#Pallet Wrap Reusable

Explore tagged Tumblr posts

Text

Reusable Pallet Wraps: A Practical Solution for Logistics

Embracing sustainable practices is now essential. Alternatives such as reusable pallet wraps and U-boat covers are crucial for fulfilling both operational and ecological requirements. They represent the future of packaging in logistics.

0 notes

Text

Logistics Packaging Market: Advanced Technologies in Packaging Design

The Logistics Packaging Market is expected to experience robust growth during the forecast period, driven by increasing global trade activities, the rapid expansion of e-commerce, and the rising demand for durable and efficient packaging solutions across various industries. Innovations in sustainable materials and customized packaging solutions are also contributing to market expansion.

Read Complete Report Details of Logistics Packaging Market: https://www.snsinsider.com/reports/logistics-packaging-market-2728

Market Segmentation

By Packaging Durability Type

Flexible Logistics Packaging

Description: Includes lightweight and adaptable materials such as films, wraps, and bags used for packaging.

Growth Drivers: Rising demand for cost-effective and space-saving solutions in logistics.

Trends: Adoption of biodegradable and recyclable flexible materials.

Rigid Logistics Packaging

Description: Includes sturdy and durable containers such as crates, pallets, and drums.

Growth Drivers: Increased use in heavy-duty and long-distance transportation.

Trends: Growing use of returnable and reusable rigid packaging solutions.

By Material Durability Type

Durable Goods

Description: Packaging solutions for long-lasting products like electronics, machinery, and furniture.

Growth Drivers: Growth in international trade of durable goods.

Trends: Use of customized and protective packaging to prevent damage during transit.

Non-Durable Goods

Description: Packaging for perishable or short-lifespan goods like food, beverages, and healthcare products.

Growth Drivers: Increased demand for logistics solutions in the food and pharmaceutical industries.

Trends: Emphasis on temperature-controlled and sustainable packaging solutions.

By Material

Plywood

Growth Drivers: Preferred for packaging heavy and fragile goods due to its high strength-to-weight ratio.

Trends: Use of treated plywood to enhance durability and prevent moisture damage.

Wood

Growth Drivers: Traditional material used for crates and pallets, especially in export packaging.

Trends: Shift towards certified and sustainably sourced wood materials.

Corrugated

Growth Drivers: Lightweight and recyclable, widely used in e-commerce and retail packaging.

Trends: Innovations in corrugated box design to improve strength and reduce material usage.

Plastic

Growth Drivers: Durable and versatile, used in both flexible and rigid packaging solutions.

Trends: Increasing use of recycled and biodegradable plastics.

Steel

Growth Drivers: Utilized for high-value and heavy-duty logistics needs.

Trends: Development of lighter steel packaging solutions to reduce costs.

Others

Growth Drivers: Includes innovative materials such as composite and foam-based packaging.

Trends: Exploration of new materials with better environmental profiles.

By End-Users

Automotive

Growth Drivers: Rising demand for protective packaging for automotive parts and components.

Trends: Use of reusable packaging solutions to reduce costs and waste.

Healthcare

Growth Drivers: Growth in pharmaceutical logistics and demand for temperature-sensitive packaging.

Trends: Adoption of tamper-proof and sterile packaging solutions.

Food & Beverages

Growth Drivers: Expanding global food trade and the need for protective and insulated packaging.

Trends: Use of innovative materials to extend product shelf life.

Manufacturing

Growth Drivers: Increasing industrial production and export of machinery and equipment.

Trends: Emphasis on robust packaging to ensure safety during transportation.

Consumer Goods

Growth Drivers: Rising e-commerce activities driving demand for lightweight and protective packaging.

Trends: Customization and branding through packaging design.

Others

Growth Drivers: Includes niche sectors such as electronics and textiles requiring specialized logistics packaging.

Trends: Tailored solutions for unique industry needs.

By Type

Individual Packaging

Description: Packaging designed for single items or units.

Growth Drivers: High demand in the e-commerce and retail sectors.

Trends: Focus on aesthetic appeal and sustainability.

Inner Packaging

Description: Protective materials used within outer packaging to secure products.

Growth Drivers: Increased focus on product safety during transit.

Trends: Use of air cushions, foam, and other shock-absorbent materials.

Outer Packaging

Description: Larger packaging solutions for bulk and long-distance transportation.

Growth Drivers: Rising exports and need for robust packaging.

Trends: Development of collapsible and reusable outer packaging.

Regional Outlook

North America

Growth Drivers: Strong e-commerce market and advanced logistics infrastructure.

Trends: Emphasis on sustainable packaging solutions to align with environmental regulations.

Europe

Growth Drivers: High export volume and stringent packaging standards.

Trends: Increasing investment in biodegradable and recyclable materials.

Asia-Pacific

Growth Drivers: Rapid industrialization, urbanization, and e-commerce growth.

Trends: Expansion of logistics networks in emerging markets like India and Southeast Asia.

Latin America

Growth Drivers: Growing trade activities and development of regional logistics hubs.

Trends: Demand for cost-effective and durable packaging solutions.

Middle East & Africa

Growth Drivers: Expanding oil & gas exports and increasing food imports.

Trends: Focus on customized and robust packaging for industrial applications.

Market Trends and Opportunities

Sustainability: Rising focus on environmentally friendly materials, including biodegradable plastics and recyclable corrugated packaging.

