#Non Woven Bag Printing Machines

Explore tagged Tumblr posts

Text

Best Non Woven Bag Printing Machine Manufacturing Company in India

Decent Print Lines is a prominent manufacturer and supplier of Non Woven Bag Printing Machines in India, renowned for delivering high-quality, reliable, and efficient printing solutions. Specializing in advanced printing technology, Decent Print Lines designs machines that ensure precision, durability, and superior print quality on non-woven bags. These machines are engineered to meet the growing demand for eco-friendly packaging solutions, providing vibrant and long-lasting prints on various sizes and styles of non-woven bags.

Decent Print Lines’ Non Woven Bag Printing Machines are user-friendly, with features like easy operation, low maintenance, and high-speed printing capabilities, making them ideal for both small and large-scale production. The company emphasizes innovation, incorporating the latest technological advancements to enhance productivity and reduce operational costs. With a strong commitment to customer satisfaction, Decent Print Lines offers comprehensive after-sales support, including installation, training, and technical assistance, ensuring that clients receive the best possible value. Whether you’re a startup or an established business, Decent Print Lines provides a reliable and efficient solution for all your non-woven bag printing needs.

For More Details

Contact us:- +91-9911433180

Email Id:- [email protected]

Address:- Plot No. 4, Gali No. 1, Rao Colony, Sihi Gate, Faridabad, Ballabgarh - 121004, Haryana, India- 203208

#Non Woven Bag Printing Machines#Non Woven Bag Printing Machine#Non Woven Bag Printing Machines manufacturers#Non Woven Bag Printing Machines manufacturer#Non Woven Bag Printing Machines suppliers#Non Woven Bag Printing Machines manufacturer in India

0 notes

Text

Uses and Functions of Non Woven Bag Printing Machine

Introduction

In recent years, the global movement towards sustainability and eco-consciousness has spurred a significant shift in consumer behavior and industrial practices. As businesses strive to reduce their environmental footprint, the demand for eco-friendly alternatives to traditional plastic bags has surged. Enter non-woven bags — lightweight, durable, and reusable alternatives that have gained widespread popularity. At the heart of this eco-friendly revolution lies the non-woven bag printing machine, a marvel of modern engineering that enables the mass production of customized, environmentally responsible bags. Let’s delve deeper into the efficiency and functionality of these innovative machines.

The Rise of Non-Woven Bags

Non-woven bags are crafted from synthetic or natural fibers bonded together through a mechanical, thermal, or chemical process — without the need for weaving. This manufacturing method results in bags that are strong, tear-resistant, and capable of carrying heavy loads. Moreover, non-woven bags are reusable, recyclable, and biodegradable, making them a sustainable choice for environmentally conscious consumers and businesses alike.

Advantages of Non-Woven Bag Printing Machines

Customization: Non-woven bag printing machines offer unparalleled flexibility, allowing businesses to create bespoke designs and branding solutions tailored to their unique requirements.

Speed and Efficiency: With rapid printing capabilities and automated processes, these machines enable high-volume production without compromising on quality or accuracy.

Cost-Effectiveness: By streamlining production workflows and minimizing material waste, non-woven bag printing machines help businesses optimize their operational costs and maximize profitability.

Environmental Sustainability: By facilitating the production of reusable and recyclable non-woven bags, these machines support sustainability initiatives and contribute to the reduction of plastic waste.

Non-woven bag printing machines are the unsung heroes of modern manufacturing, offering a multitude of uses and functions in various industries.

Functions of Non Woven Bag Printing Machine

Customization Made Easy

These machines empower businesses to personalize non-woven bags with logos, designs, and messages, enhancing brand visibility and communication.

Promotional Powerhouses

Ideal for creating branded merchandise, custom-printed non-woven bags serve as effective promotional tools at trade shows, events, and marketing campaigns.

Sustainable Packaging Solutions

In retail, these machines help elevate packaging by customizing non-woven bags with brand aesthetics, product showcases, and eco-friendly messaging.

Memorable Event Souvenirs

From conferences to weddings, custom-printed non-woven bags make practical and memorable giveaways, leaving a lasting impression on attendees.

Environmental Advocacy

By enabling the production of reusable and recyclable bags, these machines contribute to environmental sustainability efforts, promoting eco-conscious consumption.

In essence, non-woven bag printing machines are more than just production tools — they’re enablers of creativity, sustainability, and brand empowerment in a rapidly evolving world.

Best Non Woven Bag Printing Machine Companies in India

If you are looking for a Best Non Woven Bag Printing Machine in India, then look no further than Decent Print Line. Decent prinline is a leading manufacturer and supplier of non woven bag printing machine in India.

For more details, please contact us!

