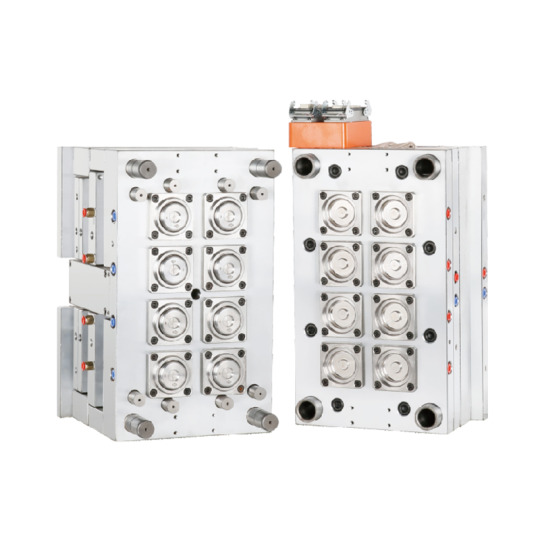

#Plastic Bottle Cap Mould

Explore tagged Tumblr posts

Text

#Ashish Tools#Plastic Bottle Cap Mould#High-Quality Moulds#Custom Mould Design#Precision Moulds#Industry Experience

0 notes

Note

https://www.tumblr.com/sturnioz/762637555496812544/hear-me-out-because-shyreader-is-over-alll-the

To go with this

Reader and chris are at a party and Chris has to go talk to someone about selling shit and reader is just sat on the couch alone freaking out in till Matt and Nate see her and go sit with her to make sure she ok (Matt and Nate yell at Chris’s for leaving her alone after)

"stay here, yeah? don't move," chris murmurs in your ear, his breath warm against your cheek, his grip firm and possessive on your shoulder. "m'serious, alright? jus' need to go talk to someone. i'll be back."

you open your mouth to respond, but the words refuse to come out, caught in the tightness of your throat as he gives your shoulder a squeeze before rising from the couch, his frame silhouetted against the pulsing lights of the party as he runs a hand through his messy hair, pushing through the crowded living-room.

the moment he's gone, a wave of discomfort crashes over you. alone and surrounded by a sea of unfamiliar faces, your anxiety is spiked — your hearts racing, thudding wildly in your chest while your thoughts spiral into chaos.

you sink deeper into the plush cushions of the couch, hoping they might swallow you up and help you disappear. the music around you blurs into words you struggle to understand, and the laughter and conversations you hear mould into one and becomes suffocating, amplifying your panic.

"hey, ki— woah.. eaaasy," a voice suddenly cuts through the noises, jolting you from your spiralling thoughts. you look up, startled, to find nate and matt standing beside the couch, concern and curiosity written across their expressions. nate flops down beside you while matt quietly settles in on the other side, the former's voice calm and steady as he continues, "y'good? why're you alone?"

"where's chris?" matt asks next, cutting through your fog of anxiety before you can even muster a response to nate.

the answers to both questions feel trapped, tangled in your throat, and you struggle to form words.

sensing your distress, matt places an open bottle of water in your trembling hands, guiding it toward your mouth. you squeeze the plastic between your fingers as you take a few cautious sips, the chilled water flowing down your throat, soothing the tightness and helping you regain your breath.

"y'know..." nate drawls, lounging back comfortably on the couch, adjusting the brim of his cap. "if i ever get big rich — like m'talkin' win all the money in the world — m'gonna buy a house boat."

you blink, a little taken aback by the sudden confession, and your eyebrows nit together in confusion as you stare at him, the panic momentarily forgotten. "you mean.. like a boathouse?"

"nah.. like a house boat." nate insists.

"the house is already attached to the boat?" you ask, your curiosity piqued. you barely feel matt's fingers gently press against your hands, guiding the water bottle back to your lips for another sip, ensuring you stay hydrated and centred.

"like a house on water, y'know?" nate grins. "gonna buy me a biiig one of those."

you swallow the water in your mouth, "why?"

"i just need a house boat."

"but why?" matt asks this time, tilting his head slightly as he studies nate.

"bro, think about it.. i can travel anywhere i want and stay in the comfort of my own home. why wouldn't you want one?"

matt hums lowly, nodding slowly as his gaze drifts over to you for a moment, noticing that your panic has subsided due to nate successfully grabbing your undivided attention.

satisfied, matt takes a sip from his beer and glances over the rim at chris, who returns back, a wad of cash clutched in his hand.

"you're a fuckin' idiot," matt mouths quietly, and chris rolls his eyes in response, shoving the cash hastily into his pocket.

"was watchin' her the entire time, kid — was across the fuckin' room," chris shoots back defensively as he curls his hand around your arm and pulls you up from the couch to sit between matt and nate before he draws you down onto his lap.

you barely register the shift, still engrossed by nate's house boat conversation, but you do sink back into a familiar chest, getting comfortable and feeling more at ease as you continue to listen to nate's rambling.

