#Physical Vapor Deposition Industry

Explore tagged Tumblr posts

Text

Physical Vapor Deposition Market Outlook: Forecasting Market Trends and Growth for the Coming Years

Latest Research Report on “Physical Vapor Deposition Market” | Survey with Valuable Insights

The 2024 market research report for Physical Vapor Deposition Market offers a comprehensive analysis of the industry, covering key aspects such as trends, opportunities, risks, and drivers. It provides a detailed evaluation of the market's revenue, size, and volume, while also assessing the product portfolios, capacities, and revenues of leading companies. Additionally, the report delves into various industry segments.

According to Straits Research, the global Physical Vapor Deposition Market market size was valued at USD XX Billion in 2023. It is projected to reach from USD XX Billion in 2024 to USD XX Billion by 2032, growing at a CAGR of 5% during the forecast period (2024–2032). The report places particular emphasis on the Industrial Adhesive market, examining its overall size, segment size (including product type, application, and geography), competitive landscape, current status, and development trends. It also offers strategic insights for companies to navigate the challenges posed by COVID-19.

Get a sample PDF of the report at https://straitsresearch.com/report/physical-vapor-deposition-market/request-sample

TOP Key Industry Players of the Physical Vapor Deposition Market

Oerlikon Balzers (Oerlikon Group)

IHI Corporation

Silfex Inc. (Lam Research Corp.)

Impact Coatings AB

Singulus Technologies AG

Applied Materials, Inc.

ULVAC Inc.

Veeco Instruments Inc.

Buhler AG

Semicore Equipment, Inc.

Platit AG

Kurt J Leskar

Physical Vapor Deposition Market Segmental Analysis

As a result of the Physical Vapor Deposition market segmentation, the market is divided into sub-segments based on product type, application, as well as regional and country-level forecasts.

By Technology

Thermal Evaporation

Sputtering

Io Plating

By Category

PVD Equipment

PVD Materials

PVD Services

By Application

Microelectronics

Data Storage

Solar Products

Cutting Tools

Medical Equipment

Others

You can check In-depth Segmentation from here: @ https://straitsresearch.com/report/physical-vapor-deposition-market/request-sample

Regional Analysis Physical Vapor Deposition Market

The regional analysis section of the report offers a thorough examination of the global Physical Vapor Deposition market, detailing the sales growth of various regional and country-level markets. It includes precise volume analysis by country and market size analysis by region for both past and future periods. The report provides an in-depth evaluation of the growth trends and other factors impacting the Physical Vapor Deposition market in key countries, such as the United States, Canada, Mexico, Germany, France, the United Kingdom, Russia, Italy, China, Japan, Korea, India, Southeast Asia, Australia, Brazil, and Saudi Arabia. Moreover, it explores the progress of significant regional markets, including North America, Europe, Asia-Pacific, South America, and the Middle East & Africa.

New Additions in the 2024 Report:

Expanded Industry Overview: The report now includes a more comprehensive and detailed industry overview.

In-Depth Company Profiles: Enhanced profiles providing deeper insights into key industry players.

Customized Reports and Analyst Support: Tailored reports and direct access to analyst support available upon request.

Insights on Market Developments: Updated information on recent market trends and future growth opportunities.

Regional/Country-Specific Customization: Reports tailored to specific regions and countries according to your needs.

Key Highlights

Examine the Physical Vapor Deposition Market: This includes an introduction, analysis of product types and applications, an overview of the market, and a country-by-country market analysis. The study also explores market opportunities, risks, and driving forces.

Profile Manufacturers: The research focuses on manufacturers of Physical Vapor Deposition, including detailed profiles, primary business activities, recent news, sales, pricing, revenue, and market share.

Competitive Landscape Overview: Provide an overview of the competitive landscape among the world's leading manufacturers, highlighting their sales, revenue, and market share.

Market Segmentation Analysis: Illustrate the market segmented by type and application, with detailed breakdowns of sales, price, revenue, market share, and growth rate for each segment.

Regional Market Analysis: Analyze key regions, including North America, Europe, Asia Pacific, the Middle East, and South America. This includes sales, revenue, and market share data segmented by manufacturers, types, and applications.

Production Cost Investigation: Investigate production costs, essential raw materials, and the production methods used in the industry.

Reasons to Purchase This Report:

Access to Comprehensive Information: Gain access to an extensive collection of analysis, research, and data that would be challenging to acquire independently. This report offers valuable insights, saving you considerable time and effort.

Enhanced Decision-Making: Equip yourself with detailed insights into market trends, consumer behavior, and key industry factors. This report provides essential information for strategic planning, including decisions on investments, product development, and marketing strategies.

Achieving Competitive Advantage: Stay ahead in your industry by understanding market dynamics and competitor strategies. This report delivers deep insights into competitor performance and market trends, enabling you to craft effective business strategies and maintain a competitive edge.

Credibility and Reliability: Trust in the expertise of industry professionals and the accuracy of thoroughly researched data. Authored by experts and grounded in rigorous research and analysis, this report enhances credibility and reliability.

Cost-Effective Research: Reduce research expenses by investing in this comprehensive report instead of conducting independent research. It provides a cost-effective means of accessing detailed analysis and insights on a specific topic without requiring extensive resources.

To Understand How Covid-19 Impact Is Covered in This Report - https://straitsresearch.com/report/physical-vapor-deposition-market/request-sample

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Address: 825 3rd Avenue, New York, NY, USA, 10022

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Physical Vapor Deposition Market#Physical Vapor Deposition Market Share#Physical Vapor Deposition Market Size#Physical Vapor Deposition Market Research#Physical Vapor Deposition Industry#What is Physical Vapor Deposition?

0 notes

Note

Are manufactured diamonds really indistinguishable from natural diamonds? And do you have an opinion on whether manufactured diamonds will make natural diamonds obsolete?

Physically? Chemically? Yup, they are in every way, shape and form diamonds. Back in the old days, when they made synthetic diamonds via a process called chemical vapor deposition, it was sometimes possible to distinguish them visually under magnification. Nowadays, the technology has improved to the point where I, a graduate gemologist, cannot visually distinguish between them with any of the tools I have available. Advanced laboratory testing and very expensive equipment is required.

They've certainly caused a shake-up in the diamond industry, with the price of LG crashing tremendously the last two years and taking the price of earth-mined with it. Long term...? Obsolescence is a spectrum. If the earth-mined diamond industry tanks, so will the supply, prices will rise... it'll be interesting to see. I think earth-mined will still have some cachet once things level off. We've had synthetic colored stones for 150 years at this point, and people still want Columbian emeralds.

Now, what I think is SUPER COOL about LG diamonds is that because the material is so cheap, comparatively speaking, they're doing REALLY AWESOME THINGS with them. Like this ring, carved entirely out of a lab grown-diamond:

Or this super unique flame-cut diamond:

People are experimenting with weird shapes, odd colors, oddball cuts and experimental designs, which I think is SUPER COOL. Diamonds are beautiful (I'm aware of the industry and synthetic demand and all that jazz. The fact remains, they are beautiful stones. Look at a well-cut diamond in good lighting. They are stunning and magical) and I'm really excited to see what they'll come up with next, design-wise. I wear lab-grown diamonds. So does my husband. I like 'em.

9 notes

·

View notes

Text

Ethical and Sustainable: The Beauty of Lab-Grown Diamonds

Introduction:

Lab-grown diamonds, also known as synthetic diamonds, are created in a laboratory using advanced technology that mimics the natural diamond formation process. Unlike mined diamonds, lab-grown diamonds are not extracted from the earth, making them a more sustainable and ethical alternative.

The Science Behind Lab-Grown Diamonds:

Explain the chemical vapor deposition (CVD) and high-pressure, high-temperature (HPHT) methods used to create lab-grown diamonds.

