#PVC window frame making machine

Explore tagged Tumblr posts

Text

The Art of Crafting a Wedding Tent: A Comprehensive Step-by-Step Guide

When planning an outdoor wedding, the tent is more than just a shelter; it’s the heart of the celebration, setting the stage for unforgettable memories. As leading Tent Manufacturers and Suppliers in Indore, understanding the meticulous process behind crafting these tents ensures the delivery of durable, stylish, and functional structures. From material selection to final assembly, here’s an inside look at how wedding tents are manufactured to perfection.

1. Material Selection: Laying the Foundation for Quality

The first step in crafting a top-tier wedding tent is selecting the right materials. Two fabrics dominate the industry: canvas and PVC (Polyvinyl Chloride), each bringing unique qualities to the table.

Canvas: Loved for its natural, rustic appeal, canvas is breathable and eco-friendly, making it ideal for outdoor weddings. However, it requires waterproofing treatments to handle weather conditions.

PVC Texture: For a smooth, present day see, PVC is the go-to alternative. Its weather-resistant and waterproof properties make it perfect for unpredictable climates. It’s also lightweight, allowing for both clear and opaque tent designs.

The tent's framework is equally important, typically made from corrosion-resistant aluminum or galvanized steel. These materials ensure the structure is lightweight yet sturdy, offering the stability required for large wedding gatherings.

2. Design and Customization: Tailoring the Tent to Perfection

Once the materials are chosen, the plan stage starts. Wedding tents can be customized to match the theme and scale of any event, making this stage crucial for creating the perfect ambiance.

Pole Tents: Featuring dramatic peaks supported by central poles, these tents are perfect for large, luxurious weddings, especially when paired with the Best Royal Wedding Furniture Set.

Frame Tents: Without center poles, these offer a flexible layout, allowing for elegant decor such as Wedding Flower Stage Decoration and spacious seating arrangements.

Clear-Span Tents: Ideal for maximizing space, these tents have no interior poles, making them the perfect choice for grand events that require a seamless, unobstructed flow.

With the help of CAD (Computer-Aided Design) software, manufacturers create custom designs that include essential features like windows, doorways, and decorative elements such as a Pink and White Wedding Gate, perfectly enhancing the overall aesthetic.

3. Precision Cutting and Sewing: Ensuring a Seamless Fit

Once the design is finalized, the fabric is cut to exact specifications. Precision is key here—laser cutters or automated machines ensure that each piece fits together flawlessly. This accuracy prevents any issues during assembly and guarantees a clean, professional look.

After cutting, the fabric pieces are sewn together using specialized machines. For fabrics like PVC, heat sealing is used instead of traditional stitching to create watertight seals, ensuring the tent remains leak-proof even in harsh weather conditions.

4. Crafting the Metal Frame: The Skeleton of the Tent

The frame of the tent forms its structural backbone. Aluminum or steel tubes are cut, bent, and welded into shape using high-tech machinery. These components are designed to easily interlock, allowing for quick assembly and disassembly on-site.

If the tent design includes clear sections, such as transparent windows or a decorative Wedding Flower Stage Decoration, clear PVC panels are added at this stage to allow natural light to fill the tent while maintaining a luxurious look.

5. Rigorous Quality Control: Ensuring Perfection

Before the tent is shipped, it goes through a rigorous quality control process. Each tent is fully set up in a designated testing area to ensure:

Fabric Integrity: Checking for any defects like holes or stitching errors.

Structural Strength: Ensuring the frame is strong enough to support the tent under various conditions.

Weather Resistance: Simulating wind and rain to ensure the tent is ready for outdoor use.

Adjustments are made as needed, ensuring the final product meets industry standards for Luxuries Tent Manufacturers and Suppliers in Indore.

6. Packaging and Shipping: Delivering the Dream Tent

Once the tent passes all quality checks, it’s carefully packaged for shipping. The fabric is folded and stored in waterproof containers, while the metal framework is securely bundled to avoid any damage during transport.

Whether shipped directly to the customer or a rental facility, manufacturers often provide on-site setup services or detailed assembly instructions, making the process hassle-free for event planners and coordinators.

Conclusion: The Craftsmanship Behind Wedding Tents

Crafting a wedding tent is an intricate blend of design, engineering, and craftsmanship. From choosing the highest-quality materials to ensuring every seam and joint is flawless, the process results in a tent that is both functional and stunning. For outdoor weddings, these tents become more than just shelters—they are the backdrop for life’s most cherished moments.

At Ranka Tent Suppliers, we pride ourselves on being the premier Tent Manufacturers and Suppliers in Indore. Whether you're in need of a tent with a Pink and White Wedding Gate, a Best Royal Wedding Furniture Set, or stunning Wedding Flower Stage Decoration, we ensure your event is covered with style and grace. By understanding the manufacturing process, you can be confident that your tent will provide the perfect setting for your special day, ensuring your celebration is sheltered in luxury and elegance.

#tent supplier#wedding tent suppliers#luxuries tent manufacturers and supplier in indore#best royal wedding furniture set

0 notes

Text

Exploring the Versatility of Plastic Extrusion Products Directly from Manufacturers!

In Australia, plastic extrusion products are utilised primarily for safeguarding industrial machines in automobile development, electric and electronics, aviation and military, marine and boating, healthcare, agriculture, and a few other private sector businesses.

Because they specialise in producing plastic extrusions with remarkable endurance and flexibility, reputed manufacturers provide a guarantee of the product's effectiveness and security throughout usage.

On the other hand, the plastic extrusion process provides various benefits to firms looking to make high-quality items efficiently and cost-effectively. One of the primary benefits of plastic extrusion is its adaptability.

The procedure can be used to make everything from simple smooth tubes and profiles to sophisticated forms and designs including perforated tubes, circular wraps, heat-shrink, and solar conductors.

