#PipeExtrusionMachine

Explore tagged Tumblr posts

Text

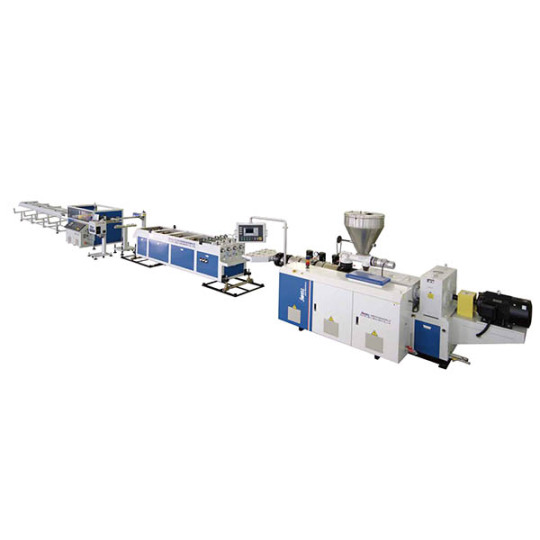

PVC Four-pipe Extrusion Machine

Performance&Advantages Performance characteristics: The latest type of four PVC electrical bushing production line adopts a twin-screw extruder with high output and good plasticization performance, and is equipped with a mold optimized for flow path design. Four pipes discharge evenly and the extrusion speed is fast; Four vacuum cooling tanks can be individually controlled and adjusted without affecting each other in the production process; Four out of the traction cutting integrated design, save space. Universal rotary clamping, no change clip block. Chipless cutting speed, high precision, accurate cutting length. Optional automatic laser printing system. Planetary Saw Cutting Machine Performance & Advantages The equipment running stably and reliably, adopt high-speed rotating saw, Circular Saw blade cut the pipe. Suitable for extra thick large - diameter pipe; Cemented carbide cutting blades, high wear resistance and long service life; Powerful suction chips Dust removal used ionic wind, equipped with dust filters collection device. In view of the large diameter PVC pipe is equipped with a dedicated chamfering cutter, tungsten carbide blade, sharp and durable; The internal structure of advanced design, make the PVC pipe cutter surface smooth and tidy, chamfer Angle and uniformity nice. For small diameter PVC pipe, we had a special high-speed cutting machine dust - free. Ribbon cuttings avoid the pollution of dust on the work shop. Main technical specification Model Pipe diameter Extruder Main Power Capacity JWG-PVC32 Φ16-32mm SJZ65/132 37kw 250~300kg/h JWG-PVC32-H Φ16-32mm SJZ80/156 55kw 300~400kg/h Product image display Read the full article

#HDPEMarinePipeExtrusionMachine#HighSpeedExtrusionMachineforHDPEWaterPipe/GasPipe#LargeDiameterHDPESolidWallPipeExtrusionMachine#NewCorrugatedPipeExtrusionMachineforVentilationSystem#PEHeatInsulationPipeExtrusionMachine#PE/PPDoubleWallCorrugatedPipeExtrusionMachine#PipeExtrusionMachine#PPR/PERT/PEXCool&HotWaterPipeExtrusionMachine#PVCDualPipeExtrusionMachine#SiliconCorePipeExtrusionMachine#Three-layerPVCSolidWallPipeCo-extrusionExtrusionMachine#UPVC/CPVCPipeExtrusionMachine

0 notes

Text

#pvcpipemachine#hdpepipemackingmachine#pvcmixercooler#cpvcpipemackingmachine#twinscrewandbarrel#singlesscrewandbarrel#bimetallicscrew#tungsten carbidecoating#superbimetalliccoating#pipeextrusionmachine#plasticmachinemanufacturers

