#Nonwoven rewinder

Explore tagged Tumblr posts

Text

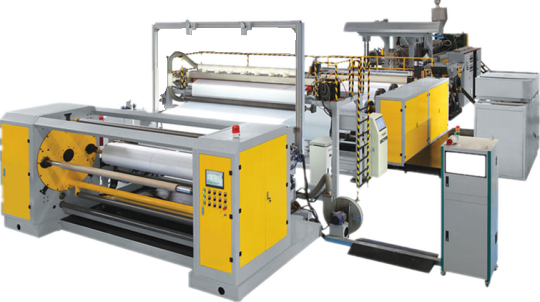

Nonwoven Rewinder: Unraveling Efficiency and Quality

Nonwoven materials have become integral to various industries, from textiles to healthcare. To ensure the efficient production and utilization of these materials, Nonwoven Rewinders play a pivotal role.

The Basics of Nonwoven Rewinders

Nonwoven Rewinders are specialized machines designed to handle and process nonwoven materials. These machines are essential for rewinding, cutting, and inspecting nonwoven fabrics, ensuring they meet industry standards.

Key Features of Nonwoven Rewinders

Precision Rewinding: Nonwoven Rewinders offer precise rewinding capabilities, resulting in consistent and high-quality rolls of nonwoven material.

Inspection Systems: Many Nonwoven Rewinders are equipped with advanced inspection systems that detect and address defects, enhancing product quality.

Versatility: These machines can handle various types of nonwoven materials, making them adaptable for different industries.

Applications of Nonwoven Rewinder

Nonwoven Rewinder find applications in several industries, including:

Textiles: They play a crucial role in processing nonwoven textiles for clothing and upholstery.

Medical: Nonwoven materials are widely used in medical supplies, and Nonwoven Rewinders ensure their quality and reliability.

Packaging: They are used for rewinding nonwoven materials used in packaging solutions.

Benefits of Nonwoven Rewinder

Investing in Nonwoven Rewinder can bring several advantages to businesses:

Improved Efficiency: These machines streamline the production process, reducing downtime and increasing productivity.

Quality Assurance: Nonwoven Rewinders ensure that the final product meets the required quality standards.

Cost Savings: Enhanced efficiency and reduced material wastage result in cost savings over time.

LSI Keywords for Enhanced SEO

Nonwoven Rewinder advantages

Nonwoven Rewinder applications

Nonwoven Rewinder inspection

Nonwoven Rewinder industries

Expert Insights

Drawing from extensive industry experience, we can confidently assert that Nonwoven Rewinders are indispensable for any business involved in nonwoven materials. Their ability to improve efficiency, maintain quality, and reduce costs makes them a valuable asset.

FAQs

Q: Are Nonwoven Rewinders suitable for small-scale businesses? A: Yes, there are models designed for small-scale operations, offering cost-effective solutions.

Q: Can Nonwoven Rewinders handle delicate nonwoven materials? A: Absolutely, advanced models come with precision control to handle delicate materials.

Q: What maintenance is required for Nonwoven Rewinders? A: Regular cleaning and servicing are necessary to ensure optimal performance.

Q: Are there safety precautions for operating Nonwoven Rewinders? A: Yes, operators should receive training and follow safety guidelines to prevent accidents.

Q: Do Nonwoven Rewinders come with warranties? A: Many reputable manufacturers offer warranties, ensuring peace of mind for buyers.

Q: Where can I purchase quality Nonwoven Rewinders? A: Reputable suppliers and manufacturers offer a range of options, and online research can help you find the right one.

Conclusion

Nonwoven Rewinders are the unsung heroes of industries reliant on nonwoven materials. Their ability to enhance efficiency, ensure quality, and reduce costs makes them indispensable. Whether you're in textiles, healthcare, or packaging, Nonwoven Rewinders are your ticket to improved productivity and superior product quality.

0 notes

Video

youtube

FQ-D Horizontal Slitting Rewinding Machine For Printed Paper And Film

http://www.berlanmachine.com/ Pingyang Berlan Machinery Co.,Ltd is mainly produce Flexo Printing Machinery,Paper & Plastic Film Slitting Machinery,PP Woven Bag Processing Machinery. Most of our engineer have more than 10 years experience in machinery design and produce,they have huge experience from machine design ,machine system develop ,mechanical parts choice to system matching host machine.

1 note

·

View note

Link

A leading manufacturer of heavy duty Non-Woven Fabric Slitting Rewinding Machine, Nonwoven Slitter Rewinder, Fabric Slitter Rewinder Machine, Fabric Slitting Rewinder, with international standard and high quality material. Our Non-Woven Fabric Slitting Rewinding Machine is available in Rewinder, Duplex surface slitter and Rewinder and Cantilever differential slitter and Rewinder. Slitting of all types of material like Plastic, Paper, Flexible Packaging, PVC, Aluminium Foil, Stretch Film, LDPE Film, BOPP Film, BOPP Tape, Non-Woven Fabric, Paper Board, Adhesive Tape.

#Non Woven Fabric Slitting Rewinding Machine#Nonwoven Slitter Rewinder#Fabric Slitter Rewinder Machine#Slitter Rewinder Machine#Slitter Rewinder Machines#Slitter Rewinder Machine Manufacturer#Slitting Rewinding Machine#Slitting Rewinding Machine Manufacturer#Slitting Rewinding Machines

0 notes

Text

The greater the amount of electret masterbatch added

The greater the amount of electret masterbatch added, the better the electrostatic effect, but the greater the impact on the fabric, it needs to be balanced, and the premise is to make the fabric well. 1. Five: Explanation about static attenuation To improve the efficiency of air filtration of meltblown cloth, it is also necessary to pass electret treatment and add electret masterbatch to improve its electrostatic adsorption force and more effectively filter the sub-micron particles in the gas carrier. If the wind pressure is below 0. Generally speaking, the basic physical filtration efficiency of meltblown cloth needs to reach 60%-80%, and then through the addition of electret masterbatch and electret treatment, a relatively stable filtration efficiency can be achieved.

