#Pickling Tanks Manufacturer

Explore tagged Tumblr posts

Text

Water Storage Tanks | Industrial Water Storage Tank - Frontier Polymers

Frontier water tanks are expertly manufactured using LLDPE linear low-density polyethylene to ensure durability and reliability. Our industrial water storage tank resin is specifically chosen for its high ESCR environmental stress crack resistance. guaranteeing a long lifespan for the tank.

We take pride in producing 4-layer UV-stabilized water storage tanks that effectively prevent degradation and cracking. .With our commitment to quality, you can trust that our tanks will meet your needs and provide reliable water storage solutions.

For more information » on Frontier Polymers Pvt Ltd. Visit us & give us a call now » at +91 98 9999 8545 or mail us at [email protected]

#Water Storage Tanks#Water Tank Manufacturers#Triple Layer Water Tank#Industrial Water Storage Tank#Plastic Pickling Tanks

0 notes

Text

Fume Scrubbers Manufacturers - Uk Enviro System

UK Enviro System, a renowned Fume Scrubbers Manufacturers in India. They are known for offering superior fume scrubbers that efficiently manage dangerous pollutants, eliminate particle matter, and neutralise acid gases. For its fume scrubbers, UK Enviro System offers installation, maintenance, and repair services in addition to manufacturing.

Visit: https://frptank.in/fume-scrubber/

1 note

·

View note

Text

Acid Fume Extraction System

Acid Fume Extraction acid fume extraction system, zinc white fume extraction system, acidic fume extraction systems manufacturer, supplier exporter in India. Acid Fume Extraction systems are designed for each application in such a way as to assure adherence to the emission restrictions of the acid fume neutralisation system while providing effective scrubbing.

#acid fume extraction system manufacturer#pickling tanks#pickling plant#galvanizing tank#scrubber system manufacturer#fume extraction system manufacturers in Bangalore#fume extraction system for welding

1 note

·

View note

Text

PP Pickling Tank

A PP Pickling Tank is a kind of tank that very essential for industrial sectors to store liquid, semi-liquid, and gaseous material. PP Tank, and Pickling Tank demanded by many Industrial Sectors.

Established in 1991, Shivas Project is one of the leading PP Pickling Tank, PP Tank Manufacturers, and Pickling Tank Manufacturers in India. We are specialists in manufacturing, supplying, and exporting high-quality tanks that are designed with quality-approved material.

We designed the custom PP Tank, and Pickling Tank solution to the valuable customers' unique needs. Our team works on various production technology to fulfill all the highest satisfaction levels of the customers. If you want to know additional details about the company and our products, then free to call us. Call us @ +(91)-9311332301

Visit Here - https://www.shivasprojects.com/pp-pickling-tanks.html

0 notes

Photo

The use of Polypropylene (PP) Pickling Tanks provides a range of benefits to manufacturing industries across many sectors. From the food and beverage industry to the automotive and aerospace sectors, PP Pickling Tanks are a wise choice for a variety of applications.

#Polypropylene (PP) Pickling Tanks#manufacturing industries#food and beverage industry#automotive and aerospace sectors

0 notes

Text

The Stainless Steel Sheet Manufacturing Industry: A Comprehensive Overview

United Stainless LLP is a leading Stainless Steel Sheet Manufacturer in India. Stainless steel sheet manufacturing is a cornerstone of modern industry, providing a material that is highly versatile, durable, and corrosion-resistant. From construction to automotive, household appliances to aerospace, stainless steel sheets are used in countless applications due to their unique properties. In India, the demand for stainless steel continues to rise, as manufacturers focus on delivering high-quality materials that meet international standards. This blog will explore the Stainless Steel Sheet Manufacturer industry, its process, key players in the market, and the growing demand for stainless steel in India.

Overview of Stainless Steel

Stainless steel is an alloy composed primarily of iron, with at least 10.5% chromium. This chromium content forms a thin, protective oxide layer on the surface of the steel, preventing corrosion and rust. Other elements such as nickel, molybdenum, and nitrogen are often added to enhance specific properties like formability, strength, or corrosion resistance.

The unique characteristics of stainless steel make it an ideal material for various industrial applications. It is durable, recyclable, resistant to heat and chemicals, and has an attractive appearance. These qualities make stainless steel sheets an indispensable material in industries that require strength, hygiene, and long-term durability.

The Manufacturing Process of Stainless Steel Sheets

The SS Sheet Manufacturer in India begins with the melting of raw materials such as iron ore, nickel, and chromium in an electric furnace. The furnace heats the raw materials to extremely high temperatures (up to 1500°C) to melt them together. Once the materials are thoroughly melted and mixed, they are cast into slabs or ingots.

