, and Opportunities in the Infrastructure and Construction Sectors

The Geogrids Market is witnessing a robust growth trajectory, driven by increasing demand from industries such as mining, construction, and transportation. Geogrids are versatile materials used in geotechnical and civil engineering projects to reinforce soil and provide structural support, making them crucial in various applications like highways, railways, parking lots, and more. As infrastructure projects expand globally, the geogrids market is set for significant expansion. In this blog, we will explore the key market dynamics, projected growth, key players, and applications of geogrids, offering a comprehensive look at this growing industry.

1. Market Overview and Size

The geogrids market was valued at $1.60 billion in 2023 and is projected to grow to $1.72 billion by 2024, reflecting an upward trend in demand across multiple sectors. By 2030, the market is expected to reach $2.65 billion, with a compound annual growth rate (CAGR) of 7.50% from 2024 to 2030. This steady growth underscores the increasing adoption of geogrids, driven by their role in improving the efficiency, safety, and longevity of construction projects.

2. Key Market Drivers

Several key factors are driving the growth of the geogrids market:

Increasing Infrastructure Development: As governments around the world focus on upgrading and expanding infrastructure, the demand for geotechnical solutions like geogrids is on the rise. Geogrids help stabilize soil in roadways, railways, and other heavy-duty infrastructure, enhancing their durability and performance.

Demand from the Mining Industry: Mining operations often require reinforcement solutions to stabilize mine roads, stockpiles, and tailings dams. Geogrids are an effective solution to enhance soil stability in mining regions, further boosting market demand.

Growing Transportation Networks: The expansion of transportation networks, particularly in emerging economies, has led to an increased use of geogrids for reinforcing roads, highways, and railways, where soil strength and stability are crucial.

Environmental Sustainability: Geogrids help reduce the use of construction materials, lowering environmental impact and costs. This aligns with global trends toward more sustainable building practices, encouraging the adoption of geogrids.

3. Market Segmentation by Type

The geogrids market is segmented by type into several categories, each offering distinct advantages based on application and material composition:

Plastic Geogrids: Plastic geogrids are one of the most widely used types due to their versatility and cost-effectiveness. They offer excellent reinforcement properties and are used in a variety of applications, including roads, railways, and parking lots.

Steel Plastic Composite Geogrids: These geogrids combine the strength of steel with the flexibility of plastic, making them ideal for heavy-duty applications. Steel plastic composite geogrids are particularly popular in mining, highways, and other projects requiring high load-bearing capacity.

Fiberglass Geogrids: Known for their high tensile strength and durability, fiberglass geogrids are often used in roads, railways, and airport runways, where long-term stability and resistance to deformation are essential.

Polyester Geogrids: Polyester geogrids are often used in transportation infrastructure due to their high resistance to soil deformation and their ability to provide long-lasting support under various environmental conditions.

Others: This category includes geogrids made from materials such as polypropylene and other specialized polymers, which are used for specific, niche applications where particular reinforcement properties are needed.

4. Segmentation by Application

Geogrids are used in a wide range of applications, each benefiting from their ability to enhance soil reinforcement and improve the stability of the structure:

Mining: In the mining industry, geogrids are used to stabilize roads, slopes, and stockpiles. Their ability to reinforce weak soils in mining areas makes them an essential part of maintaining safe and efficient mining operations.

Railways and Highways: The construction of railways and highways often requires robust reinforcement solutions due to the heavy loads and continuous traffic these structures endure. Geogrids provide the necessary support to ensure long-term stability and prevent soil settlement.

Parking Lots and Marinas: Geogrids are used to reinforce parking lots, marinas, and other paved areas, preventing ground settlement and improving the durability of these surfaces under heavy traffic.

Other Applications: Geogrids also find use in areas such as landfills, reservoirs, and foundation projects. Their versatility allows them to be customized for various civil engineering and geotechnical applications.

5. Regional Analysis

The geogrids market is experiencing growth across different regions, driven by regional infrastructure projects, mining activities, and transportation network expansions:

North America: The North American geogrids market is dominated by the U.S., with significant demand from transportation infrastructure, mining, and construction projects. The region’s strong focus on infrastructure improvement and sustainability is expected to fuel continued market growth.

Europe: Europe’s geogrids market is growing steadily, with the demand for environmentally sustainable construction solutions driving market trends. The construction of highways, bridges, and railways is a key factor contributing to the market's expansion.