Website — https://www.decentprintline.com/

Contact — +91–9911433180

Email — [email protected]

Address — Plot №4, Gali №1, Rao Colony, Sihi Gate, Faridabad, Ballabgarh — 121004, Haryana, India

#Non Woven Bag Printing Machine#Non Woven Bag Printing Machine manufacturer#Non Woven Bag Printing Machine supplier#Non Woven Bag Printing Machine manufacturer in India#Non Woven Bag Printing Machine supplier in India#Decent printline

2 notes

·

View notes

Text

youtube

Fully Automatic Non Woven Paper bag Making Machine-Laxmi Enterprises

Fully Automatic Non Woven Carry bag Making Machine - International Traders Channel - #LaxmiEnterprises #Fully Automatic Non Woven Fully #Automatic Non Woven Carry bag Making Machine Non Woven Carry bag #Making #Machine Fully Automatic Non Woven #NonWoven #Youtube

#non woven machinery#non woven machine operator#non woven machine spare parts#non woven machine manufacturers in china#non woven machinery germany#non woven machine parts hs code#non fabric machine#non woven bags machine#non woven printing machine#non woven cutting machine#non woven bags machine price in delhi#non woven sealing machine#non woven bag machine manufacturer in ahmedabad#non woven bag machine price in kolkata#non woven stitching machine#non woven machine price#non woven fabric machine price in india#non woven printing machine 16x22#non woven carry bag machine price#non woven bag machine price in india#second hand non woven bag making machine#second hand non woven bag making machine in india#non woven fabric manufacturing machine price#non woven bag printing machine 4 colour#non woven bag machine for sale#used non woven machine for sale#non woven sealing machine for sale#non woven types#non woven methods#non woven uses

0 notes

Text

0 notes

Text

Top 10 Features to Look for in a Non Woven Bag Printing Machine

As the demand for eco-friendly non-woven bags continues to rise, having a reliable and efficient printing machine is essential for manufacturers. Choosing the right non-woven bag printing machine can significantly impact productivity and print quality. Here are the top 10 features to consider when selecting one:

1. Print Quality

Look for a machine that offers high-resolution printing. Crisp, clear images and vibrant colors are crucial for attracting customers and enhancing brand visibility.

2. Printing Speed

Consider the machine's production speed. A higher printing speed can increase efficiency, allowing you to meet large order demands without compromising quality.

3. Versatility

Choose a machine that can handle various bag sizes and types. This flexibility will enable you to expand your product range and cater to different customer needs.

4. Ease of Use

User-friendly interfaces and controls make operation easier for your team. Look for machines with intuitive designs that require minimal training.

5. Durability and Build Quality

A sturdy machine made from high-quality materials will ensure longevity and reliability, reducing maintenance costs and downtime.

6. Eco-Friendly Options

With a focus on sustainability, consider machines that use eco-friendly inks and processes. This aligns with the green ethos of non-woven bags and can attract environmentally conscious customers.

7. Maintenance and Support

Check for the availability of technical support and spare parts. A machine that is easy to maintain will save you time and money in the long run.

8. Advanced Technology

Look for features like automatic registration, multi-color printing, and digital controls. These technologies can enhance precision and efficiency.

9. Cost-Effectiveness

Evaluate the initial investment and operating costs. A machine that balances price with performance will provide better returns on investment.

10. Reputation and Reviews

Research manufacturers and read customer reviews to gauge reliability and performance. A reputable brand with positive feedback is often a safer choice.

Conclusion

Investing in the right non-woven bag printing machine is crucial for enhancing production capabilities and meeting market demands. By considering these ten features, you can make an informed decision that will drive your business forward and help you produce high-quality, eco-friendly bags efficiently.

0 notes

Text

Non-Woven Bag Making Machines in Patna: Arya Industries

Arya Industries stands tall as the premier supplier of non-woven bag-making machines in Patna, Bihar. In today’s eco-conscious world, non-woven bags have gained immense popularity due to their reusable, biodegradable, and environmentally friendly properties. With plastic pollution being a global issue, businesses and individuals are rapidly shifting to non-woven bags, and Arya Industries has established itself as a trusted provider of the machines that produce these bags. From small-scale entrepreneurs to large industrial setups, Arya Industries caters to a wide range of customers looking to manufacture non-woven bags.

Why Arya Industries is the Best Choice

There are several reasons why Arya Industries has earned its reputation as the leading provider of non-woven bag-making machines in Patna:

High-Quality Machines: Arya Industries offers machines built with precision engineering, ensuring durability, efficiency, and long-lasting performance.

Advanced Technology: The machines provided by Arya Industries are equipped with the latest technology, enabling businesses to manufacture non-woven bags of various sizes and designs with ease.

Comprehensive Range: Arya Industries offers a wide variety of non-woven bag-making machines that cater to different production needs. Whether you’re looking for manual or fully automatic machines, Arya Industries has you covered.

Affordable Pricing: Despite offering state-of-the-art machines, Arya Industries ensures that their products are priced competitively. This makes it easier for new and established businesses to invest in high-quality machinery without breaking the bank.

Exceptional After-Sales Service: Arya Industries is known for its top-notch customer service. From installation to maintenance and troubleshooting, they provide comprehensive support to ensure that their customers get the most out of their machines.