Discuss the similarities and differences between lab-grown diamonds and mined diamonds in terms of their physical properties.

Benefits of Lab-Grown Diamonds:

Ethical and sustainable: Lab-grown diamonds are conflict-free and do not contribute to environmental damage associated with mining.

Affordability: Lab-grown diamonds are often more affordable than mined diamonds of the same quality.

Customization: Lab-grown diamonds can be customized to specific specifications, allowing for unique and personalized jewelry.

Durability: Lab-grown diamonds are just as durable as mined diamonds and can be set in the same types of jewelry.

Choosing a Lab-Grown Diamond:

Discuss factors to consider when selecting a lab-grown diamond, such as carat weight, cut, clarity, and color.

Explain the importance of working with a reputable jeweler who specializes in lab-grown diamonds.

The Future of Lab-Grown Diamonds:

Explore the growing popularity of lab-grown diamonds and their potential to disrupt the traditional diamond industry.

Discuss the ethical and environmental implications of choosing lab-grown diamonds over mined diamonds.

Conclusion:

Lab-grown diamonds offer a beautiful and ethical alternative to mined diamonds. With their affordability, customization options, and sustainability benefits, lab-grown diamonds are gaining popularity among consumers who value both style and ethical considerations.

2 notes

·

View notes

Text

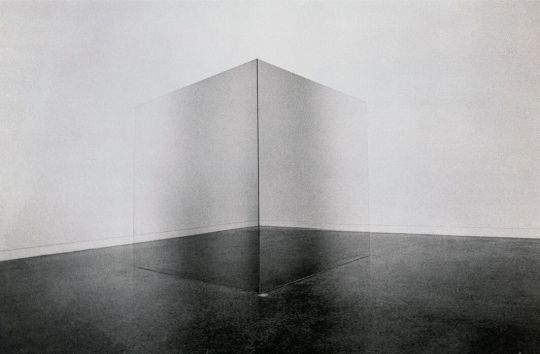

ART | "Larry Bell - works from the 1970s" at Hauser & Wirth Monaco

Larry Bell first came to attention as part of the light and space movement in Los Angeles in the 1960s. This exhibition will focus on his architecturally scaled works from the 1970s, known as standing walls. The large scale works in this show are among his most ambitious early works, and follow a rigorous, radical and austere economy of means. They reflect a change in Bell’s work that occurred in the late 1960s when he abandoned the use of metal frames in his sculptures, towards free-standing glass panels joined with silicone, allowing him to work on a much grander scale, determined by the body. This also saw him move away from the pure form of the cube, towards an exploration of architectural and mural geometries, not just squares but corners and zig-zags.

The exhibition will consist of the four large-scale glass sculptures from the early 1970s, along with ‘Moving Ways,’ a monumental late 1970s wall work. These works highlight Bell’s historic contribution to a severely pared down aesthetic and how his work at this stage addresses not just the viewer’s gaze but the perceiving body (Bell’s recourse to corporeal phenomenology), both characteristics that can be allied to minimalism. To signal and compliment the exhibition, a more recent, highly colored glass work will be installed outdoors in the Jardins des Boulingrins adjacent to the gallery, during the course of the exhibition. The rare, museum-quality works that will be shown come primarily from important Italian collections, such as the Panza Collection. This includes the work ‘Untitled’ (1970) which was featured in a key solo exhibition of Bell’s work in Rome in 1974.

Larry Bell, born in Chicago in 1939, is one of the most renowned and influential artists to emerge from the Los Angeles art scene of the 1960s, alongside contemporaries Ed Ruscha and Robert Irwin. Known foremost for his refined surface treatment of glass and explorations of light, reflection and shadow through the material, Bell’s understanding of the potential of glass and light allows him to expand visual and physical fields of perception, and his sculptures to surpass traditional bounds of the medium.

Since 1969, Larry Bell has used his own high-vacuum coating system that allows him to deposit thin metal films onto his glass surfaces, harnessing a little-known technique developed for aeronautics to create a highly original body of work.

Bell’s use of commercial industrial pro-cesses in his studio since the 1960s, demonstrates his unparalleled skill and dedication in each step of his sculptures’ fabrication. He has said: ‘Although we tend to think of glass as a window, it is a solid liquid that has at once three distinctive qualities: it reflects light, it absorbs light, and it transmits light all at the same time.’

In 1978, Larry Bell began experimenting with a modified version of the vacuum coating process, to make his ‘vapor drawings’ on paper. The unique large-scale wall work ‘Moving Ways’ (1978), made from applying aluminum on black paper, comprises five individual drawings hung together to make up a multi-paneled composition. In the ‘vapor drawings,’ Bell controls the density of the metallic coating, much like his glass works, in order to vary degrees of transparency and opacity across their surface. Thus, the drawings emulate and complement the elusive, reflective and spatial qualities that are present in his sculptural works.

Outside in the Jardins des Boulingrins, the major sculpture ‘The Blue Gate’ (2021) will be shown. This much more recent work shows the development of Bell’s practice. This is most apparent though his masterful adoption of color achieved by employing the very different medium of monochrome color-laminated glass. While related to the earlier standing walls in its scale and relation to the body, here the form has also become more complex through the use of contained or intersecting forms and triangular glass panes to create diagonals. This work is comprised of panes of vibrant amethyst purple and peacock blue. These colors overlap revealing a variety of mixed hues through their layers. It shows how Bell delights in colour contrasts and complementarity, as well as their mixing through the special transparency afforded by glass. Displayed in the Mediterranean light that has attracted artists through the centuries, this work will be especially impactful.

Image: Two Glass Walls, 1971-1972, 2 coated glass panels, Larry Bell. Photo: Gian Sinigaglia, Felicity Samuel Gallery, London 4 june - 31 august 2024

3 notes

·

View notes

Text

Lab Grown Diamond Engagement Rings

Lab grown diamond engagement rings have emerged as a popular and sustainable alternative to traditional mined diamonds, offering couples the chance to embrace modern technology while still adhering to the timeless tradition of symbolizing their love and commitment. Here's what you need to know about lab-grown diamond engagement rings:

What are Lab-Grown Diamonds?

Lab-grown diamonds are real diamonds produced in a controlled environment using advanced technological processes that mimic the natural conditions under which diamonds form over billions of years. The two primary methods used to create these diamonds are High Pressure High Temperature (HPHT) and Chemical Vapor Deposition (CVD). Despite their artificial origin, lab-grown diamonds possess the same physical, chemical, and optical properties as their mined counterparts.

Benefits of Choosing Lab-Grown Diamonds

Sustainability: Lab-grown diamonds offer a more sustainable and environmentally friendly option than mined diamonds. Their production requires significantly less disruption to the Earth's surface and reduces the environmental damage associated with traditional diamond mining practices.

Ethical Considerations: With lab-grown diamonds, consumers can avoid the ethical concerns linked to the diamond mining industry, such as labor exploitation and funding conflict zones. This makes them an appealing choice for those looking to make socially responsible purchases.

Cost-Effectiveness: Generally, lab-grown diamonds are more affordable than natural diamonds. This price difference allows buyers to either save money or opt for a larger or higher quality diamond for the same budget.

Quality and Variety: Lab-grown diamonds come in a wide range of sizes, shapes, and colors, offering a breadth of options for customization and personalization. They are graded using the same criteria as mined diamonds (cut, color, clarity, and carat), ensuring buyers can select a high-quality gemstone that meets their preferences.

Considerations When Purchasing

Certification and Grading: Ensure your lab-grown diamond comes with a certificate from a reputable grading entity, such as the Gemological Institute of America (GIA) or the International Gemological Institute (IGI). This documentation provides an unbiased assessment of the diamond's characteristics and authenticity.