Asia Pacific: Asia Pacific is the fastest-growing region in the geogrids market, driven by rapid industrialization and urbanization in countries like China and India. The construction of transportation networks, including roads and railways, is particularly robust in this region.

Latin America: Latin America is witnessing significant growth in the geogrids market, driven by infrastructure projects and mining activities in countries such as Brazil, Chile, and Mexico.

Middle East & Africa: In the Middle East & Africa, the market is seeing demand from construction projects related to oil and gas infrastructure, as well as transportation networks. As regional economies diversify and develop, the adoption of geogrids in infrastructure projects is expected to increase.

6. Key Market Players

Several prominent companies lead the geogrids market, offering innovative solutions and expanding their product portfolios to meet growing demand. These key players include:

Feicheng Lianyi: A leading manufacturer of geogrids, Feicheng Lianyi has established a strong market presence with a focus on high-quality products.

Tensar: A well-known name in geotechnical materials, Tensar offers a wide range of geogrid solutions for reinforcing soil and improving the stability of infrastructure.

Maccaferri: Maccaferri is a global leader in the production of geogrids, offering solutions for civil engineering projects, including transportation infrastructure and mining.

NAUE Secugrid: NAUE Secugrid is a major player in the production of geogrids, particularly focusing on sustainable solutions for soil reinforcement in various sectors.

TechFab India, GSE, and Tencate: These companies are key players in the Asian market, providing geogrid solutions for a range of civil engineering applications.

Bonar, TENAX, and Atarfil: These players are involved in producing high-quality geogrids for use in various infrastructure projects, including roads, railways, and parking lots.

Other Notable Players: Other companies like Shandong New Slightly Geotechnical Material, Hengshui Baoli Engineering Rubber, and Nilex are contributing to market growth through their specialized geogrid solutions.

7. Challenges in the Geogrids Market

Despite its strong growth prospects, the geogrids market faces certain challenges:

High Initial Cost: Geogrids, especially those made from steel or fiberglass, can be expensive to manufacture and install. This can limit adoption in regions or sectors with budget constraints.

Competition from Alternative Solutions: Traditional soil reinforcement techniques, such as concrete and asphalt, still compete with geogrid solutions, especially in established markets where these methods are deeply integrated.

Technological Barriers: While geogrids offer many benefits, the need for constant innovation in material science to improve performance and reduce costs is an ongoing challenge.

8. Future Prospects and Trends

The geogrids market is poised for growth driven by several emerging trends:

Sustainability and Eco-friendly Solutions: The focus on sustainable construction practices is likely to boost the adoption of geogrids, as they reduce the need for traditional building materials, thereby lowering environmental impact.

Technological Advancements: Innovations in materials, such as biodegradable geogrids and those with enhanced tensile strength, will help meet the evolving needs of the construction industry.

Increasing Infrastructure Investment in Developing Regions: As infrastructure development accelerates in emerging economies, particularly in Asia Pacific and Africa, the demand for geogrids will continue to grow, providing new opportunities for manufacturers.

9. Conclusion

The geogrids market is on a strong growth trajectory, driven by increasing demand from the construction, mining, and transportation industries. With their ability to reinforce soil and improve the longevity of structures, geogrids are becoming an indispensable component in civil engineering projects worldwide. As the market evolves, technological advancements, sustainability concerns, and regional infrastructure growth will continue to shape the industry. For businesses and investors, the geogrids market offers exciting opportunities in the coming years, particularly in emerging regions and sectors focused on sustainable development.

0 notes

Text

How Laser Engraving Works: A Guide to the Technology

The revolutionary technology known as laser engraving has completely transformed the way we leave lasting impressions on a variety of materials. OTOEL, an engraving company, is dedicated to sharing knowledge about this technology's functions, uses, and benefits. This comprehensive guide will explore the nuances of laser engraving, encompassing everything from fundamental concepts to the various kinds of laser engravers and their applications.

Comprehending Laser Engraving

What is Engraving by Laser?

A concentrated laser beam evaporates material off an object's surface in laser engraving, a precise marking method. This procedure produces a permanent design that might be very complex and detailed. Laser engraving is more precise and versatile than previous engraving techniques because it uses light energy instead of physical tools.

How Does Laser Cutting Operate?

