#Pharmaceutical Pellets

Explore tagged Tumblr posts

Text

Top Pharmaceutical Pellets Manufacturers in Hyderabad

Pharma pellets are small, spherical or cylindrical granules containing active pharmaceutical ingredients (APIs) or drug substances. They are typically produced using various techniques such as extrusion-spheronization, pelletization, or layering processes. These pellets can be coated with polymers or other materials to modify their release characteristics, improve stability, or mask taste. Pharma pellets offer several advantages over traditional dosage forms like tablets or capsules, including better dose uniformity, enhanced bioavailability, reduced side effects, and flexibility in formulation design. They are commonly used in pharmaceutical manufacturing for controlled-release or multiparticulate dosage forms.

If you are searching for the Top Pharmaceutical Pellets Manufacturers in Hyderabad, then we suggest you check out Bhasya International Private Limited. We are one of the leading manufacturers, exporters, and suppliers of distinct pharmaceutical products

Bhasya International Private Limited is a reputable pharmaceutical manufacturer, exporter, and supplier of pharmaceutical products, including pharmaceutical pellets. If anyone is looking for top pharmaceutical pellets manufacturers in Hyderabad, then consider exploring Bhasya International Private Limited for their needs. It's always essential to conduct thorough research and due diligence when selecting a supplier for pharmaceutical products to ensure quality, compliance, and reliability.

Visit : Top Pharma Companies in India to knowmore !

1 note

·

View note

Text

Shreeji Pharma International – Trusted pharma manufacturer and exporter from India.

#pharmaceutical company in india#cosmetic chemicals suppliers in india#veterinary raw materials suppliers#pellets manufacturer in india#pharmaceutical companies in india

0 notes

Text

https://www.vjinstruments.com/products/spheronizer/

Unleashing Precision and Efficiency with the Spheronizer

Discover the Spheronizer by VJ Instruments, a cutting-edge device designed to optimize the granulation process in pharmaceutical and laboratory settings. With its innovative technology, the Spheronizer ensures consistent particle size and shape, enhancing product quality and performance.

#VJ Instruments Spheronizer#Particle shaping#Spheronization technology#Pellet uniformity#Pharmaceutical processing#Drug delivery optimization

0 notes

Text

Pharmaceutical Pellets Market Overview, Competitive Analysis and Forecast 2031

#Pharmaceutical Pellets Market#Pharmaceutical Pellets Market Scope#Pharmaceutical Pellets Market Report#Pharmaceutical Pellets Market Research

0 notes

Text

#Largest pharmaceutical api manufacturers in india#Pharmaceutical pellets manufacturers#Best Active pharmaceutical ingredient manufacturers in india#Top excipients manufacturers in india#active pharmaceutical ingredient companies#pharmaceutical ingredients manufacturers#dutasteride API manufacturers in India

1 note

·

View note

Text

Trailer park Steve AU part 12 part 1 | part 11 | ao3

ha haaaa, i lied about waiting until monday. cw: angst, gory imagery, implied prescription drug abuse

In his dream it’s raining pills.

Steve is crying in his car as rainbow pellets rain from the sky, and then he’s pounding on the Munson’s door while the pills burst into fine powder against his hair, his skin, his clothes. Eddie doesn’t come to the door but suddenly he’s there, teleported outside of it, apologizing right away when Steve demands to know what’s wrong.

“I don’t understand what happened.”

A flash of eyes, of lips; his face doesn’t fully form, but he sweeps one of those perusing looks all over Steve, sees his frayed edges and invites him in to stitch them up.

They talk and laugh for hours — dream logic where the seconds are minutes are years — letting their knees knock together, letting their pinky fingers brush. All the while little pills plink plink against the siding, pharmaceutical hail storm, and suddenly it's morning; Steve has drifted off; Steve has never slept so well. There’s a throw blanket made of cat fur and the smell of coffee and scrambled eggs, Wayne humming sleepily to himself at the stove, waving a spatula in greeting when he spots Steve getting up.

“Mornin'!” he grins. “Ed’s still sleepin’, but feel free to stick around.”