Reputable manufacturers frequently use substances such as polypropylene, LDPE, HDPE, ABS, polyamide, PVC (flexible & rigid), polycarbonate, thermoplastic polyurethane, PBT, and TPEs in the process of extrusion, enabling them to make a wide range of items for different industries.

The plastic protrusions, in particular, have a wide range of applications, including blow-moulded extrusion corrugators for corrugated tubing, standard plastic extruders for tube, cable, and profile-producing goods, vacuum testing for complex shapes, and co-extrusion for multi-layer or multi-coloured products.

Furthermore, plastic extrusion provides remarkable uniformity in product quality, allowing companies to produce large quantities of products with little variation.

The use of multiple materials in the extrusion process allows producers to develop top-quality UV-protected products with unique features, such as longevity and can withstand harsh weather and chemicals.

For instance, when these plastic extrusions are used in large transport vehicles, cars, or aircraft, they do not break down by changing their physical state and shape and never lose their natural elasticity.

These features make their plastic extrusion products appropriate for a wide range of applications from building door frames and window profiles to pipes and electrical enclosures.

Therefore, contact a reliable manufacturer and get suitable products for your business needs.

Source

0 notes

Text

Top 10 Must-Have Tools For Any DIY Project

Top 10 Must-Have Tools For Any DIY Project

Have you ever had an urge of wanting to build something? Something unique or something custom. But the cost of ordering a custom design is just too much. So you decide to take matters into your own hands. But don’t know where to begin? Well, we are here to help you. We can help you with this expedition of creating something custom and unique right at your home. This article will explore the top 10 tools you require for any DIY Project.

Top 10 Beginner Friendly DIY Tools

· Tape measure

A tape measure or measuring tape is a flexible tool, used for measuring length. Depending on whether you want to use it for general household DIY or for professional use you can either get the 30m tape measure or the 50m tape measure.

· Adjustable spanner

An adjustable spanner is an open-ended wrench with a movable jaw that can be adjusted to any size. It is advised to get an adjustable spanner set for home use as it saves you from getting an entire wrench set from which you will have to sort through to get to the right sized wrench that you need.

· Wrench

Having a wrench for home projects can come in very handy. They are generally used for gripping, fastening, turning, tightening and loosening things like pipes, pipe fittings, nuts and bolts. This not only assists you in your DIY urges but will also help in home renovations and fixing.

· Utility knife

A utility knife; also called a box cutter, a razor blade knife, a carpet knife, or a stationery knife; is a common tool used in various trades and crafts for a variety of purposes. It is a safe-to-use tool as it is covered with a PVC handle and can only open when certain buttons/levers are moved.

· Screwdriver

A screwdriver is used to insert or remove any screws. It is advised to have a screwdriver set for easy repair of any cracks or broken windows or hinges. Not only that, they can also be used for creating any connections in your DIY Projects and leave no loose screws.

· Hammer

A hammer for DIY Enthusiasts is as useful as their dominant hand. You can use this for used for general carpentry, framing, nail pulling, cabinet making, assembling furniture, upholstering, finishing, riveting, bending or shaping metal, striking masonry drills and steel chisels, and so on. With so many uses, it is a must-have item in your toolkit.

· Drill machine

Moving on to power tools, a safe-to-use drill machine is a must-have for all DIYers. Why? Because it is used to cut holes into or through metal, wood, or other materials. Not only that it can also be used to create small attachments and other home projects where you have to hang something on a wall.

· Circular saw

The most common function of a circular saw is to make cuts in a straight line on pieces of lumber. A circular saw is most suitable for any type of woodwork. Especially for people who are new to DIYing and don’t know how to cut straight pieces, this tool is very handy.

· Angle grinder

An angle grinder for home renovation can make your home look new and shiny. It is used for grinding, polishing, cutting and a lot more. This multi-use tool is a must for your DIY toolkit, especially if you want it to turn into a regular activity.

· Jigsaw

A jigsaw is used for cutting metal, wood, resin and almost all materials. As a result, when you want to create some funky shapes or some unique design that is only in your head, you can use this tool and bring it to life.

Must Haves In Your Safety Kit

Safety is the most important thing when it comes to any and all types of DIYing. You need to make sure that you are taking care of yourself and are using safety equipment like goggles, gloves, etc. As the saying goes, “Safety First”, you must have a safety kit wherever you are doing some form of home renovation or DIY Project. Along with that make sure you also have a medical kit with bandages, gauze, and disinfectant at your place, in case of any injuries.

Links:

https://atozshop.co.in/?s=tape%20measure

0 notes

Text

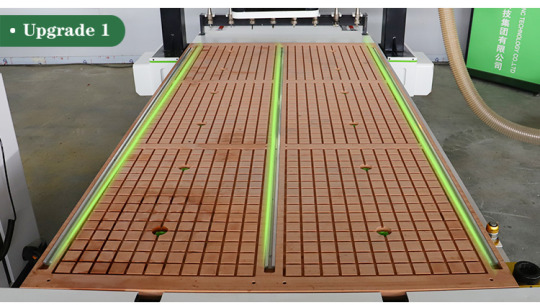

4 X 8 Linear Atc CNC Router with Automatic Tool Changer

This is the 2022 latest linear ATC CNC router machine, this machine has CNC router tool changer, so its tool change time is very short, which can save a lot of tool change time and improve machine processing efficiency. It has built-in eject pins and a controllable dust cover with built-in machine lubrication system for accurate material loading every time. So this machine can process wood, MDF, particleboard, plywood, OSB, melamine board, etc. It is widely used in cabinet manufacturing industry. It can also process acrylic, plastic, soft metals and many other different materials.

4x8 cnc router with vacuum table

CNC linear cutting machines is used for decorations, musical instruments, wood crafts, wood furniture, wood door making, cabinet making, windows, and tables. Now the best linear ATC wood CNC machine for sale at affordable price.