0 notes

Text

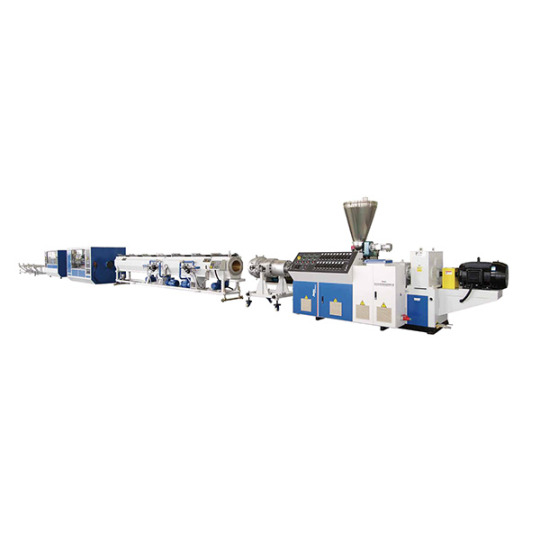

UPVC/CPVC Pipe Extrusion Machine

Performance&Advantages A variety of specifications and models of PVC twin-screw extruder can produce pipes of different diameters and different wall thicknesses. Specially designed screw structure with uniform plasticization and high output. Extrusion molds made of high quality alloy steel, internal flow channel chrome plating, polishing treatment, wear and corrosion resistance; with a dedicated high-speed sizing sleeve, pipe surface quality is good; The special cutter for PVC pipe adopts a rotating clamping device, which does not require replacing the fixture with different pipe diameters. With chamfering device, cutting, chamfering, one-step molding. Support optional online belling machine. PVC Pipe Die Head It is for PVC 20-1000mm pipe production, split-flow frame design, very much suitable for temperature sensitive material. Adapting chrome plating mold steel, special surface hardness treatment, so that die head runner will have good flow. Easily disassembly design will offer quick change and will not affect production. Vacuum Tank/Spray Cooling Tank Performance &Advantages According to the specifications of the pipes can be selected single room or double room design of the vacuum tank; SUS304 stainless steel vacuum tank and pipeline with long service life; Accurate temperature control and water level control;The large capacity of water filters and spare bypass;Centralized water supply and drainage; Optional PLC frequency conversion precision control of vacuum degree, lower equipment energy consumption and noise; The sizing sleeve made of high-quality materials such as alloy copper and stainless steel is particularly selected to ensure good heat conduction and a good cooling sizing effect. The inner surface of the sizing sleeve is treated with a chrome-plated special coating that provides high wear resistance and high smoothness. Water film type, disc type, dry type and other structural designs are suitable for high-speed, high-volume extrusion of different raw material pipes. Main technical specification Model Pipe diameter Extruder Main Power Capacity JWG-PVC160 Φ63-1600mm SJZ65/132 37kw 250~300kg/h JWG-PVC250 Φ75-250mm SJZ65/132 37kw 250~300kg/h JWG-PVC315 Φ160-315mm SJZ80/156 55kw 300~400kg/h JWG-PVC450 Φ200-450mm SJZ80/156 75kw 400~500kg/h JWG-PVC630 Φ315-630mm SJZ92/188 110kw 650~750kg/h JWG-PVC800 Φ400-800mm SJZ92/188 132kw 850~1000kg/h JWG-PVC1000 Φ500-1000mm SJZ110/220 160kw 1100~1500kg/h Product image display Read the full article

#HDPEMarinePipeExtrusionMachine#HighSpeedExtrusionMachineforHDPEWaterPipe/GasPipe#LargeDiameterHDPESolidWallPipeExtrusionMachine#NewCorrugatedPipeExtrusionMachineforVentilationSystem#PEHeatInsulationPipeExtrusionMachine#PE/PPDoubleWallCorrugatedPipeExtrusionMachine#PipeExtrusionMachine#PPR/PERT/PEXCool&HotWaterPipeExtrusionMachine#PVCDualPipeExtrusionMachine#SiliconCorePipeExtrusionMachine#Three-layerPVCSolidWallPipeCo-extrusionExtrusionMachine#UPVC/CPVCPipeExtrusionMachine

0 notes

Text

UPVC/CPVC Pipe Extrusion Machine

Performance&Advantages A variety of specifications and models of PVC twin-screw extruder can produce pipes of different diameters and different wall thicknesses. Specially designed screw structure with uniform plasticization and high output. Extrusion molds made of high quality alloy steel, internal flow channel chrome plating, polishing treatment, wear and corrosion resistance; with a dedicated high-speed sizing sleeve, pipe surface quality is good; The special cutter for PVC pipe adopts a rotating clamping device, which does not require replacing the fixture with different pipe diameters. With chamfering device, cutting, chamfering, one-step molding. Support optional online belling machine. PVC Pipe Die Head It is for PVC 20-1000mm pipe production, split-flow frame design, very much suitable for temperature sensitive material. Adapting chrome plating mold steel, special surface hardness treatment, so that die head runner will have good flow. Easily disassembly design will offer quick change and will not affect production. Vacuum Tank/Spray Cooling Tank Performance &Advantages According to the specifications of the pipes can be selected single room or double room design of the vacuum tank; SUS304 stainless steel vacuum tank and pipeline with long service life; Accurate temperature control and water level control;The large capacity of water filters and spare bypass;Centralized water supply and drainage; Optional PLC frequency conversion precision control of vacuum degree, lower equipment energy consumption and noise; The sizing sleeve made of high-quality materials such as alloy copper and stainless steel is particularly selected to ensure good heat conduction and a good cooling sizing effect. The inner surface of the sizing sleeve is treated with a chrome-plated special coating that provides high wear resistance and high smoothness. Water film type, disc type, dry type and other structural designs are suitable for high-speed, high-volume extrusion of different raw material pipes. Main technical specification Model Pipe diameter Extruder Main Power Capacity JWG-PVC160 Φ63-1600mm SJZ65/132 37kw 250~300kg/h JWG-PVC250 Φ75-250mm SJZ65/132 37kw 250~300kg/h JWG-PVC315 Φ160-315mm SJZ80/156 55kw 300~400kg/h JWG-PVC450 Φ200-450mm SJZ80/156 75kw 400~500kg/h JWG-PVC630 Φ315-630mm SJZ92/188 110kw 650~750kg/h JWG-PVC800 Φ400-800mm SJZ92/188 132kw 850~1000kg/h JWG-PVC1000 Φ500-1000mm SJZ110/220 160kw 1100~1500kg/h Product image display Read the full article

#HDPEMarinePipeExtrusionMachine#HighSpeedExtrusionMachineforHDPEWaterPipe/GasPipe#LargeDiameterHDPESolidWallPipeExtrusionMachine#NewCorrugatedPipeExtrusionMachineforVentilationSystem#PEHeatInsulationPipeExtrusionMachine#PE/PPDoubleWallCorrugatedPipeExtrusionMachine#PipeExtrusionMachine#PPR/PERT/PEXCool&HotWaterPipeExtrusionMachine#PVCDualPipeExtrusionMachine#SiliconCorePipeExtrusionMachine#Three-layerPVCSolidWallPipeCo-extrusionExtrusionMachine#UPVC/CPVCPipeExtrusionMachine

