#PBTnews

Explore tagged Tumblr posts

Text

PBT Unraveled: Exploring Applications and Manufacturing Methods

Polybutylene terephthalate, or PBT for short, might sound like a complex scientific mouthful. But behind this technical term lies a remarkable material with a wide range of applications in our everyday world. Chemically similar to its more well-known cousin PET (used in plastic bottles), PBT boasts impressive strength and crystalline structure. Today, we'll delve into the world of PBT, exploring its properties and the surprising places you might encounter this versatile material.

Introduction

Polybutylene terephthalate (PBT), a distinguished member of the polyester polymer family, has sparked considerable commercial interest owing to its remarkable versatility across a broad spectrum of applications. From automotive components to electrical and electronic devices, medical equipment, and beyond, PBT finds its place in an array of industries. Its extensive product range encompasses various grades tailored for injection molding, including reinforced, filled, impact-modified, and flame-retardant formulations. The unfilled PBT grades boast a diverse range of melt viscosities, offering ample processing flexibility in techniques like injection molding and extrusion. These techniques facilitate diverse applications, from crafting PBT fibers through melt-blowing to producing rods, slabs, fiber optic buffer tubes, and brake cable liners. Moreover, flame-retardant and lubricated versions of PBT are available in both filled and unfilled variants. Notably, glass-reinforced PBT grades exhibit enhanced mechanical properties compared to non-reinforced resins, showcasing significant increases in tensile, moduli, flexural, and compressive strengths, making them pivotal across numerous demanding applications.

PBT’s unique properties include:

Built to Last: PBT stands out for its dimensional stability and resistance to moisture. This makes it highly durable under heat and harsh chemicals.

Strength You Can Count On: Don't be fooled by its weight - PBT packs a punch. It boasts high strength, toughness, and stiffness, making it resistant to impact and deformation even at elevated temperatures.

Heat Doesn't Faze It: Bring on the heat! PBT has a high heat deflection temperature, meaning it can withstand both short bursts and long-term exposure to high temperatures without warping.

Electrical Champion: Looking for an insulator? Look no further! PBT offers excellent electrical resistance and dielectric strength, safeguarding electrical components from discharge and ensuring safe operation. The low dielectric loss makes it ideal for high-frequency electronics.

Chemical Fortress: Harsh chemicals are no match for PBT. It boasts resistance to a wide range of chemicals, from acids and solvents to oils and greases. Plus, it offers good UV and stain resistance, keeping things looking sharp.

Manufacturing Process

PBT is manufactured by polycondensation of terephthalic acid or dimethyl terephthalate with 1,4–butanediol using catalyst. The primary raw materials utilized in the production of PBT include 1,4-butanediol (BDO), dimethyl terephthalate (DMT), purified terephthalic acid (PTA), and catalysts.

In the PBT production process, a mixture comprising dimethyl terephthalate as the primary component of terephthalic acid alkyl ester and 1,4-butanediol (referred to as BD) as the main constituent glycol is blended in appropriate proportions within a mixing vessel.

A transesterification catalyst is introduced and conditioned in the mixture, which is then transferred to a transesterification reaction vessel via a pump, set to a predetermined reaction temperature.

During the transesterification reaction, two or three sequentially arranged stirring vessels equipped with stirring blades facilitate the process, leading to the formation of methanol as a by-product. Tetrahydrofuran (THF), resulting from the breakdown of methanol and also present with BD and water, is separated in a distillation tower. Subsequently, a polymerization catalyst is introduced, initiating the polymerization reaction stage. Initially, multiple vertical or horizontal stirring vessels are utilized for the prepolymerization phase, followed by a final polymerization step employing a horizontal stirring vessel.

In a continuous polycondensation process for materials like polyethylene terephthalate, operating within a relatively low viscosity range and under subatmospheric pressure. Oligomers with low polymerization degrees, resulting from esterification or transesterification reactions, are continuously supplied to one end of these reactors, allowing for the successive progression of the polycondensation reaction down to the downstream tray, or during the transfer of oligomers from one stirring vessel to another.

An apparatus designed for the continuous production of polybutylene terephthalate consists of a series of reactors: the first reactor facilitates the reaction between an aromatic dicarboxylic acid, primarily terephthalic acid or its derivative, and a glycol, mainly 1,4-butanediol. Subsequently, the oligomer undergoes polycondensation in the second reactor, generating a low polymerization product with an average degree of polymerization varying from 25 to 40. The third reactor further polycondenses the low polymerization product. Optionally, a fourth reactor is incorporated to further polycondense the polyester from the third reactor, achieving an average degree of polymerization of 150 to 200, thereby yielding a high molecular weight polyester characterized by superior heat stability and exceptional hydrolysis resistance. The first and second reactors operate without stirrers powered by an external source.

Within this apparatus, the second reactor takes the form of an approximately cylindrical vessel type, functioning as a flow reactor within a double cylinder structure. This reactor features an inner cylinder opening within the vessel and an inlet for the process solution at the lower part of the double cylinder structure. The process solution traverses through tubes of a shell and tube type heat exchanger positioned on the exterior of the inner cylinder, where it is heated to a predetermined temperature, then ascends to the level of the inner cylinder opening before descending through the inner cylinder. Throughout this process, the solution is stirred using a series of doughnut-type trays affixed to the inner wall of the outer cylinder. Additionally, the vessel includes an outlet for volatile matters and reaction by-products situated at its upper part. The inventors have identified areas for enhancement concerning the short pass and thermal decomposition reactions of the process solution.

