#PP Woven Ground Covers

Explore tagged Tumblr posts

Text

PP WOVEN GROUND COVER

Alpine FIBC PVT.LTD. is a best manufacturer, exporters and suppliers of high quality PP Woven Ground Cover in India, USA, Germany, France, UK, Italy, Canada, Spain, Netherlands, Portugal, Greece, Sweden, Argentina, Chile, Poland. We are the leading manufacturers and Exporters of PP Woven Ground Covers. The Ground Covers offered by us are made on advanced lines looms. Our fabric is made from 100 % virgin polypropylene granules & special UV & Color additives which gives it high tensile strength and UV resistance against the harshest environments and can last for a long term. Our ground is available in both Stripes and square marking lines and customized lines as per requirements.

We offer a wide range of customized PP woven ground cover from 3.0 oz to 4.1 oz per square yard and it comes in widths ranging from 3’ ft. to 13’ft. Flat. And we can offer maximum up to 2500’ standard roll length.

2 notes

·

View notes

Text

All You Must Know About PP Woven Fabric

The pp cover manufacturers constitute a key centre of production. Shankar Packaging Ltd is a prominent manufacturer of PP woven textiles and Our geotextile is widely used to filter, stabilize, drain, reinforce, and isolate soils in many construction processes. For more information visit our blog.

#PP woven geotextiles#woven polypropylene material#polypropylene ground cover#woven polypropylene bags#pp cover manufacturers#laminated woven bags#manufacturer of PP woven textiles#fibc bags manufacturers in ahmedabad

0 notes

Text

PP Woven Fabric: Essential Material for Reliable Packaging Solutions

PP woven fabric, commonly known as polypropylene woven fabric, is an essential material in various industries, particularly packaging, agriculture, and construction. This versatile material is favored for its strength, durability, and cost-effectiveness. In India, the demand for PP woven fabric has skyrocketed, thanks to its numerous applications in multiple sectors. In this article, we will delve into the various aspects of PP woven fabric, its benefits, and the leading PP woven fabric manufacturers and polypropylene fabric manufacturers in India.

What It Is and Its Importance

PP woven fabric refers to a strong, durable fabric made from polypropylene, a thermoplastic polymer. The woven structure of the fabric provides exceptional tensile strength, making it ideal for heavy-duty applications such as bulk packaging, agricultural coverings, and geotextiles. This fabric can also be laminated for additional protection against moisture, UV rays, and chemical exposure.

The importance of PP woven fabric lies in its versatility. Whether it’s used in industrial packaging, farming, or flood control, PP woven fabric offers reliable solutions for demanding environments. Moreover, it is lightweight, easy to handle, and can be customized in various shapes and sizes to meet specific needs.

PP Fabric Manufacturers: Industry Leaders in India

PP woven fabric manufacturers play a crucial role in supplying high-quality materials for a range of industrial applications. India, being one of the largest exporters of polypropylene products, is home to several well-established manufacturers that produce and supply PP woven fabric globally. These manufacturers ensure that the fabric meets stringent quality standards, and they offer both standard and customized products based on client specifications.

Leading polypropylene fabric manufacturers in India provide options that cater to industries such as food packaging, fertilizer storage, and building materials. With a strong commitment to sustainability, many Indian manufacturers also produce eco-friendly PP woven fabrics, which are recyclable and reduce environmental impact.

Applications of Fabric in Various Industries

The applications of PP woven fabric are vast, and its usage spans across multiple industries:

Packaging Industry: PP woven fabric is widely used in packaging for agricultural products, chemicals, cement, and more. Its ability to withstand heavy weights makes it an ideal material for bulk bags and sacks.

Agriculture: In agriculture, PP woven fabric is used for covering crops, creating protective barriers, and constructing ground covers. The fabric's UV resistance ensures that it lasts longer under the sun, providing long-term protection for crops.

Construction: The construction industry uses PP woven fabric for applications such as scaffolding nets, geo-textiles, and as a barrier material for soil stabilization. Its durability and resistance to weather elements make it ideal for construction-related purposes.

Flood Control: PP woven fabric is often used to make sandbags for flood control. The fabric’s strength ensures that the sandbags can hold large amounts of sand and resist damage during floods.

Benefits of Using PP Fabric

PP woven fabric offers numerous benefits, making it one of the most preferred materials for industrial and agricultural applications:

Strength and Durability: Thanks to its woven structure, PP woven fabric is incredibly strong, capable of withstanding high tensile forces. It is also resistant to tearing, making it ideal for heavy-duty uses.

Lightweight: Despite its strength, PP woven fabric is lightweight, which makes it easy to transport and handle in large quantities. This quality is particularly important in the packaging industry, where reducing transportation costs is crucial.

Weather-Resistant: PP woven fabric can be treated to resist UV rays, moisture, and chemicals. This makes it suitable for outdoor applications where exposure to the elements is common.

Cost-Effective: One of the major advantages of PP woven fabric is its cost-effectiveness. Compared to other packaging materials, PP woven fabric provides an affordable solution without compromising on quality.

Customizable: PP woven fabric can be manufactured in various colors, sizes, and thicknesses to meet the specific requirements of different industries. Manufacturers can also print branding and product information directly onto the fabric, enhancing its functionality.

Polypropylene Manufacturers in India: Commitment to Quality

The leading Polypropylene fabric manufacturers in India are known for their commitment to producing high-quality products. By using advanced machinery and adhering to international quality standards, these manufacturers ensure that their products meet the stringent demands of the global market. Indian manufacturers are particularly recognized for their ability to offer customized solutions that cater to specific industrial needs.

Moreover, many PP woven fabric manufacturers in India have embraced sustainability practices by creating recyclable PP woven fabrics. This not only benefits the environment but also reduces the waste generated from non-recyclable materials, thus supporting a greener future.

Innovations in Woven Fabric Manufacturing

PP woven fabric manufacturers are continually innovating to meet the evolving demands of industries. Advances in weaving technology, fabric coating, and lamination have enhanced the properties of PP woven fabric, making it even more durable and weather-resistant. Additionally, manufacturers are working on creating fabrics with improved load-bearing capacity for use in heavy-duty applications like industrial bulk packaging.