The ATC CNC router machine is equipped with a 9.0kw air-cooled spindle, and two tool change methods are available: linear tool change and disc tool change. Usually used in conjunction with labelling machines and automatic loading and unloading platforms.

This 4x8 CNC machine has a rotary device equipped on the one side of working table. When users need to process cylindrical materials, they can clamp the cylindrical piece onto the rotary device. Then rotary device rotates and at the same time the spindle engraves on the surface of the work piece. This machine with rotary device is suitable to process cylindrical materials. Users can design and make beautiful cylindrical sculpture crafts with it.

This is the professional linear ATC CNC router, this ATC CNC router with tool changer, so this machine has very high machining speed and cutting precision, and this 4x8 CNC router is equipped with a 9KW(12HP) air-cooled spindle and a 12 High-speed tool changers, these can be used to perform complex and diverse machining tasks. If you would like to own a linear ATC CNC router, then please contact us.

Hot applications of Industrial CNC Router With Auto Tool Changer:

>Wooden furniture industry: solid wood and composite doors, cabinet doors, sliding doors, paint-free doors, lacquered doors, soft-packed doors, flat panel carving, solid wood carving, panel furniture processing, antique mahogany furniture processing, solid wood mural carving and other industries;

>Wooden crafts industry: clock and watch frames, craft photo frames, calligraphic cards, electrical counter-tops, sporting equipment, thin aluminum plate engraving and carving;

>Advertising industry: acrylic, PVC, MDF, artificial stone, plexiglass, plastic, copper, aluminum and other soft metal plates.

0 notes

Text

#PVC window frame making machine#PVC window profile machine#PVC window frame production line#PVC door frame making machine

1 note

·

View note

Text

Cabinet Making CNC Machine/ CNC Kitchen Cabinet Wooden Door

The cabinet making cnc machine is our newly-developed CNC Router with combined function of material loading and unloading for cabinet-making, widely used in home decoration, shop and office furniture. It is equipped with Italy HSD Spindle, Italy Boring unit and advanced Syntec control system, Japanese Yaskawa servo and Taiwan reducers.

Custom and general Cabinet Making Machineis one of the most popular applications for CNC routers. IGOLDENCNC CNC routers have brought industry standards to a new level with our quality and components, delivering what you would find in much higher-priced CNC routers at a cost competitive with the less industrial designs.

📷

Features of Cabinet Making Machine:

* Square tube lathe bed with more solid structure and strong stability because of low center of gravity.

• Vacuum table in 4zones can fix materials of different sizes effectively.

• Taiwan TBI balls screws, HIWIN square guide rails, high precision, large load bearing and stable running.

• Gantry-travelling, sturdy, reliable and stable, non-deforming, high locating accuracy.

• Mach3 control system, with computer controlled, very stable.

• Unique ability to save several point of origin on several workpieces.

• No engraving saw-tooth, smooth undersurface, legible contour, by high-power spindle.

• Auto seeking original point system, a good way to improve the working effeciency.

• Large compatibility of drawing software, such as Type3, artcam and some other CAD or CAM.

Cabinet Making Machine application:

* Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows.

* The wood products: voice box, game cabinets, computer tables, sewing machines table, instruments.

* Plate processing: insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti-Bate board, epoxy resin, ABS, PP, PE, PEHD and other carbon mixed compounds.

* Decorate industry: Acrylic, PVC,MDF, artificial stone, organic glass, plastic and soft metals such as copper, aluminum plate engraving and milling process.

Model

1325 CNC Nesting Machine

Working area

1300*2500mm

Spindle

ATC 9KW HQD air cooling spindle

Inverter

Fuling

Motor

Dorna servo motors

Driver

Dorna servo driver

Control System

Taiwan LNC control system

Table

Double layer Vacuum table + position cylinder + secondary dust collection + Pusher system

Oil lubrication

Automatic lubrication

Limit

Omron limit

Transmission

XY axis Taiwan helical rack Z axis Taiwan ball screw

Rail

X,Y,Z axis Germany Square guide rail

Screw

Z axis TBI ball screw

Bed

Thick steel welded big square tube

Gangry

Strong frame

Pillars

Steel pillar(Suitable for high-end customers)

Cabinet

Independent cabinet

Voltage

3 phase/380V

Color

As requirement

Tools

1 box(10 pieces)

Company Information

Jinan iGolden CNC Equipment Co.,Ltd. is a R&D,manufacturing,sales integration company that specializing in router cnc, laser engraving and cutting machine, plasma cutting machine, cutting plotter,etc.The main configuration all adopt top parts which imported from Italy, Japan,Germany, etc.We adopt international advanced producing technologies to improve our products.Our products are widely used in advertising,woodworking, artworks, model, electric, CAD/CAM Industry Model, Clothing, Package Printing, Marking, Laser Sealing and so on.And welcome to visit us for more choices.

2 notes

·

View notes

Text

10 Amazing Things You Can Do With Custom Neon Signs

How much do you understand about custom LED neon sign; custom bar signs neon;

Neon signs are a staple of any modern business. Whether you’re promoting your new shop on the street or just want to add a little extra flare to your bar, neon signs are a great way to do so. But what if you don’t have any neon sign supplies at home? No problem! In this post, we’ll show you 10 amazing things you can do with ( custom neon signs ) that you might never have thought of before. So get creative and let your neon signs do all the talking!

What are custom neon signs?

Custom neon signs are perfect for any event. From weddings to birthday parties, they really add an extra level of excitement. Here are some amazing things you can do with custom neon signs: You can use them as a decoration for your party or event. You can use them as marketing tools. You can use them to promote your business.