Customization Options: Arya Industries understands that every business has different needs. Therefore, they offer machines that can be customized to suit the specific production requirements of their clients.

Types of Non-Woven Bag Making Machines Offered by Arya Industries

Arya Industries provides a wide array of machines for manufacturing non-woven bags. Here are some of the popular types of non-woven bag-making machines available:

Fully Automatic Non-Woven Bag Making Machine

Features: This machine is ideal for businesses with high production demands. It can produce different types of non-woven bags, including handle bags, box-type bags, D-cut bags, and more. It comes with features like automatic control, digital display, and ultrasonic welding technology for strong seams.

Price: ₹6,50,000 to ₹8,50,000 (depending on the model and specifications).

Benefits: Reduces labor costs, high-speed production, versatile bag styles.

Semi-Automatic Non-Woven Bag Making Machine

Features: The semi-automatic machine is a great option for small to medium-sized businesses. It requires some manual intervention but still offers decent production capacity. It can produce various styles of bags and is relatively easy to operate.

Price: ₹4,50,000 to ₹6,00,000.

Benefits: More affordable than fully automatic machines, reliable production quality, suitable for businesses with moderate production requirements.

Manual Non-Woven Bag Making Machine

Features: This machine is perfect for startups or small-scale businesses that are just entering the non-woven bag industry. It requires manual operation but is cost-effective and easy to maintain.

Price: ₹1,00,000 to ₹2,50,000.

Benefits: Budget-friendly, simple operation, low maintenance, ideal for businesses with low production needs.

Non-Woven Fabric Printing Machine

Features: Non-woven fabric bags often require branding, and Arya Industries provides specialized printing machines that can print logos, designs, and text on the bags. The printing machines are compatible with different inks and offer clear, durable prints.

Price: ₹2,00,000 to ₹3,50,000.

Benefits: Customization of bags, high-quality prints, suitable for brand-conscious businesses.

Handle Attachment Machine

Features: Some non-woven bags require handles, and Arya Industries offers a machine specifically designed to attach handles securely and efficiently. It can be integrated with other bag-making machines or used independently.

Price: ₹1,50,000 to ₹3,00,000.

Benefits: Improves production speed for handle bags, easy operation, durable handle attachment.

Pricing and Value for Money

Arya Industries offers flexible pricing options, ensuring that businesses of all sizes can find the right machine within their budget. The prices range from ₹1,00,000 for manual machines to ₹8,50,000 for fully automatic setups. This broad price spectrum allows both startups and established businesses to choose a machine that fits their financial and operational needs.

In addition to the competitive prices, the long-term value of these machines is evident in their robust build, low maintenance costs, and energy efficiency. The machines are designed to deliver consistent performance over extended periods, providing excellent return on investment (ROI) for businesses.

Conclusion

If you’re looking to invest in non-woven bag-making machines in Patna, Arya Industries is the go-to destination. Their commitment to quality, innovation, and customer satisfaction sets them apart from the competition. With a comprehensive range of machines tailored to various production needs and budget-friendly prices, Arya Industries ensures that you have the right equipment to succeed in the booming non-woven bag industry. Whether you are a new entrepreneur or an established business owner, Arya Industries is your reliable partner in creating sustainable, eco-friendly products.

Visit: https://www.aryaindustries.co/

0 notes

Text

Printed Non Woven Bags supplier & Manufacturer in Delhi

Glance India A prominent manufacturer and supplier of Non Woven Bags, Printed Non Woven Bags, D Cut Non Woven Bags , W Cut Non Woven Bags, U Cut Non Woven Bags, Loop Handles & Box Bags, Non woven laundry bags, Non Woven Cake Bags in India. We’re able to meet our clients’ wide range of demands throughout the globe because of our ability to produce large quantities at a low unit cost. Because we are a direct manufacturer, supplier and wholesaler, we can offer you the most reasonable price in the industry. A solid and efficient machine is essential to the growth of your business, and you must ensure that your machines are as efficient and productive as possible. No matter where your manufacturing facility is located globally, your high-speed nonwoven bag-making will be delivered on time. We believe in best products quality & 100% customer satisfaction.

more info :- https://glanceindia.co.in/printed-non-woven-bags-manufacturer-in-delhi.php

0 notes

Text

Non-woven fabric bags district 1

Non-woven fabric bags are bags made from non-woven fabric, often used to replace plastic bags to minimize environmental impact.Non-woven fabric bags district 1

Product information

Here are some details about non-woven bags:

Material :

Non-woven fabric is a fabric created by heat-pressing polypropylene (PP) or other synthetic fibers without going through the weaving process like traditional fabrics. This helps create a fabric that is light, soft and durable.

Advantage :

Durable and lightweight : District 1 non-woven fabric bags are durable and very lightweight, convenient to carry.

Environmentally friendly : Polypropylene material is recyclable and biodegradable, helping to reduce plastic waste.