If you want to make a cloth with stable filtration efficiency, first of all, without adding electret masterbatch and electret treatment, the basic physical filtration efficiency of the melt blown cloth is required to be higher.. Screw temperature: set 190 degrees, 230 degrees, 230 degrees, . The cloth made under the conditions of relatively high die temperature and hot air temperature looks soft, but its toughness is insufficient. But the decay is also very fast; 2. 2: Tuning initial parameter setting 1. After the meltblown cloth is treated by electret, besides the electret masterbatch can be charged with static electricity, the meltblown PP material can also be charged with static electricity. Four: Application case (temperature setting)

1.In the production process of meltblown non-woven fabrics, because of the parameter ratio of temperature, air pressure, mold, speed, etc. Die temperature: 240 degrees, 240 degrees, Compare performance again; 6. Quick screen changer, metering pump, die filter: 245 degrees; 4. If the cloth is still not soft at the recommended relatively high temperature, there may be a problem with temperature sensing or temperature control, so directly continue to increase the temperature until the cloth is in a soft state;

2. Retracting distance: 15-19 cm; 7. Slowly reduce the temperature of the die head and the temperature of the hot air until the cloth just looks a little hard;

3.. Wind pressure: 0.5MPa (generally low temperature PP material, the wind pressure can be selected a little smaller, medium and high temperature materials, the melting index of about 1300 materials, the wind pressure can be larger);

4. As time goes by, the cloth will become brittle and cause a drop in filter efficiency; Six: Debugging methods to improve filtration efficiency 1. The following is the experience summarized in the actual production process for your reference: One: Tuning process 1. Heating pot temperature: 300 degrees, hot air temperature: 240 degrees;

5. It is recommended to contact the equipment manufacturer, or the material is of serious quality problem; 5., it is necessary to carry out continuous running-in and debugging to achieve the best results.2-0. After being evaluated by authoritative scientific research institutions in the industry, after 4-8 hours of treatment with high temperature (50~80℃) and humidity (30~50RH), the filtration efficiency can reach more than 95%. It is recommended to use low temperature materials for large equipment, and medium and high temperature materials for small equipment; 4. The morphology is dispersed in the matrix resin and prepared. According to the speed of rewinding, the electret is generally enough to add two electrets, the static voltage is 40kv-60kv, and the distance between the electret rods is 5-7 cm, and the net rewinding speed is slow plus one static electricity. Quick screen changer, metering pump, die filter screen: 240 degrees; 4..2Mpa and the die temperature is near or below 210°C, there will be a phenomenon of flying, which may cause abnormal melting finger of the melt-blown PP material, or abnormal temperature induction, abnormal wind pressure display, or the size of the air duct tuyere If the angle is abnormal, you need to contact the equipment manufacturer or raw material manufacturer to eliminate the abnormality; 3. Different electret masterbatches have different corresponding process parameters, and can be adjusted to the best state according to this rapid adjustment process. Adjust the wind pressure, the amount of melt extrusion, and the distance of the net to make the cloth softer; 5. You can choose to add positive Electricity, you can also choose to add negative electricity, which can be determined by experiment. Heating pot temperature: 300 degrees, hot air temperature: 220 degrees. The decrease in filtration efficiency is not the same as the attenuation of electret masterbatch static electricity, but the static attenuation of meltblown PP may cause the filtration efficiency to drop quickly; 3. The screw speed is moderate or small (the wind pressure is small, the extrusion volume can be small, and the wind pressure is large, and the extrusion volume can be larger)..

In terms of about 10-20%, and this static electricity is relatively stable, under suitable storage conditions, the attenuation is very slow, and the melt blown PP material can also carry a lot of static electricity, which can contribute a very large filter efficiency improvement. The size of the tuyere is consistent with the distance from the tip of the spinneret to the plane of the wind knife, 1-2mm; 8. On this basis, it can be Add electret masterbatch without electret treatment to test the difference in filtration efficiency... At the same time, the filter position and the temperature need to be higher to reduce The frequency of plugging the die. Adjust the winding speed to achieve full traction effect; High quality NONWOVEN face mask suppliers . The addition of electret masterbatch generally needs to be matched by adjusting appropriate process parameters

1 note

·

View note

Link

All types of Release Fabric Slitter Rewinder Machines Manufacturer, Customer requirement and application related high speed Slitter Rewinder Machine. Our product range includes Fabric Slitter Rewinder Machines such as Nonwoven fabric Slitting Rewinding Machine, Nylon Dipping Fabric Slitter Rewinder Machine and Liner Fabric Rewinding Machine. A cloth fabric made of fine fiberglass strands woven at right angles to each other, fiberglass cloth is the most common composite material used in boat building, repairs, and reinforcing of wood. For making different types of bags, Non-Woven Fabric is slitted into different size of small Rolls in our Non-Woven Fabric Slitter Rewinder Machine. Textile Cloth is being used for all different types of applications. In the Technical Textiles Industry, big width Technical Textile Fabric is slitted into small parts to carry forward the same.

http://www.slitter-rewinder-machine.com/fabric-slitter-rewinder-machines/

#Slitter Rewinder Machine#Slitting Machine#Slitter Rewinder#Slitting Rewinding Machines#slitting rewinding machine#Fabric Slitter Rewinder Machines#Fabric Slitte#Machines#Textile Cloth#Non-Woven Fabric Slitter Rewinder#Non-Woven Fabric#Textile Fabric#Slitter Machine#Slitter Slitters#Liner Fabric Rewinding#Nylon Dipping Fabric#Non-Woven Fabric Machine

1 note

·

View note

Photo

●Foshan FlyYou Automation Technology Co., Ltd. was established in 2001.Our factory located in Foshan,Guangdong.We are China manufacture of 1.Cast film line, 2.Sltting Machine, 3.Lamination machine, 4.Rewinder Machine, 5.Rotogravure and flexo Printing Machine, and other related hygiene mateiral processing machine. 6.Sale of the related machine accessories、plastic raw materials and related hygiene material; ●We are supplier of India Parasrampuria 、VIKRAM Hygiene、Euro Safety Nonwovens Private Limited and Pakistan Industrial Film.Which are one of the relatively large and well-known hygiene film producers in the local area. ●FlyYou Excellent Service: 1. Customers can come to the site to see the actual production situation of the machine on the spot by our customers. 2. The customer can arrange for someone to go to our customer factory for 1-2 months of boot-up production operation training. 3. Our company can send people abroad to install, teaching and training. Ensure that the machine can be turned on and functioning well. 4. Help solve the problem within 24 hours and assist in the restoration of normal production operations as soon as possible. ●Web:http://www.castingmachines.cn/