Types of neon signs

Neon signs are a popular way to advertise and let people know about your business. Neon signs come in many different shapes and sizes, so there's bound to be a sign that would fit your needs. Here are some of the most common types of neon signs: -Decal neon signs: These are the simplest type of neon sign, where you just place a decal on a window or door. -Poster neon signs: These are similar to decals but instead of being attached to the surface, they're suspended from the ceiling or walls. -Plaque neon signs: These are similar to poster neon signs but they have metal frames that make them look more official. -Lighted neon signs: These are the fancier type of neon signs and they usually come with light fixtures inside them. They're perfect for businesses that want to give off an air of luxury or sophistication.

How to make a custom neon sign

Making a custom neon sign is a great way to show off your creative side and make a statement about your business. Here are some tips for making the process as easy as possible: 1. Choose the right material. Neon signs are typically made from PVC or metal, and both materials have their own advantages and disadvantages. PVC neon signs are cheaper and more versatile, but they can be less durable and may not last as long as metal neon signs. Metal neon signs are heavier and more expensive, but they're also more durable and look nicer. It's important to choose the right material for your business and budget accordingly. 2. Get started with sketching. Before you start cutting any fabric or tubing, it's important to have a rough idea of what you're aiming for. Draw out your design on paper or CAD software, then transfer it onto the material you'll be using. If you're using PVC, make sure to adjust the dimensions so that the seams will be hidden when the sign is installed. 3. Cut out the pieces with a laser cutter or CNC machine. Once you've got your design cut out, it's time to start assembling your neon sign! Use screws, nails or wire ties to attach the various pieces together, then secure them with painter's tape if necessary in order to avoid water damage later on. 4. Install your neon sign! Now all you need is some bright lights and your business will be ready for attention!

What to do with a custom neon sign once you have it

If you've ever wanted to create a one-of-a-kind neon sign, but weren't sure where to start, this guide is for you. In this article, we'll show you how to get started with custom neon signs and some of the amazing things you can do with them. First, decide what type of Neon sign you want to create. There are many different types of Neon signs available, from simple letters and numbers to full-blown graphics. Once you decide on the style of your Neon sign, find a supplier who can build it for you. Once your Neon sign is ready, it's time to get creative! You can use your Neon sign for all sorts of purposes - from advertising your business or event to adding a little bit of fun to your home. And don't forget - custom Neon signs make great gifts!

Conclusion

Neon signs are one of the most popular and versatile pieces of outdoor advertising out there. With all sorts of creative ways to use them, neon signs can be a powerful tool for your business or event. Here are 10 amazing things you can do with custom neon signs:

0 notes

Text

5 easy ways to create your home more energy efficient

Making your home more energy efficient can be fun as well as practical. Most people don't think about their energy consumption at home, but it's important to do your part to save on bills. Do you want to expect your home to be more energy efficient but feel like you don't have time? Here are five easy ways to create your home more energy efficient:

Five easy ways to create your home more energy efficient

1. Use a programmable thermostat

When I say programmable, I don't mean programs for pets or kids! Programmable thermostats allow users to set temperature schedules based on the time of day, weather conditions, and occupancy levels. You can use the built-in sensors to remotely control your heating and cooling system if you're away from home or asleep at night. Even if you're using them to save money (and who doesn't want that?), they'll help reduce the electricity you use and save you some cash.

2. Change out old bulbs

You've probably heard this tip before, but did you know that many traditional incandescent lightbulbs still work just fine? So long as they have not been changed in 15 years, they can hold their own against newer LED lighting and sometimes even CFLs. If you need to replace these bulbs, try looking for ones that are Energy Star certified. These bulbs offer higher lumens per watt than standard bulbs, which means they consume less power and produce less heat.

3. Insulate ductwork

Ductwork carries heated air throughout your house, bringing it back down where needed. But the way it does this is inefficient—it can transfer 80 percent of its heat through the ducts and only 20 percent of it into the room being cooled or warmed. To improve efficiency, you should insulate around the exterior of the ducts to prevent the warm air from escaping into neighboring rooms. Plus, if the ducts are well insulated, they won't radiate quite as much heat into surrounding spaces.

4. Seal cracks & gaps in windows & doors

The best solution for sealing out cold drafts is caulking. Caulk comes in two varieties—polyvinyl chloride (PVC) and silicone. Both types provide good long-term protection, but PVC gets brittle over time. Silicone provides superior performance; however, it may require periodic reapplication. Both options are available in adhesive or caulk gun form, so you can apply them yourself. Be sure to seal any joints between framing members, including those behind switches and outlets.

5. Install a solar thermal water heater

Solar thermal water heaters use the sun's rays to create steam. As the sunlight heats the collector tubes, it turns into water vapor. The hot water then circulates through pipes to your shower, washing machine, tub, or wherever else you want. Because this type of technology provides a continuous hot water supply, you can avoid having to wait until nighttime to shower. And unlike typical electric water heaters, these systems can reduce peak electrical demand. In addition, they are easier and cheaper to install.

With these five tips, you can keep your home cool without running up big utility bills. And if you think about it, it makes sense. After all, how often do we really take advantage of accessible, natural energy sources? When was the last time you left an open window overnight or took a chilly dip in the pool?

In conclusion, there are a number of Easy Ways To Increase Energy Efficiency At Home. Some simple changes can help you cut down on your energy bills and help the environment too. Check out our tips to get started and prepare your home for winter!

0 notes

Text

Reciprocating Saw Uses Guide

Reciprocating saws are versatile for remodeling and demolition. They are excellent for cutting away unneeded materials any hardware you need to redesign or detach.

It works just like a hacksaw but operated by a machine. They are good to use for windows, walls, frames, doors, plumbing system, roof, and many more. Even demolition firms recommend this nifty saw since demolishing doesn't require any precise cutting method.

Thus, this type of saw is perfectly fit for the job due to its inability to cut accurately.

What we mentioned above is just the general purpose of the reciprocating saws. Experienced hobbyists, carpenters, engineers, and seasoned homeowners often use the saw for numerous purposes that you will surely find useful once you check them out below:

Floor Removal

Flooring, such as tiles and wallpaper, is easy to remove due to the saw’s motion that goes back and forth, along with its motor power.