Outside the rain comes harder, heavy knocks against the roof, and when Steve peers into the pan he sees that Wayne’s frying up dead birds. "Just about ready."

He spears a fork into a wing. The feathers start to smoke. “You take your coffee black?”

—

“Ma, you gotta get a job.”

“Hmm?”

She’s watching I Love Lucy.

Steve's head is in his hands.

His elbows are going numb where they’re propped on the breakfast table, and his temples throb, a steady band of pressure like a giant's palm around the sides and back of his skull, pulsing down his aching neck. He’s been staring at next month’s budget for so long it looks like hyro…hiero—?

Whatever. Egyptian shit.

He can’t tell if he’s shit at math or if the math just doesn’t work, but either way it’s not working, and neither is his fucking mom, and he finds himself thinking about this one time in middle school when they took a field trip to a factory with a big hydraulic press. Got to tour the control room; got to pick which fruits to crush.

He remembers the watermelon most vividly of all: the way the rind groaned under the machine’s steady weight, splintering slivers snaked over striped flesh; slowly, slowly, then suddenly, boom!!

Watermelon guts on the concrete floor.

(That was also the first time he got to touch a girl's butt; all the girl's squealed and jumped back from the explosion, and one of them backed herself right into his hand. It was Liz Collins, and it was one hundred percent an accident, because, like, gross, Liz Collins, but still.

Memorable day for two reasons.

God, he needs a nap.)

“A job, ma,” he sighs, a little louder this time. “I can... I don’t know, I can maybe ask around, see if anybody’s hiring? Or- talk to Claudia. Or Karen,” he snaps his fingers by his ear, “or Joyce! She might— yeah. Yeah, she might be able to call and put in a good word at Melvalds...”

She might also be busy being far the fuck away from here. He taps his pencil against his cheek as envy crashes over him. He should be in California. Should spend his time hitting on beach babes and surfing sunny waves instead of drowning in debt and wondering why he’s on a first-name basis with so many random moms.

His mom still hasn’t acknowledged a single word he's said. "Hello? Ma? What d'you think?"

She turns to look at him finally. Gives him a dreamy, lovely smile.

She always was so pretty. “…I’m sorry; what were you saying?”

—

Steve flushes his mom’s pills.

—

part 13

tagging whoever commented recently if your settings will let me @acedorerryn @ahsokatanoss @annabanannabeth @anne-bennett-cosplayer @awolfstudio @bananahoneycomb @bronwenmarie @cinnamon-mushroomabomination @courtjestermunson @cuips-not-cute @eddie-munsons-missing-nipple @eriquin @estrellami-1 @evillittleguy @fandomfix8 @grtwdsmwhr @hellion-child @hotluncheddie @jackiemonroe5512 @jaytriesstuff @lololol-1234 @messrs-weasley @nburkhardt @noodle-shenaniganery @ppunkpuppyy @rani-mayida @runninriot @sadcanadianwinter @silver-snaffles @singmeyoursimpsong @slowandsteddie @slutforcoffein @space-invading-pigeon @spookednsaucy @steddieas-shegoes @stevesbipanic @steves-strapcollection @teatimeeverybody @th30ra3k3n @thealwithnoname @thestarslittleking @thesuninyaface @trensu @vacantwatchers @violetsteve @wormdebut @yourmom-isgay @zoeweee @zombiecreatures

#trailer park steve au#steddie#steddie fic#steve harrington#eddie munson#wayne munson#steve harrington's parents#st fic#my writing#my fic

726 notes

·

View notes

Text

When scientists examined pellets from recycled plastic collected in 13 countries they found hundreds of toxic chemicals, including pesticides and pharmaceuticals. The results are published in a study led by scientists at the University of Gothenburg. Because of this, the scientists judge recycled plastics unfit for most purposes and a hinder in the attempts to create a circular economy. Delegates, scientists and health and environmental advocates from around the world are traveling to Nairobi, Kenya for the meeting of the third session of the Plastics Treaty Intergovernmental Negotiating Committee (INC-3), held from 13–19 November 2023 . There scientists will urge delegates to heed the latest science showing that because toxic chemicals are used to make all plastics, and plastics will adsorb other chemicals during use, there are no plastics that can be deemed safe or circular. "Plastic recycling has been touted as a solution to the plastics pollution crisis, but toxic chemicals in plastics complicate their reuse and disposal and hinder recycling," says Professor Bethanie Carney Almroth, of the University of Gothenburg.

