#PVA (PolyVinyl Alcohol)

Explore tagged Tumblr posts

Text

PVA Market on the Rise: What’s Fueling the Surge?

The global polyvinyl alcohol market is anticipated to reach USD 1,648.9 million by 2030 registering a CAGR of 6.4% according to a new report by Grand View Research, Inc. The increasing need for bio-based PVA products is expected to be a key factor driving the global industry growth over the forecast period. Polyvinyl alcohol (PVA), a synthetic water-soluble polymer, has been the key ingredient used in the formulation process in various end-use industries. The key end-use industries include food packaging, construction, electronics, coatings, printing, textile, cosmetics, and paper. PVA is mainly driven by the demand from the food packaging industry, as it is a material with better water solubility and biodegradable properties.

There are lesser-known substitutes available for PVA on account of its properties including ethanol and water solubility, coupled with resistance to grease and oil. However, stringent regulations hindered product usage in various application segments. The National Institute for Occupational Safety and Health (NIOSH) described several preventive and environmental safety measures after PVA exposure. The generation of solid waste can affect human health, especially children, who are more susceptible to these hazardous pollutants.

On the basis of end-uses, the industry has been further categorized into food packaging, paper, construction, electronics, and others. The food packaging segment dominated the global industry in 2022 with a significant market growth rate. The increasing need for biocompatible and nontoxic packaging solutions in the food & beverage industry is expected to drive the PVA industry growth.

Growing hygiene consciousness among consumers coupled with rising standard of living is propelling demand for detergents. In addition, growth witnessed by the hospitality industry is also contributing significantly to the production of detergents. This, in turn, supplementing overall demand for PVA in form of film in the detergent packaging industry.

The rising solid waste volumes in this region are projected to fuel the demand for PVA in packaging applications over the forecast period. In addition, rising innovation in packaging, and consumer demand for safety, convenience, technology, and sustainability, are expected to fuel the regional market growth over the forecast period.

Polyvinyl Alcohol Market Report Highlights

The food packaging segment dominated the global industry in 2022 and accounted for the maximum share of 32.4% of the overall revenue share.

Asia Pacific led the global industry and accounted for a share of 53.6% of the overall revenue in 2022 with a CAGR of 5.8% from 2023 to 2030. Increasing demand for PVA from various end-use sectors mainly, paper, is expected to propel the segment growth over the forecast period.

Prominent players operating in the polyvinyl alcohol (PVA) market are E. I. du Pont de Nemours and Company; Nippon Synthetic Chemical Industry Co.; Eastman Chemical Company; Sekisui Chemical Co. Ltd.; Kuraray Co. Ltd.; Sinopec Sichuan Vinylon; Anhui Wanwei Group Co., Ltd., and others.

Polyvinyl Alcohol Market Segmentation

Grand View Research has segmented the global polyvinyl alcohol market on the basis of end-use and region:

Polyvinyl Alcohol (PVA) End-Use Outlook (Volume, Tons; Revenue, USD Million, 2018 - 2030)

Paper

Food Packaging

Construction

Electronics

Others

Polyvinyl Alcohol (PVA) Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

North America

US

Europe

Germany

UK

Asia Pacific

China

Japan

Central & South America

Brazil

Middle East & Africa

Key Players in the Polyvinyl Alcohol (PVA) Market

I. du Pont de Nemours and Company

Nippon Synthetic Chemical Industry Co.

Eastman Chemical Company

Sekisui Chemical Co. Ltd.

Kuraray Co. Ltd.

Sinopec Sichuan Vinylon

Anhui Wanwei Group Co., Ltd.

Order a free sample PDF of the Polyvinyl Alcohol (PVA) Market Intelligence Study, published by Grand View Research.

0 notes

Text

PVA (alcool polyvinylique), Prévisions de la Taille du Marché Mondial, Classement et Part de Marché des 13 Premières Entreprises

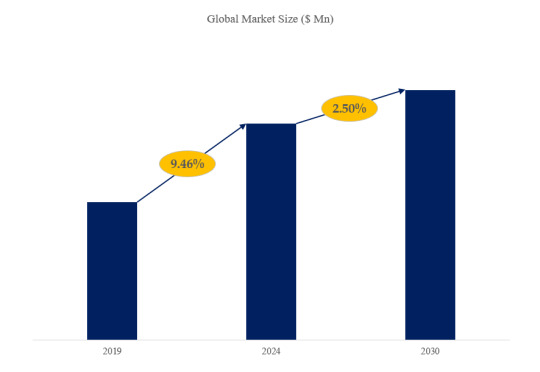

Selon le nouveau rapport d'étude de marché “Rapport sur le marché mondial de PVA (alcool polyvinylique) 2024-2030”, publié par QYResearch, la taille du marché mondial de PVA (alcool polyvinylique) devrait atteindre 3903 millions de dollars d'ici 2030, à un TCAC de 2.5% au cours de la période de prévision.

Figure 1. Taille du marché mondial de PVA (alcool polyvinylique) (en millions de dollars américains), 2019-2030

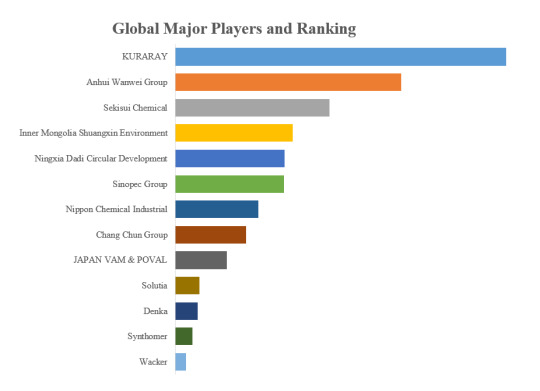

Selon QYResearch, les principaux fabricants mondiaux de PVA (alcool polyvinylique) comprennent KURARAY, Anhui Wanwei Group, Sekisui Chemical, Inner Mongolia Shuangxin Environment, Ningxia Dadi Circular Development, Sinopec Group, Nippon Chemical Industrial, Chang Chun Group, JAPAN VAM & POVAL, Solutia, etc. En 2023, les cinq premiers acteurs mondiaux détenaient une part d'environ 67.0% en termes de chiffre d'affaires.