It can be used as an "automatic" scraping blade thanks to its push and pull mechanism. Sturdy floorings such as linoleum and ceramic tiles can be removed cleanly from the floor once you operate the saw at its sides.

The motor’s strength can easily loosen the tiles, even if glued shut for several years. It’s also guaranteed to be less messy than using scraping blades.

Cutting Metal Pipes

You can easily remove PVC pipes using reciprocating saws. However, both electricians and plumbers often use this power tool to cut down metal pipes as well.

Even AC installers treat this as an optional tool when lessening the size of the appliance’s pipes. A double-faced blade for plunge cuts is the best accessory to attach for additional cutting precision.

Otherwise, you can buy the most durable blades instead to make the pipework much better.

Window and Door Installation

Beginners in DIY construction or hardware installation tend a common mistake of miscalculating measurements, particularly when attaching a door or a window.

This is where the reciprocating saws come handy because they can cut down the doors, windows or their respective frames to install the hardware correctly.

All you need to do is to shave some areas of the equipment to fit doors and windows.

Use Different Accessories WIth It

You can resolve the problem of imprecise woodcuts only by attaching a scraping blade to the saw.

The saw's back-and-forth mechanism can adjust adjusting the shapes of materials by tossing out the smallest unwanted parts away.

Sanding paper is also a handy accessory for the saw when working on wood finishes or scrubbing away sturdy rusts after cleansing it with a solution. It can also help you when gardening if you use specialized blades for tasks such as pruning.

Grooming Your Plants

Other homeowners also use the saw as an optional gardening tool. The elderly and those who are suffering from muscle pain can groom plants once again with this "automatic" pruner. You can remove or trim bushes and trees alike without too much effort.

youtube

It also helps you balance, particularly when reaching high branches, which is impossible to do with chainsaws.

Additionally, you only need to use one hand when operating the saw to help you balance much better, especially when you're on top of a ladder.

The following uses can make the reciprocating saws a convenient tool not just for renovation and demolitions.

3 notes

·

View notes

Text

Reciprocating Saw Uses & Buying Guide

Reciprocating saws are versatile for remodeling and demolition. They are excellent for cutting away unneeded materials any hardware you need to redesign or detach.

It works just like a hacksaw but operated by a machine. They are good to use for windows, walls, frames, doors, plumbing system, roof, and many more.

Even demolition firms recommend this nifty saw since demolishing doesn’t require any precise cutting method. Thus, this type of saw is perfectly fit for the job due to its inability to cut accurately.

Reciprocating Saw Uses

What we mentioned above is just the general purpose of the reciprocating saws. Experienced hobbyists, carpenters, engineers, and seasoned homeowners often use the saw for numerous purposes that you will surely find useful once you check them out below:

Floor Removal

Flooring, such as tiles and wallpaper, is easy to remove due to the saw’s motion that goes back and forth, along with its motor power.

It can be used as an "automatic" scraping blade thanks to its push and pull mechanism. Sturdy floorings such as linoleum and ceramic tiles can be removed cleanly from the floor once you operate the saw at its sides.

The motor’s strength can easily loosen the tiles, even if glued shut for several years. It’s also guaranteed to be less messy than using scraping blades.

Cutting Metal Pipes

You can easily remove PVC pipes using reciprocating saws. However, both electricians and plumbers often use this power tool to cut down metal pipes as well. Even AC installers treat this as an optional tool when lessening the size of the appliance’s pipes.

A double-faced blade for plunge cuts is the best accessory to attach for additional cutting precision. Otherwise, you can buy the most durable blades instead to make the pipework much better.

Window and Door Installation

Beginners in DIY construction or hardware installation tend a common mistake of miscalculating measurements, particularly when attaching a door or a window.

This is where the reciprocating saws come handy because they can cut down the doors, windows or their respective frames to install the hardware correctly. All you need to do is to shave some areas of the equipment to fit doors and windows.

Use Different Accessories WIth It

You can resolve the problem of imprecise woodcuts only by attaching a scraping blade to the saw.

youtube

The saw's back-and-forth mechanism can adjust adjusting the shapes of materials by tossing out the smallest unwanted parts away.

Sanding paper is also a handy accessory for the saw when working on wood finishes or scrubbing away sturdy rusts after cleansing it with a solution.

It can also help you when gardening if you use specialized blades for tasks such as pruning.

Grooming Your Plants

Other homeowners also use the saw as an optional gardening tool. The elderly and those who are suffering from muscle pain can groom plants once again with this "automatic" pruner.

You can remove or trim bushes and trees alike without too much effort. It also helps you balance, particularly when reaching high branches, which is impossible to do with chainsaws.

Additionally, you only need to use one hand when operating the saw to help you balance much better, especially when you're on top of a ladder.

How to Choose Reciprocating Saw

Choosing a reciprocating saw shot must require certain factors to consider. All you need are the following specifications in order to acquire the best type of saw that will be perfect for your wood cutting hobbies:

Performance

The performance of your reciprocating saw is very important. The factors that affect this are the stroke length and its cutting speed.

The stroke length should be set at 1 1/8 to 1 1/4 inches. You also need to find a cutting power of 3000 strokes per minute. The saw should be efficient as well, which is why you need to use a blade changing mechanism for an easier means of switching the blades.

��A reciprocating saw with an orbital action is also efficient as it makes cutting faster as well.

You can compare different reciprocating saw shots based on performance alone. But if you need to focus on its usage, especially when working on long projects, then the two other factors are also important to observe.

Motor Power

Battery-powered tools have strong performance that’s fit for heavy duties.

That’s why you8 need to check reciprocating saws with an amp motor ranging from 7 to 15. Picking a reciprocating saw shot needs to provide a powerful motor that can cut materials with ease.

Battery

You will need voltages for your amperes. That’s why you need to pick a strong type of battery ranging from 12 to 36V.