Customization: Growing demand for tailored packaging solutions to cater to industry-specific needs.

Technology Integration: Adoption of IoT-enabled packaging for real-time tracking and monitoring during transit.

E-Commerce Growth: Increased emphasis on lightweight, durable, and cost-effective packaging to support last-mile delivery.

Market Outlook

The Logistics Packaging Market is poised for substantial growth through 2032, driven by increasing globalization, advancements in packaging materials, and rising consumer demand for efficient and sustainable packaging. Innovations in design and technology will play a key role in shaping the market, with a strong emphasis on reducing environmental impact while enhancing product safety and cost-efficiency.

About Us:

SNS Insider is a global leader in market research and consulting, shaping the future of the industry. Our mission is to empower clients with the insights they need to thrive in dynamic environments. Utilizing advanced methodologies such as surveys, video interviews, and focus groups, we provide up-to-date, accurate market intelligence and consumer insights, ensuring you make confident, informed decisions.

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

0 notes

Text

DIY Modern Wooden Christmas Tree: Step-by-Step Guide to Holiday Crafting

The holiday season is the perfect time to let your creativity shine! This year, why not add a touch of modern elegance to your Christmas decor with a DIY wooden Christmas tree? These minimalist, eco-friendly trees are easy to craft and bring a warm, rustic charm to your space. Whether you're looking for an alternative to traditional trees or just want to add a unique piece to your home, this step-by-step guide will help you create a stunning wooden Christmas tree.

🔴 Why Choose a Wooden Christmas Tree? Wooden Christmas trees are growing in popularity for several reasons

🌿 Eco-Friendly - They’re reusable and reduce the need for cutting down real trees.

🌿 Durable - Unlike real trees, wooden trees last for years.

🌿 Customizable - You can design them to suit your style and space.

🌿 Space-Saving - Ideal for small homes or apartments.

🌿 Budget-Friendly - With basic tools and materials, you can create a tree for a fraction of the cost of a store-bought one.

🔴 Tools and Materials Before diving into the project, gather these materials and tools:

🌿Wooden dowels, planks, or recycled pallet wood 🌿 Saw (hand saw, jigsaw, or circular saw) 🌿 Sandpaper (medium and fine grit) 🌿 Wood screws or nails 🌿 Drill 🌿 Measuring tape 🌿 Wood glue (optional) 🌿 Paint, stain, or varnish (optional) 🌿 Decorations: string lights, ornaments, or garlands

.........Visit ur a shop for recommend tools.......

🔴 Choose Your Tree Design

There are many ways to design a wooden Christmas tree. Here are a few popular options:

1. Flat Wall-Mounted Tree A minimalist design mounted directly on the wall, perfect for tight spaces.

2. Freestanding Ladder Tree - Resembling a ladder, this design allows you to hang ornaments on each "rung."

3. Tiered Tree - Made of horizontal wooden planks arranged in a tree shape.

4. Branch Tree - Assembled with real branches or dowels to mimic a tree's natural look.

( Decide on the style that best suits your space and decor )

🔴 Measure and Cut the Wood

🌲 Use a measuring tape to determine the dimensions of your tree. A good starting point is a height of 4–6 feet for a freestanding tree.

🌲 Mark the wood using a pencil and ruler to ensure precise cuts. 🌲 Cut the wood into desired lengths. For a tiered tree, cut planks into progressively shorter pieces to form a triangular shape. 🌲 Sand all edges to smooth any rough surfaces.

🔴 Assemble the Tree

Depending on your chosen design, follow these assembly instructions:

🌲 Flat Wall-Mounted Tree: Lay the planks in a triangular tree shape on the floor. Secure them with screws or nails, ensuring even spacing. Attach the tree to the wall using hooks or strong adhesive strips.

🌲 Freestanding Ladder Tree: Create two vertical supports from longer planks. Nail or screw shorter planks horizontally between the supports. (Ensure stability by checking that the structure doesn’t wobble )

🌲 Tiered Tree: Drill a hole through the center of each plank. Stack the planks on a central dowel or pole, starting with the largest at the bottom. Use spacers or small blocks between planks for even spacing.

🌲 Branch Tree: Arrange branches or dowels in a tree shape, securing them with screws or glue. (Attach a sturdy base to hold the tree upright)

🔴 Sand and Finish

Once assembled, sand the entire tree again to smooth rough spots.

🌵Apply a wood stain or paint for a polished look. Neutral tones like white, gray, or natural wood are popular for modern aesthetics. (Let the finish dry completely before decorating)

🔴 Decorate Your Tree

Now for the fun part , decorating!

🌲Lights - Wrap string lights around the tree for a warm glow. Battery-powered options work well for freestanding designs. 🌲Ornaments - Hang lightweight ornaments, keeping the design minimalist and balanced. 🌲Garlands - Use simple garlands made of beads, fabric, or paper for a stylish touch. 🌲Star or Topper - Add a sleek star or another modern topper to complete the look.

🔴 Additional Tips for Success 🔴

🌼 Safety First Always wear protective gear like gloves and goggles when using power tools.

🌼Recycle Materials Use leftover wood or repurpose old furniture for an eco-friendly project.

🌼Experiment Don’t be afraid to add personal touches like unique paint patterns, etching, or custom decorations.