Figure 2. Classement et part de marché des 13 premiers acteurs mondiaux de PVA (alcool polyvinylique) (Le classement est basé sur le chiffre d'affaires de 2023, continuellement mis à jour)

The key market drivers for the PVA (Polyvinyl Alcohol) market:

1. Increasing Demand for Eco-Friendly and Biodegradable Materials: The growing focus on sustainability and the shift towards environmentally-friendly products have driven the demand for PVA, a water-soluble and biodegradable polymer, as a replacement for traditional petroleum-based materials.

2. Expansion of the Packaging Industry: The increasing use of PVA in various packaging applications, such as water-soluble films, coatings, and adhesives, has been a significant driver for the market growth.

3. Rising Adoption in the Textile and Paper Industry: PVA's versatility in textile and paper applications, including as a sizing agent, binder, and coating material, has contributed to its widespread adoption in these industries.

4. Increasing Demand for Emulsifiers and Dispersants: PVA's ability to act as an effective emulsifier and dispersant in various industrial and consumer applications has driven its demand in the chemicals industry.

5. Expansion of the Construction and Building Materials Sector: The use of PVA in construction materials, such as cement and concrete admixtures, as well as in adhesives and sealants, has been a key driver for the market.

6. Growth of the Personal Care and Cosmetics Industry: PVA's applications in the personal care and cosmetics industry, including as a thickening agent, emulsifier, and film former, have contributed to the market's expansion.

7. Advancements in PVA Production and Processing Technologies: Improvements in PVA manufacturing processes and the development of new, high-performance PVA grades have made these products more accessible and appealing to a wider range of industries.

8. Increasing Demand for Water-Soluble and Dissolvable Products: The growing demand for water-soluble and dissolvable products, such as laundry detergent pods and medical devices, has fueled the need for PVA as a key ingredient.

9. Expansion of the Pharmaceutical and Medical Device Industry: The use of PVA in various pharmaceutical and medical applications, such as drug delivery systems, wound dressings, and medical implants, has been a significant driver for the market.

10. Rising Adoption in the Electronics and Semiconductor Industry: PVA's applications in the electronics and semiconductor industry, including as a protective coating and cleaning agent, have contributed to the growth of the PVA market.

À propos de QYResearch

QYResearch a été fondée en 2007 en Californie aux États-Unis. C'est une société de conseil et d'étude de marché de premier plan à l'échelle mondiale. Avec plus de 17 ans d'expérience et une équipe de recherche professionnelle dans différentes villes du monde, QYResearch se concentre sur le conseil en gestion, les services de base de données et de séminaires, le conseil en IPO, la recherche de la chaîne industrielle et la recherche personnalisée. Nous société a pour objectif d’aider nos clients à réussir en leur fournissant un modèle de revenus non linéaire. Nous sommes mondialement reconnus pour notre vaste portefeuille de services, notre bonne citoyenneté d'entreprise et notre fort engagement envers la durabilité. Jusqu'à présent, nous avons coopéré avec plus de 60 000 clients sur les cinq continents. Coopérons et bâtissons ensemble un avenir prometteur et meilleur.

QYResearch est une société de conseil de grande envergure de renommée mondiale. Elle couvre divers segments de marché de la chaîne industrielle de haute technologie, notamment la chaîne industrielle des semi-conducteurs (équipements et pièces de semi-conducteurs, matériaux semi-conducteurs, circuits intégrés, fonderie, emballage et test, dispositifs discrets, capteurs, dispositifs optoélectroniques), la chaîne industrielle photovoltaïque (équipements, cellules, modules, supports de matériaux auxiliaires, onduleurs, terminaux de centrales électriques), la chaîne industrielle des véhicules électriques à énergie nouvelle (batteries et matériaux, pièces automobiles, batteries, moteurs, commande électronique, semi-conducteurs automobiles, etc.), la chaîne industrielle des communications (équipements de système de communication, équipements terminaux, composants électroniques, frontaux RF, modules optiques, 4G/5G/6G, large bande, IoT, économie numérique, IA), la chaîne industrielle des matériaux avancés (matériaux métalliques, polymères, céramiques, nano matériaux, etc.), la chaîne industrielle de fabrication de machines (machines-outils CNC, machines de construction, machines électriques, automatisation 3C, robots industriels, lasers, contrôle industriel, drones), l'alimentation, les boissons et les produits pharmaceutiques, l'équipement médical, l'agriculture, etc.

0 notes

Text

PVA GIVES A SUSTAINABLE BOOST TO PAPER PRODUCTION

The water-soluble polymer PVA is a crucial ingredient in paper production. PVA acts as a binder and enhances the strength of the paper, making it more resilient to oils and greases. Moreover, it has also transformed the paper industry by promoting eco-friendly practices.

Source - https://ankushenterprise.com/what-is-polyvinyl-alcohol-and-what-are-its-uses/

0 notes

Text

Moisture-resistant hairstyling agent: Development of a humidity-induced shape memory polymeric material

NIMS and Nihon L'Oréal K.K. have developed a shape memory polymeric material responsive to humidity. This innovative material, when applied to a person's hair and allowed to dry, serves as an exceptionally moisture-resistant hairstyling agent. The research was published in Advanced Materials Interfaces. Hairstyles play a crucial role in personalizing one's appearance and showing self-confidence. Demand for effective and functional hairstyling products has been growing. Weather-related humidity and sweat from exertion have long been a problem for hairstyle stability. Most currently available hairstyling products (e.g., hair sprays and gels) merely create a physical barrier on the hair's surface, offering limited protection against humidity. There is a considerable expectation for the development of advanced, highly moisture-resistant hairstyling agents. This research team recently developed a humidity-responsive shape memory polymeric composite designed as a moisture-resistant hairstyling agent. The material's moisture resistance stems from the hydrogen bonding between polyvinyl alcohol (PVA) and naturally occurring cellulose microcrystals (CMs), forming a robust PVA/CM network.

