#Pipe Rack Roller

Explore tagged Tumblr posts

Text

SPM Equipment is manufacturer & Suppliers of Horizontal Pipe Rack Roller and. With Teflon coated options handles on sides for easy installation in UAE, Malaysia, Australia, USA, Russia.

#Pipe Rack Roller#Pipe Rack Roller Suppliers#Pipe Rack Roller Manufacturer#Best Pipe Rack Roller Suppliers#Top Pipe Rack Roller Manufacturers#spmequipment

0 notes

Text

Country Pipeline Equipment - Russia, USA, UAE, Australia, Malaysia, MEXICO, GERMANY, SAUDI ARABIA, SINGAPORE, EQYPT, TURKEY.

https://spmequipment.com/cross-country-pipeline-equipment/

SPM EQUIPMENT offers a wide range of Cross Country Pipeline Equipment. Polyurethane Disc Plug Mandrel is required for Pipe Bending Machine in pipe bending. It gives support inside the surface of the pipe.

Permit more degree of bend without wrinkles. Our offered cross country pipeline equipment is perfect for holding pipe “out of roundness” to a minimum in a standard bending system

#pipe fit-up outer clamp#pipe rack roller suppliers#beam clamp pipe roller#Cross Country Pipeline Equipment

1 note

·

View note

Text

How to Choose the Right Pallet Racking System for Your Warehouse

If you run a warehouse, you know how quickly chaos can take over. Picture rows of goods stacked haphazardly, making it nearly impossible to find anything. Sounds like a nightmare, right? That’s where pallet racking systems come into play. They’re the backbone of efficient warehouse operations, helping you keep things organized, maximize space, and ensure safety. But with so many options out there, how do you choose the right one? Let’s break it down.

Understanding Your Needs

Before you dive into the world of pallet racking systems, you need to take a step back and assess your warehouse’s unique requirements. Think of it as getting to know your warehouse on a deeper level.

Assessing Warehouse Space

Start by measuring your available space. What’s the height of your warehouse ceilings? How wide are your aisles? Understanding these dimensions will help you choose a system that fits like a glove. Remember, every square inch counts when you’re trying to maximize storage.

Inventory Characteristics

What kind of inventory are you dealing with? Are your products bulky, fragile, or perishable? Knowing the nature and size of your goods is crucial. For instance, storing pallets of frozen food requires a different setup than managing lightweight electronics.

Load Requirements

Not all pallet racks are created equal. Some are built to handle heavy-duty loads, while others are better for lighter goods. Make sure to factor in the weight of your pallets to avoid overloading your racks and compromising safety.

Types of Pallet Racking Systems

Now that you’ve got a clear picture of your needs, let’s explore the different types of pallet racking systems. Think of this as your menu of options.

Selective Pallet Racking

This is the most common type, and for good reason. It’s simple, cost-effective, and provides easy access to every pallet. If you’re running a business with high turnover or diverse inventory, this could be your go-to option.

Drive-In and Drive-Through Racking

These systems are perfect for warehouses handling large volumes of similar products. They work like a multi-lane garage, allowing forklifts to drive directly into the racks. While they save space, they’re not ideal for operations needing frequent pallet rotation.

Push-Back Racking

With push-back racking, pallets are loaded onto nested carts on inclined rails. When one pallet is removed, the next rolls forward. It’s a fantastic choice for warehouses needing high-density storage without sacrificing access.

Pallet Flow Racking

This system operates on a first-in, first-out (FIFO) principle. Gravity takes the wheel here, with rollers moving pallets from the loading to the picking end. It’s efficient, but you’ll need to ensure proper maintenance to keep things running smoothly.

Cantilever Racking

If you’re storing long, awkward items like pipes or lumber, cantilever racking is your best bet. Its open design makes it easy to store and retrieve goods that wouldn’t fit on traditional racks.

Key Factors to Consider

Choosing the right pallet racking system isn’t just about finding what works today. You’ve got to think about the long haul.

Budget Considerations

Let’s be honest, cost matters. While you don’t want to skimp on quality, it’s important to find a solution that fits within your budget. Consider not just the initial investment but also long-term costs like maintenance and potential upgrades.

Safety Standards

Safety isn’t negotiable. Look for systems that comply with industry standards and ensure regular inspections. A minor oversight can lead to major accidents, so don’t cut corners here.

Scalability and Flexibility

Your business is growing, right? Choose a system that can grow with you. Modular designs and adjustable racks can save you from having to overhaul your setup down the line.

Implementation Tips

Alright, you’ve picked your system. Now it’s time to make it a reality.

Choosing a Reliable Supplier

Not all suppliers are created equal. Do your homework, read reviews, and ask for references. A good supplier will not only provide high-quality products but also offer valuable advice tailored to your needs.

Professional Installation

Installing a pallet racking system isn’t a DIY job. Hire professionals who know the ins and outs of the process. Trust me, it’s worth the investment to ensure everything is set up safely and correctly.

Regular Maintenance

Even the best systems need a little TLC. Schedule routine inspections to check for wear and tear. Addressing small issues early can save you from costly repairs and potential safety hazards.

Conclusion: Making the Right Choice

Choosing the right selective pallet racking system is a big decision, but it doesn’t have to be overwhelming. By understanding your needs, exploring your options, and considering key factors like budget and safety, you’re well on your way to transforming your warehouse into a well-oiled machine. So, what are you waiting for? Start planning and watch your warehouse’s efficiency soar!