Lab grown diamond engagement rings offer a modern, ethical, and sustainable choice for couples looking to celebrate their love. With advancements in technology continuing to improve the quality and accessibility of these diamonds, they represent a compelling option for those willing to embrace innovation without compromising on the beauty and durability that diamonds are known for.

Whether you're drawn to lab-grown diamonds for their ethical appeal, their environmental benefits, or their affordability, there's no denying that they are a symbol of progress in the jewelry industry, marrying tradition with the promise of a more sustainable future.

Shop Now - https://llprivatejewellers.com/collections/lab-grown-diamond-engagement-rings

#EngagementRings#engagementrings#engagement rings#engagement ring#engagement#engagement photos#engagement photo#Engagement Rings#Diamond#diamond rings#diamond engagement rings#diamond ring#diamond jewellery#diamond jewelry#Diamond Ring#Jewelry#jewelry lover#jewelry collection#jewelry designer#jewelry store#Jewelry designer#vancouver#canada#jewellery#jewelry for sale#shopping#online#women#love#proposal

6 notes

·

View notes

Text

Thermal Spray Coating Equipment Market: Growth, Trends, and Future Outlook

Introduction

The Thermal Spray Coating Equipment Market has been experiencing rapid growth due to increasing demand for durable and wear-resistant coatings across various industries. This market is driven by advancements in coating technologies, rising adoption in the aerospace and automotive industries, and the growing emphasis on extending the lifespan of industrial components. As industries continue to prioritize cost efficiency and performance, the thermal spray coating market is expected to expand significantly in the coming years.

Market Overview

Current Market Size and Growth Trends

The global thermal spray coating equipment market was valued at approximately USD 10.5 billion in 2023 and is projected to grow at a CAGR of 6.8% from 2024 to 2032, reaching an estimated USD 18 billion by the end of the forecast period. This growth is fueled by increasing demand in sectors such as aerospace, automotive, healthcare, and energy.

Regional Market Insights

North America: The largest market, driven by heavy industrialization, aerospace investments, and stringent regulations on corrosion protection.

Europe: Strong presence of automotive and aerospace manufacturers, along with stringent sustainability regulations, fueling growth.

Asia-Pacific: The fastest-growing region, with China, India, and Japan investing in advanced manufacturing technologies.

Latin America & Middle East: Emerging as potential markets due to expanding oil & gas and construction industries.

Key Market Drivers

Rising Demand for Corrosion and Wear Resistance: Thermal spray coatings help protect equipment from wear, oxidation, and extreme environmental conditions, reducing maintenance costs.

Growth in Aerospace & Automotive Sectors: The increasing need for lightweight and heat-resistant coatings in aircraft and automotive components is a key market driver.

Advancements in Coating Technologies: Innovations such as plasma spray, high-velocity oxygen fuel (HVOF), and cold spray techniques are improving coating efficiency and performance.

Expansion of Industrial and Energy Sectors: The power generation, oil & gas, and manufacturing industries are adopting thermal spray coatings to enhance the durability of their equipment.

Leading Players in the Thermal Spray Coating Equipment Market

Major companies dominating the thermal spray coating equipment industry include:

Oerlikon Metco (Switzerland) – A leading player offering advanced thermal spray solutions.

Praxair Surface Technologies (USA) – Specializes in high-performance coating solutions for aerospace and industrial applications.

Flame Spray Technologies (Netherlands) – Focuses on innovative and cost-effective coating systems.

Metallisation Ltd. (UK) – Known for its expertise in arc spray and plasma spray technologies.

TST Coatings (USA) – A key player in advanced ceramic and metallic coating technologies.

Challenges and Roadblocks

Despite strong market growth, the industry faces several challenges:

High Initial Investment Costs: The setup and maintenance costs of thermal spray coating equipment are significant, limiting adoption among small-scale manufacturers.

Lack of Skilled Workforce: Specialized training is required to operate advanced thermal spray systems, creating a talent gap in the industry.

Stringent Environmental Regulations: Compliance with regulations regarding airborne emissions and waste disposal adds complexity to the industry’s operations.

Competition from Alternative Coating Technologies: Techniques such as PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition) provide competition to traditional thermal spray methods.

Future Outlook

The future of the thermal spray coating equipment market looks promising, with increasing R&D investments and industry collaborations driving innovation. The adoption of robotic automation in thermal spray processes, along with eco-friendly coating solutions, is expected to revolutionize the industry. Additionally, the growth of additive manufacturing and 3D printing in industrial applications is creating new opportunities for thermal spray coatings.

Conclusion

The thermal spray coating equipment market is set to witness robust growth, fueled by technological advancements and the expanding need for high-performance coatings across various industries. Companies investing in sustainable, cost-effective, and high-efficiency thermal spray solutions will be at the forefront of this evolving market. As industries strive for greater durability and performance, thermal spray coating technologies will continue to play a crucial role in shaping the future of manufacturing and industrial protection.

Looking to stay ahead in the thermal spray coating industry? Keep up with the latest innovations and market trends by following our blog!

0 notes

Text

Semiconductor Abatement Systems Market Report 2024-2032 by Reports and Insights

The Reports and Insights, a leading market research company, has recently releases report titled “Semiconductor Abatement Systems Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Semiconductor Abatement Systems Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Semiconductor Abatement Systems Market?

The global semiconductor abatement systems market size reached US$ 800.7 million in 2023. Looking forward, Reports and Insights expects the market to reach US$ 1,998.9 million in 2032, exhibiting a growth rate (CAGR) of 10.7% during 2024-2032.

What are Semiconductor Abatement Systems?

Semiconductor abatement systems are advanced tools used in the semiconductor manufacturing process to remove hazardous gases and chemicals. These systems play a critical role in maintaining a safe and clean working environment by efficiently neutralizing and treating exhaust gases and process by-products. Semiconductor abatement systems are essential for controlling emissions and ensuring compliance with environmental regulations in semiconductor fabrication facilities. They are designed to handle a wide range of toxic gases, including fluorine, chlorine, and arsine, providing a reliable and efficient solution for managing waste gases in semiconductor manufacturing.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1856

What are the growth prospects and trends in the Semiconductor Abatement Systems industry?

The semiconductor abatement systems market growth is driven by various and trends. The market for semiconductor abatement systems is a critical component of the semiconductor industry, fueled by the rising need for advanced manufacturing processes and strict environmental guidelines. These systems play a vital role in eliminating hazardous gases and chemicals used in semiconductor manufacturing, ensuring both a safe workplace and adherence to regulatory standards. Market growth is driven by factors like increased adoption of abatement systems in semiconductor fabrication plants, a growing emphasis on sustainability, and the demand for effective solutions for managing waste gases. Furthermore, ongoing technological advancements, including the creation of more efficient and economical abatement systems, are driving the market's expansion. Hence, all these factors contribute to semiconductor abatement systems market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Type:

Wet Abatement Systems

Dry Abatement Systems

By Process:

Etch Abatement Systems

Chemical Vapor Deposition (CVD) Abatement Systems

Physical Vapor Deposition (PVD) Abatement Systems

Chemical Mechanical Planarization (CMP) Abatement Systems

Others

By End-Use:

Semiconductor Manufacturers

Foundries

Packaging and Assembly Service Providers

Others

By Application:

Logic and Memory Devices

Micro-electromechanical Systems (MEMS)

Power Devices

Optoelectronics

Others

By Sales Channel:

Direct Sales

Distributor Sales

Market Segmentation By Region:

North America

United States

Canada

Europe

Germany

United Kingdom

France

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

Rest of Asia Pacific

Latin America

Brazil

Mexico

Argentina

Middle East & Africa

Saudi Arabia

South Africa

United Arab Emirates

Israel

Who are the key players operating in the industry?

The report covers the major market players including:

Applied Materials Inc.

Lam Research Corporation

Tokyo Electron Limited

Hitachi High-Technologies Corporation

Axcelis Technologies Inc.