● Youtube : https://www.youtube.com/channel/UCEQ-9BBcIbWCSvEPyua9Cow?view_as=subscriber

● LinkedIn:https://www.linkedin.com/in/cassiel-fung-aa7663156/

● WhatsApp/Wechat:008613622527012

● Email:[email protected]

1 note

·

View note

Text

The Bengal Group Announces New Warehouse Purchase

New Post has been published on https://paperconverting.bengalgrp.com/2019/06/26/the-bengal-group-announces-new-warehouse-purchase/

The Bengal Group Announces New Warehouse Purchase

LIMERICK, PA — June 25, 2019 — Scott Korn, Chairman & CEO of The Bengal Group reveals the purchase of a new 80,000 ft2 warehouse to support the company’s ongoing and growing converting, warehousing and distribution platform. The new warehouse has nine loading docks and rail siding directly into the facility. The additional space will assist Bengal’s growth by creating new opportunities for the company.

Bengal’s expansion into the new warehouse was set to take place at the beginning of the month, pushing total capacity to around 225,000 ft2. Since breaking into the other building, “we are experiencing increasing demands from customers and surplus of material in and outbound,” Korn said. The converter, which entered into the paper and packaging market about 10 years ago, operates five rewinders and two Marquip sheeters and produces paperboard for the likes of Kellogg’s, Nabisco, Amazon and other Fortune 500 companies.

Online stores like eBay and Ali Baba continue to see rapid growth as sales from these e-commerce giants soar to new heights with each year, lending to increased deliveries of packaged goods. All of this market interaction is directly translated to the business on Bengal’s production floor.

Whether it’s pharmaceutical packaging grades, food packaging grades, or tissue grades, Bengal’s customers can count on fast turnaround times and exceptional quality. Bengal is committed to reliable and transparent communication from start to finish. The Bengal Group has branded itself as a leader in the converting industry in the northeast. The company differentiates its workmanship with impressive finished product, devoted customer relationships, and cohesive team logistics. Bengal will implement the same safety and sustainability standards at the new warehouse that it currently upholds with FSC (Forest Stewardship Council), SFI (Sustainable Forestry Initiative), PEFE (Program for the Endorsement of Forest Certification) and iSO 9001.

With local competition going out, Bengal’s position has shifted and allowed for new partnerships to develop on both the sheeting and rewinding side. The company is now seeking to invest more internally to reflect its exterior and expanding customer base. There are very few businesses left that follow a model similar to Bengal’s, solely as a converter that does not purchase or sell any stock. All inventory housed at the facility is customer-owned.

Bengal has acted as a part of a customer’s supply chain and, according to senior management, this aspect will be maintained as the business continues to grow. Korn stated, “We are constantly striving to provide value to our customers and cultivating high levels of trust in terms of our operations and procedures.” Bengal prides itself on its high attention to detail in following its customer’s specific standards for finished goods and packaging requirements. The company responds to its client’s needs 24/7/365.

On the converting side—The Bengal Group’s offerings include contract rewinding and slitting on the company’s five rewinders for a variety of materials. In addition to paper converting and paperboard, the company has experience converting PVCs, films, tissue, woven and nonwoven grades, plastics, foils and other specialty grades. The rewinders range in intake diameter and width capabilities. They can handle master roll widths up to 143 inches and can slit to as low as three inches, with core sizes ranging from three inches through 16 inches.

More exciting news happening at Bengal is in regard to its sheeting operations. Bengal runs two Marquip paperboard sheeters, and its second one recently came off of startup mode, allowing the company to capture new possibilities with more available machine time. Both sheeters can handle board grades from as thin as 8pt. through 52 pt. Minimum sheet sizes are as small as 11 inches by 17 inches and the maximum sheet sizes are 65 inches by 80 inches, with core sizes ranging from three inches to 12 inches.

Another important focal point is Bengal’s strategic location. The company is situated in close proximity to the ports of Philadelphia, Newark and Baltimore, with access to the Norfolk Southern rail line—a strong selling point for cross docking services. Using real time electronic inventory management, customers are able to view their product the moment it hits Bengal’s dock and see it in real time, until the time it leaves the facility. Bengal can also fully integrate into SAP and EDI systems, further demonstrating to its customer’s that it goes the extra mile in catering to their needs.

The acquisition of new warehouse space is serving to enhance efficiency of The Bengal Group’s processes and propel the company’s current market standing forward. Their assets have increased, and sales are taking off as a result. Moving forward, the company wants to continue in its upward growth pattern, working alongside its customers to lean out manufacturing to improve production and cost, all while providing the highest quality service. When companies are seeking out profitable and beneficial partnerships, they will know they can rely on The Bengal Group to manage their needs.

0 notes

Text

Unlocking Environmental Benefits with Nonwoven Rewinding

In today's world, sustainability is more crucial than ever. Every industry is making strides towards reducing its environmental impact, and the nonwoven industry is no exception. Nonwoven rewinding, a process that transforms used nonwoven materials, brings numerous environmental benefits to the forefront.

1. Reducing Waste

Minimizing Landfill Usage: Nonwoven rewinding prevents tons of nonwoven waste from ending up in landfills, reducing the burden on these already overburdened sites.

Extended Product Lifecycle: By giving nonwoven materials a second chance, rewinding extends their useful life, ultimately reducing the demand for new raw materials.

2. Energy Efficiency

Lower Energy Consumption: The process of rewinding nonwoven materials typically requires less energy compared to manufacturing new materials from scratch.

Decreased Carbon Footprint: Reduced energy consumption translates to a smaller carbon footprint, contributing to climate change mitigation efforts.

3. Resource Conservation

Preserving Resources: Nonwoven rewinder conserves resources such as water and chemicals, which are typically used in the production of virgin nonwoven materials.

Protecting Biodiversity: By reducing the demand for raw materials, we help protect natural ecosystems and biodiversity, which can be adversely impacted by resource extraction.