Meatco Distributor

3265 Gateway Rd, Suite 350, Brookfield, WI

800–558–5104

0 notes

Text

India Warehouse Show 2024 Kicks Off Today: Visit Sigma Racks at Booth B25B

The much-anticipated India Warehouse Show 2024 starts today, bringing together industry leaders, innovators, and professionals from around the globe. This year's event, held at the prestigious Yashobhoomi ICCC in Dwarka, New Delhi, promises to be a hotspot for the latest advancements in warehouse and storage solutions. Sigma Racks is thrilled to be a part of this grand event, showcasing our cutting-edge products at Booth B25B from July 11-13.

Discover Sigma Racks' Innovative Storage Solutions

At Sigma Racks, we pride ourselves on offering state-of-the-art storage solutions tailored to meet the diverse needs of our clients. Here's a glimpse of what we have in store for you at the India Warehouse Show 2024:

1. Pallet Racking

Our Pallet Racking systems are designed for high-density storage and easy accessibility. They are ideal for warehouses that require efficient use of vertical space, allowing you to store large quantities of goods securely and systematically.

2. Drive-In/Drive-Through Pallet Rack

Maximize your storage capacity with our Drive-In/Drive-Through Pallet Racks. These systems are perfect for storing homogenous products in large quantities, providing a high-density storage solution that allows forklifts to enter the rack structure for loading and unloading.

3. Longspan Shelving

Longspan Shelving is versatile and easy to assemble, making it an excellent choice for storing a wide variety of items. Whether you need to store small parts or large, bulky items, our Longspan Shelving can be customized to suit your requirements.

4. Mezzanine System

Optimize your warehouse space with our Mezzanine Systems. These systems create additional floorspace within your existing warehouse, offering a cost-effective way to expand your storage capacity without the need for building extensions.

5. Cantilever Racks and Cable Tray Systems

Our Cantilever Racks are ideal for storing long, bulky items such as pipes, lumber, and steel bars. Coupled with our Cable Tray Systems, they provide a comprehensive solution for managing and organizing your inventory efficiently.

6. Skeleton Racks

Skeleton Racks are designed for heavy-duty storage needs. Their robust structure ensures durability and reliability, making them suitable for storing large and heavy items safely.

7. ASR Racking

Automated Storage and Retrieval (ASR) Racking systems are the future of warehouse management. These systems enhance productivity by automating the storage and retrieval process, reducing human error, and increasing operational efficiency.

8. Box Conveyor Systems

Streamline your warehouse operations with our Box Conveyor Systems. These systems facilitate the efficient movement of goods within your warehouse, improving workflow and reducing handling time.

9. Autonomous Mobile Robots (AMRs)

Our AMRs are designed to revolutionize your warehouse operations. These robots can navigate autonomously, transporting goods throughout your warehouse with precision and efficiency, thereby reducing labor costs and increasing productivity.

10. Carton Flow Racking

Carton Flow Racking is perfect for first-in, first-out (FIFO) inventory management. These systems use inclined shelves equipped with rollers, ensuring that products are always accessible and efficiently rotated.

11. Shuttle System Tray Building

Enhance your storage density and efficiency with our Shuttle System Tray Building. This automated system uses shuttles to move trays within the rack structure, optimizing space utilization and speeding up the storage and retrieval process.

Visit Us at Booth B25B

We invite you to visit Sigma Racks at Booth B25B during the India Warehouse Show 2024. Our team of experts will be on hand to demonstrate our innovative products and discuss how they can be tailored to meet your specific needs. Don’t miss this opportunity to explore the latest advancements in warehouse technology and network with industry leaders.

Join us from July 11-13 at Yashobhoomi ICCC, Dwarka, New Delhi, and see how Sigma Racks can transform your warehouse operations. We look forward to meeting you and exploring new opportunities together. See you at the show!

#warehousing racks#slotted angle racks#HDR#mezzanine system#pallet racking#cantilever racking system#racks#industrial racking#storage solutions

0 notes

Text

Pallet Racking in Dubai: Maximizing Warehouse Efficiency and Space Utilization

Pallet racking systems are indispensable for efficient warehouse management, particularly in a bustling hub like Dubai. With its rapid economic growth and thriving logistics sector, the demand for optimized storage solutions is at an all-time high. In this blog, we will explore the various types of racking systems available in Dubai, their benefits, and how to choose the right one for your business needs.

Understanding Pallet Racking Systems

Pallet racking is a material handling storage aid system designed to store materials on pallets (or "skids"). There are several types of pallets racking systems, each tailored to different storage requirements and warehouse configurations.

Types of Pallet Racking Systems

1) Selective Pallet Racking

Description: The most common type, offering direct access to each pallet.

Advantages: Easy access to products, flexibility, and compatibility with most forklifts.

Ideal For: Warehouses with a wide variety of products and lower turnover rates.

2) Drive-In/Drive-Through Racking

Description: Allows forklifts to drive directly into the racking system to pick up or deposit pallets.

Advantages: Maximizes storage density by reducing aisle space.

Ideal For: High-volume storage of similar products and last-in, first-out (LIFO) inventory systems.

3) Push-Back Racking

Description: Pallets are loaded on a series of nested carts that move along inclined rails.

Advantages: High storage density, better product accessibility than drive-in racking.

Ideal For: Warehouses with a moderate variety of products and medium turnover rates.

4) Pallet Flow Racking

Description: Uses gravity rollers to move pallets from the loading end to the picking end.

Advantages: First-in, first-out (FIFO) inventory management, high-density storage.

Ideal For: Warehouses with high turnover rates and perishable goods.

5) Cantilever Racking

Description: Features arms extending from a central column, suitable for long or bulky items.

Advantages: Flexibility in storing irregularly shaped items, easy access.

Ideal For: Storing pipes, lumber, and other long items.