Read more.

9 notes

·

View notes

Text

Common Additives in Emulsion Polymer Formulations: What They Do and Why They Matter

Emulsion polymers have become essential materials in industries such as paints, coatings, adhesives, textiles, and paper manufacturing. Their versatility, performance, and environmental friendliness — especially in water-based systems — make them highly attractive. However, the success of an emulsion polymer formulation doesn’t rest solely on the polymer particles themselves. A carefully selected set of additives plays a crucial role in defining the stability, functionality, and performance of the final product.

Let’s explore the common additives used in emulsion polymer formulations, what they do, and why they are so important.

1. Surfactants: Stabilizing the System

Surfactants are fundamental to emulsion polymerization. Their primary role is to stabilize the polymer particles within the aqueous medium.

Function: Surfactants reduce the interfacial tension between the monomer and water, allowing the formation of fine, stable droplets. They also prevent particles from aggregating during polymerization.

Types: Anionic, cationic, and nonionic surfactants are commonly used, depending on the desired properties of the final emulsion.

Importance: Without effective surfactants, emulsions would be unstable, leading to coagulation, poor film formation, and inconsistent product quality.

Choosing the right surfactant can also influence final properties like gloss, film flexibility, and water resistance.

2. Initiators: Starting the Reaction

Initiators are chemicals that trigger the polymerization process by generating free radicals.

Function: They decompose under heat or light to produce free radicals, which then react with monomer molecules to form polymer chains.

Types: Common examples include ammonium persulfate (APS) for thermal initiation and photoinitiators for UV-based processes.

Importance: The choice and amount of initiator directly impact polymer molecular weight, reaction rate, and particle size distribution.

Controlled initiation ensures a uniform polymerization process, affecting not only the structure of the polymer but also its final performance in application.

3. Buffers and pH Adjusters: Controlling the Reaction Environment

Maintaining the correct pH during emulsion polymerization is crucial for system stability and polymer performance.

Function: Buffers prevent large swings in pH, while pH adjusters (like ammonia or acids) fine-tune the system’s acidity or alkalinity.

Importance: Incorrect pH levels can destabilize the emulsion, interfere with initiator activity, and even lead to unwanted side reactions.

A stable pH helps in producing emulsions with consistent viscosity, particle size, and shelf-life.

4. Protective Colloids: Enhancing Stability

Protective colloids like polyvinyl alcohol (PVA) or hydroxyethyl cellulose are sometimes added alongside or instead of surfactants.

Function: They physically adsorb onto the surface of polymer particles, providing steric stabilization.

Importance: Protective colloids enhance mechanical stability, preventing shear-induced coagulation during handling and application.

They are particularly important for emulsions that will undergo high-shear processes like spraying or brushing.

5. Defoamers: Managing Foam

Foam generation is a common issue during emulsion polymerization and product application.

Function: Defoamers (typically silicone or mineral oil-based) suppress and break foam.

Importance: Excessive foam can lead to air entrapment in films or coatings, compromising appearance and mechanical properties.

Adding a suitable defoamer ensures a smooth surface finish and efficient processing.

Why Additives Matter in Emulsion Polymer Formulations

While the polymer forms the backbone of the emulsion, additives are the architects that shape its final performance. They:

Improve the stability of the emulsion during manufacturing, storage, and application.

Optimize the reaction kinetics for better control over molecular structure and particle size.

Tailor the surface properties and application behavior of the final product.

Enhance durability, appearance, and environmental resistance of coatings, adhesives, and films.

A poorly chosen additive — or even the wrong dosage — can result in emulsion instability, poor film formation, reduced shelf life, or failure under service conditions.

Conclusion

In the world of emulsion polymers, the additives behind the scenes are just as important as the polymers themselves. Understanding the role of surfactants, initiators, buffers, protective colloids, and defoamers allows formulators to design high-performance emulsions tailored to specific industrial needs. As industries push toward greener, more efficient, and high-performance materials, the smart selection and balancing of these additives will continue to be a key driver of innovation.

0 notes

Text

Growing Demand for PVA Films in Healthcare, Packaging, and Agrochemicals

The polyvinyl alcohol (PVA) films market is on a transformative journey, catering to industries such as healthcare, food packaging, electronics, and agrochemicals. These films stand out for their water solubility, biodegradability, and excellent barrier properties, meeting modern industry demands for efficiency and sustainability.

Market Growth

Polyvinyl Alcohol Films Market is expected to grow at a CAGR of 6.1% during the forecast period, from an estimated USD 429 million in 2023 to USD 577 million by 2028. Polyvinyl alcohol (PVA) films are experiencing a rising demand driven by several compelling factors.

In healthcare, PVA films enhance safety by enabling single-dose packaging for pharmaceuticals and encapsulating active ingredients. Their growing adoption in polarizing plates is driven by demand for high-performance LCDs and other displays. Meanwhile, the agrochemical sector benefits from PVA’s water-soluble films that reduce human exposure to chemicals.

The medical and healthcare sector is emerging as the fastest-growing segment in the polyvinyl alcohol (PVA) films market due to its unique capabilities. PVA films, known for their biocompatibility and water solubility, are ideal for applications such as surgical drapes, drug delivery systems, and wound care products. Their dissolvable nature simplifies procedures, minimizing patient discomfort and infection risks. Additionally, they are increasingly used in pharmaceutical packaging, offering effective barriers against moisture and oxygen to prolong medication shelf life. With advancements in healthcare and a focus on patient safety, this segment is poised for remarkable growth, revolutionizing medical applications.

Food packaging also sees innovation through PVA films, offering eco-friendly wrapping solutions with impressive moisture and gas barriers, extending product shelf life. Sustainability efforts are further advanced by a push for bio-based PVA films and regulations promoting green alternatives.

While challenges like high production costs persist, collaboration, regional market expansion, and innovative solutions present vast growth opportunities. As industries pivot towards sustainable practices, PVA films are set to redefine packaging and material solutions for a greener future.