Continue Reading.

243 notes

·

View notes

Text

When scientists examined pellets from recycled plastic collected in 13 countries they found hundreds of toxic chemicals, including pesticides and pharmaceuticals. Because of this, the scientists judge recycled plastics unfit for most purposes and a hinder in the attempts to create a circular economy. The results are published in a study led by scientists at the University of Gothenburg. Delegates, scientists and health and environmental advocates from around the world are traveling to Nairobi, Kenya for next week's meeting of the third session of the Plastics Treaty Intergovernmental Negotiating Committee (INC-3).

Read more.

35 notes

·

View notes

Text

Exploring the World of Industrial Machinery: Ball Mill Manufacturers, FBD Fluid Bed Dryers, and Spheronizers

In the realm of industrial machinery, three key players stand out: Ball Mill Manufacturers, FBD Fluid Bed Dryers, and Spheronizers. Each plays a crucial role in various industries, contributing to the global economy.

Ball Mill Manufacturers

Ball mills are indispensable in industries such as mineral processing, paints, and ceramics, among others. They are used for grinding and blending materials into very fine powders. The manufacturers of these machines are known for their engineering prowess and commitment to quality. They ensure that these machines are designed and built to withstand the rigors of heavy-duty operations, while providing optimal performance.

FBD Fluid Bed Dryers

Next, we have the FBD Fluid Bed Dryers. These machines are essential in the pharmaceutical industry, where they are used for drying granules, powders, and other particulate materials. The principle behind their operation is simple yet effective - hot air is introduced into a plenum below a perforated plate, and as the air rises, it lifts and mixes the material, allowing for efficient and uniform drying. Manufacturers of these machines prioritize precision, reliability, and energy efficiency, ensuring that their products meet the stringent requirements of the pharmaceutical industry.

Spheronizers

Last but not least, we have Spheronizers. These machines are used to form spherical pellets from a wet mixture or granulation. The process involves spinning the material in a friction plate, causing the particles to roll and form into spheres. This technique is widely used in the pharmaceutical industry, particularly in the production of controlled-release drugs. Spheronizer manufacturers focus on ensuring that their machines offer high levels of precision and consistency, which are critical in pharmaceutical applications.

In conclusion, Ball Mill Manufacturers, FBD Fluid Bed Dryers, and Spheronizers are key players in the industrial machinery sector. Their contributions are vital in various industries, particularly in pharmaceuticals, where precision, reliability, and efficiency are of utmost importance. As we continue to advance technologically, we can expect these machines to evolve and become even more efficient and reliable, further solidifying their roles in the industrial sector.

2 notes

·

View notes

Text

【The ultimate guide to choosing the perfect Dry Ice Cleaning Machineand dry ice machine for your needs】

UNDERSTANDING YOUR REQUIREMENTS

1. Determine your application area:

Before diving into machine specifications, determine your primary application. Whether it’s industrial cleaning, food preservation, or special effects in the entertainment industry, understanding your specific use case will allow you to more accurately select the machine that’s best for you.Or you can tell us your needs and we will recommend the best solution for you.

2. Dry ice quantity issue:

Consider the amount of dry ice you need. Industrial applications may require high-capacity machines, while smaller equipment can meet smaller-scale needs. Understanding your production requirements is critical.You can refer to 【Dry Ice Production Demystified: Go Behind the Scenes and Uncover the Magic of Pelletizers】and 【How to set up your own dry ice manufacturing factory?】Learn more about dry ice in two articles.