0 notes

Text

Come post presidential election 2024… heil to the Wharton chief firebrand -

more worrisome than an ovarian cyst

every race, religion, nationality, gender, creed, et cetera with impunity dissed brigand able, eager, ready and willing to punch contenders throwing his fist against rival – one nasty and brutish soul after reading, you get the gist how dictator wannabe lurching with tremendous oaf fish shill

blatantly, flagrantly, and glad-handedly zapping usurping power, breeding dissent soundlessly slithering, spreading vile disinformation onto social media platforms targeting undecided electorates analogous to casting dark shadows across the edge of night hissed tory revoked eclipsed loosing unfettered horrors.

Das boot trump out-

(oust him to) Waterloo

Eagerly awaits you

the bully in the white house and true.

Whit that, yawl get a lucky strike if ya keep yar show

as my Reince prescience foretells this poe

fur one quarter off hiz terminal daze starring down

(with bad medicine), thee ole scarecrow.

╰☆╮ Thankfully, I'm not a royal heir

to the power monger hoarders╰☆╮

which comb hen might handy when borders

hermetically sealed - per heil hit lore

caw zing a furor with his stark jumbo je lay bean orders.

I don't wanna don a duck dynasty outfit,

or that of a woodchucker but...holy mother f*cker

and kudos to any heckler,

who deems steam roller trump as a mean trucker.

Thus - for the umpteenth attempt to post

without any intention to induce rabid reaction to roast

my ass (albeit scrawny just to be cheeky),

I dick rye America will burn like toast the legacy of democracy transparent as a ghost

if....mister money bags - to the finish line

of presidential electorate, he doth coast.

My anti Donald trump screed continues tut try

tip picture conjure pixelated stress less or more

WE MUST DO MORE THAN YODEL LOUD: (and preach to the choir)

out....out...get...life not death, he seems to ab hoar

ding dong Donald drake...out...of...here...

without...his security detail or...coat....of...

(Emperor wears no clothes) armor.

I will not condone political measures

from that mane lion kapo -

jabbering indiscretion.

Herewith follows a poem (concatenated with above lines) I dashed off in a huff - to douse

dat auld don trumpeting joie de vivre

fin de siecle utopia of yesteryear

puffin sewerage bilge - strike n horror n ma eyes -

for opinion aye espouse

based on scary political fracas and looming nightmare -

whar mo' will grouse

to obstruct trump access to black keys to white house

that a looming presidential nightmare

doth not become real - gruff louse

he will crush sacred freedoms,

whence western civilization goes off bluff

analogous to a rabid cat terminating

the life of more'n Mickey Mouse.

DUCK AFTER DUMP - PING THE DON -

a pipe dream that will never take shape.

Air ring ma thoughts - no matter aye ham

juiced one twenty first century mwm ape

serves as genuine s cape

to fly (during pitch black hours of night)

on his witch a ma call it...

to escape temporarily the cares and concerns

of an uncertain world,

where as an outlier from madding crowd I gape

at the sheer insanity

trumpeting strumpets donning an innate

prejudice and senselessness purr

blind faith toward self avowed demigod --

seize whore viz Caesar - forever linkedin with maxim

Veni, Vedi, Vici - idolized statecraft motto

Trump perfects with his witch's brew he doth stir

his hair coiffed and puffed like it whir

wind blown kickstart ting mobs to stir

paying Deep Purple bodyguards to evict ruckus-causing murmur

oh...how the masses will let this country

go to hell in handbasket -

blithely purging the Iran Nuclear Deal,

The Paris Climate Agreement

plus rack up stratospheric global debt

cause zing this one measly mortal male to fret

Boom, boom, boom gotta get get

that totalitarian rule will force every man,

woman and child to march....het

two...three...four, while the billionaire

turns a third blind eye speeds away in his foo fighter jet

argh...heavens to Betsy Ross,

Condoleezza Rice, Nancy Reagan,

Barenaked Ladies, and Goo Goo Dolls,

how did the fickle finger of fate let

this pompous ass allergic to law and order sowing, loosing, and fomenting insurrection crowdsourcing, wherever anarchy met

vacuums up majority votes across world wide quartered, (tattered), and webbed net

to finagle vox populi,

and groom hooligan nasty ruffian thugs

with smashed face as his smart pet

GoLong Daddy story short -

pondering my rental circumstance

will be upended if this ret

chad, evil, googly-eyed, gastronomic,

narcissistic bullish Don will set

the spark for world war three -

via gone ah re: ha...ha...ha...to all vet

tureens within the sea to shining cyber sea

American crucible melting pot -

with verbal whips,

whose invective blast sucker punching

DACA, and those

who strain to uphold economic backbone,

he does NOT STOP to undermine stoop labor,

which anonymous backs, he bloodies via twittering whetstone

unless....Katrina and the Waves, superman

or the Sabrina can oust him yet.

0 notes

Text

Industrial racking systems are metal structures used to store goods in warehouses and other industrial facilities. They are designed to be strong, durable, and safe, and they can be customized to fit the specific needs of a business. There are many different types of industrial racking systems available, including:

Selective pallet racks: These are the most common type of industrial racking system. They are used to store palletized goods on horizontal beams.

Drive-in/drive-thru racks: These racks are designed to allow forklifts to drive inside them, which can save time and space.

Cantilever racks: These racks are used to store long, bulky items, such as pipes and lumber.

Carton flow racks: These racks use rollers to move cartons from one end of the rack to the other, which can help to improve picking efficiency.

0 notes

Text

top pipe rack roller suppliers in usa

Looking for reliable pipe rack roller suppliers in the USA? Find the top manufacturers offering innovative, high-performance solutions tailored to your needs.

1 note

·

View note

Text

PIPELINE CONSTRUCTION EQUIPMENT

SPM Equipment, Oil and gas construction, Pipeline equipment Exporter & manufacturing company in India believes, its success is directly attributable to its employees and its partnerships with customers, vendors, and alliance partners.