Emerging Trends in the Polyvinyl Alcohol (PVA) Films Market

Biodegradability Focus: Increasing demand for eco-friendly packaging solutions due to growing environmental awareness.

Technological Advancements: Innovations in bio-based PVA films and enhanced production processes.

Regulatory Push: Governments promoting sustainable alternatives to traditional plastics.

Healthcare Expansion: Growing adoption for single-dose pharmaceutical packaging and medical applications.

Rising Use in Electronics: PVA films are essential for polarizing plates in LCDs and other display technologies.

Asia-Pacific Dominance: Rapid industrial growth and stringent environmental regulations driving demand in the region.

To Know more Download PDF Brochure:

Asia Pacific is set to lead growth in the Polyvinyl Alcohol (PVA) Films Market, driven by rising demand for sustainable packaging solutions among its expanding middle class. The region benefits from a robust industrial base in countries like China and India, alongside heightened awareness of environmental issues and PVA's role in reducing plastic waste. Stringent regulations and eco-conscious consumer preferences further bolster market expansion, positioning Asia Pacific as a key player in the adoption of PVA films across industries.

#PolyvinylAlcohol#PVAFilms#SustainablePackaging#EcoFriendlySolutions#PlasticWasteReduction#MedicalApplications#FoodPackaging#AgrochemicalPackaging#InnovativeMaterials

0 notes

Text

Dissolvable plastics, also known as water-soluble plastics, are eco-friendly materials designed to break down in water or biodegradable conditions. Made from substances like polyvinyl alcohol (PVA) or starch-based polymers, they offer a sustainable alternative to traditional plastics, reducing environmental waste. These materials are commonly used in packaging, detergent pods, medical applications, and agricultural films. As industries seek greener solutions, dissolvable plastics are crucial in minimising pollution and promoting a circular economy.

Source URL : https://adrecoplastics.co.uk/dissolvable-plastics-eco-friendly-biodegradable-solution

#plastic moulding#plastic injection moulding#Plasticmanufacturing#UKinjectionMoulding#Plastictoolingcompany

0 notes

Text

PVA GH17R Price Increases in Delhi Market After Stability

After remaining stable for several days, On March 11,2025, the price of Polyvinyl Alcohol (PVA) GH17R in the Delhi market has increased by Re.1/kg today. The new price stands at Rs.236/kg, up from Rs.235/kg. This price change may impact industries such as adhesives, textiles, paper coatings, and construction materials, where PVA is widely used for its strong binding and film-forming properties. The global Polyvinyl Alcohol (PVA) market was valued at approximately USD 1.3 billion in 2024 and is projected to grow at a CAGR of 5.1%, reaching nearly USD 2 billion by 2032. The increasing demand for eco-friendly packaging, adhesives, and water-soluble films is a major driver of this growth, Indian PVC Prices, Indian PVC Price, Indian Prices PVC, Indian Price PVC, Indianpetrochem, PVC Prices In India.

0 notes

Text

U.S. Polyvinyl Alcohol Prices, News, Trend, Graph, Chart, Monitor and Forecast

Polyvinyl Alcohol (PVA) prices have been a key point of discussion in the global market, influenced by various factors such as raw material costs, supply chain dynamics, demand fluctuations, and regional economic conditions. The price trends of PVA have witnessed significant variations in recent years due to changes in the cost of vinyl acetate monomer (VAM), which is the primary raw material used in its production. Any volatility in VAM prices directly impacts the cost structure of PVA manufacturers, leading to fluctuations in market prices. The supply chain has also faced disruptions due to geopolitical tensions, trade restrictions, and transportation challenges, further affecting price stability. Additionally, energy costs play a crucial role in determining production expenses, with rising fuel and electricity prices leading to increased manufacturing costs and, subsequently, higher prices for polyvinyl alcohol.

The demand for PVA is driven by multiple industries, including adhesives, textiles, paper, packaging, construction, and pharmaceuticals. The growing application of polyvinyl alcohol in water-soluble films, food packaging, and sustainable products has contributed to an increase in demand, creating upward pressure on prices. Environmental concerns have also led to the adoption of PVA-based biodegradable materials, particularly in the packaging sector, further boosting its market value. However, fluctuations in industrial activities, particularly in major consumer regions such as North America, Europe, and Asia-Pacific, have led to price variations. The economic slowdown in certain countries has affected construction and textile sectors, leading to temporary declines in PVA demand and impacting prices accordingly. Conversely, the rapid industrialization and urbanization in emerging economies have spurred demand growth, keeping prices stable or pushing them higher.

Get Real time Prices for Polyvinyl Alcohol (PVA): https://www.chemanalyst.com/Pricing-data/polyvinyl-alcohol-1108

The Asia-Pacific region, particularly China, plays a dominant role in the polyvinyl alcohol market, with the country being a major producer and consumer. The supply chain disruptions caused by COVID-19 initially led to price instability, but recovery in manufacturing activities has helped stabilize prices. However, environmental regulations in China have imposed restrictions on chemical production, leading to reduced supply and occasional price spikes. Meanwhile, in North America and Europe, polyvinyl alcohol prices are influenced by import-export dynamics, as domestic production capacities are limited. Any changes in trade policies or tariffs impact supply availability, causing fluctuations in market prices. The European market has also seen a shift toward sustainable alternatives, increasing the demand for bio-based PVA, which carries a premium price compared to conventional grades.

Seasonal factors also contribute to PVA price trends, as demand from industries such as textiles and construction varies throughout the year. The monsoon season in certain regions reduces construction activities, leading to a temporary dip in demand and prices. Conversely, increased construction and infrastructure projects during peak seasons drive prices upward. Additionally, the influence of currency exchange rates plays a role in determining the cost of imports and exports, affecting overall market pricing. The depreciation of local currencies against the US dollar in some regions has led to higher import costs, translating into elevated prices for end-users.

Technological advancements in production methods have helped manufacturers optimize costs and improve supply efficiency, stabilizing prices to some extent. Companies are investing in research and development to enhance PVA quality and reduce production costs, which may impact long-term pricing trends. However, regulatory policies concerning environmental sustainability and emissions control continue to challenge producers, as compliance costs add to the overall expenses, keeping prices under pressure.

