#Non Destructive Testing

Explore tagged Tumblr posts

Text

NDT non-destructive testing refers to a range of techniques used to evaluate the properties and integrity of materials, components, or systems without causing any damage to them.

1 note

·

View note

Text

Maximize Component Integrity with Fluorescent Penetrant Inspection

Fluorescent Penetrant Inspection is essential for ensuring the structural integrity of your components. Our NDT experts utilize advanced FPI methods to highlight even the smallest imperfections, providing you with confidence in the reliability of your products.

#ndt inspection services#ndt testing#non destructive inspection#non destructive testing#ndt#ndttraining#business#non destructive entry#services#Fluorescent Penetrant Inspection

0 notes

Text

VeriPac technology stands out as a key solution in this critical area, offering advanced, non-destructive methods for verifying package integrity. By integrating state-of-the-art leak detection and integrity testing, VeriPac helps pharmaceutical manufacturers meet stringent regulatory standards and maintain the highest levels of sterility. As the industry continues to evolve, VeriPac's innovative technology will remain a vital tool in protecting the efficacy and safety of pharmaceutical products, ensuring they reach patients in optimal condition.

#non destructive testing#vacuum decay leak testing#container closure integrity testing#container closure integrity

0 notes

Text

Understanding Ferrite Testing in Pune: A Comprehensive Guide

Ferrite testing, a critical aspect of non-destructive testing (NDT), plays a pivotal role in ensuring the integrity and quality of welds, particularly in stainless steel components. In Pune, a hub of industrial activity, the demand for accurate and reliable ferrite testing services is paramount to maintaining safety standards and operational efficiency across various sectors.

Ferrite Testing Services in Pune

Ferrite testing services in Pune are essential for industries ranging from manufacturing to construction, where the properties of stainless steel must meet stringent specifications. These services involve the measurement of ferrite content within welds, which directly impacts their mechanical and corrosion-resistant properties. Integrated NDE offers comprehensive ferrite testing services in Pune, utilizing advanced NDT techniques to provide precise and reliable results.

Importance of Non Destructive Testing (NDT) in Pune

Non-destructive testing (NDT) in Pune is integral to ensuring the structural integrity and safety of industrial components without causing damage. Ferrite testing, as part of NDT, assesses the ferrite content in stainless steel welds to determine their susceptibility to corrosion, cracking, and mechanical failure over time. This proactive approach helps industries in Pune mitigate risks and enhance the longevity of their assets.

Ferrite Testing: Methodology and Applications

The methodology of ferrite testing involves using electromagnetic induction to measure the ferrite content in stainless steel welds. This process is non-invasive and provides immediate results, making it ideal for on-site inspections and quality control in Pune's industrial settings. Integrated NDE employs trained technicians and state-of-the-art equipment to conduct ferrite inspections accurately and efficiently.

Ferrite Testing of Welds in Pune

In Pune, ferrite testing of welds is crucial for verifying weld quality and compliance with industry standards such as ASME, AWS, and API. By assessing the ferrite content, engineers and inspectors can determine the weld's structural integrity, its ability to withstand environmental conditions, and its performance under stress. This meticulous testing process ensures that welds meet the specified ferrite range, thereby enhancing reliability and safety.

Ferrite Testing in Stainless Steel: Ensuring Durability and Performance

Stainless steel's corrosion resistance and mechanical strength depend significantly on its ferrite content. Ferrite testing in Pune's stainless steel applications ensures that components meet design specifications and regulatory requirements. Whether for aerospace, automotive, or infrastructure projects, accurate ferrite testing by Integrated NDE helps businesses in Pune deliver products that are durable, safe, and cost-effective.

Choosing Integrated NDE for Ferrite Testing Services

Integrated NDE stands out in Pune's NDT landscape for its commitment to excellence and client satisfaction. With years of experience and a team of certified professionals, Integrated NDE offers tailored ferrite testing solutions that meet the unique needs of Pune's diverse industries. Their expertise spans across various sectors, including oil and gas, manufacturing, and power generation, ensuring comprehensive support for quality assurance and regulatory compliance.