1 note

·

View note

Text

Industrial Warehouse Racking Columbus OH

Industrial Warehouse Racking: The Backbone of Efficient Storage Solutions

Industrial Warehouse Racking Columbus OH play a critical role in modern logistics and storage operations. Designed to maximize space, improve organization, and streamline operations, these systems are essential for businesses handling large volumes of inventory. From retail warehouses to manufacturing facilities, racking solutions ensure optimal storage efficiency while prioritizing safety and accessibility.

What is Industrial Warehouse Racking?

Warehouse racking refers to the structured storage system used to stack materials and products in a warehouse. These systems typically consist of metal frameworks with multiple levels of shelves, allowing businesses to make the most of vertical space. They are designed to accommodate heavy loads while ensuring durability, flexibility, and accessibility.

Different industries employ a variety of racking systems, each tailored to specific storage needs. Choosing the right type of racking depends on factors like the size and weight of inventory, warehouse dimensions, and operational requirements.

Types of Warehouse Racking Systems

Selective Racking:

The most common and straightforward type, selective racking provides direct access to every pallet. This system is ideal for warehouses handling a variety of products with a high turnover rate. It’s versatile and cost-effective but may require more floor space.

Drive-In and Drive-Through Racking:

Designed for high-density storage, these systems allow forklifts to drive into the racking structure to place or retrieve pallets. Drive-in systems have one access point, while drive-through racking allows access from both ends, improving efficiency for warehouses with large quantities of similar items.

Pallet Flow Racking:

A dynamic solution, pallet flow racking uses inclined rollers to move pallets automatically from one end to the other. This system is ideal for first-in, first-out (FIFO) inventory management, commonly used in industries like food and beverage.

Cantilever Racking:

Perfect for long or bulky items like pipes, lumber, or steel, cantilever racking features horizontal arms extending from a single vertical column. Its open design ensures easy storage and retrieval of oversized products.

Push-Back Racking:

This high-density system allows pallets to be stored on carts that slide backward along inclined rails. Push-back racking is ideal for last-in, first-out (LIFO) inventory systems, optimizing space for products with low rotation.

Benefits of Warehouse Racking

Maximized Space: Racking systems utilize vertical space, freeing up floor space for other operations.

Improved Efficiency: Organized racking reduces the time required to locate and retrieve items.

Enhanced Safety: Durable materials and secure structures minimize risks in the warehouse environment.

Scalability: Modular designs make racking systems easy to expand or reconfigure as storage needs grow.

Conclusion

Industrial Warehouse Racking Columbus OH are indispensable in today’s fast-paced supply chain environment. By optimizing space, improving inventory management, and enhancing operational efficiency, these systems enable businesses to meet the demands of a competitive market. Investing in the right racking solution is not just a choice—it’s a necessity for streamlined and safe warehouse operations.

#pallet rack warehouse & supply#warehouse mezzanine systems cincinnati ohio#Industrial Warehouse Racking cincinnati ohio

0 notes

Text

Introduction to Rolling Mill Stand, Types, Structure, and Material

The rolling mill stand is one of the main components of the rolling mill and is used to support and fix the rolls and other components. It is usually welded from steel plates, has high strength and stiffness, and can withstand various forces and torques during the rolling process. The accuracy and stability of the rolling mill stand directly affect the quality and output of the rolled products.

Types of Rolling Mill Stand

The types of rolling mill stands can be divided according to different classification methods. Depending on the purpose and type of rolling mill, rolling mill stands can usually be divided into two types: open and closed.

Open Stand

The open stand is a common type of rolling mill stand. Its advantages include easy processing and manufacturing, convenient loading and unloading, and convenient roll change. However, this kind of stand has low strength and stiffness and a large bounce value, so it is suitable for intermediate rolling mills and finishing rolling mills with small rolling forces.

Closed Stand

The closed stand is a newer type of rolling mill stand with high strength and stiffness, and is suitable for blooming mills and slab rolling mills with large rolling forces. The processing and manufacturing of this kind of frame is difficult, and it is inconvenient to load, unload and change rollers. However, the bounce value is small and the accuracy is high.

In addition, according to the structural form of the stand, the rolling mill stand can also be divided into two types: integral type and split type. An integral rack refers to a rack welded by one or several steel plates. It has high strength and rigidity, but is heavy and inconvenient to disassemble and assemble. A split frame refers to a frame welded by two or more steel plates. It is easy to disassemble and assemble, but has low accuracy.

When selecting the type of rolling mill stand, it is necessary to comprehensively consider factors such as the purpose of the rolling mill, the shape and size of the rolled product, and the size of the rolling force. At the same time, attention needs to be paid to the manufacturing and repair costs of the rack to ensure its economy and feasibility.

Structure of Rolling Mill Stand

The structure of the rolling mill frame mainly includes the frame base, upper beam, column, lower beam, work roll bearing seat, work roll bearing, work roll bearing cover, bearing cooling water pipe and other components. Among them, the frame base and the upper beam are connected by welding, the column and the lower beam are also connected by welding, the column is fixed on the base, and both ends of the lower beam are placed on the base. The work roll bearing seat is fixed on the column, and the work roll bearing cover is placed on the work roll bearing seat. The bearing cooling water pipe passes through the work roll bearing cover and enters the work roll bearing seat to cool the work roll bearing.

In addition, the structural design of the rolling mill stand needs to take into account the shape, size and process requirements of the rolled products, as well as the manufacturing and maintenance of the stand. A well-structured frame can ensure the stability and accuracy of the rolling process and facilitate manufacturing and maintenance. The manufacturing process of the rack includes steps such as steel plate welding, steel casting processing, and mechanical processing. It is necessary to ensure the accuracy and stability of the rack, and to conduct quality inspection and control.