The next stage involves hot rolling the slabs, which reduces the thickness of the steel and shapes it into a sheet. During this process, the slabs are passed through a series of rollers at high temperatures. Once the desired thickness is achieved, the hot-rolled sheet is cooled and annealed (a heat treatment process that increases the material's ductility and reduces its hardness). After annealing, the stainless steel sheet undergoes cold rolling, which refines the surface finish and increases the strength of the material.

Finally, the sheets are cut to size, polished, and undergo surface treatments such as pickling or passivation to remove any impurities or scale from the surface. The result is a high-quality stainless steel sheet that is ready for use in various applications.

Applications of Stainless Steel Sheets

The versatility of stainless steel sheets makes them suitable for a wide range of industries. Some of the major sectors that rely heavily on stainless steel sheets include:

Construction and Architecture: Stainless steel is used in building facades, roofing, cladding, and interior applications. Its corrosion resistance and aesthetic appeal make it a popular choice in modern architectural designs.

Automotive Industry: Stainless steel sheets are used in exhaust systems, catalytic converters, and structural components of vehicles due to their strength, heat resistance, and lightweight properties.

Aerospace Industry: Aircraft components, engine parts, and structural components are made from stainless steel sheets because of their durability and ability to withstand extreme temperatures.

Food and Beverage Industry: Stainless steel sheets are used in the manufacture of equipment such as tanks, sinks, and tables, thanks to their hygienic properties and resistance to corrosion.

Medical Industry: Surgical instruments, hospital equipment, and pharmaceutical equipment are often made from stainless steel due to its ability to be easily sterilized.

Household Appliances: Stainless steel sheets are widely used in the production of refrigerators, ovens, dishwashers, and other household appliances because of their sleek appearance, durability, and resistance to staining and rust.

Countries We Supply Stainless Steel Sheet

Stainless Steel Sheet Manufacturer in Vietnam

Stainless Steel Sheet Manufacturer in Taiwan

Stainless Steel Sheets Manufacturers USA

Stainless Steel Sheet Suppliers in UAE

Stainless Steel Sheet Suppliers in Srilanka

Stainless Steel Sheet Suppliers in Qatar

Growing Demand for Stainless Steel Sheets in India

India’s growing industrialization and urbanization have led to an increased demand for stainless steel sheets. Industries such as construction, automotive, and infrastructure are driving this demand, especially as the government invests heavily in infrastructure projects like roads, bridges, and airports. Additionally, the automotive industry’s shift towards electric vehicles is creating new opportunities for SS Sheet Manufacturer.

The rising awareness of sustainability and recycling is also contributing to the demand for stainless steel, as it is 100% recyclable. Furthermore, stainless steel’s long lifecycle and minimal maintenance requirements make it a cost-effective solution for various industries.

Conclusion

Stainless Steel Sheet Supplier in India is a dynamic and growing industry in India, supported by a strong industrial base and increasing demand across multiple sectors. With advancements in technology and a focus on sustainability, manufacturers are continuously improving the quality of stainless steel sheets to meet global standards. As industries expand, the Stainless Steel Sheet Supplier industry will continue to play a pivotal role in supporting India's economic growth and infrastructure development.

#Stainless Steel Sheet Manufacturer in India#ss sheet manufacturer in india#Stainless Steel Sheet Manufacturer#Stainless Steel Sheet

0 notes

Text

Inconel 600 or Monel Fasteners: Choosing the Best Alloy for Your Application

Choosing the right fastener material is crucial for ensuring longevity and affects your project's overall performance. When it comes to high-performance applications that demand resistance to corrosion, high temperatures, and harsh environments, two alloys stand out: Inconel 600 and Monel.

With This blog let’s help you make the right decision for your project: Inconel 600 or Monel fasteners

Let’s begin with understanding both these alloy types and their ideal industry applications:

Inconel 600

Inconel 600 is a nickel-chromium-iron superalloy known for its exceptional strength and resistance to oxidation, creep rupture, and carburization. Its high nickel content makes it highly resistant to corrosion in a wide range of environments, including oxidizing, reducing, and acidic conditions. Here at Online Fittings, we offer a variety of Inconel 600 fasteners, including bolts, nuts, washers, and screws, in various sizes and thread types to meet your specific needs.