To easily figure out the performance of your battery when being used on a reciprocal saw under a certain motor power, simply look for the watt hours by multiplying the batter’s voltage with the amp hours of your saw’s motor power.

The reciprocating saw is a convenient tool that’s not just for renovation and demolitions. Keep in mind that you can improvise anything using a power tool only by exploiting its mechanisms and specs.

In the case of reciprocating saws, its back-and-forth motion is excellent for performing different tasks, such as the ones we mentioned, with better precision and speed.

1 note

·

View note

Text

PVC window frame making machine

PVC door/window frame profile making machine is one of our advantage products , xinda precision machinery company has focused on plastic machinery over 21 years with rich experience and strong technology , our machinery exported to 25 countries , such as Iran , Turkey , Vietnam , UAE , Africa , Germany , America , etc.

we continue to perfect the design and quality , ensure the top quality and the turn-key service including installation , test running and training workers in your local factory . we are your trustworthy partner ! please contact Mr John Yu to get more details .Mr John Yu +86 13301561523 ; Email : [email protected]

The PVC UPVC profile making machine consist of twin screw extruder , vacuum calibration device , hauling off machine , automatic cutter , tipping table . the main spare parts adopt the top quality famous brand , such as ABB converter , SIEMENS motors , SCHNEIDER electric parts , OMRON temperature meters , etc . special design the screw and barrel , it’s high efficiency extrusion and easy to disassemble for maintenance . it can process the PVC powder or PVC + wood powder .

#PVC window frame making machine#PVC window profile making machine#PVC window frame production line#PVC window machine

1 note

·

View note

Text

What Is the Process of Plastic Extrusion in Melbourne?

Whether you are considering working with cold plastic or have already been accepted into a plastics manufacturing company, know the benefits of plastic extrusion in Melbourne. Cold plastic is made of soft PVC, which is a popular material for the production of packaging and toys. Extrusion makes it possible to produce multi-layer objects from one piece of extruded material by forcing the material through an object die cut out.

Plastic extrusion is a shape-forming process with a long history and many benefits. The process can be used to create a range of products, from truck window pelmets, and garden hoses for watering plants to plastic bottles for storing beverages. The properties that make cold plastic useful include transparency, lightweight, and resistance to ultraviolet decay.

What is the Plastic Extrusion Process?

The plastic extrusion process is the shaping of molten or soft thermosetting plastics while they are in a fluid state near their melting point. This mechanical shaping occurs as a result of direct pressure applied through screw mechanisms that provide forces against the outer surfaces of the material being shaped.

The process eliminates the need for difficult and costly machining operations that could be required to create complex shapes from solid blocks of material. Extrusion is used to create simple and complex shapes, ranging from thin sheets of plastic to pipes and tubes.

It can be used to create high volumes of a single product in a short time frame. This helps companies fulfil large orders more quickly without having to hire additional staff or purchase expensive equipment.

Source

0 notes

Text

Best Budget Laser Engraver?

Laser engraving is one of the best ways to add a personal touch to your projects. From logos on business cards to initials on cutting boards, you'll always find new uses for lasers.

From my testing, I've found that if you want to do some serious laser cutting, a diode laser isn't a great solution. However, if you want to do laser engraving, this is a great option. Specifically, I do a lot of laser engraving on hardwood, plywood, cardboard, kraft paper, and even stone.

A5 Pro Laser Engraver

Acrylic is also supported, just make sure you work in a well ventilated area as the fumes are horrible. Never laser engrave or cut PVC that emits hydrogen chloride gas.

Now for the fun stuff. Here are some tests I did with this unit. First, the fun pig butcher design on the cutting board. You can easily engrave names, initials or even entire recipes on the surface.

Cardboard projects are always fun to put together. You can get dark engravings, and the uniform surface is a great material for laser engraving.

The next one is the largest raster engraving I've ever done on plywood. Lightburn uses dithering to simulate grayscale effects. Dither with small dots to simulate shades of gray. The entire sculpting process for this 10x10 portrait took less than four hours.

Having a laser is one thing. Sending the design to the laser is another story. This usage is very difficult, but Atomstack has several great solutions for you.

Laser GRBL is software provided by Atomstack. This is an open source project with a lot of online support from a great developer community.

Lightburn is software that many people use on their machines. Lightburn offers a full 30-day trial, then a G-Code license for just $40. It works on Mac and PC.

The Atomstack Laser Master Engraver enlarges the entire working area to 410 x 400 mm. This is one of the largest work areas on a budget machine of this type. The increased work area compared to the first version is a huge upgrade.

S20 Pro Laser Engraver

The engraving machine is constructed with extruded aluminum rails and hardened plastic brackets. While this won't win any power contests, you don't need a powerful engraver. Unlike CNC, which applies constant pressure to the frame as it engraves the wood, the only pressure on the laser is the actual movement of the gantry.

I found that even when I ran it at a top speed of 3000mm/min (1.9 in/sec) it held up fine and still produced very detailed engravings. Movement comes from stepper motors and timing belts.

A nice addition is a synchronized y-axis. A metal rod runs the length of the x-axis and keeps the opposite ends of the engraver aligned. I've found that some engravers get misaligned at high speeds. The rod locks everything in space.

If you've run out of gift ideas for your loved one, how about a laser engraver? Compared to the lasers below for etching, this ATOMSTACK A5 has an eye-safe solution. It has a solid steel construction which makes it more precise during the engraving process. According to the manufacturer, it will be done in 10-20 minutes, depending on how accurately you understand the instructions.

The Atomstack A5 is equipped with a 20W laser head that allows you to engrave wood; bamboo, cardboard, plastic, leather, printed circuits, aluminum oxide items, painted metal. The printer can also be used to cut thick paper, cardboard, non-woven, balsa, acrylic, thin plastics. It features a large working surface area (measuring 410 x 400 mm) for handling the most demanding processes, and is laser engraved with an accuracy of approximately 0.01 mm.

