#Photopolymerization

Explore tagged Tumblr posts

Text

Addressing key challenges of photoresponsive, visible light 3D printing

Vat photopolymerization, a light-based 3D printing technique, conventionally relies on UV light to rapidly transform liquid resins into intricate solid objects. However, the use of visible light as an alternative approach has gained significant attention, particularly for its promising applications in tissue engineering and soft robotics. While visible light offers mild reaction conditions, improved energy efficiency, and biocompatibility, slower curing speeds have posed a significant limitation. In response, researchers have intensified efforts to overcome this limitation, focusing on developing high-speed curing methods that harness visible light irradiation. A significant constraint of conventional UV-based 3D printing is its incompatibility with smart materials, particularly photoresponsive polymers. These polymers incorporate light-sensitive compounds, or chromophores, in their structure, enabling reversible changes in physical or chemical properties upon light exposure.

Read more.

6 notes

·

View notes

Text

#Stereolithography (SLA)#3D Printing#Rapid Prototyping#Photopolymerization#High Precision Manufacturing#Innovative Design#Industrial Applications#Eco-Friendly Technology#Complex Geometries#Manufacturing Solutions.

1 note

·

View note

Text

Photopolymerization Advanced Polymerization System (APS), a technology that offers great advances for the photopolymerization of dental materials and greater esthetics.

https://fgmus.com/aps-technology/

0 notes

Text

You know that stuff at the dentist's office that hardens when you add light to it? That's a whole class of reaction called photopolymerization and they use to 3D print ceramics. The polymers form a matrix around the clay particles, so when you lock in the matrix by cross-linking (fusing the polymers*), the clay is instantly hard, no heat needed.

#cool fact#photopolymerization#instantly hard? me when character the writers absolutely did not intend to be attractive#* it's not JUST fusing the polymers but that's the general idea

1 note

·

View note

Text

Photopolymerizer

Another Maza design. I am so glad someone around here can animate rotation.

14 notes

·

View notes

Photo

3Dプリンターとは3D CADデータを元に3次元の立体造形物を出力(プリント)する装置です。

3Dプリンターには様々な方式があります。

基本的にはどれも1層1層積んでいく仕組みですが、方式によって得意不得意があります。

方式によって、造形物の精度、扱える材料とその物性、造形可能なサイズ、スピード、メンテナンス性など、様々な特徴の差異があります。 また、メーカー各社の独自用語が存在するなど、同じ方式を指していてもそれを表す用語がいくつもあるケースがあり、全体像の把握には、それら表記ゆれに対するケアが必要です。

3Dプリンターの方式はISOで分類が規定されておりますので、その区分を参考にしながら、主要な方式を網羅的にまとめました。

海外では既に3Dプリンターを「実生産」で使うことが��たり前に。 そのノウハウが一足飛びに得られるとしたら?

1つの製品に、何個の部品が使われていますか?会社全体では、何種類の部品がありますか? 多い企業では万単位の部品が存在すると思います。

それらの部品の中から3Dプリンターでの生産に向いている部品を自動で見つけ出し、 続々と生産を効率化していけるシステムがあるとしたら、御社の生産はどう変わるでしょう?

3Dプリンターでの部品実生産ノウハウを御社にインストールするシステム CASTOR 目次 現在主流 FDM方式 最も古い 光造形方式 高精細で表現力が最も高い インクジェット方式 結合剤を噴射する バインダージェット方式 金属3Dプリンターの世界を一変 BMD方式 従来型の金属3Dプリンター パウダーベッド方式 シート積層法 指向性エネルギー堆積法 CIM(Cast in motion)方式 3Dプリンターの仕組み 3Dプリンターは材料を1層1層積み上げていくことで、高さのある造形物を出力します。

様々な方式はありますが、基本的に層を重ねていくことで造形するという点に変わりはありません。 そのように、原理としては非常にシンプルです。

扱える材料も、プラスチック(樹脂)、金属、カーボン等、様々な材料を使って造形することができます。

3Dプリンターとは 3次元造形 現在主流 FDM方式 日本語表記:熱溶解積層方式(Fused Deposition Modeling) ISO分類:材料押出法(Material Extrusion) その他表記:FFF方式(Fused Filament Fabrication) FDM方式の概要 FDM方式とは、3Dプリンター世界シェアNo.1である米国Stratasys社が開発した方式です。 現在3Dプリンターにおいて主流の方式です。

FDM方式による造形 熱で溶かした樹脂をノズルから押し出し、ソフトクリーム製造機のようなイメージで、一筆書きで1層1層積み重ねて造形していきます。 この画期的な方式はストラタシス創設者のスコットクランプがグルーガンを見て想起したという逸話が残っています。

FDM方式 FDM方式の強み 本物の熱可塑性樹脂を使えること、だからこその強度・耐熱が強み 熱可塑性樹脂は射出成形で用いられており、量産する最終製品でよく使われるプラスチック材料です。代表的なものにABS樹脂等があります。