Inconel 600 is the ideal choice for applications requiring exceptional high-temperature strength, oxidation resistance, and resistance to creep rupture. Its ability to withstand harsh environments makes it suitable for use in:

1. Jet engines 2. Nuclear reactors 3. Chemical processing equipment 4. Gas turbines 5. Heat exchangers 6. Furnace components 7. Cryogenic applications (at limited temperatures)

Monel

Monel is a nickel-copper alloy that offers excellent resistance to various corrosive media, including seawater, sulfuric acid, and hydrofluoric acid. It also boasts superior mechanical properties at both high and cryogenic temperatures. You have the liberty to choose from our online vast selection of Monel fasteners, including hex cap screws, square neck bolts, U-bolts, and coupling nuts, ensuring you have the right fastener for your application.

Monel is ideally used in industries that demand superior resistance to saltwater corrosion, sulfuric acid, and hydrofluoric acid. Its good strength at both high and low temperatures makes it a versatile option for:

1. Marine equipment 2. Offshore oil and gas rigs 3. Chemical processing plants 4. Pulp and paper mills 5. Pickling tanks 6. Desalination plants

Key Factors to Consider When Choosing Between Inconel 600 and Monel Fasteners

Here’s a breakdown of key factors to consider whilst deciding between Inconel 600 and Monel fasteners:

Property Inconel 600 Monel

Maximum Service Temperature, 1600°F (871°C), 800°F (427°C)

Strength

Higher, Lower

Oxidation Resistance

Excellent, Excellent

Chloride Stress Cracking

Good, Excellent

Cost

Higher, Lower

Additional pointers to consider:

1. Size and thread type: Ensure the fasteners are the correct size and thread type for your application. Look for an alloy fastener manufacturer who can customize each inch for your requirements.

2. Head style: The head style of the fastener (e.g., hex head, socket head) should be compatible with the installation tools and space constraints of your application.

3. Surface finish: Consider the desired surface finish (e.g., plain, zinc-plated) for factors like corrosion resistance and aesthetics.

Why Choose Online Fittings for Your Inconel 600 and Monel Fastener Needs?

At Online Fittings, we are committed to providing our customers with the highest quality Inconel 600 and Monel fasteners. We offer a comprehensive selection of fasteners in various sizes, thread types, and head styles to meet the demands of your project.

The experts at Online Fittings are always here to help you select the right fasteners to ensure the success of your project.

Let Online Fittings be your one-stop shop for all your Inconel 600 and Monel fastener needs. Contact us today to discuss your project requirements and receive a custom quote quote.

0 notes

Text

PP Spiral Tank Manufacturer

Sunfiber is a PP Spiral Tank Manufacturer in Ahmedabad, Gujarat. Sunfiber is Founded in 2017 in Ahmedabad, Gujarat, India. We are Manufacturer, Exporter and Supplier of HDPE Spiral Tank, HDPE Storage Tank, HDPE Reactor, HDPE Vessel, HDPE Nutsche, PP Spiral Tank, PP Storage Tank, PP Reactor, PP Vessel, PP Nutsche, Stirrer, FRP Blower, PP FRP Blower, HDPE Scrubber, PP Scrubber, HDPE Pipes, HDPE Fittings, PPRC Pipes & Fittings, FRP Ventury, PP Pump, PP Valve. Overview: We offer a diverse selection including PP square tanks, HDPE rectangular tanks, PP horizontal tanks, and HDPE pickling tanks. Our spiral tanks excel in various industrial processes, prized for their corrosion resistance, exceptional impact strength, and low maintenance needs. They extrude high-density polyethylene (HDPE) or polypropylene (PP) as strips at 220°C onto a pre-heated, rotating mandrel. Each layer melds seamlessly, creating a cylindrical structure with distinct outer rings and a smooth interior finish. They tailor tank wall thickness for liquid storage and weld the base to the cylinder using advanced extrusion. We offer a wide array of accessories to tailor each tank precisely to your requirements. Sunfiber is a PP Spiral Tank Manufacturer in Ahmedabad, Gujarat, and a Supplier of PP Spiral Tank in Madhya Pradesh including locations like Indore, Bhopal, Jabalpur, Gwalior, Ujjain, Sagar, Dewas, Satna, Ratlam, Rewa, Katni, Singrauli, Burhanpur, Khandwa, Bhind, Chhindwara, Guna, Shivpuri, Vidisha, Chhatarpur, Damoh, Mandsaur, Khargone, Neemuch, Pithampur, Narmadapuram, Itarsi, Sehore, Morena, Betul, Seoni, Datia, Nagda, Dindori. For additional information, please feel free to contact us. View Product: Click Here Read the full article

0 notes

Text

Comparative Analysis of HDPE and Polypropylene Components

In industrial applications, the selection of material is crucial for ensuring durability and efficiency. High-Density Polyethylene (HDPE) and Polypropylene (PP) are two prominent thermoplastics widely utilized due to their robust properties. This article presents an in-depth comparison of HDPE and PP, examining their properties, applications, and material selection criteria.