Design diversity : District 1 non-woven fabric bags can be produced in many different sizes, colors and designs.

Easy printing : The surface of non-woven fabric is easy to print, suitable for advertising and marketing.

Non-woven fabric bags district 1

Application :

Shopping bag : Replaces traditional plastic bags, helps reduce plastic waste.

Gift bags : Used as gift bags in events and festivals.

Promotional bags : Many businesses use non-woven bags to print logos and promotional information.

Process of making non-woven bags in District 1

The process of making non-woven bags includes the following basic steps:

1. Receive request

Customer contact : Customer contacts the manufacturer or supplier to place an order.

Determine needs : Discuss specific requirements such as quantity, size, color, design, intended use, and budget.

Non-woven fabric bags district 1

2. Design

Sample Design : The design team will create a sample bag based on the customer's requirements. Elements such as logo, images, and advertising messages will be carefully considered.

Approve sample : Send design sample to customer for approval. If there are any edits, adjustments will be made as requested.

3. Choose material and color

Fabric selection : Choose non-woven fabric with suitable color.

Choose accessories : If needed, choose accessories such as zippers, buttons, handles, etc.

Non-woven fabric bags district 1

4. Cut and sew

Fabric cutting : Non-woven fabric is cut to the required size and shape using a specialized cutting machine.

Bag Sewing : Fabric sections are sewn together according to the approved design. Details such as handles, side pockets, or inner linings are also sewn at the same time.

5. Printing

Print logos and designs : Use printing technologies such as silk screen printing, heat transfer printing, or digital printing to print design details onto the bag.

Check print quality : Make sure print details are clear, sharp and free of color smudges.

Non-woven fabric bags district 1

6. Quality control

Product Inspection : Each bag is thoroughly inspected to ensure there are no sewing or printing errors, and that it meets the correct quality standards.

Packing : After inspection, the bags are carefully packed for protection during transportation.

7. Delivery

Order confirmation : Reconfirm with customer about quantity and quality of bags.

Delivery : Arrange for bag delivery to customer address as agreed.

Receive feedback : After the customer receives the goods, receive feedback and handle any problems that arise.

Non-woven fabric bags district 1

8. After-sales

After-sales service : Provide after-sales service such as warranty, technical support if needed.

Evaluation and Improvement : Collect feedback from customers to improve production processes and services.

Product information

ZOZO FABRIC BAG FACTORY

Hotline: 0879679686

Email: [email protected]

Working hours : 8:00-17:30

Address: No. 8, T4B Street, Tay Thanh, Tan Phu, HCMC

Factory: 965/36/29 Quang Trung, Ward 14, Go Vap, HCM

Fanpage: Fabric bag sewing factory

See also:

Specializing in making canvas bags District 6

Specializing in making canvas bags in Dong Nai

Specializing in making canvas bags in District 6

0 notes

Text

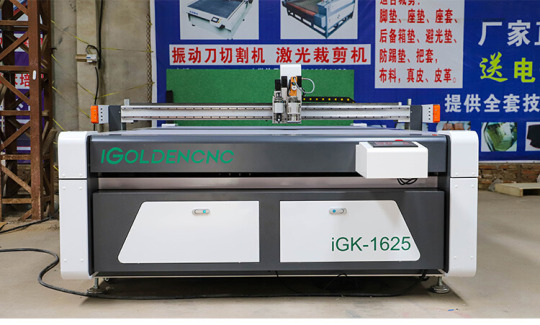

CNC Leather & Fabric Oscillating Knife Cutting Machine

Oscillating knife machine is suitable for cutting various thin flexible materials. The digital cutting machine is designed for small batch production, which can save costs while maintaining speed and accuracy. This digital cutting machine is used in various industries such as packaging, printing, advertising display, leather processing, architectural modeling, composite materials, and tool modeling.

An oscillating knife cutting machine, also known as a CNC oscillating knife cutter, is a specialized cutting tool used in various industries for precision cutting of a wide range of materials. It operates by rapidly moving a knife blade back and forth in an oscillating motion to cut through materials with high precision and minimal material waste. These machines are highly versatile and are used for cutting materials like fabrics, leather, foam, rubber, paper, cardboard, composites, and more.

A vibrating knife option is an important tool for companies that need to process flexible materials. These flexible materials include packaging foam, foam core, blender foam, corrugated plastic, or cardboard. These materials all pose challenges to traditional router planning or cutting tools, but the “saw action” of the oscillating knife makes it easy to cut these materials, providing a clean cutting edge without fraying.

Oscillating Knife Cutting Machine Advantages

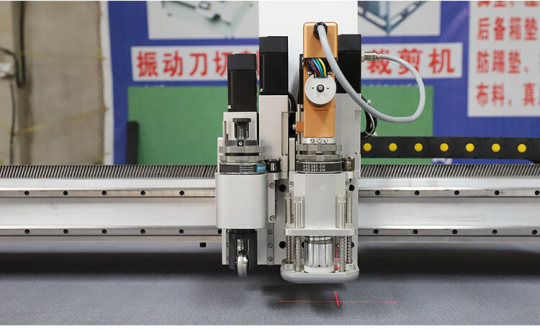

Knife Options: These machines can be equipped with various knife types, including straight blades, serrated blades, V-shaped blades, and more, depending on the specific material and cutting requirements.

