#Non-ferrous Metal Baler

Explore tagged Tumblr posts

Text

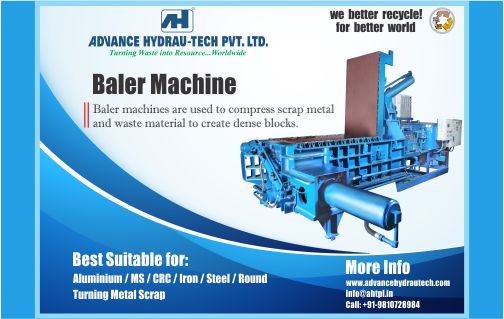

Baler Machine Makes Scrap Processing Easy

Metal Scrap Baling Machine is most versatile machine in recycling industry. The baler machines compact scrap from different directions to produce high density bundles that can be efficiently utilized for subsequent purposes. We are India's largest and most reliable manufacturer of scrap processing machines. Our balers are designed to compact a wide range of materials, including aluminum, MS, CRC, turning, iron, paper, and plastic with the capability to compress 5 to 30 tons of scrap per day

youtube

Key Features:

✅ Effectively compacts recyclable materials (both Ferrous and Non-ferrous)

✅ Decreases waste volume, facilitating convenient transportation

✅ Produces environmentally friendly and cost-effective products

✅ Capable of compressing 5 to 30 tons of scrap per day

0 notes

Text

MATERIAL RECOVERY FACILITY EQUIPMENT

https://www.hcmswrecycling.com/mrf-material-recovery-facility-equipment.html

After the manual pre-sorting process, garbage is screened by a trommel screen, and to maximizing extraction of different kinds of recyclable material, partially by NIR technology, it can be sorted by color or by material, and then separated recyclables will be processed by solid waste baler machine for transport.

To provide recyclable garbage more value, it is received and sorted using the Hengchuang material recovery facility equipment (Clean MRF sorting equipment) technology from solid waste management equipment manufacturer. According to the physical characteristics of the waste, clean MRF separates polymers (often PET and HDPE), ferrous and non-ferrous metals, paper, glass, etc.

PET bottles can also be produced from used PET bottles, depending on the purity of the recycled PET bottles. PET bottles may be produced from used PET bottles, depending on the quality of the recycled PET flakes. By adding virgin grade plastic resin to low purity recycled plastic, we may create high quality plastic items.

Clean MRF Sorting Equipment Functions

Material Recovery Facilities (MRFs) use a variety of MRF sorting equipment to process and separate recyclable materials. Some common types of clean MRF sorting equipment include:

MRF Conveyor belt: waste sorting conveyor belts is used to transport materials through the MRF. They may be equipped with sensors or other technologies to help identify and sort different types of materials.

Trommel screens: Wholesale Trommel screen is cylindrical screens that rotate to separate materials based on size and density. They are often used to remove larger contaminants from the recycling stream.

Air classifiers: Air classifiers use air streams to separate materials based on their weight and density. They can be used to separate materials such as paper from heavier materials like plastic bottles.

Eddy current separators: Eddy current separator machine use magnetism to separate non-ferrous metals (such as aluminum) from other materials.

Optical sorters: optical sorter recycling use cameras and other sensors to identify and sort materials based on their physical characteristics, such as color and shape.

Magnetic separators: Magnetic separator machine use magnetism to separate ferrous metals (such as steel) from other materials.

The specific MRF sorting equipment used in an MRF will depend on the types of materials being processed and the desired end products.

Clean MRF Material Recovery Facility Equipment Advantages

Material Recovery Facilities (MRFs) are facilities that are designed to sort, process, and store recyclable materials. There are several advantages to using clean MRF sorting equipment:

Increased efficiency: clean MRF sorting equipment is specifically designed to efficiently sort and process recyclable materials, which can help to increase the overall efficiency of the facility.

Enhanced separation: clean MRF sorting equipment can effectively separate different types of recyclable materials, ensuring that they are properly sorted and stored for later processing.

Reduced contamination: By accurately sorting materials, clan MRF sorting equipment can help to reduce the contamination of recyclables, which can improve the quality of the materials and increase their value.

Cost savings: clean MRF sorting equipment can help to reduce labor costs, as the clean MRF sorting equipment can handle much of the sorting and processing tasks that would otherwise be performed manually.

Environmental benefits: Using clean MRF sorting equipment can help to reduce the amount of waste that is sent to landfills, as more materials can be recycled and repurposed. This can help to reduce the negative environmental impacts of waste disposal.