Material Properties

High-Density Polyethylene (HDPE):

HDPE, a polymer derived from ethylene, is distinguished by its high strength-to-density ratio. Key properties include:

Chemical Resistance: HDPE’s resilience against a broad spectrum of chemicals makes it suitable for manufacturing containers and piping systems exposed to harsh substances.

Temperature Resistance: HDPE operates effectively within a temperature range extending from slightly above freezing to boiling points.

Durability: The material’s toughness and impact resistance ensure long-term performance in various industrial applications.

Flexibility: Despite its rigidity, HDPE possesses a degree of flexibility that allows it to absorb impact forces.

Polypropylene (PP):

PP, synthesized from the monomer propylene, shares similarities with HDPE but exhibits distinct characteristics:

Chemical Resistance: PP’s excellent chemical resistance makes it ideal for fabricating containers and tanks for chemical storage.

Temperature Range: PP outperforms HDPE in high-temperature environments due to its higher melting point.

Strength and Rigidity: PP is more rigid than HDPE, providing greater structural integrity for applications requiring stiffness.

Molding and Joining: PP’s ease of molding into complex shapes and its ability to be joined by welding techniques (excluding HF-welding) enhance its versatility.

Applications

The application of HDPE and PP varies based on their inherent properties:

HDPE Applications:

Industrial Equipment: Utilized in the construction of tanks, pipes, and valves, HDPE’s chemical resistance and durability are pivotal.

Packaging: HDPE’s robustness makes it suitable for producing bottles, containers, and transport boxes that require strength and durability.

Consumer Goods: HDPE’s ability to withstand environmental wear makes it ideal for products such as toys and outdoor furniture.

PP Applications:

PP PICKLING Tank: Designed for the pickling process, these tanks leverage PP’s chemical resistance and durability to withstand harsh conditions.

Automotive Parts: PP’s lightweight and rigidity contribute to automotive components that improve fuel efficiency and performance.

Packaging Solutions: PP is used to manufacture chemically resistant bottles, food-grade containers, and durable transport solutions.

Conclusion

The selection between HDPE and PP is dictated by specific application requirements. HDPE is favoured for its exceptional durability and chemical resistance, making it suitable for a wide range of industrial and consumer products. PP’s superior temperature tolerance and rigidity make it ideal for high-temperature applications and components requiring structural stiffness. By understanding the unique properties and applications of each material, informed decisions can be made to optimize product performance and longevity.

0 notes

Text

Understanding Carbon Steel Flanges: Applications and Manufacturing

Carbon metal flanges are important components in piping systems, widely applied in numerous industries for connecting pipes, valves, pumps, and one-of-a-kind equipment. They play an important function in making sure the integrity and efficiency of fluid or fuel transfer within a system.

In this weblog put up, we are able to delve into the traits, applications, and production techniques of carbon metallic flanges, losing mild on their importance in diverse business settings.

Introduction to Carbon Steel Flanges:

Carbon metal flanges are piping additives which can be often crafted from carbon metal, an alloy consisting especially of iron and carbon. These flanges come in various shapes, sizes, and strain scores to accommodate different piping necessities. Common kinds of carbon metallic flanges consist of weld neck, slip-on, socket weld, threaded, and blind flanges, each serving precise purposes in piping systems.

Characteristics of Carbon Steel Flanges:

1. Strength and Durability: Carbon steel possesses top notch mechanical homes, inclusive of immoderate tensile electricity and hardness, making carbon steel flanges rather durable and suitable for traumatic applications.

2. Corrosion Resistance: While carbon metal is vulnerable to corrosion, proper floor treatment and coating can beautify the corrosion resistance of carbon metal flanges, extending their provider existence in corrosive environments.

3. Versatility: Carbon metal flanges are properly applicable with a sizable kind of fluids, gases, and temperatures, making them versatile additives in severa industries together with oil and fuel, petrochemical, electricity generation, and creation.

Applications of Carbon Steel Flanges:

1. Oil and Gas Industry: Carbon metallic flanges are considerably utilized in upstream, midstream, and downstream operations inside the oil and gas organization, including drilling, manufacturing, refining, and transportation of hydrocarbons.