Summer 🍁

Creating a DIY modern wooden Christmas tree is a rewarding and enjoyable project that adds a touch of uniqueness to your holiday decor. Not only is it a fun way to express your creativity, but it also promotes sustainability and reduces waste. With this step-by-step guide, you’re ready to craft a beautiful, lasting centerpiece for your home.

Happy crafting and happy holidays!

Wood mdad™️ 💚

wood mdad More artical

DIY wooden Christmas tree Modern Christmas tree ideas Eco-friendly holiday decor Minimalist Christmas tree design How to make a wooden Christmas tree Christmas crafting ideas Sustainable holiday decor

0 notes

Text

Rubber Pallet Bands

Pallet Bands (also referred to as “oversized rubber bands” or “mover bands”) are an ideal replacement for single use stretch wrap. Economical and easy to use, pallet bands contain and secure palletized items during movement within a warehouse. A single band is large enough to stabilize most loads, but additional bands can be used for heavier loads.

Increase Efficiency with Reusable Pallet Bands: Reusable pallet bands can be used to create significant savings with no equipment and minimal storage space required. No longer waste time applying and reapplying stretch wrap or tape, when pallet bands can be applied and removed in seconds. Additionally, pallet bands enable full visibility of labels or bar codes.

Sustainable Warehouse Options: In general, rubber bands are a sustainable product. They can be reused in many different ways and, therefore, reduce plastic waste. This makes them the perfect product for warehouses and other facilities looking for new ways to reduce their carbon footprint.

Available in 72″ to 112″ circumferences.

Color coded by size.

Excellent for use on furniture or as mover bands.

Reduce packaging waste.

Ribbed for extra holding power.

Not freezer grade.

See all the sizes available. Call us at 813 242 6995 or reach out to [email protected] for other sizes not listed.

#quickpakinc#pricing news#quick pak inc#free pallet wrapper#stretch film#stretch film pricing#coreless film#resin pricing#free machine#rubber pallet bands

0 notes

Text

Shipping Packaging

Shipping Packaging: Essentials for Secure and Efficient Transit

Shipping packaging is crucial in ensuring items reach their destination in optimal condition. Whether for personal or business needs, using the right materials can make a significant difference in the safety and efficiency of the shipping process. This article explores key aspects of shipping packaging, highlighting best practices, essential materials, and considerations for different types of items.

The Importance of Quality Shipping Packaging

Quality packaging protects products from damage during transit, especially when traveling long distances or through multiple handling stages. Damaged goods lead to customer dissatisfaction, returns, and additional costs. Investing in reliable, durable packaging materials can minimize these issues, providing peace of mind for both sender and receiver.

Essential Packaging Materials

Various packaging materials are available to accommodate different shipping needs. Here are some essentials:

Cardboard Boxes: Cardboard boxes are the most common shipping containers, valued for their versatility and cost-effectiveness. They come in various sizes and thicknesses, suitable for a wide range of items. For fragile or high-value products, double-walled boxes provide extra protection.

Packing Tape: A strong, durable packing tape ensures that boxes stay securely closed during transit. Look for water-resistant, high-tensile-strength tape to withstand different environmental conditions.

Bubble Wrap: Bubble wrap is essential for protecting delicate or fragile items. It provides a cushioning layer that absorbs shocks and reduces the impact of movement.

Packing Paper: Packing paper is an eco-friendly alternative to bubble wrap for less fragile items. It fills empty spaces in boxes, preventing items from shifting during transit.

Foam Peanuts: These small, lightweight pieces are ideal for filling gaps in boxes and adding extra cushioning. Foam peanuts are particularly useful for irregularly shaped or fragile items.

Shrink Wrap: This plastic film secures items to prevent shifting within larger boxes or pallets. It’s commonly used for shipping multiple items together.

Packaging Techniques for Safe Shipping

Proper packaging techniques are as important as quality materials. Here are some tips:

Choose the Right Box Size: Select a box that fits the item well, leaving enough room for padding but not so much that items can shift significantly.

Use Cushioning Strategically: Place bubble wrap or packing paper around the item and any gaps within the box. For fragile items, wrap each piece individually.

Seal All Openings: Apply packing tape along all seams, not just the top and bottom. This provides added strength and security.

Label with Care: Use “Fragile” or “This Side Up” labels when necessary to alert handlers to the nature of the package.

Eco-Friendly Shipping Packaging Options

Sustainability is becoming increasingly important in packaging. Many companies now offer eco-friendly options like recycled cardboard, biodegradable packing peanuts, and reusable containers. Choosing sustainable packaging materials not only reduces environmental impact but also enhances a company's image among environmentally conscious consumers.

Conclusion

Using the right Shipping Packaging materials and techniques can make a significant difference in the outcome of your shipments. Investing in high-quality boxes, padding, and secure sealing methods will protect your items and ensure they reach their destination intact. For eco-conscious shippers, sustainable options are available, making it easier to ship responsibly without compromising protection.

0 notes

Text

Congratulations, DHL Express Germany GmbH, winning the DACH Customer Excellence Awards 2024

The decision has been made and we are proud to announce the winners of this year’s DACH Customer Excellence Awards & DACH Customer Excellence Summit 2024. It has been another close run for the win of our trophies and the winner is in the category “Logistic & Transport” DHL Express Germany GmbH. Congratulations on a great submission. Here a short sneak peek on the entry:

DHL Express Germany GmbH is part of the DHL Group and is responsible for national and international shipping of time-sensitive shipments with the business areas of sales, operations, customer service, human resources, IT and finance.