Edwards Vacuum LLC

Aeronex Inc.

DAS Environmental Expert GmbH

MKS Instruments Inc.

AMEC International Limited

TEL NEXX, Inc.

Ultra Clean Holdings, Inc.

CVD Equipment Corporation

View Full Report: https://www.reportsandinsights.com/report/Semiconductor Abatement Systems-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Semiconductor Abatement Systems Market share#Semiconductor Abatement Systems Market size#Semiconductor Abatement Systems Market trends

0 notes

Text

The Role of PVD Wall Art in Luxury Interior Design

When it comes to luxury interior design, every detail counts. From statement furniture to bespoke lighting, each element works together to create a cohesive and sophisticated aesthetic. Among these elements, PVD wall art has emerged as a game-changer, bringing a seamless blend of elegance, durability, and innovation to high-end interiors. This modern design feature is not just about style—it represents a shift toward cutting-edge technology and timeless appeal.

What Is PVD Wall Art?

PVD (Physical Vapor Deposition) wall art refers to decorative pieces enhanced with a specialized coating process that uses thin-film deposition technology. This process not only adds stunning visual effects but also provides unmatched durability, making it ideal for luxury spaces. One standout material used in PVD wall art is the stainless steel gold sheet, known for its mirror-like shine and luxurious golden hue.

Fabrinox, a leader in premium metal design solutions, has been at the forefront of creating exceptional PVD wall art that captures the essence of luxury interiors. With their innovative craftsmanship and commitment to quality, they deliver designs that elevate any space they adorn.

Why Choose PVD Wall Art for Luxury Interiors?

Here are some reasons why PVD wall art is a must-have for luxury interior design:

Unparalleled Aesthetic Appeal PVD wall art instantly adds a sophisticated and polished look to interiors. Whether it’s the lustrous shine of a stainless steel gold sheet or intricate patterns, PVD-coated wall art exudes opulence. These pieces can serve as statement focal points or subtle accents, depending on the design vision.

Durability That Lasts a Lifetime The PVD coating process enhances the resistance of materials against wear, corrosion, and scratches. This ensures that the art remains pristine for years, making it a sustainable choice for high-traffic luxury spaces like hotels, offices, and residences.

Customization for Unique Spaces Fabrinox offers tailored PVD wall art solutions that cater to individual tastes and design requirements. From minimalist patterns to intricate designs on a stainless steel gold sheet, the possibilities are endless, allowing you to create a truly unique space.

Versatility Across Applications PVD wall art complements various interior styles, from modern and industrial to classic and opulent. Whether used in a living room, office lobby, or five-star hotel, it seamlessly integrates into any setting, enhancing its luxury quotient.

Eco-Friendly and Sustainable Design With sustainability becoming a priority in design, PVD-coated products offer an eco-friendly alternative. The process produces minimal waste and uses materials that are recyclable, making it an environmentally conscious choice.

Applications of PVD Wall Art in Luxury Interiors

Living Rooms and Lounges A bold piece of PVD wall art featuring a stainless steel gold sheet can transform a living room into an elegant retreat. It acts as a centerpiece, drawing attention and reflecting the room's ambient lighting for added warmth.

Corporate Offices and Lobbies In high-end office spaces, PVD wall art can project a professional yet luxurious image. Fabrinox specializes in creating designs that are both contemporary and inviting, perfect for corporate settings.

Hospitality Spaces Luxury hotels and restaurants often use PVD wall art to enhance their interiors, from grand entrance walls to intimate dining areas. The metallic sheen of a stainless steel gold sheet exudes sophistication, leaving a lasting impression on guests.

Why Choose Fabrinox for PVD Wall Art?

Fabrinox is a trusted name in the industry, known for its expertise in crafting high-quality PVD wall art and other metal products. Their commitment to innovation and excellence ensures that each piece they create stands out in both design and functionality. By integrating materials like stainless steel gold sheets into their creations, they bring a new level of luxury to interior spaces.

Conclusion

As luxury interior design continues to evolve, PVD wall art is becoming a staple for creating sophisticated and timeless spaces. With its unmatched aesthetic appeal, durability, and versatility, it’s no wonder that designers and homeowners alike are turning to this modern art form. Brands like Fabrinox make it easy to incorporate stunning pieces, ensuring your interiors are nothing short of extraordinary.

If you’re looking to elevate your space with innovative and luxurious design elements, consider the elegance and durability of PVD wall art. It’s more than just décor—it’s a statement.

Also Read:

Eco-Friendly Benefits of Aluminium Honeycomb Panels in India

Top Applications of Rose Gold PVD Coating in Modern Design

Originally published at https://fabrinoxofficially.blogspot.com

0 notes

Text

Uses & Benefits of Molybdenum Crucibles

Molybdenum crucibles are highly specialized containers used in various high-temperature applications, especially in metallurgy, materials science, and electronics. Molybdenum’s unique properties make these crucibles highly advantageous for numerous processes. Here’s a detailed overview of the uses and benefits of molybdenum crucibles:

Uses of Molybdenum Crucibles

Metal Melting and Casting:

Molybdenum crucibles are extensively used in the melting and casting of high-temperature metals, such as titanium, tantalum, and tungsten. They can withstand the extreme heat required for these processes without deformation.

Sintering Processes:

Used in sintering for various materials, including ceramics and hard metals. Molybdenum crucibles facilitate the densification of powders at elevated temperatures, ensuring uniform heating and optimal material properties.

Chemical Vapor Deposition (CVD):

Crucibles are utilized in CVD processes for producing thin films and coatings in the semiconductor and electronics industries. Molybdenum’s thermal stability makes it suitable for these applications.

Physical Vapor Deposition (PVD):

Similar to CVD, molybdenum crucibles are employed in PVD processes for depositing materials onto surfaces in a vacuum, critical for producing advanced materials.

Research and Development:

Commonly used in laboratories for high-temperature research applications, such as studying material properties, phase transitions, and reactions involving solid-state materials.

Nuclear Industry:

Due to their resistance to corrosion and ability to withstand high temperatures, molybdenum crucibles are utilized in processes related to nuclear materials handling and processing.

Glass and Ceramics Manufacturing:

Molybdenum crucibles are used in the production of high-temperature glass and ceramic materials, where they provide excellent thermal and mechanical properties.

Benefits of Molybdenum Crucibles

High Melting Point:

Molybdenum has a melting point of approximately 2623°C (4743°F), making it one of the best materials for high-temperature applications. Molybdenum crucibles can endure extreme temperatures that would cause many other materials to fail.

Excellent Thermal Conductivity:

Molybdenum exhibits high thermal conductivity, ensuring efficient heat transfer during melting and sintering processes. This property helps achieve uniform heating and better material characteristics.

Chemical Resistance:

Molybdenum is resistant to most acids and alkalis at elevated temperatures, making crucibles ideal for use in chemically aggressive environments. This minimizes the risk of contamination and prolongs the crucible’s lifespan.

Low Vapor Pressure:

Molybdenum has a low vapor pressure at high temperatures, which helps maintain the integrity of the process and reduces material losses during operations.

Mechanical Strength:

Molybdenum crucibles exhibit exceptional mechanical strength, enabling them to withstand the stresses associated with high-temperature processes without breaking or deforming.

Versatility:

These crucibles can be used in various applications, including metal processing, advanced material fabrication, and research, making them versatile tools in industrial and scientific settings.

Customizability:

Molybdenum crucibles can be tailored to meet specific dimensions, shapes, and features, allowing for customization according to particular needs, which enhances usability in specialized applications.

Environmentally Friendly:

Molybdenum is a naturally occurring element, and its use in crucibles can be more environmentally friendly compared to some other materials. Additionally, molybdenum products are often recyclable.

Cost-Effectiveness:

Although molybdenum crucibles may have a higher initial cost, their durability and long service life can result in lower overall costs in high-temperature processes compared to less durable materials.