1 note

·

View note

Text

Factors To Buy Hydraulic Metal Baler

A hydraulic metal baler presses for metal scrap, plastic, alloy scrap/ ferrous metal and also alloy scrap/ non-ferrous metal in numerous kinds. There are numerous companies that supply hydraulic steel balers as well as it can be frustrating to choose the right one. Due to the boost in automation, more businesses have begun to make use of hydraulic steel balers to end up being extra competitive. The most effective aspect of hydraulic metal balers is the truth that they are extremely automated as well as yet very simple in operation through both by hand run direction control value. One of these would certainly push the scrap and also the other would run the leading cover. The solitary portable units would install over the channel also since there is hand-operated front door procedure for opening and closing. There are several advantages of using a hydraulic metal baler which is what this blog post takes a look at. Some of the benefits of the balers are as follows. Advantages of Hydraulic Steel Baler Fully automatic procedures. High speed. Reduced power usage however rapid manufacturing rate. Low upkeep. Extremely economical. Most of the reputable hydraulic steel balers are worldwide considered. Hand lever operated versions and complete automated models are readily available. The balers can either be made use of for non-ferrous and ferrous scrap products. The balers can be changed/ made according to the needed bundle weight, thickness and also dimension. Low upkeep costs and also straightforward balers. Can be easily operated by someone. Machine business consistently test the equipments before their shipment which leads to just good-quality equipments being offer. They come with many security attributes. Complete bale ejection Used for Different Industries The hydraulic baling machine is normally suitable for reusing processing industries, steel jobs, ferrous and non-ferrous metal smelting sectors. It has the ability to extrude any kind of sort of steel remaining materials steel shavings, waste light weight aluminum and also waste copper into qualified charging such as octagon child, cylinder, cuboid as well as various other forms. The purpose of the hydraulic metal baler is to decrease the expenses of smelting and also transport. Attributes of Hydraulic Steel Baler The hydraulic driving has actually been embraced for all sorts of devices. The PLC automatic or manual control procedures are optional. There is no requirement for foundation bolts for setup. The diesel would certainly be furnished as power in position without the power supply. Baler out kind such as front press, hand over as well as side press. The extruding force has regarding 8 courses anywhere from 63 loads to 44 tons and the manufacturing performance is from 0.5 tons a hr to 20 hours a hr. The bundle size and also chamber box dimension may be personalized according to the demands of the customer, as well as one can choose the blades for the chamber box. Verdict With numerous benefits, it is apparent why individuals take into consideration a hydraulic metal baler as the ideal solution. See to it to research study concerning the brand name that you purchase the baler from. When you liked this informative article and you would want to get details with regards to waste recycling machine factory (www.wasterequip.com) i implore you to go to our internet site.

1 note

·

View note

Text

Metal Scrap Baling Press in Ahmedabad

The mechanical recycling process, which includes the use of the metal scrap bailing press, transforms garbage into forms of metal, concrete, or glass that can be used in the future. So we Shree Rameshwar Eng are here to discuss some questions relating to Metal Scrap Baling Press in Ahmedabad. This process is used to reduce the amount of metal waste that needs to be disposed of and helps to keep recycling rates high.

What is metal baling scrap?

Metal scrap baling is a process of breaking down large pieces of metal into smaller more manageable sizes by baling. This can be done by either hammering them down or using a baler. But it would be easy for an individual to use a metal scrap baling machine in Ahmedabad.

Metal scrap baling is a process that removes metal from scrap pieces by using a machine that wraps the metal around rollers. The scrap is then dropped down a chute and cut into smaller pieces. The recycling process begins with the collection of materials from businesses and households. Once the materials have been collected, they are sorted into categories before they can be transported to a recycling facility. The most common categories are metals, glass, plastics, and paper. After the materials are sorted, they are cleaned and processed into new products.

How does a metal scrap baling machine is useful?

It is a type of machine that compacts scrap metal into manageable bales for transport. Most scrap metal recycling facilities will accept scrap metal in any form; however, using a baling press to compress scrap before transport can reduce your overall transportation costs. In addition, baling your scrap can make it easier to store on site before transport. Metal Scrap Baling Press does take as scrap material,

Metal Scrap Baling Press in Ahmedabad does take scrap material, but other scrap recycling machines are available for other types of scrap. These baling presses are operated with an electric motor and have a capacity ranging from 300kg to 1 ton. Some models have a pre-pressing chamber to increase the density of the bales. The press is operated with an electric motor and has a capacity ranging from 300kg to 1 tone.