Many manufacturers are also developing eco-friendly alternatives by using recycled polypropylene in their production processes. These innovations contribute to reducing the overall environmental footprint, which is increasingly becoming a priority for both manufacturers and customers.

Choosing the Right Woven Fabric Supplier

When selecting a PP woven fabric manufacturer, it’s important to consider factors such as product quality, customization options, and the manufacturer’s reputation. A reliable supplier should have a track record of delivering high-quality products that meet specific industry requirements. Additionally, the ability to customize fabric size, weight, and color can be crucial for businesses with unique packaging needs.

Manufacturers that offer fast delivery times, competitive pricing, and excellent customer service should be prioritized, as these factors play a significant role in maintaining a smooth supply chain. Furthermore, working with polypropylene fabric manufacturers in India who focus on sustainable practices can benefit companies aiming to reduce their environmental impact.

Conclusion

PP woven fabric is a versatile and reliable material widely used across industries. With its strength, durability, and cost-effectiveness, it remains a preferred choice for packaging, agriculture, and construction applications. The leading PP woven fabric manufacturers and polypropylene fabric manufacturers in India continue to innovate, providing high-quality solutions to meet the ever-growing demand for polypropylene-based products.

Frequently Asked Questions (FAQs) about PP Fabric

1. What is PP woven fabric made of?

PP fabric is made from polypropylene, a type of thermoplastic polymer. The material is woven into a strong fabric that is durable, lightweight, and resistant to moisture and chemicals.

2. What are the main uses of PP woven fabric?

PP woven fabric is commonly used in packaging, agriculture, construction, and flood control. It is used to make bulk bags, ground covers, geotextiles, and sandbags due to its strength and durability.

3. How long does PP woven fabric last in outdoor conditions?

PP woven fabric treated with UV-resistant coating can last several years in outdoor conditions without significant degradation. Its resistant properties make it ideal for long-term outdoor use.

4. Can PP woven fabric be recycled?

Yes, PP woven fabric is recyclable. Many manufacturers are now producing eco-friendly versions that can be recycled, contributing to reduced environmental impact.

0 notes

Text

Spunbond Polypropylene Non Woven Fabric | Favourite Fab

At Favourite Fab, we take pride in offering high-quality spunbond polypropylene non-woven fabric, a versatile material that has become essential across various industries. Known for its durability and functionality, our spunbond fabric meets the needs of diverse applications, from healthcare to agriculture.

What is Spunbond Polypropylene Non-Woven Fabric?

Spunbond polypropylene non-woven fabric is made by extruding polypropylene fibers and bonding them together through heat and pressure. This process results in a lightweight, durable, and breathable fabric that is both functional and eco-friendly.

Key Features

Durability: Spunbond fabric is resistant to tearing and wear, making it ideal for applications requiring long-lasting materials.

Breathability: The fabric allows air and moisture to pass through, enhancing comfort in products such as medical textiles and protective gear.

Lightweight: Easy to handle and transport, spunbond polypropylene is perfect for various manufacturing processes.

Customizable: Available in different weights, colors, and finishes, our spunbond fabric can be tailored to meet specific customer needs.

Applications

Medical: Used in surgical gowns, masks, and drapes, offering protection while maintaining comfort.

Hygiene Products: Essential in the production of disposable diapers and feminine hygiene products.

Agriculture: Employed for crop covers and ground mats, promoting healthy plant growth and protecting against pests.

Packaging: Ideal for eco-friendly bags and packaging solutions that reduce plastic waste.

Conclusion

Spunbond polypropylene non-woven fabric from Favourite Fab is your go-to solution for durability, versatility, and sustainability. We are dedicated to delivering high-quality materials that meet the evolving needs of our clients across various industries.

0 notes

Text

PP Fibrillated Yarn: Enhancing Durability in Woven Fabrics

In the world of textiles, the quest for durability and resilience has led to the emergence of innovative materials that enhance the longevity of products. One such material making waves in the industry is PP (Polypropylene) fibrillated yarn. Renowned for its strength and versatility, PP Fibrillated Yarn Price is revolutionizing the way woven fabrics are manufactured, providing a myriad of benefits for various applications. In this blog, we will explore what PP fibrillated yarn is, its unique properties, its applications, and how it enhances the durability of woven fabrics.

Understanding PP Fibrillated Yarn

PP fibrillated yarn is a type of synthetic yarn produced from polypropylene, a thermoplastic polymer that is widely used in various industries. The term "fibrillated" refers to the process of creating numerous thin fibers from a single strand of yarn. This process results in a network of interconnected fibers that provide enhanced strength and durability.

The unique structure of fibrillated yarn gives it a larger surface area compared to traditional yarns, allowing for PP Fibrillated Yarn Suppliers with other materials. This characteristic is particularly advantageous in woven fabrics, where the integrity and strength of the weave are crucial for performance.

Properties of PP Fibrillated Yarn

PP fibrillated yarn possesses several properties that contribute to its effectiveness in enhancing the durability of woven fabrics:

1. High Tensile Strength

One of the standout features of PP fibrillated yarn is its high tensile strength. This property allows it to withstand significant stress and strain, making it ideal for applications that require durable materials. Woven fabrics made with PP fibrillated yarn can endure heavy loads without compromising their structural integrity.

2. Moisture Resistance

PP fibrillated yarn is naturally resistant to moisture, which prevents mold and mildew growth in textiles. This moisture resistance is crucial for maintaining the quality and longevity of woven fabrics, especially in outdoor applications where exposure to the elements is common.

3. UV Stability

Exposure to sunlight can degrade many synthetic materials over time. However, PP fibrillated yarn has good UV stability, allowing it to maintain its strength and color even when subjected to prolonged sun exposure. This makes it an excellent choice for outdoor textiles, such as tarps and canopies.

4. Lightweight

Despite its strength, PP fibrillated yarn is lightweight, which is an essential characteristic for many textile applications. This property enables the creation of durable yet manageable fabrics, reducing the overall weight of the final product without sacrificing performance.

5. Flexibility and Softness

PP fibrillated yarn retains a degree of flexibility and softness, making it suitable for applications where comfort is essential. This balance between durability and softness allows manufacturers to create woven fabrics that are not only tough but also pleasant to the touch.