DHL Express Germany GmbH has around 2,500 employees and offers its services from 34 service centers throughout Germany.

Direct integration into the global DHL Express organization ensures a connection to the worldwide DHL network. Our network includes more than 220 countries and territories, in which around 100,000 "Certified International Specialists" offer around 2.5 million customers outstanding service quality.

Reusable Pallet Wraps are an offer from DHL Express Germany GmbH to avoid plastic waste in logistics. We use this innovation both within our network and offer our customers the option of securing packages consolidated on pallets.

Congratulations again and look forward to seeing you next year on 17th of October 2025 in Wiesbaden. www.dach-cxa.com

#cx#dachcxa#cxstrategy#cxmanagement#customerexperience#cxtransformation#cxleaders#cxinsights#dachcxs#ccxp

0 notes

Text

Pallets for Sale: Affordable & Fast Shipping

Finding a reasonable price for wooden pallets that also assures quality may appear to be a difficult task. However, there are other strategies for optimizing your purchases, such as balancing money and durability. Understanding the many possibilities necessitates a certain level of expertise, particularly in separating between overly attractive offers and genuine deals. This comprehensive blog will explore the vital ways to choose affordable wooden pallets for sale without compromising their stability. We will also discuss how you can find the best value pallets and tips to make the right purchase.

Choosing the Best Paletts: Considerations and Choices

Determining the Crucial Elements

Various elements need to be considered when choosing affordable wooden pallets. Firstly, determine a light pallet for lesser weights or a heavy-duty pallet for heavier loads based on the type of goods that need to be transported or stored. Next, consider the necessary dimensions; custom-made pallets may be required for uncommon items. Reusability is another crucial factor to consider. For both financial and environmental reasons, choose a recyclable or reusable pallet.

Various Pallet Options Available

You can explore the various options available after you have decided on your method. Low-cost wooden pallets and recycled and used pallets are affordable options. You can expect a top condition from new pallets, which are often required for specific certifications. Customized pallets, like made-to-measure wood or plastic pallets, provide a tailored solution for certain requirements.

Comparing Materials

Wooden Pallets: It is popular and cost-effective, with several recyclable and repairable options.

Plastic Pallets: They are durable, simple to maintain, and often used under severe hygienic requirements.

Customized Metal Pallets: It is perfect for heavy loads and thorough use.

Particular Transportation and Storage Solutions

Are you a logistics professional? If so, you often search for ideal solutions that optimize functionality and price. Additionally, wooden pallet boxes and foldable logistics pallets provide benefits like cargo protection and space savings. For logistical purposes, lightweight pallets save on transportation expenses; heavy-duty pallets are recommended since they have the durability needed for long-term storage.

Sustainable Management: Affordable & Eco-friendly Wooden Pallets

Logistics' environmental concerns are becoming increasingly essential. Therefore, investing in an environmentally friendly wooden shipping container shows a commitment to sustainable development, which means investing in recyclable and resistant products. An environmentally friendly option for traditional pallets is wooden storage containers or pallets constructed from recycled materials. Varieties such as used or recycled pallets are also an affordable and eco-friendly alternative for businesses looking to reduce their carbon emission while controlling their budget.

Effects of Eco-Pallets on the Environment

It helps to lessen the industrial waste by reusing and recycling pallets.

It encourages the use of sustainable materials to help reduce greenhouse gas emissions.

Recyclable pallets lessen waste treatment costs and waste disposal.

Eco-pallets are committed to environmentally conscious supply chain methods.

Best Pallets for Fast Shipping

Choosing the appropriate pallet for fast shipping is vital to guarantee the goodness and safety of the goods:

Heat-Treated Wood: Heat-Treated Wood pallets are essentially required for international shipping in order to comply with phytosanitary laws.

Uniform Dimensions: Standard sizes such as 48×40 inches provide similarity with various storage and transport systems.

Four-Way Entry: It increases handling efficiency by enabling pallet jacks and forklifts to access the pallet from all sides.

Conclusion

As we wrap up this guide, we hope you understand that discovering affordable, high-quality wooden pallets is an unquestionable benefit for optimizing your business purchases. The diverse options of wooden pallets meet your expectations regarding durability and cost, whether you're a craftsperson, a major distributor, or a retailer. Move toward responsible decision-making and satisfaction that is assured without sacrificing your expectations. Explore various USA pallets at USA Pallet & Warehousing Inc., where you can enjoy a great purchasing experience combining excellence and profitability. Make the right decision today!

FAQs

How can I determine the strength of a wooden pallet before purchasing it?

First, evaluate the pallets' cracks, swollen nails, or broken boards. If possible, do a load test. Choose pallets marked HT (Heat-treated), which indicates that they have been processed to increase their robustness.

What are some maintenance and lifespan-extending tips for wooden pallets?

There are various tips to maintain your wooden pallets and extend their lifespan:

Avoid mildew by storing pallets in a dry place.

Don't overload them.

Quickly repair any damage.

Regular maintenance, such as treatment and sanding with particular products. It helps to lengthen their usage.