TYPES OF DRY ICE CLEANERS AND DRY ICE PELLETIZERS

1. Dry ice cleaning machine(Dry ice blasting machine):

Compressed air is used to accelerate dry ice pellets to supersonic speeds and spray them onto the surface being cleaned. The high-speed ice particles hit the dirt, and through the freezing and mechanical action of the ice, the dirt is peeled off the surface.It is widely used for cleaning machinery and equipment, production lines, building surfaces, etc. It is especially suitable for the food and pharmaceutical industries because the cleaning process does not require water or chemicals.(Want to learn more about Dry Ice Cleaning?)

· P7X Dry ice cleaning machine: Very suitable for cleaning carbon deposits and oil stains in car engines. It can effectively complete cleaning without damaging engine parts etc..(Suitable for use in car repair service centers, auto repair shops, home cleaning and maintenance, etc.)Go to view product details

· A625i Dry ice cleaning machine: Suitable for cleaning oily molds, motor windings, paint rust cleaning, and printing machine ink residues etc.. (Suitable for rubber factories, shoe factories, factory machine maintenance, etc.)Go to view product details

· P60 Dry ice cleaning machine: Used for car interior renovation and cleaning, car seat cushions, surface glue residue, and oil stain cleaning etc..(Suitable for use in car repair service centers, auto repair shops, home cleaning and maintenance, etc.)Go to view product details

· T6 Dry ice cleaning machine: Used for PCB circuit board renovation and cleaning, soldering residue, surface glue residue, oil stains, PPS material deburring, etc. (Suitable for component factories, component maintenance, factory machine maintenance, etc.)Go to view product details

· B3+ Dry ice cleaning machine: Used for cleaning motor winding dust, printing machine ink, oil sludge, rust stains, heavy oily metal, etc.(Used to clean and maintain a variety of industrial equipment, including engines, pumps, valves, pipes, etc.)Go to view product details

Generally speaking, the dry ice cleaning machine is an efficient, environmentally friendly, and multi-purpose cleaning equipment. Its working principle is based on high-speed spraying of dry ice particles to clean the surface through freezing and mechanical impact. The advantages of this cleaning method include being water-free, leaving no chemical residue, being non-abrasive, suitable for a variety of surfaces and materials, and having a wide range of applications in a variety of industries.

For potential users, when choosing a dry ice cleaning machine suitable for specific needs, factors such as cleaning objectives, working environment, cleaning effect requirements, production capacity and budget need to be considered. Whether in industrial, food, medical or other industries, dry ice cleaning machines have demonstrated their excellent performance in improving cleaning efficiency and protecting equipment surfaces.You can also tell us your needs and our engineers will recommend the most suitable solution for you. Contact an engineer now >>

2. Dry ice pellet machine(Dry Ice Granulator Machine):

Dry ice pelletizer is a piece of equipment specially used to turn liquid carbon dioxide (CO2) into solid carbon dioxide (dry ice) pellets.

Dry ice pelletizers usually deliver liquid CO2 into the machine through a liquid carbon dioxide supply system. Liquid carbon dioxide undergoes a series of cooling and pressurization processes, causing its temperature and pressure to rise. The pressurized liquid carbon dioxide passes through the nozzle or spray head and enters a relatively low-pressure environment. In this environment, liquid CO2 rapidly relaxes and expands, lowering its temperature and turning into a solid state. Because the temperature drops sharply, liquid CO2 turns into a gaseous state and forms tiny CO2 particles, known as dry ice particles.

The Dry ice machine can efficiently convert liquid CO2 into a large number of evenly distributed dry ice pellets. The advanced control system can achieve precise control of parameters such as temperature, pressure and particle size to ensure the production of dry ice that meets requirements. Some Dry Ice Granulator have adjustable mechanisms that allow the user to select different sizes of dry ice pellets. There is no need to add any chemicals during the manufacturing process, and the waste material is CO2 gas, so the dry ice pelletizer is considered a relatively environmentally friendly production method. Most Dry Ice Pelletizer Making Machine are equipped with automated operation functions, including automatic adjustment and monitoring systems to improve production efficiency.

3. Dry Ice Block Machine(Dry ice briquetting machine):

A dry ice block press is a piece of equipment specifically designed to compress dry ice pellets or pieces into block form.