Precision: Oscillating knife cutters offer high precision and can cut intricate shapes, patterns, and curves with sharp corners. This makes them well-suited for industries that require intricate or custom designs.

Software and Design: Design your cutting patterns using computer-aided design (CAD) or computer-aided manufacturing (CAM) software. The machine’s software then translates these designs into cutting paths.

Tool Control: Many oscillating knife cutters come with multiple toolheads, allowing for different tools to be used in one machine. For instance, you can use a knife for cutting, a creasing tool for scoring, or a pen for marking.

Depth and Speed Control: Adjust the cutting depth and cutting speed to match the material you’re working with. Different materials may require different settings for optimal results.

Material Hold-Down: These machines often use vacuum tables, conveyor systems, or other methods to hold down the material during cutting, ensuring precision and preventing material shift.

Applicable materials of oscillating knife cutting machine:

Oscillating knife machine is suitable for cutting various thin flexible materials. The digital cutting machine is designed for small batch production, which can save costs while maintaining speed and accuracy. This digital cutting machine is used in various industries such as packaging, printing, advertising display, leather processing, architectural modeling, composite materials, and tool modeling.

Leather,sticker,cardboard,Plastic box,corrugated cardboard,film,foam board,acrylic board,rebound rubber,rubber cloth,gasket material,garment cloth,footwear material,bags materials,non-woven fabrics,carpets,sponge,PU,EVA,XPE,PVC,PP,PE,PTFE,ETFE,and composites,whose thickness of above materials is below 22 mm.

Oscillating knife cutting machines are valuable tools for industries that require precision cutting of soft and semi-rigid materials. They offer efficiency, speed, and accuracy, making them suitable for both mass production and custom manufacturing. When used correctly, these machines can improve productivity and the quality of the final products.

CNC Knife Cutting Machines

Complementing other areas within our cutting machine range, the CNC knife cutting tables bring even greater versatility to the cutting process. These beautifully made, sophisticated machines are produced by one of the largest, specialized manufacturers of CNC cutting tables in the world. This total focus on innovative machines with very elegant software has culminated in a sophisticated range of CNC knife cutting machines which will cut an ever increasing range of materials at maximum speed with minimum waste.

This very wide range of flatbed cutting machines includes models with fixed beds and moving conveyors so that any material format – sheet, roll or a combination of both, can be processed. Ideal for short run, fast response working, these systems are also eminently suitable for full scale production as well as prototyping.

Add to this the large range of cutting tools that can be carried on the multi-tool cutting head – fixed blade, pizza wheel [rotary blade], electric or pneumatic oscillating blade, milling and routing, kiss cut, ultrasonic and pen – and the sheer versatility is clear.

Processing advantages

Automatic feeding system with intelligent correction function

This product uses a full-automatic feeding platform, which realizes the automatic work of feeding and cutting, saving labor costs. With the automatic deviation-feeding system, it can overcome the deformation problem of flexible materials in the printing or embroidery process, intelligently handle the deformation matching, and realize the automatic search Edge cutting.

Cutting tool without pollution

Compared with laser cutting, the cutting speed of the cutter is faster, no odor, and the cutting edge will not be carbonized. It is especially suitable for cutting intimate apparel such as swimwear and cycling clothes. Customers can also configure different types of tools according to the cutting material to meet the processing of different materials.

Automatic edge-finding and precise cutting

This product applies the industry’s advanced precise visual recognition algorithm and fine numerical control cutting technology. It searches and locates the graphic position through the vision system, controls the precise movement of the cutting head to the corresponding position, and automatically aligns and cuts along the edge with an error of less than 0.5MM.

Automatic operation saves costs

Fully-automatic feeding platform, continuous cutting, no special care required, easy operation; this product supports multiple layout methods, can achieve seamless stitching and cutting of the same graphic, reduce waste consumption; integrate its various high-quality functions, achieve faster speed, save material More and better performance. So as to reduce production costs and improve production efficiency.

0 notes

Text

How are non-woven bags manufactured?

In today’s environmentally conscious market, non-woven bags have become a popular alternative to plastic bags. These bags are not only reusable and durable but also provide an excellent surface for high-quality printing, making them ideal for branding and promotional purposes. At Decent Print Lines, we specialize in providing top-of-the-line Non Woven Bag Printing Machines designed to deliver exceptional print quality and efficiency.

Why Invest in a Non Woven Bag Printing Machine?

Investing in a non-woven bag printing machine offers numerous benefits, including:

High Precision Printing: Achieve sharp, vibrant prints that stand out.

Cost-Effective Production: Increase production rates while reducing costs.