A laser engraver's operation can be divided into multiple crucial steps:

Design Development: Use a graphic design program like CorelDRAW or Adobe Illustrator to create a digital design. The design needs to be transformed into a laser engraver-compatible format.

Configuration of the Machine: The type of material and intended engraving depth are considered while calibrating the laser engraver. Adjusting variables like focus, power, and speed helps to maximize the engraving process.

Procedure for Engraving: When the laser beam is directed toward the material's surface, layers of the material are vaporized to generate the desired pattern. Numerous variables, such as the laser engraver's settings and the characteristics of the material, affect the engraving's depth and quality.

Finishing Touches: After engraving, more procedures may be used to improve the engraved surface's longevity or attractiveness.

The Principles of Laser Engraving Science

The concepts of thermal dynamics and photonics underlie laser engraving. Localized melting or vaporization of the substance results from heat generated by the concentrated laser beam striking it. This leads to:

Ablation: The process of vaporizing away material, commonly used to remove stricter things like metals.

Melting: Rather than total vaporization, heat can produce melting in softer materials like wood or plastic.

Laser Engraver Types

There are numerous varieties of laser engravers on the market right now, including:

CO2 Engraving Lasers: These work perfectly with non-metal leather, acrylic, and wood materials. They function at a wavelength that biological molecules can readily absorb.

Fiber Laser Cutters: Fiber lasers, well-known for their adaptability, work well on metals and some polymers. They don't have any consumables that need to be replaced, so they require little maintenance.

YAG lasers: Unlike CO2 lasers, these are mainly employed for marking metal and are capable of deeper etching.

Uses for Laser Engraving

Numerous industries use laser engraving for a variety of purposes.

Manufacturing: Logos or serial numbers are used for branding, traceability, and part identification.

Jewelry making: Maintains the integrity of the material while enabling complex designs and customization.

Medical Devices: Surgical equipment that bears permanent markings guarantees adherence to regulatory requirements.

Promotional Products: Adding a personalized touch to gifts or business supplies with custom engravings raises brand awareness.

Benefits of Laser Cutting

Employing a laser engraving service has the following advantages:

Precision and Accuracy: Laser engravers can create wonderful details compared to previous methods.

Speed and Efficiency: The procedure is quicker than many traditional procedures, making it suitable for high-volume production.

Durability: Laser engraving leaves behind long-lasting, wear-resistant marks that are permanent.

Non-contact Process: There is less chance of contamination or distortion because the material is not physically touched during engraving.

Conclusion

With its unmatched accuracy, speed, and versatility, laser engraving technology significantly develops marking procedures. OTOEL, an engraving firm committed to quality, is aware of the value of this technology in a range of settings, including production and customized gifts. Using cutting-edge laser engravers, companies can produce superior outcomes that stand out in the competitive market.

Whether you want to buy a laser engraver or are considering using a laser engraving service for your next project, knowing how this technology operates will help you make decisions that align with your objectives. Take advantage of everything that laser technology has to offer and confidently embrace the future of engraving!

0 notes

Text

Automotive Metal Oil Seal Market Insights and Growth Outlook 2024 - 2032

The automotive industry is constantly evolving, and one of the crucial components in ensuring vehicle longevity and performance is the metal oil seal. This article provides an in-depth examination of the automotive metal oil seal market, including its definition, key drivers, challenges, market trends, and future outlook.

Understanding Automotive Metal Oil Seals

What are Metal Oil Seals?

The automotive metal oil seal market is poised for significant growth, driven by the increasing demand for reliable sealing solutions in modern vehicles.

Metal oil seals are critical components used to prevent the leakage of oil and other fluids in automotive applications. They are typically made from a combination of metal and elastomer materials, providing durability and effective sealing properties under various conditions. These seals are essential for maintaining optimal engine performance and protecting internal components from contaminants.

Types of Metal Oil Seals

Single Lip Oil Seals: These seals have a single lip and are commonly used in applications where only one side needs protection.

Double Lip Oil Seals: Featuring two lips, these seals provide enhanced protection against leakage and contaminants, making them suitable for more demanding environments.

Spring-Loaded Oil Seals: These seals incorporate a spring that applies pressure to the lip, ensuring a tighter seal and better performance over time.

Market Overview

Market Size and Growth

The automotive metal oil seal market has experienced steady growth over the past few years, driven by the increasing production of vehicles globally and the rising demand for high-performance sealing solutions. With advancements in material science and manufacturing technologies, the market is expected to continue its upward trajectory.