Dry ice block presses typically use previously produced dry ice pellets or chips as raw material. These pellets or chips are usually prepared through an overhead dry ice pelletizer or other means. Dry ice raw material is transported to the compression zone and heated to a certain level. The purpose of heating is to cause the dry ice pellets or blocks to begin to soften and melt. After heating, the softened dry ice is placed in a compression zone, where compression machinery or a hydraulic system exerts tremendous pressure to compress the dry ice into blocks. The compressed dry ice blocks pass through the cooling system, where they are quickly cooled and re-solidified to form solid dry ice blocks. The formed dry ice blocks enter the collector through the collection system, and then enter the packaging area through the conveyor system for final packaging.

Go to view product details >>

Main feature:

Efficient production: The dry ice block press can efficiently convert dry ice pellets or fragments into large, solid dry ice.

Uniformity of dry ice blocks: Compression machinery and control systems ensure uniform shape and size of dry ice blocks, suitable for different applications.

Save space: Dry ice in block form is easier to store and transport than in crushed or pellet form, thus saving space.

Energy savings: Previously produced dry ice pellets or crumbs are used as raw material, reducing the need for additional refrigeration and helping to save energy.

Automated operation: Most modern dry ice block presses are equipped with automated operation functions, including automatic adjustment and monitoring systems to improve production efficiency.

Application areas:

Food and pharmaceutical transportation: Dry ice blocks are widely used in cold chain transportation to keep food and pharmaceuticals at low temperatures.

Laboratory and scientific research: In laboratories and scientific research fields, dry ice blocks are used to prepare low-temperature environments, such as refrigeration reagents.

Special effects production: Dry ice cubes are often used in film productions and stage performances to create special smoke and cold fog effects.

Environmentally Friendly Cleaning: Dry ice cubes are also used in the cleaning industry for cleaning and removing dirt, especially for electrical equipment cleaning.

Overall, the dry ice block press provides a reliable production method for producing large blocks of dry ice, suitable for the different needs of multiple industries.

RODUCTION CAPACITY

Evaluate the machine's productivity in pounds per hour. Make sure it fits your needs without sacrificing quality. To meet high-volume demand, faster production may be required.

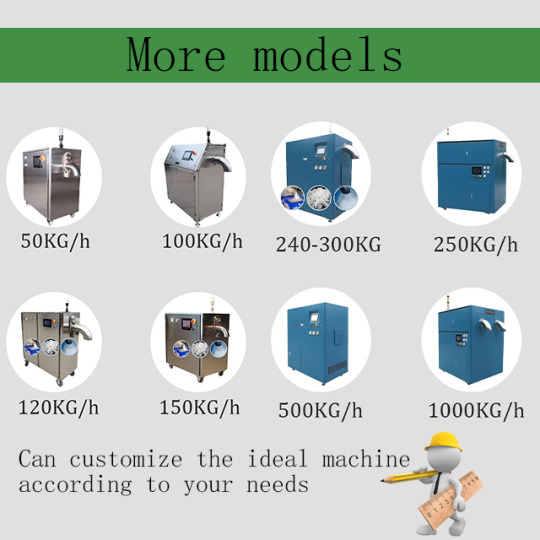

OLLITAL aims to provide customers with more choices in production capacity. Independently developed: 50KG/H (110 lbs/H), 100KG/H (220 lbs/H), 150KG/H (330 lbs/H), 250KG/H (551 lbs/H), 500KG/H (1102 lbs/H), and 1000KG/H (2204 lbs/H) dry ice pellet machine. Or you can tell us your needs and our engineers will customize the most suitable solution for you according to your needs. Contact an engineer immediately for customization >>

TECHNICAL SPECIFICATIONS

1. Size and portability:

Consider the physical size of the machine. A compact, portable unit may be better for versatility and ease of use, especially if you work from different locations or have limited space. If you need to move your cleaning equipment between job sites, choosing a dry ice blaster that is compact and portable may be key. This is important for tasks that require frequent movement or operation in limited spaces.