そのため、試作(プロトタイプ)であっても、最終製品に近い物性のリアルで機能的な試験も可能であり、製造業において重宝されています。

他の方式では紫外線硬化樹脂を用いるものが多いため、ABSそのものではなくABSに近い物性を持つ「ABSライク樹脂」が開発されています。

多様な物性の素材が使える FDM方式、特にハイエンド機種では産業界で求められる様々な物性の樹脂に広く対応しています。

エンジニアリングプラスチック、スーパーエンプラまで使えるなら、特殊用途の最終製品まで使えるイメージが沸くのではないでしょうか。

段差も目立ちにくいキメの細かな機種も 初期の頃は層を積み上げた際にできる段差が目立つ傾向がありました。

しかし近年では、材料も装置も進化していることから、従前より段差も目立ちにくくなりました。

FDM方式の弱点 FDM方式は比較的積層痕が目立ちやすいため、物性よりも外観のなめらかさ、プロダクトデザインにおける表現力を重視する用途では、FDM方式よりインクジェット方式の方が適していると言えるでしょう。

また、FDM方式だけでは金属の造形ができません。そのため、金属で造形したい場合は金属専用の3Dプリンターを導入する必要があります。(※FDM方式と組み合わせて金属造形するシステムは存在します。)

どのようなシーンで選ぶべきか? 製造業における試作(ラピッドプロトタイピング)、治具・工具の製作、最終製品の造形をしたい場合で、強度が求められるものはFDM方式を選ぶと良いでしょう。

FDM方式について詳しい解説はこちら

FDM方式の製品一覧はこちら

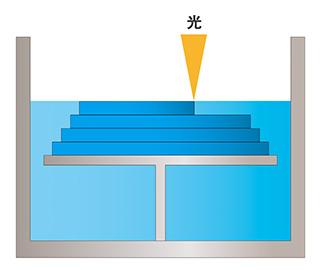

3Dプリンターで何をしたいですか? 最も古い 光造形方式 ISO分類:液槽光重合法(Vat PhotoPolymerization) その他表記:SLA方式(Stereo Lithography Apparatus) 光造形方式はSLA方式とも呼ばれます。 さらにSLAの中には、レーザー光を用いるレーザー方式と、一括面露光をするDLP方式があります。

光造形方式の概要 光造形方式は、最も古い3Dプリンターの方式です。 液体状の光硬化樹脂のプールに光を照射し、1層1層重ねて造形します。

光造形 レーザー方式 レーザー光を照射し、光に触れた箇所が硬化される仕組みです。光造形方式の中でも古くからある方式です。

DLP方式 プロジェクターのように像を作り、一括面露光する仕組みです。

造形物の面積が広い場合はレーザー方式と比較して高速露光できることが強みですが、像を作る際、ピクセル単位で描画することから、照射する範囲を広げると解像度が落ち寸法精度が出にくく、また造形物の表面は水平・垂直の両方向に積層痕(段差)が出てしまいます。

光造形方式の強み きめの細かな造形物が作りやすいこと、個人向けでは安価なモデルが多数登場していることが挙げられます。 造形速度は比較的速い傾向があります。

光造形方式の一般的な弱点 産業用途の光造形機は高額なものが多く、コストが高くなりがちです。

紫外線硬化樹脂を用いるという性質から��太陽光など光による劣化が起こりやすくなる性質があります。 吊り下げ方式のため大型のモデルの造形に適していなかったり、変形が起こる可能性もあります。 そのため、耐久性を求める用途、最終製品として用いる用途ではベストとは言えません。

また、造形後のアルコール���溶剤での洗浄や二次加工、剥離によるサポート除去など後処理に手間が掛かるものが多いです。

どのようなシーンで選ぶべきか? 歴史的経緯として古くはラピッドプロトタイピングに多く使われてきましたが、3DプリンターのDDM(デジタル・ダイレクト・マニュファクチャリング:最終製品や治工具の製造に3Dプリンターを利用する)が浸透するにつれ、役割は変わりつつあると感じます。

個人向けの3Dプリンターでは良い機種が揃ってきていますので、強度・耐久性を必要としないシーンで小さなサイズのモデルを手軽に造形したい場合にお勧めです。

光造形方式の弱点を克服した機種がStratasysから登場 従来型の光造形方式の3Dプリンターの弱点であった耐久性の弱さや生産性の低さを克服した機種がOrigin Twoです。

Origin Twoは量産でも高精細であり、最終製品のパーツ生産に使用されることを想定しています。

高精細で表現力が最も高い インクジェット方式 ISO分類:材料噴射法(Material Jetting/マテリアルジェッティング) その他表記:PolyJet方式※Stratasys社 インクジェット方式の概要 インクジェット方式という通称もありますが、正式分類では材料噴射法と言います。

その名の通り、材料を噴射し、それに対し光を当てて1層1層積んでいきます。 構造が2Dプリンターでいうインクジェットプリンターに類似していることから、インクジェット方式と呼ばれています。

高精細でリアルな造形物を作ることができる方式です。

インクジェット方式 インクジェット方式の強み 高精細な造形物 第一に、高精細な造形物を作ることができるということが挙げられます。 積層痕の目立たないなめらかな造形物を作りたいなら、まず選択肢にあげると良いでしょう。

機種によってはカラー材料の使用や、フルカラー造形も 紙にカラー印刷できるように、3Dプリンターでもカラー印刷できる機種があります。 その原理は、2Dプリンターが複数カラーのインクを用いてカラー印刷を可能にしているのと同様で、複数のカラー材料を用いることで色を再現します。