Conclusion

In conclusion, ferrite testing services in Pune, provided by Integrated NDE, are indispensable for industries seeking reliable NDT solutions. By conducting thorough ferrite inspections, businesses can enhance product quality, extend asset lifespan, and maintain operational efficiency. For companies in Pune looking to optimize their welding processes and ensure compliance with international standards, partnering with Integrated NDE ensures peace of mind and superior outcomes.

#ferrite testing in pune#ferrite testing services#non destructive testing in Pune#ndt testing#ferrite testing#ferrite inspection#ferrite testing of welds#ferrite testing stainless steel#destructive testing#non destructive testing#ndt inspection services

0 notes

Text

Integrated NDE Solution in Pune: Precision in Ultrasonic Thickness Measurement

Ensuring the integrity and safety of materials and structures is crucial in many industries, and ultrasonic thickness measurement (UTM) is a key non-destructive testing method used for this purpose. Integrated NDE Solution in Pune specializes in providing comprehensive ultrasonic thickness measurement services, leveraging advanced technologies to deliver precise and reliable results. This article explores the importance of UTM, its benefits, and the state-of-the-art services offered by Integrated NDE Solution.

Understanding Ultrasonic Thickness Measurement

Ultrasonic thickness measurement is a non-destructive testing (NDT) method used to determine the thickness of a material from one side. This technique employs high-frequency sound waves to measure the time it takes for an ultrasonic pulse to travel through the material and reflect back to the transducer. By calculating the travel time, the thickness of the material can be accurately determined.

Importance of Ultrasonic Thickness Measurement

Material Integrity: Ensures that materials have the required thickness and are free from thinning or erosion.

Safety Compliance: Verifies that components meet industry safety standards, reducing the risk of failures and accidents.

Preventive Maintenance: Identifies areas of concern before they become critical, enabling timely maintenance and repairs.

Quality Control: Confirms that materials conform to the specified thickness, maintaining the integrity and quality of the final product.

Cost Savings: Prevents costly failures and downtime by ensuring the correct material thickness from the start.

How Ultrasonic Thickness Measurement Works

Ultrasonic thickness measurement involves several steps and the use of advanced equipment:

Preparation: The surface of the material is cleaned to ensure accurate readings.

Couplant Application: A couplant (gel or liquid) is applied to the surface to facilitate the transmission of sound waves.

Transducer Placement: The ultrasonic transducer is placed on the surface, emitting high-frequency sound waves into the material.

Sound Wave Reflection: The sound waves travel through the material and reflect back when they reach the opposite surface or an internal flaw.

Measurement: The time it takes for the sound waves to return to the transducer is measured.

Thickness Calculation: The material thickness is calculated based on the sound wave travel time and the known velocity of sound in the material.

Benefits of Ultrasonic Thickness Measurement

Non-Destructive: Does not damage or alter the material being tested.

Accurate: Provides precise and reliable thickness measurements.

Quick and Efficient: Delivers immediate results, enabling rapid decision-making.

Versatile: Applicable to a wide range of materials, including metals, plastics, and composites.

Portable: UTM equipment is often portable, allowing for on-site testing.

Integrated NDE Solution in Pune: Leaders in Ultrasonic Thickness Measurement

Integrated NDE Solution in Pune is a leader in non-destructive testing, offering a broad spectrum of NDT services, including ultrasonic thickness measurement. Their expertise, state-of-the-art equipment, and commitment to quality make them a trusted partner for industries requiring reliable thickness measurements.

Comprehensive NDT Services Offered

Ultrasonic Thickness Measurement (UTM)

Remote Visual Inspection (RVI)

Magnetic Particle Inspection (MPI)

Ultrasonic Testing (UT)

Radiographic Testing (RT)

Liquid Penetrant Testing (LPT)

Eddy Current Testing (ECT)

Portable Hardness Testing

Ferrite Testing

Industries Served

Integrated NDE Solution in Pune caters to a diverse array of industries, including:

Aerospace: Ensuring the safety and reliability of aircraft components.

Automotive: Inspecting critical parts to prevent failures.