High Purity:

Molybdenum crucibles can be produced with high purity levels, which is crucial for applications requiring minimal contamination during material processing.

Summary

Molybdenum crucibles are essential tools in high-temperature applications due to their unique properties, including high melting points, chemical resistance, and mechanical strength. These advantages make them invaluable in industries such as metallurgy, electronics, and material science, contributing to efficient and reliable processing of materials.

M-Kube Enterprise is an Indian company catering customized laboratory products, laboratory consumables, and laboratory solutions in India, Australia, the USA, New Zealand, Singapore, Malaysia, South Korea, Dubai, the Philippines, Indonesia, and Vietnam.

#MolybdenumCrucibles#HighTemperatureApplications#MetalMelting#MaterialScience#ThermalProcessing#MetallurgicalTools#IndustrialCrucibles#AdvancedMaterials#HighTempResearch#CustomCrucibles#MetalCasting#SinteringProcesses#CVDApplications#PVDTechnology#NuclearMaterialsHandling#GlassManufacturing#CeramicManufacturing#ChemicalResistance#HighThermalConductivity#RefractoryMaterials#MKubeEnterprise#LabConsumables#CustomLabProducts#GlobalLabSolutions#LabSuppliesIndia#LaboratoryEquipmentUSA#MaterialScienceSolutions#CustomIndustrialProducts#LabProductsAsia#LabSuppliesWorldwide

1 note

·

View note

Text

Evaluation of Different Surface Treatment Methods

Overwhelmed by the countless surface treatment processes and their confusing definitions? Don’t worry! This blog simplifies everything for you with clear definitions and detailed process diagrams, helping you grasp the essentials of various surface treatment processes in just minutes!

1. PVD (Physical Vapor Deposition)

PVD is an industrial manufacturing process, belonging to a type of coating technology, primarily using physical means to heat or excite materials to deposit thin films. This technique, also known as vacuum coating or vapor deposition, is commonly employed in surface treatments of cutting tools, various molds, and in the manufacturing processes of semiconductor devices.

AD: Compared to chemical vapor deposition, physical vapor deposition has a wider range of applications. Almost all materials can be used to prepare thin films through physical vapor deposition.

DIS: The uniformity of film thickness is indeed a concern in physical vapor deposition.

PVD Physical Vapor Deposition 01

PVD Physical Vapor Deposition 02

2. Mechanical Polishing

Mechanical polishing relies on the grinding and rolling action of very fine polishing particles, as well as cutting and plastic deformation of the material surface, to remove protrusions from the polished surface of the metal sample, thus obtaining a smooth surface.

AD: The equipment structure is relatively simple, and the price is generally lower compared to other methods.

DIS:

Mechanical polishing is challenging for polishing workpieces with complex shapes or surfaces featuring special patterns or textures.

It tends to generate metal dust, which can affect the health of polishing workers.

It requires a high level of skill from workers, making it difficult to control the consistency and stability of workpiece quality.

Mechanical processing inevitably leaves microscopic cracks and residual stress on the workpiece surface, which may affect the quality and lifespan of the workpiece and pose safety hazards for production.

mechanical polishing

3. Chemical Polishing

Chemical polishing is a method that relies on the selective dissolution of surface irregularities on samples through the chemical etching action of chemical reagents, eliminating scratches and leveling surfaces.

AD: Chemical polishing does not require special fixtures or DC power supply equipment. It is simple to operate, energy-efficient, and not limited by the size or shape of the workpiece. Additionally, the direct cost of polishing is relatively low.

DIS: The pollution issue is particularly severe, as handling the waste liquid generated during the polishing process can increase costs.

Chemical Polishing

4. Electropolishing

Electropolishing, also known as electrochemical polishing or electrolytic polishing, utilizes the phenomenon of electrochemical dissolution generated by the anode in an electrolytic cell to selectively dissolve micro-protrusions on the anode surface, resulting in a smoother surface. In this process, the workpiece to be polished serves as the anode, while an inert metal acts as the cathode. Both poles are immersed in an electrolyte solution, and a direct current is passed through to achieve selective anodic dissolution, thereby increasing the brightness of the workpiece surface.

AD:

Consistent internal and external color, long-lasting luster, and the ability to smooth out concave areas that mechanical polishing cannot reach.

High production efficiency and low cost, suitable for large-scale sample preparation.

Enhanced corrosion resistance of the workpiece surface, applicable to all stainless steel materials.

DIS:

The quality of electrolytic polishing is influenced by the specifications of the electrolyte, as well as the current and voltage settings, making it difficult to determine the correct parameters.

Achieving satisfactory results for samples with cast iron or impurities is more challenging.

The electrolyte composition is complex, requiring careful attention to safety during use.

Electropolishing 01

Electropolishing 02

5. Spray Painting

spray painting is a coating method where the liquid is dispersed into uniform and fine droplets using a spray gun or disk atomizer, typically with the aid of pressure or centrifugal force, and applied to the surface of the object to be coated.

AD: Fast construction, good surface smoothness, no texture differences.

DIS: Spray painting machines are relatively expensive, and there is a significant amount of paint wastage.

Spray Painting

6. Powder Coating

Powder coating is a process where powder coating material is sprayed onto the surface of a workpiece using powder coating equipment (electrostatic spray gun). Under the influence of static electricity, the powder evenly adheres to the surface of the workpiece, forming a powdery coating layer.

AD:

Powder coatings do not contain VOCs (volatile organic compounds), eliminating issues such as fire hazards, toxicity, and environmental pollution.

Minimal material loss and high utilization.

Easy control of coating thickness, high construction efficiency, low construction difficulty, and energy and labor-saving.

Scratch-resistant, impact-resistant, durable, and excellent chemical resistance.

DIS:

The investment required for manufacturing powder coatings and replacing coating equipment is significant.

Color matching for powder coatings can be challenging, and changing colors or types during coating is more cumbersome and costly.

Cannot be used on substrates with poor heat resistance such as plastic, wood, or paper.

Powder coatings are susceptible to clumping during storage due to pressure, temperature, and humidity fluctuations.

Powder Coating

7. Sandblasting

Sandblasting, using compressed air as the driving force, involves high-speed jet streams of abrasive materials (such as copper ore sand, quartz sand, emery, iron sand, and sea sand) being sprayed onto the surface of workpieces, causing changes in the appearance or shape of the workpiece surface. Due to the impact and cutting action of the abrasives on the workpiece surface, the surface cleanliness and roughness of the workpiece are altered. This process improves the mechanical properties of the workpiece surface, enhancing fatigue resistance, increasing adhesion between the workpiece and coatings, prolonging the durability of the coatings, and facilitating coating leveling and decoration.

AD:

Sandblasting can quickly clean the surface of objects, and the surface quality after sandblasting is good, effectively prolonging the lifespan of objects.

Sandblasting can be adapted to various types of objects, whether they are made of steel, ceramic, or plastic.

Simple operation.

DIS:

Sandblasting generates a large amount of dust and waste, causing environmental pollution.

Sandblasting operations require certain knowledge and skills; incorrect operation may damage the surface of objects.

Sandblasting requires regular maintenance and cleaning to ensure its proper functioning.

Sandblasting

8. Shot Peening

Shot peening is a widely used surface strengthening process in factories. It involves bombarding the surface of workpieces with shot particles to implant residual compressive stress, thereby enhancing the fatigue strength of the workpiece through cold working. This technique is extensively used to improve the mechanical strength, wear resistance, fatigue resistance, and corrosion resistance of components. Types of shot particles include steel shot, cast iron shot, glass beads, ceramic beads, etc.