391 notes

·

View notes

Note

Yugi will receive a two gift wrapped boxes. One was long but narrow and flat, wrapped not in wrapping paper, but instead what appeared to be actual papyrus. The other was much a much smaller rectangle, wrapped in purple paper with light violet hearts all over it. Opening the first, they would find a black case containing a khopesh. The khopesh's blade was black, with a slight violet hue. In place of the fuller, a number of carefully etched decorative designs ran up the center of the blade all the way down to near the hilt- where an especially large design of the millennium eye was embossed. The handle itself was composed of gold with horn scales, with small violet gemstones embedded periodically on the hilt, and another moulding of the eye acting as a pommel. The grip itself was more simple, the black horn was shaped ergonomically, with lines etched into it to make avoid slippage. But when gripped by the handle, as if to wield it, the blade would immediately become slick with a slightly greenish fluid. The note attached, addressed to Yami, would explain it to be a paralytic venom- meant to stun but not kill.. But warned them to be careful nonetheless. The second gift box contained.. What appeared to be a water bottle. It was colorfully designed, with what appeared to be a nebula on the plastic of the bottle. The gaseous clouds were primarily purple and violet in hue, and the design was somehow not static, shifting very slowly, the stars twinkling as if the surface was a livestream of space itself. The lid was a much more simple purple color, with a cap that flipped open to allow them to open it for a drink, and could be kept open with a little clasp. Between the drinking hole and the clasp- only visible when the bottle was closed, was a little switch reading "Full" on one side, and "Empty" on the other, currently set to Empty. The note would explain that, when the switch was set to full, whatever liquid was placed inside the bottle would be constantly refilled and keep at a refrigerated temperature. Setting it to empty would empty the bottle for when it wasn't in use, but would keep a memory of the last liquid until the bottle was opened and filled with something else- allowing Yugi to change their choice in drink. The note would explain that right now, it was set to a protein shake. And at the bottom, Equius would write a short note wishing Yugi a happy birthday and expressing a hope that they have a good time and that the gifts are sufficient.

Yugi will give control over to his Other to open his gift first, admittedly curious himself by the size and the earlier conversation with Equius. Yami's hands run over the textured paper, brows furrowing slightly as he spares a glace at the more ornate pattern of his Partner's present. He begins to unwrap the large box, much more carefully than Kaiba's booster packs he'd been tearing into earlier, and then opens the black case. Gasps a soft "Oh," as he admires the ornate curved sword he can only assume must be Egyptian in origin, the Wadjet eyes all but confirming his hunch.

His eyes light up as he gently takes it from its case to better admire. Though he knows nothing about weapons, even he can recognize and appreciate the fine craftsmanship that must have gone into the present. A small smile crosses his lips as he wraps a hand around the hilt to pose with, only for the oozing green fluid to catch him by surprise. He returns the sword to its case to read the note with a quiet, amused "Huh."

"you okay, other me??"

"Mhm. Equius really went all out, it's almost a shame I'll never get to put it to proper use," he chuckles, then sits back on his ankles as he sets the large case aside. "It's your turn."

His violet eyes close for just a second, opening again with a brighter, wide eyed expression and hearts for pupils.

Yugi doesn't hesitate, grabbing up his smaller present with a big grin. He tries to be careful with the cute paper, hoping to maybe use it again for origami or such, only to end up giving in and tearing it anyway. He's too excited to see what Equius had come up with!

His eyes sparkle as he takes the water bottle, turning it over in his hands to admire the shifting image of stars and colorful clouds. He's mesmerized for a few seconds before he takes the note. His smile grows and grows as he reads about the magic properties of this vessel, and he can't help but chuckle a little when he learns the contents Equius had included. Flips the little switch to Full in order to give it a try.

"huh. that's actually not so bad."

#ooc#answers#ic action#not ic visible#I burned out writing Yami's part a lil bit but they are both very appreciative omggggggggg

4 notes

·

View notes

Text

For Protein Shakers and Gym Shakers Choose Us

We can create shaker bottles with the company logo and favourite colour for you. For your brand, create bespoke items. You're prepared to use superior YONGSTAR shakers to develop your brand or that of your company. As a reputable shaker bottle maker, Yongstar Shaker specialises in creating unique Gym Shakers bottles in your preferred design, colour, and branding. We have been producing protein shaker bottles for a variety of customers, including some well-known supplement companies, for the last several years. With exceptional quality, a reasonable pricing, and superior service, we have established a solid reputation with our customers. We're glad you're here, custom protein shaker cups.