In the structure of the rolling mill stand, the following points need to be noted:

The rigidity and strength of the frame must be sufficient to withstand various forces and torques during the rolling process.

The accuracy of the stand must be high, especially for high-precision rolling mills, the accuracy of the stand must be higher.

The structure of the rack must be reasonable to facilitate manufacturing and maintenance, and the convenience of installation, debugging, and maintenance must also be taken into consideration.

The material of the frame should be made of high-strength steel or steel castings with high strength and stiffness. At the same time, attention should be paid to the quality and performance of the material.

Material of Rolling Mill Stand

The materials of rolling mill stands can be selected according to different needs and uses. Common rolling mill frame materials include carbon steel, alloy steel, cast steel, etc.

Carbon Steel

Carbon steel is a common rolling mill frame material with good strength, stiffness and wear resistance. Commonly used carbon steels include Q235, Q345, etc.

Alloy Steel

Alloy steel is made by adding a certain amount of alloy elements to carbon steel to improve its strength, hardness, corrosion resistance and oxidation resistance. Commonly used alloy steels include 40CrNiMo, 16MnCr5, etc.

Cast Steel

Cast steel is a material obtained by casting method and has good plasticity, toughness and wear resistance. Commonly used cast steels include ZG270-500, ZG310-570, etc.

When selecting rolling mill frame materials, comprehensive considerations need to be made based on factors such as the purpose of the rolling mill, working conditions, and processing technology. For example, for large rolling mills, materials with higher strength and stiffness need to be selected; for small and medium-sized rolling mills, materials with relatively low strength and stiffness can be selected. At the same time, it is also necessary to pay attention to the quality and performance of materials and carry out quality inspection and control.

Rolling mill stands are usually made of high-strength steel or steel castings, which have high strength and stiffness and can withstand various forces and torques during the rolling process. At the same time, the quality and performance of materials will also affect the accuracy and service life of the frame.

Manufacturing Process of Rolling Mill Stand

The manufacturing process of rolling mill stands includes steel plate welding, steel casting processing, mechanical processing, etc. During the manufacturing process, attention needs to be paid to ensuring the accuracy and stability of the frame, as well as quality inspection and control.

Installation and Debugging of Rolling Mill Stand

During the installation and debugging process of the rolling mill stand, attention must be paid to ensuring its position accuracy and stability, and parameter adjustment and optimization must be performed at the same time to ensure the stability of the rolling process and product quality.

Maintenance of Rolling Mill Stand

The rolling mill frame requires regular maintenance, including checking and adjusting the tightening and lubrication of parts and components, to ensure its normal operation and service life.

At Last

In short, understanding the type, structure, materials, manufacturing process, installation, commissioning and maintenance of the rolling mill frame can help you better understand its function, and make more accurate choices when purchasing a rolling mill stand or building a rebar rolling mill production line.

0 notes

Text

TIANXIANGHAO STEEL PIPE MACHINE

Steel pipe machine is a manufacturing system that is used to produce different types of steel pipes, such as spiral welded pipes, longitudinal welded pipes, seamless pipes, and galvanized pipes. The spiral pipe machine for sale used in the steel pipe production process are designed to form, weld, and shape the steel pipes according to the required specifications and standards. The production of steel pipes is vital for various industries such as oil and gas, water supply, construction, and transportation. Overall, steel pipe production lines are essential for meeting the demand for high-quality steel pipes in various industries.

TIANXIANGHAO STEEL PIPE MACHINE FOR SALE

Spiral Welded Pipe Production Line

Large Diameter Spiral Welded Pipe Production Line

Small Diameter Spiral Welded Pipe Production Line

Heavy Duty Spiral Welded Pipe Production Line

Thin Wall Spiral Welded Pipe Production Line

Stainless Steel Spiral Welded Pipe Production Line

Steel Pipe Hydrostatic Pressure Testing Machine

Hydrostatic Pressure Testing Machine for Large Diameter Pipe

Hydrostatic Pressure Testing Machine for Small Diameter Pipe

Hydrostatic Pressure Testing Machine for Ultra High Pressure Steel Pipe

Steel Pipe Chamfering Machine

Chamfering Machine for Large Diameter Steel Pipe End

Chamfering Machine for Small Diameter Steel Pipe End

Double Station Chamfering Machine for Steel Pipe

Automatic Steel Pipe Chamfering Machine

High Frenquency Welded Steel Pipe Production Line

High Frenquency Welded Pipe Production Line for Small Diameter Pipe

Steel Pipe Delivery Machine

Steel Pipe Conveyor

Steel Pipe Rotating Roller Table

Steel Pipe Puller

Steel Pipe Dropper

Steel Pipe Storage Rack

Anti-corrosion and Insulated Steel Pipe Production Line

3PE Anti-corrosion Steel Pipe Production Line

Plastic Coated Steel Pipe Anti-Corrosion Production Line

Polyethylene (PE) Insulated Steel Pipe Production Line

Steel Pipe Testing & Expanding Machine

Steel Pipe End Expanding Machine

Industrial X Ray Equipment for Steel Pipe Inspection

Ultrasonic Steel Pipe Testing Equipment

Advantages Of Using Steel Pipe Machines

Increased precision: Steel pipe machines can produce pipes with high precision and accuracy. The accuracy of the dimensions and thicknesses of the pipes ensures uniformity and consistency, making it easier to install and maintain the pipes.

Efficiency: Steel pipe machines can produce large quantities of pipes in a short amount of time, increasing overall production efficiency. Automated processes help to reduce labor costs and increase output.

Customization: Steel pipe machines can manufacture pipes of various sizes, shapes, and thicknesses, offering flexibility in terms of customization.