0 notes

Text

PVC Four-pipe Extrusion Machine

Performance&Advantages Performance characteristics: The latest type of four PVC electrical bushing production line adopts a twin-screw extruder with high output and good plasticization performance, and is equipped with a mold optimized for flow path design. Four pipes discharge evenly and the extrusion speed is fast; Four vacuum cooling tanks can be individually controlled and adjusted without affecting each other in the production process; Four out of the traction cutting integrated design, save space. Universal rotary clamping, no change clip block. Chipless cutting speed, high precision, accurate cutting length. Optional automatic laser printing system. Planetary Saw Cutting Machine Performance & Advantages The equipment running stably and reliably, adopt high-speed rotating saw, Circular Saw blade cut the pipe. Suitable for extra thick large - diameter pipe; Cemented carbide cutting blades, high wear resistance and long service life; Powerful suction chips Dust removal used ionic wind, equipped with dust filters collection device. In view of the large diameter PVC pipe is equipped with a dedicated chamfering cutter, tungsten carbide blade, sharp and durable; The internal structure of advanced design, make the PVC pipe cutter surface smooth and tidy, chamfer Angle and uniformity nice. For small diameter PVC pipe, we had a special high-speed cutting machine dust - free. Ribbon cuttings avoid the pollution of dust on the work shop. Main technical specification Model Pipe diameter Extruder Main Power Capacity JWG-PVC32 Φ16-32mm SJZ65/132 37kw 250~300kg/h JWG-PVC32-H Φ16-32mm SJZ80/156 55kw 300~400kg/h Product image display Read the full article

#HDPEMarinePipeExtrusionMachine#HighSpeedExtrusionMachineforHDPEWaterPipe/GasPipe#LargeDiameterHDPESolidWallPipeExtrusionMachine#NewCorrugatedPipeExtrusionMachineforVentilationSystem#PEHeatInsulationPipeExtrusionMachine#PE/PPDoubleWallCorrugatedPipeExtrusionMachine#PipeExtrusionMachine#PPR/PERT/PEXCool&HotWaterPipeExtrusionMachine#PVCDualPipeExtrusionMachine#SiliconCorePipeExtrusionMachine#Three-layerPVCSolidWallPipeCo-extrusionExtrusionMachine#UPVC/CPVCPipeExtrusionMachine

0 notes

Text

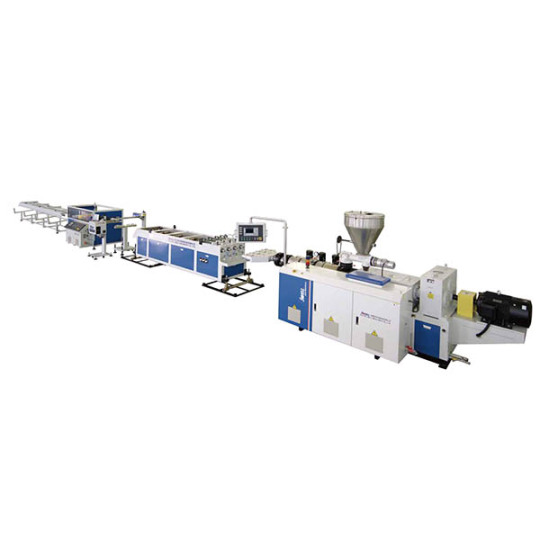

PVC Dual Pipe Extrusion Machine

Performance&Advantages Corresponding to the different requirements of pipe diameter and output, there are two types of SJZ80 and SJZ65 special twin-screw extruders optional; the dual pipe die evenly distributes the material output, and the pipe extrusion speed is quickly plasticized; High-efficiency double-vacuum cooling box can be controlled separately, and the adjustment operation is convenient in the production process; Dustless cutting machine, double station independent control, fast speed, accurate cutting length. Pneumatically rotating clamps eliminates the need to change clamps. With chamfering device optional. Caterpillar Hall-off Unit Performance & Advantages For different pipe diameter and extruder speed requirements, we designed all kinds of the Hall-off unit, have two caterpillars, three caterpillars, four caterpillars, six caterpillars until upto 16 caterpillars. The wide adjustable range for the Hall-off unit, running is stable and reliable, and small noise. Each caterpillars by a separate asynchronous or servo motor drive, Via digital controller keep the accuracy of the caterpillar speed synchronization. The large capacity compression air cylinder, contact length is overlength between the pipe and the caterpillar, can ensure a high friction tractive force. based on the switchable control for the 1/2 caterpillar, can switch to each other between the big pipe diameter and small pipe diameter, large scope of working for the Hall-off unit. Main technical specification Model Pipe diameter Extruder Main Power Capacity JWG-PVC63(Two strand) Φ16-63mm SJZ65/132 37kw 250~300kg/h JWG-PVC110(Two strand) Φ50-110mm SJZ80/156 55kw 300~400kg/h JWG-PVC200(Two strand) Φ50-200mm SJZ80/173 75kw 400~500kg/h Product image display Read the full article

#HDPEMarinePipeExtrusionMachine#HighSpeedExtrusionMachineforHDPEWaterPipe/GasPipe#LargeDiameterHDPESolidWallPipeExtrusionMachine#NewCorrugatedPipeExtrusionMachineforVentilationSystem#PEHeatInsulationPipeExtrusionMachine#PE/PPDoubleWallCorrugatedPipeExtrusionMachine#PipeExtrusionMachine#PPR/PERT/PEXCool&HotWaterPipeExtrusionMachine#PVCDualPipeExtrusionMachine#SiliconCorePipeExtrusionMachine#Three-layerPVCSolidWallPipeCo-extrusionExtrusionMachine#UPVC/CPVCPipeExtrusionMachine