Construction: Verifying the integrity of structural components.

Oil and Gas: Ensuring the reliability of pipelines and equipment.

Power Generation: Maintaining the integrity of infrastructure components.

Manufacturing: Ensuring the quality of machined parts and assemblies.

Ultrasonic Thickness Measurement in Action

Case Study: Oil and Gas Pipeline Inspection

In the oil and gas industry, the reliability of pipelines is crucial. Integrated NDE Solution was approached by a leading oil and gas company to conduct ultrasonic thickness measurement on pipeline materials. Using advanced ultrasonic equipment, the team measured the wall thickness of the pipelines, ensuring they met the specified standards for corrosion resistance and mechanical strength. The inspection helped prevent potential failures and ensured the safety and reliability of the pipeline network.

Case Study: Aerospace Component Verification

A major aerospace manufacturer required ultrasonic thickness measurement for critical components used in aircraft engines. Integrated NDE Solution employed advanced ultrasonic equipment to measure the thickness of the components. The precise measurements confirmed that the materials met the stringent specifications required for aerospace applications, ensuring the safety and performance of the aircraft engines.

Advanced Ultrasonic Thickness Measurement Equipment

Integrated NDE Solution in Pune utilizes the latest UTM equipment to ensure the highest level of accuracy and reliability in their inspections. Some of the advanced equipment includes:

Digital Ultrasonic Thickness Gauges: Portable devices that provide rapid, on-site thickness measurements.

High-Frequency Transducers: Used for measuring the thickness of thin materials with high precision.

Dual-Element Transducers: Ideal for measuring corroded materials and rough surfaces.

Through-Coating Transducers: Capable of measuring the thickness of materials through coatings and paint.

The Role of Certified Technicians

The effectiveness of ultrasonic thickness measurement largely depends on the expertise of the technicians conducting the tests. Integrated NDE Solution in Pune employs certified technicians who undergo rigorous training and continuous professional development. Their skills and knowledge ensure that clients receive the highest quality of service.

Commitment to Quality and Safety

Integrated NDE Solution in Pune is dedicated to maintaining the highest standards of quality and safety. They adhere to international standards and best practices, ensuring that all inspections are performed with utmost precision and reliability. This commitment to excellence has earned them a stellar reputation in the industry.

Customer-Centric Approach

At Integrated NDE Solution in Pune, customer satisfaction is a top priority. They work closely with clients to understand their specific needs and tailor their services accordingly. Whether it’s a small-scale inspection or a large industrial project, they provide personalized solutions that meet the highest standards of quality and reliability.

Why Choose Integrated NDE Solution in Pune?

Expertise: Extensive experience and technical know-how in NDT services.

Technology: Utilization of the latest and most advanced testing equipment.

Quality: Commitment to providing accurate and reliable results.

Customer Service: Focus on building long-term relationships through excellent service.

Compliance: Adherence to all relevant industry standards and regulations.

Conclusion

In industries where precision and reliability are non-negotiable, Integrated NDE Solution in Pune stands out as a leader in non-destructive testing, particularly in ultrasonic thickness measurement. Their dedication to quality, use of advanced technology, and customer-centric approach make them the go-to choice for businesses across various sectors. By partnering with Integrated NDE Solution, companies can ensure the integrity and safety of their materials and components, safeguarding their operations and reputation.

Integrated NDE Solution in Pune continues to set the standard for excellence in non-destructive inspection. Their expertise in ultrasonic thickness measurement and other NDT services is pivotal in industries where safety and reliability are crucial. As technology advances and industries evolve, Integrated NDE Solution remains at the forefront, offering unparalleled service and support to their clients.

In conclusion, for businesses seeking the highest standards in ultrasonic thickness measurement, non-destructive testing methods, and comprehensive NDT services, Integrated NDE Solution in Pune is the trusted partner that delivers results. Their innovative approach, advanced technology, and unwavering commitment to quality ensure that every inspection meets the stringent requirements of today’s demanding industrial environments.