Applications of PP Fibrillated Yarn

The versatility of PP fibrillated yarn allows it to be used in a variety of applications across different industries:

1. Agricultural Textiles

In the agricultural sector, PP fibrillated yarn is commonly used to produce netting, shade cloths, and ground covers. The strength and durability of the yarn ensure that these products can withstand harsh environmental conditions while protecting crops and promoting healthy growth.

2. Geotextiles

PP fibrillated yarn is also used in geotextiles, which are fabrics used in civil engineering and landscaping projects. These textiles provide soil stabilization, erosion control, and drainage solutions. The high tensile strength and moisture resistance of PP fibrillated yarn enhance the durability and effectiveness of geotextiles in various applications.

3. Industrial Fabrics

In industrial settings, PP fibrillated yarn is employed to create durable fabrics for products such as tarps, bags, and containers. The ability to withstand heavy loads and environmental stresses makes it a preferred choice for manufacturers seeking reliable and long-lasting materials.

4. Furniture and Upholstery

PP fibrillated yarn is also making its way into the furniture and upholstery markets. Its combination of strength, softness, and resistance to wear makes it an excellent choice for producing durable fabrics that can withstand daily use while maintaining their aesthetic appeal.

5. Sports and Outdoor Gear

In the world of sports and outdoor equipment, PP fibrillated yarn is used to create strong, lightweight fabrics for items such as tents, backpacks, and outdoor gear. The moisture resistance and UV stability of the yarn ensure that these products remain functional and visually appealing, even with frequent exposure to the elements.

Enhancing Durability in Woven Fabrics

The integration of PP fibrillated yarn into woven fabrics significantly enhances their durability through several mechanisms:

1. Improved Bonding

The fibrillated structure of the yarn increases the surface area available for bonding during the weaving process. This leads to stronger inter-fiber connections, resulting in woven fabrics that can withstand higher levels of stress and strain.

2. Resistance to Wear and Tear

Woven fabrics made with PP fibrillated yarn exhibit superior resistance to abrasion and wear. This characteristic is particularly important for products subjected to constant movement or friction, ensuring that they maintain their integrity over time.

3. Longevity of Outdoor Textiles

The moisture and UV resistance of PP fibrillated yarn contribute to the longevity of outdoor woven fabrics. These properties prevent deterioration from environmental factors, allowing products to retain their functionality and appearance for extended periods.

4. Versatility in Design

The flexibility and softness of PP fibrillated yarn allow for creative designs in woven fabrics. Manufacturers can create products that are not only durable but also visually appealing, meeting consumer demands for both performance and aesthetics.

Conclusion

PP fibrillated yarn is a game-changer in the textile industry, offering a unique combination of strength, moisture resistance, and versatility. Its ability to enhance the durability of woven fabrics makes it an invaluable material for a wide range of applications, from agriculture to outdoor gear.

As the demand for durable and reliable textiles continues to grow, the adoption of PP fibrillated yarn is likely to expand. Fibrillated Polypropylene Yarn who embrace this innovative material can create products that meet the evolving needs of consumers while contributing to sustainability and performance.

In a world where durability is paramount, PP fibrillated yarn stands out as a solution that not only enhances the longevity of woven fabrics but also opens the door to new possibilities in design and application. Whether for outdoor use, industrial products, or agricultural needs, the advantages of PP fibrillated yarn make it a compelling choice for manufacturers and consumers alike.

Frequently Asked Questions (FAQs):

What advantages does Singhal Industries' PP fibrillated yarn offer for woven fabrics? Singhal Industries' PP fibrillated yarn provides exceptional tensile strength, moisture resistance, and UV stability, making it ideal for enhancing the durability of woven fabrics. This yarn ensures that the products maintain their integrity even in harsh conditions, making it a preferred choice for various applications in agriculture, outdoor gear, and industrial textiles.

How does Singhal Industries ensure the quality of its PP fibrillated yarn? At Singhal Industries, quality control is paramount. The company employs advanced manufacturing processes and rigorous testing standards to ensure that its PP fibrillated yarn meets high-performance criteria. This dedication to quality guarantees that the yarn delivers superior durability and reliability in all applications.

In which industries can I find Singhal Industries' PP fibrillated yarn being used? Singhal Industries' PP fibrillated yarn is versatile and can be found in various industries, including agriculture, civil engineering, industrial textiles, and outdoor gear manufacturing. Its strength and durability make it suitable for a wide range of applications, from geotextiles to sports equipment and furniture upholstery.

0 notes

Text

How to Get the Best Woven Fabric at the Most Affordable Rates

Polypropylene (PP) woven fabric is widely used in different sectors because of its excellent strength, elasticity and reasonable price. Thus, the search for high-quality pp woven fabric manufacturer in India has been on the rise, and India has become one of the leaders in the market, which is home to many leading manufacturers. In this article, we will discuss about the top players in the market for PP woven fabric in India and where you can get the best prices to fulfill your requirements.

PP Woven Fabric and its Properties

PP woven fabric is a kind of textile that is produced by weaving polypropylene strips into a robust and sturdy mesh like structure. Being very strong and at the same time quite resistant to moisture, this fabric is used in packaging materials, agriculture, construction, and many other areas. Key applications of PP woven fabric include:Key applications of PP woven fabric include:

- Packaging: Applied in the production of bags, sacks and geotextile materials.

- Agriculture: These are used in crop protection, as ground covers, and as shade nets.

- Construction: Used to prevent seepage of water and also as a reinforcement material.

The Cheapest PP Woven Fabric in India

To get the best offers on PP woven fabric in India one has to look for the best option available, quality of the fabric, price and how reliable the suppliers are. Here are some tips to help you secure the best deals:Here are some tips to help you secure the best deals:

1. Online Marketplaces:

Some of the sources for obtaining a large variety of PP woven fabric suppliers from India include IndiaMART, TradeIndia, and Alibaba. These platforms enable one to compare and contrast products, prices, and the supplier’s rating hence increasing our chances of getting a good deal. Guarantees, reviews, and specifications of many manufacturers are available on the internet and can be used to make a proper choice.

2. Trade Shows and Exhibitions:

Visit trade fairs and exhibitions that are specific to the domains of textiles and packaging material to find the best PP woven fabric maker. Mega events like India International Trade Fair (IITF) and Plastindia are to establish contacts with the suppliers, to see the products and to discuss and conclude business deals.