We sell Protein Shakers bottles for protein shakes. PP is often used to manufacture plastic shaker bottles. Plastic called polypropylene has outstanding all-around qualities and is a linear polymer with high density, no side chains, and high crystallinity. Typical items include shaker bottles, barrels, basins, furniture, woven bags, bottle caps, automobile bumpers, and more. PP plastic, often known as polypropylene, has the following characteristics: specific gravity of 0.9–0.91 g/cm3, shrinkage during moulding of 1.0–2.5%, and moulding temperature of 160–220 °C. Since PP is a crystalline polymer, it performs better overall than PE material. Products made of polypropylene (PP) are lightweight, durable, and chemically resistant. Low dimensional accuracy, inadequate stiffness, poor weather resistance, post-shrinking, quick ageing, embrittlement, and distortion after demoulding are drawbacks of polypropylene. The often used protein shaker bottle in everyday life is composed of PP material.

Amorphous in nature, PP polyester should have a melting point over 220 degrees and a thermal deformation temperature of about 121 degrees. However, since it is a macromolecular polymer, tiny analytical oligomers are more prone to precipitate at higher temperatures. The majority of these chemicals are harmful to human health. Additionally, because boiling water is often 100 degrees, the basic plastic shakers won't have a mark above that temperature. After thorough washing, the plastic shaker bottle may be used in the microwave and reused. There are several shaker bottles that need special care. Visit us online at http://www.yongstarshaker.com/

5 notes

·

View notes

Text

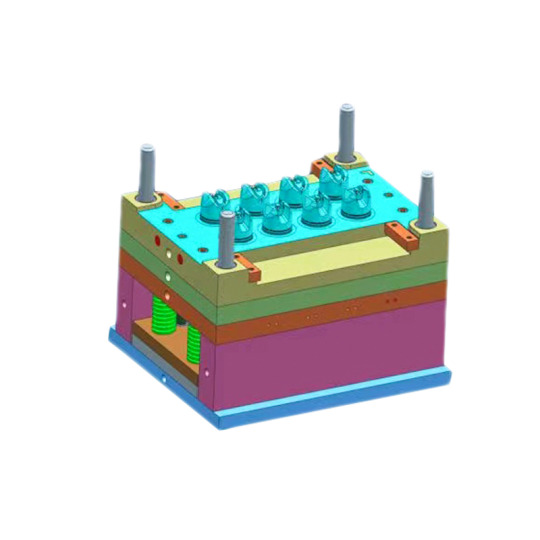

How Does the Plastic Molding Process Work?

Plastic molding is a popular and versatile way to create many everyday plastic items. It has changed how we make everything from basic toys and bottle caps to advanced car parts and medical tools. In this blog post, we'll look at the various techniques, steps, and applications of plastic molding.

What is Plastic Molding?

Plastic moulding is the technique of shaping plastic material into the required forms with the use of a mould. The process that yields the final form involves melting plastic resin and then pumping or squeezing it into a mould cavity. It's where the resin cools and solidifies. The primary goal of plastic moulding is the production of trustworthy, intricately detailed items with precise specifications.

Types of Plastic Molding

There are several plastic molding techniques, each with its unique advantages and applications. Some of the most common methods include:

1. Injection Molding:

Injection molding is one of the most widely used plastic molding techniques. In this process, plastic pellets are melted and injected into a mold cavity under high pressure. The molten plastic fills the mold, takes its shape, and cools down to form a solid part. Injection molding is ideal for producing high-volume, high-precision parts with complex geometries.

2. Blow Molding:

Blow molding is used to create hollow plastic objects such as bottles, containers, and automotive fuel tanks. The process involves heating a plastic tube (parison) and inflating it within a mold cavity using compressed air. As the plastic expands, it conforms to the shape of the mold, creating a hollow part.

3. Compression Molding:

Compression molding involves placing a preheated plastic material into an open mold cavity. The mold is then closed, and pressure is applied to shape the plastic. This method is commonly used for creating large, intricate parts and is well-suited for thermosetting plastics.

4. Rotational Molding:

Rotational molding, or rotomolding, is used to produce large, hollow parts such as tanks, containers, and playground equipment. In this process, a powdered plastic material is placed in a mold, which is then heated and rotated around multiple axes. The plastic melts and coats the interior of the mold, forming a hollow part as it cools.

5. Extrusion Molding:

Extrusion molding is a continuous process used to create long, linear plastic products such as pipes, tubing, and sheets. In this method, plastic pellets are melted and forced through a die, which shapes the material into the desired profile. The extruded plastic is then cooled and cut to the required length.

The Plastic Molding Process

While each plastic molding technique has its unique steps and equipment, the general process can be broken down into several stages:

1. Material Selection:

The first step in the plastic molding process is selecting the appropriate plastic material. The choice of material depends on factors such as the desired properties of the final product, the intended application, and cost considerations. Common materials used in plastic molding include polyethylene, polypropylene, polystyrene, and polyvinyl chloride (PVC).