Metal Scrap Baling Press such as aluminum cans, copper wire, and steel cans. The scrap metal is placed in the designated loading area of the press. The operator then starts the press an

d the hydraulic ram pushes the metal against the side of the press chamber.

Where to sell scrap material?

You've accumulated a stockpile of scrap metal and now you're wondering where to sell it. The obvious answer is to find a local scrap yard, but you're concerned about getting the best price possible. You decide to do a bit of research and find that there are other options worth considering. There are a few things you should know before making a decision.

It also makes it easier to transport waste products to recycling facilities. There are a few places where you can sell your metal scrap baling.

In general, you will likely find three options: a scrap yard, a recycling center, or online. If you choose to go with a scrap yard, you will be paid by weight for the scrap metal that you bring in. The payment for recycling centers may vary slightly, but it is typically based on weight as well.

What kind of material is accepted by the metal baling press ?

Numerous types of metal can and are recycled. The common metals that are accepted at recycling facilities are aluminum, copper, lead, nickel, tin, titanium, and zinc. Ferrous metals contain an appreciable amount of iron and are attracted by a magnet. Non-ferrous metals do not contain iron and are not attracted by a magnet.

Scrap metal recycling is the process of reusing scrap metal to create new products. This helps to reduce energy usage and pollution. Most recycling centers accept ferrous and non-ferrous metals. Ferrous metals are made of iron and have a magnetic property.

Our company, Shree Rameshwar Eng, is situated in Ahmedabad, and we offer a wide range of hydraulic machinery that is specially constructed to order. This machinery includes hydraulic presses, bending machines, molding machines, and Metal Scrap Baling Press in Ahmedabad.

0 notes

Text

High-Nickel & Special Alloys Scrap Buyer & Seller, Copper Ingots, Largest Metal scrap yards in UAE, Ferrous Scrap Buyer & Seller

PGI Group

is an internationally acknowledged metal recycling expert group with operations extending Middle East, Far East, South East, US, UK, Europe, and Africa. We are a trusted name in the recycling industry with over 300 employee assets spread across three yards located in different parts of UAE and one in Thailand. Over the last two decades, PGI has emerged a key raw material supplier for several domestic and foreign metal manufacturers and foundries across the globe.

Capacity

We procure, process, and recycle all kinds of

ferrous and non-ferrous metals

, using advanced machineries and equipments. We recycle most types of metal scrap including Aluminium, Brass, Bronze, Stainless Steel, HMS, high & low Nickle alloys, and Zinc in our facilities. We handle Aluminium, Copper, Lead, Copper wires, Copper cable, and Aluminium cables for cleaning, sorting, and recycling.

Our first UAE facility in Sharjah is spread across 1,20,000 sq. feet while the second facility has 100,000 sq. feet area. The third scrap metal yard situated in Al Sajaa has an area of 20,000 square feet. Cumulatively, we handle ~200,000 metric tonnes of metal scrap annually, consistently mostly

non-ferrous metals

Machinery

We have advanced machines and equipment to handle different types of scrap metal and recycling requirements. Here are some of the machines used in our yards.

Excavation grabbersare used to moving scrap metals in bulk or move heavy metals from one place to another using a claw-like structure in the machine. Our yard has 12 excavator grabbers.

Forkliftsare used to carry heavy loads between two locations. We are equipped with 13 Forklifts with different capacities (3 tons, 5 tons, and 7 tons) at our yard.

Mobile cranescome with a boom in which a hook is suspended to shelves and wire ropes. They are used to pull heavy metal from one place to another.

A fixed grabberwith a capacity of 10-meter distance reach is used to shift metals within the yard.

Hydraulic Baler machinesare heavy speed, fully automated machines used to reduce the scrap materials in two dimensions with hydraulic force.

Automatic Insulated Copper Wire (ICW)plant facilitates the segregation of copper wire from insulation in bulk quantity.

Hamos machinesare the electro separators used for the dry separation of metals from plastics and other non-conductive materials.

Shearing machines are used to cut a large variety of metal scrap into suitable sizes.

Peeling machinesare another method to segregate insulations from the metalcore. This machine ensures that the final product contains no plastic.

Plasma cutting machinesare essential machinery in our yard, as we often need to cut oversized metals into required smaller sizes.

Handheld XRF elemental analyseris used for high-throughput testing and spectrochemical analysis.