Looking ahead, the polyvinyl alcohol market is expected to witness a steady price trend, influenced by raw material availability, economic conditions, industrial demand, and environmental regulations. The increasing adoption of PVA in eco-friendly applications will likely sustain demand, supporting price stability. However, market participants must remain vigilant about geopolitical developments, energy costs, and supply chain challenges that could lead to price volatility in the coming years.

Get Real time Prices for Polyvinyl Alcohol (PVA): https://www.chemanalyst.com/Pricing-data/polyvinyl-alcohol-1108

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Polyvinyl Alcohol#Polyvinyl Alcohol Price#Polyvinyl Alcohol Price Monitor#India#united kingdom#united states#Germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

Water-Soluble Synthetic Polymers Market Research Report 2024(Status and Outlook)

The global Water-Soluble Synthetic Polymers market size was valued at US$ 4.56 billion in 2024 and is projected to reach US$ 6.78 billion by 2030, at a CAGR of 6.8% during the forecast period 2024-2030.

The United States Water-Soluble Synthetic Polymers market size was valued at US$ 1.23 billion in 2024 and is projected to reach US$ 1.78 billion by 2030, at a CAGR of 6.3% during the forecast period 2024-2030.

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/281448/watersoluble-synthetic-polymers-market-market-921

Water-Soluble Synthetic Polymers are engineered materials that dissolve in water, used in various industrial applications including water treatment and personal care products.

The global market is growing steadily, driven by water treatment needs and industrial applications. In 2023, production volume reached 2.5 million metric tons, with water treatment accounting for 45% of consumption. The market saw a 25% increase in biodegradable polymer adoption in 2023. Polyacrylamide dominates with a 40% market share, while PVA products are growing at 8% annually. North America leads with a 35% market share, while Asia Pacific is the fastest-growing region at 7.5% CAGR. The industry is focusing on developing eco-friendly alternatives, with a 35% growth in R&D investments for sustainability.

Report Overview

This report provides a deep insight into the global Water-Soluble Synthetic Polymers market covering all its essential aspects. This ranges from a macro overview of the market to micro details of the market size, competitive landscape, development trend, niche market, key market drivers and challenges, SWOT analysis, value chain analysis, etc.

The analysis helps the reader to shape the competition within the industries and strategies for the competitive environment to enhance the potential profit. Furthermore, it provides a simple framework for evaluating and accessing the position of the business organization. The report structure also focuses on the competitive landscape of the Global Water-Soluble Synthetic Polymers Market, this report introduces in detail the market share, market performance, product situation, operation situation, etc. of the main players, which helps the readers in the industry to identify the main competitors and deeply understand the competition pattern of the market.

In a word, this report is a must-read for industry players, investors, researchers, consultants, business strategists, and all those who have any kind of stake or are planning to foray into the Water-Soluble Synthetic Polymers market in any manner.

Global Water-Soluble Synthetic Polymers Market: Market Segmentation Analysis

The research report includes specific segments by region (country), manufacturers, Type, and Application. Market segmentation creates subsets of a market based on product type, end-user or application, Geographic, and other factors. By understanding the market segments, the decision-maker can leverage this targeting in the product, sales, and marketing strategies. Market segments can power your product development cycles by informing how you create product offerings for different segments.

Key Company

Ashland Inc

Arkema SA

DuPont

The Dow Chemical Company

BASF

Gantrade

Kuraray Group

SNF Group

Kemira Oyj

AkzoNobel

Gelita AG

Shandong polymers Bio-chemicals Co. Ltd

Sumitomo Seika Chemicals Company

Market Segmentation (by Type)

Polyacrylamide

Polyvinyl Alcohol

Polyacrylic Acid

Others

Market Segmentation (by Application)

Water Treatment

Detergents & Households Products

Petroleum

Paper making

Other

Geographic Segmentation

Market, Global Outlook and Forecast 2024-2030North America (USA, Canada, Mexico)

Market, Global Outlook and Forecast 2024-2030Europe (Germany, UK, France, Russia, Italy, Rest of Europe)

Market, Global Outlook and Forecast 2024-2030Asia-Pacific (China, Japan, South Korea, India, Southeast Asia, Rest of Asia-Pacific)

Market, Global Outlook and Forecast 2024-2030South America (Brazil, Argentina, Columbia, Rest of South America)

Market, Global Outlook and Forecast 2024-2030The Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria, South Africa, Rest of MEA)

Key Benefits of This Market Research:

Market, Global Outlook and Forecast 2024-2030Industry drivers, restraints, and opportunities covered in the study

Market, Global Outlook and Forecast 2024-2030Neutral perspective on the market performance

Market, Global Outlook and Forecast 2024-2030Recent industry trends and developments

Market, Global Outlook and Forecast 2024-2030Competitive landscape & strategies of key players

Market, Global Outlook and Forecast 2024-2030Potential & niche segments and regions exhibiting promising growth covered

Market, Global Outlook and Forecast 2024-2030Historical, current, and projected market size, in terms of value

Market, Global Outlook and Forecast 2024-2030In-depth analysis of the Water-Soluble Synthetic Polymers Market

Market, Global Outlook and Forecast 2024-2030Overview of the regional outlook of the Water-Soluble Synthetic Polymers Market:

Key Reasons to Buy this Report:

Market, Global Outlook and Forecast 2024-2030Access to date statistics compiled by our researchers. These provide you with historical and forecast data, which is analyzed to tell you why your market is set to change

Market, Global Outlook and Forecast 2024-2030This enables you to anticipate market changes to remain ahead of your competitors

Market, Global Outlook and Forecast 2024-2030You will be able to copy data from the Excel spreadsheet straight into your marketing plans, business presentations, or other strategic documents

Market, Global Outlook and Forecast 2024-2030The concise analysis, clear graph, and table format will enable you to pinpoint the information you require quickly

Market, Global Outlook and Forecast 2024-2030Provision of market value (USD Billion) data for each segment and sub-segment