#ultrasonic thickness measurement#non destructive testing method#non destructive testing#ultrasonic thickness

0 notes

Text

the no.1 oilandgastraining institute in Kerala,India

#oil and gas#qa qc courses in kerala#safetytraining#professionalcourse#construction#mechanical engineering#oildrilling#offshore#natural gas#training#ndttraining#non destructive testing#weldingcourses

0 notes

Text

Dolphitech's innovative Non Destructive Inspection technologies redefine quality assurance, offering efficient, versatile solutions for safeguarding aerospace assets.

0 notes

Text

Why Do Engineering Safety Inspection Services Matter in Management and Supervision?

In today’s competitive industrial world, safety is no longer a luxury; it’s a fundamental cornerstone of successful operations. Accidents not only have devastating human consequences, but they also lead to costly downtime, production delays, and potential legal ramifications. To read more visit

#ndtinspection#nondestructiveevaluation#metallurgy#engineeringinspection#engineeringservices#construction#nondestructivetesting#visualinspection#weldingengineer#ndt#welding engineering inspection services#engineering safety inspection services#ndt inspection services#non destructive evaluation#non destructive testing

0 notes

Text

Non-destructive Testing Meets Nanotechnology: Exploring Innovations and Applications

Introduction Non-destructive testing (NDT) has long been a cornerstone in ensuring the integrity and safety of structures, components, and materials across various industries. As technology advances, the integration of nanotechnology into NDT has opened up new frontiers, offering unprecedented levels of precision, sensitivity, and efficiency. This article provides an overview of the convergence…

View On WordPress

0 notes

Text

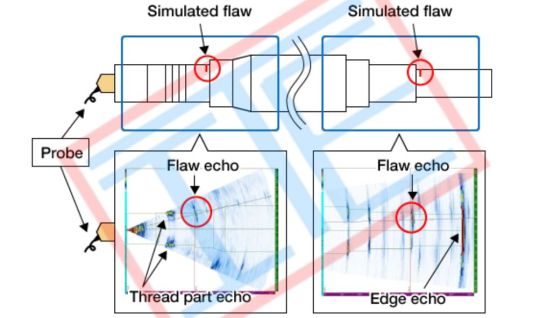

Phased Array Ultrasonic Testing services in India

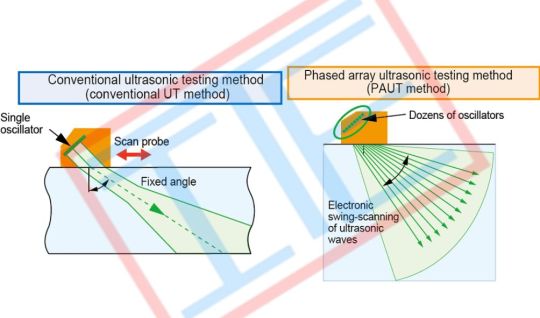

Phased Array Ultrasonic Testing (PAUT) services in India have gained significant popularity in recent years. PAUT is a non-destructive testing technique that uses ultrasonic waves to inspect materials for defects or flaws. It offers several advantages over traditional methods, making it a preferred choice for material testing in various industries.

PAUT inspection involves the use of an array of ultrasonic transducers that can be electronically controlled to emit and receive ultrasonic waves at different angles. This allows for the creation of a detailed and accurate image of the material being tested. The ability to control the angle and focus of the ultrasonic waves makes PAUT testing highly versatile and effective in detecting both surface and subsurface defects.

One of the major benefits of PAUT testing is its speed and efficiency. With traditional ultrasonic testing methods, multiple scans are required to cover the entire area being inspected. However, with PAUT, multiple beams can be emitted simultaneously, covering a larger area in a single scan. This not only reduces the inspection time but also increases productivity and cost-effectiveness.

Another advantage of PAUT inspection is its ability to provide real-time imaging. The data collected from the ultrasonic waves can be displayed as a visual image, allowing for immediate analysis and interpretation. This real-time imaging feature enables faster decision-making and reduces the need for additional testing or re-inspection.