Optical Emission Spectrometerused to determine the chemical composition of metallic samples.

Safety measures

Safety and security of our employees is of utmost importance to us. Our HSE Officer has been mandated by management to follow “Safety First”. We use industry best practices for

scrap metal recycling

. We take all precautions to ensure our people are protected from all safety hazards and provide them a safe working environment. We have a dedicated safety officer who regularly trains the employees to make sure that proper safety guidelines are followed at each stage of processing. We promote health and safety training to maximize safety in our yards.

Our yard workers are equipped with PPE kits including safety helmet, safety goggles, safety dress & jackets, protective gloves, and heavy-duty boots to prevent injury and loss of life.

We strictly monitor and guide everyone who deals with hazardous materials to follow instructions. It is mandatory for the employees who work in the Lead section to use respiratory protective masks to protect themselves from Lead poisoning during the recycling process. We have safety alarm installed in our yard to prevent fire accidents. Fire-extinguisher, water-pumping station, CO2 and dry-powder is fixed at all locations in the yard. We conduct regular safety toolbox meetings to bring safety awareness among labours and supervisors. We take all precautionary measures to manage safe operations & movement of vehicles.

A day in the yard

The yard is a bustling hub of activities with cargo trucks moving in an out of the facility every day. The metal scrap cargo is first weighed and then goes through rigorous quality checks using an XRF (X-ray fluorescence) handheld analyser, a non-destructive analytical technique used to determine the elemental composition of materials. The load is then cleaned and sorted for further processing including briquetting into desired shapes or recycling if needed. The final product is then dispatched and exported to customers across the globe. The waste generated is either recycled or effectively disposed of as per environment authority guidelines. The cleaning and packaging processes depends on customer requirements. We have the technology and capability to meet specific customer needs.

Our employees receive regular training in quality assurance, machine handling and recycling processes. They follow the best practices in sorting, segregating, and processing various types of scrap metal cargo that we receive in our yard.

Whether you are a corporate or an individual business looking to sell or buy metal scrap, we offer the best, most competitive prices, and we have the capability and resources to handle any metal requirement on timely basis.

Contact us today.

0 notes

Photo

Waste Collection System

The collection of solid waste is a fairly complex issue. Garbage sorting equipment supplier believes that solid waste can be divided into two types according to the collection method. One type is waste that can be recycled at the waste collection point, such as old newspapers, non-ferrous metals, waste steel, rubber, plastic, etc. Collected by the waste material recycling system belonging to the commercial sector, the other type, such as factory waste residue, dust, daily life garbage and so on. Because this kind of waste has relatively low utilization value, it is particularly easy to be ignored and discarded arbitrarily, which causes greater harm to the environment. There is a large-scale application of solid waste treatment or comprehensive utilization, and the amount is too small. Decentralized treatment or utilization is often not economically feasible and technically difficult. Therefore, it is necessary to collect a small amount of waste scattered in various factories or sources. Transport to the appropriate disposal site.

Municipal solid waste has many types, complex components, and different properties, so its classification methods are also many. According to its physical properties, it is divided into organic waste and inorganic waste; according to its form, it is divided into solid waste and slurry waste; Its hazardous status is divided into toxic and hazardous waste. Waste and general waste; by industry, there are mining waste, metallurgical waste, chemical waste, civil waste, etc .; according to the requirements of different treatment methods, it can be divided into combustible waste and non-combustible waste, compostable waste and non-compostable waste, and Resource-based waste and difficult-to-resource waste, etc. According to the source, the mouth is divided into industrial solid waste, agricultural solid waste, mining solid waste, urban domestic waste, radioactive solid waste, and many countries in Europe and the United States are classified according to this principle. Japan divides solid waste into industrial solids.

Both physical waste and general solid waste. Starting from the management of solid waste in China, it is usually divided into three categories: industrial solid waste, hazardous solid waste and general solid waste (referring to urban solid waste and agricultural solid waste)

The collection of domestic garbage can be divided into three stages.

The first stage is the process in which garbage is generated from households to trash cans. There are many ways to generate and collect garbage at this stage. Whether it is classified collection or mixed collection, fixed-point collection, regular collection, or on-site collection. The collection of domestic garbage in China in 2001 was still based on fixed points and regular timing. Therefore, residents from the households to the bins are responsible for the garbage;

The second stage is the process of garbage collection from garbage collection trucks to various garbage collection points. This process is related to the collection method of garbage collection trucks. The garbage collection trucks use the container exchange type to transport empty garbage bins and put them in the garbage. At the collection point, the actual trash can is transported back to the treatment and disposal site or the transfer station, and after it is discharged, it is sent to the next collection point. The fixed container collection system is still used (the garbage truck loads the garbage in the garbage bin at the collection point into the garbage collection year, and the garbage bin is still put back in place).