Quality: Steel pipe machines ensure that the pipes manufactured are of consistent quality, with no defects or variations. This ensures that the pipes are safe and durable, reducing the need for repairs or replacements.

Sustainability: Steel pipe machines use efficient, environmentally friendly processes, minimizing waste and improving sustainability. Steel pipes are also highly recyclable, reducing the environmental impact of manufacturing and disposal.

ADVANCEMENTS AND INNOVATIONS IN STEEL PIPE MACHINE TECHNOLOGY

Advancements and innovations in steel pipe machine technology have led to significant improvements in the manufacturing process, resulting in better quality and efficiency. Here are some of the recent advancements and innovations in steel pipe machine technology:

1. CNC technology - With the help of computer numerical control (CNC) technology, pipe production line can be programmed to produce highly precise and complex pipe shapes. This technology reduces the need for manual labor and increases production efficiency.

2. Laser-cutting systems - Laser cutting systems are used to cut and shape pipes with high accuracy and precision. They help to reduce material waste and increase production efficiency.

3. Automation - Automation has become a common feature in steel pipe machines, improving production efficiency and reducing labor costs. Automated robotic systems can complete tasks such as loading and unloading raw materials or finished products.

4. Advanced welding technology - Advanced welding technology of spiral welded pipe production line has been developed to improve the strength and durability of steel pipes. These technologies include plasma welding, TIG/MIG welding, and high-frequency welding.

5. Non-destructive testing - Non-destructive testing technology is used to ensure the quality and consistency of manufactured pipes. These techniques, such as ultrasonic testing or magnetic particle inspection of our ultrasonic pipe inspection equipment, can detect defects and inconsistencies in the production process.

6. Additive manufacturing - 3D printing has been recently explored as a potential alternative method for manufacturing steel pipes. While still in its early stages, this technology has the potential to revolutionize the industry by producing complex pipes in a more efficient and automated way.

Overall, these advancements have revolutionized the steel pipe industry, improving productivity, efficiency, and quality. The industry is likely to continue to invest in these technologies, leading to more innovative manufacturing processes in the future.

THE IMPORTANCE OF QUALITY CONTROL IN STEEL PIPE MANUFACTURING

Quality control is an essential aspect of steel pipe manufacturing. It ensures that the final product meets the required standards and specifications. Quality control helps in maintaining consistency in the manufacturing process, reducing manufacturing costs, and enhancing customer satisfaction. Below are some reasons why quality control is critical in steel pipe manufacturing.

1. Compliance with Standards: Steel pipes are used in various industries, and the required standards may differ from one industry to another. Quality control ensures that the pipes meet the specified standards, preventing issues such as pipe failures, equipment damage, and product recalls.

2. Consistency in Manufacturing: Quality control establishes a consistent manufacturing process, resulting in products of uniform quality. This consistency helps to prevent defects, reduce scrap rates, and increase efficiency.

3. Cost Savings: By preventing defects, quality control can reduce costs associated with production, inspection, and rework. It also helps to minimize the risk of product recalls, thus avoiding significant financial losses.

4. Customer Satisfaction: Quality control ensures that the final product meets customer specifications and expectations. By providing high-quality products, customers are more likely to be satisfied and continue to do business with the manufacturer.

5. Safety: Defective steel pipes can cause significant safety hazards in various industries. Quality control helps to prevent such hazards by ensuring the pipes meet safety standards and are free from defects. In conclusion, quality control is critical in steel pipe manufacturing. It ensures compliance with required standards, establishes consistency in manufacturing, reduces costs, enhances customer satisfaction, and improves safety.

1 note

·

View note

Text

warehouse pallet racking system

1. Structural Components:

Upright Frames: These are vertical columns that support the weight of the racking system. They are typically anchored to the warehouse floor and can vary in height to accommodate different storage needs.

Horizontal Beams: These are horizontal bars that connect the upright frames on each level and support the pallets. Beam lengths can be adjusted to fit various pallet sizes.

Pallet Supports: Wire mesh or wooden decking that sits on top of the horizontal beams and provides a flat surface for the pallets to rest on.

Bracing: Diagonal braces or horizontal braces are used to stabilize the upright frames and ensure the overall structural integrity of the system.

2. Types of Warehouse Pallet Racking Systems:

Selective Racking: This is the most common type of pallet racking. It allows for direct access to each pallet, making it suitable for businesses with a wide variety of SKUs and frequent inventory turnover.

Drive-In/Drive-Through Racking: These systems maximize storage space by allowing forklifts to drive directly into the racking structure. Drive-in racks have one entry point, while drive-through racks have entry and exit points on opposite sides.

Push-Back Racking: This system uses carts or rollers to store multiple pallets deep. When a new pallet is loaded, it pushes the existing pallets back, creating a dynamic storage system.

Pallet Flow Racking: Pallets are loaded on one end and flow down inclined rollers or wheels to the other end. This system is suitable for FIFO (First-In, First-Out) inventory management.

Cantilever Racking: Designed for the storage of long or irregularly shaped items, such as lumber or pipes, cantilever racks have arms that extend from vertical columns.

Mezzanine Racking: This system involves the construction of an intermediate floor or mezzanine within the warehouse, effectively doubling the storage space.

3. Considerations When Choosing a Warehouse Pallet Racking System:

Inventory Type: Consider the type of goods you are storing, their size, weight, and palletization. Different racking systems are suited for different types of inventory.

Space Utilization: Evaluate the available warehouse space and the vertical height that can be utilized for storage.

Access Needs: Determine whether you require direct access to each pallet (selective racking) or if you can use systems like drive-in or push-back racking.

Inventory Rotation: Consider whether you need FIFO or LIFO (Last-In, First-Out) inventory management, as this will influence the choice of racking system.