3. Direct Manufacturer Contact:

Contacting the manufacturers including Gopinath Enterprise, Rishi FIBC Solutions, Sandeep Polymers and Commercial Syn Bags Ltd can assist in getting a direct quote and thus a cheaper price. It is mostly easier and cheaper to get in touch with manufacturers who are then able to offer better solutions and prices.

4. Bulk Purchasing:

It is advised that if you plan to buy the PP woven fabric, it would be better to do so in bulk to get the most economical rates per unit. Some companies give discounted rates for bulk purchase because they can produce the items at a rather low cost.

5. Local Distributors:

Local distributors and dealers have the advantage of prior linkages with the manufacturers hence can offer better prices. They can also provide quicker delivery and other services such as storage and handling services.

Conclusion

India has emerged to be a big producer of PP woven fabric used in different industries and comes up with quality products. Leading manufacturers Sudarshan Addpack. To get the best prices of PP woven fabric, one has to search for the product online, visit trade fairs, directly approach the manufacturers, consider buying in large quantities and liaise with the local distributors. Thus, you can get the high-quality PP woven fabric at lower prices and guarantee the effectiveness of your business processes.

0 notes

Text

From Concept to Completion: How PP Woven Fabrics Shape Modern Industries

Polypropylene woven fabrics, a cornerstone in the textile industry, have seen exponential growth and application across various sectors. Their versatility, durability, and cost-effectiveness make them indispensable in modern industries. Polypropylene, a thermoplastic polymer, is known for its high tensile strength, resistance to chemicals, and low moisture absorption. These properties, when woven into fabrics, create materials that are both strong and adaptable, serving a wide range of industrial needs.

The Manufacturing Process

Polypropylene woven fabric manufacturers employ advanced techniques to produce high-quality materials. The process begins with the polymerization of propylene gas into polypropylene resin. This resin is then melted and extruded through a spinneret, forming continuous filaments. These filaments are drawn to align the polymer molecules, enhancing tensile strength and durability. Afterward, the filaments are woven into fabric using circular or flat weaving looms. The weaving process interlaces the filaments, creating a robust fabric that can withstand heavy loads and harsh environmental conditions. Polypropylene woven fabrics manufacturers focus on quality control at every stage of production. The fabrics undergo rigorous testing for tensile strength, elongation, UV resistance, and chemical resistance. These tests ensure that the final product meets industry standards and can perform reliably in various applications.

Applications Across Industries

Agriculture In agriculture, polypropylene woven fabrics are used extensively for crop protection, soil stabilization, and packaging. These fabrics are ideal for making sacks and bags that store grains, seeds, and fertilizers. Their resistance to moisture and pests ensures that the contents remain safe and dry. Additionally, woven fabrics are used in shade nets and ground covers to protect crops from excessive sunlight and weed growth, promoting healthier plant growth and higher yields.

Construction The construction industry relies heavily on polypropylene woven fabrics for their strength and durability. These fabrics are used in the production of geotextiles, which are essential for soil reinforcement, erosion control, and drainage systems. Geotextiles made from polypropylene woven fabrics provide a stable foundation for roads, highways, and embankments, preventing soil erosion and ensuring long-term structural integrity. Furthermore, they are used in scaffolding nets and tarpaulins, protecting construction sites and materials from environmental elements.

Packaging Polypropylene woven fabrics are widely used in the packaging industry due to their lightweight and high strength. These fabrics are used to create bags, sacks, and flexible intermediate bulk containers (FIBCs), commonly known as jumbo bags. FIBCs are capable of carrying large quantities of materials, such as chemicals, minerals, and agricultural products, making them indispensable in logistics and transportation. The durability of polypropylene woven fabrics ensures that these containers can withstand rough handling and transportation stresses.

Healthcare In the healthcare sector, polypropylene woven fabrics play a crucial role in the production of disposable medical products. These fabrics are used to manufacture surgical gowns, masks, caps, and shoe covers. The fabric's resistance to fluids and pathogens ensures a sterile environment, protecting healthcare workers and patients from infections. Additionally, woven fabrics are used in the production of hospital bed linens and mattress covers, providing comfort and hygiene in medical facilities.

Consumer Goods Polypropylene woven fabrics are also prevalent in the consumer goods sector. They are used to make reusable shopping bags, which are eco-friendly alternatives to single-use plastic bags. These bags are durable, lightweight, and capable of carrying heavy loads, making them a popular choice among environmentally conscious consumers. Additionally, woven fabrics are used in the production of luggage, backpacks, and outdoor gear, where their strength and resistance to wear and tear are highly valued.

Environmental Impact and Sustainability

As concerns about environmental sustainability grow, polypropylene woven fabric manufacturers are taking steps to reduce their ecological footprint. Polypropylene is a recyclable material, and many manufacturers are incorporating recycled polypropylene into their production processes. This not only reduces the demand for virgin polypropylene but also minimizes waste. Additionally, the durability and reusability of polypropylene woven fabrics contribute to a reduction in single-use plastics, promoting a more sustainable approach to packaging and material use.

Manufacturers are also exploring biodegradable additives that can enhance the environmental friendliness of polypropylene woven fabrics. These additives help the fabric break down more quickly under certain conditions, reducing the long-term impact on the environment. By investing in sustainable practices and materials, Polypropylene woven fabric manufacturers are aligning with global efforts to promote eco-friendly industrial processes.

Innovations and Future Trends

The future of polypropylene woven fabrics is bright, with ongoing innovations driving new applications and improvements in performance. One notable trend is the development of smart fabrics, which integrate electronic components into the woven structure. These smart fabrics can monitor and respond to environmental changes, providing real-time data and enhancing the functionality of products in sectors such as healthcare, agriculture, and construction.

Polypropylene woven fabric manufacturers are also leveraging automation and digital technologies to improve efficiency and precision in production. Automated weaving machines and digital quality control systems ensure consistent product quality and reduce production costs. By embracing these technological advancements, manufacturers can meet the growing demand for high-performance polypropylene woven fabrics.

Conclusion

From concept to completion, polypropylene woven fabrics have become integral to modern industries, offering unmatched versatility, strength, and sustainability. As Polypropylene fabric manufacturers in India continue to innovate and adopt eco-friendly practices, these fabrics will play an even more significant role in shaping the future of various sectors. Whether in agriculture, construction, packaging, healthcare, or consumer goods, polypropylene woven fabrics provide the reliability and performance needed to meet the demands of a rapidly evolving world.