Versatility: Capable of printing on various sizes and styles of non-woven bags.

Sustainability: Supports the production of eco-friendly products, aligning with consumer demand.

Features of Our Non Woven Bag Printing Machine

Advanced Technology: Our machines are equipped with the latest technology, ensuring consistent and high-quality prints.

User-Friendly Interface: Easy to operate with minimal training, allowing for quick setup and efficient production.

Durable Construction: Built with high-grade materials to withstand continuous operation, ensuring long-term reliability.

Customizable Options: Available in various configurations to meet specific production needs.

Applications

Our non-woven bag printing machines are ideal for a range of applications, including:

Retail Branding: Customize shopping bags with logos and designs that enhance brand visibility.

Promotional Bags: Print vibrant graphics for giveaways and promotional events.

Event Bags: Produce personalized bags for conferences, weddings, and other special occasions.

Why Choose Decent Print Lines?

At Decent Print Lines, we are committed to delivering quality machines that meet the specific needs of our clients. With years of experience in the printing industry, we offer reliable solutions that help businesses expand their capabilities and achieve their goals.

Contact Us Today:

Phone: +91–9911433180

Email: [email protected]

Address: Plot No.4, Gali No.1, Rao Colony, Sihi Gate, Faridabad, Ballabgarh — 121004, Haryana, India

Discover how our Non Woven Bag Printing Machines can transform your production process and help you stay ahead in the competitive market.

#decent print line#non woven bag printing machine#Non Woven Bag Printing Machine in India#Non Woven Bag Making Machine

0 notes

Text

Non-woven bag making machines are industrial machines used in the manufacturing of eco-friendly, durable, and reusable non-woven polypropylene (PP) bags. These machines are designed to produce bags without the use of weaving or knitting processes, making them cost-effective and environmentally friendly.

Features of a non-woven bag making machine:

Feeding Mechanism: These machines have a feeding system that takes the non-woven fabric rolls as input material. The fabric is typically made of spunbond non-woven polypropylene, a material known for its strength, durability, and recyclability.

Printing Unit (Optional): Some machines have an integrated printing unit that allows customization of the bags with logos, designs, or information as per customer requirements.

Ultrasonic Sealing/Cutting: Non-woven bag making machines use ultrasonic technology for sealing and cutting the fabric. This process ensures strong, neat seals without the need for thread or glue.

Handle Attachment: Some machines are equipped with systems to attach handles to the bags, whether through ultrasonic welding, punching, or other mechanisms.

Automatic Counting and Stacking: These machines often come with automatic counting and stacking systems to facilitate easy packaging and handling of the produced bags.

Speed and Efficiency: Non-woven bag making machines can produce bags at high speeds, ensuring efficient production to meet commercial demands.

For more details, ▪ Visit:- https://www.indiantradebird.com/ ▪ Call:- +91 8511142701

0 notes

Text

Mini Offset Printing Machine | Offset Printing Machine - Autoprint

The new generation 1510 & 1520 Colt single color mini offset printing machine from Autoprint, is highly suitable for printing single color Invitations, Letter Heads, Bill Books, Vouchers, Challans, Envelopes & Hand Bills on various types of substrates like Color Wove, Maplitho, Art Paper & Board Up to 300 gsm. Knight series machines are engineered to deliver high-quality printing including 4 color jobs in 4 passes. Knight NX can be used for printing on Non-Woven Bags. In Auto Creaser we can do Creasing, Perforation, Half Cut & Spine & Hinge Creasing.

Autoprint is one of the leading mini-offset printing manufacturers in India.

Autoprint colt series comprises of mini offset single color printing machine such as:

Autoprint 1510 colt, Autoprint 1510 colt 7K, Autoprint 1520 colt, Autoprint 1520 colt 7K, Autoprint Knight, Autoprint Knight NX. Autoprint printing machines are a new generation’s mini offset printing machines which is highly suitable for entry level printing entrepreneurs, DTP units, large Xerox and screen printing units as well as small enterprises.

Autoprint mini offset printing machine is a front-loading unit with a unique dry compressor, side lay registration, no sheet detector. It has a 3-cylinder chain delivery and gear-driven oscillators. The plate cylinder of the Autoprint mini offset printing machine has speed set clamps. The swing-type ink duct is a special feature which helps in cleaning the duct without removing the rollers which reflects in high productivity.

0 notes

Text

Textile Machinery - Different Products For Various Textile Processes

Textile machinery is utilized in the processing of textiles, fabrics and all forms of woven and non-woven textile items. A list of these machines is used in many parts of textile manufacturing from spinning and weaving to dyeing and warping. There are also tools used in order to extrude plastic and synthetic fiber. Some natural fibers that go well with any of this equipment are wool, cotton and silk while artificial fibers like nylon, polypropylene and polyester benefit from these machines too.