What dimensions are available for wooden pallets?

There are various sizes available, such as 120×80 cm for standard wooden pallets sizes, 100×120 cm for international pallets, and 60×80 cm for half-format pallets. Additionally, customized sizes can be made to satisfy certain client needs.

#wood waste recycling#usa pallet#wooden pallets for sale#pallets for sale#wood pallets#custom wood pallets#pallets usa#pallets#pallet dimensions#shipping container

0 notes

Text

The Right Packaging Materials for Automotive Parts 🚗📦: What You Need to Know

In the world of automotive manufacturing, packaging isn’t just about getting parts from Point A to Point B—it’s about protecting those parts, reducing costs, and making sure your supply chain runs smoothly. Whether it’s tiny bolts or heavy-duty engines, choosing the right packaging material is critical.

At Silicon Safepack Pvt. Ltd., as an industrial packaging solutions provider, we help manufacturers select the best materials to keep automotive parts safe and compliant. Here’s a quick guide on the top packaging materials and their applications:

1. Corrugated Cardboard 🛠️

Perfect for lightweight parts like nuts, bolts, and filters. It’s strong, recyclable, and easy to customize for various shapes and sizes.

2. Plastic Pallets & Containers 💪

Need to move heavy components like engines or transmissions? Plastic pallets are durable, reusable, and can withstand moisture, making them ideal for big, bulky items.

3. Foam Inserts & Bubble Wrap 🧩

For delicate items like sensors and electronics, foam inserts and bubble wrap offer the perfect cushioning to prevent damage during transit.

4. Metal Containers 🔒

When maximum protection is required, especially for valuable or oversized parts, metal containers are the way to go. Strong, secure, and built to last.

5. Wooden Crates 🌲

Best for heavy-duty machinery and oversized parts, wooden crates provide the strength needed to keep these components safe during long trips.

No matter the part or packaging need, Silicon Safepack Pvt. Ltd. provides custom industrial packaging solutions that balance cost-efficiency, protection, and sustainability. We ensure that automotive components arrive safely, on time, and in compliance with industry standards

#IndustrialPackaging#AutomotivePackaging#PackagingMaterials#PackagingSolutions#SustainablePackaging#SiliconSafepack#LogisticsSolutions#PackagingInnovation

0 notes

Text

Reusawraps: Durable Heavy Duty Pallet Covers for Optimal Protection

Welcome to Reusawraps! Keep your pallets safe and secure with our Heavy Duty Pallet Covers. Our durable covers are designed to protect your goods during transportation and storage. Say goodbye to flimsy covers that tear easily - our reusable wraps are built to last, making them a sustainable choice for your business.

For more Information Visit: https://www.reusawraps.com/

0 notes

Text

Reusable Pallet Wrap : REUSA-WRAPS Reusable Logistics Solutions

Ready to cut costs and reduce waste? REUSA WRAPS' reusable pallet wrap is here to revolutionize your packaging game. Our wraps can be used time and again, ensuring your goods are secure and reducing your environmental footprint. It's a win-win for your business and the planet!

0 notes

Text

Best Pallet Wrap Reusable Covers for Heavy Duty Protection

Make Reusa Wraps your packaging solution of choice by selecting our Pallet Wrap Reusable and Pallet Wrapz. High-quality and durable Reusable Pallet Covers have been designed to provide the highest levels of protection for the product and the lowest levels of impact on the environment. Using Reusa Wraps, you get to incorporate quality protection to your products that also respect our environment through lesser use of wrongfully disposed materials. For more info contact us.

Phone No:- 847-767-7747

0 notes

Text

Sustainable Pharmaceutical Packaging Market: Growth in Renewable Material Adoption

The Sustainable Pharmaceutical Packaging Market is poised for substantial growth as the pharmaceutical industry aligns with global sustainability goals. Increasing regulatory mandates, rising consumer awareness about environmental conservation, and the adoption of eco-friendly materials are key factors driving the market.

Read Complete Report Details of Sustainable Pharmaceutical Packaging Market: https://www.snsinsider.com/reports/sustainable-pharmaceutical-packaging-market-2811

Market Segmentation

By Raw Material

Paper & Paper Boards

Description: Includes cartons, labels, and blister backing.

Growth Drivers: Lightweight, biodegradable, and renewable properties.

Trends: Innovations in water-resistant and durable paper packaging.

Plastic & Polymers

Description: Bio-based plastics and recycled polymers for bottles, blister packs, and vials.

Growth Drivers: Versatility and cost-effectiveness.

Trends: Increased use of biodegradable plastics like PLA (polylactic acid) and PHA (polyhydroxyalkanoates).

Aluminium Foil

Description: Used for blister packaging, sachets, and strip packs.

Growth Drivers: Excellent barrier properties against moisture, light, and air.

Trends: Shift toward lightweight and recyclable aluminum options.

Glass

Description: Vials, ampoules, and bottles.

Growth Drivers: Non-reactive, recyclable, and ideal for sensitive formulations.

Trends: Development of lightweight, break-resistant glass packaging.

Others

Description: Hybrid materials, biocomposites, and plant-based alternatives.

Trends: Rising adoption for niche pharmaceutical applications.

By Product Type

Primary Packaging

Description: Direct contact packaging such as bottles, blister packs, and tubes.