Frequently Asked Questions (FAQs)

How do polypropylene woven fabrics contribute to construction projects? Polypropylene woven fabrics are used in geotextiles for soil reinforcement, erosion control, and drainage systems, providing stability and durability in construction projects.

Are polypropylene woven fabrics suitable for medical applications? Yes, polypropylene woven fabrics are used to make disposable medical products such as surgical gowns, masks, and caps, providing protection against fluids and pathogens.

What innovations are shaping the future of polypropylene woven fabrics? Innovations such as smart fabrics, advanced coatings, and automation in production are enhancing the performance and expanding the applications of polypropylene woven fabrics.

0 notes

Text

PP Spunbond Nonwoven Fabric: Versatile, Durable, Eco-Friendly Solutions

In the world of modern manufacturing and packaging, materials that offer versatility, durability, and environmental sustainability are highly valued. PP (Polypropylene) Spunbond Nonwoven Fabric stands out as a key player in meeting these criteria, serving a wide range of applications across various industries. At Singhal Industries, we specialize in manufacturing high-quality PP Spunbond Nonwoven Fabric that meets stringent standards of performance and eco-friendliness.

What is PP Spunbond Nonwoven Fabric?

PP Spunbond Nonwoven Fabric is a type of nonwoven material made from thermoplastic polymer polypropylene. Unlike traditional woven fabrics, which are created by weaving or knitting yarns together, nonwoven fabrics are manufactured by bonding fibers together through various processes. PP Spunbond Exporter in Ahmedabad is produced by spinning and bonding polypropylene fibers together to form a strong and durable web.

Key Characteristics of PP Spunbond Nonwoven Fabric

1. Versatility:

PP Spunbond Nonwoven Fabric is incredibly versatile and finds applications in diverse industries such as agriculture, medical, automotive, construction, and packaging.

It can be engineered to have different properties like water resistance, breathability, and strength, making it suitable for a wide range of end uses.

2. Durability:

Known for its strength and durability, PP Spunbond Nonwoven Fabric offers excellent tear and tensile strength, making it ideal for applications where robust performance is essential.

It withstands harsh environmental conditions, including exposure to chemicals and UV radiation, without compromising its integrity.

3. Eco-Friendliness:

As environmental sustainability becomes increasingly important, PP Spunbond Nonwoven Fabric stands out for its eco-friendly characteristics.

It is recyclable and can be manufactured using recycled polypropylene materials, reducing overall environmental impact.

The production process of Spunbond non woven fabric manufacturer consumes less energy and water compared to traditional woven fabrics, making it a greener choice.

Applications of PP Spunbond Nonwoven Fabric

PP Spunbond Nonwoven Fabric's versatility makes it indispensable in various industries:

1. Agriculture:

Used in crop protection, greenhouse coverings, and as ground covers due to its permeability to air and water.

2. Medical and Hygiene:

Widely used in surgical gowns, face masks, and medical wipes due to its softness, breathability, and bacteria resistance.

3. Packaging:

Ideal for packaging applications such as tote bags, shopping bags, and promotional bags due to its strength, lightweight nature, and printability.

4. Automotive:

Used in car upholstery, interior trim, and insulation due to its durability, noise reduction properties, and resistance to mold and mildew.

5. Construction:

Used as geotextiles, roofing membranes, and house wrap due to its strength, moisture resistance, and ability to provide thermal insulation.

Why Choose Singhal Industries for PP Spunbond Nonwoven Fabric?

Singhal Industries is a leading manufacturer of PP Spunbond Nonwoven Fabric, offering:

High-Quality Products: We adhere to strict quality control measures to ensure our PP Spunbond Nonwoven Fabric meets international standards.

Customization: We offer customization options in terms of colors, weights, and specifications to meet specific customer requirements.

Sustainability: Our manufacturing processes emphasize sustainability, with a focus on reducing environmental impact through responsible practices.

Reliability: With years of industry experience and a commitment to customer satisfaction, Singhal Industries is a trusted partner for all your nonwoven fabric needs.

Conclusion

PP Spunbond nonwoven Supplier India continues to revolutionize industries with its versatility, durability, and eco-friendly properties. Whether you're looking for packaging solutions, medical textiles, agricultural covers, or automotive components, PP Spunbond Nonwoven Fabric from Singhal Industries offers a reliable and sustainable choice. Contact us today to explore how our innovative nonwoven fabric solutions can benefit your business.

FAQS

What is PP Spunbond Nonwoven Fabric? PP Spunbond Nonwoven Fabric is a type of material made from polypropylene fibers that are spun and bonded together. It is known for its strength, durability, and versatility in various applications.

What are the key benefits of PP Spunbond Nonwoven Fabric? PP Spunbond Nonwoven Fabric offers versatility across industries, durability against wear and tear, and eco-friendly properties as it is recyclable and can be made from recycled materials.

In which industries is PP Spunbond Nonwoven Fabric commonly used? It is used in agriculture for crop protection and ground cover, in medical applications for surgical masks and gowns, in packaging for bags and wraps, in automotive for upholstery and insulation, and in construction for geotextiles and roofing membranes.

How environmentally friendly is PP Spunbond Nonwoven Fabric? PP Spunbond Nonwoven Fabric is considered eco-friendly due to its recyclability and the potential to use recycled materials in its production. Its manufacturing process also consumes less energy and water compared to traditional fabrics.

Why choose PP Spunbond Nonwoven Fabric from Singhal Industries? Singhal Industries offers high-quality PP Spunbond Nonwoven Fabric with customization options, stringent quality control measures, and a commitment to sustainability. Our products meet international standards and are tailored to meet specific customer needs.