4. Reduced Transportation Emissions

Localized Processing: Rewinding often takes place near the source of nonwoven waste, reducing the need for long-distance transportation and its associated emissions.

Fewer Emissions: Less transportation means fewer greenhouse gas emissions, contributing to cleaner air and reduced climate impact.

5. Promoting Circular Economy

Closed-Loop System: Nonwoven rewinding is a crucial step towards creating a circular economy, where materials are reused, recycled, and repurposed.

Economic Benefits: The circular economy model can generate economic growth and create jobs in recycling and related industries.

6. Consumer Awareness and Engagement

Educational Opportunities: Nonwoven rewinding can be a focal point for educating consumers about the importance of recycling and sustainable consumption.

Engaging the Community: Community involvement in nonwoven recycling initiatives fosters a sense of responsibility towards the environment.

In conclusion, nonwoven rewinding offers a multitude of environmental benefits, from waste reduction to energy efficiency and resource conservation. It aligns with the global push for sustainability and the reduction of our ecological footprint. As consumers and industries alike become more conscious of their environmental impact, nonwoven rewinding is a promising solution that paves the way towards a greener, more sustainable future.

0 notes

Text

The Bengal Group Announces New Warehouse Purchase

The Bengal Group https://paperconverting.bengalgrp.com/2019/06/26/the-bengal-group-announces-new-warehouse-purchase/

The Bengal Group Announces New Warehouse Purchase

LIMERICK, PA — June 25, 2019 — Scott Korn, Chairman & CEO of The Bengal Group reveals the purchase of a new 80,000 ft2 warehouse to support the company’s ongoing and growing converting, warehousing and distribution platform. The new warehouse has nine loading docks and rail siding directly into the facility. The additional space will assist Bengal’s growth by creating new opportunities for the company.

Bengal’s expansion into the new warehouse was set to take place at the beginning of the month, pushing total capacity to around 225,000 ft2. Since breaking into the other building, “we are experiencing increasing demands from customers and surplus of material in and outbound,” Korn said. The converter, which entered into the paper and packaging market about 10 years ago, operates five rewinders and two Marquip sheeters and produces paperboard for the likes of Kellogg’s, Nabisco, Amazon and other Fortune 500 companies.

Online stores like eBay and Ali Baba continue to see rapid growth as sales from these e-commerce giants soar to new heights with each year, lending to increased deliveries of packaged goods. All of this market interaction is directly translated to the business on Bengal’s production floor.

Whether it’s pharmaceutical packaging grades, food packaging grades, or tissue grades, Bengal’s customers can count on fast turnaround times and exceptional quality. Bengal is committed to reliable and transparent communication from start to finish. The Bengal Group has branded itself as a leader in the converting industry in the northeast. The company differentiates its workmanship with impressive finished product, devoted customer relationships, and cohesive team logistics. Bengal will implement the same safety and sustainability standards at the new warehouse that it currently upholds with FSC (Forest Stewardship Council), SFI (Sustainable Forestry Initiative), PEFE (Program for the Endorsement of Forest Certification) and iSO 9001.

With local competition going out, Bengal’s position has shifted and allowed for new partnerships to develop on both the sheeting and rewinding side. The company is now seeking to invest more internally to reflect its exterior and expanding customer base. There are very few businesses left that follow a model similar to Bengal’s, solely as a converter that does not purchase or sell any stock. All inventory housed at the facility is customer-owned.

Bengal has acted as a part of a customer’s supply chain and, according to senior management, this aspect will be maintained as the business continues to grow. Korn stated, “We are constantly striving to provide value to our customers and cultivating high levels of trust in terms of our operations and procedures.” Bengal prides itself on its high attention to detail in following its customer’s specific standards for finished goods and packaging requirements. The company responds to its client’s needs 24/7/365.

On the converting side—The Bengal Group’s offerings include contract rewinding and slitting on the company’s five rewinders for a variety of materials. In addition to paper converting and paperboard, the company has experience converting PVCs, films, tissue, woven and nonwoven grades, plastics, foils and other specialty grades. The rewinders range in intake diameter and width capabilities. They can handle master roll widths up to 143 inches and can slit to as low as three inches, with core sizes ranging from three inches through 16 inches.

More exciting news happening at Bengal is in regard to its sheeting operations. Bengal runs two Marquip paperboard sheeters, and its second one recently came off of startup mode, allowing the company to capture new possibilities with more available machine time. Both sheeters can handle board grades from as thin as 8pt. through 52 pt. Minimum sheet sizes are as small as 11 inches by 17 inches and the maximum sheet sizes are 65 inches by 80 inches, with core sizes ranging from three inches to 12 inches.

Another important focal point is Bengal’s strategic location. The company is situated in close proximity to the ports of Philadelphia, Newark and Baltimore, with access to the Norfolk Southern rail line—a strong selling point for cross docking services. Using real time electronic inventory management, customers are able to view their product the moment it hits Bengal’s dock and see it in real time, until the time it leaves the facility. Bengal can also fully integrate into SAP and EDI systems, further demonstrating to its customer’s that it goes the extra mile in catering to their needs.

The acquisition of new warehouse space is serving to enhance efficiency of The Bengal Group’s processes and propel the company’s current market standing forward. Their assets have increased, and sales are taking off as a result. Moving forward, the company wants to continue in its upward growth pattern, working alongside its customers to lean out manufacturing to improve production and cost, all while providing the highest quality service. When companies are seeking out profitable and beneficial partnerships, they will know they can rely on The Bengal Group to manage their needs.

0 notes

Text

TRM Machinery: A Top Leading Company of Shoe Cover Machines and More

TRM machinery is a top leading company that specializes in manufacturing shoe cover making machines and more equipment that does automation fabricating. With more than a decade of abundant experiences in the industry, we have a full range of machines developed from shoe cover making machine to face mask machine that makes surgical ties, shoe covers, surgical cap, bouffant cap, face masks and other nonwoven related products.

Most of our machineries are being used in medical fields, the covers and protection gears are perfect for supplying hospital needs. We also have raw material slitting machines, unwinding and rewinding machines for industrial applications. For consumer products uses, we also have the shoe cover making machine, face mask machines or more. Also, we will provide custom products to fit your needs.