* Machine size: View the actual dimensions of your dry ice blaster, including length, width, and height. Make sure the machine is sized to fit your workplace and can be easily stored or carried.

* Weight: In addition to size, consider the weight of your dry ice blaster. The lightweight design can improve portability, reduce the burden of transportation, and make the device easier to carry and operate.

* Easy to carry design: Choose a machine with a user-friendly carrying design, such as handles, wheels, or other structures for easy movement. These designs make it easier for operators to move equipment from one location to another.

* Versatility: Some portable dry ice blasters are designed for versatility and can be used in a variety of applications. This flexibility increases the equipment's usefulness and makes it suitable for different types of cleaning tasks.

* Easy to store: Consider the storage needs of the machine when not in use. Some machines may have folding or removable parts to make it easier to store in limited spaces.

* Power and energy requirements: Consider the power and energy requirements of your dry ice blaster. Portable devices are often easier to connect to different types of power sources, such as batteries, generators, or standard electrical outlets.

When selecting a dry ice blaster, considering size and portability can ensure the equipment is better suited to your job requirements, increasing operational flexibility and efficiency.

2. Automation and control:

Automation and control are crucial considerations when selecting a dry ice pelletizer and cleaning machine. Look for user-friendly controls and automation features. An intuitive interface and automation streamline operation, making the machine easier for operators of all skill levels to use.

* Intuitive interface: Choose a dry ice granulator/cleaner with an intuitive interface. An intuitive control panel or touch screen makes it easier for operators to understand and operate the equipment, reducing training time.

* User-friendly controls: Consider choosing a machine with user-friendly controls. Simple buttons, knobs or digital controls allow operators to easily adjust and monitor cleaning parameters.

* Default program: Look for machines with preset cleaning programs. Preset programs improve operational consistency and efficiency, reducing manual setup and adjustments by the operator.

* Automation features: Understand whether the machine has automated functions, such as automatic nozzle adjustment, cleaning trajectory planning, etc. These features simplify the cleaning process and reduce operator intervention.

* Remote control and monitoring: If possible, choose machines that support remote control and monitoring. In this way, operators can monitor and adjust the cleaning process remotely, increasing the operational flexibility of the equipment.

* Fault diagnosis and alarm system: Look for machines with fault diagnosis and alarm systems. These systems can detect and report potential problems in a timely manner, helping to quickly resolve faults and improve equipment reliability.

* Data logging and reporting: Some advanced dry ice cleaning machines have data logging and reporting capabilities that can record key parameters during the cleaning process. This is very useful for quality control and traceability.

* Programmability: If you need to personalize it for a specific application, consider choosing a machine with some programmability to accommodate different cleaning needs.

By choosing a dry ice pelletizer/cleaner with an intuitive interface, automated features, and user-friendly controls, you can increase the ease of use of your equipment, reduce training costs, and ensure consistent cleaning results among operators of different skill levels .

Choosing the perfect dry ice machine requires a thorough understanding of your specific needs, technical specifications, and cost considerations. By carefully evaluating these factors, you will be able to make an informed decision that meets your application requirements and provides long-term value.

Whether you're venturing into a new business or upgrading an existing setup, investing the time in selecting the right dry ice machine is a critical step toward efficiency and success.

If you want to know more about Dry Ice Pellet Manufacturing Machinery or you want to build a dry ice production line, please refer to [Dry Ice Production Demystified: Go Behind the Scenes and Uncover the Magic of Pelletizers].

In this era of cleaning revolution, choose a dry ice cleaning machine to make cleaning easier, more efficient and more environmentally friendly! Thank you for reading our blog, if you have any questions or cooperation intentions, please feel free to contact us. Let us help the cleaning industry together and create a better future!

2 notes

·

View notes

Text

Discover Shreeji Pharma International's commitment to quality, innovation, and customer satisfaction. We ensure excellence in pharmaceutical sourcing and supply.

#pharma chemicals#pharmaceuticals raw materials suppliers#pellets manufacturer in india#pharmaceutical company in india#veterinary raw materials suppliers

0 notes

Text

Top Pharmaceutical Pellets Manufacturers in Hyderabad

Top Pharmaceutical Pellets Manufacturers in Hyderabad, Bhasya International. We have been tirelessly working to manufacture a wide range of products.