2. Petrochemical Industry: In petrochemical plant life, carbon metallic flanges facilitate the switch of chemical substances, solvents, and gases among processing gadgets, reactors, distillation columns, and garage tanks.

3. Power Generation: Carbon steel flanges are essential additives in energy plant life, wherein they are a part of piping structures in boilers, turbines, condensers, and other essential devices involved in strength technology.

4. Water Treatment: Carbon metallic flanges play a key characteristic in water remedy centers, in which they are used to connect pipes, valves, and pumps in water delivery structures, wastewater treatment plant life, and desalination flowers.

Manufacturing Process of Carbon Steel Flanges:

The production of carbon metallic flanges includes numerous steps, collectively with:

1. Material Selection: High-tremendous carbon steel, normally ASTM A105 or ASTM A350, is chosen for fabricating flanges, making sure the preferred mechanical houses and corrosion resistance.

2. Forming: The selected carbon metallic cloth is heated and shaped using forging, casting, or machining strategies to achieve the desired flange form and dimensions.

3. Machining: The fashioned flange blanks go through precision machining operations including turning, drilling, and milling to gain smooth surfaces, accurate dimensions, and proper sealing surfaces.

4. Heat Treatment: Heat treatment tactics inclusive of annealing, normalizing, or quenching and tempering can be applied to decorate the mechanical houses and durability of the flanges.

5. Surface Treatment: The finished flanges also can undergo ground treatment techniques which consist of pickling, passivation, or coating to enhance corrosion resistance and ground give up.

Conclusion:

Carbon metal flanges are critical additives in piping systems for the duration of numerous industries because of their electricity, sturdiness, and flexibility. Whether in oil and gasoline, petrochemical, strength era, or water treatment packages, carbon metal flanges play an important function in facilitating the inexperienced and reliable switch of fluids and gases. Understanding the characteristics, packages, and manufacturing gadget of carbon steel flanges is important for ensuring their right choice, installation, and performance in business settings.

0 notes

Text

Hot Dipped Galvanized Tank: Know About The Features And Advantages Of The Material

If you are looking for the best liquid storage solutions in any industry, Hot dipped galvanized tank in Johanasburg is the appropriate solution for you. You have already seen other varieties available on the market, but these square-shaped steel tanks are ready affordable and beneficial option for most of the industry owners. Hot-dip galvanized is an effective metal anti-corrosion. Rust steel immersed in liquid zinc melts at around 500 °C, and steel members are attached to the surface of the zinc layer, which performs the purpose of anti-corrosion.

In addition, Simple hot-dip galvanizing technology can significantly increase the service life of the metal. We will tell you about the methods of metal coating and the types of equipment used.

What Is The Process Of Making A Hot Dipped Galvanized Tank?

Hot dip galvanizing is a process of coating iron and steel with zinc, which bonds with the surface of the base metal in a bath of molten zinc at a temperature of about 449 degrees (840 degrees F) and results in a physical bond between zinc and iron. In nature, pure zinc reacts with oxygen to form zinc oxide (ZnO), which further reacts with carbon dioxide to form zinc carbonate (ZnCO3) which protects the steel underneath from further corrosion.

Features Of Hot Dipped Galvanized Coating

The main of this material is widely used in applications where corrosion resistance is required without the cost of stainless steel and is therefore considered superior in terms of cost and life cycle. The signature of galvanizing is the pattern of crystallization on the surface of the metal, and the zinc coating will corrode completely before the underlying steel begins to corrode. The cost of hot-dip galvanizing is much lower than painting or powder coating. Along with the hot-dip galvanizing tank, the HDG steel water tank in Johanasburg has been used around the world for more than a century because it provides long-lasting, low-maintenance corrosion protection.

Steps Of Hot Galvanizing

Hot-dip galvanizing is the process of applying a protective zinc coating to a welded metal structure by immersing it in a bath of molten zinc. There are three main steps in the hot-dip galvanizing process:

Surface Preparation For Hot-dip Galvanizing:

When manufactured metal structures enter production for galvanizing, they are suspended using wire or equipment on a technological crossbeam, which is subsequently moved by cranes.

The steel products then undergo a series of three preparation steps: degreasing, pickling, and fluxing. Degreasing removes dirt, oil, and organic residues, while acid etching removes scale and iron oxide.

The final surface preparation step, fluxing, removes any remaining oxides and coats the steel with a protective layer to prevent further oxidation before galvanizing. Proper preparation of the product is very important so that the zinc will not react with a contaminated steel surface.