後から塗装をする必要がなく、塗装時間の短縮や手間を省く事ができます。

上位機種ではPANTONE®カラー対応のフルカラー造形が可能な機種もあり、色にこだわるプロダクトデザインで、完成物とのイメージ乖離を防ぎます。

透明なクリア材料や、ゴムの質感の再現まで 複数の材料を同時に扱うことができる機種もあります。 アッセンブリ加工が必要なものが、ワンショットで造形できます。

デザイナーが思い浮かべたプロダクトのコンセプトを何もない所から具現化する強力なツールとなるでしょう。

3Dプリンターが描く未来の世界に最も近いものがこのインクジェット方式の3Dプリンターかもしれません。尚、この分野はストラタシス社がかなりリードしています。

布や皮革の生地に対して直接3Dプリントできる機種も 麻やフェルト、スウェードや皮革などの「生地」に3Dプリントする方式がハイブランドや大手メーカーにて採用されはじめています。

硬質素材だけではなく、ゴムのように柔軟性のある素材を含め、60万色フルカラーで3Dプリントできる機種があります(Stratasys J850 Prime FabriX)。

Stratasys J850 Prime FabriX インクジェット方式の弱み 強度・耐久性についてはFDM方式に劣ります。 噴射した材料���光を照射し硬化させるため、太陽光での劣化もあります。その面では光造形方式と同じです。

どのようなシーンで選ぶべきか? 試作におけるデザイン性・外観の再現での用途では群を抜きます。 デザインの価値が高まる中、メーカーにおけるデザイン部門・設計部署での導入に最適です。 構想設計から最終段階まで、リアリティを持った試作品を気軽に何度も出し直しして調整しながら創ることが可能です。

Stratasysのインクジェット(PolyJet)方式について詳しい解説はこちら

PolyJet方式の製品一覧はこちら

3Dプリンターで何をしたいですか? 結合剤を噴射する バインダージェット方式 日本語表記:粉末接着方式 ISO分類:結合材噴射法(Binder jetting) その他表記:バインダージェッティング方式 バインダージェット方式の概要 インクジェット方式(マテリアルジェッティング)は材料自体を噴射する方式でした。 それに対して、バインダージェット方式は、バインダー(=結合剤)の方を噴射することで造形物を固めます。 元々は石膏に結合剤を吹き付けて固める方式でした。 石膏という材質から後加工での着色がしやすく、フィギュアの造形や、簡易なデザインイメージの確認に用いられていました。

その後、金属、樹脂、セラミック等の材料でも造形できるようになり適用できる幅は広がりました。 尚、このバインダージェット方式の生みの親であるMITの研究者は、現在Desktop Metal社で金属3Dプリンターの開発に携わっています。

バインダージェット方式 バインダージェット方式の強み サポート材が不要であること、着色がしやすいこと、造形速度が速いことが挙げられます。

バインダージェット方式の弱点 表面精度が粗いこと、強度が弱いこと、粉末を取り扱い除去する必要があり、粉末の飛散による危険性や粉じん対策が必要であること、造形後に後処理の手間が掛かることが挙げられます。

どのようなシーンで選ぶべきか? 強度は求めないデザイン確認の用途に適合すると思います。

金属3Dプリンターの世界を一変 BMD方式 英語表記:Bound Metal Deposition方式 ISO分類:- その他表記:ADAM方式(Atomic Diffusion Additive Manufacturing) BMD方式の概要 金属3Dプリンターは金属粉を取り扱うため、取り扱いが容易ではありませんでした。 それを劇的に改善したのがBMD方式です。

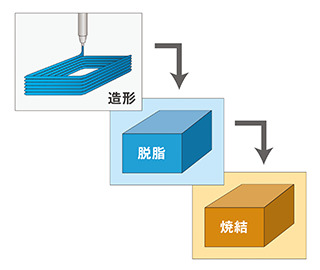

BMD方式は、3つの段階を経て金属の造形物を作ります。

BMD方式 1.3Dプリンターでの造形 まず3Dプリンターで造形します。金属とポリマーとワックスでできた素材を熱で溶解し、積層します。 しかしこれだけでは金属部品として求められる物性が得られません。 そこで、次の段階に進みます。

2.専用の脱脂装置でバインダーを除去する 金属とバインダーが混ざった状態から、ワックスを除去します。

溶剤を用いた工程が不要となる新しい方式の装置が登場しています。

3.専用の焼結装置で焼結する ピーク温度1400℃で焼結し、固めます。

これは製造業の世界では歴史があるMIM(Metal Injection Molding)の技術を応用したものです。

製品としてはこの金属3Dプリンターを含む3つの装置を1つのシステムとして提供する形式で販売されています。

BMD方式の強み 従来の金属3Dプリンターと異なり、専用の部屋を用意する必要がありません。

従来方式では、金属粉の粉塵対策、不活性化ガスを用いるための設備投資等、総合して投資規模・総保有コストが大きくなりがちでしたが、それを解決しています。

���た、3Dプリンター本体はFDM方式で造形するため、従来工法では実現できなかった複雑な形状も精度高く造形可能です。

金属3Dプリンターの導入をためらっていた企業様にこそ検討いただきたい方式です。

BMD方式の弱点 焼結の際にガスを使います。このガスのランニングコストも導入判断の評価ポイントになるでしょう。 ただし、ガスの使用量は機種によって大きな差があります。

また、有機溶剤を扱うため、オフィスで使うには局所排気装置が必要になります。 (しかし、総保有コストを考えると圧倒的な削減ができると言って良いでしょう。)

どのようなシーンで選ぶべきか? 金属素材で低コストに造形したい、金属の製品開発を高速化したい、金属パーツの多品種少量生産に使いたいといったシーンでは最適な方式です。