The third stage of garbage collection and transportation is to transport the garbage collected in each collection area to a transfer station or various types of garbage processing and disposal sites. If a city has a garbage sorting system factory, determine the number of garbage collection sites to which each collection area should be sent and the amount of waste to be transported. Disposal fees> the most economical.

Qunfeng offers commissioning and training after machine or installation is supplied and installed. Our main products including municipal solid waste(msw), vertical waste transfer station project, plastic baler machine, weighing apparatus, underground or overground vertical waste transfer station system, underground waste container system, baler machine, etc.

If you want to know more about waste sorting plant, you can click here.

0 notes

Text

BE Equipment offers a wide variety of Two Ram Balers for baling cardboard, paper, plastic bottles, UBC, aluminum cans, non-ferrous metals, shrink wrap, textiles, clothing, and more. https://www.beequipment.com/recycling-equipment/two-ram-baler/ …pic.twitter.com/kouAALwbE7

BE Equipment offers a wide variety of Two Ram Balers for baling cardboard, paper, plastic bottles, UBC, aluminum cans, non-ferrous metals, shrink wrap, textiles, clothing, and more. https://www.beequipment.com/recycling-equipment/two-ram-baler/ … pic.twitter.com/kouAALwbE7

from Twitter Search / Beequipment https://twitter.com/Beequipment/status/1248279798016888833 via https://twitter.com/Beequipment

0 notes

Text

Metal Baler And Scrap Bundling Machine

Scrap bundling machine or compactor use to compress all types of metal scrap. From aluminum to MS all types of ferrous and non ferrous scrap can be compressed with scrap bundling machine manufacture by India's Largest Manufacturer.

Why Most of Buyer Choose us?

1. Most Advanced and Cost Effective Machines

2. Present in 70+ Countries

3. Finest in house Infrastructure in India

4. All the components are In house production

5. Most professional, certified and trained Sale service engineer

6. Winner of various awards in India and worldwide in Recycling

0 notes

Text

Baler Machine for Scrap Bundling

Baler machine is considered as one of the most vital scrap processing machines in the recycling industry. This machine compresses a wide range of scrap material to bundle them and produce high density bundles for further processing. All the balers manufactured by Advance Hydrau-Tech are ideal for customers looking to bale medium to large quantities of scrap (ferrous and non-ferrous) stainless steel, aluminium and copper scrap. Advance Hydrau Tech’s baler machine is automatic and can easily process up to 10 tons/hr of metal scrap.

Benefits and Features of Baler machine:

· All types of ferrous and nonferrous scrap can be processed.

· High Productivity

· Easy installation

· PLC Controlled Machines

· Highly efficient hydraulic systems

youtube

0 notes

Text

Metal Baler For Scrap Compacting/Bundling - Triple Action Model

Metal Balers Manufacturer by Advance Hydrau-Tech is based on quality and widely demand for the productivity. Our Metal Scrap bundling machines are best suitable for Aluminum, MS, Mild Steel, CRC scrap and for all types of ferrous/non ferrous scrap material.

Features:

1 Available in both PLC Controlled and Semi-Automatic variants

2 . Every scrap baler is efficiently equipped with three separate operating compactors which work on scrap compressing

3. Automatic lubrication system

4. Multi-information PLC display for operation and troubleshooting

5. Replaceable wear-resistant plates are supplied with the Bailing Press for longer life of feeding chamber

6. Shearing blades on the edges of top lid and chamber are available for shearing oversized material

7. Additional scrap feeding hopper for enhancing the productivity of the baler

8. Inclusion of Check Valves and Limit Valves to avoid any accident

9. Post sale support and service

10. Customization of the Baling Press as per your specific requisites to include any required features.

#MetalBaler#MetalScrapBaler#AdvanceHydrautech#metalscrapbundling#Scrapbaler#Balingpress#Balingmachine

0 notes

Text

Finding Out About Metal Scrap Balers And Their Reliable Suppliers

Balers would be the advanced machines that are not only productive concerning material use but may also be readily utilized for industrial purposes. Balers can be employed with a crane and will be controlled by a remote. One of many very most useful balers at the industrial-scale are metal scrap balers. Metal Scrap Balers cut and then crush the waste or extra scrap metal arranging these in the form of bales. The ideal thing about using metal scrap balers is they work economically with substances no more than tin cans, so large as vehicles; now isn't that amazing? Investing in massive parts of machinery such as for example China hydraulic baler can be heavy on the pocket, and which explains the reason why you want to invest on some thing that goes using the waste of your business and to benefit you back. Alloy Scrap Balers work to recycle scrap metal, therefore they can be utilized again industrially.