Galvanizing:

After surface preparation, the steel structure is immersed in a molten bath containing at least 98% zinc. The structure is lowered at an angle that allows air to escape from tubular molds or other pockets so that the zinc can circulate freely within the product. While the part is in the galvanizing bath, the iron in the steel reacts with the zinc to form an iron-zinc bimetallic layer and an outer layer of pure zinc.

Control:

The final step is quality control of the coating. In the first stage, a visual check of the quality of the coating is carried out. At the next stage, the thickness of the zinc coating is monitored using a magnetic thickness gauge. The coating parameters are assessed for their compliance with the requirements of GOST 9.307-89.

Advantages Of Using Hot Galvanized Coating On Tank

Hot-dip galvanizing provides several benefits to the tank it protects.

Low processing cost: hot-dip galvanized anti-rust cost is lower than the cost of other paint coatings.

Durable: the standard thickness of hot-dip galvanized rust can be maintained for 50 years or more in a rural environment without having to patch. Standard hot dip galvanized rust layer can be maintained for 20 years in urban or offshore areas without having to patch.

Good reliability: the galvanized layer with steel is metallurgically bonded to become part of the steel surface and therefore a more reliable persistent coating.

The hardness of the coating: zinc coating forms a special metallurgical structure, this structure can withstand the transportation and use of mechanical damage.

Complete protection: plated parts Each part can be plated with zinc, even the recesses, sharp corners, and hiding places can be fully protected.

Saving Time and Effort: The galvanizing process is faster than other coating construction methods and can avoid the brushing time required on-site after installation.

All these and other benefits provide a Hot dipped galvanized tank with a long service life without additional maintenance.

Source link: https://klighthouse.com/hot-dipped-galvanized-tank-know-about-the-features-and-advantages-of-the-material/