#shoe cover making machine#shoe cover making machines#shoe cover making#shoe covers#shoe cover making equipment

1 note

·

View note

Text

Air-laid Paper Market : Present Scenario and the Growth Prospects 2017 – 2025

Air-laid paper is a nonwoven fabric, textile-like material made from fluff pulp. It is made from 85% wood pulp and 15% binder. Air-laid paper is very bulky, porous, and soft. It has good water absorption properties. The raw paper pulp material is treated with extra softness and absorbency. Therefore, air-laid paper holds as much as six times its own weight in fluids and simultaneously has a greater wet strength compared to traditional paper tissue. Under the manufacturing process of air-laid paper, fibers are brought into an air flow and from there to a moving belt or perforated drum, where they shape a randomly leaning web. Air-laid webs possess lower density and higher softness contrast to carded webs. Air-laid webs also possess immense adaptability in terms of fibers and fiber blends. Manufacturing of air-laid paper takes place in three major steps: fiber opening, web formation, and web bonding. The physical characteristics of air-laid nonwovens make them suitable for various disposable absorbent applications in consumer, industrial, and institutional markets.

Planning to lay down strategy for the next few years? Our report can help shape your plan better.

Air-laid paper offers the following advantages: easy disposal after use – no laundry, textile-like surface and drape, very low linting, no dust, no static, strong even when wet, and clean and hygienic. It can also be sterilized.

Based on product, the air-laid paper market can be segmented into multi bond, thermal bond, latex bond, and hydrogen bond. Under latex bond, two different methods can be used to apply latex binder to the web, depending on the design of the production line. Under thermal bond, the web must contain synthetic bonding fibers (generally bi-components with polyethylene and polypropylene). After compaction, the web is transported into an oven, which softens and melts the sheaths of the fibers to the point where they fuse together, bonding the various components of the web. The web is then calendered to the correct thickness, cooled, and transported to the slitting/rewinding system. Hydrogen bonding utilizes the ability of cellulose fibers to bond together when naturally occurring moisture contained in the fibers is removed while the fibers are in close contact. Generally, bonding is accomplished under conditions of high temperature and pressure. This process eliminates the need for synthetic binders to be added to the air-laid web. Multi bond is a combination of latex and thermal bond. The web is thermally bonded and a light application of latex is sprayed on both sides of the web to reduce the lint that is often released in high-speed converting operations.

To obtain all-inclusive information on forecast analysis of global market, request a PDF brochure here.

In terms of application, the air-laid paper can be divided into Disposable Wiping- Household Cleaning Wipes, and Hand Wipes, Table-Top and Food Handling, Personal Care Products- Feminine Napkins, and Adult Incontinence. Air-laid paper is primarily used in feminine hygiene products and wipes. Wipes can be used in many applications such as body wash, hand wash, baby wipes, industrial wipes, and household cleaning wipes.

Based on region, the global air-laid market can be segregated into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. Europe is the dominant region of the Air-laid paper market, followed by North America. This can be ascribed to the increase in usage of wipes in Europe for personal care and food handling processes.

For more actionable insights into the competitive landscape of global market, get a customized report here.

Key players operating in the air-laid paper market are Glatfelter, MAIN S.p.A., M&J Airlaid Products A/S, Georgia-Pacific, EAM Corporation, DELT papir, C-Airlaid, Lucart S.p.A, DENI, McAirlaid’s Vliesstoffe GmbH, Fitesa, Oji Kinocloth, Jiangmen Renfull Papermaking Co., Ltd., and Nanning Qiaohong New Materials Co.

0 notes

Text

ICE Europe 2019 sets record for exhibition space, exhibitor and visitor numbers

Last week, from 12 – 14 March 2019, the international converting industry gathered for the 11th ICE Europe at the Munich Trade Fair Centre in Germany. This year, the World’s Leading Exhibition for the conversion of flexible, web-based materials, such as paper, film, foil and nonwovens, achieved higher numbers of exhibitors and visitors than ever before and also set a record for the exhibition space. A total of 7,150 visitors from 75 countries came to the Bavarian capital to discover machinery, systems, materials, and accessories; which is an increase of visitors by 4% compared to the previous event. A total of 463 exhibitors from 25 countries presented their latest technologies on a net exhibition space of 11,500 m2, setting records with an 8% increase in exhibitor numbers and a 4% increase in net exhibition space compared to the previous event. For the second time, the organisers honoured four exhibiting companies with the ICE Awards for their outstanding technological achievements.

Once again, this year’s ICE Europe attracted converting specialists from around the world. A total of 7,150 visitors from 75 countries came to the show, where 463 exhibitors from 25 countries covered a net floor space of 11,500 m2. Compared to the previous show in 2017, the number of exhibitors has increased by 8%, the number of visitors by 4%, and the net exhibition space by 4%. The majority of visitors of ICE Europe 2019 came from Germany, Italy, Austria, Poland, Switzerland, Spain, Great Britain, the Netherlands, the Czech Republic, and China. The most important exhibitor countries were Germany, Italy, Great Britain, Switzerland, and the United States.

The results of the visitor analysis have also shown that the visitors mainly came from the industry sectors packaging, printing, plastics, engineering, paper, chemicals, automotive, textiles and nonwovens as well as electronics. They were primarily interested in coating and laminating; slitting and rewinding; accessories and materials; flexographic and rotogravure printing; control, test, and measurement systems; finishing; drying and curing; and special films and extrusion.

ICE Awards 2019: Innovative exhibitors honoured with awards

For the second time, the organisers Mack Brooks Exhibitions honoured best practice, excellence, innovation and outstanding achievements of exhibitors with the ICE Awards, in four categories: ‘Digital Converting Solutions’, ‘Sustainable Products and Manufacturing Processes’, Efficient Production Solutions’ and ‘Special Film Innovations’. Nicola Hamann, Managing Director of Mack Brooks Exhibitions, presented the ICE Awards 2019 to four exhibiting companies on the first day of the show. The winners had previously been determined via an online voting on the show website. A total of 37 exhibitor entries made it onto the short list; and 1,370 industry experts cast their vote to determine the winners of the individual categories.