PAUT testing is widely used in various industries such as aerospace, oil and gas, power generation, manufacturing, and infrastructure. In the aerospace industry, PAUT is used for inspecting critical components such as aircraft wings, turbine blades, and engine parts. In the oil and gas industry, it is used for inspecting pipelines, storage tanks, and pressure vessels. In power generation, PAUT is used for inspecting boilers, turbines, and heat exchangers.

India has witnessed a significant growth in the demand for PAUT services due to its numerous advantages and applications. Several testing service providers in India offer PAUT inspection services to cater to the growing needs of industries. These service providers use advanced PAUT equipment and employ trained technicians who are proficient in operating and interpreting the results from PAUT systems.

When selecting a PAUT testing service provider in India, it is important to consider factors such as experience, expertise, and certifications. The service provider should have a proven track record in performing PAUT inspections and should be equipped with state-of-the-art equipment. Additionally, they should have a team of qualified technicians who are trained in conducting PAUT inspections and interpreting the results accurately.

In conclusion, PAUT inspection services in India have gained immense popularity due to their speed, efficiency, and accuracy. The ability to detect both surface and subsurface defects makes PAUT an ideal choice for material testing in various industries. With the growing demand for reliable non-destructive testing methods, PAUT is expected to continue being widely used in India's industrial sectors.

If you are looking for testing service in Delhi/NCR, India worldwide. Look no further now, contact us : +91-9810059715, +91-9953489999 . Our Address is F 22-23, Site C, Surajpur Industrial Area, UPSIDC, Greater Noida, 201306.

#paut inspection#paut testing#non destructive testing#ultrasonic testing equipment#material testing#stainless steel welding#steel welding

0 notes

Text

Non-Destructive Testing (NDT) is a pivotal technique that has revolutionised quality control and safety assessment across various industries in India. As the nation continues to grow and develop in sectors like infrastructure, manufacturing, aerospace, and energy, the importance of NDT cannot be overstated. This article delves into the significance of NDT for India, exploring its applications, benefits, and how it can contribute to the country’s development.

0 notes

Text

Enhance Safety with Professional Penetrant Inspection Services

Protect your equipment and components with MyNDT’s professional Penetrant Inspection. Our non-destructive testing method efficiently identifies surface defects, such as cracks and leaks, in non-porous materials. Trust our certified technicians to provide clear, accurate results that help you stay ahead of potential failures.

#ndt inspection services#ndt testing#non destructive inspection#non destructive testing#ndttraining#ndt#non destructive entry#business#services#Penetrant Inspection

0 notes

Text

As contact lens manufacturing continues to evolve, the VeriPac system stands as a testament to the power of technology in driving progress and innovation. Its impact extends beyond the manufacturing floor, influencing the standards of quality assurance and setting new benchmarks for excellence in product inspection. With its proven track record of reliability and precision, the VeriPac system remains an indispensable tool for ensuring the quality and safety of contact lenses, ultimately enhancing the overall experience for consumers worldwide.

0 notes

Text

Certified Dye Penetrant Inspection Services in Pune

Here at Integrated NDE, we take great pride in offering the best Dye Penetrant Inspection (DPI) services in Pune. Consider DPI as a material detective, able to uncover hidden fissures and defects that are not apparent to the unaided eye. From metals to ceramics, this non-destructive testing technique works flawlessly on a variety of materials.

Our DPI Process:1) Surface washing: To make sure the surface is clear of any impurities that could conceal flaws, we begin by carefully washing it. Using Penetrant: After that, a dye that is visible or fluorescent is applied. This dye uses capillary action to infiltrate into surface-breaking defects. 3) Dwell Time: The penetrant is allowed to fully permeate any flaws by remaining on the surface for a predetermined amount of time.

4) Removing Extra Penetrant: To ensure that the dye inside the flaws remains in situ, excess dye is carefully removed. 5) Developer Application: To extract the penetrant from the defects and produce visible signs, a developer is applied. 6) Inspection: After that, our knowledgeable inspectors look over the surface in the right lighting to look for any flaws. Why Opt for DPI?