Market, Global Outlook and Forecast 2024-2030Indicates the region and segment that is expected to witness the fastest growth as well as to dominate the market

Market, Global Outlook and Forecast 2024-2030Analysis by geography highlighting the consumption of the product/service in the region as well as indicating the factors that are affecting the market within each region

Market, Global Outlook and Forecast 2024-2030Competitive landscape which incorporates the market ranking of the major players, along with new service/product launches, partnerships, business expansions, and acquisitions in the past five years of companies profiled

Market, Global Outlook and Forecast 2024-2030Extensive company profiles comprising of company overview, company insights, product benchmarking, and SWOT analysis for the major market players

Market, Global Outlook and Forecast 2024-2030The current as well as the future market outlook of the industry concerning recent developments which involve growth opportunities and drivers as well as challenges and restraints of both emerging as well as developed regions

Market, Global Outlook and Forecast 2024-2030Includes in-depth analysis of the market from various perspectives through Porter’s five forces analysis

Market, Global Outlook and Forecast 2024-2030Provides insight into the market through Value Chain

Market, Global Outlook and Forecast 2024-2030Market dynamics scenario, along with growth opportunities of the market in the years to come

Market, Global Outlook and Forecast 2024-20306-month post-sales analyst support

Customization of the Report

In case of any queries or customization requirements, please connect with our sales team, who will ensure that your requirements are met.

Chapter Outline

Chapter 1 mainly introduces the statistical scope of the report, market division standards, and market research methods.

Chapter 2 is an executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the Water-Soluble Synthetic Polymers Market and its likely evolution in the short to mid-term, and long term.

Chapter 3 makes a detailed analysis of the market's competitive landscape of the market and provides the market share, capacity, output, price, latest development plan, merger, and acquisition information of the main manufacturers in the market.

Chapter 4 is the analysis of the whole market industrial chain, including the upstream and downstream of the industry, as well as Porter's five forces analysis.

Chapter 5 introduces the latest developments of the market, the driving factors and restrictive factors of the market, the challenges and risks faced by manufacturers in the industry, and the analysis of relevant policies in the industry.

Chapter 6 provides the analysis of various market segments according to product types, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 7 provides the analysis of various market segments according to application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 8 provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and capacity of each country in the world.

Chapter 9 introduces the basic situation of the main companies in the market in detail, including product sales revenue, sales volume, price, gross profit margin, market share, product introduction, recent development, etc.

Chapter 10 provides a quantitative analysis of the market size and development potential of each region in the next five years.

Chapter 11 provides a quantitative analysis of the market size and development potential of each market segment (product type and application) in the next five years.

Chapter 12 is the main points and conclusions of the report.

Get the Complete Report & TOC @ https://www.24chemicalresearch.com/reports/281448/watersoluble-synthetic-polymers-market-market-921 Table of content

Table of Contents 1 Research Methodology and Statistical Scope 1.1 Market Definition and Statistical Scope of Water-Soluble Synthetic Polymers 1.2 Key Market Segments 1.2.1 Water-Soluble Synthetic Polymers Segment by Type 1.2.2 Water-Soluble Synthetic Polymers Segment by Application 1.3 Methodology & Sources of Information 1.3.1 Research Methodology 1.3.2 Research Process 1.3.3 Market Breakdown and Data Triangulation 1.3.4 Base Year 1.3.5 Report Assumptions & Caveats 2 Water-Soluble Synthetic Polymers Market Overview 2.1 Global Market Overview 2.1.1 Global Water-Soluble Synthetic Polymers Market Size (M USD) Estimates and Forecasts (2019-2030) 2.1.2 Global Water-Soluble Synthetic Polymers Sales Estimates and Forecasts (2019-2030) 2.2 Market Segment Executive Summary 2.3 Global Market Size by Region 3 Water-Soluble Synthetic Polymers Market Competitive Landscape 3.1 Global Water-Soluble Synthetic Polymers Sales by Manufacturers (2019-2024) 3.2 Global Water-Soluble Synthetic Polymers Revenue Market Share by Manufacturers (2019-2024) 3.3 Water-Soluble Synthetic Polymers Market Share by Company Type (Tier 1, Tier 2, and Tier 3) 3.4 Global Water-Soluble Synthetic Polymers Average Price by Manufacturers (2019-2024) 3.5 Manufacturers Water-Soluble Synthetic Polymers Sales Sites, Area Served, Product Type 3.6 Water-Soluble Synthetic Polymers Market Competitive Situation and Trends 3.6.1 Water-Soluble Synthetic Polymers Market Concentration Rate 3.6.2 GlobalCONTACT US: North Main Road Koregaon Park, Pune, India - 411001. International: +1(646)-781-7170 Asia: +91 9169162030

Follow Us On linkedin :- https://www.linkedin.com/company/24chemicalresearch/

0 notes

Text

PVA for Polarizer Market, Global Outlook and Forecast 2025-2032

Polyvinyl alcohol (PVA) for polarizers is a specialized polymer material used in the production of polarizing films. These films are integral to various optical applications, including LCD and OLED displays, sunglasses, and optical filters. PVA films possess excellent optical properties such as high transparency, polarization efficiency, and mechanical durability, making them indispensable in modern display technologies.

Market Size

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/287293/global-pva-for-polarizer-forecast-market-2025-2032-773

The global PVA for Polarizer market was valued at USD 1,094 million in 2023 and is projected to reach USD 1,498.78 million by 2030, growing at a CAGR of 4.60% during the forecast period. The demand for high-quality polarizing films in LCD and OLED displays is a primary driver of this growth.

Regionally, North America accounted for USD 285.07 million in 2023, with a projected CAGR of 3.94% between 2025 and 2030. The Asia-Pacific region, particularly China, Japan, and South Korea, dominates the market due to the presence of major display panel manufacturers.

Market Dynamics (Drivers, Restraints, Opportunities, and Challenges)

Drivers:

Rising Demand for LCD and OLED Displays: The increasing adoption of smartphones, televisions, and tablets has significantly driven the demand for high-performance polarizers.