0 notes

Text

Large Diameter HDPE Solid Wall Pipe Extrusion Machine

The performance and advantages of our equipment Extruder is JWS-H series High efficiency, high output single screw extruder. The special screw barrel structure design ensures ideal melt uniformity at lower solution temperatures.Designed for large-diameter pipe extrusion, the spiral distribution structure mold is equipped with an in-mold suction pipe internal cooling system. Combined with a special low-sag material, it can produce ultra-thick-walled, large-diameter pipes.Hydraulic opening and closing two-stage vacuum tank, computerized centralized control and coordination of multiple crawler tractors, chipless cutter and all units, a high degree of automation. The optional wire rope tractor can make the initial operation of the large-caliber tube more convenient. Polyolefin Pipe Die Head PO die head is designed by JWELL Machinery Co.,ltd for high speed & high output pipe extrusion,which can produce pipe diameter from 16mm to 3000mm, adapting spiral design to make even material arrangement, low head melt temperature, low pressure consumption, reduction of innerstress as well shinning pipe surface. Modularity structure to cause easily disassemble and material change. Main technical specification Model Pipe diameter Extruder Capacity JWPEG-800 Φ400-800mm JWS-H120/38 1100-1300kg/h JWPEG-1000 Φ500-1000mm JWS-H120/38 1100-1300kg/h JWPEG-1200 Φ630-1200mm JWS-H90/38+90/38 1800-2000kg/h JWPEG-1600 Φ1000-1600mm JWS-HH90/38+120/38 2000-2200kg/h JWPEG-2500 Φ1400-2500mm JWS-H120/38+150/38 2200-2500kg/h Product image display Read the full article

#HDPEMarinePipeExtrusionMachine#HighSpeedExtrusionMachineforHDPEWaterPipe/GasPipe#LargeDiameterHDPESolidWallPipeExtrusionMachine#NewCorrugatedPipeExtrusionMachineforVentilationSystem#PEHeatInsulationPipeExtrusionMachine#PE/PPDoubleWallCorrugatedPipeExtrusionMachine#PipeExtrusionMachine#PPR/PERT/PEXCool&HotWaterPipeExtrusionMachine#PVCDualPipeExtrusionMachine#SiliconCorePipeExtrusionMachine#Three-layerPVCSolidWallPipeCo-extrusionExtrusionMachine#UPVC/CPVCPipeExtrusionMachine

0 notes

Text

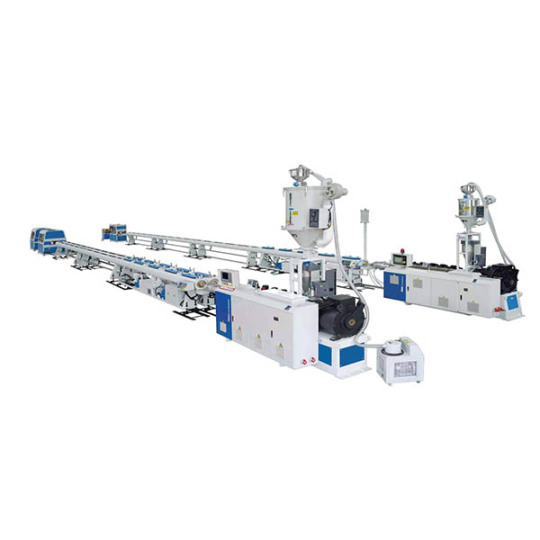

Small-caliber PE/PPR/PE-RT/PA Single-pipe, Dual-pipe High-speed Extrusion Machine

Performance&Advantages The main screw adopts BM high-efficiency type, and the output is fast and plasticized well. The wall thickness of pipe products is precisely controlled and very less waste of raw materials. Tubular extrusion special mold, water film high-speed sizing sleeve, equipped with integrated flow control valve with scale.Servo-controlled high-speed double-belt haul off unit, supporting high-speed chipless cutter and winder, adapt to high-speed production operation. Dual pipe extrusion line can double the output and occupy less factory space. Polyolefin Pipe Die Head PO die head is designed by JWELL Machinery Co.,ltd for high speed & high output pipe extrusion,which can produce pipe diameter from 16mm to 3000mm, adapting spiral design to make even material arrangement, low head melt temperature, low pressure consumption, reduction of innerstress as well shinning pipe surface. Modularity structure to cause easily disassemble and material change. Vacuum Tank/Spray Cooling Tank According to the specifications of the pipes can be selected single room or double room design of the vacuum tank; SUS304 stainless steel vacuum tank and pipeline with long service life; Accurate temperature control and water level control;The large capacity of water filters and spare bypass;Centralized water supply and drainage; Optional PLC frequency conversion precision control of vacuum degree, lower equipment energy consumption and noise; The sizing sleeve made of high-quality materials such as alloy copper and stainless steel is particularly selected to ensure good heat conduction and a good cooling sizing effect. The inner surface of the sizing sleeve is treated with a chrome-plated special coating that provides high wear resistance and high smoothness. Water film type, disc type, dry type and other structural designs are suitable for high-speed, high-volume extrusion of different raw material pipes. Main technical specification Model Pipe diameter Extruder Capacity Main Power PE/PERT 75 Φ20-75mm JWS-H 60/40 380-420kg/h 110kw 350-400kg/h 90kw JWS 65/33 200-240kg/h 75kw PPR 75 Φ20-75mm JWS-H 60/40 300-340kg/h 110kw 280-320kg/h 90kw JWS 65/33 160-195kg/h 75kw PE/PERT 32 Φ16-32mm JWS-H 60/40 380-420kg/h 110kw 350-400kg/h 90kw Product image display Read the full article

#HDPEMarinePipeExtrusionMachine#HighSpeedExtrusionMachineforHDPEWaterPipe/GasPipe#LargeDiameterHDPESolidWallPipeExtrusionMachine#NewCorrugatedPipeExtrusionMachineforVentilationSystem#PEHeatInsulationPipeExtrusionMachine#PE/PPDoubleWallCorrugatedPipeExtrusionMachine#PipeExtrusionMachine#PPR/PERT/PEXCool&HotWaterPipeExtrusionMachine#PVCDualPipeExtrusionMachine#SiliconCorePipeExtrusionMachine#Three-layerPVCSolidWallPipeCo-extrusionExtrusionMachine#UPVC/CPVCPipeExtrusionMachine