2. Mold Design and Fabrication:

Once the material is chosen, the next step is designing and fabricating the mold. The mold is typically made from steel or aluminum and consists of two halves: the cavity (female) and the core (male). The mold design must account for factors such as part geometry, draft angles, and cooling channels to ensure proper part ejection and dimensional accuracy.

3. Material Melting:

In the injection molding process, plastic pellets are fed into a hopper and then transferred to a heated barrel, where they are melted. The molten plastic is then pushed through a nozzle into the mold cavity by a reciprocating screw or plunger. In other molding methods, such as compression molding, the plastic material is preheated before being placed in the mold.

4. Injection or Compression:

For injection molding, the molten plastic is injected into the mold cavity under high pressure, ensuring it fills the entire cavity and takes the shape of the mold. In compression molding, the preheated plastic material is placed in the open mold, which is then closed and subjected to pressure to shape the plastic.

5. Cooling and Solidification:

Once the plastic fills the mold cavity, it begins to cool and solidify. Proper cooling is crucial to prevent defects such as warping, sink marks, and internal stresses. Cooling channels within the mold help regulate the cooling process and ensure uniform temperature distribution

6. Part Ejection

After the plastic has solidified, the mold opens, and the finished part is ejected. Ejection mechanisms such as ejector pins or plates are used to push the part out of the mold without causing damage. The mold is then ready for the next cycle.

7. Finishing and Quality Control:

The final step involves trimming any excess material (flash) from the part and performing quality control checks to ensure the part meets specifications. This may include inspecting for defects, measuring dimensions, and conducting functional test.

Applications of Plastic Molding

Plastic molding is used in a wide range of industries and applications due to its flexibility and cost-effectiveness. Some common applications include:

Automotive:

Dashboard components, bumpers, and interior trim.

- Packaging:Bottles, containers, and caps.

- Consumer Goods:Toys, household items, and electronics enclosures.

- Medical Devices: Syringes, IV components, and diagnostic equipment.

- Construction:Pipes, fittings, and insulation materials.

The plastic molding process is a cornerstone of modern manufacturing, enabling the production of high-quality, cost-effective plastic parts for a wide range of applications. By understanding the different molding techniques, stages of the process, and key considerations, manufacturers can optimize their operations and deliver superior products to the market.

Whether it's injection molding, blow molding, compression molding, rotational molding, or extrusion molding, each method offers unique advantages that contribute to the ever-evolving world of plastic manufacturing.

Who we are?

HLH is a distinctive blend of Western and Eastern expertise, founded by industry veteran Vader Yu from China and Director James Murphy from the UK. We support innovative companies worldwide, leveraging our skills and experience to quickly manufacture high-quality prototypes and production parts. If you would like to get an instant quote, submit your CAD file here.

#hlhrapid #prototypes #manufacturing #injectionmoulding

0 notes

Text

Custom Bottle Cap Moulds for Distinctive Packaging

Our Cap Mould Factory is your secret weapon for creating standout bottle cap designs. Elevate your brand's packaging today! Customize your beverage's identity with our Cap Mould Factory's innovative bottle cap molds. Quality and style, all in one!

0 notes

Text

Our company manufactures high-quality PET plastic bottle cap moulds for neck sizes ranging from 46 mm to 96 mm, ideal for sealing PET fridge bottles and jars used in packaging snacks, cookies, spices, and more. Our moulds are precision-engineered for all machine types, ensuring shorter cycle times, durability, and reliable performance. We also provide excellent after-sales service and mould support to ensure your continued success.

#PET Cap Moulds#PET Bottle Cap Moulds#Plastic Bottle Cap Manufacturer#Cap Moulds Manufacturer#High-Precision Moulds

0 notes

Text

Need top-quality plastic caps? Look no further! Our plastic cap mould factory is the go-to destination for all your cap manufacturing needs. With years of experience and a commitment to excellence, our factory produces high-precision moulds that ensure perfect fit and functionality. We utilize cutting-edge technology and advanced techniques to deliver superior products that meet industry standards. Trust our skilled team to provide efficient and reliable solutions for your cap production. Choose our plastic cap mould factory for exceptional quality and professional service.

0 notes

Text

Optimizing E-commerce Packaging with HDPE Plastic Bottles

Packaging plays a pivotal role in ensuring the safe and efficient delivery of products to consumers in e-commerce. As the demand for online shopping continues to rise, businesses are constantly seeking sustainable packaging solutions that balance functionality, cost-effectiveness, and environmental responsibility. One such solution gaining popularity is the use of High-Density Polyethylene (HDPE) plastic bottles in e-commerce packaging. This article explores the benefits of HDPE plastic bottles and their potential to revolutionize the e-commerce packaging landscape.

Why is Packaging Crucial in E-commerce?