0 notes

Text

### What is a Bulk Bag (Ton Bag)? A Comprehensive Guide!

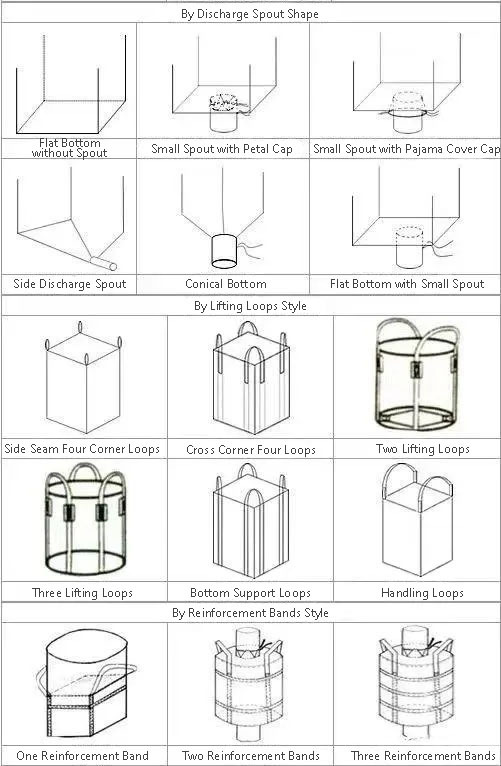

#### International Standard Bulk Bag Patterns

Bulk bags, also known as FIBC (Flexible Intermediate Bulk Containers), super sacks, big bags, ton bags, or jumbo bags, are flexible transport packaging containers. They are characterized by their moisture-proof, dust-proof, radiation-resistant, strong, and secure properties. Structurally, they possess sufficient strength, making loading and unloading highly efficient and convenient. As a result, bulk bags have seen rapid development in recent years. These bags are generally made from woven polyester fibers such as polypropylene (PP) or polyethylene (PE).

### Features

Bulk bags facilitate the transportation of large quantities of bulk powdered materials. They are known for their large volume, lightweight, and ease of loading and unloading, making them one of the most common packaging materials. Key characteristics include simple structure, light weight, foldability, minimal space occupancy when empty, and cost-effectiveness.

### Characteristics

1. **Load Capacity**: Ranges from 0.5 to 3 tons, with volumes between 500 to 2300 liters. The safety factor can be designed to 3:1, 5:1, or 6:1 based on user requirements.

2. **Content Type**: Divided into bulk goods bags and small package goods bags, suitable for both single-use and reusable applications.

3. **Shape**: Available in round, square, and U-shaped configurations.

4. **Lifting Structure**: Includes top lift, side lift, and bottom lift types, typically featuring inlet and outlet spouts.

### Performance

- **Usage Types**: Reusable / Single-use

- **Shapes**: Square / Rectangular

- **Lifting Methods**: Top lift / Side lift / Bottom lift

- **Inlet**: With inlet spout / Without inlet spout (large opening / waterproof cover)

- **Outlet**: With outlet spout / Without outlet spout

- **Materials**: Polypropylene (PP)

- **Load Capacity**: 0.3 tons - 2 tons

### Usage Precautions

1. Do not stand under the bulk bag during lifting operations.

2. Attach the hook to the center of the lifting loop or sling; avoid tilting, single-sided lifting, or diagonal pulling.

3. Prevent the bag from rubbing, hooking, or colliding with other items during operations.

4. Do not pull the lifting loops outward.

5. When using a forklift, avoid contact between the fork and the bag body to prevent punctures.

6. Use pallets during warehouse handling to avoid carrying the bag by hooks to prevent swinging.

7. Keep the bag upright during loading, unloading, and stacking.

8. Do not drag the bag on the ground or concrete.

9. For outdoor storage, place the bag on a pallet and cover it tightly with an opaque tarpaulin.

10. After use, wrap the bag in paper or an opaque tarpaulin and store it in a ventilated area.

### Applications

Suitable for packaging chemical raw materials, pharmaceutical raw materials, plastic raw materials, food additives, feed additives, metallurgical powders, ore powders, refractory materials, and other industries using bulk bags.

Shenzhen East Green International Freight Forwarding company, specializing in the transportation of bulk and oversized cargo via sea. Such as engineering vehicles, large machinery, steel materials, ton bags, etc.. We look forward to cooperate with you and are available for any inquiries at your convenience.

Tyin Meng

Contact Information:(+86) 18528265381 (Wechat or Whatsapp)

1 note

·

View note

Text

The Versatile World of PP Woven Fabric: An In-Depth Exploration

Polypropylene (PP) woven fabric is an incredibly versatile material widely used in various industries due to its strength, durability, and cost-effectiveness. Its applications range from packaging and agriculture to construction and geotextiles. In this article, we will delve into the characteristics, production process, and applications of PP woven fabric, with a particular focus on manufacturers, especially those based in India and those that might be "near me."

Understanding PP Woven Fabric

PP woven fabric is made from polypropylene, a type of thermoplastic polymer. This fabric is created by weaving polypropylene strips in a crisscross pattern, which gives it excellent tensile strength and durability. The resulting material is lightweight yet robust, making it ideal for various heavy-duty applications.

Key Characteristics:

Durability: PP woven fabric is resistant to wear and tear, making it suitable for repeated use.

Chemical Resistance: It is resistant to many chemicals, including acids and bases, ensuring its integrity in harsh environments.

Water Resistance: This fabric does not absorb water, making it ideal for outdoor use.

Lightweight: Despite its strength, PP woven fabric is lightweight, which makes it easy to handle and transport.

Production Process of PP Woven Fabric

The production of PP woven fabric involves several steps:

1. Extrusion: Polypropylene granules are melted and extruded into flat tapes or filaments.

2. Weaving: These tapes are then woven into fabric using circular or flat weaving looms.

3. Lamination: For certain applications, the woven fabric is laminated with a layer of polyethylene to enhance its properties.

4. Cutting and Sewing: The fabric is cut into desired shapes and sizes and then sewn to make various products like bags, tarpaulins, and geotextiles.

Applications of PP Woven Fabric

The versatility of PP woven fabric lends itself to a myriad of applications across different sectors:

Packaging: One of the most common uses of PP woven fabric is in packaging. It is used to make bags for storing and transporting goods such as grains, sugar, flour, and animal feeds. These bags are known for their strength and durability, protecting the contents from damage during transit.

Agriculture: In the agricultural sector, PP woven fabric is used to create ground covers, weed mats, and nursery bags. These products help in weed control, moisture retention, and soil erosion prevention, thereby enhancing crop yield and quality.