BMD方式の3Dプリンター Desktop Metal特設ページはこちら

3Dプリンターで何をしたいですか? 従来型の金属3Dプリンター パウダーベッド方式 ISO分類:粉末床溶融結合法(Powder Bed Fusion) その他表記:PBF方式 パウダーベッド方式の中には、レーザー熱源方式と、電子ビーム熱源方式があります。

レーザビーム熱源方式(Selective Laser Melting/SLM) 電子ビーム熱源方式(Electron Beam melting/EBM) パウダーベッド方式の概要 パウダーベッド方式は、金属粉末を敷き詰めた床に光線を照射し、その熱で焼結させる方式です。 金属のほかにナイロンや樹脂も用いられるケースがあります。

従来は金属を3Dプリンターで造形する際の主要な方式でした。

パウダーベッド方式 方式1.レーザー熱源方式 ハイパワーなレーザー光を照射することで金属粉末を焼結させます。

方式2.電子ビーム熱源方式 レーザーではなく電子ビームを照射する方式です。 レーザー熱源方式では難しかった銅の造形も可能な方式です。

パウダーベッド方式の強み BMD方式の登場で情勢は変わっていますが、金属を造形できる3Dプリンターとして有力な方式であったと言えます。

パウダーベッド方式の弱点 機器本体が高額であるということに加え、工場において設置する部屋の確保、粉塵対策・不活性化ガスの排出対策の空調設備など、装置外の投資規模が大きくなること。 オペレーターが金属粉末を吸入するリスク、金属粉末が工場内に拡散するリスクがあること。

サポート材の除去に手間が掛かること、表面がざらついた造形物になること、などが挙げられます。

どのようなシーンで選ぶべきか? 現時点では、まずパウダーベッド方式の弱点を克服したBMD方式を検討いただき、BMD方式では適合しない場合にパウダーベッド方式をあわせて検討いただくというのが良いと思います。

シート積層法 ISO分類:シート積層法(Sheet Lamination) シート積層法の概要 シート積層法は、薄いシートを重ね合わせて、接着剤や超音波で結合させる方式です。 結合した素材をレーザーでカットし成形します。

シート積層法の強み PVC、金属、紙等、他の方式ではあまり見られない材料を用いて造形可能です。 また、複数の金属素材を合わせて使うことができること等が挙げられます。

シート積層法の弱点 廃棄材料が多く出る可能性があること、他の方式に比べ造形精度が低いこと、中空構造が作りにくいこと、等が挙げられます。

どのようなシーンで選ぶべきか? 紙やPVCで造形したい場合、異なる金属素材を接合して用いたい場合などのシーンで有効になると思います。

3Dプリンターで何をしたいですか? 指向性エネルギー堆積法 ISO分類:指向性エネルギー堆積法(Directed Energy Deposition) その他表記:レーザーデポジション、レーザーメタルデポジション(LMD) 指向性エネルギー堆積法の概要 指向性エネルギー堆積法は、金属粉末を吹き付けながらレーザー光を照射することで肉盛り溶接する方式です。

指向性エネルギー堆積法の強み 金属の造形物ができること、異種材料を組み合わせて母材��は異なる金属の造形ができること、高熱で溶融するため耐久性が高い造形物ができること。また、大型造形が得意で造形速度も速い。

指向性エネルギー堆積法の弱点 金属粉末を扱うため取り扱いに注意を要すること、表面は粗い仕上がりになること、造形できる形状に制約が大きいこと等が挙げられます。

どのようなシーンで選ぶべきか? こちらも、まず従来型金属3Dプリンターの弱点を克服したBMD方式を検討いただき、BMD方式では適合しない場合に指向性エネルギー堆積法の機種を検討いただくというのが良いと思います。

CIM(Cast in motion)方式 CIMではまず「型を造るための枠」を3Dプリンターで高速造形します。その枠の中にエポキシ樹脂を流し込み、それが型になります。このエポキシ樹脂は熱硬化性樹脂のため、オーブンで加熱し固めることで機械的特性に優れた型が得られます。 型を造形するために用いた枠は、水に浸すとフレーク状に砕けるため容易に除去可能です。造形した型は、表面精度を高めるため切削加工で研磨する等、仕上げ処理を施して完成です。

型を造形するCIM方式 FRP用の成形型などにおいては、型を3Dプリンターで造形する方式が実用化されています。

パウダーベット方式 アルテックがお手伝いできること 3Dプリンターには様々な方式があり、非常に多くのメーカーがあります。

アルテックではお客様のニーズにお応えする上で、実績があり信頼性が高く、時代に適合したベストだと思えるメーカーのみ、厳選して取り扱っております。

(3Dプリンターの方式・仕組み・特徴を解説(2024年最新版) - 3Dプリンターならアルテックから)