0 notes

Text

Energy-saving HDPE Solid Wall Pipe High-speed Extrusion Machine

Advantages (1) reliable connection: polyethylene pipe systems are connected by electrothermal fusion, and the strength of the joint is higher than that of the pipe body (2) good low-temperature impact resistance: the low-temperature embrittlement temperature of polyethylene is very low, and it can be used safely in the temperature range of - 60-60 ℃. During construction in winter, pipe embrittlement will not occur due to the good impact resistance of the material. (3) good stress cracking resistance: HDPE has low notch sensitivity, high shear strength and excellent scratch resistance, and its environmental stress cracking resistance is also very outstanding. (4) good chemical corrosion resistance: HDPE pipeline can resist the corrosion of a variety of chemical media, and the chemicals in the soil will not cause any degradation to the pipeline. Polyethylene is an electrical insulator, so it will not rot, rust or electrochemical corrosion; In addition, it does not promote the growth of algae, bacteria or fungi. (5) aging resistance and long service life: polyethylene pipes containing 2-2.5% uniformly distributed carbon black can be stored outdoors or used for 50 years without being damaged by ultraviolet radiation. (6) good wear resistance: the comparative test of wear resistance between HDPE pipe and steel pipe shows that the wear resistance of HDPE pipe is 4 times that of steel pipe. In the field of mud transportation, compared with steel pipe, HDPE pipe has better wear resistance, which means that HDPE pipe has longer service life and better economy. (7) good flexibility: the flexibility of HDPE pipeline makes it easy to bend. In engineering, obstacles can be bypassed by changing the pipeline direction. In many cases, the flexibility of pipeline can reduce the consumption of pipe fittings and reduce the installation cost. (8) small flow resistance: HDPE pipe has smooth inner surface, and its Manning coefficient is 0.009. The smooth performance and non adhesion characteristics ensure that HDPE pipeline has higher transportation capacity than traditional pipes, and also reduce the pressure loss and water transmission energy consumption of the pipeline. (9) convenient handling: HDPE pipe is lighter than concrete pipe, galvanized pipe and steel pipe. It is easy to handle and install, and lower labor and equipment requirements mean that the installation cost of the project is greatly reduced. (10) a variety of new construction methods: HDPE pipeline has a variety of construction technologies. In addition to the traditional excavation method, it can also be constructed by a variety of new non excavation technologies, such as pipe jacking, directional drilling, lining, pipe cracking, etc., which is a good choice for some places where excavation is not allowed. Performance&Advantages Our company's latest research and development of energy-saving high-speed production line, suitable for high-speed polyolefin pipe extrusion. 35% energy saving and 1x increase in production efficiency.Specifically designed 38-40 L/D screw structure and the feeding slot barrel make the melt extrusion and plasticizing effects greatly improved. High-torque, high-strength gearboxes ensure stable operation of the equipment. Extrusion molds and sizing sleeves adopt the most advanced design structure. The PLC variable frequency control vacuum tank, servo-driven multi-track tractor, and high-speed chipless cutter are equipped with a meter weight control system. The pipe extrusion weight is more accurate. Main technical specification Model Pipe diamete Extruder Capacity Main Power JWPEG-H75 Φ16-75mm JWS-H60/40 350kg/h 90kw JWPEG-H125 Φ20-125mm JWS-H60/40 450kg/h 110kw JWPEG-H160 Φ50-160mm JWS-H75/38 550kg/h 132kw JWPEG-H315 Φ75-315mm JWS-H75/38 650kg/h 160kw JWPEG-H500 Φ160-500mm JWS-H90/38 900kg/h 250kw JWPEG-H630 Φ315-630mm JWS-H90/38 1050kg/h 280kw Product image display Read the full article

#HDPEMarinePipeExtrusionMachine#HighSpeedExtrusionMachineforHDPEWaterPipe/GasPipe#LargeDiameterHDPESolidWallPipeExtrusionMachine#NewCorrugatedPipeExtrusionMachineforVentilationSystem#PEHeatInsulationPipeExtrusionMachine#PE/PPDoubleWallCorrugatedPipeExtrusionMachine#PipeExtrusionMachine#PPR/PERT/PEXCool&HotWaterPipeExtrusionMachine#PVCDualPipeExtrusionMachine#SiliconCorePipeExtrusionMachine#Three-layerPVCSolidWallPipeCo-extrusionExtrusionMachine#UPVC/CPVCPipeExtrusionMachine

0 notes

Text

Large Diameter HDPE Solid Wall Pipe Extrusion Machine

The performance and advantages of our equipment Extruder is JWS-H series High efficiency, high output single screw extruder. The special screw barrel structure design ensures ideal melt uniformity at lower solution temperatures.Designed for large-diameter pipe extrusion, the spiral distribution structure mold is equipped with an in-mold suction pipe internal cooling system. Combined with a special low-sag material, it can produce ultra-thick-walled, large-diameter pipes.Hydraulic opening and closing two-stage vacuum tank, computerized centralized control and coordination of multiple crawler tractors, chipless cutter and all units, a high degree of automation. The optional wire rope tractor can make the initial operation of the large-caliber tube more convenient. Polyolefin Pipe Die Head PO die head is designed by JWELL Machinery Co.,ltd for high speed & high output pipe extrusion,which can produce pipe diameter from 16mm to 3000mm, adapting spiral design to make even material arrangement, low head melt temperature, low pressure consumption, reduction of innerstress as well shinning pipe surface. Modularity structure to cause easily disassemble and material change. Main technical specification Model Pipe diameter Extruder Capacity JWPEG-800 Φ400-800mm JWS-H120/38 1100-1300kg/h JWPEG-1000 Φ500-1000mm JWS-H120/38 1100-1300kg/h JWPEG-1200 Φ630-1200mm JWS-H90/38+90/38 1800-2000kg/h JWPEG-1600 Φ1000-1600mm JWS-HH90/38+120/38 2000-2200kg/h JWPEG-2500 Φ1400-2500mm JWS-H120/38+150/38 2200-2500kg/h Product image display Read the full article