Packaging in e-commerce is crucial for several reasons. Firstly, it ensures the safe and intact delivery of products to customers, protecting them from damage during transit. Secondly, it serves as a branding and marketing tool, creating a positive first impression and reinforcing brand identity. Efficient packaging also plays a role in reducing shipping costs, as properly sized and lightweight packaging minimizes transportation expenses. Moreover, environmentally conscious packaging choices can enhance a company’s reputation and appeal to eco-conscious consumers. Overall, packaging is a multifaceted component in e-commerce, impacting product protection, brand image, cost efficiency, and sustainability.

Understanding HDPE Plastic Bottles: A Green Alternative

High-Density Polyethylene, commonly known as HDPE, is a type of plastic known for its durability, versatility, and recyclability. HDPE is widely used in various industries, including packaging, due to its ability to resist moisture (when sealed using an Induction Seal or EPE wad), chemicals, and impacts. The material is lightweight yet robust, making it an ideal choice for packaging applications where strength and resilience are paramount.

What makes HDPE stand out as a green alternative is its recyclability. Unlike some other plastics, HDPE can be recycled multiple times without a significant loss in quality. This property aligns with the growing consumer demand for eco-friendly packaging solutions and helps businesses reduce their environmental footprint.

What are the Advantages of HDPE Plastic Bottles in E-commerce Packaging?

1. Durability and Strength:

HDPE plastic bottles are renowned for their robustness. In e-commerce, where products may undergo various handling and transportation processes, durability is a key consideration. HDPE bottles provide excellent resistance to impact, ensuring that products remain intact during shipping.

2. Lightweight Nature:

The lightweight nature of HDPE contributes to cost savings in terms of transportation. As e-commerce businesses often calculate shipping costs based on weight, using lightweight packaging materials like HDPE can result in reduced transportation expenses.

3. Moisture Resistance:

E-commerce packages may encounter varying weather conditions during transit. HDPE’s resistance to moisture ensures that products remain protected from rain or humidity, reducing the risk of damage.

4. Recyclability:

One of the most significant advantages of HDPE is its recyclability. The ability to recycle HDPE plastic bottles supports the circular economy, where materials are reused rather than disposed of, ultimately reducing environmental impact.

5. Versatility in Design:

HDPE plastic bottles offer versatility in design, allowing for customization to meet specific packaging needs. Whether it’s creating bottles of different shapes or incorporating features like handles, HDPE can be moulded to suit various requirements.

6. Cost-Effectiveness:

HDPE is a cost-effective material, making it an attractive choice for businesses looking to optimize their packaging without compromising on quality. Its affordability, coupled with its durability, presents a compelling case for its use in e-commerce packaging.

7. Reducing Pilferage:

HDPE Bottles can be coupled with a Cap having a tamper-evident ring and/or an Induction Seal Wad. If the cap is opened, the ring and/or seal will break. Hence, the user will know that the package is no longer company-sealed. This feature prevents pilferage in the journey of the package from the manufacturer to the end user.

Regent Plast’s Square Bottles have Tripple Protection of a) Plug, b) Induction Seal Wad, and c) Tamper Evident Rings.

Applications of HDPE Plastic Bottles in E-commerce

1. Beverage Packaging:

HDPE bottles are commonly used for packaging beverages in the e-commerce sector. Whether it’s water, juices, or sports drinks, HDPE provides a secure and lightweight solution for transporting liquids.

2. Personal Care Products:

The personal care industry benefits from HDPE packaging for products such as shampoos, lotions, and body washes. The material’s resistance to moisture and durability ensures that these products reach consumers in pristine condition.

3. Pharmaceuticals, Nutraceuticals and Health Products:

E-commerce platforms selling pharmaceuticals and health products can leverage HDPE’s suitability for packaging medications and supplements. The material’s ability to protect against external elements is crucial in maintaining the integrity of these products.

4. Household and Cleaning Products:

HDPE plastic bottles are ideal for packaging household and cleaning products. Their durability and resistance to chemicals make them well-suited for containing a variety of cleaning solutions.

What are the Challenges and Considerations in E-Commerce Industry?

While HDPE plastic bottles offer numerous advantages, it’s essential to acknowledge potential challenges and consider them in the decision-making process:

1. Environmental Impact of Plastic:

While HDPE is recyclable, it is important to recognize that plastic, even when recycled, has environmental implications. Businesses should continue exploring alternative materials and packaging methods to further reduce their reliance on plastics.

2. Consumer Perception:

Some consumers are becoming increasingly conscious of plastic use and may prefer businesses that use alternative, more sustainable materials. Communicating the recyclability of HDPE and a commitment to environmental responsibility can help address these concerns.

Read More-https://regentplast.com/optimizing-e-commerce-packaging-with-hdpe-plastic-bottles/

#packaging#manufacturing#hdpebottles#innovation#chemicalpackaging#hdpe plastic container manufacturer#durabilitymatters#recycling

0 notes

Text

Guide to Understanding Different Types of Plastic Processing Machines

Plastics are everywhere. We use them daily in our consumer goods, kitchen, and drive cars made of plastic materials. But have you ever realised how the everyday plastic product is built before it reaches the retail market?