Construction: The construction industry utilizes PP woven fabric for applications such as scaffolding sheets, temporary fences, and safety nets. Its high tensile strength and resistance to environmental factors make it suitable for these heavy-duty uses.

Geotextiles: PP woven fabric is extensively used in geotextiles, which are essential in civil engineering projects. These fabrics are used for soil stabilization, erosion control, and drainage. They provide long-lasting solutions for infrastructure projects, ensuring stability and longevity.

Furniture and Home Textiles: PP woven fabric is also used in the manufacture of furniture and home textiles. It is used to make upholstery, carpet backing, and mattress covers due to its durability and ease of maintenance.

PP Woven Fabric Manufacturers in India

India is one of the leading producers of PP woven fabric, with numerous manufacturers catering to both domestic and international markets. The country’s manufacturers are known for their high-quality products, competitive pricing, and adherence to international standards.

Finding a PP Woven Fabric Manufacturer Near You

If you are looking for a "pp woven fabric manufacturer near me," it is important to consider factors such as the manufacturer’s reputation, product quality, and service reliability. Many local manufacturers offer excellent products that meet international standards. Here are some tips to find a reliable manufacturer near you:

Research Online: Use search engines and business directories to find manufacturers in your vicinity. Websites like IndiaMART, TradeIndia, and Alibaba list numerous suppliers with detailed information about their products and services.

Check Reviews and Testimonials: Look for reviews and testimonials from previous clients. This can give you an idea of the manufacturer’s reliability and product quality.

Visit Trade Shows and Exhibitions: Trade shows and exhibitions are great places to meet manufacturers in person. They provide an opportunity to see product samples and discuss your requirements directly with the suppliers.

Request Samples: Before making a large order, request samples to evaluate the quality of the fabric. This can help you ensure that the manufacturer meets your specifications.

Verify Certifications: Ensure that the manufacturer adheres to international quality standards. Certifications like ISO 9001 can be an indicator of their commitment to quality.

Conclusion

PP woven fabric is an essential material in various industries due to its strength, durability, and versatility. From packaging and agriculture to construction and geotextiles, its applications are vast and varied. India stands out as a major hub for pp woven fabric manufacturer, offering high-quality products to both domestic and international markets.

Whether you are looking for a "pp woven fabric manufacturer in India" or a "pp woven fabric manufacturer near me," it is crucial to do thorough research and choose a reliable supplier. By considering factors like quality, reputation, and customer service, you can find a manufacturer that meets your needs and ensures the success of your projects.

FAQ on PP Woven Fabric

1. What is PP woven fabric?

PP woven fabric is a material made from polypropylene strips woven in a crisscross pattern, known for its durability, strength, and lightweight properties.

2. What are the common uses of PP woven fabric?

It is used in packaging (bags for grains, sugar), agriculture (ground covers, weed mats), construction (scaffolding sheets, safety nets), and geotextiles (soil stabilization, erosion control).

3. Is PP woven fabric waterproof?

Yes, PP woven fabric is water-resistant, making it suitable for outdoor applications.

4. How is PP woven fabric made?

It is produced by extruding polypropylene into tapes, which are then woven into fabric, often followed by lamination for additional properties.

5. Where can I find PP woven fabric manufacturers?

India is a leading producer, with many manufacturers offering high-quality products. You can also search online directories or attend trade shows to find local suppliers.

#pp woven fabric manufacturer#pp woven fabric manufacturer in india#pp woven fabric manufacturer near me

0 notes

Text

2 notes

·

View notes

Text

Geotextile Fabric: Applications Across Different Industries

Geotextiles are permeable textiles made predominantly of components like polypropylene as well as polyester. The PP woven geotextiles can be described as a material made by intertwining more than two filaments, yarn strips, or any other element generally with right angles. For more information visit our blog.

#nonwoven geotextile#PP woven geotextiles#PP non woven geotextile#geotextile fabric suppliers in India#geo fabric#Woven Geo Fabric#polypropylene ground cover

0 notes

Text

Ultimate Guide to PP Woven Fabric: Manufacturing Process and Top Suppliers

Introduction

PP (Polypropylene) woven fabric, renowned for its strength and durability, is a versatile material extensively used across diverse industries. Manufactured by weaving polypropylene fibers, this fabric exhibits exceptional resistance to tearing, puncturing, and abrasion. Its robustness makes it ideal for various applications, from agriculture to packaging and construction.

In agriculture, PP woven fabric is commonly employed for sacks, tarpaulins, and ground coverings, providing protection to crops and facilitating storage. In the packaging industry, it serves as the backbone for FIBC (Flexible Intermediate Bulk Containers), ensuring secure transportation of goods. Moreover, PP woven fabric finds applications in construction projects, offering scaffolding nets, debris containment, and erosion control barriers. With its recyclability and eco-friendly properties, PP woven fabric continues to be a preferred choice for sustainable packaging solutions, further solidifying its importance across industries.

Manufacturing Process of PP Woven Fabric Roll

PP woven fabric is produced through a meticulous process that involves several key steps, each crucial for achieving the desired quality and characteristics of the final product. Here’s a detailed breakdown of the manufacturing process:

Raw Material Selection

Extrusion of Polypropylene Granules

Weaving Process

Lamination (if applicable)

Cutting and Sewing

Understanding the intricate manufacturing process of PP woven fabric underscores the importance of precision, expertise, and quality control at every stage. By leveraging advanced technologies and adhering to strict quality standards, manufacturers can produce PP woven fabric that meets the diverse needs of various industries and applications.

Quality Control Measures

Quality control is paramount in ensuring the reliability and performance of PP woven fabric. Here are some essential quality control measures implemented throughout the manufacturing process:

Raw Material Inspection

Production Process Monitoring

Testing Procedures

Compliance Standards

Quality Assurance Team

Implementing robust quality control measures not only ensures the reliability and performance of PP woven fabric but also enhances customer satisfaction and trust in the product.

Suppliers of PP Woven Fabric

Choosing the Right Supplier

When selecting a supplier for your PP woven fabric needs, it’s crucial to consider several factors to ensure quality, reliability, and efficiency. Look for experienced suppliers with a proven track record of delivering high-quality products on time. Reliability, product consistency, and customer service are key aspects to prioritize. Additionally, consider factors such as pricing, flexibility, and production capacity to meet your business requirements.