0 notes

Text

Mastering the Art of Precision Particles from VJ Instruments Spheronizer

Perhaps the worst nightmare of most manufacturing processes, especially in pharmaceuticals, chemicals, and food production, would be to have inconsistent particle size, and hence, resultant particle shape. Particles that are irregularly shaped often lead to inefficiencies in coating, poor uniformity in drug delivery, and increased quality control issues. As the demand for accuracy in product recipes continually rises, there should be an immediate solution to outweigh these mounting problems while attaining increased standards in production. This is where the VJ Instruments Spheronizer illuminates as a means to achieving accuracy in particle shaping and manufacturing quality standards.

Common Problems with Particle Shaping Solved by VJ Instruments Spheronizer

For example, in the pharmaceutical processing industry for drug preparation, particles should be of the same size and shape. This avoids huge variations in coating thickness caused by irregularly shaped particles, which leads to unpredictable release profiles, and consequently affects the overall effectiveness of the product. In the food industry, this irregular shape of particles leads to poor flavor distribution, resulting in an unbalanced consumer experience.

Common legacy pelletizing technologies do not provide precision in terms of product uniformity, especially in particle size. As a result, manufacturers face more frequent variability in products, increased waste, and higher production costs simply because they lack the correct equipment. The VJ Instruments Spheronizer has been made precisely for such a purpose.

How VJ Instruments Spheronizer Operates

The VJ Instruments Spheronizer is a device used to transform nondiscrete particles into almost perfectly round spheres through spheronization. This is particularly valuable in pharmaceutical processing, where pellets must be uniform to be coated, granulated, or used for controlled drug delivery.

The Spheronizer uses centrifugal force to turn particles in a disc or bowl and allows them to grind on the surface and against each other. Gradually, particles become more rounded and more spherical.

Technically described, the machine is built for simplicity and is easy to use, not only for the most skilled technician but also for general workers who can achieve precise results with ease.

VJ Instruments Spheronizer Key Features:

Adjustable Rotational Speed:��Allows particles of desired size and sphericity based on the application requirements.

Compact Design: Suitable for laboratories with limited space but requiring high accuracy.

Efficient Throughput: Ensures consistent quality in both high-volume and low-volume production, effective for both small-scale testing and large operations.

Real-World Applications and Benefits

The VJ Instruments Spheronizer has proven itself to be a universally essential tool across several industries. In the pharmaceutical sector, the size uniformity of the pellets produced improves coatability and drug release profiles. More efficient coating leads to better patient outcomes, particularly for extended-release drugs.

In the food industry, the Spheronizer produces granules that are uniformly shaped, ensuring that flavorings, seasonings, or additives evenly cover the whole mass. Additionally, it reduces waste by eliminating over-coating or overuse of ingredients.

A case study shows how one company, which faced various drug release problems due to low pellet uniformity, installed the VJ Instruments Spheronizer. As a result, variations in pellet uniformity were minimized by 30%, while the usage of coating materials was reduced by 20%, leading to a good return on investment.

Common Misconceptions and Clarifications

Many people believe that the Spheronizer technology is only associated with the pharmaceutical industry. Although it is useful for the pharmaceutical industry , the VJ instruments Spheronizer can be used in chemical , cosmetic , and even the food industry, where uniform particle shaping is vital.

Another false impression is that the Spheronizer is difficult to use. In fact, the equipment is designed for simplicity, with a user-friendly control mechanism that allows even novice operators to adjust the settings based on their needs.

Ready to Scale Up Your Manufacturing?

Find out how the VJ Instruments Spheronizer can give you operational improvements and consistent high-performance results. Contact us today to see how this revolutionary technology can become part of your lab.