AD:

Simple equipment, low cost

Not restricted by the shape and position of the workpiece

Convenient operation

DIS:

Poor working environment

Low unit output

Lower efficiency compared to shot blasting

Shot Peening

9. Electroplating

Electroplating is a process that involves using electrolysis to deposit a metal film onto the surface of metal or other material components. This process helps prevent metal oxidation (such as rusting), enhances wear resistance, conductivity, reflectivity, corrosion resistance, and improves aesthetics.

AD: Attractive surface appearance, excellent corrosion resistance, strong mechanical properties.

DIS: Improper handling of generated wastewater and exhaust may lead to environmental pollution, high energy consumption, and potential health hazards to humans.

Electroplating

10. Anodizing (Anodic Oxidation)

Anodizing refers to the process where aluminum and its alloys, under specific electrolyte and process conditions, form an oxide film on the surface of aluminum products (the anode) due to the action of an external electric current.

AD:

Anodizing can form a dense oxide film on the surface of metal, effectively preventing oxidation and corrosion.

It increases the hardness of the metal surface, making it more resistant to wear and scratches, thus extending its lifespan.

Different colors of oxide films formed on the metal surface enhance its aesthetic appearance and decorative properties.

The roughness of the metal surface increases after anodizing, which promotes adhesion between coatings and substrates, making the coating more durable.

An insulating oxide film formed on the metal surface improves its insulation properties.

DIS:

Particularly when dealing with large areas or thicknesses of metal products, significant energy consumption increases production costs.

Strict control of processing conditions and operating standards is required, leading to longer processing times that may affect production efficiency.

The oxide film formed during anodizing may affect the dimensions and shapes of the metal, posing a certain risk to the normal operation of high-precision or high-demand components.

The anodizing process is mainly suitable for certain metals such as aluminum, magnesium, and titanium. For other metals like steel, copper, and silver, the anodizing process may not be applicable or effective.

Although the oxide film formed by anodizing has high hardness and corrosion resistance, it may be damaged under certain conditions such as mechanical wear or chemical corrosion, requiring regular maintenance and repair.

Anodizing Anodic Oxidation

11. EPD (Electrophoretic deposition)

Electrophoretic deposition is a process where, under the influence of an applied voltage between positive and negative poles, charged paint particles in an electrophoretic coating migrate toward the cathode. They react with alkaline substances generated on the cathode surface, forming insoluble deposits on the surface of the workpiece.

AD:

Safety in production: Electrophoretic coating uses water as a solvent, making it non-toxic and non-flammable.

High-quality coating: Electrophoretic paint has strong adhesion, uniform thickness, and excellent corrosion resistance.

High utilization rate: Electrophoretic paint is efficiently used.

DIS:

Limited applicability to small and medium-sized parts due to equipment constraints.

Restricted to conductive substrates and single-layer coating: Once a part is coated with electrophoretic paint, it becomes an insulator, preventing further electrophoretic coating.

Limited color options: Electrophoretic paint colors are predominantly dark.

EPD Electrophoretic deposition

12. Micro-arc Oxidation

Micro-arc oxidation, also known as micro-plasma oxidation, is a process where, through a combination of electrolyte and specific electrical parameters, an instant high-temperature and high-pressure effect is generated on the surface of aluminum, magnesium, titanium, and their alloys via arc discharge. This process results in the growth of a ceramic coating layer primarily composed of metal oxide on the substrate.

AD:

The metal oxide layer formed by micro-arc oxidation is metallurgically fused with the substrate, resulting in high bond strength. The ceramic layer has a dense structure, good toughness, and exhibits characteristics such as wear resistance, corrosion resistance, high-temperature shock resistance, and electrical insulation. It can also meet requirements for thermal insulation, catalysis, antibacterial properties, etc.

The process has a wide range of applications and is environmentally friendly during processing.

DIS: The surface may be rough and uneven.

Micro arc Oxidation

13. Metal Brushing

Metal brushing is a manufacturing process involving repeatedly scraping aluminum plates with sandpaper to create lines. The main process consists of three parts: degreasing, sanding, and washing. During the brushing process, a special film technique applied after anodizing treatment enables the metal surface to form a film layer containing metal components. This process makes each fine scratch clearly visible, allowing the metal to exhibit a subtle sheen amidst its matte finish.

AD:

Wear-resistant, high-temperature-resistant, and corrosion-resistant.

Easy maintenance and cleaning in daily use.

Fine texture.

Long lifespan.

DIS: Relatively expensive price.

Metal Brushing

14. Etching

Etching is a technique that removes part of the material through chemical reactions or physical impacts. Etching typically refers to photolithographic etching, where after exposure and development, the protective film on the area to be etched is removed. When exposed to a chemical solution during etching, it dissolves and corrodes the material, creating a concave or hollow effect.

AD:

Metal etching processes can create extremely precise shapes and patterns, and the consistency of the metal etching process ensures that each product in mass production has the same quality and characteristics.

Etching processes can be applied to various metals, including copper, nickel, gold, silver, iron, and some non-metallic materials.

Metal etching processes generate relatively little waste, and in many cases, waste can be recycled and treated.

High efficiency.

DIS:

Etching processes require precise control of factors such as chemical solution concentration, temperature, and etching time, leading to high complexity.

High equipment and manufacturing costs: Etching processes require specialized equipment and materials such as etching tanks, power supplies, heat exchangers, etc. Additionally, precise control of the production process is needed to ensure product quality and consistency.

Workers may be exposed to hazards such as chemical substances, high temperatures, and noise.

Etching

15. IMD (In-Mold Decoration technology)

IMD, also known as non-painting technology, is an internationally popular surface decoration technique. It involves applying a surface-hardened transparent film, printing the pattern layer in the middle, and injecting the back molding layer. The ink is sandwiched between layers, making the product resistant to friction, preventing surface scratches, and maintaining color brightness for an extended period without fading.

AD:

Strong scratch resistance and corrosion resistance.

Long service life.

Excellent three-dimensional effect.

Strong resistance to dust, moisture, and deformation.

Color can be changed as desired.

Patterns can be easily modified.

DIS:

Long lead time.

Prone to issues such as film detachment and distortion.

High defect rate in products.

IMD In Mold Decoration technology 01

IMD In Mold Decoration technology 02

16. OMD (Out Mold Decoration)

OMD is an extension of IMD (In-Mold Decoration) technology that integrates visual, tactile, and functional elements. It combines printing, texture structure, and metallization characteristics to achieve 3D surface decoration.

AD:

Substrate material is not limited, can be metal or plastic.

Can achieve 3D shapes.

Can encapsulate internal structures (back-molding).

Allows for simultaneous processing of multiple small products.

DIS:

High equipment investment.

Unable to achieve complex 3D shapes.

OMD Out Mold Decoration

17. Laser Engraving

Laser engraving, also known as laser etching or laser marking, is a surface treatment process based on optical principles. It involves using a laser beam to engrave permanent marks on the surface of a material or within transparent materials.

AD:

Fast marking speed, low cost

Attractive patterns, high resolution, and high precision

Wear-resistant

DIS: Limited color options

18. EDM (Electrical Discharge Machining)

EDM is a specialized machining method that utilizes the erosive effect produced by pulsed discharges between two electrodes immersed in a working fluid to remove conductive materials. It is also known as spark machining or spark erosion machining. The tool electrode is typically made of materials with good conductivity, high melting points, and easy machinability, such as copper, graphite, copper-tungsten alloy, and molybdenum. During the machining process, there is wear on the tool electrode, but it is usually less than the material removal from the workpiece metal, and in some cases, it can be negligible.

AD:

Capable of machining materials and complex-shaped workpieces that are difficult to cut using conventional cutting methods, such as sharp corners.

Does not produce burrs and tool marks.

Tool electrode material does not need to be harder than the workpiece material.

Enables automation due to the direct use of electrical energy.

DIS: Low efficiency.

EDM Electrical Discharge Machining 01

19. Laser Etching

Laser etching involves the treatment of steel surfaces with high-energy density lasers to create patterns such as snake skin, etchings, pearlescent finishes, or other forms of textures.