Why Choose DPI? DPI is a flexible, affordable, and extremely sensitive method of detecting surface-breaking faults, even at the tiniest ones. It is a dependable option for regular inspections in a number of sectors, such as industrial, automotive, and aerospace.

Our Expertise: Our staff at Integrated NDE has received the greatest certifications and training available. We guarantee the integrity and safety of your components by using the most up-to-date methods and tools to deliver accurate and trustworthy findings.

Applications: DPI is perfect for checking machined items, castings, forgings, and welds. Our services are made to satisfy the demanding needs of many sectors, whether they be for automotive or aerospace components.

Get in touch with us: Go to Integrated NDE for reliable Dye Penetrant Inspection services in Pune. In each inspection, we promise to provide quality and dependability. For additional information, see our article on dye penetrant inspection.

At Integrated NDE, we take the highest care to ensure the safety and soundness of your components, treating them like a detective uncovering buried secrets.

#dye penetrate inspection#dye penetrate testing#dye penetrate inspection services in pune#non destructive testing#destructive testing#non destructive weld testing#ndt inspection services#"non destructive inspection#non destructive testing radiography#ndt testing

0 notes

Text

Integrated NDE Solution in Pune: Precision in Ferrite Testing for Austenitic and Duplex Stainless Steels

In the realm of industrial manufacturing and engineering, the integrity and quality of materials are crucial. Non-destructive testing (NDT) methods, such as ferrite testing, play a significant role in ensuring the reliability of materials, especially in critical applications involving austenitic stainless steel and duplex stainless steels. Integrated NDE Solution in Pune excels in providing comprehensive NDT services, with a specialized focus on ferrite testing. This article delves into the intricacies of ferrite testing, highlights its benefits, and explores the cutting-edge services and equipment offered by Integrated NDE Solution.

Understanding Ferrite Testing

Ferrite testing is a non-destructive method used to measure the ferrite content in austenitic and duplex stainless steels. Ferrite content is a critical parameter in determining the mechanical properties, corrosion resistance, and weldability of these materials. The presence of an appropriate amount of ferrite ensures the material’s optimal performance in service environments, particularly in applications involving high temperatures and corrosive media.

Importance of Ferrite Content

Corrosion Resistance: Correct ferrite content enhances the corrosion resistance of stainless steels.

Mechanical Properties: Ferrite influences the toughness and strength of the material.

Weldability: Optimal ferrite levels prevent issues such as hot cracking during welding.

Thermal Stability: Ferrite content affects the material’s behavior under high temperatures.

How Ferrite Testing Works

Ferrite testing typically involves using a ferrite meter or a magnetic induction device to measure the ferrite content in stainless steel materials. The process is straightforward and involves the following steps:

Surface Preparation: The surface of the sample is cleaned to ensure accurate readings.

Calibration: The ferrite meter is calibrated using standard reference materials with known ferrite content.

Measurement: The probe of the ferrite meter is placed on the surface of the sample, and the ferrite content is read directly from the device.

Analysis: The results are analyzed to determine if the ferrite content is within the acceptable range for the specific application.

Benefits of Ferrite Testing

Non-Destructive: Does not damage or alter the sample being tested.

Quick and Accurate: Provides immediate and precise measurements of ferrite content.

Versatile: Applicable to both austenitic and duplex stainless steels.

Portable: Ferrite meters are portable, allowing for on-site testing.

Cost-Effective: Relatively low cost compared to other analytical techniques.

Integrated NDE Solution in Pune: Pioneers in Non-Destructive Testing

Integrated NDE Solution in Pune is a leader in the field of non-destructive testing, offering a broad spectrum of NDT services, including ferrite testing. Their expertise, state-of-the-art equipment, and commitment to quality make them a trusted partner for industries requiring reliable inspection services.

Comprehensive NDT Services Offered

Ferrite Testing

Magnetic Particle Inspection (MPI)

Ultrasonic Testing (UT)

Radiographic Testing (RT)

Liquid Penetrant Testing (LPT)

Eddy Current Testing (ECT)

Visual Inspection (VI)

Industries Served

Integrated NDE Solution in Pune caters to a diverse array of industries, including:

Aerospace: Ensuring the safety and reliability of critical components.