As a leading provider of PP woven fabric, Formosa Synthetics Pvt. Ltd. offers a comprehensive range of products tailored to meet diverse industry needs. Our state-of-the-art manufacturing facilities ensure superior quality and consistency in every batch of fabric produced. With a commitment to customer satisfaction and timely delivery, we strive to exceed expectations in every aspect of our service.

Factors to Consider When Choosing a Supplier

Selecting the right supplier for your PP woven fabric needs is crucial for the success of your project or business. Quality, reliability, and consistency are paramount in ensuring that your products meet the required standards and deadlines. Here are some key factors to keep in mind:

Quality Assurance

Production Capacity

Technical Expertise

Supply Chain Transparency

Cost-effectiveness

Communication and Support

Flexibility and Customization

By considering these factors when choosing a supplier for PP woven fabric, you can ensure a successful partnership that meets your quality standards, timelines, and business objectives.

Conclusion

In conclusion, PP woven fabric emerges as a stalwart material, revered for its resilience and adaptability across industries. Its manufacturing process, meticulously executed with a keen eye on quality control measures, ensures the production of high-performance fabric consistently. When sourcing suppliers, prioritizing factors such as quality assurance, production capacity, and technical expertise is pivotal. By partnering with a reputable provider like Formosa Synthetics Pvt. Ltd., businesses can secure access to top-tier PP woven fabric, tailored to their specific needs. Embracing this versatile and eco-friendly material not only ensures reliability but also fosters innovation and sustainability in packaging, agriculture, and construction realms, reinforcing its status as a cornerstone of modern industrial applications.

Read More

#PPwovenfabric#manufacturing#qualitycontrol#supplierselection#FormosaSynthetics#sustainability#industrialapplications#agriculture#packaging#construction#resilience#versatility

0 notes

Text

PP Woven Fabric Manufacturer in Surat

PP woven fabric, also known as polypropylene woven fabric, is a versatile and durable material widely used in various industries. It is made from polypropylene, a thermoplastic polymer, which is extruded into flat threads.

These threads are then woven together to create a strong and flexible fabric. PP woven fabric offers excellent strength-to-weight ratio, tear resistance, and water resistance, making it ideal for applications such as packaging, agriculture, construction, and transportation.

It is commonly used for making bags, sacks, tarpaulins, geotextiles, and other industrial products. With its affordability, recyclability, and wide range of applications, PP woven fabric has become a popular choice in many industries.

Use of PP Woven Fabric

PP woven fabric has numerous applications across various industries. It is commonly used for packaging purposes, such as making bags, sacks, and bulk containers. These bags are used for storing and transporting goods like grains, fertilizers, chemicals, and cement.

PP woven fabric is also utilized in agriculture for manufacturing greenhouse covers, shade nets, and ground covers. In the construction industry, it is used for making scaffolding nets, debris netting, and geotextiles for soil stabilization.

Additionally, PP woven fabric finds applications in the transportation sector for producing truck covers, pallet covers, and tarpaulins. Its versatility, strength, and resistance to wear and tear make it a preferred choice for various industrial needs.

What is the price of PP woven fabric?

The price of PP woven fabric can vary depending on several factors such as the quality, width, weight, and customization requirements. Generally, the price is determined by the cost of raw materials, manufacturing processes, and market demand.

On average, the price range of PP woven fabric can be between $0.50 to $3.50 per square meter. However, it's important to note that this is a rough estimate and prices may differ based on specific suppliers, order quantities, and geographical locations. It is advisable to contact manufacturers or suppliers directly to obtain accurate and up-to-date pricing information for PP woven fabric.

How do you manufacture a PP woven bag?

To manufacture a PP woven bag, the following steps are typically involved:

Material Preparation: Polypropylene (PP) resin is mixed with additives and extruded into flat tape threads.

Weaving: The flat tape threads are woven on a circular loom into a fabric sheet, which forms the body of the bag.

Printing: The fabric may undergo a printing process to add logos, labels, or other designs.

Cutting and Stitching: The fabric sheet is cut into desired bag sizes. The edges are folded and stitched to form the bag shape.

Lamination and Gusseting (Optional): For added strength and stability, the bags may be laminated with a protective coating and gussets may be added to expand the bag's capacity.

Finishing: The bags are inspected for quality, trimmed, and prepared for packaging and shipping.

Singhal Industries, being a prominent manufacturer of PP woven bags, would have their specific manufacturing processes and quality control measures in place to produce high-quality bags as per customer requirements and industry standards.

Who is the exporter of PP woven bags?

Singhal Industries, a renowned manufacturer of PP woven bags, is also an exporter of their products. As an exporter, Singhal Industries has the capability to supply PP woven bags to customers worldwide. They have a strong global presence and a wide network of clients in various industries.

Singhal Industries focuses on delivering high-quality PP woven bags that meet international standards and customer specifications. Their bags are known for their strength, durability, and reliability, making them suitable for diverse applications such as packaging, agriculture, construction, and more.

With their expertise in manufacturing and exporting, Singhal Industries ensures timely delivery and competitive pricing to meet the needs of their international customers. They have a dedicated team that oversees the export process, including documentation, logistics, and customs clearance, to ensure a smooth and hassle-free experience for their clients.

Singhal Industries strives to establish long-term partnerships with their export customers by providing superior products, exceptional customer service, and reliable support. Their commitment to quality and their extensive experience in the industry make them a trusted exporter of PP woven bags.

In conclusion, PP woven fabric and bags have gained immense popularity due to their versatility and durability. PP woven fabric, made from polypropylene, offers excellent strength, tear resistance, and water resistance.

It finds applications in packaging, agriculture, construction, and transportation industries. Singhal Industries, a renowned manufacturer and exporter, produces high-quality PP woven bags that meet international standards. With a strong global presence and a wide network of clients, Singhal Industries ensures timely delivery and competitive pricing.

Their commitment to quality and customer satisfaction has established them as a trusted supplier in the market. PP woven bags from Singhal Industries are reliable, strong, and tailored to meet the diverse needs of customers worldwide.

0 notes

Link

Looking for the pp woven fabric manufacturer? Ambica Polymer is one of the largest producers and exporters of polypropylene woven technical textiles from India. With assured quality right from the first stage of manufacturing.

1 note

·

View note