#HDPEMarinePipeExtrusionMachine#HighSpeedExtrusionMachineforHDPEWaterPipe/GasPipe#LargeDiameterHDPESolidWallPipeExtrusionMachine#NewCorrugatedPipeExtrusionMachineforVentilationSystem#PEHeatInsulationPipeExtrusionMachine#PE/PPDoubleWallCorrugatedPipeExtrusionMachine#PipeExtrusionMachine#PPR/PERT/PEXCool&HotWaterPipeExtrusionMachine#PVCDualPipeExtrusionMachine#SiliconCorePipeExtrusionMachine#Three-layerPVCSolidWallPipeCo-extrusionExtrusionMachine#UPVC/CPVCPipeExtrusionMachine

0 notes

Text

Energy-saving HDPE Solid Wall Pipe High-speed Extrusion Machine

Advantages (1) reliable connection: polyethylene pipe systems are connected by electrothermal fusion, and the strength of the joint is higher than that of the pipe body (2) good low-temperature impact resistance: the low-temperature embrittlement temperature of polyethylene is very low, and it can be used safely in the temperature range of - 60-60 ℃. During construction in winter, pipe embrittlement will not occur due to the good impact resistance of the material. (3) good stress cracking resistance: HDPE has low notch sensitivity, high shear strength and excellent scratch resistance, and its environmental stress cracking resistance is also very outstanding. (4) good chemical corrosion resistance: HDPE pipeline can resist the corrosion of a variety of chemical media, and the chemicals in the soil will not cause any degradation to the pipeline. Polyethylene is an electrical insulator, so it will not rot, rust or electrochemical corrosion; In addition, it does not promote the growth of algae, bacteria or fungi. (5) aging resistance and long service life: polyethylene pipes containing 2-2.5% uniformly distributed carbon black can be stored outdoors or used for 50 years without being damaged by ultraviolet radiation. (6) good wear resistance: the comparative test of wear resistance between HDPE pipe and steel pipe shows that the wear resistance of HDPE pipe is 4 times that of steel pipe. In the field of mud transportation, compared with steel pipe, HDPE pipe has better wear resistance, which means that HDPE pipe has longer service life and better economy. (7) good flexibility: the flexibility of HDPE pipeline makes it easy to bend. In engineering, obstacles can be bypassed by changing the pipeline direction. In many cases, the flexibility of pipeline can reduce the consumption of pipe fittings and reduce the installation cost. (8) small flow resistance: HDPE pipe has smooth inner surface, and its Manning coefficient is 0.009. The smooth performance and non adhesion characteristics ensure that HDPE pipeline has higher transportation capacity than traditional pipes, and also reduce the pressure loss and water transmission energy consumption of the pipeline. (9) convenient handling: HDPE pipe is lighter than concrete pipe, galvanized pipe and steel pipe. It is easy to handle and install, and lower labor and equipment requirements mean that the installation cost of the project is greatly reduced. (10) a variety of new construction methods: HDPE pipeline has a variety of construction technologies. In addition to the traditional excavation method, it can also be constructed by a variety of new non excavation technologies, such as pipe jacking, directional drilling, lining, pipe cracking, etc., which is a good choice for some places where excavation is not allowed. Performance&Advantages Our company's latest research and development of energy-saving high-speed production line, suitable for high-speed polyolefin pipe extrusion. 35% energy saving and 1x increase in production efficiency.Specifically designed 38-40 L/D screw structure and the feeding slot barrel make the melt extrusion and plasticizing effects greatly improved. High-torque, high-strength gearboxes ensure stable operation of the equipment. Extrusion molds and sizing sleeves adopt the most advanced design structure. The PLC variable frequency control vacuum tank, servo-driven multi-track tractor, and high-speed chipless cutter are equipped with a meter weight control system. The pipe extrusion weight is more accurate. Main technical specification Model Pipe diamete Extruder Capacity Main Power JWPEG-H75 Φ16-75mm JWS-H60/40 350kg/h 90kw JWPEG-H125 Φ20-125mm JWS-H60/40 450kg/h 110kw JWPEG-H160 Φ50-160mm JWS-H75/38 550kg/h 132kw JWPEG-H315 Φ75-315mm JWS-H75/38 650kg/h 160kw JWPEG-H500 Φ160-500mm JWS-H90/38 900kg/h 250kw JWPEG-H630 Φ315-630mm JWS-H90/38 1050kg/h 280kw Product image display Read the full article

#HDPEMarinePipeExtrusionMachine#HighSpeedExtrusionMachineforHDPEWaterPipe/GasPipe#LargeDiameterHDPESolidWallPipeExtrusionMachine#NewCorrugatedPipeExtrusionMachineforVentilationSystem#PEHeatInsulationPipeExtrusionMachine#PE/PPDoubleWallCorrugatedPipeExtrusionMachine#PipeExtrusionMachine#PPR/PERT/PEXCool&HotWaterPipeExtrusionMachine#PVCDualPipeExtrusionMachine#SiliconCorePipeExtrusionMachine#Three-layerPVCSolidWallPipeCo-extrusionExtrusionMachine#UPVC/CPVCPipeExtrusionMachine