Growth Drivers: Increasing demand for sustainable alternatives for single-use products.

Trends: Introduction of bio-based blister packs and compostable pouches.

Secondary Packaging

Description: Cartons, boxes, and shrink wraps for grouping primary packages.

Growth Drivers: Rising emphasis on lightweight and recyclable materials.

Trends: Use of mono-materials for easier recycling.

Tertiary Packaging

Description: Bulk packaging solutions for transportation and storage.

Growth Drivers: Growing focus on reusable and durable materials for logistics.

Trends: Integration of smart labels and eco-friendly pallets.

By End Users

Contract Packaging

Description: Outsourced packaging solutions for pharmaceutical companies.

Growth Drivers: Increasing preference for cost-efficient and sustainable packaging.

Trends: Collaboration with eco-friendly suppliers and manufacturers.

Institutional Pharmacy

Description: Includes hospitals and healthcare facilities.

Growth Drivers: Rising demand for easy-to-recycle and tamper-evident packaging.

Trends: Customizable sustainable solutions for single-dose administration.

Retail Pharmacy

Description: Packaging for over-the-counter drugs and prescriptions.

Growth Drivers: Focus on attractive, eco-friendly, and lightweight packaging.

Trends: Use of QR codes on packaging for recycling instructions.

Pharma Manufacturing

Description: Packaging integrated into the production line.

Growth Drivers: Compliance with strict environmental regulations.

Trends: Automation of sustainable packaging processes.

By Region

North America

Growth Drivers: Strict regulatory frameworks and a high focus on sustainability.

Trends: Adoption of recycled and bio-based packaging materials.

Europe

Growth Drivers: The EU's Green Deal and increased funding for sustainable packaging R&D.

Trends: Shift toward mono-materials and compostable solutions.

Asia-Pacific

Growth Drivers: Expanding pharmaceutical industries in China and India.

Trends: Investments in low-cost sustainable packaging technologies.

Latin America

Growth Drivers: Growing healthcare infrastructure and demand for eco-friendly packaging.

Trends: Increased use of lightweight, cost-effective packaging.

Middle East & Africa

Growth Drivers: Rising pharmaceutical exports and packaging standardization.

Trends: Adoption of reusable and recyclable packaging for cost efficiency.

Market Trends and Opportunities

Sustainability Initiatives: Pharmaceutical companies are committing to net-zero packaging goals, driving innovation in sustainable materials and designs.

Regulatory Compliance: Governments and international organizations are implementing stricter sustainability standards.

Technological Advancements: Smart packaging solutions with digital integration, such as RFID tags and QR codes for end-of-life recycling.

Consumer Awareness: Demand for eco-friendly packaging from environmentally conscious consumers.

Market Outlook

The Sustainable Pharmaceutical Packaging Market is projected to grow robustly as environmental considerations reshape industry priorities. Increased investment in R&D, rising consumer awareness, and evolving regulatory landscapes will drive innovation. Bio-based plastics and paper-based materials are expected to dominate, while Asia-Pacific and Europe lead in adoption rates due to their expansive markets and stringent environmental policies.

About Us:

SNS Insider is a global leader in market research and consulting, shaping the future of the industry. Our mission is to empower clients with the insights they need to thrive in dynamic environments. Utilizing advanced methodologies such as surveys, video interviews, and focus groups, we provide up-to-date, accurate market intelligence and consumer insights, ensuring you make confident, informed decisions.

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

0 notes

Text

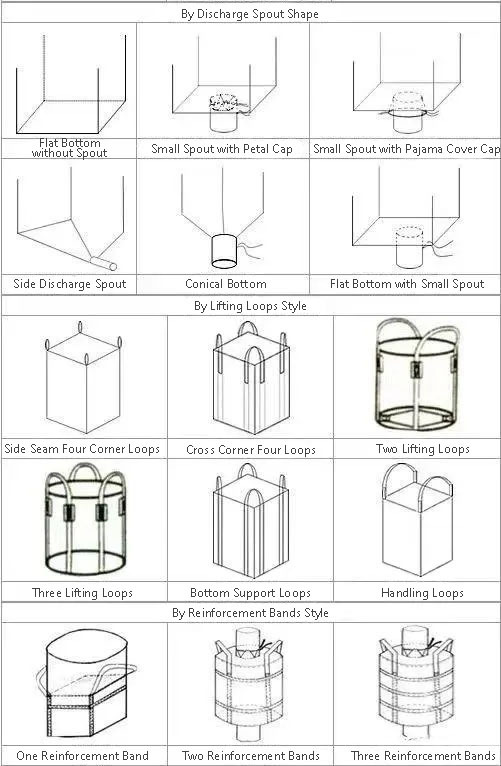

### What is a Bulk Bag (Ton Bag)? A Comprehensive Guide!

#### International Standard Bulk Bag Patterns

Bulk bags, also known as FIBC (Flexible Intermediate Bulk Containers), super sacks, big bags, ton bags, or jumbo bags, are flexible transport packaging containers. They are characterized by their moisture-proof, dust-proof, radiation-resistant, strong, and secure properties. Structurally, they possess sufficient strength, making loading and unloading highly efficient and convenient. As a result, bulk bags have seen rapid development in recent years. These bags are generally made from woven polyester fibers such as polypropylene (PP) or polyethylene (PE).