Different plastic processing machinery that streamline the plastic-making process are available in the manufacturing unit. That said, each machine is integrated with other functions to give the final shape to a plastic.

Understanding plastic processing machines involves knowledge about the various types of devices, their components, processes, and applications. In this blog, we will discuss the kinds of plastic processing machines, their method of making plastic products, and their applications in various industries.

Types of Plastic Processing Machines

Let’s discover the four main types of plastic processing machines and understand each machine’s functions and applications. Here are the most common types of plastic processing machines that you should know if you are a manufacturer of plastic materials.

1. Injection Moulding Machines

Injection moulding is one of the most useful plastic processing machinery for making large volumes of single plastic products. Smaller, low-density and recycled plastic granules are heated and shaped to make one plastic product in the injection moulding process.

● Process of Injection Moulding Machines

In the injection moulding process, the three main units i.e. injection unit, mould, and clamping unit, work together to make a plastic product. Inside the injection unit, plastic granules are put down in a hopper. Further, the hopper feeds the barrel unit, where the barrel screw warms up the plastic. Gradually, the screw in the barrel pushes the plastic into the mould cavity until it is completely molten. Lastly, the plastic firms itself during the process and gets completely cool.

As the process begins, the clamping unit closes the mould cavity securely during the injection and moulding process. And as soon as the plastic takes shape, the clamp pushes out the final product.

● Application of Injection Moulding Machines

Injection moulding machines are highly in demand in various industries.

Packaging industry: Plastic containers, Plastic bottles, Bottle caps

Automobile Industry: Car interiors, mechanical parts

Electrical components, electrical switches, electric connectors

Medical devices and Lego toys

Furniture industry: Chairs, tables, seat covers or cushions

2. Blow Moulding Machines

Blow moulding machines are a simpler process that involves making hollow plastic products. Interestingly, you can rely on blow moulding machines to make hollow-shaped bottles, containers, and other hollow parts due to the very nature of hollow moulds used in them.

● Process of Blow Moulding Machines

The process of blow moulding, as the name suggests, is to blow the melted plastic into the hollow shape of the mould. It starts when the molten plastic is squeezed into a hollow form. Then, the clamping unit securely holds and closes the mould to prevent plastic leaks in the next steps. A tube-like structure allows air to inflate the plastic and form its desired shape during the process.

● Applications of Blow Moulding:

Blow moulding is a plastic processing machinery that can create plastic objects for the following industries.

Plastic packaging industry: jars, drums and jugs.

Food packaging industry: Beverage bottles

Household use: Personal care items

Industrial tanks, water storage tanks, and cosmetic plastic bottles

Automobile industry: Fuel tanks, air ducts, interior and exterior vehicle parts

3. Plastic Granulator Machines

Plastic granulator machines are the most commonly used systems to recycle waste plastic and industrial scraps. These machines have in-built rotor blades that crush the polymers into small particles. The smaller granules are then processed in the plastic manufacturing industries to make the final product.

● Applications of Plastic Granulator Machines

Similar to other plastics processing machinery, granulated plastic is useful for various purposes:

Construction materials, including pipes and profiles.

Automobile parts

Plastic toys

Medical Packaging

4. Inspection Machines

Inspection machines are designed with a high-state technology to detect the capabilities of the final product. Once the final product passes through the last stage, detection systems provide more accurate information about the durability of the plastic or glass products.

Many businesses use leak detection, drum tester and spark testing machines to check the following attributes:

Plastic leaks to prevent the product from melting in high temperatures

Sparks to avoid extremely hot plastic from running into fire hazards

Sizes of bottlenecks

Takeaway

Each machine plays a distinctive role in plastic processing, transforming raw materials into a myriad of everyday wonders. Injection moulding efficiently presents large volumes of consistent plastic products, while blow moulding breathes life into bottles. Plastic recycling granulator champions sustainability and inspection systems and highly regards precision quality control.

Together, any plastics processing machinery focuses on innovation, shaping our world from intricate components to versatile packaging. In plastic processing, even inspection machines are critical—a testament to the resilience and adaptability of this ever-evolving industry.

If you liked this blog, please share and pass on the knowledge to fellow readers.

Follow Mitchell Industries for all your Plastic Manufacturing Processes

We are highly committed to keeping the plastic production process easy. Mitchell Industries is an exporter, importer and manufacturer of plastic processing machinery in Australia. We have highly trained engineers, designers and workers who can provide valuable guidance in installing and maintaining our high-end machines.

The best thing about our service is that we sell small plastic recycling machines like granulators to intricate injection moulding machines at a fair price. Further, our devices have advanced software to help you achieve a faster production rate. We don’t settle for less – call us today for further enquiries.