AD: High welding accuracy and small heat-affected zone, suitable for repairing precision molds.

DIS:

Welding wire is relatively expensive, leading to lower efficiency.

Bulky equipment makes mobility difficult, and unsuitable for on-site operations. Welding repairs need to be performed on a workbench, making it impractical for large molds or workpieces.

Repairing irregular-shaped defects can be challenging compared to straight-line repairs.

Large heat-affected zones during welding repairs increase the likelihood of workpiece sagging, deformation, and undercutting.

Lower welding accuracy, unable to meet the requirements of high-precision molds.

Many mold repairs require preheating, insulation, and other processes, making them cumbersome and time-consuming.

Laser Etching

20. Pad Printing

Pad printing, also known as tampon printing, is a specialized printing method that involves using a steel (or copper, thermoplastic) plate with an engraved design. A curved surface pad made of silicone rubber material is used to pick up ink from the plate's surface. The ink is then transferred onto the desired object's surface by pressing the pad against it, resulting in the printing of text, patterns, or other images.

AD:

Wide application range: Pad printing is commonly used on products with recesses or on the back of objects where screen printing is not feasible. It can achieve clean printing results even on uneven surfaces.

Convenient operation: Equipment can be operated semi-automatically or fully automatically, with low labor costs and high production efficiency.

DIS:

Ordinary results.

Pad printing cannot create patterns with large areas.

Due to the clear edges of the recesses processed by steel plates, gradient colors cannot be produced.

Pad Printing

21. Screen Printing

Screen printing refers to a printing method that uses a screen as the printing plate, which is made into a screen printing plate with images or text through photosensitive plate-making methods. Screen printing consists of five main elements: the screen printing plate, squeegee, ink, printing table, and substrate. The basic principle of screen printing is that the ink can pass through the mesh holes of the image/text part of the screen printing plate, while the non-image/text part of the mesh holes cannot pass through the ink. During printing, ink is poured into one end of the screen printing plate, and a certain pressure is applied to the inked area on the screen printing plate using a squeegee. At the same time, the squeegee moves steadily towards the other end of the screen printing plate, and the ink is squeezed from the mesh holes of the image/text part onto the substrate.

AD:

Screen printing can use various types of inks: oil-based, water-based, synthetic resin emulsion-based, powder, etc.

Screen printing plates are flexible and have a certain elasticity, suitable for printing on soft materials such as paper and fabric, as well as on hard objects such as glass and ceramics.

Screen printing requires low printing pressure, making it suitable for printing on fragile objects.

Thick ink layer with strong coverage.

Not limited by the surface shape or size of the substrate. Screen printing can be applied on flat surfaces, as well as on curved or spherical surfaces. It is suitable for printing on both small and large objects.

DIS:

Only one color can be printed at a time.

Plate-making and film output costs are relatively high, making it unsuitable for small-batch production.

Poor performance when used on uneven surfaces.

Ink quantity cannot be easily controlled.

Screen Printing

22. Direct Thermal Printing

Direct thermal printing refers to a method where a thermal-sensitive agent is coated on paper to create thermal recording paper. When subjected to heat, the thermal recording paper causes a physical or chemical change in the substance (coloring agent) to produce an image.

AD:

Fast printing speed and low noise level.

Clear printing and easy to use.

DIS: Direct thermal printers cannot print duplicates directly, and the printed documents cannot be permanently archived.

Direct Thermal Printing

23. Thermal Transfer Printing

Thermal transfer printing works by first digitally printing the desired image onto transfer paper using specialized transfer ink in an inkjet printer. Then, a dedicated heat transfer machine applies high temperature and pressure to accurately transfer the image onto the surface of the product, completing the printing process.

AD:

Simple printing process with accurate positioning.

Does not cause damage to the material.

Suitable for printing images with color gradients and on multiple materials.

DIS:

Poor breathability.

Fine cracks may appear in the printed pattern on clothing when stretched.

Poor durability.

Thermal Transfer Printing

24. Planographic Printing

Planographic printing is a printing method that uses flat printing plates. It is the most widely used printing process globally and is also employed in the manufacturing of semiconductor and MEMS devices. Planographic printing, also referred to as "offset printing" or "indirect printing," is a common commercial printing technology. It involves transferring images or text from flat printing plates onto rubber blankets, which are then used to print onto paper or other materials.

AD:

Fast printing speed, relatively low printing cost, and high print quality.

Suitable for large-scale and repeat printing jobs.

DIS:

Requires preparation of preliminary work such as plate making and setup.

Not suitable for short-run printing and customization.

Planographic Printing 01

Planographic Printing 02

25. Curved Surface Printing

Curved surface printing involves placing ink into engraved plates with text or patterns, and then transferring them onto curved surfaces. The text or patterns are then transferred onto the surface of the molded product using the curved surface. Finally, methods such as heat treatment or ultraviolet light exposure are used to cure the ink.

AD:

Wide applicability: It can be used for printing on various curved surfaces, such as cylinders, spheres, and irregular shapes.

High customization: It can print complex patterns, text, and images on curved surfaces, achieving personalized customization.

High production efficiency, and stable quality.

DIS:

Higher cost due to the need for more equipment and technical support.

Subject to limitations of printing machinery and technology, some specific shapes of curved surfaces may not be fully covered.

Design complexity may increase as designers need to consider the variations and distortions of curved surfaces.

Ink curing in surface printing may be uneven or incomplete due to the influence of the surface shape.

Curved Surface Printing

26. Hot Stamping

Hot stamping refers to a process where hot stamping materials or hot stamping patterns are transferred onto objects such as paper, cardboard, fabric, or coated materials using heat and pressure. Hot stamping is commonly used in the binding process, especially on covers.

AD:

Precision and meticulous craftsmanship, with minimal equipment errors, resulting in finer patterns on hot-stamped items.

Capable of performing three-dimensional hot stamping.

Energy-efficient, reducing environmental pollution, and offering fast hot stamping speeds.

DIS:

The high precision requirement of the hot stamping process for equipment leads to increased costs.

The process involves relatively complex and intricate procedures.

Hot Stamping

27. Water Transfer Printing

Water transfer printing is a technique that transfers printed images or graphics from a flat surface onto the surface of different materials using water. It is divided into two types: water immersion transfer and water overlay transfer (curved surface overlay). Water immersion transfer is mainly used for transferring text and photographic images, while water overlay transfer is primarily used for complete transfer over the entire surface of an object.

AD:

Aesthetic appeal: It can transfer any natural patterns, photos, and graphics onto products.

Innovation: Water transfer printing technology can overcome the limitations of traditional printing methods such as heat transfer, offset printing, screen printing, and surface coating, allowing for the creation of complex shapes and angles.

Versatility: Applicable to surface printing on hardware, plastics, leather, glass, ceramics, wood, etc. (not suitable for fabric and paper).

Personalized design.

Efficiency: No need for plate-making; direct printing and immediate transfer.

DIS:

Transferred images or graphics are prone to deformation.

Fully manual operation leads to high labor costs and low production efficiency.

Water Transfer Printing

28. Flat Screen Printing

Flat screen printing involves fixing printing molds onto square frames, which are usually made of polyester or nylon mesh (screen) with hollow patterns. The patterned areas of the screen allow ink to pass through, while the non-patterned areas are sealed with a polymer film layer to block the mesh openings. During printing, the screen is pressed tightly against the fabric, ink is poured onto the screen, and a squeegee is used to repeatedly scrape and press the ink through the patterns onto the fabric surface.

AD:

Convenient plate-making process, with large repeat lengths, multiple color matching options, ability to print fine patterns without color bleeding, high ink volume, and the capability to achieve a three-dimensional effect. Suitable for printing on silk, cotton, synthetic fabrics, and knitted fabrics, especially for high-end fabrics with small batches and multiple variety requirements.