### Features

Bulk bags facilitate the transportation of large quantities of bulk powdered materials. They are known for their large volume, lightweight, and ease of loading and unloading, making them one of the most common packaging materials. Key characteristics include simple structure, light weight, foldability, minimal space occupancy when empty, and cost-effectiveness.

### Characteristics

1. **Load Capacity**: Ranges from 0.5 to 3 tons, with volumes between 500 to 2300 liters. The safety factor can be designed to 3:1, 5:1, or 6:1 based on user requirements.

2. **Content Type**: Divided into bulk goods bags and small package goods bags, suitable for both single-use and reusable applications.

3. **Shape**: Available in round, square, and U-shaped configurations.

4. **Lifting Structure**: Includes top lift, side lift, and bottom lift types, typically featuring inlet and outlet spouts.

### Performance

- **Usage Types**: Reusable / Single-use

- **Shapes**: Square / Rectangular

- **Lifting Methods**: Top lift / Side lift / Bottom lift

- **Inlet**: With inlet spout / Without inlet spout (large opening / waterproof cover)

- **Outlet**: With outlet spout / Without outlet spout

- **Materials**: Polypropylene (PP)

- **Load Capacity**: 0.3 tons - 2 tons

### Usage Precautions

1. Do not stand under the bulk bag during lifting operations.

2. Attach the hook to the center of the lifting loop or sling; avoid tilting, single-sided lifting, or diagonal pulling.

3. Prevent the bag from rubbing, hooking, or colliding with other items during operations.

4. Do not pull the lifting loops outward.

5. When using a forklift, avoid contact between the fork and the bag body to prevent punctures.

6. Use pallets during warehouse handling to avoid carrying the bag by hooks to prevent swinging.

7. Keep the bag upright during loading, unloading, and stacking.

8. Do not drag the bag on the ground or concrete.

9. For outdoor storage, place the bag on a pallet and cover it tightly with an opaque tarpaulin.

10. After use, wrap the bag in paper or an opaque tarpaulin and store it in a ventilated area.

### Applications

Suitable for packaging chemical raw materials, pharmaceutical raw materials, plastic raw materials, food additives, feed additives, metallurgical powders, ore powders, refractory materials, and other industries using bulk bags.

Shenzhen East Green International Freight Forwarding company, specializing in the transportation of bulk and oversized cargo via sea. Such as engineering vehicles, large machinery, steel materials, ton bags, etc.. We look forward to cooperate with you and are available for any inquiries at your convenience.

Tyin Meng

Contact Information:(+86) 18528265381 (Wechat or Whatsapp)

1 note

·

View note

Text

The Benefits of Using Pallet Covers for Your Business

In the realm of logistics and warehousing, every detail counts. From safeguarding products to optimizing storage space, businesses continuously seek innovative solutions to streamline their operations. One such solution that often goes overlooked is the implementation of pallet covers. These seemingly simple additions offer a multitude of benefits that can significantly impact a company's efficiency and bottom line. Let's delve into the advantages of incorporating pallet covers into your business strategy.

Protection Against External Elements

Shielding from Weather Conditions

Pallet covers serve as a protective barrier against various external elements, with weather conditions being a prominent concern. Whether it's rain, snow, or intense sunlight, exposure to the elements can compromise the integrity of goods during storage and transit, pallet covers act as a shield, preventing moisture from seeping into packaging and safeguarding products from potential damage caused by extreme temperatures.

Dust and Debris Protection

Moreover, pallet covers offer protection against dust, debris, and other airborne particles that can accumulate on stored goods over time. By keeping products clean and free from contaminants, businesses can uphold quality standards and enhance customer satisfaction.

Preservation of Product Quality

Maintaining Freshness

For businesses dealing with perishable goods or sensitive materials, maintaining product freshness is paramount. Pallet covers play a crucial role in preserving the quality of such items by creating a controlled environment that mitigates exposure to external factors. By extending the shelf life of products, businesses can minimize waste and maximize profitability.

Preventing Pest Infestation

Additionally, pallet covers serve as a deterrent against pests and rodents that can wreak havoc on stored goods. By effectively sealing off palletized inventory, businesses can reduce the risk of infestation, thereby avoiding costly damage and potential regulatory issues.

Enhanced Efficiency and Organization

Streamlined Handling

Implementing pallet covers contributes to streamlined handling processes within warehouses and distribution centers. By encapsulating palletized loads, these covers facilitate easier identification, stacking, and transportation of goods. This not only saves time but also reduces the likelihood of errors and accidents during handling operations.

Maximizing Storage Space

Furthermore, pallet covers enable businesses to maximize their storage space by allowing for vertical stacking of palletized loads. This efficient use of space translates to cost savings and optimized inventory management, as businesses can store more products within the same footprint.

Cost-Effectiveness and Sustainability

Reusability and Durability

Pallet covers are not only cost-effective but also environmentally sustainable. Unlike single-use packaging materials, such as shrink wrap or cardboard boxes, pallet covers are reusable and durable, providing long-term value for businesses. By investing in quality covers, companies can significantly reduce their packaging waste and environmental footprint.

Customization and Branding Opportunities

Moreover, pallet covers offer customization options that allow businesses to reinforce their branding and messaging. Whether through custom printing or labeling, companies can utilize pallet covers as a branding tool, effectively promoting their brand identity throughout the supply chain.