Automotive: Inspecting critical parts to prevent failures.

Construction: Verifying the integrity of structural components.

Oil and Gas: Ensuring the reliability of pipelines and equipment.

Power Generation: Maintaining the integrity of infrastructure components.

Chemical Processing: Ensuring the material integrity in corrosive environments.

Ferrite Testing in Action

Case Study: Power Generation Component Inspection

In the power generation industry, the integrity of components such as pressure vessels and heat exchangers is paramount. Integrated NDE Solution was approached by a leading power plant operator to conduct ferrite testing on critical components made of austenitic stainless steel. The ferrite content was measured to ensure it met the required specifications, preventing issues related to thermal fatigue and corrosion.

Case Study: Duplex Stainless Steel Pipeline Inspection

A major oil and gas company required ferrite testing for duplex stainless steel pipelines to ensure they could withstand the harsh conditions of subsea environments. Integrated NDE Solution employed their advanced ferrite meters to measure the ferrite content accurately. The results confirmed that the pipelines had the optimal ferrite content, ensuring their durability and resistance to stress corrosion cracking.

Advanced Ferrite Testing Equipment

Integrated NDE Solution in Pune utilizes the latest ferrite testing equipment to ensure the highest level of accuracy and reliability in their inspections. Some of the advanced equipment includes:

Ferrite Meters: State-of-the-art devices that provide accurate and repeatable measurements of ferrite content.

Calibration Standards: Reference materials with certified ferrite content used to calibrate ferrite meters for precise readings.

Portable Ferrite Meters: Lightweight and portable meters that allow for convenient on-site testing.

The Role of Certified Technicians

The effectiveness of ferrite testing largely depends on the expertise of the technicians conducting the tests. Integrated NDE Solution in Pune employs certified technicians who undergo rigorous training and continuous professional development. Their skills and knowledge ensure that clients receive the highest quality of service.

Commitment to Quality and Safety

Integrated NDE Solution in Pune is dedicated to maintaining the highest standards of quality and safety. They adhere to international standards and best practices, ensuring that all inspections are performed with utmost precision and reliability. This commitment to excellence has earned them a stellar reputation in the industry.

Customer-Centric Approach

At Integrated NDE Solution in Pune, customer satisfaction is a top priority. They work closely with clients to understand their specific needs and tailor their services accordingly. Whether it’s a small-scale inspection or a large industrial project, they provide personalized solutions that meet the highest standards of quality and reliability.

Why Choose Integrated NDE Solution in Pune?

Expertise: Extensive experience and technical know-how in NDT services.

Technology: Utilization of the latest and most advanced testing equipment.

Quality: Commitment to providing accurate and reliable results.

Customer Service: Focus on building long-term relationships through excellent service.

Compliance: Adherence to all relevant industry standards and regulations.

Conclusion

In industries where precision and reliability are non-negotiable, Integrated NDE Solution in Pune stands out as a leader in non-destructive testing, particularly in ferrite testing for austenitic and duplex stainless steels. Their dedication to quality, use of advanced technology, and customer-centric approach make them the go-to choice for businesses across various sectors. By partnering with Integrated NDE Solution, companies can ensure the integrity and safety of their materials and components, safeguarding their operations and reputation.

Integrated NDE Solution in Pune continues to set the standard for excellence in non-destructive inspection. Their expertise in ferrite testing and other NDT services is pivotal in industries where safety and reliability are crucial. As technology advances and industries evolve, Integrated NDE Solution remains at the forefront, offering unparalleled service and support to their clients.

In conclusion, for businesses seeking the highest standards in ferrite testing, non-destructive inspection, and comprehensive NDT services, Integrated NDE Solution in Pune is the trusted partner that delivers results. Their innovative approach, advanced technology, and unwavering commitment to quality ensure that every inspection meets the stringent requirements of today’s demanding industrial environments.

0 notes

Text

Non Destructive Testing | 4 Biomed

NDT, is a method of testing and analysis that is used in the manufacturing industry to evaluate the properties of a material, component, structure.

0 notes