The Atomstack A5 tool can record without refocusing, and works with many engraving software programs, such as LaserGRBL, LightBurn, and for PCs running XP, Windows 7, Windows 8, or Windows 10. It also works on MAC systems, and the supported engraving styles are NC, BMP, JPB, PNG, and DXF.

1 note

·

View note

Text

Purchase top class UPVC Fabrication Machinery at Very Affordable Price

UPVC Fabrication Machineries are used to fabricate windows, doors, skylights, etc. They are also known as PVC frame machineries. These machines are used for making frames and other parts of windows, doors, skillets, etc. So, if you want to purchase the top class UPVC machinery at very affordable prices, then you should visit the official website of LGFSysmac.

Visit @ https://www.lgfsysmac.com/product-category/upvc-fabrication-machinery/

0 notes

Text

An Overview: What is Plastic Recycling and Why is it Important?

Plastic is one material that has gained a significant spot in every environmental debate. Reason - it is a material well known for its flexible use with a flip side of harming the environment with its non-biodegradable ability.

We use plastic products because they are cost-efficient, long-lasting and highly versatile. And rightfully so, because It makes up a considerable part of our daily life, from the toothbrush to the house construction.

But it is also vital to understand that this helpful material is becoming a global problem. As per a recent study, roughly 40% of the ocean’s surface today is filled with plastic. And if our plastic consumption continues in a similar proportion, it is estimated that there will be more plastic in the ocean than fish.

Everyone who uses or produces plastic contributes to the increase in plastic waste and we don’t expect this trend to slow down anytime soon. Fortunately, we can reduce our plastic footprint by recycling it! Plastic recycling is extremely beneficial, as it allows us to keep the plastics we already have while turning them into new and different products using recycling machines.

In this article, we aim to briefly explain what plastic recycling is, how to refine it with plastic processing machinery, and why it is so beneficial.

What is Plastic Recycling?

Plastic recycling is turning plastic waste into useful products using recycling machines. Recycling can extend a product’s life, reduce the initial demand for fresh raw materials, and minimise the amount of waste in landfills and oceans. What’s interesting is that recycling plastic requires much less energy than manufacturing it.

The first step in understanding plastic recycling is knowing what types of plastic are recyclable.

We use various kinds of plastics for a variety of reasons and some of them include:

● High-Density Polyethylene (HDPE)

Due to its chemical resistant properties, HDPE is widely used for shampoo, conditioner, motor oil, Home cleaning products, etc,

● Low-Density Polyethylene (LDPE)

LDPE is most commonly used for making plastic bags. It is also used for producing different containers, dispensing bottles, plastic parts for computer components, and moulded laboratory supplies.

● Polyvinyl Chloride (PVC)

PVC is highly versatile and offers many possible usages; including, window framing, plumbing pipes, blood storage pouches, etc.

● Polypropylene (PP)

PP is usually used in food containers, lunch boxes, take-out food boxes, and ice-cream containers.

What are the Stages of Plastic Recycling?

Plastic recycling is done in stages, with each stage involving collecting, sorting, shredding and reprocessing the plastic ready to be used in new products. Let us understand each stage in brief-

Stage #1: Collection

The collection is the first stage of the recycling process. It involves gathering plastic products from homes and businesses that are no longer needed or wanted. Local Authorities do the collection directly or through a waste management company.

Stage #2: Sorting

The next stage involves separating the different types of plastic-based on their chemical composition. It allows for greater efficiency in the recycling process, as some types of plastic can be recycled far more easily than others.

Stage #3: Washing

This stage involves washing and drying off any remaining dirt or residue from previous uses so that new items made from recycled material will be safe for consumers.

Stage #4: Shredding

After washing and drying, they send plastic to a nearby facility for the shredding process. They remove the material from its original form by cutting it into smaller pieces using a shredder, which produces flakes that can be used to make new products such as clothing tags or carpeting backing.

Stage #5: Reprocessing

Reprocessing is the final stage that involves melting the sorted plastic. After melting, they mould the plastic using injection moulding machines into the final products.

Conclusion

Plastic recycling is a vital step to keeping our environment safe and clean. It might seem insignificant, but every piece of plastic you recycle is one less piece of plastic entering the environment. You might not see the lasting effects of your efforts today, but they will continue to add value.

By educating ourselves and taking charge of our waste management, we can share the responsibility of leaving a better planet for generations to come. We hope that you'll take action by recycling your plastic, encouraging others to do the same. Happy recycling!

#inspection machine#Recycling Machine#blow moulding machines#Plastic Injection Moulding Machine Weisheng Automation#injection moulding

0 notes

Text

Nesting CNC/CNC Wood Work Machines

The nesting CNC machine is numerical control equipment explicitly molded for the manufacturing of panel furniture. Its main function is to cut wooden boards. While processing, the cutting machine includes cutting, punching, grooving, and other processes. Generally, through the blueprint of intelligent software, nesting CNC machine automatically heightens the typesetting design, generate the effect map, and perform operations such as spontaneous modifications, and involuntarily generate diverse paths. Therefore, it saves and ameliorates sheet utilization. Fortunately, the CNC nesting machine is commonly used in the furniture industry such as a cabinet, wardrobe, solid wood, paint-free, solid wood composite, and suite doors. Imagine what one felder nesting cnc has done for various homes, and office doors. If you want to bring panel furniture to life, the cnc nesting machine for sale is your best buddy.

Nesting cnc Router features:

1. This model adopts full steel heavy duty body frame with tempering treatment,which could ensure the processing accuracy and heavy cutting performance.

2. It is equipped with disc types tools changer with 16pcs tools holders that improves work efficiency and is more convenient.