Key Market Drivers

Growing Automotive Production: As vehicle manufacturing increases, the demand for reliable sealing solutions, including metal oil seals, rises correspondingly.

Rising Need for Engine Efficiency: Modern engines are designed to be more efficient, and effective sealing is vital for maintaining performance and reducing emissions.

Technological Advancements: Innovations in materials and designs have led to improved performance characteristics of metal oil seals, further driving their adoption in various automotive applications.

Competitive Landscape

Major Players

The automotive metal oil seal market is characterized by several key players, including:

SKF Group: A global leader in bearing and seal technologies, SKF offers a wide range of metal oil seals designed for diverse automotive applications.

Freudenberg Sealing Technologies: Known for its advanced sealing solutions, Freudenberg provides high-performance metal oil seals that meet stringent industry standards.

Trelleborg Group: Trelleborg specializes in engineered polymer solutions, including metal oil seals, catering to various sectors within the automotive industry.

Market Challenges

Despite the positive growth outlook, the automotive metal oil seal market faces several challenges:

Material Costs: Fluctuations in the prices of raw materials can impact production costs, affecting the pricing of metal oil seals.

Competition from Alternative Sealing Solutions: The emergence of advanced sealing technologies, such as polymer seals, poses a competitive threat to traditional metal oil seals.

Regulatory Compliance: Adhering to various automotive regulations and standards can complicate product development and market entry for manufacturers.

Future Trends

Innovations Shaping the Market

The automotive metal oil seal market is expected to witness several trends that will influence its growth:

Smart Sealing Solutions: The integration of IoT technology into sealing solutions could enhance monitoring and performance, providing real-time data on seal condition.

Sustainability Initiatives: As the automotive industry shifts towards sustainability, manufacturers are likely to focus on eco-friendly materials and production processes for oil seals.

Expansion in Electric Vehicles: The growth of electric vehicles (EVs) presents new opportunities for metal oil seals, particularly in applications where efficient sealing is critical for battery and drive systems.

Conclusion

While challenges such as material costs and competition from alternative technologies exist, ongoing innovations and the rise of electric vehicles present exciting opportunities. As the industry continues to evolve, stakeholders must stay informed about trends and developments in the metal oil seal sector to capitalize on emerging opportunities.

#Automotive Metal Oil Seal Market Size#Automotive Metal Oil Seal Market Trend#Automotive Metal Oil Seal Market Growth

0 notes

Text

PP Jumbo Bags: A Comprehensive Guide

PP (Polypropylene) jumbo bags, also known as FIBC (Flexible Intermediate Bulk Containers), are one of the most widely used forms of packaging for bulk materials. Their versatility, strength, and durability make them ideal for transporting a wide variety of products, including grains, chemicals, construction materials, and more. This article delves into the world of PP jumbo bags, covering their manufacturing process, uses, advantages, and frequently asked questions.

Understanding PP Woven Jumbo Bags

PP woven jumbo bags are made from polypropylene, a thermoplastic polymer. The fabric is woven to create a robust and durable material, which can withstand the rigors of carrying heavy loads. These bags are often referred to as "big bags" or "bulk bags" due to their ability to hold anywhere from 500 kg to 2,000 kg of materials, depending on the design.

PP woven jumbo bags are most commonly used in industries like agriculture, construction, and mining, where large volumes of materials need to be transported efficiently. The woven structure ensures that the bags are both lightweight and resistant to tears and punctures, making them ideal for handling heavy goods over long distances.

Types of PP Jumbo Bags

There are several types of PP jumbo bags available in the market, each tailored for specific applications. The most common types include:

U-panel bags: These are the most commonly used PP jumbo bags. They have two seams running from the top to the bottom, creating a "U" shape when viewed from the side.

Circular woven bags: These bags are made from tubular fabric and do not have any side seams, which gives them additional strength and load-bearing capacity.

Baffle bags: These are designed with internal baffles that help maintain the bag's shape, making them more stable when stacked.

Single-loop and double-loop bags: These are designed for easy lifting, with one or two lifting loops that can be easily hooked to cranes or forklifts.

Each type of bag has its own set of benefits, depending on the application. Whether transporting fine powders or large aggregates, there's a PP jumbo bag suited for the task.