Textile machinery is offered in the market as brand new items but there are also used ones that manufacturers may consider purchasing. These are available through Internet venues and other local equipment providers within a certain locale. Some of the most popular traders or dealers of these industrial products belong to associations like the Association of Machinery and Equipment Appraisers and American Textile Machinery Association.

In other countries, there are yet other organizations where these traders are linked to. Generally, no broderie textile matter what name the dealers are associated with, the following products are included in their product catalogue.

Machinery for sewing, garment and embroidery

Among a list of names in the textile equipment department, those in the sewing and embroidery processes are always sought after by textile industries. Popular machine names are sewing machines, garment cutting machines, embroidery machines, hemming machines and overlock machines. There are also very specific products like flat ironers, denim sewing machines and needle detector machines. There are those that deal with heavy fabrics, trimmings and button holes. In this department, all items gear to aspects of sewing, embroidery and garment manufacture.

Weaving machines

Weaving is also another important process in the textile industry that is why some of the best textile machinery is made for this particular endeavor. A company may choose from rapier looms, warping machines, water jet looms, carpet making machines and jacquards machine. Some other items in the brochure are beaming machines, sizing machines and needle looms. With each product name, one will be able to learn about its real function.

Other forms of machines for textile manufacturing

Dyeing is also catered to by a list of textile machinery. The continuous dyeing machine is included as well as the centrifugal hydro-extractors machine. Padders, jiggers and dosing machines are highly recommended for this part of the process. There are also items particularly made for knitting, spinning, laundry, printing and finishing. Some traders provide textile machines for footwear, bags and others for leather manufacture.

0 notes

Text

How Start Non Woven Fabric Bag Manufacturing Business?

Starting a non-woven fabric bag manufacturing business is a promising venture due to the rising demand for eco-friendly and reusable bags. With governments banning plastic bags in many regions, non-woven bags offer an environmentally sustainable alternative. Here's a step-by-step guide to help you start your own non-woven bag manufacturing business.

1. Market Research and Business Plan

Start by conducting thorough market research to understand the demand, target customers, and competition. Create a business plan that includes your goals, financial projections, and strategies for marketing and distribution.

2. Choose the Right Location

Select a location with easy access to raw materials, labor, and transportation facilities. A small or medium-sized unit with around 500–1000 sq. ft. of space can accommodate basic machinery and storage.

3. Procure Machinery and Equipment

To manufacture non-woven bags, you'll need specialized machinery like:

Non-woven bag making machine

Printing machine (optional for custom designs)

Cutting machine

You can start with semi-automatic or fully automatic machines depending on your budget.

4. Raw Material Sourcing

The primary raw material for making these bags is non-woven polypropylene fabric. Ensure you choose a reliable supplier to source high-quality material in various GSM (Grams per Square Meter) according to your product range.

5. Manufacturing Process

The manufacturing process is simple and includes:

Feeding the fabric

Cutting and stitching into desired shapes (D-cut, U-cut, loop handle bags)

Optional printing for branding

6. Licensing and Registration

Register your business as a small-scale industry (SSI) and obtain necessary licenses like a GST number and pollution control clearance.

7. Marketing and Distribution

Promote your non-woven bags to local retailers, supermarkets, and e-commerce platforms. Highlight the eco-friendly and reusable nature of your bags to attract conscious consumers.

Conclusion

Starting a non-woven bag manufacturing business is a profitable and environmentally responsible venture. With the right planning, machinery, and raw materials, you can establish a successful operation. For high-quality non-woven fabric, contact Favourite Fab today!

0 notes

Text

Non Woven Bag Making Machines in Patna: Arya Industries

In today’s eco-conscious world, the demand for environmentally friendly products is at an all-time high. One of the most significant shifts in consumer preferences has been the move away from single-use plastic bags to more sustainable alternatives like non-woven bags. These bags are not only reusable but also biodegradable, making them a preferred choice for businesses and individuals alike. Behind this transformation in the packaging industry are innovative machine manufacturers like Arya Industries, who have been at the forefront of providing advanced Non-Woven Bag Making Machines.

Why Non-Woven Bags?

Before diving into Arya Industries’ role, it's important to understand the significance of non-woven bags. Unlike plastic bags, which are made from harmful petrochemicals and take hundreds of years to decompose, non-woven bags are made from fibers that are bonded together mechanically, chemically, or thermally. These bags are durable, reusable, recyclable, and environmentally safe. With increasing global awareness of environmental degradation and the harmful effects of plastic pollution, businesses across various sectors are shifting towards non-woven bags for packaging and branding purposes.

Arya Industries: A Leader in Non-Woven Bag Making Machines

Arya Industries has earned a stellar reputation as the leading provider of Non-Woven Bag Making Machines. Based in Patna, the company has served clients across India and has helped countless businesses transition from traditional packaging methods to environmentally friendly alternatives. With a commitment to quality, innovation, and customer satisfaction, Arya Industries has established itself as a pioneer in the field.