Metal scrap balers can differ in terms of ferrous and non-ferrous stuff. That is particularly valuable for monitoring purposes, therefore that the right bales might be arranged. From the metallic scrap balers, materials are compacted in size in the shape of a log and then cut into place lengths.

Metal Scrap Baler Benefits

Industrial trash is becoming among the greatest issues in the world. Reusing and recycling of these waste materials is nearly a necessity, and one of the very best methods to save funds. Not only does this assist in conserving the natural environment, but also helps in reducing your industrial expenses too. There are a few exceptions in materials which can't decompose, whereas quite a few materials such as aluminium, paper is readily recyclable. The Metal scrap balers are mostly useful for shredding, compacting etc..

The major question would be, what sort of recyclable items may be recycled via a metallic scrap baler? Those things including machinery parts, windows, autoparts, iron pipes, aluminum and tin cans, replacements, electronic appliances and also vehicles, all may be recycled with the support of the metallic scrap baler.

Finding Providers

Finding hydraulic baler supplier could be very hard, particularly when you are looking for a baler at a spending budget. There are numerous directories on the internet that provide you with a listing of companies providing metal trash balers with easy features. It's possible to consult with them regarding the design, weightreduction, engineering, features and usage.

Research entirely through your method looking into website links, telephone numbers, company reviews as well as also the item features in regards to the metallic scrap baler you get your eyes on. Organizations supply you with the very best facts about the metal scrap balers, therefore compare and contrast by contacting many of them also make your decision wisely.

0 notes

Text

Shear Balers Market : Get Facts About Business Strategies 2028

Shear Balers Market: Introduction

Shear balers can be defined as the equipment used as compactors in various industries such as the automotive industry and metal industry, among others. Shear balers are used for the recovery of the waste material that is generated from industrial processes and in the recycling industry. Furthermore, shear balers incorporate a unique patented swinging wings compression box. Shear balers are designed as highly versatile machines to compress and shear a variety of different materials such as timber, tire, metal and paper & plastic materials, among others. In addition, shear balers are also used to compress and shear the bulky or over-sized scrap, construction demolition scrap as well as high-density mixed scrap & bales. A shear baler can be operated in two modes: as a baler and as a shear.

Moreover, the automatic cycle for cutting and compacting makes shear balers particularly efficient for the recovery and processing of scrap material. Shear balers consist of several mechanical systems and a large number of components with very narrow operating specifications. Shear balers are being stationary or mobile, that is also used to bailing ferrous and non-ferrous metals. Stationary shear balers are generally loaded by a crane, and they have a large capacity pressure range to scrap various materials in different industries.

Request For Report Sample@ https://www.persistencemarketresearch.com/samples/27382

Shear balers can be categorised into fixed, semi-mobile and mobile. Semi-mobile shear balers are transportable & versatile, and heavy-duty shear balers can be used for metal scrap processors of materials of different sizes. Mobile shear balers are mounted on hydraulic platforms, which makes them easy to transport. They are suitable for the any site as they help eliminate costly civil works and locations with energy-supply issues. All that can be considering efficient and low investment in shear balers, that portable shear balers move easily from one location to another.

Shear Balers Market: Dynamics

Rising waste material recycling or recovery activities in different industries, such as the automotive industry, plastic & paper industry, metal waste or biomass waste, etc., are among the key factors expected to drive the global shear balers market. Some other factors, such as the robust structural design of the shear balers that makes it lowest to highest production equipment and energy efficient consumption systems in the recycling industry. Moreover, the hydraulic system in shear balers is designed to increase the production, along with low energy consumption and low noise production. All these factors are also expected to boost the demand for shear balers in the global recycling industry during the forecast period.

However, shear balers require high maintenance with regular lubrication and the proper inspection of all wearable surfaces & pivot points. This results in the need for high maintenance of shear balers in terms of cost, which is likely to hamper the growth of the global shear balers market in the near future.

Shear Balers Market: Segmentation

The global shear balers market can be segmented on the basis of type, application and region.