Key PBT Technologies & Processes

Key licensors of PBT technology, such as Hitachi, Uhde Inventa-Fischer, and Lurgi Zimmer AG, offer a comprehensive range of process variations, covering both the DMT and PTA routes as well as batch and continuous processes. Various design configurations exist, ranging from a 5-Reactor (5-R) setup to a more compact 2-Reactor (2-R) arrangement. Recent advancements in technology, such as the Zimmer COMBI reactor, Uhde Inventa-Fischer ESPREE, and DISCAGE reactors, propose a 2-R design that integrates esterification and pre-polycondensation into a single reactor, thereby reducing overall investment costs.

Zimmer Poly Butylene Terephthalate (PBT) Process

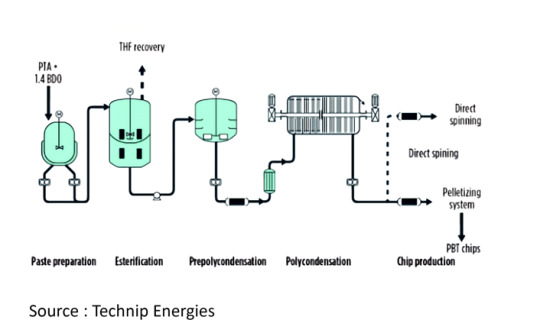

The primary starting materials for producing PBT are purified terephthalic acid (PTA) and 1,4-butanediol (BDO). A standard manufacturing facility is comprised of several key sections: raw material handling, paste preparation, esterification, prepolycondensation, final polycondensation, and pelletizing.

BDO, combined with a catalyst, is consistently mixed and introduced into the paste preparation vessel alongside terephthalic acid and comonomers at specific molar ratios. During the subsequent esterification phase, PTA and BDO react to create the ester bis-hydroxybutylterephthalate (BHBT) and oligomers, while also releasing water/THF.

The resultant product progresses to prepolycondensation, where the reaction continues, then moves on to the polycondensation stage. Here, the reaction concludes by removing BDO, residual THF, and water.

The polymer melt is then transferred via polymer discharge pumps, possibly passing through a polymer filter, for chip production. In this phase, the polymer is granulated using an underwater pelletizer and cooling system, preparing it for subsequent drying and packaging.

Vapors generated during esterification are released and channeled into a process column for rectification. BDO, BHBT, and oligomers are recycled back into the esterification process, while water/THF is directed for THF recovery.

The byproduct THF, predominantly produced during esterification, can undergo purification for further utilization in an additional rectification unit (a 3-stage column system).

Applications of Polybutylene Terephthalate (PBT)

Automotive

PBT is a versatile material used throughout cars, from external parts like windshield wiper covers and mirror housings to internal components like handles and fans. It's especially common in electrical systems, where it makes connectors, sensor housings, fuse boxes, and even parts of motors and ignition systems.

Electronics & Electricals

Because PBT is an excellent insulator, it stops electricity from leaking or causing breakdowns in electronic devices. This is why many different electrical parts are made from PBT. Here are some examples: switches, circuit breakers, power sockets, cable linings, connectors, and transformer insulation.

Industrial

PBT is tough stuff! It's strong, stiff, and can handle a good amount of impact, even in the short term. This makes it ideal for industrial parts that need to last a long time and take a beating. Think about things like fluorescent lamp bases, street lamp reflectors, pump parts, filters, and even packaging components. They all benefit from PBT's ruggedness.

Consumer Goods

PBT's strength and ability to handle heat and electricity make it a great choice for many everyday items. You'll find it in things like iron handles, oven door knobs, appliance housings, and even office furniture because it's both durable and looks good.

Market Outlook:

The demand for Polybutylene Terephthalate (PBT) is strongly influenced by the spanning Electrical & Electronics and Automotive industries. In Electrical & Electronics, PBT is favored for its excellent electrical properties at high temperatures, making it a preferred material for various components. Its high heat resistance and dimensional stability are particularly valued in this sector. Similarly, the Automotive industry plays a significant role in the PBT market, extensively using the thermoplastic in both interior and exterior automotive parts. PBT's ability to withstand high processing temperatures ensures the durability and performance of these parts. The demand from these sectors highlights PBT's versatility and reliability in meeting the stringent requirements of Electrical & Electronics and Automotive applications, positioning it as a key driver in the market.

Polybutylene Terephthalate (PBT) Major Players

Major players in the Global Polybutylene Terephthalate (PBT) market are Kanghui New Material Technology Co., Ltd., BASF, Henan Kaixiang Chemical, Lanxess/DuPont, Yizheng Chemical Fibre, Sabic Innovative Plastics, Nantong Xingchen Synthetic Material (Blue Star group), Saudi International Petrochemical (Sipchem), Toray BASF PBT Resin Sdn Bhd, Toray Japan, DuBay Polymer, Toray Industries (India) Private Limited, and Others.

Conclusion:

In conclusion, Polybutylene Terephthalate (PBT) is a formidable engineering plastic renowned for its robustness, rigidity, and superior machining attributes. With exceptional chemical resistance, along with outstanding bearing and wear properties, PBT stands as a premier choice in various industrial applications. PBT's properties such as electrical resistance and high dielectric strength make it useful in the electrical and electronic sectors. Also, the blend of excellent mechanical and electrical properties, along with strong thermal stability and chemical resistance, is the reason behind the usage of PBT in the automotive sector.

#PBT#PBTprices#PBTmarket#PBTpricetrend#PBTpriceforecast#PBTnews#PBTdemand#PBTsupply#PBTmarketprice#priceofPBT

1 note

·

View note