Forklift Equipment: Ensure that your forklifts and material handling equipment are compatible with the chosen racking system.

A well-designed warehouse pallet racking system can significantly improve warehouse efficiency, space utilization, and inventory management. It’s crucial to select the right system based on your specific business needs and inventory characteristics. Regular maintenance and safety inspections are also essential to ensure the safe operation of the racking system.

0 notes

Text

Exploring the Range of Bakery Equipment for Sale

Introduction

The world of baking is a harmonious blend of artistry and science, and having the right bakery equipment can make all the difference in producing delectable pastries, bread, and treats. Whether you're launching a new bakery venture or upgrading an existing one, the availability of bakery equipment for sale offers a wide array of tools designed to streamline processes and ensure consistent, high-quality baked goods.

In this article, we delve into the diverse range of bakery equipment available for purchase, empowering bakers to create culinary delights that leave lasting impressions.

Mixing and Preparation Equipment

Stand Mixers: These versatile machines come in various sizes and capacities, aiding in the preparation of dough, batters, and fillings with precision and efficiency.

Planetary Mixers: Designed for heavy-duty mixing, they are ideal for larger batches of dough and can handle various attachments like dough hooks and whisks.

Dough Sheeters: These machines flatten dough to desired thicknesses, facilitating the production of consistent pie crusts, puff pastry, and laminated dough.

Dividers and Rounders: Essential for portioning and shaping dough, these machines ensure uniformity and save time during bulk production.

Ovens and Baking Equipment for sale

Convection Ovens: Offering even heat distribution, convection ovens are suitable for baking a variety of items including cookies, muffins, and bread.

Deck Ovens: Mimicking the traditional brick oven, deck ovens are favored for artisanal bread and pizza baking due to their ability to retain high heat.

Rotary Rack Ovens: Ideal for large-scale baking, these ovens accommodate multiple racks and provide consistent results for a range of baked goods.

Proofing Cabinets: These units create controlled environments for dough to rise, ensuring optimal fermentation before baking.

Pastry and Decorating Equipment

Pastry Bags and Tips: Essential for precise piping and decoration of cakes, cupcakes, and pastries.

Dough Cutters and Rollers: These tools help shape and cut dough for croissants, Danish pastries, and more.

Cake Decorating Turntables: Enabling smooth and even icing application, these turntables are a must-have for cake decoration.

Cooling and Display Equipment

Bakery Racks and Shelves: Designed to accommodate trays and pans, these racks aid in cooling freshly baked goods.

Display Cases: Showcasing your creations effectively, these cases help attract customers and maintain product freshness.

Choosing the Right Equipment

Assess Your Needs: Determine the volume and variety of baked goods you plan to produce to guide your equipment choices.

Quality and Durability: Opt for reliable brands and equipment that are built to withstand the demands of a commercial bakery.

Budget Considerations: While investing in high-quality equipment is crucial, balancing costs with your business plan is equally important.

Space Requirements: Ensure your bakery has adequate space for the equipment you intend to purchase.

Conclusion

Bakery equipment for sale opens doors to culinary possibilities and business growth. Whether you're kneading dough, baking exquisite pastries, or decorating elaborate cakes, the right equipment can elevate your creations to new heights. By carefully selecting and investing in high-quality tools, you're setting the stage for a successful bakery venture that delights customers and sets your bakery apart in a competitive market.

0 notes

Text

15 bathroom storage ideas for organization

Most bathrooms in typical apartments are not known for their size or convenience, which complicates storage in the bathroom. We will consider several ideas that will help to place necessary items more ergonomically. Vanities If the bathroom is small, the space under the sink should be used to its maximum. Vanities can have a base, stand on legs, or be wall-mounted, which reduces storage space but facilitates cleaning. When choosing a vanity, it's important to take into consideration the size of the bathroom: the wider the furniture, the more space is used for storage. Drawers These designs are handy because they make it easier to access the contents: when you open a deep drawer, all the items are visible, rather than hidden in the far corners. A pull-out design is invaluable in niche cabinets and under-sink vanities. Inside, you can place not just toiletries, but also outlets for a curling iron or hairdryer. The photo shows a design with a well-thought-out system for storing electrical appliances, household chemicals, and a basket for laundry. Wall Cabinets Closed cabinets that hang on the wall are an essential element of a bathroom storage system. They can be located above the washing machine, toilet, or sink. Behind their facades, cabinets hide tubes and jars of cosmetics that you should not leave in sight. Cabinets with mirror doors are particularly functional. Open Shelves On compact shelves, people usually store items that should always be within reach (shampoos and soap), as well as decor that emphasizes the individuality of the interior. The advantage of shelves is that they can be placed in any area: above the bath, above the washing machine or door, in the corner. For example, chrome corner shelves are handy because they take up little space, have hooks for sponges, and can be attached without drilling. The photo shows bathroom shelves made by hand. Built-in Shelves Even a small recess in the wall can be used for storage, especially in a small bathroom. The wooden shelf shown in the first photo has become the main highlight of the interior. But if you don't want to leave most items in sight, you can close the design by attaching fabric or a roller blind. Freestanding Shelves This storage idea is suitable for spacious bathrooms. Open structures look light and stylish, they can be rearranged if necessary, and the contents can be changed depending on needs. Keep in mind that an abundance of items makes a room cluttered, so it is recommended to use baskets and boxes to maintain order. Niches Also readDesign of niches in the bathroom If during renovation open pipes were hidden in a drywall box, recesses may have formed in some places. Usually, they are not left unutilized and are transformed into shelves for storing various bathroom items. Shelf-niches can consist of several parts or form a whole structure. Wheeled Shelves Mobile racks are made of metal or plastic and offer a wide choice of shapes. Wheels allow using them anywhere, and compact sizes - fit even in a small area. Storage on Rails You can use this convenient device as a bar for drying towels and sponges, attaching baskets to it, and hanging hooks for various items. A rail allows for optimal storage organization even in the smallest bathroom. In the photo is a white rail matching the tile, mounted without drilling. Radius Shelves For owners of tulip-shaped sinks, this accessory is a real find, as the space under the plumbing fixture with a leg often remains empty. The curved shape of the rack fills the space to the maximum, and movable rollers allow you to adjust the position of the structure. Storage under the Tub You should plan such a system at the initial stage of renovation, as it is made to order according to the size of the tub. It could be open shelves, folding or sliding drawers. There is enough space under the tub to store not only cleaning products but also a basin. The photo shows a combined bathroom with shelves built in next to the tub. Towel Ladder This fashionable accessory instantly turns the bathroom stylish and unique. It's the optimal solution for towel storage and drying in a spacious bathroom. Pockets Pockets for storing tubes, combs and other small items are one of the most budget-friendly and useful life hacks. You can hang them on the wall, door, or shower curtain rod. Baskets Eco-style enthusiasts, as well as fans of Scandinavian and rustic design, use baskets in the bathroom not only for dirty laundry storage. Woven containers can be placed on open shelves to add coziness to the interior, hidden in cabinets for sorting items, or hung on the wall. The photo shows a basket with a hinged lid, complementing an interior with elements of rustic style. Compact Dresser Another interesting bathroom storage idea is a portable plastic dresser with sliding drawers. This accessory comes in handy if you need additional storage space in the bathroom: you can place the dresser on the washing machine, toilet table, or use it in a country house. Photo Gallery Organizing storage in the bathroom often requires a considerable investment, but the examples reviewed prove that creating a stylish and comfortable interior sometimes only takes a small budget and some imagination. Read the full article