0 notes

Text

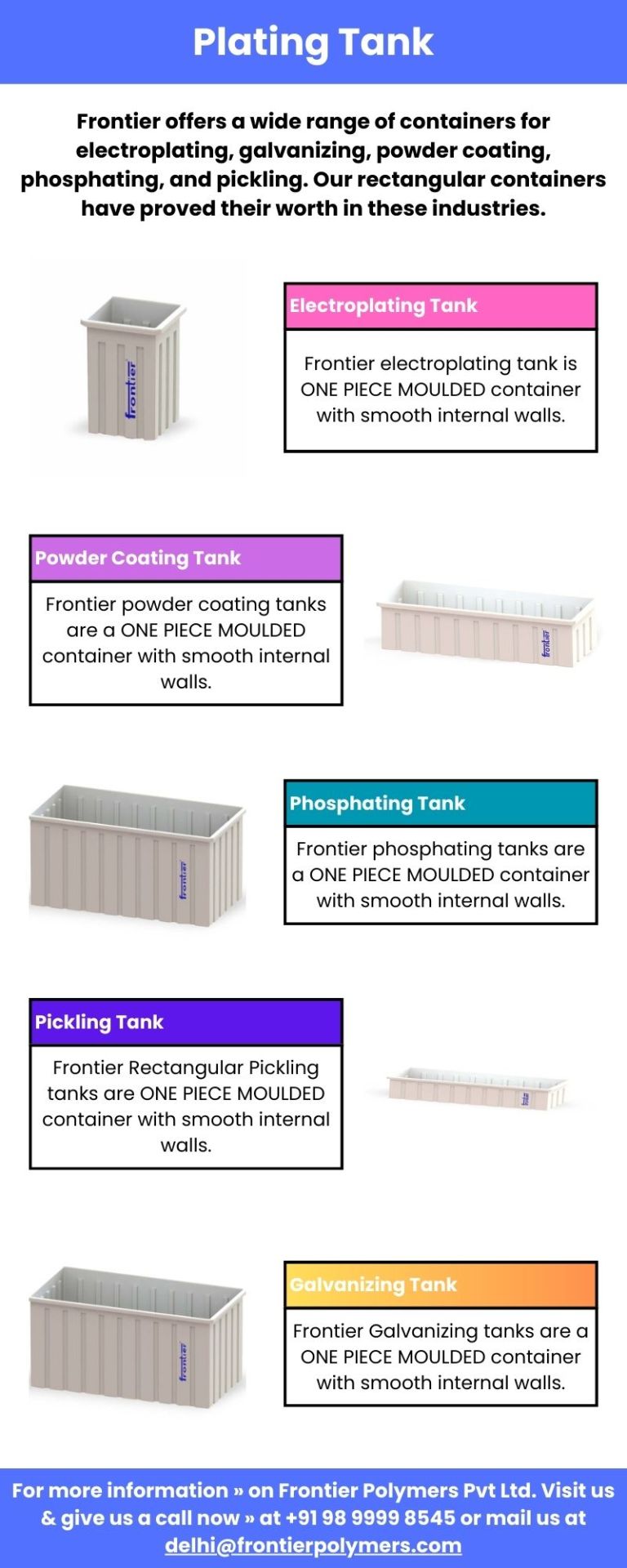

Plating | Electroplating Tank | Powder Coating Container - Frontier Polymers

Explore top-quality Plating Tanks at frontierpolymers.com! Our range includes Galvanizing Tanks, Electroplating Tanks, Powder Coating Containers, and Pickling Tanks. Crafted with precision, our Plating Tanks meet the highest industry standards. Whether it's Galvanizing, Electroplating, Powder Coating, or Pickling, our tanks ensure optimal performance. Durable and corrosion-resistant, these tanks are designed to withstand various chemical processes.

Elevate your industrial processes with our reliable Plating Tanks that guarantee efficiency and longevity. Choose Frontier Polymers for cutting-edge solutions in Plating Tanks and enhance your manufacturing operations.

For more information » on Frontier Polymers Pvt Ltd. Visit us & give us a call now » at +91 98 9999 8545 or mail us at [email protected]

0 notes

Text

Pickling Tank Manufacturers

Shivas Projects is India's trusted and experienced brand, We are India's prominent Pickling Plant Manufacturers & Suppliers. Offer a superior range of Pickling Plant that are designed by high professionals.

We are using high-quality raw materials and multi-advanced technology in the manufacturing process. All categories of Pickling Plant are available as per national and international quality standards. Most Affordable and best to fulfill to precise requirements of our clients. Visit Here - https://www.shivasprojects.com/pp-pickling-tanks.html

0 notes

Text

welded Insulated container

DSW welded Insulated container

supplies dewars and cryogenic tanks to safely contain liquefied gases such as nitrogen, oxygen, argon and carbon dioxide. These gases are stored at extremely low temperatures and in a liquid state.

Category: Dewar CylinderTag: welded Insulated container

Description

Welded Insulated Container

Inspection guarantee of welded Insulated container:

The relevant welding seams will be subject to 100% RT non-destructive testing and penetrant testing (PT) according to the technological requirements of storage tank production. High-purity nitrogen (up to 99.999%) will be used to conduct the strength testing. Finally, advanced helium mass spectrometer leak detectors (with precision up to 2×10-9Pa.L/s) will be used to conduct Helium mass spectrometer leak detection. The inner containers of the storage tanks will be passivated by overall pickling to meet the cleanliness requirements for dangerous goods. Imported ultraviolet black light lamps will be used to make sure that there is no oil stain and other organic impurities in the inner containers. The inner and outer containers, after cleaning, will be assembled at a time interval less than 2.5 hours. After assembling, the inner containers and interlayers will be filled with nitrogen to protect them from dust and organic impurities, so as to ensure the cleanliness. The inner and outer surfaces of the outer containers will be subject to overall sandblasting treatment to meet the requirements of Sa-2.5 standard. When the surfaces of steel plates show the metallic color, a vacuum cleaner will be used to suck off the dust adhered to the surface so as to further ensure the vacuum degree in the interlayer. Special high-quality perlite is used as the insulation material in the interlayer. The perlite will be treated by using our company’s special process before being in the interlayer. All the internal cylinders of welded Insulated container, after manufactured, will be subject to the gas-tight and pressure performance tests. Both the internal and outer cylinders will be subject to rigorous Helium mass spectrum leak detection. After the production is completed, all the pipe openings will be opened to carry out nitrogen purging and replacement, so as to meet the oxygen usage standard. After this, all the pipelines and valves will be sealed and the tanks will be filled with 0.2MPa high-purity nitrogen for protecting the tanks.

0 notes

Text

Lightweight Stainless Steel: Advancements in Strength-to-Weight Ratios

Stainless steel has long been recognized for its exceptional durability and resistance to corrosion. However, the traditional image of stainless steel often conjures thoughts of heavy, industrial-grade materials. In recent years, there have been significant advancements in the development of lightweight stainless steel, which have revolutionized various industries. In this blog, we will delve into the world of lightweight stainless steel, exploring its properties, manufacturing processes, and the remarkable impact it has had on the strength-to-weight ratios in modern engineering.