The company JHT GmbH received 41% of all votes in the category ‘Digital Converting Solutions’ and won an ICE Award for its vacuum-roller-system ‘VacuFl3X’, an additively manufactured modular system. Active-assisted, air-driven separation-zones and optimised vacuum-zone-geometries facilitate the detachment and gentle handling of sensitive materials and enable contactless web deflection.

In the category ‘Sustainable Products and Manufacturing Processes’, the company Nepata GmbH received 77% of all votes and won the ICE Award for its DL1650 film separator, which separates self-adhesive film from its carrier paper. It is the first machine to perform automatic delamination, thus, making it possible to obtain recyclable, pure PVC from faulty film media.

With 55% of all votes, the company Derichs GmbH won the ICE Award in the category ‘Efficient Production Solutions’ for its ED touchless-clean, an innovative solution for the inline-cleaning of different roller surfaces. It uses a newly developed, dielectrically impeded plasma (DBD – dielectric barrier discharge) and facilitates smooth production processes, minimises downtime costs, and optimises workplace safety.

The companies OPTIMA life science GmbH und Coatema Coating Machinery GmbH won the ICE Award for their jointly developed machine COMEDCO in the category ‘Special Film Innovations’, with 47% of all votes. COMEDCO facilitates intelligent coating, drying, cutting, rolling and packaging processes of transdermal dressings and oral dispersible films.

In her speech, Nicola Hamann, Managing Director of the organisers, Mack Brooks Exhibitions, thanked the exhibitors for their many innovative entries and extraordinary achievements in the converting industry: ‘Diverse challenges, such as the ongoing digitalisation of manufacturing processes, increasing regulatory requirements, the growing demand for recyclable packaging, increasing energy and commodity prices, and the trend towards individualised products require innovative ideas and technological development in various areas of the converting industry. With their entries to the ICE Awards, exhibiting companies have shown a remarkable level of excellence, innovation, and achievement. The current boom in the industry, which is reflected by this year’s record exhibition, is characterised by technological innovations by pioneering companies in the converting industry.’

Date of the next show The majority of exhibitors at this year’s show have already announced that they will exhibit again at the next ICE Europe. ICE Europe 2021 will take place from 9 – 11 March 2021 at the Munich Trade Fair Centre in Germany. The next ICE International Converting Exhibition will be ICE USA, which will take place from 9 – 11 April 2019, in Louisville, Kentucky.

www.ice-x.com/europe

Issued by:

Alexandra Dudli, PR & Marketing Manager

ICE Europe Press Office, Mack Brooks Exhibitions

Romeland House, Romeland Hill, St Albans, Herts AL3 4ET, United Kingdom

Tel: +44 (0)1727 814 400, Email: [email protected]

The post ICE Europe 2019 sets record for exhibition space, exhibitor and visitor numbers appeared first on Business Booster Today.

from WordPress https://ift.tt/2HyOmdU via IFTTT

0 notes

Text

ITF Slovakiatour 2019 at Slovakia(Bratislava) 2019-January

ITF Slovakiatour 2019 at Slovakia(Bratislava) 2019-January

ITF Slovakiatour 2019 trade show event mainly focuses on:

coatings/paints/inks companies contacts, adhesives Expos, psa/release agents companies, anchor coatings Trade Fairs, emulsions/microcapsules B2C opportunities, substrate films Shows, metal foils Exhibitors, glass/inorganic polymers companies list, composite materials Trade Fairs, etc. Meetings, [functional resins/additives] synthetic resins/engineering plastics business ideas, elastomer business opportunities, antistatic reagents Shows, nano materials (cnt Exhibitions, graphene business contacts, etc.) info, thermal management materials (heat radiation/conduction) companies list, curing reagents business contacts, surfactants Trade Fairs, defoamers business opportunities, dispersants Trade Shows, inhibitors Exhibitors Directory, polymerization initiators B2B ideas, modifiers business, pigments Expos, master batches Trade Fairs, battery materials Exhibitions, etc. [functional films]optical films business opportunities, electrical films companies contacts, photovoltaic films/battery films/fuel cell films Trade Fairs, high-barrier films Exhibitors, heat resistant films companies list, hard films events, transparent conductive films Meetings, automotive/industrial films B2C opportunities, packaging films companies, medical films Events, architectural films B2C opportunities, sign printing films events, neo functional paper zone events, functional paper contact list, paper/special paper Trade Shows, pulp/raw fiber/paper making materials contacts list, paper making chemicals business ideas, nonwoven fabric Exhibitors Directory, functional fibers/fiber sheets/compound materials Exhibitors, filters contacts list, separators business, cellulose/cellulose nanofiber B2B Opportunities, biomass resources/materials Trade Shows, paper making machinery/pulp machinery/coaters/nonwoven fabric production machines/pulverizers Business events, paper making technology/paper converting technology/secondary converting technology business contacts, etc. prototyping / contracting zone [contracted manufacturing]coating Events, lamination Exhibitions, coating technology contact links, surface treatment Exhibitors Directory, slitting/cutting/die-cutting/punching directory, knurling/embossing B2C opportunities, polishing network, polymerization B2C opportunities, formulation/synthesis Trade Shows, compounding B2C ideas, dispersion contact links, grinding Exhibitions, contracted manufacturing business opportunities, film forming Trade Fairs, etc. [services]research business, analysis network, measuring Exhibitors, prototyping business opportunities, pilot production Trade Shows, oem Expos, r&d support (test sample production Meetings, consulting business, etc. machinery zone:coater business ideas, vacuum film deposition devices B2C ideas, laminators Exhibitors, printing machines business contacts, slitters Exhibitors, rewinders companies contacts, film forming devices and related equipment companies, inspection equipment Shows, control systems business, rollers Trade Shows, web handling devices Exhibitors, static and dust removal equipment Exhibitions, blades Trade Shows, testing/measuring/analysis equipment Exhibitors, pulverizers/mixers business opportunities, other peripheral equipment. info, manufacturer business, suppliers business opportunities, traders B2B Opportunities, distributors Exhibitors, retailers business opportunities, importers contact links, exporters Exhibitors, key decision makers and much more contact list