0 notes

Text

LAP: A Highly Efficient Blue Light Photoinitiator Driving Innovation in Hydrogel and Bio-Printing Technologies With the rapid advancement of 3D printing, biomaterials, and photopolymerization technologies, the demand for efficient, low-toxicity photoinitiators has become increasingly urgent. LAP (Lithium phenyl-2,4,6-trimethylbenzoylphosphinate) is an innovative compound that has garnered significant attention for its role as a photoinitiator in various hydrogel formulations. As a blue light photoinitiator, LAP operates under blue light, rapidly initiating the curing of photosensitive hydrogel materials. This compound is particularly well-suited for use in photopolymer formulations, including hydrogel-based materials for 3D printing, coatings, inks, and bio-printing applications. LAP represents a significant advancement in the field of photoinitiators, offering several advantages over traditional UV-based photoinitiators. Due to its exceptional performance and broad range of applications, LAP has become a key player in photopolymerization technologies. In this article, we will explore the properties, applications, and benefits of LAP, as well as its potential in both biomedical and industrial sectors. Key Characteristics of LAP LAP possesses several distinctive properties that make it highly effective and versatile: - Excellent Water Solubility: LAP demonstrates outstanding solubility in water, with a dissolution rate of 4.7 wt%. This makes it an ideal choice for water-based formulations, ensuring easy integration into various hydrogel systems without causing precipitation or instability. - Long Wavelength Absorption: LAP effectively cures under violet and blue light in the range of 350-410 nm, particularly at 405 nm. This allows the use of longer-wavelength light, which causes less cellular and tissue damage compared to traditional ultraviolet (UV) wavelengths. - High Reactivity and Low Toxicity: LAP exhibits excellent cell compatibility, making it suitable for biomedical applications such as tissue engineering and cell-based 3D printing. At the recommended concentrations, LAP demonstrates superior photoinitiating capabilities without exhibiting detectable cytotoxicity. - Avoidance of Alkaline Additives: It is important to avoid contact with alkaline additives when using LAP, as they may interfere with its reactivity and overall performance. Applications of LAP LAP finds broad applications across various industries, particularly in areas where precise control over the curing of photosensitive materials is required: - 3D Printing: LAP is widely used in water-based 3D printing applications, particularly in bio-printing, where the use of biocompatible photoinitiators is essential. It enables rapid and efficient curing of hydrogels used in printing tissue engineering and regenerative medicine scaffolds. - Bio-Printing: In bio-printing, LAP facilitates the crosslinking of hydrogels containing live cells, providing a non-toxic, efficient, and controllable method for creating complex 3D cell-laden structures. Its long-wavelength absorption ensures that cells are not harmed by the curing light, making it ideal for creating viable tissue constructs. - Water-Based Coatings and Inks: LAP is also used in water-based coatings and inks, where it acts as a photoinitiator to cure the formulation under blue light. Its high-water solubility and low toxicity make it an excellent choice for developing environmentally friendly and safe coatings and inks. - Cell-Based Hydrogel Curing: LAP is effective in curing cell-laden hydrogels, making it an ideal option for applications such as cell encapsulation or tissue engineering. The ability to use blue light allows for fine control over the curing process without the harmful effects of UV light. - Long Wavelength Curing Systems: LAP is highly effective in long-wavelength curing systems, where its ability to absorb light in the 350-410 nm range is particularly beneficial. This feature expands its application to specialized curing processes that require precise light control. Cost Optimization: A Key to Industrialization Given LAP’s performance advantages and increasing market demand, our team has made significant progress in process development, establishing a mature manufacturing technology that paves the way for large-scale production. By optimizing production workflows and raw material sourcing, we aim to reduce costs, making LAP more competitive in the market and fostering its widespread adoption in photopolymerization materials and bio-printing applications. Future Outlook LAP’s highly efficient photopolymerization properties and biocompatibility hold tremendous potential in fields such as medicine, materials science, and 3D printing. As we continue to optimize LAP’s production technology, this photoinitiator will drive innovative applications at a lower cost and higher performance, facilitating the deeper integration of research and industry. The introduction of LAP marks a new era for photopolymerization and hydrogel technologies. Looking forward, we will continue to explore its potential across various fields, accelerating technological innovation and industrial advancement. Sales Link Lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) CAS 85073-19-4 on Watson Read the full article

0 notes

Link

0 notes

Text

The Impact of Dental 3D Printing: Market Trends and Innovations in Dentistry

Dental 3d Printing Industry Overview

The global dental 3D printing market size is anticipated to reach USD 15.9 billion by 2030, according to the new report of Grand View Research, Inc. The market is expected to expand at a CAGR of 26.4% from 2024 to 2030. The rising geriatric population globally and the rising number of patients with dental problems are anticipated to drive the market. Furthermore, the escalating demand for customized dental materials is likely to boost the growth of the market over the forecast period. The outbreak of coronavirus has caused havoc across all industries. Initially, the dental 3D printing market was impacted negatively by the outbreak, as most dental clinics and offices were closed in many parts of the world due to the global restrictions in early 2020. Furthermore, there was a decline in the number of dental procedures performed every year.

However, there has been a recovery in 2021, in most regions, especially Europe and North America as dental services regained normalcy. The dental 3D printing market in the Asia Pacific has been slower to recover, especially in India and China. However, the factors that had previously fuelled 3D dental printing, such as the expansion of corporate chains and dental clinics and the rising dental set-ups and the, are still in place. This is expected to drive the demand for dental 3D printers in the coming years. The need for faster turnaround times, smoother clinical workflows, and fewer dental appointments are likely to boost the market growth. Dental professionals are more likely to invest in advanced technologies like CAD/CAM and dental 3D printing to decrease the time taken to deliver dental treatment and appliances, hence the patients may be more likely to choose these solutions for the same reason.