The Versatility of Stainless Steel Plates and stainless steel Sheets

Before we delve into the lightweight variants of stainless steel, it's essential to understand the role of stainless steel plates and sheets in various applications.

Stainless Steel Plates and Sheets

Stainless steel plates and stainless steel sheets are fundamental building blocks in many industries. They are crafted from high-quality stainless steel, an alloy known for its resistance to corrosion and staining, making it ideal for a wide range of applications. These applications include kitchen appliances, architecture, automotive components, and industrial machinery, among others.

Manufacturing Stainless Steel Products

The process of manufacturing stainless steel products involves several crucial steps:

1. Melting and Refining: High-quality raw materials are melted and refined in furnaces to create a homogeneous stainless steel alloy.

2. Casting: The molten stainless steel is cast into specific shapes, such as billets or slabs.

3. Hot Rolling: The cast material is hot-rolled into sheets or plates of varying thickness.

4. Cold Rolling: If needed, the hot-rolled stainless steel sheets are cold-rolled to achieve the desired thickness and finish.

5. Finishing: The sheets or plates are then subjected to various finishing processes, which can include cutting, pickling, and surface treatments to enhance their properties.

Advancements in Lightweight Stainless Steel

Traditionally, stainless steel is known for its strength and durability. However, the introduction of lightweight stainless steel has expanded its utility into areas where weight is a critical factor. These advancements have been made possible through innovations in alloy composition and manufacturing techniques.

1. Alloy Composition

The development of lightweight stainless steel begins with careful consideration of alloy composition. By altering the ratio of elements such as nickel, chromium, and molybdenum, engineers can create stainless steel sheet metal with reduced density while retaining its strength and corrosion resistance. This lightweight stainless steel is often referred to as "high-strength, low-density stainless steel."

2. Advanced Manufacturing Techniques

In addition to alloy composition, advanced manufacturing techniques have played a pivotal role in producing lightweight stainless steel. Precision control over the rolling and annealing processes ensures that the final product possesses the desired mechanical properties while maintaining a lower weight.

3. Automotive Industry

One of the primary beneficiaries of lightweight stainless steel is the automotive industry. The demand for vehicles that are more fuel-efficient and environmentally friendly has driven the need for lighter materials. Lightweight stainless steel is now being used in the production of components such as exhaust systems, chassis, and body panels, reducing vehicle weight and improving fuel economy.

4. Aerospace Applications

In the aerospace sector, where every ounce counts, lightweight stainless steel has become a game-changer. It is used in the construction of aircraft components, including structural elements and fuel tanks. This not only reduces fuel consumption but also enhances the overall performance and longevity of aircraft.

5. Architecture and Construction

Architects and builders are also embracing lightweight stainless steel for its aesthetic appeal and durability. It is used in the construction of modern, sleek buildings and bridges. The reduced weight makes installation and transportation more efficient, while the material's corrosion resistance ensures longevity in challenging environmental conditions.

6. Consumer Electronics

The consumer electronics industry benefits from lightweight stainless steel in the production of laptops, smartphones, and wearables. This not only reduces the overall weight of these devices but also ensures their robustness and resistance to wear and tear.

The Economic Aspect: Stainless Steel Price

Despite the numerous advantages of lightweight stainless steel, it's important to address the economic aspect, particularly stainless steel prices. While these advanced alloys offer a host of benefits, they can be more expensive to produce than traditional stainless steel. However, the long-term cost savings resulting from improved fuel efficiency, reduced maintenance, and extended product lifespans often justify the initial investment.

The Future of Lightweight Stainless Steel

The development and adoption of lightweight stainless steel are expected to continue growing in the coming years. As industries across the board seek to reduce their environmental impact and enhance efficiency, lightweight stainless steel offers a compelling solution. Its versatility, strength, and resistance to corrosion make it an attractive choice for a wide range of applications.

In conclusion, the evolution of lightweight stainless steel has ushered in a new era in engineering and design. This remarkable material has significantly improved strength-to-weight ratios in industries ranging from automotive to aerospace, contributing to more sustainable and efficient solutions. For those looking to source high-quality stainless steel plates and stain steel sheets, consider Shree Venktesh Wires and Steels Pvt Limited. They have established themselves as leading stockists and distributors of Jindal Stainless Ltd., a reputable provider of stainless steel products. Contact them today to explore the possibilities of lightweight stainless steel in your industry.

#Stainless steel plates#stain steel sheets#manufacturing stainless steel products#stainless steel sheet metal

0 notes