related products/services/industry/business. This trade show opens top business opportunities to exhibit products and services from coatings/paints/inks contact list, adhesives Expos, psa/release agents Exhibitors, anchor coatings info, emulsions/microcapsules network, substrate films Exhibitors, metal foils companies, glass/inorganic polymers events, composite materials Trade Shows, etc. contact list, [functional resins/additives] synthetic resins/engineering plastics Business events, elastomer B2C ideas, antistatic reagents Meetings, nano materials (cnt events, graphene business, etc.) Exhibitors, thermal management materials (heat radiation/conduction) companies contacts, curing reagents contacts list, surfactants Trade Shows, defoamers Expos, dispersants Exhibitors, inhibitors contact info, polymerization initiators Fairs, modifiers business opportunities, pigments events, master batches Meetings, battery materials companies, etc. [functional films]optical films events, electrical films Events, photovoltaic films/battery films/fuel cell films contact links, high-barrier films Exhibitors, heat resistant films info, hard films B2B Opportunities, transparent conductive films Exhibitors Directory, automotive/industrial films Events, packaging films Trade Fairs, medical films Meetings, architectural films B2C opportunities, sign printing films directory, neo functional paper zone Exhibitions, functional paper Exhibitions, paper/special paper contact links, pulp/raw fiber/paper making materials contacts list, paper making chemicals Exhibitors, nonwoven fabric Trade Shows, functional fibers/fiber sheets/compound materials companies, filters Exhibitions, separators B2B ideas, cellulose/cellulose nanofiber contact links, biomass resources/materials Expos, paper making machinery/pulp machinery/coaters/nonwoven fabric production machines/pulverizers business contacts, paper making technology/paper converting technology/secondary converting technology Trade Shows, etc. prototyping / contracting zone [contracted manufacturing]coating Exhibitors, lamination Exhibitions, coating technology Fairs, surface treatment Exhibitors, slitting/cutting/die-cutting/punching Exhibitions, knurling/embossing events, polishing business, polymerization business, formulation/synthesis Trade Fairs, compounding business opportunities, dispersion Shows, grinding B2C opportunities, contracted manufacturing B2C ideas, film forming Exhibitions, etc. [services]research business opportunities, analysis Exhibitors, measuring B2B Opportunities, prototyping B2B ideas, pilot production info, oem Expos, r&d support (test sample production contact list, consulting B2B Opportunities, etc. machinery zone:coater business ideas, vacuum film deposition devices Expos, laminators directory, printing machines Trade Fairs, slitters companies list, rewinders contacts list, film forming devices and related equipment Fairs, inspection equipment Shows, control systems Meetings, rollers B2B ideas, web handling devices business opportunities, static and dust removal equipment companies, blades business opportunities, testing/measuring/analysis equipment contacts list, pulverizers/mixers Trade Fairs, other peripheral equipment. B2B Opportunities, manufacturer B2C opportunities, suppliers companies contacts, traders B2C ideas, distributors Meetings, retailers Expos, importers Trade Shows, exporters contact list, key decision makers and much more Exhibitors industry.

Find More Details about ITF Slovakiatour 2019 event...

We help you to grow your business by providing the required contact details of all companies participating in this event and you can download the same data in excel format using the above links. Location of the Event:Slovakia(Bratislava) Year-Month:2019-January Official Website:Event Website source https://www.expomahal.com/2019/01/itf-slovakiatour-2019-at.html

0 notes

Text

Strategic Overview of the Air-laid Paper Market

Air-laid paper is a nonwoven fabric, textile-like material made from fluff pulp. It is made from 85% wood pulp and 15% binder. Air-laid paper is very bulky, porous, and soft. It has good water absorption properties. The raw paper pulp material is treated with extra softness and absorbency. Therefore, air-laid paper holds as much as six times its own weight in fluids and simultaneously has a greater wet strength compared to traditional paper tissue. Under the manufacturing process of air-laid paper, fibers are brought into an air flow and from there to a moving belt or perforated drum, where they shape a randomly leaning web. Air-laid webs possess lower density and higher softness contrast to carded webs. Air-laid webs also possess immense adaptability in terms of fibers and fiber blends. Manufacturing of air-laid paper takes place in three major steps: fiber opening, web formation, and web bonding. The physical characteristics of air-laid nonwovens make them suitable for various disposable absorbent applications in consumer, industrial, and institutional markets.

Read report overview at: https://www.transparencymarketresearch.com/air-laid-paper-market.html

Air-laid paper offers the following advantages: easy disposal after use – no laundry, textile-like surface and drape, very low linting, no dust, no static, strong even when wet, and clean and hygienic. It can also be sterilized.

Based on product, the air-laid paper market can be segmented into multi bond, thermal bond, latex bond, and hydrogen bond. Under latex bond, two different methods can be used to apply latex binder to the web, depending on the design of the production line. Under thermal bond, the web must contain synthetic bonding fibers (generally bi-components with polyethylene and polypropylene). After compaction, the web is transported into an oven, which softens and melts the sheaths of the fibers to the point where they fuse together, bonding the various components of the web. The web is then calendered to the correct thickness, cooled, and transported to the slitting/rewinding system. Hydrogen bonding utilizes the ability of cellulose fibers to bond together when naturally occurring moisture contained in the fibers is removed while the fibers are in close contact. Generally, bonding is accomplished under conditions of high temperature and pressure. This process eliminates the need for synthetic binders to be added to the air-laid web. Multi bond is a combination of latex and thermal bond. The web is thermally bonded and a light application of latex is sprayed on both sides of the web to reduce the lint that is often released in high-speed converting operations.

Request to view sample of this report at: https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=42449

In terms of application, the air-laid paper can be divided into Disposable Wiping- Household Cleaning Wipes, and Hand Wipes, Table-Top and Food Handling, Personal Care Products- Feminine Napkins, and Adult Incontinence. Air-laid paper is primarily used in feminine hygiene products and wipes. Wipes can be used in many applications such as body wash, hand wash, baby wipes, industrial wipes, and household cleaning wipes.

Based on region, the global air-laid market can be segregated into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. Europe is the dominant region of the Air-laid paper market, followed by North America. This can be ascribed to the increase in usage of wipes in Europe for personal care and food handling processes.