0 notes

Text

Shaping Healthcare Excellence: The Vital Role of Medical Cap Moulds

When it comes to healthcare, precision and quality are of utmost importance. This is particularly true when it comes to medical caps, which are an integral part of medical containers such as vials, tubes, and syringes. Medical caps not only provide a secure seal to prevent contamination but also ensure the proper dispensing and safe storage of medical substances. The production of these crucial components is made possible by medical cap moulds, which play a vital role in shaping healthcare excellence.

Medical cap moulds are specialized tools that are used in the injection moulding process to create a variety of medical caps. These moulds are designed to meet the specific requirements of the healthcare industry, such as producing caps with precise dimensions, smooth surfaces, and consistent quality.

One of the key aspects of medical cap moulds is their ability to ensure the integrity and safety of medical containers. These moulds are engineered to produce caps that provide an airtight seal, preventing the entry of contaminants and maintaining the sterility of medical substances. This is crucial in healthcare settings where maintaining hygiene and preventing infections are top priorities.

In addition to sealing, medical cap moulds also play a crucial role in the functionality of medical caps. These moulds are designed to create caps that are easy to open and close, ensuring convenient access to the contents of medical containers. The design and mechanism of the moulds help in achieving smooth and effortless cap operation, which is essential for healthcare professionals and patients.

Another important aspect of medical cap moulds is their ability to produce caps with consistent dimensions and weight. This uniformity is vital for the compatibility of medical caps with the corresponding containers. Precise dimensions ensure a perfect fit, preventing any leakage or spillage. Consistent weight distribution also contributes to the overall balance of the containers, making them easy to handle and transport.

Furthermore, medical cap moulds are designed to meet the highest standards of quality and safety. Manufacturers of these moulds adhere to strict guidelines and regulations set by regulatory bodies such as the FDA (Food and Drug Administration) and ISO (International Organization for Standardization). These standards ensure that the materials used in the moulds are safe and free from toxic substances. They also verify that the moulds are capable of producing caps that are resistant to impact, chemicals, and high temperatures.

In addition to meeting regulatory standards, medical cap moulds also go through rigorous testing and quality control procedures. This ensures that every cap produced using these moulds meets the required specifications and tolerances. Quality control measures include inspections, measurements, and functional tests to ensure the reliability and durability of the caps.

The use of medical cap moulds not only guarantees the production of high-quality medical caps but also contributes to the efficiency and productivity of the manufacturing process. These moulds are designed for high-speed production, allowing for the creation of a large number of caps in a short amount of time. This is crucial to meet the demands of the healthcare industry where efficiency and timely supply are critical.

In conclusion, medical cap moulds are essential tools in shaping healthcare excellence. medical cap mould manufacturers play a vital role in producing medical caps that provide a secure seal, ensure convenient access to medical substances, and meet regulatory standards. The precision, quality, and functionality of these moulds are crucial in maintaining the integrity and safety of medical containers. By upholding the highest standards of quality and efficiency, medical cap moulds contribute to the advancement of healthcare and the well-being of patients worldwide.

0 notes

Text

Custom Bottle Cap Moulds for Your Brand

From concept to creation, our Cap Mould Factory delivers top-notch bottle cap molds that set your brand apart. Make a lasting impression with our Cap Mould Factory's unique bottle cap molds. Experience excellence!

0 notes

Text

What are Plastic Injection Molding Parts?

Introduction:

In today's world, plastic injection molding has become an integral part of manufacturing processes across various industries. It is a highly versatile and efficient technique used to produce a wide range of plastic parts that we encounter in our daily lives. Plastic injection moulding has revolutionised the manufacture of plastic products, ranging from complicated electrical components to home items and automobile parts.We'll go into the definition of plastic injection moulding parts and the method used to create them in this blog post.

What is Plastic Injection Molding?

Plastic injection molding is a manufacturing process that involves injecting molten plastic material into a mold cavity under high pressure. The molten plastic is forced into the mold, taking the shape of the desired part. Once the plastic cools and solidifies, the mold is opened, and the finished part is ejected. This process is highly automated, enabling the production of large quantities of identical parts with high precision and efficiency.

Types of Plastic Injection Molding Parts:

Plastic injection molding can produce a vast array of parts with varying sizes, complexities, and functionalities. Some common examples of plastic injection molding parts include:

Consumer Goods:

Plastic injection molding is widely used to manufacture consumer goods such as kitchenware, toys, cosmetic containers, and household appliances. The process allows for the creation of intricate designs and precise details.

Automotive Components:

Plastic injection molding plays a crucial role in the automotive industry, producing parts like dashboards, bumpers, interior trims, and various under-the-hood components. The lightweight and durable nature of plastic make it an ideal choice for such applications.

We R D Mould & Industries are a renowned Plastic Toy mould manufacturer in Ahmedabad,Gujarat, India, provide various types of Plastic Toy Mould Including Plastic Toy Injection Mould, Plastic Toy Blow Mould & Etc.