Manufacturing Process of PP Jumbo Bags

PP woven jumbo bags are manufactured through a detailed process that ensures their strength and durability. The process begins with the extrusion of polypropylene resin into thin fibers. These fibers are then woven into a durable fabric, which forms the base material of the bags.

Once the fabric is created, it is cut and sewn into the desired shape, whether it’s a U-panel, circular, or baffle design. Additional features like lifting loops, filling spouts, and discharge spouts are added based on the intended use of the bag.

The manufacturing process also includes treatments to enhance the bags' UV resistance, ensuring that they remain durable even when exposed to sunlight for extended periods.

Applications of Jumbo Bag Plastic

The versatility of PP jumbo bags makes them ideal for a wide range of applications. Some of the most common industries that use these bags include:

Agriculture: PP woven jumbo bags are used to transport grains, seeds, fertilizers, and animal feed. The bags protect the contents from moisture and contamination, ensuring that the products remain fresh during transportation.

Construction: In the construction industry, jumbo bags are used to transport sand, gravel, cement, and other building materials. Their strength allows them to hold large quantities of these heavy materials.

Chemicals: Many chemical companies use PP jumbo bags to transport bulk powders, granules, and liquids. These bags are often lined with plastic liners to prevent contamination and leakage.

Mining: Jumbo bags are used to transport mined materials like coal, iron ore, and other minerals. The bags are designed to withstand the abrasive nature of these materials, ensuring safe transport.

Weight and Capacity of Jumbo Bags

The Jumbo bag weight and capacity depend on several factors, including the type of material being transported and the design of the bag. Standard PP woven jumbo bags can carry loads ranging from 500 kg to 2,000 kg. However, there are also specially designed jumbo bags that can hold up to 3,000 kg of materials.

The weight of the empty bag itself is relatively light, usually ranging from 2 to 5 kg, depending on the size and design. This makes them easy to handle, even when empty.

Benefits of Using PP Jumbo Bags

PP jumbo bags offer several benefits over traditional packaging materials. These include:

Durability: PP woven jumbo bags are incredibly strong and resistant to tears and punctures, ensuring that the contents remain secure during transportation.

Cost-effective: These bags are relatively inexpensive to produce, making them a cost-effective solution for transporting bulk materials.

Reusable: Many PP jumbo bags can be reused multiple times, reducing the need for single-use packaging and helping companies save on packaging costs.

Space-efficient: When empty, jumbo bags can be folded flat, making them easy to store and transport.

Customizable: PP jumbo bags can be customized with various features like liners, spouts, and lifting loops to suit specific needs.

Environmental Impact of Jumbo Bag Plastic

While Jumbo bag plastic offer many advantages, their environmental impact is an important consideration. Polypropylene is a type of plastic, which means that it does not decompose naturally. However, many manufacturers are now offering recyclable and reusable options, reducing the overall environmental footprint of these bags.

Additionally, some companies are exploring the use of biodegradable materials in the production of jumbo bags. While this technology is still in its infancy, it represents a promising step toward more sustainable packaging solutions.

Customization Options for PP Jumbo Bags

One of the most appealing features of PP jumbo bags is their ability to be customized according to the specific needs of a business. Customization options include:

Size and shape: PP jumbo bags can be manufactured in a variety of sizes and shapes, depending on the requirements of the materials being transported.

Liners: For products that need additional protection from moisture or contamination, jumbo bags can be fitted with internal liners made of plastic or other materials.

Printing: Businesses can have their logos, safety warnings, or product details printed directly onto the jumbo bags for easy identification and marketing purposes.

UV protection: For outdoor storage, jumbo bags can be treated with UV inhibitors to prevent degradation from prolonged exposure to sunlight.

Future Trends in PP Woven Jumbo Bags

The future of PP woven jumbo bags looks promising, with innovations in sustainability and design. As industries continue to prioritize eco-friendly packaging, we can expect to see more recyclable and biodegradable options in the market.

Additionally, advancements in material science may lead to even stronger, lighter, and more versatile PP jumbo bags, further enhancing their appeal across various industries.

FAQs

Q1: What are PP woven jumbo bags made of?PP woven jumbo bags are made from polypropylene, a durable thermoplastic polymer. The material is woven to create a fabric that is both lightweight and strong, capable of holding large quantities of material.