On the basis of type, the shear balers market has been segmented as:

Medium-duty fixed shear balers

On the basis of application, the shear balers market has been segmented as:

Timber recycling

Construction and demolition processing

Metal recycling

Tire recycling

Biomass recycling

Paper and plastic recycling

Waste and e-waste processing

Product destruction

Request For Report Table of Content (TOC)@ https://www.persistencemarketresearch.com/toc/27382

Shear Balers Market: Regional Outlook

Globally, the installation of shear balers depends upon the rising demand for recycling or recovery equipment in various end-use industries such as automotive, paper & plastic and others. Asia Pacific is estimated to account for a dominant share in the shear balers market owing to the strong investments in China, Japan and India towards developments, along with technological advancements to recover and recycle waste products and material.

The shear balers market in North America and Europe is expected to register substantial growth owing to the rising demand for waste management and waste recycling equipment to reuse scrap metals in these regions. The Middle East & Africa shear balers market, followed by the Latin America shear balers market, is expected to witness considerable growth in the near future.

Shear Balers Market: Market participants

Some of the market participants identified across the value chain of the shear balers market are:

LEFORT

Patikima Linija UAB

Idromec Spa

PRM Waste Systems Ltd.

HWH Machines

Ecotecnica Engineering srl

Jaguar Equipamentos

COLMAR EQUIPMENT

IMABE IBÉRICA S.A.

ANDRITZ

JMC Recycling Ltd.

Copex

Metso

Femco Group

Know More About Report@ https://www.persistencemarketresearch.com/market-research/shear-balers-market.asp

0 notes

Text

Aluminum wire scrap,Alloy wheel scrap,Alluminium Engine scrap , aluminum sheets scrap

Aluminum scrap from Africa

Aluminum scrap exportation

Aluminum scrap shipments

Aluminum scrap for sale

Aluminum scrap cathode

Aluminum scrap: Aluminum wire scrap,Alloy wheel scrap,Alluminium Engine scrap , aluminum sheets scrap, Aluminum content 75%, 95%,99%,99.7% high quality good service low price fast delivery 1. Reasonable price and high purity 2. Puritys: 95% 99.7% Basic information: 1. Place of origin: Hungary 2. Material: Aluminum 3.Color: silver white 4. Shape: flat 5. Non-secondary Composition: Si : 0.2-0.6% Fe : 0.35% Cu : 0.1% Mn : 0.1% Mg : 0.45-0.9% Cr : 0.1% Zn : 0.1% Packaging Detail: 1.Compressed into rectangular block 2. 50kgs/bag, 1000kgs/bag 3. 50kgs/bale, 50kgs/bundle 4. 20mt/20'fcl, 25mt/40 fcl Contact for details. This lot of Aluminum Extrusion Scrap is being sold in an asset liquidation sale conducted by the owner in order to recover funds and storage space. Product Aluminum Extrusion Scrap Quantity 500 MT Details Aluminum extrusion scrap 6063 1. Competitive price and high purity 2. Purity: 99% Basic Information: Silvery white, luster, tough and light texture, malleable. The element name: Aluminum The element type: Metal Elements atomic weight: 26.98 The relative atomic mass: 26.98 Density: 2.702 g/cm3 Melting point: 660.37 ?C Boiling point: 2467.0 ?C Ignition point: 550 ?C Specification of Aluminum scrap 6063 Si: 0.2-0.6%&nsp; Fe: 0.35%&nsp; Cu: 0.1%&nsp; Mn: 0.1%&nsp; Mg: 0.45-0.9%&nsp; Cr: 0.1%&nsp; Zn: 0.1%&nsp; Application: 1.mainly used for melting ingot 2.discontinuous melting with scrap 3.easy control and operation 4.fast melting 5.energy saving This Scrap Aluminium is produced in the production of industrial waste.Such as:Scrap Aluminium Wire,Scrap Aluminium block and so on 6. It mainly used for drawing back non-ferrous metal typical material is :wasted copper, aluminum, cable, aluminum stuff, wasted auto spare part, non-ferrous metal scrap, dross for printing, broken glass contains non-ferrous, electronic waste etc.

high quality Aluminum scrap,aluminum scrap,wire scrap,alloy wheel scrap,aluminium engine,wheel scrap,aluminium engine scrap aluminum

aluminum scraps 6063 suppliers aluminum scraps baler for sale aluminum scraps dealers in chennai aluminum scrap dealers in delhi aluminum scrap dealers in uae