Medical Equipment:

Many medical devices and equipment are made through plastic injection molding. This technique is effective for producing items like syringes, IV connectors, surgical instruments, and disposable medical components.

Electronics:

To make casings, connectors, switches, and other components, plastic injection moulding is frequently employed in the electronics sector. The process allows for the integration of features like snap-fits, threads, and internal structures, facilitating the assembly of electronic devices.

Packaging Materials:

The production of packaging materials like bottles, caps, closures, and containers depends on plastic injection moulding. The procedure is perfect for mass manufacturing since it guarantees constant quality, narrow tolerances, and rapid production rates.

Benefits of Plastic Injection Molding Parts:

The popularity of plastic injection molding can be attributed to its numerous advantages, including:

Cost-effective:

Injection molding offers economies of scale by allowing for high-volume production, minimizing unit costs.

Design Flexibility:

The method makes it possible to create detailed and sophisticated part designs, which gives a great deal of freedom for customization and utility.

Apart from Plastic Toy Mould Exporters We're also dealing in Plastic Toy Injection Mould And Plastic Toy Blow Mould & Etc.

Rapid Production:

Injection moulding is a production method that produces huge numbers of pieces in a short amount of time.

Variety of Materials:

Thermoplastics, elastomers, and composites, which have a wide range of mechanical and chemical properties, can all be used in plastic injection moulding.

High Precision:

Injection moulding offers exceptional repeatability and dimensional accuracy, assuring uniform quality across several pieces.

Conclusion:

Plastic injection molding has revolutionized the manufacturing industry by enabling the efficient production of high-quality plastic parts. Its versatility, cost-effectiveness, and design flexibility have made it the preferred method for producing a wide range of products across various sectors. By understanding the process and benefits of plastic injection molding, manufacturers can harness its capabilities to create innovative and reliable plastic components that meet the demands of modern consumers.

0 notes

Text

Screw Thread Mould

https://www.gmmoldtech.com/products/screw-thread-mould.html

The screw thread plastic injection mold, a special part of the plastic injection molding process, is used for mass production of screw thread.

Nowadays, molded screw threads are everywhere -- on the cap of a Coca-Cola bottle, on the nut linking the drain pipe to the underside of the kitchen sink. So here comes a lot of screw thread plastic injection molding companies to perform the process of screw thread mould. GM-TECH, as a leading custom plastic injection molding company, will continuously spare efforts to produce high quality injection molds.

Features of Screw Thread Mould

Short cycle time

With plastic injection molding machine,the screw thread can be manufactured quickly.

Better maintenance

High precision injection molds of screw thread are tools requiring high maintenance. Everything must be timed, and that timing must be maintained to get the best productivity.

Low cost

Large plastic molds can be performed spontaneously to save the labor and material cost.

Fast ventilation

Usually the thread is formed in a blind pocket. Trapped gas will be vent out.

Mould design services

The Specification of Screw Thread Mould

Part material

PP

Cavity

1

runner

cold runner

Mold accuracy

+ / - 0.02

Mold steel

1.2343

Moldbase steel

1.173

Mold life

100W

Mold standard

HASCO

Mold structure

2 slides

Exporting country

Italy

Delivery time

4 weeks

Mold quality customer satisfaction

98%

FAI pass rate

98%

Project cooperation service customer satisfaction

95%

How does Screw Thread Mould Work?

There are four general steps to produce screw thread plastic injection mold.

Split tooling

Numerous screw-threaded parts are injection moulded by this step.

Thread jumping

This is the cheap plastic injection molding to produce screw thread molding product. It is very widely used for the manufacture of closure threads.

Collapsible coring

It is very convenient to manufacture common injection molded plastics.

Rotary unscrewing

Rotary unscrewing is used where split line witness cannot be tolerated or often when larger numbers of impressions are required.

0 notes

Text

Ashish Tools is a leading provider of injection moulds for PET preforms, offering exceptional design and engineering solutions for efficient preform production. Our injection moulds are crafted with high precision, ensuring uniformity and strength in every preform produced. Trust Ashish Tools for advanced moulds that support high-output production with minimal downtime.

#InjectionMoulding#PETPreformMould#InjectionMould#PreformMoulds#IndustrialManufacturing#PackagingIndustry

0 notes

Text

Discover the leading plastic cap mould factory, revolutionizing the industry with cutting-edge technology and unparalleled expertise. Our factory specializes in the production of high-quality moulds for plastic caps, ensuring precision and durability. With state-of-the-art machinery and a skilled team, we guarantee exceptional results that meet the strictest standards. Trust our experienced engineers to create customized solutions tailored to your specific needs. Partner with us for reliable, cost-effective, and timely delivery. Experience the difference with our plastic cap mould factory and unlock unlimited possibilities for your packaging requirements. Contact us now for a seamless manufacturing experience!

0 notes