Q2: How much weight can a jumbo bag hold?The weight capacity of a jumbo bag depends on its design and construction. Standard PP jumbo bags can carry loads ranging from 500 kg to 2,000 kg, with some specialized bags holding up to 3,000 kg.

Q3: Are PP jumbo bags recyclable?Yes, many PP jumbo bags are recyclable. Manufacturers are increasingly offering recyclable options, helping to reduce the environmental impact of these plastic bags.

0 notes

Text

Cellular Confinement Systems: Revolutionizing Soil Stabilization and Infrastructure Resilience

The global cellular confinement systems market is set for remarkable growth, driven by increasing infrastructure development and the need for enhanced ground stabilization solutions. Valued at approximately USD 280 million in 2022, the market is projected to reach about USD 2.3 billion by 2028, with a compound annual growth rate (CAGR) of 15.50% during the forecast period from 2022 to 2028. This substantial growth underscores the expanding role of cellular confinement systems in modern construction and civil engineering.

Why Cellular Confinement Systems?

Cellular confinement systems, also known as geocells, are designed to improve the stability and durability of soil structures by confining and stabilizing granular materials. These systems are widely used in applications such as road construction, erosion control, and slope stabilization. Their ability to enhance load-bearing capacity and reduce soil erosion makes them a critical component in building resilient infrastructure.

Get Sample pages of Report: https://www.infiniumglobalresearch.com/reports/sample-request/776

Technological advancements are driving the evolution of cellular confinement systems, with innovations in materials and design enhancing their performance and versatility. These systems are becoming increasingly sophisticated, offering improved durability, ease of installation, and environmental benefits.

Market Dynamics and Growth Drivers

Several factors are contributing to the growth of the global cellular confinement systems market:

Rising Infrastructure Development: The growing demand for infrastructure development, including roads, highways, and urban projects, is driving the need for effective soil stabilization solutions. Cellular confinement systems offer a cost-effective and efficient method for improving soil stability and supporting construction projects.

Enhanced Erosion Control: The increasing focus on erosion control and environmental protection is boosting the demand for cellular confinement systems. These systems help prevent soil erosion in areas prone to heavy rainfall and other environmental factors, making them valuable in various applications.

Technological Advancements: Innovations in geocell materials, such as high-strength polymers and improved design features, are enhancing the performance and applicability of cellular confinement systems. Advances in manufacturing processes are also contributing to cost reductions and increased adoption.

Sustainable Construction Practices: The shift towards sustainable construction practices and green building solutions is driving the adoption of cellular confinement systems. These systems contribute to environmental conservation by reducing soil erosion and promoting effective land use.

Challenges and Opportunities

The market faces challenges such as the high initial cost of cellular confinement systems and the need for specialized installation techniques. Additionally, competition from alternative soil stabilization methods can impact market growth.

However, significant opportunities exist. The increasing focus on infrastructure development and sustainable construction practices is driving demand for advanced cellular confinement systems. Innovations in materials and design, along with expanding applications, offer promising growth avenues.

Regional Analysis

North America: The North American market benefits from significant infrastructure development and maintenance projects. The U.S. and Canada are key markets, driven by ongoing urbanization and transportation infrastructure improvements.

Europe: Europe’s focus on sustainable construction and environmental protection supports the growth of cellular confinement systems. The market is driven by projects aimed at improving soil stability and controlling erosion in both urban and rural settings.

Asia-Pacific: The Asia-Pacific region is experiencing rapid growth due to increasing infrastructure investments and urban development. Countries such as China and India are major contributors to market expansion, driven by extensive construction and infrastructure projects.

Latin America and Middle East & Africa: These regions are showing gradual growth, influenced by infrastructure development and environmental management needs. The demand for cellular confinement systems is rising as countries focus on improving soil stability and erosion control.

Report Overview : https://www.infiniumglobalresearch.com/reports/global-cellular-confinement-systems-market

Competitive Landscape

The cellular confinement systems market is competitive, with several key players and numerous regional manufacturers. Major companies include:

Geosynthetics, Inc.: A leading provider of geocell solutions known for its innovative products and extensive experience in soil stabilization.

Celltech Plastics Ltd.: Specializes in high-performance cellular confinement systems and geosynthetic materials for various applications.

Presto Geosystems: Offers a range of geocell products designed for soil stabilization, erosion control, and infrastructure development.

Soil Stabilization Products, Inc.: Provides advanced cellular confinement systems and solutions for improving soil stability and reducing erosion.