Gather more insights about the market drivers, restrains and growth of the Dental 3d Printing Market

Moreover, the rising investment by major players, rapid technological advancements, and rising consumer awareness, are estimated to boost the demand for dental 3D printers, thereby fueling the growth of the market over the forecast period. The growing trend of resorting to dental procedures to enhance the personality is promoting the players in the dental 3D printing market to help dental professionals address the demand in the least possible time. Besides the rising demand for bridges and crowns among the aged population, the popularity of shaded printing material is increasing, owing to surging consumer proclivity for natural-looking teeth, especially among millennials.

Browse through Grand View Research's Medical Devices Industry Research Reports.

The global bipolar forceps market size was estimated at USD 962.2 million in 2024 and is projected to grow at a CAGR of 5.2% from 2025 to 2030.

The global electro-medical and electrotherapeutic apparatus market size was estimated at USD 66.2 billion in 2024 and is projected to grow at a CAGR of 6.4% from 2025 to 2030.

Dental 3D Printing Market Segmentation

Grand View Research has segmented the global dental 3D printing market on the basis of application, technology, end-use, and region:

Dental 3D Printing Application Outlook (Revenue, USD Billion, 2018 - 2030)

Orthodontics

Prosthodontics

Dentures

Temporary Tooth

Permanent Tooth

Implantology

Dental 3D Printing Technology Outlook (Revenue, USD Billion, 2018 - 2030)

Vat Photopolymerization

Stereolithography

Digital Light Processing

Polyjet Technology

Fused Deposition Modelling

Selective Laser Sintering

Others

Dental 3D Printing End-use Outlook (Revenue, USD Billion, 2018 - 2030)

Dental Clinics

Dental Laboratories

Academic And Research Institutes

Dental 3D Printing Regional Outlook (Revenue, USD Billion, 2018 - 2030)

North America

US

Canada

Europe

UK

Germany

France

Italy

Spain

Denmark

Sweden

Norway

Asia Pacific

China

Japan

India

Australia

South Korea

Thailand

Latin America

Brazil

Mexico

Argentina

Middle East & Africa

South Africa

Saudi Arabia

UAE

Kuwait

Key Companies profiled:

3D Systems

Stratasys Ltd.

Renishaw

Roland DG

SLM Solutions

EnvisionTec

DentsPly Sirona

Straumann

Form Labs

Prodways

Planmeca

Order a free sample PDF of the Dental 3d Printing Market Intelligence Study, published by Grand View Research.

0 notes

Link

0 notes

Text

0 notes

Text

Researchers propose 3D printing of high-performance elastomers through vat photopolymerization

Acrylate-based ultraviolet (UV)-curable resins are currently used as raw materials to obtain desired performance by adjusting the types and ratios of oligomer and reactive monomers in the resin system. However, due to low degree of free-radical polymerization, the elastomers prepared by vat photopolymerization (VPP) technology show low strength, poor resilience, and unsatisfactory mechanical properties. In a study published in Advanced Materials , the research group led by Prof. Wu Lixin from Fujian Institute of Research on the Structure of Matter of the Chinese Academy of Sciences proposed 3D printing of high-performance elastomers through vat photopolymerization. The researchers analyzed the structure-property relationship between molecular weight and mechanical properties, and selected polytetramethylene ether glycols (PTMGs) with different molecular weights (Mn=1000, 2000, 3000 g mol-1, respectively) as reactants to react with isophorone diisocyanate (IPDI). The obtained polyurethane blocked oligomers (PUBs) exhibited high viscosities.

Read more.

10 notes

·

View notes

Text

How SLA Enhances Product Design

One of the standout features of SLA is its accuracy. Traditional methods often struggle with intricate details, but SLA delivers impressive precision. This level of detail is crucial for industries like aerospace and medical devices, where every tiny element matters. For instance, custom implants made with SLA can significantly improve patient care. Thus, SLA not only boosts design quality but also contributes to better outcomes. Click the link and visit our website for more information!

#Stereolithography (SLA)#3D Printing#Rapid Prototyping#Photopolymerization#High Precision Manufacturing#Innovative Design#Industrial Applications#Eco-Friendly Technology#Complex Geometries#Manufacturing Solutions

1 note

·

View note

Text

How Can Good Oral Hygiene Help To Improve Mental Health?

Stained and crooked teeth can make a person introverted, and it can affect the mental health of the person. Healthy white teeth will visibly increase the confidence level of the person, and you will notice that oral hygiene is interrelated with mental health.

You will be astonished to know that the improved and elevated mood releases serotonin and dopamine which produce good vibes and it improves mental health. And to do that, you need Camphorquinone for teeth whitening.

Fresh breath

It is quite obvious that no one wants smelly breath. Therefore, the only way you can prevent bad breath is to take care of oral hygiene properly. The bad smells often signal you, and it may work as a symptom of any oral disease.

To maintain good oral health, you need to keep a proper routine to clean your mouth by using teeth-cleaning products. You should also opt for Camphorquinone to get the best possible results.

You may get the teeth whitening with photopolymerization option which will help you to purchase the product, and in a way, you can improve the smell of your breath.

The products related to photopolymerization come along with the teeth whitening discount code which helps the consumers to purchase the product to improve oral hygiene.

Therefore, for cavity-free and white teeth, a regular dental care routine can help you to stay away from you from oral diseases. So, the next time you are feeling low, invest in the best dental products and beautify your smile.