Advancements in Display Technologies: Innovations in OLED and micro-LED displays require high-quality PVA films, contributing to market expansion.

Growth in Automotive Displays: The automotive industry’s shift towards digital dashboards and infotainment systems is bolstering the need for efficient polarizer films.

Rising Demand for LCD and OLED Displays: The increasing adoption of smartphones, televisions, and tablets has significantly driven the demand for high-performance polarizers.

Advancements in Display Technologies: Innovations in OLED and micro-LED displays require high-quality PVA films, contributing to market expansion.

Growth in Automotive Displays: The automotive industry’s shift towards digital dashboards and infotainment systems is bolstering the need for efficient polarizer films.

Restraints:

High Manufacturing Costs: The production of high-purity PVA films involves complex manufacturing processes, leading to elevated costs.

Availability of Substitutes: Alternative materials with similar polarization capabilities pose a potential challenge to PVA adoption.

High Manufacturing Costs: The production of high-purity PVA films involves complex manufacturing processes, leading to elevated costs.

Availability of Substitutes: Alternative materials with similar polarization capabilities pose a potential challenge to PVA adoption.

Opportunities:

Expansion of AR and VR Applications: The rise of augmented reality (AR) and virtual reality (VR) devices presents a growing market for polarizing films.

Eco-Friendly Alternatives: Development of biodegradable PVA films can open new avenues for sustainable applications.

Expansion of AR and VR Applications: The rise of augmented reality (AR) and virtual reality (VR) devices presents a growing market for polarizing films.

Eco-Friendly Alternatives: Development of biodegradable PVA films can open new avenues for sustainable applications.

Challenges:

Supply Chain Disruptions: Geopolitical tensions and raw material shortages can impact production capabilities.

Stringent Environmental Regulations: Compliance with stringent environmental standards can increase operational costs for manufacturers.

Supply Chain Disruptions: Geopolitical tensions and raw material shortages can impact production capabilities.

Stringent Environmental Regulations: Compliance with stringent environmental standards can increase operational costs for manufacturers.

Regional Analysis

North America

The market in North America is driven by technological advancements and demand for high-resolution displays.

Major manufacturers in the USA and Canada focus on R&D to enhance PVA film properties.

The market in North America is driven by technological advancements and demand for high-resolution displays.

Major manufacturers in the USA and Canada focus on R&D to enhance PVA film properties.

Europe

Germany, the UK, and France are key players in this market, with a growing emphasis on sustainable display solutions.

Increasing automotive applications contribute to regional growth.

Germany, the UK, and France are key players in this market, with a growing emphasis on sustainable display solutions.

Increasing automotive applications contribute to regional growth.

Asia-Pacific

China, Japan, and South Korea dominate due to strong manufacturing capabilities in the display industry.

Government initiatives in India and Southeast Asia are expected to boost local production in the coming years.

China, Japan, and South Korea dominate due to strong manufacturing capabilities in the display industry.

Government initiatives in India and Southeast Asia are expected to boost local production in the coming years.

South America

Brazil and Argentina see moderate growth, driven by the electronics sector's expansion.

Economic factors may influence investment in high-end display technologies.

Brazil and Argentina see moderate growth, driven by the electronics sector's expansion.

Economic factors may influence investment in high-end display technologies.

Middle East and Africa

Growth remains steady, with increasing adoption of digital displays in retail and transportation sectors.

Growth remains steady, with increasing adoption of digital displays in retail and transportation sectors.

Competitor Analysis

Key Players in the Market

Kuraray

Mitsubishi Chemical

Kuraray

Mitsubishi Chemical

These companies dominate the market with their extensive product portfolios and continuous innovation in PVA film production.

Market Segmentation (by Application)

LCD Display

OLED Display

Other

LCD Display

OLED Display

Other

Market Segmentation (by Type)

PVA Film

PVA Adhesive

PVA Film

PVA Adhesive

Key Company

Kuraray

Mitsubishi Chemical

Kuraray

Mitsubishi Chemical

Geographic Segmentation

North America (USA, Canada, Mexico)

Europe (Germany, UK, France, Russia, Italy, Rest of Europe)

Asia-Pacific (China, Japan, South Korea, India, Southeast Asia, Rest of Asia-Pacific)

South America (Brazil, Argentina, Columbia, Rest of South America)

Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria, South Africa, Rest of MEA)

North America (USA, Canada, Mexico)

Europe (Germany, UK, France, Russia, Italy, Rest of Europe)

Asia-Pacific (China, Japan, South Korea, India, Southeast Asia, Rest of Asia-Pacific)

South America (Brazil, Argentina, Columbia, Rest of South America)

Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria, South Africa, Rest of MEA)

FAQ

What is the current market size of the PVA for Polarizer market?

⣠The global PVA for Polarizer market was valued at USD 1,094 million in 2023 and is projected to reach USD 1,498.78 million by 2030, growing at a CAGR of 4.60%.

Which are the key companies operating in the PVA for Polarizer market?

⣠Key players include Kuraray and Mitsubishi Chemical, leading in PVA film innovation and production.

What are the key growth drivers in the PVA for Polarizer market?

⣠Growth drivers include the rising demand for LCD and OLED displays, advancements in display technologies, and increasing use in automotive displays.

Which regions dominate the PVA for Polarizer market?

⣠The Asia-Pacific region (China, Japan, and South Korea) dominates due to a strong presence of display manufacturers. North America and Europe also hold significant market shares.

What are the emerging trends in the PVA for Polarizer market?

⣠Emerging trends include AR and VR applications, eco-friendly PVA film development, and increased use in automotive and smart displays.