1. State-of-the-Art Technology

What sets Arya Industries apart is its use of cutting-edge technology. The Non-Woven Bag Making Machines provided by the company are designed using advanced engineering processes to ensure high-speed and efficient production. These machines can produce a wide variety of bag types, including D-cut, U-cut, and loop handle bags, to meet the diverse needs of businesses. The machines are equipped with automated features, reducing the need for manual intervention and ensuring precise cutting, sealing, and printing.

2. User-Friendly Machines

Arya Industries understands that businesses need machines that are not only technologically advanced but also easy to operate. The company's Non-Woven Bag Making Machines are designed with simplicity in mind, making them ideal for both large-scale manufacturers and small businesses. These machines require minimal training to operate, ensuring that businesses can get started with production quickly and efficiently.

3. Customization Options

Different businesses have different needs, and Arya Industries excels in providing tailored solutions. The Non-Woven Bag Making Machines can be customized based on the size, thickness, and design of the bags that a business wishes to produce. Whether a company is looking to produce large shopping bags or smaller promotional bags, Arya Industries can provide the right machine for the job. The company also offers customization options for printing logos, brand names, or other promotional content on the bags, making them an excellent tool for brand visibility.

4. Energy-Efficient and Cost-Effective

Another reason why Arya Industries is the best provider of Non-Woven Bag Making Machines is its focus on energy efficiency. The machines are designed to consume less power, which not only reduces operational costs but also contributes to a lower carbon footprint. For businesses looking to adopt sustainable practices, Arya Industries’ machines offer the perfect solution. Additionally, the machines are built for long-term durability, ensuring that businesses can continue producing non-woven bags without the need for frequent repairs or replacements.

5. Affordable Pricing

Despite offering advanced features and high-quality products, Arya Industries has managed to keep its pricing competitive. This makes it possible for businesses of all sizes to invest in top-tier Non-Woven Bag Making Machines without breaking the bank. Whether a startup is looking to enter the eco-friendly bag market or an established company is expanding its production line, Arya Industries offers affordable solutions that don’t compromise on quality.

6. Excellent Customer Support

Customer satisfaction is at the heart of Arya Industries’ business philosophy. The company prides itself on offering excellent after-sales support, including machine maintenance, troubleshooting, and technical guidance. Arya Industries has a dedicated team of professionals who are always ready to assist customers in resolving any issues and ensuring that their production runs smoothly.

A Sustainable Future with Arya Industries

With increasing government regulations and consumer demands for sustainable products, the need for eco-friendly packaging solutions like non-woven bags is only going to grow. Arya Industries is playing a pivotal role in this shift by providing businesses with the tools they need to produce high-quality, environmentally friendly bags. By choosing Arya Industries’ Non-Woven Bag Making Machines, businesses are not only investing in cutting-edge technology but also in a sustainable future.

Conclusion

Arya Industries is undeniably the best provider of Non-Woven Bag Making Machines in Patna in the industry. With its state-of-the-art technology, user-friendly designs, customization options, energy efficiency, and commitment to customer satisfaction, the company has set the gold standard for machine manufacturers. For businesses looking to stay ahead in the competitive market while adopting eco-friendly practices, Arya Industries offers the perfect solution. Invest in Arya Industries today, and take your business to new heights with the best Non-Woven Bag Making Machines available.

Visit: https://www.aryaindustries.co/

0 notes

Text

plastic carry bag manufacturers in vadodara

Koshambh specializes manufactures high-quality, fancy and eco-friendly plastic bags in large quantities. We offer different kinds of plastic carry bags and bags for packaging different agricultural foods and products in various colors, sizes, shapes, materials and prints as per your requirements. Equipped with innovative modern technology and infrastructure, we produce the best quality of carrying bags in bulks for every and any day usage at affordable prices. Also, our plastic products ate 100% Export Oriented Units.

We manufacture plastic bags using the best raw materials as per the type of polyethylene bags in the market. It includes High-density polyethylene (HDPE) Polypropylene (PP) Craftpaper and Non-Woven materials. Located in Halol and Manjusar, Vadodara, Gujarat, we produce 6050 metric tons of plastic bags a month. Our powerful extrusion machines and processes perfectly mix all the raw materials. Once the plastic strips are ready, we cut it in different sizes as per the customer’s requirements. The plastic bags are then strongly stitched to make sure it’s durable. The final part is printing, where we add colours and emboss branding and prints. We make sure we only give you the best quality bags so that one can carry everything and anything desire

Koshmabh understands that with a great manufacturing process comes greater responsibility. Plastic and plastic waste management is something that the world is fighting together to make our mother earth a better place for our future generations. As a leading exporter and manufacturer of the country, we also manufacture biodegradable and eco-friendly plastic bags that decompose easily and do not harm our environment.

Contact Us For more detail - inquire us at +91 265 2334401 Mail to: [email protected]

Address

301-302, Gamthi Complex, Opp. Productivity Council Productivity Road, Alkapuri, Vadodara - 390007 Gujarat India

Inquire us your requirement

0 notes