0 notes

Text

"Future of Healthcare: Innovations in the 3D Printing Medical Devices Market"

3D Printing Medical Devices Market Overview📊 :

The 3D Printing Medical Devices Market Report is a treasured source of insightful data for business strategists. It provides an in-depth assessment of numerous features of industries like market overview, present progress valuations, historical and future studies, current trends, SWOT valuations, and clients operating in several regions. The study provides valuable information to magnify the understanding, scope, and segments of this report. The report covers a comprehensive analysis of 3D Printing Medical Devices Market segmentation and regional and country breakdowns. This research will offer a clear and exact idea about the whole industry to the readers to make beneficial decisions.

According to Straits Research, the global 3D Printing Medical Devices Market size was valued at USD 2.55 Billion in 2022. It is projected to reach from USD XX Billion in 2023 to USD 9.79 Billion by 2031, growing at a CAGR of 16.1% during the forecast period (2023–2031).

This study pinpoints noteworthy trends influencing the trajectory of the Gesture Recognition market's expansion. Within this recently issued report, crucial dynamics encompassing drivers, limitations, and prospects are underscored. These aspects hold relevance for well-established market entities as well as emerging stakeholders engaged in the realms of production and supply.

Request a Sample Report @ https://straitsresearch.com/report/3d-printing-medical-devices-market/request-sample

Who are the 🏆leading players in 3D Printing Medical Devices Market?

3D Systems Corporations,

Bio3D Technologies,

Cyfuse Medical K.K.,

EnvisionTEC,

Materialise NV,

Organovo Holdings Inc.,

Oxford Performance Materials Inc.,

SLM Solutions Group AG,

Stratasys Ltd.

Moreover, the competitive analysis of the 3D Printing Medical Devices Market brings insight into the product usability profiles of the leading players. Additionally, the analysis highlights features & pricing, and informant reviews of the key products in the market.

Which segments are covered in 3D Printing Medical Devices Market?

By Component

Printers

Materials

Software & Services

Hardware

By Technology

Electron Beam Melting (EBM)

Laser Beam Melting (LBM)

Direct Metal Laser Sintering (DMLS)

Stereolithography (SLA)

Fused Deposition Modeling (FDM)

Selective Laser Melting (SLM)

Selective Laser Sintering (SLS)

Others (Photopolymerization, Digital Light Processing [DLP], etc.)

By Application

Orthopedic & Cranial Implant

Dental Restorations

Surgical Instruments

Tissue Fabrication

Custom Prosthetics

Prosthetics Implant

Wearable Medical Devices

Dentistry and Orthodontics

Others (Tissue-engineered Products, Plastic and Reconstructive Surgeries, etc.)

By Material

Plastics

Biomaterial Inks

Metals and Alloys

By End User

Hospitals and Surgical Centers

Dental and Orthopedic Clinics

Academic Institutions and Research Laboratories

Pharma-Biotech and Medical Device Companies

Clinical Research Organizations

The market is largely fragmented and the vast majority of the players functioning in the global 3D Printing Medical Devices Market are taking steps to raise their market footprint, by concentrating on product diversification and development, therefore making them seize a larger share of the market. The study highlights current market trends and provides a forecast. We also have highlighted future trends in the 3D Printing Medical Devices Market that will impact the demand during the forecast period. Overall, this report is an important resource for businesses seeking to stay ahead of the competition in the 3D Printing Medical Devices Market industry. With its complete analysis of recent developments and the latest emerging trends, it offers valuable insights into the market that can be used to grow effective growth strategies and enhance market positioning.

Access Detailed Segmentation @ https://straitsresearch.com/3d-printing-medical-devices-market/segmentation

Regional Analysis

Largest Market: The 3D Printing Medical Devices Market is dominated by North America, which holds the largest share due to factors such as advanced infrastructure, high consumer awareness, and significant investment in related industries. The region's well-established specific sectors further bolster its leading position in the market.

Fastest Growing Market: The fastest-growing market for 3D Printing Medical Devices Market is Europe. This growth is driven by a combination of rising disposable incomes, increasing adoption of specific products or services, and supportive government initiatives. Additionally, the expanding related industries in this region contribute to its rapid market expansion.

Our Report Offers:

– Market share assessments for the regional and country-level segments.

– Strategic recommendations for the new entrants.

– Competitive landscaping mapping the key common trends.

– Company profiling with detailed strategies, financials, and recent developments.

– Supply chain trends mapping the latest technological advancements.

Buy Now full 3D Printing Medical Devices Market report @ https://straitsresearch.com/buy-now/3d-printing-medical-devices-market/

An international 3D Printing Medical Devices Market research report delves into the competitive landscape of global markets, scrutinizing companies and manufacturers. The report's competitive analysis spotlights the strategic actions undertaken by key players across diverse industries. These actions encompass a spectrum of activities including new product introductions, expansions, agreements, joint ventures, partnerships, and recent acquisitions. This comprehensive market report sheds light on a myriad of facets within marketing research, spanning crucial industry trends, market size, estimated market share, sales volume, emerging patterns, product consumption, customer inclinations, historical data, forward-looking forecasts, and meticulous analysis of key players.