Emerging players and local manufacturers also contribute to market dynamics, offering diverse solutions and catering to specific regional needs.

Conclusion

The global cellular confinement systems market is poised for substantial growth, driven by rising infrastructure development, enhanced erosion control needs, and technological advancements. With revenue expected to reach approximately USD 2.3 billion by 2028, the market presents ample opportunities for innovation and investment. As the demand for effective soil stabilization and sustainable construction solutions continues to rise, cellular confinement systems will play a crucial role in shaping the future of infrastructure development.

0 notes

Text

Composite Strengthening Systems Market: Market Size, Share, and Growth Projections

The global composite strengthening systems market size is expected to reach USD 264.4 million by 2030, and expanding at a CAGR of 7.6% from 2024 to 2030, according to a new report by Grand View Research, Inc. The market growth is attributed to the rising demand for repairs and retrofitting of old buildings worldwide. Moreover, the demand for lightweight and sustainable building materials in the U.S., Canada, South Korea, and Germany is expected to drive the demand for composite strengthening systems over the forecast period.

Composite Strengthening Systems Market Report Highlights

Based on product, the Fiber-Reinforced Polymer (FRP) segment dominated the market and was valued at USD 117.7 million in 2023. The high strength-to-weight ratio, durability, and lightweight properties of FRP composite strengthening systems make them suitable for strengthening concrete structures while adding minimal weight to the overall building.

Fabric-reinforced cementitious matrix (FRCM) products is expected to grow at the fastest CAGR of 7.0% over the forecast period. FRCM systems consist of a cementitious matrix reinforced with high-strength fibers, such as carbon, glass, or aramid. These materials offer high tensile strength, flexural strength, and crack resistance. They also provide excellent durability, fire resistance, and resistance to moisture and chemical exposure, resulting in the substantial growth of the product.

In 2023, Asia Pacific was valued at USD 67.3 million in the global market. In the Asia Pacific market, rising demand for buildings with higher sustainability in countries, such as India, China, and Japan, is expected to impact the dynamics of the composite strengthening systems market.

The composite strengthening systems market in Europe is projected to expand at a CAGR of 7.1% over the forecast period. European countries have a rich culture of ancient and historic places such as castles, palaces, town halls, and churches. This results in continuous renovation activities related to strengthening of structures to preserve them. This is expected to keep the demand for composite strengthening systems market in the region over the coming years.

Central & South America is highly susceptible to natural disasters such as earthquakes or hurricanes. For instance, according to the U.S. National Hurricane Center (NHC), tropical storm Pilar of 2023 hit the Pacific coast areas of Honduras, Guatemala, Costa Rica, Nicaragua, and El Salvador. These natural disasters are projected to increase the demand for strengthening solutions as part of risk mitigation strategies.

The composite strengthening systems market is moderately consolidated owing to the presence of several medium and small players around the world. Players in the market compete on the basis of quality, price, product performance, and technological innovation.

For More Details or Sample Copy please visit link @: Composite Strengthening Systems Market Report

Composite strengthening systems are used in buildings and infrastructural structures to increase their strength and load-bearing capacity. They are mainly preferred for retrofitting and rehabilitating aging structures as they help improve their service life. The majority of such retrofitting and rehabilitation projects are assigned to contractors who procure the composite strengthening system from the manufacturers and use it.

Some of the major raw materials used to produce composite strengthening systems include carbon fiber and E-glass fabrics. This is due to their high tensile strength, light weightiness, and durability of these materials. These materials improve the load-bearing capacity of the buildings without adding any excessive weight to the structures. Some of the major suppliers of raw materials are JPS Composite Materials, LeapTech, LLC., BGF Industries, Hexcel, Mitsubishi Chemical Corporation, and Solvay.

Raw materials that are required to manufacture composites include E-glass fabrics, carbon fiber, and others. The individual product markets are characterized by the presence of a large number of suppliers operating across the globe and catering to multiple application industries. However, few composite manufacturers are integrated into their operations and manufacture high-cost raw materials such as carbon fibers. These factors lead to medium to high bargaining power of suppliers over the forecast period.

The high cost of raw materials for composites is likely to challenge manufacturer’s procurement operations. Moreover, the growing demand for these raw materials by other manufacturing industries is likely to pose a challenge for composites manufacturers.