0 notes

Text

HDPE Steel Wire Frame Plastic Pipe(SRTP)pipe Extrusion Machine

HDPE Steel Wire Frame Plastic Pipe Features: (1) Good creep resistance good, high tensile and long-lasting mechanical strength (2) Good temperature resistance (3) Good rigidity and impact resistance, good size stablity and flexible (4) Small coefficient of thermal expansion (5) Rapid cracking will not occur (6) Steel and plastic composite materials are even and reliable. (7) Anti-corrosion on double-sided (8) Good self tracing ability (9) Performance adjustment for the product structure is convenient and flexible.(10) Various special electric fusion joint. Fast and reliable installation Specifications Nominal pressure: 0.6MPa--3.5MPa Dimensions: DN50-DN1200 Performance and advantages of our equipment Steel Wire Frame Plastic Pipe, also called SRTP pipe, is a new type of steel framed polyethylene plastic pipe. It adopts the raw material of high tensile over-plastic Steel wire mesh frame and thermoplastic PE. Steel wire mesh as reinforced framework and based on HDPE, it also adopts high performance HDPE modified bond resin to connect the inner space HDPE and outer space HDPE with steel wire frame closely, so that it can have an excellent compounding effect. Since the high tensile steel wire reinforcements are warped in continuous thermoplastic plastic, this composite pipe take the essence and discard the dross of steel pipe and plastic pile.Three layers steel wire reinforced composite pipe is widely frame are widely used in the area of city water supply, civil engineering, fossil oil, natural gas, chemical industry, power transmission pipelines, metallurgical mines, sea water transport, shipbuilding, agriculture and the laying of fiber optic cables. Product image display Read the full article

#HDPEMarinePipeExtrusionMachine#HighSpeedExtrusionMachineforHDPEWaterPipe/GasPipe#LargeDiameterHDPESolidWallPipeExtrusionMachine#NewCorrugatedPipeExtrusionMachineforVentilationSystem#PEHeatInsulationPipeExtrusionMachine#PE/PPDoubleWallCorrugatedPipeExtrusionMachine#PipeExtrusionMachine#PPR/PERT/PEXCool&HotWaterPipeExtrusionMachine#PVCDualPipeExtrusionMachine#SiliconCorePipeExtrusionMachine#Three-layerPVCSolidWallPipeCo-extrusionExtrusionMachine#UPVC/CPVCPipeExtrusionMachine

0 notes

Text

Large Diameter HDPE Hollow-wall Coiled Pipe Extrusion Machine

Pipe characteristics The pipe winding corrugated structure is reasonable, which is conducive to expanding the contact surface with the soil and the backfill filled in the pipeline trough and the pipe itself jointly bear the pressure of the surrounding soil, resulting in the joint action of pipe and soil. There is a vertical inner rib in the middle of the pipe ripple, which greatly improves the stability of the wave crest and is conducive to compression and impact resistance. The width of the welding surface of the plastic strip is large and the effect is good, which makes the seam tensile strength of the pipe high. The pipe connection adopts socket electric melting to ensure zero leakage, and the stainless steel clamp connection is convenient and reliable. Scope of application Corrosive sewage pipes for seawater, industry, chemical plant, pharmaceutical plant and other industries;Old city reconstruction, rainwater and sewage diversion project, sewage treatment plant and waste treatment plant drainage;Municipal, construction engineering, buried drainage, power plant and other large projects;Irrigation and drainage of farmland; Performance and advantage Large diameter HDPE hollow-wall coiled pipe is one of the best replacements for cement pipe. Jwell is one of the earliest qualified suppliers for this line. We have strong technical advantage and rich experience in pipe production providing excellent pipe machine characterised of stable performance and easy operation.The comprehensive indexes of Jwell machine reach the domestic Top level. 1. The main extruder adopts efficient single screw extruder ensuring high speed and perfect quality extrusion; 2. Composite head is used with spiral rotational molding type with ingenious structure and unique design to ensure product quality; 3. Pipe product has high ring stiffness, mining used anti-static mashgas drainage and exhaust pipes can be produced by this machine; 4. Special pipe connectiot with convenient operation and economic construction. Main technical specification Model Pipe diameter Extruder Motor power Capacity Total power JW800 200-800mm JW75×30/JW55×30 45/18.5kw 400kg/h 120kw JW1200 300-1200mm JW90×30/JW65×30 75/30kw 550kg/h 200kw JW1600 800-1600mm JW100×30/JW75×30 110/45kw 650kg/h 300kw JW2400 1200-2400mm JW120×30/JW75×30 132/55kw 750kg/h 400kw JW3000 1800-3000mm JW150×30/JW90×30 200/90kw 900kg/h 600kw Product image display Read the full article

#HDPEMarinePipeExtrusionMachine#HighSpeedExtrusionMachineforHDPEWaterPipe/GasPipe#LargeDiameterHDPESolidWallPipeExtrusionMachine#NewCorrugatedPipeExtrusionMachineforVentilationSystem#PEHeatInsulationPipeExtrusionMachine#PE/PPDoubleWallCorrugatedPipeExtrusionMachine#PipeExtrusionMachine#PPR/PERT/PEXCool&HotWaterPipeExtrusionMachine#PVCDualPipeExtrusionMachine#SiliconCorePipeExtrusionMachine#Three-layerPVCSolidWallPipeCo-extrusionExtrusionMachine#UPVC/CPVCPipeExtrusionMachine

0 notes

Text

High Pressure RTP Twisted Composite Pipe Extrusion Machine

Performance and advantages of our equipment The thermoplastic reinforced pipe RTP has three layers: the inner layer is anti-erosion and wearing-resistant PE pipe; The middle layer is reinforced twisting layer (the material is high-intension synthesized fiber, or glass fiber, carbon fiber or fine metal thread); The outer layer is PE for protection use. The most popular reinforce material is Aramid fiber. This line is mainly composed of inner tube extrusion and outer coating extrusion systems, multiple sets of winding machines, cooling setting devices, winders and control systems. The use of computerized centralized data control enables accurate control of the precise weight control of the inner tube, simultaneous traction control, automatic tube-lined coiling, and automatic multi-station precise layer control in the process. The advantages and applications of RTP pipe: RTP winding reinforced composite pipe is a new type of plastic composite pipe that is resistant to high pressure, corrosion resistance and flexibility. Used in petroleum, water supply and other high pressure transportation environment. The inner layer of the product is a corrosion-resistant and wear-resistant polyethylene pipe, the middle layer is a reinforced winding layer, and the outer layer is a protective polyethylene layer. The working pressure of the aramid fiber-reinforced RTP tube can be as high as 9-14 MPa and the burst pressure can be as high as 40 MPa. Main technical specification Model Pipe diameter Extruder Capacity Total power JWG-RTP-160 Ø63~Ø160 JWSGX65/38 120-300kg/h 160kw JWG-RTP-250 Ø75~Ø250 JWSGX75/38 300-500kg/h 210kw JWG-RTP-315 Ø110~Ø315 JWSGX75/38 300-500kg/h 210kw Product image display Read the full article