Hand scraping of the ink on the hot table allows for unlimited printing repeats.

DIS:

Due to the long distance between color frames, it is difficult to achieve overlapping colors.

Manual fabric placement, manual lifting of the frame, and hand scraping of the ink result in high labor intensity and uneven ink scraping.

The heat source for the hot table is typically steam heating, though some use electric heating, which consumes a lot of electricity and is prone to accidents.

29. Calendering

Calendering, also known as pressing, is the final process of finishing leather. It involves using the plasticity of fibers under heated conditions to flatten or create parallel fine diagonal lines on the surface of the fabric, enhancing the gloss of the fabric. This process is typically carried out using a swing calender machine or a bottom leather rolling machine. Usually, it involves two passes: the first pass compresses the leather body, done after even wetting, followed by stacking to balance moisture content. The second pass is for calendering, which results in a smooth and glossy leather surface with a compacted leather body, thus achieving the finished leather.

Conclusion

With such an array of surface finishing processes available, navigating through their definitions and intricacies can be daunting. However, this blog streamlines the information by organizing definitions and process diagrams, making it effortless to grasp the various surface treatment techniques in just a few minutes. Each method's advantages and disadvantages are neatly presented, enabling a quick understanding of their applications, efficiencies, and limitations.

Related Posts

Metal Materials and Corresponding Processing Techniques

Wood Materials and Corresponding Processing Techniques

Acrylic Materials and Corresponding Processing Techniques

#surface treatment#surface finishing#custom display stand#custom pop display#solid displays#retail pop displays

0 notes

Text

Lab Grown Diamond Jewellery in Delhi | India: Lavmi Jewels

The arrival of lab-grown diamond jewelry in India has brought about a revolutionary change in the Indian jewelry business in recent years. Eco-friendly and sustainable diamond alternatives are rapidly gaining popularity, and Lavmi Jewels is leading this movement. With their gorgeous collection of lab-grown diamond jewelry, Lavmi Jewels, famous for their exquisite creativity and dedication to quality, are transforming the jewelry industry, especially in Delhi.

What Are Lab-Grown Diamonds?

Lab Grown Diamond Jewellery in Delhi is becoming increasingly popular due to its combination of elegance and sustainability. Lab-grown diamonds, occasionally referred to as created or cultured diamonds, are produced in carefully regulated lab settings utilizing cutting-edge technological processes. These are like real diamonds in their physical, chemical, and optical characteristics. They are created using two main techniques:

High-Pressure High Temperature (HPHT): Mimics the natural diamond formation process under the Earth's crust.

Chemical Vapor Deposition (CVD): Uses a carbon-rich gas mixture to grow diamond crystals layer by layer.

Lab-grown diamonds are produced in a matter of weeks without causing any environmental disruption, in contrast to real diamonds, which take billions of years to form. Because of this, they are an ethical and sustainable option for customers who are concerned about the environment.

Reason for choosing Lab-Grown Diamond Jewellery?

Eco-Friendly and Sustainable: The use of lab-grown diamonds replaces the need for mining, which frequently causes serious environmental harm. Choosing lab-grown diamonds helps protect the environment and lessen the carbon imprint.

Ethical and Conflict-Free: Conventional diamond mining is frequently linked to moral dilemmas, such as abuses of human rights. Since lab-grown diamonds are manufactured ethically and without conflict, they provide a guilt-free substitute.

Affordable Luxury: The price of lab-grown diamonds is usually 20–40% lower than that of real diamonds. Customers can acquire larger, better-quality diamonds without breaking the bank thanks to this affordability.

High Quality and Variety: Because lab-grown diamonds come in a wide range of sizes, shapes, and colors, there are countless options for making one-of-a-kind, customized jewelry.

Lab-Grown Diamond Jewellery in India: A Rising Trend

Beautiful jewelry designs have long been produced in India, and lab-grown diamonds are giving this rich tradition a modern makeover. The need for sustainable jewelry solutions is growing as more people become aware of environmental issues. Lab-grown diamond jewelry is growing popular in cities like Delhi, with Lavmi Jewels leading the way.

Lavmi Jewels: Redefining Elegance in Delhi

Lavmi Jewels is a well-known brand in the fine jewelry industry and is situated in the busy center of Delhi. From wedding bands and engagement rings to fashionable designs and everyday wear, their wide selection of lab-grown diamond jewelry suits a variety of preferences and events. This is what makes Lavmi Jewels unique:

Exceptional Craftsmanship: Lavmi Jewels creates classic designs that display professionalism and beauty by fusing traditional creativity with modern technology.

Certified Quality: At Lavmi Jewels, each lab-grown diamond is certified trustworthy, guaranteeing that you are purchasing real, premium gemstones.

Customized Designs: Lavmi Jewels provides custom jewelry services that let you design unique items that express your uniqueness and personality.

Customer-Centric Approach: Providing an unmatched purchasing experience, Lavmi Jewels is dedicated to openness and client pleasure.

Popular Lab-Grown Diamond Jewellery Options at Lavmi Jewels

A large selection of jewelry made with lab-grown diamonds is available at Lavmi Jewels. Among their favorite choices are:

Engagement Rings: Celebrate your love with ethically sourced and dazzling engagement rings. Lavmi Jewels offers solitaire, halo, and vintage-style designs that capture the essence of romance.

Wedding Bands: Symbolize your eternal bond with exquisite wedding bands, available in classic and contemporary styles.

Necklaces and Pendants: Add a touch of glamour to any outfit with stunning necklaces and pendants featuring sparkling lab-grown diamonds.

Earrings: From elegant studs to statement danglers, Lavmi Jewels offers a variety of earrings for every occasion.

Bracelets: Adorn your wrists with delicate and intricate diamond bracelets that exude sophistication.

Lab-Grown Diamond Jewellery in Delhi: The Lavmi Jewels Experience

Delhi, a city famous for its advanced customer service and lively culture, has accepted the trend of lab-grown diamond jewelry. Customers looking for premium, eco-friendly jewelry in the city now frequently visit Lavmi Jewels. What makes buying at Delhi's Lavmi Jewels special is as follows:

Personalized Consultation: Expert jewelry consultants help you choose or design the perfect piece tailored to your needs.

State-of-the-Art Showroom: Lavmi Jewels’ showroom in Delhi offers a luxurious shopping environment where you can explore their collections at leisure.

Online shopping convenience: For customers who prefer to shop from the comfort of their homes, Lavmi Jewels provides a seamless online shopping experience with detailed product descriptions and secure payment options.

The Future of Lab-Grown Diamonds in India

As buyers in India grow highly mindful of sustainable and ethical sources, lab-grown diamonds are expected to become more popular. Leading this shift are jewelry companies such as Lavmi Jewels, which provide superior craftsmanship and creative designs. Lavmi Jewels is dedicated to giving clients stylish and eco-friendly solutions as the market for lab-grown diamond jewelry keeps expanding.

Conclusion

More than a fashion statement, lab-grown diamond jewelry is a step toward sustainable luxury. Lavmi Jewels has transformed the jewelry market with its beautiful designs, moral business methods, and customer-focused philosophy. If you're seeking Lab Grown Diamond Jewellery in Delhi | India, Lavmi Jewels is your ultimate destination.

Experience the brilliant color of lab-grown diamonds by perusing Lavmi Jewels' stunning selection, whether you're in Delhi or another part of India.

0 notes

Text

Global Lab Grown Diamond Market Size, Share and Forecast 2032

Global lab grown diamond market is projected to witness a CAGR of 16.39% during the forecast period 2025-2032, growing from USD 14.28 billion in 2024 to USD 48.10 billion in 2032. The market has experienced significant growth in recent years and is expected to maintain a strong pace of expansion in the coming years.