#VJ Instruments Spheronizer#Particle shaping#Spheronization technology#Pellet uniformity#Pharmaceutical processing#Drug delivery optimization

0 notes

Text

Pharmaceutical Pellets Market Overview, Competitive Analysis and Forecast 2031

#Pharmaceutical Pellets Market#Pharmaceutical Pellets Market Scope#Pharmaceutical Pellets Market Report#Pharmaceutical Pellets Market Research

0 notes

Text

The Role of Oxygen Scavengers in the Oil and Gas Industry: Applications and Benefits

The oil and gas industry is a vital sector of the global economy. It provides the energy required to power our homes, businesses, and industries. However, the products and processes used in this industry are often subject to oxidation, which can lead to corrosion, spoilage, and other detrimental effects. Oxygen scavengers are a class of chemical compounds that can help prevent these problems. In this article, we'll explore the role of oxygen scavengers in the oil and gas industry, as well as their applications and benefits. Additionally, we'll touch on the use of oxygen scavenging films in food packaging and oxygen scavenger pharmaceutical packaging.

What are Oxygen Scavengers?

Oxygen scavengers are chemical compounds that react with and remove oxygen from their surroundings. They are commonly used in a variety of applications where oxygen can cause damage or spoilage. Oxygen scavengers can take the form of powders, pellets, or films, and they are often added to products or packaging to protect them from the harmful effects of oxygen.

Applications of Oxygen Scavengers in the Oil and Gas Industry

In the oil and gas industry, oxygen scavengers are used to prevent corrosion, a process that occurs when oxygen reacts with metal surfaces. Corrosion can cause leaks, equipment failures, and other safety hazards. Oxygen scavengers work by removing oxygen from the environment, thus preventing it from reacting with metal surfaces. This helps to extend the life of equipment and prevent safety hazards.

Another application of oxygen scavengers in the oil and gas industry is in the preservation of oil and gas products. When oil or gas is exposed to oxygen, it can undergo oxidation, which can cause it to spoil or degrade. Oxygen scavengers can be used to remove oxygen from storage tanks, pipelines, and other equipment, thus helping to preserve the quality of these products.

Benefits of Oxygen Scavengers in the Oil and Gas Industry

The use of oxygen scavengers in the oil and gas industry offers several benefits, including:

Corrosion Prevention: By removing oxygen from the environment, oxygen scavengers can help prevent corrosion, which can extend the life of equipment and prevent safety hazards.

Improved Product Quality: Oxygen scavengers can help preserve the quality of oil and gas products by preventing oxidation and spoilage.

Cost Savings: By preventing corrosion and improving product quality, oxygen scavengers can help reduce maintenance costs and prevent the need for costly repairs.

Oxygen Scavenging Films in Food Packaging and Pharmaceutical Packaging

Oxygen scavenging films are also used in food packaging and pharmaceutical packaging. In these applications, oxygen scavengers help to preserve the freshness and quality of the products by removing oxygen from the packaging. This helps to extend the shelf life of the products and prevent spoilage.

In food packaging, oxygen scavenging films are commonly used for products such as meat, cheese, and baked goods. These products are particularly susceptible to spoilage caused by oxygen exposure. Oxygen scavenging films can help to prevent this by removing oxygen from the packaging.

In pharmaceutical packaging, oxygen scavenging films are used to preserve the quality and efficacy of drugs. Oxygen exposure can cause degradation of certain drugs, which can reduce their effectiveness. Oxygen scavenging films can help to prevent this by removing oxygen from the packaging.

Conclusion

Oxygen scavengers play a vital role in the oil and gas industry, as well as in food packaging and pharmaceutical packaging. They offer several benefits, including corrosion prevention, improved product quality, and cost savings. By removing oxygen from the environment, oxygen scavengers can help to extend the life of equipment and products, prevent spoilage, and preserve the effectiveness of drugs. As such, they are an important tool in maintaining the safety, quality, and efficiency of various products and processes.

#Oxygen scavenger pharmaceutical packaging#Oxygen scavenging films in food packaging#corrosion blocker#rust inhibitor for water#Oilfield chemicals manufacturer in India#Oilfield chemicals exporter in India#petrochemical companies#petrochemical industries#petrochemical solutions#oil and gas industry#oil and gas companies

6 notes

·

View notes