0 notes

Text

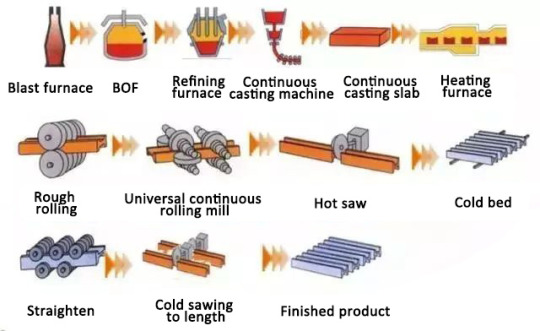

H-Beam Production Process

Generally, small and medium-sized (H400×200 and below) H-beams mostly use square billets and rectangular billets, and larger-sized (H400×200 and above) H-beams mostly use special-shaped billets, and continuous casting billets can be used for both rectangular and special-shaped billets. After being weighed, the billet from continuous casting is loaded into a step-by-step (or pusher type, there are relatively few pusher furnaces used to produce section steel) heating furnace and heated to 1200-1250°C to be released from the furnace. Most of the walking heating furnaces adopt double preheating burners arranged up and down, which can provide the best temperature control for billets of different specifications and save fuel.

After the billet comes out of the furnace, it is first descaled with 10-25MPa high-pressure water, and then sent to the billet mill for rolling. The blanking machine is generally a two-roll reversible rolling mill (there is also a three-roll rolling mill for small steel, but the process limitation is not conducive to the production organization), and the blanking machine needs to be rolled for about 5 to 13 passes, and then the rolled piece The hot saw is only responsible for cutting off the unformed part of the head, but the flying shear can cut the head, segment and tail. The rolled pieces after head cutting are sent to the finishing rolling mill for rolling. The finishing rolling of small-sized section steel of major domestic manufacturers adopts the form of continuous rolling, and the finishing rolling of large-size section steel is reversible rolling. After finishing rolling, it is generally sent directly to the cooling bed for cooling, but there are also sections that are segmented before the cooling bed or cut after the cooling bed. Due to the relatively large difference between the thickness of the legs and the thickness of the waist of large-sized section steel, if it is placed flat, the cooling speed of the waist and legs is inconsistent, causing waves at the waist, so vertical cooling is generally used. However, the mainstream manufacturers of small-sized H-beams all adopt stepping tooth cooling beds, which are placed obliquely on the rack. Using stepping tooth cooling beds can not only reduce the defects caused by the original chain hauling mechanism, but also easily control the cooling of steel speed. The cooled H-beam is sent to the straightening machine for straightening. Due to the large section modulus of H-beams, 8-roll, 9-roll or 10-roll straightening machines are generally used for straightening, and the maximum distance between straightening rollers can reach 2200mm. After being straightened, the steel is sent to the marshalling stand for grouping and waiting for sawing. After being cut by a cold saw according to a fixed length, it is sent to the inspection table to check the size, shape and surface quality, and then sorted, stacked and bundled. sent to the warehouse. For unqualified products, according to the type of defect, corresponding re-straightening, grinding, welding repair and other treatments will be carried out, and then they will enter the corresponding quality inspection program and then be classified into storage after passing the inspection. In order to improve the operating rate of the rolling mill and reduce the roll changing time, almost all manufacturers adopt a quick roll changing system, that is, the rolls required for the next variety are assembled in advance while producing. When changing rolls, just pull out all the original racks and replace them with new racks that have been installed. Each frame is equipped with a quick connector panel, which includes cooling water, hydraulic pressure, thin oil and dry oil pipe joints and positioning connection devices for connecting rods. The device is easy and fast to disassemble and connect, and the entire roll changing time is about 10-20 minutes. According to the roll changing experience of small steel, the overall roll changing time is generally about 45-70 minutes. Read the full article

0 notes