SEND US AN E-MAIL VIA: [email protected]

Red grouper fish for sale

Frozen chicken wings, drum sticks, breasts, paws and whole chicken for sale

HALAL chicken feet, paws, legs, breast, drum sticks and other chicken parts

Grade A Frozen Pork Ears, Hind and forefeet, tail and other parts

Frozen pork tail with bones, frozen pork ears for bulk export

Copper Wire Scrap 99.99% purity / Red Scrap Copper Wire / millberry copper wire/Cu.Millberry

Research chemicals for sale

buy pure Gold Dust 99.9% purity gold from nuggets

buy Gold Bullion Bar. Pure Gold Bars

buy high quality silver bars 99.9% pure silver

buy high quality Nickel Sulphate

purchase Caustic Soda Flakes online

Wowwee Fingerlings Baby Monkey Interactive Pet finger toy monkey

OEM Customized Mobile Phone Case for iPhone 8 Case with Shockproof TPU Edge,for iPhone 8 Cover Case

used tires used tyres from Germany 3/4/5/6/7mm A Grade+++

Square Gift Cardboard Box White Packing Box With Ribbon For Jewelry Packaging Wholesale

pvc insulated electric wire copper wire

2017 China quality copper wire price per foot wholesale

Pure Millberry Copper,Copper Scraps,Copper Wire Scrap 99.9%

buy Copper Sulphate online

Baby diapers for exportation

electrolyte copper cathode 99.99% copper content

Aluminum wire scrap,Alloy wheel scrap,Alluminium Engine scrap , aluminum sheets scrap

Aluminum Scrap UBC, Wheel scrap and Wire scrap available

high purity 99.9% copper wire scrap for bulk export

Pure copper ingots, wire and cathodes for sale

long burning time hardwood Sawdust briquette charcoal for bbq

Top quality DIN white beech wood pellets for bulk supply

puchase Sodium Hydroxide Pearls/flakes 99% Caustic Soda Price

A4 snow white Copy paper

HDPE Granulates for bulk supply

A4 80gsm White Copier/ Printer Office Copy Paper 2500 Sheets 5 Reams Box

Office Depot A4 White 80-100 gsm Colour Business copy copier paper 5 reams Box

Double A A4 copy and printing paper

Adult Diapers

SEND US AN E-MAIL VIA: [email protected]

Read the full article

#aluminumscrap6063suppliers#aluminumscrapalibaba#aluminumscrapdealersuk#aluminumscrapdealersusa#aluminumscrapexporters#aluminumscrapexportersdubai#aluminumscrapexportersusa#aluminumscrapforsale#aluminumscrapforsaleincanada#aluminumscrapforsaleinchina#aluminumscrapforsaleinthephilippines#aluminumscrapforsaleinu.s.a#aluminumscrappricealibaba#aluminumscrapsellerinuae#aluminumscrapsellers#aluminumscrapsuppliers#aluminumscrapsuppliersinaustralia#aluminumscrapsuppliersincanada#aluminumscrapsuppliersinindia#aluminumscrapsuppliersinuae#aluminumscrapsuppliersinuk#aluminumscrapsuppliersinusa#aluminumwheelscrapsellers#scrapaluminumbuyerssuppliers#scrapaluminumcansforsale#scrapaluminumplateforsale#scrapaluminumsheetsforsale#scrapaluminumtubingforsale#scrapaluminumwheelsforsale

0 notes

Text

Scrap Metal Alberta

Throughout the previous 10 years, we have been providing modern clients, and in addition ranchers, with an answer for their piece metal or their old gear.

Regardless of whether it is on a nonstop premise at a creation shop, or somebody is simply completing a yard cleanup, we have containers that we give for nothing out of pocket. In the event that the undertaking is sufficiently enormous, we can give excavators, end dumps, and a metal baler.

We process the metal, isolate the non-ferrous, and after that, we pull it to end clients or other supply offices where it gets encouraged arranged for re-utilize.

0 notes

Text

Hydraulic Scrap Compactor or waste Compression Machine is used to compress scrap material and handle a variety of ferrous and non-ferrous scrap. We have single action baler specially designed to compress low volume of scrap such as aluminum, MS, iron, steel and CRC. Advance Hydrau-Tech is one of the largest manufacturer and pioneer in creating highly advanced and efficient metal scrap processing machines. These single action baling press are tested on various parameters to ensure flawless performance and defect-free nature.

0 notes