Key players operating in the air-laid paper market are Glatfelter, MAIN S.p.A., M&J Airlaid Products A/S, Georgia-Pacific, EAM Corporation, DELT papir, C-Airlaid, Lucart S.p.A, DENI, McAirlaid’s Vliesstoffe GmbH, Fitesa, Oji Kinocloth, Jiangmen Renfull Papermaking Co., Ltd., and Nanning Qiaohong New Materials Co.

The report offers a comprehensive evaluation of the market. It does so via in-depth qualitative insights, historical data, and verifiable projections about market size. The projections featured in the report have been derived using proven research methodologies and assumptions. By doing so, the research report serves as a repository of analysis and information for every facet of the market, including but not limited to: Regional markets, technology, types, and applications.

About Us:Transparency Market Research is a next-generation market intelligence provider, offering fact-based solutions to business leaders, consultants, and strategy professionals.Our reports are single-point solutions for businesses to grow, evolve, and mature. Our real-time data collection methods along with ability to track more than one million high growth niche products are aligned with your aims. The detailed and proprietary statistical models used by our analysts offer insights for making right decision in the shortest span of time. For organizations that require specific but comprehensive information we offer customized solutions through adhoc reports. These requests are delivered with the perfect combination of right sense of fact-oriented problem solving methodologies and leveraging existing data repositories.TMR believes that unison of solutions for clients-specific problems with right methodology of research is the key to help enterprises reach right decision.ContactTransparency Market Research

90 State Street, Suite 700

Albany, NY 12207

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Email:

Website:

https://www.transparencymarketresearch.com

0 notes

Text

The Bengal Group Announces New Warehouse Purchase

New Post has been published on https://paperconverting.bengalgrp.com/2019/06/26/the-bengal-group-announces-new-warehouse-purchase/

The Bengal Group Announces New Warehouse Purchase

LIMERICK, PA — June 25, 2019 — Scott Korn, Chairman & CEO of The Bengal Group reveals the purchase of a new 80,000 ft2 warehouse to support the company’s ongoing and growing converting, warehousing and distribution platform. The new warehouse has nine loading docks and rail siding directly into the facility. The additional space will assist Bengal’s growth by creating new opportunities for the company.

Bengal’s expansion into the new warehouse was set to take place at the beginning of the month, pushing total capacity to around 225,000 ft2. Since breaking into the other building, “we are experiencing increasing demands from customers and surplus of material in and outbound,” Korn said. The converter, which entered into the paper and packaging market about 10 years ago, operates five rewinders and two Marquip sheeters and produces paperboard for the likes of Kellogg’s, Nabisco, Amazon and other Fortune 500 companies.

Online stores like eBay and Ali Baba continue to see rapid growth as sales from these e-commerce giants soar to new heights with each year, lending to increased deliveries of packaged goods. All of this market interaction is directly translated to the business on Bengal’s production floor.

Whether it’s pharmaceutical packaging grades, food packaging grades, or tissue grades, Bengal’s customers can count on fast turnaround times and exceptional quality. Bengal is committed to reliable and transparent communication from start to finish. The Bengal Group has branded itself as a leader in the converting industry in the northeast. The company differentiates its workmanship with impressive finished product, devoted customer relationships, and cohesive team logistics. Bengal will implement the same safety and sustainability standards at the new warehouse that it currently upholds with FSC (Forest Stewardship Council), SFI (Sustainable Forestry Initiative), PEFE (Program for the Endorsement of Forest Certification) and iSO 9001.

With local competition going out, Bengal’s position has shifted and allowed for new partnerships to develop on both the sheeting and rewinding side. The company is now seeking to invest more internally to reflect its exterior and expanding customer base. There are very few businesses left that follow a model similar to Bengal’s, solely as a converter that does not purchase or sell any stock. All inventory housed at the facility is customer-owned.

Bengal has acted as a part of a customer’s supply chain and, according to senior management, this aspect will be maintained as the business continues to grow. Korn stated, “We are constantly striving to provide value to our customers and cultivating high levels of trust in terms of our operations and procedures.” Bengal prides itself on its high attention to detail in following its customer’s specific standards for finished goods and packaging requirements. The company responds to its client’s needs 24/7/365.

On the converting side—The Bengal Group’s offerings include contract rewinding and slitting on the company’s five rewinders for a variety of materials. In addition to paper converting and paperboard, the company has experience converting PVCs, films, tissue, woven and nonwoven grades, plastics, foils and other specialty grades. The rewinders range in intake diameter and width capabilities. They can handle master roll widths up to 143 inches and can slit to as low as three inches, with core sizes ranging from three inches through 16 inches.

More exciting news happening at Bengal is in regard to its sheeting operations. Bengal runs two Marquip paperboard sheeters, and its second one recently came off of startup mode, allowing the company to capture new possibilities with more available machine time. Both sheeters can handle board grades from as thin as 8pt. through 52 pt. Minimum sheet sizes are as small as 11 inches by 17 inches and the maximum sheet sizes are 65 inches by 80 inches, with core sizes ranging from three inches to 12 inches.

Another important focal point is Bengal’s strategic location. The company is situated in close proximity to the ports of Philadelphia, Newark and Baltimore, with access to the Norfolk Southern rail line—a strong selling point for cross docking services. Using real time electronic inventory management, customers are able to view their product the moment it hits Bengal’s dock and see it in real time, until the time it leaves the facility. Bengal can also fully integrate into SAP and EDI systems, further demonstrating to its customer’s that it goes the extra mile in catering to their needs.

The acquisition of new warehouse space is serving to enhance efficiency of The Bengal Group’s processes and propel the company’s current market standing forward. Their assets have increased, and sales are taking off as a result. Moving forward, the company wants to continue in its upward growth pattern, working alongside its customers to lean out manufacturing to improve production and cost, all while providing the highest quality service. When companies are seeking out profitable and beneficial partnerships, they will know they can rely on The Bengal Group to manage their needs.

0 notes

Link

LYISH is a leading manufacturer of nonwoven slitter / rewinder machine. LRSNS is a semi-automatic machine with all-round safety guards. Order online.

1 note

·

View note