#HDPEMarinePipeExtrusionMachine#HighSpeedExtrusionMachineforHDPEWaterPipe/GasPipe#LargeDiameterHDPESolidWallPipeExtrusionMachine#NewCorrugatedPipeExtrusionMachineforVentilationSystem#PEHeatInsulationPipeExtrusionMachine#PE/PPDoubleWallCorrugatedPipeExtrusionMachine#PipeExtrusionMachine#PPR/PERT/PEXCool&HotWaterPipeExtrusionMachine#PVCDualPipeExtrusionMachine#SiliconCorePipeExtrusionMachine#Three-layerPVCSolidWallPipeCo-extrusionExtrusionMachine#UPVC/CPVCPipeExtrusionMachine

0 notes

Text

Parallel Twin-screw Extruder HDPE PP DWC Pipe extrusion machine

Application scope It is mainly used for large-scale water conveyance, water supply, drainage, sewage discharge, exhaust, subway ventilation, mine ventilation, farmland irrigation, etc. with working pressure below 0.6MPa. 1. Municipal Engineering: used as drainage and sewage pipe. 2. Construction works: used as rainwater pipe, underground drainage pipe, sewage pipe and ventilation pipe of buildings. 3. Railway and highway communication equipment: used as the protective tube of communication cable and optical cable. 4. Industry: widely used for sewage pipes in chemical industry, hospital, environmental protection and other industries. 5. Agricultural garden project: used for drainage of farmland, fruit and tea gardens and forest belts. 6. Road Engineering: used as seepage and drainage pipe of railway and expressway. 7. Mine: used as mine ventilation, air supply and drainage pipe. 8. Perforated double wall corrugated pipe: it can be used as seepage and drainage pipe of saline alkali land expressway. 9. Golf course and football field project: used as seepage and drainage pipe of golf course and football field. Performances and advantages of our equipment: Jwell introduced European advanced technology and newly developed parallel-parallel twin screw extruder HDPE/PP DWC pipe line, which has the following characteristics: 1. Adopt two parallel twin-screw extruders, and the mixing effect is excellent.It is possible to use both powdered and granular raw materials at the same time without the need for granulation and low raw material costs; 2. The extruder is equipped with a side feeding system, which can adjust the calcium powder filling ratio at any time online, and the formula exchange is convenient; 3. Extruder has vacuum vents. To make the inner and outer walls of the pipe dense and smooth without bubbles; 4. The screw & barrel are building block type. maintenance and replacement easily. Main technical specification Model Pipe diameter Max speed Capacity Total power JWSBL-600 200-600mm 5m/min 800kg/h 500kw JWSBL-1000 200-1000mm 2.5m/min 1200kg/h 710kw JWSBL-1200 800-1200mm 1.5m/min 1400kg/h 800kw Product image display Read the full article

#HDPEMarinePipeExtrusionMachine#HighSpeedExtrusionMachineforHDPEWaterPipe/GasPipe#LargeDiameterHDPESolidWallPipeExtrusionMachine#NewCorrugatedPipeExtrusionMachineforVentilationSystem#PEHeatInsulationPipeExtrusionMachine#PE/PPDoubleWallCorrugatedPipeExtrusionMachine#PipeExtrusionMachine#PPR/PERT/PEXCool&HotWaterPipeExtrusionMachine#PVCDualPipeExtrusionMachine#SiliconCorePipeExtrusionMachine#Three-layerPVCSolidWallPipeCo-extrusionExtrusionMachine#UPVC/CPVCPipeExtrusionMachine

0 notes

Text

Small Diameter Single Wall Corrugated Pipe extrusion machine

Performance and advantages of our equipment This series production line is suitable for the production of small-diameter single-wall corrugated pipe with raw materials such as PP/PE/PA. The special mold can be molded at one time. The surface of the product pipe is smooth and delicate, and the ripple is clear and uniform. Widely used in wire and cable threading pipe, automotive interior circuit protection pipe, concrete pipe, farmland pipe and other fields. Company products all over the world, as well as Russia, India, South Korea, Indonesia, the Middle East, North and Latin Americas, Spain, Italy etc., more than 150 countries and regions, praised by users. '' Excellent Quality, Perfect All'' is Jwell's quality policy, and all staff's working direction. '' Be honest'' is the core idea for us to contribute'' Century JWELL'' Main technical specification Model Pipe diameter Max speed Capacity Total power JWDBW32 16-32mm 24m/min 50kg/h 35kw JWDBW50 16-50mm 30m/min 80kg/h 45kw Product image display Read the full article

#HDPEMarinePipeExtrusionMachine#HighSpeedExtrusionMachineforHDPEWaterPipe/GasPipe#LargeDiameterHDPESolidWallPipeExtrusionMachine#NewCorrugatedPipeExtrusionMachineforVentilationSystem#PEHeatInsulationPipeExtrusionMachine#PE/PPDoubleWallCorrugatedPipeExtrusionMachine#PipeExtrusionMachine#PPR/PERT/PEXCool&HotWaterPipeExtrusionMachine#PVCDualPipeExtrusionMachine#SiliconCorePipeExtrusionMachine#Three-layerPVCSolidWallPipeCo-extrusionExtrusionMachine#UPVC/CPVCPipeExtrusionMachine

0 notes