List of Major Companies in the Composite Strengthening Systems Market

Master Builders Solutions

Concrete Repairs Ltd.

Shanghai Horse Construction Co., Ltd

Blome International

Bhor Chemicals and Plastics Pvt. Ltd.

Simpson Strong-Tie Company, Inc.

Sika Canada Inc.

Freyssinet

Gateway Composites LLC

Norcon Corporation

#CompositeStrengtheningSystemsMarket#CompositeStrength#IndustrialCompositeStrengthening#FiberReinforcedPolymer#BuildingMaterials#ConstructionIndustry

0 notes

Text

High-Quality PTFE Glass-Filled Rods by Goa Polymer for Industrial Use

Polytetrafluoroethylene (PTFE) is a popular material due to its impressive non-stick properties, high resistance to chemicals, and low friction coefficient. PTFE glass-filled rods, in particular, have become a top choice in various industries, including automotive, aerospace, and electronics, due to their enhanced strength and durability. Goa Polymer offers high-quality PTFE glass-filled rods that combine excellent mechanical properties with superior wear resistance, making them ideal for demanding applications. In this guide, we’ll explore the benefits, applications, and features of PTFE glass-filled rods, as well as what makes Goa Polymer’s products stand out in the market.

Why Choose PTFE Glass-Filled Rods?

When PTFE is filled with glass, it gains added stiffness, strength, and dimensional stability without compromising on its intrinsic chemical resistance. PTFE glass-filled rods are suitable for applications where regular PTFE lacks the durability needed to withstand continuous or heavy use.

Key Benefits of PTFE Glass-Filled Rods:

Increased Stiffness and Stability: The addition of glass fibers enhances the rigidity and overall stability, making these rods more resistant to deformation.

Exceptional Chemical Resistance: PTFE glass-filled rods resist a wide range of chemicals, including acids, alkalis, and solvents, which makes them ideal for harsh environments.

Low Friction Surface: Like pure PTFE, glass-filled PTFE has low friction, reducing wear on mating surfaces and allowing for smoother motion in applications like bearings and bushings.

Improved Thermal Properties: The glass filling improves the material’s ability to withstand higher temperatures, making it suitable for applications that require thermal resistance.

When looking for the best PTFE glass-filled rods that meet these needs, Goa Polymer has the expertise and quality assurance to deliver products that excel in performance and longevity.

Goa Polymer: Trusted Quality in PTFE Glass-Filled Rods

Goa Polymer has established itself as a leading manufacturer of PTFE products, specializing in PTFE glass-filled rods that offer unmatched quality and consistency. The company uses advanced manufacturing techniques to ensure that each PTFE rod meets stringent quality standards, providing customers with products that are not only durable but also reliable.

What Sets Goa Polymer Apart?

Precision Manufacturing: Goa Polymer employs cutting-edge technology to produce PTFE glass-filled rods that meet exact specifications, ensuring uniformity in every rod.

Quality Assurance: Each PTFE rod undergoes rigorous testing to guarantee that it meets the highest standards, ensuring excellent performance in various industrial settings.

Competitive Pricing: Goa Polymer offers affordable PTFE glass-filled rods without compromising on quality, providing value for money in every purchase.

Primary Applications of PTFE Glass-Filled Rods

PTFE glass-filled rods are incredibly versatile, finding applications in numerous industries due to their durability, stability, and resistance to wear and chemicals. Here’s a look at some of the primary uses:

Automotive Industry: PTFE glass-filled rods are widely used in the automotive sector for components like bushings, seals, and gaskets. Their strength and resistance to extreme temperatures make them an ideal choice.

Aerospace: The aerospace industry demands materials that can withstand high-stress environments. Goa Polymer’s PTFE glass-filled rods provide the durability and dimensional stability necessary for aerospace applications, particularly in areas requiring chemical and temperature resistance.

Electrical Insulation: PTFE’s insulating properties make these glass-filled rods suitable for electrical components that need to remain stable and non-reactive in varied conditions.

Chemical Processing: In industries where exposure to corrosive chemicals is common, PTFE glass-filled rods are valued for their resistance to chemical damage and ability to perform in aggressive environments.

Industrial Machinery: PTFE glass-filled rods are used in industrial machinery for components like slideways, bearings, and rollers, where low friction and wear resistance are essential.

Specifications and Customization Options by Goa Polymer