The benefits of incorporating pallet covers into your business operations are undeniable. From protecting against external elements and preserving product quality to enhancing efficiency and reducing costs, pallet covers offer a range of advantages that can positively impact your bottom line. By investing in these simple yet effective solutions, businesses can safeguard their goods, streamline their operations, and contribute to a more sustainable future.

0 notes

Video

youtube

Coreless Hand Wrap, time to drop the core.

HYBRiD Plus 3 Coreless hand film increases wrapping productivity, reduces waste, enhances employee safety, and lowers total pallet wrapping costs. HYBRiD Plus 3 Coreless film Necks Down Less, thus significantly decreasing the number of revolutions to wrap a pallet, and HYBRiD Plus 3 Coreless continues to contract around the load even after you have finished wrapping.

Through the HYBRiD Plus 3 coreless manufacturing process, we reinforce the edges of the film so that, the roll completely unwinds, No more throwing away unusable rolls. HYBRiD Plus 3 coreless is light weight and easy to use, plus, the most important part HYBRiD Plus 3 Coreless saves you money, because you just use less film!

Engineered Ultra High-Performance Film Series, strives for sustainability through technology by eliminating the need for paper cores when utilizing our QuickFix dispenser inserts.

100% of cost is used – No paper cores and film runs totally off dispenser.

New reusable plastic QuickFix dispenser.

Eliminates 5,400 pounds of paper cores per truckload

Bulk pack design eliminates corrugated material.

Reduces the carbon footprint.

0 notes

Text

Uses Of Needle Punching Fabrics

Needle punching is a versatile textile process that involves punching barbed needles through fibers to interlock them, creating a non-woven fabric. This method produces fabrics with various properties suitable for a wide range of applications. Here, we explore the diverse uses of needle-punched fabrics across industries.

Apparel Industry: Needle-punched fabrics find applications in the apparel industry for creating garments such as jackets, vests, and hats. These fabrics offer excellent insulation, making them ideal for winter wear. Additionally, they are lightweight and breathable, providing comfort to the wearer while offering protection against cold weather conditions.

Automotive Sector: In the automotive sector, needle-punched fabrics are utilized for interior components like floor carpets, trunk liners, and headliners. These fabrics are durable, abrasion-resistant, and provide sound insulation, enhancing the comfort and aesthetic appeal of vehicles. Moreover, they are easy to clean, making them suitable for automotive applications.

Geotextiles: Geotextiles made through needle punching are extensively used in civil engineering and construction projects. These fabrics serve various purposes such as erosion control, soil stabilization, and drainage. They prevent soil erosion, reinforce slopes, and facilitate water drainage, making them indispensable in road construction, landscaping, and environmental protection projects.

Filtration: Needle-punched fabrics are employed in filtration applications across industries such as healthcare, automotive, and industrial manufacturing. These fabrics act as filter media for air, liquids, and particulate matter. They effectively remove contaminants, dust, and pollutants, ensuring cleaner air and water in filtration systems.

Home Furnishings: Needle-punched fabrics are used in home furnishings like carpets, rugs, and upholstery. They offer durability, stain resistance, and thermal insulation, making them suitable for high-traffic areas in residential and commercial spaces. Additionally, these fabrics come in a variety of colors and designs, enhancing the aesthetic appeal of interiors.

Medical Textiles: In the healthcare sector, needle-punched fabrics find applications in medical textiles such as wound dressings, surgical gowns, and disposable bed linens. These fabrics are hypoallergenic, breathable, and provide barrier protection against contaminants. They are also used in orthopedic supports and medical implants for their comfort and biocompatibility.

Industrial Applications: Needle-punched fabrics are utilized in various industrial applications such as insulation pads, protective clothing, and gaskets. They offer thermal insulation, chemical resistance, and mechanical strength, making them suitable for harsh operating environments. Moreover, these fabrics can be engineered to meet specific performance requirements, making them versatile in industrial settings.

Agriculture: In agriculture, needle-punched fabrics are used for crop protection, weed control, and mulching. These fabrics provide a barrier against weeds, retain soil moisture, and regulate temperature, promoting plant growth and enhancing crop yield. Additionally, they are UV resistant and biodegradable, making them environmentally friendly alternatives to traditional agricultural materials.

Packaging: Needle-punched fabrics are employed in packaging applications such as protective packaging, pallet wraps, and container liners. These fabrics offer cushioning, impact resistance, and moisture protection, ensuring the safe transportation and storage of goods. They are also recyclable and reusable, contributing to sustainable packaging solutions.

Crafts and DIY Projects: Needle-punched fabrics are popular among crafters and DIY enthusiasts for various projects such as quilting, felting, and embroidery. These fabrics provide a versatile medium for creative expression, allowing for intricate designs and textures. They can be easily manipulated and embellished, making them ideal for crafting personalized gifts and decorations.

In conclusion, needle-punched fabrics serve a multitude of purposes across industries, ranging from apparel and automotive to geotextiles and medical textiles. Their versatility, durability, and performance characteristics make them indispensable in various applications, contributing to innovation and sustainability across sectors. As technology advances and new materials are developed, the uses of needle-punched fabrics are likely to expand further, driving continued growth and innovation in the textile industry.

0 notes