Global 3D Printing Medical Devices Market Research Report Forecast 2031

Chapter 1:- 3D Printing Medical Devices Market Overview

Chapter 2:- Economic Impact on Industry

Chapter 3:- Production, Business Opportunities with Potential Analysis

Chapter 4:- Rising Trends and New Technologies with Key Players

Chapter 5:- 3D Printing Medical Devices Market Manufacturing Cost Analysis

Chapter 6:- Technology Progress, Development Process and Downstream Buyers

Chapter 7:- Marketing Strategy Analysis, Distributors/Traders

Chapter 8:- Market Share by Key Countries in These Regions

Chapter 9:- Show the Market by Type and Application, With Sales Market Share and Growth Rate

Chapter 10:- Appendix and Data Source

Click to View the Full Report TOC: https://straitsresearch.com/report/3d-printing-medical-devices-market/toc

Key Questions Answered by Our 3D Printing Medical Devices Market Report

What are the key drivers of growth in the 3D Printing Medical Devices Market, and how do they vary across regions and segments?

How are advancements in technology and innovation affecting the 3D Printing Medical Devices Market, and what new opportunities and challenges are emerging as a result?

Which market players are currently leading the pack in terms of market share and product innovation, and what strategies are they employing to maintain their positions?

What regulatory and policy changes are on the horizon that could affect the 3D Printing Medical Devices Market, and how are market players adapting to these changes?

What are the emerging trends and market disruptors that are likely to shape the 3D Printing Medical Devices Market in the years to come, and what can businesses do to stay ahead of the curve?

How are consumer preferences and behaviors evolving with regard to 3D Printing Medical Devices Market, and what implications do these trends have for market players?

Buy Now full 3D Printing Medical Devices Market report @ https://straitsresearch.com/buy-now/3d-printing-medical-devices-market/

Thanks for reading this article; you can also get separate chapter-wise sections or region-wise report versions like North America, Europe, or Asia.

About Us:

Contact Us:

Email: [email protected]

Website: https://straitsresearch.com/

0 notes

Text

Dental 3d Printing Market Size, Trends, and Business Outlook 2024 - 2030

The global dental 3D printing market size was estimated at USD 3.1 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 26.4% from 2024 to 2030.

3D printing dentistry has established a strong position in today’s dental products due to the combination of state-of-art technology and a potential footprint. The design and development of advanced products such as invisible aligners, advanced fabrication to provide an aesthetic look, and delivery positioning are some of the factors that are increasing the demand and adoption of dental 3D printers. The user-friendliness and ease of 3D printing procedures have promoted the dentistry industry to print products that can meet the dental requirements of different individuals. These printers will increase the output and also reduce fabrication time. Furthermore, the digitalized workflow will also overcome procedural discomfort and enhance customer satisfaction.

The market is growing at a significant rate and is expected to grow further in emerging economies. The American College of Prosthodontists stated that about 15% of the edentulous population makes dentures each year. Edentulism affects the most vulnerable populations – economically disadvantaged and aging populations. Around 120 million people in the U.S. are missing at least one tooth and more than 36 million Americans do not have any teeth. These numbers are expected to grow in the next two decades. The majority of aged population needs to go for replacements of the tooth. However, even partially toothless, aged or young people undergo dental procedures as they view dental implants as a viable option.

Gather more insights about the market drivers, restrains and growth of the Dental 3D Printing Market

Dental 3D Printing Market Report Highlights

• By application, the orthodontics segment dominated the market in 2023 and is expected to witness significant growth over the forecast period. The growth of the segment is due to the increasing number of patients with misalignment and gaps in the teeth. Such factors are driving the market players to focus on the development of products associated with orthodontics

• Based on the technology, the others segment is projected to register the highest growth rate in the market owing to the rising investments in R&D related to material jetting, electron beam melting, and binder jetting techniques

• The dental laboratories was the dominant segment in the end-use segment in 2023. The segment is anticipated to exhibit the highest CAGR of 26.7% during the forecast period. The growing adoption of advanced technologies in laboratories is augmenting the growth of the segment

• North America is expected to maintain its lead in the dental 3D printing market owing to the technological advancements, rising R&D, and presence of major medical device manufacturers in the region

Browse through Grand View Research's Medical Devices Industry Research Reports.

• The global smart orthopedic implants market size was valued at USD 25.7 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2024 to 2030.

• The global pulse electromagnetic field (PEMF) therapy devices market size was valued at USD 523.4 million in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 6.0% from 2024 to 2030.

Dental 3D Printing Market Segmentation

Grand View Research has segmented the global dental 3D printing market on the basis of application, technology, end-use, and region:

Dental 3D Printing Application Outlook (Revenue, USD Billion, 2018 - 2030)

• Orthodontics

• Prosthodontics

o Dentures

o Temporary Tooth

o Permanent Tooth

• Implantology

Dental 3D Printing Technology Outlook (Revenue, USD Billion, 2018 - 2030)

• Vat Photopolymerization

o Stereolithography

o Digital Light Processing

• Polyjet Technology

• Fused Deposition Modelling

• Selective Laser Sintering

• Others

Dental 3D Printing End-use Outlook (Revenue, USD Billion, 2018 - 2030)

• Dental Clinics

• Dental Laboratories

• Academic And Research Institutes

Dental 3D Printing Regional Outlook (Revenue, USD Billion, 2018 - 2030)

• North America

o U.S.

o Canada

• Europe

o U.K.

o Germany

o France

o Italy

o Spain

o Denmark

o Sweden

o Norway

• Asia Pacific

o China

o Japan

o India

o Australia

o South Korea

o Thailand

• Latin America

o Brazil

o Mexico

o Argentina

• Middle East & Africa

o South Africa

o Saudi Arabia

o UAE

o Kuwait

Order a free sample PDF of the Dental 3D Printing Market Intelligence Study, published by Grand View Research.

0 notes