Key Benefits of This Market Research:

Industry drivers, restraints, and opportunities covered in the study

Neutral perspective on the market performance

Recent industry trends and developments

Competitive landscape & strategies of key players

Potential & niche segments and regions exhibiting promising growth covered

Historical, current, and projected market size, in terms of value

In-depth analysis of the PVA for Polarizer Market

Overview of the regional outlook of the PVA for Polarizer Market:

Key Reasons to Buy this Report:

Access to date statistics compiled by our researchers. These provide you with historical and forecast data, which is analyzed to tell you why your market is set to change

This enables you to anticipate market changes to remain ahead of your competitors

You will be able to copy data from the Excel spreadsheet straight into your marketing plans, business presentations, or other strategic documents

The concise analysis, clear graph, and table format will enable you to pinpoint the information you require quickly

Provision of market value (USD Billion) data for each segment and sub-segment

Indicates the region and segment that is expected to witness the fastest growth as well as to dominate the market

Analysis by geography highlighting the consumption of the product/service in the region as well as indicating the factors that are affecting the market within each region

Competitive landscape which incorporates the market ranking of the major players, along with new service/product launches, partnerships, business expansions, and acquisitions in the past five years of companies profiled

Extensive company profiles comprising of company overview, company insights, product benchmarking, and SWOT analysis for the major market players

The current as well as the future market outlook of the industry concerning recent developments which involve growth opportunities and drivers as well as challenges and restraints of both emerging as well as developed regions

Includes in-depth analysis of the market from various perspectives through Porter’s five forces analysis

Provides insight into the market through Value Chain

Market dynamics scenario, along with growth opportunities of the market in the years to come

6-month post-sales analyst support

In case of any queries or customization requirements, please connect with our sales team, who will ensure that your requirements are met.

Chapter Outline

Chapter 1 mainly introduces the statistical scope of the report, market division standards, and market research methods.

Chapter 2 is an executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the PVA for Polarizer Market and its likely evolution in the short to mid-term, and long term.

Chapter 3 makes a detailed analysis of the market's competitive landscape of the market and provides the market share, capacity, output, price, latest development plan, merger, and acquisition information of the main manufacturers in the market.

Chapter 4 is the analysis of the whole market industrial chain, including the upstream and downstream of the industry, as well as Porter's five forces analysis.

Chapter 5 introduces the latest developments of the market, the driving factors and restrictive factors of the market, the challenges and risks faced by manufacturers in the industry, and the analysis of relevant policies in the industry.

Chapter 6 provides the analysis of various market segments according to product types, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 7 provides the analysis of various market segments according to application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 8 provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and capacity of each country in the world.

Chapter 9 introduces the basic situation of the main companies in the market in detail, including product sales revenue, sales volume, price, gross profit margin, market share, product introduction, recent development, etc.

Chapter 10 provides a quantitative analysis of the market size and development potential of each region in the next five years.

Chapter 11 provides a quantitative analysis of the market size and development potential of each market segment in the next five years.

Chapter 12 is the main points and conclusions of the report.

Get the Complete Report & TOC @ https://www.24chemicalresearch.com/reports/287293/global-pva-for-polarizer-forecast-market-2025-2032-773

Table of content

Table of Contents 1 Research Methodology and Statistical Scope 1.1 Market Definition and Statistical Scope of PVA for Polarizer 1.2 Key Market Segments 1.2.1 PVA for Polarizer Segment by Type 1.2.2 PVA for Polarizer Segment by Application 1.3 Methodology & Sources of Information 1.3.1 Research Methodology 1.3.2 Research Process 1.3.3 Market Breakdown and Data Triangulation 1.3.4 Base Year 1.3.5 Report Assumptions & Caveats 2 PVA for Polarizer Market Overview 2.1 Global Market Overview 2.1.1 Global PVA for Polarizer Market Size (M USD) Estimates and Forecasts (2019-2030) 2.1.2 Global PVA for Polarizer Sales Estimates and Forecasts (2019-2030) 2.2 Market Segment Executive Summary 2.3 Global Market Size by Region 3 PVA for Polarizer Market Competitive Landscape 3.1 Global PVA for Polarizer Sales by Manufacturers (2019-2025) 3.2 Global PVA for Polarizer Revenue Market Share by Manufacturers (2019-2025) 3.3 PVA for Polarizer Market Share by Company Type (Tier 1, Tier 2, and Tier 3) 3.4 Global PVA for Polarizer Average Price by Manufacturers (2019-2025) 3.5 Manufacturers PVA for Polarizer Sales Sites, Area Served, Product Type 3.6 PVA for Polarizer Market Competitive Situation and Trends 3.6.1 PVA for Polarizer Market Concentration Rate 3.6.2 Global 5 and 10 Largest PVA for Polarizer Players Market Share by Revenue 3.6.3 Mergers & Acquisitions, Expansion 4 PVA for Polarizer Industry Chain Analysis 4.1 PVA for Polarizer Industry Chain Analysis 4.2 Market Overview of Key Raw Material

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/287293/global-pva-for-polarizer-forecast-market-2025-2032-773

Follow Us On linkedin :- https://www.linkedin.com/company/24chemicalresearch/

0 notes

Photo

Multifunctional self-healing liquid metal hydrogel developed for human-computer interaction

Recently, researchers from the Hefei Institutes of Physical Science (HFIPS) of the Chinese Academy of Sciences, led by Prof. Tian Xingyou and Prof. Zhang Xian, along with associate Prof. Yang Yanyu from the College of Materials Science and Engineering at Zhengzhou University, used gallium indium alloy (EGaIn) to initiate the polymerization and serve as flexible fillers to construct liquid metal/polyvinyl alcohol(PVA)/P(AAm-co-SMA) double network hydrogel.

"The resulting material was super-stretchable and self-healing," said Li Xiaofei, first author of the paper, "it will promote the research and practical application of hydrogels and liquid metal in intelligent devices and military fields."

The study was published in Materials Horizons.

Most conductive hydrogels suffer from subpar mechanical qualities and lack desirable self-recovery and self-healing abilities, severely limiting hydrogels' potential uses. Liquid metals like gallium indium alloy (EGaIn) can toughen polymers by conforming to their changing shapes. Also, gallium (Ga) in EGaIn can initiate vinyl monomer's free radical polymerization.

Read more.

#Materials Science#Science#Self healing#Liquid metals#Hydrogels#Gallium#Indium#Polymers#Polyvinyl alcohol

12 notes

·

View notes

Text

0 notes