3. Because of its control system ,it's easy to operation.

4. Adopts high rigidity steel gantry with optimized design to offer the good support of high loading cutting.

5. Its automatic central lubrication system ensures the long-term using life efficiently.

Product application

1. Woodworking: wooden doors and furniture, windows, tables and chairs, cabinets and panels, 3-D boards, MDF, musical instrument, etc.

2. Advertising: show bills, logotypes, sign boards, 3-D models, acrylic cutting, LED/neon billboards, 3-D letters, light boxes, dies, molds.

3. Handicraft industry: sculpture of copper, aluminum engraving, metal molds, polyethylene film, PVC, etc.

Decorations and ornaments: acrylic, decorative board, artificial stone, organic glass, non-ferrous metals (aluminum, copper, brass), etc.

Our machines can process a lot of beautiful furniture, and it can also process a variety of materials, such as wood, MDF, aluminum, billboards and so on. Its processing speed is very fast, and many customers use this machine to make beautiful crafts.

9 details about the selection of nesting CNC router kits Detail

1: The brand and power of the nesting CNC router spindle The nesting machine needs to cut the material. It is recommended to use a high-power spindle, which has a fast cutting speed and good results. Moreover, the power of the spindle directly affects the processing effect of the product. Detail

2: Motor used by CNC nesting machine Among the many motors used, the stepper motor is the one with lower efficiency (suitable for woodworking engraving machines with lower output). However, there are many manufacturers who want quality and make it reasonable to invest in motors. And they will choose domestic servo motors (the actual processing speed is less than 8 meters). But from a long-term point of view, considering the service life and actual production benefits, it is undoubtedly the best choice for imported servo motors (the actual empty line can reach 60~80m/min, and the processing speed can reach 15~25m/min). Detail

3: Absorption capacity of CNC nesting router Speaking of adsorption capacity, we have to raise a knowledge misunderstanding. Many customers think that the suction and clamp dual-purpose table is better and saves electricity during processing. But in fact, its adsorption effect is far less than that of the full adsorption table. In the area of the splint, the cutting process cannot be carried out, and the plate is wasted in disguise. Moreover, the full adsorption table is actually partitioned, and the non-entire board can be opened with a single adsorption area to achieve the purpose of saving electricity (generally, the partition of the nesting CNC router table is a six-zone design of the table structure). Detail

4: Vacuum pump matched with adsorption table Now that we have mentioned the adsorption table, we have to talk about the vacuum pump. There are two types of vacuum pumps such as air-cooled and water-cooled. Generally, imported air-cooled vacuum pumps have higher suction power, but the price is generally too high, and the actual cost performance is not high. The domestic water-cooled vacuum pump is less noisy than air-cooled and has greater suction. However, the use of water-cooled vacuum pumps in areas with lower temperatures needs to pay attention to the problem of antifreeze (usually clean water or add antifreeze every day). Therefore, we can choose a suitable vacuum pump according to your actual needs. Detail

5: CNC nesting machine body frame What many manufacturers and customers often overlook is the importance of the frame structure of the bed, because the frame of the nesting CNC router and ordinary woodworking engraving machine is basically similar to those who are not engaged in production and processing. But in fact, the bed is the basis of the entire equipment, which implies many neglected details. When the motor of the nesting CNC router machine is running, the speed is very fast. In order to ensure that it does not shake during the processing, a bed frame with both stability and timeliness is required. This requires manufacturers to have very strong machining capabilities and professional processing personnel (excellent manufacturers will generally be equipped with dedicated five-face milling equipment for this treatment). If the bed is not heavy enough to produce jitter, it will directly affect the accuracy of the processing. Therefore, it can affect the quality of the product. Especially for the 6-meter-long double-station CNC nesting machine equipment, if it is processed by a manufacturer with strong technology, it is impossible to observe the presence of welding points on the bed with the naked eye. In contrast, with equipment with inadequate processing technology, as the use time increases, a series of technical defects will appear, and various problems will gradually appear during use. Detail 6: Genuine supporting control system Do most customers think it is just some software and a system? Why is there so much difference? But what we need to understand is that CNC equipment is not just a single software that can run. Different functions and different configurations require system coordination and control. Therefore, systems with different degrees of pros and cons are like systems with different degrees of quality. The computer is the same, it may run the same, but with the increase in usage and the different styles of dismantling orders, a series of problems such as crashes, processing errors, garbled codes, and freezes will occur in the system, which not only delays production and maintenance. It's also very troublesome to get up. The more professional the manufacturer, the more high-end control system will be used, which not only has fast computing speed but also has good stability, which can fully escort buyers. Detail

7: Selection of racks for nesting CNC machine Different racks represent different degrees of accuracy and stability. If the meshing degree of the poor quality racks is not accurate enough, the wear resistance is not enough, not only the gantry movement is unstable, but also a lot of noise is generated. The use of a good rack can not only improve the accuracy and the stability of the equipment processing process but also increase the service life of the product. Detail

8: The difference in the types of CNC nesting machine guides The X, Y, and Z axes of the nesting CNC machine are equipped with guide rails, and the guide rail is also the most important part of the CNC nesting machine accessories. A high-quality guide rail can not only make the processing process faster, smoother, and more accurate. Moreover, maintenance is also very convenient. With the increase of the number of times of use, the quality of the slightly poorer will not only cause the phenomenon of slipping off, but also the phenomenon that the original set of accessories will become unable to engage after maintenance. Detail

9: The cable that should not be ignored If it is not mentioned here, many buyers or those who plan to purchase will probably not notice it. Cables for such large equipment are not mobile phone charging cables, but only to ensure the flow of current. In long-term mechanical processing, the cable has to go through tens of thousands of bends, and its interior has millions of changes per second. The strength of the signal is interspersed, and the impact of the weather on the strength of the shell must also be considered. If even a small section of the cable is damaged, the entire device will not operate normally. So the device must be returned to the factory for a new one. Therefore, a good cable must have strong wear resistance, high-temperature resistance, acid and alkali resistance, and high flexibility.

0 notes