#Nilotinib

Explore tagged Tumblr posts

Text

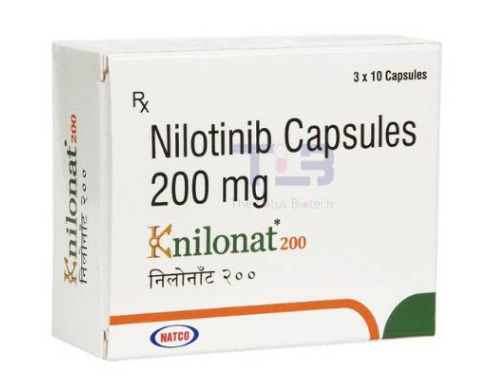

Knilonat is a chemotherapeutic drug used to treat chronic myeloid leukemia (CML). It contains the active salt nilotinib which successfully treats blood cancer by blocking certain proteins linked to uncontrolled white blood cell growth.

Enquire Now: https://snip.ly/383ub9

#Nilotinib#Nilotinib 200 MG#Oncology#Oncology Medicine#Nilotinib Capsules#Knilonat 200 MG#Knilonat 200mg Nilotinib Capsules#pharmaceutical exporter#pharmaceutical wholesaler#pharmaceutical supplier#pharmaceutical distributor#thelotusbiotech#tlb

0 notes

Text

Challenges Faced by Nilotinib API Manufacturers in India: Regulatory, Sourcing, and Market Competition

India has long been recognized as a hub for pharmaceutical manufacturing, particularly in the production of Active Pharmaceutical Ingredients (APIs). One of the significant APIs produced in India is Nilotinib, a critical component used in the treatment of chronic myeloid leukemia (CML). While the Indian pharmaceutical sector is thriving, manufacturers of Nilotinib API face a unique set of challenges that span regulatory compliance, raw material sourcing, and intense market competition.

This article delves into these key challenges and explores how Nilotinib API manufacturers in India are navigating this complex landscape.

1. Regulatory Challenges: Meeting Stringent Global Standards

One of the most pressing challenges faced by Nilotinib API manufacturers in India is adhering to stringent global regulatory requirements. The production of Nilotinib, like any API, must meet high standards of quality, safety, and efficacy, set by regulatory bodies such as the United States Food and Drug Administration (FDA), the European Medicines Agency (EMA), and India’s own Central Drugs Standard Control Organization (CDSCO).

However, the complexity of these regulations can pose significant hurdles for manufacturers, especially for those looking to export Nilotinib API to international markets. Some of the major regulatory challenges include:

Quality Control and Documentation: Regulatory bodies require exhaustive documentation for every step of the API manufacturing process, from raw material sourcing to production and final testing. Failure to comply with these documentation requirements can lead to costly delays, product recalls, or even the suspension of production licenses.

Good Manufacturing Practice (GMP) Compliance: Indian API manufacturers must ensure that their facilities comply with GMP standards, which are crucial for maintaining product safety and efficacy. Regular audits from international regulators are common, and even minor deviations from GMP guidelines can result in the loss of market access.

Navigating Multiple Regulatory Frameworks: For manufacturers that export to various regions, staying compliant with different regulatory frameworks is a challenging task. Each regulatory authority may have its own specific guidelines, and meeting these varying requirements adds an additional layer of complexity.

Despite these challenges, Indian Nilotinib API manufacturers are investing in advanced quality control systems and automated production techniques to maintain compliance and avoid costly regulatory setbacks.

2. Sourcing of Raw Materials: Dependency on Imports

Another significant challenge for Nilotinib API manufacturers in India is the sourcing of raw materials, particularly key starting materials (KSMs) and intermediates that are crucial for Nilotinib production. A considerable portion of these raw materials is imported, primarily from China, making Indian manufacturers highly dependent on international supply chains.

This reliance on imports brings several challenges:

Supply Chain Disruptions: Geopolitical tensions, trade restrictions, and events like the COVID-19 pandemic have highlighted the vulnerability of global supply chains. Any disruptions in the availability of raw materials can lead to production delays and increased costs for Indian manufacturers.

Rising Costs: The cost of importing raw materials has been steadily increasing due to factors such as fluctuating currency exchange rates, inflation, and rising shipping costs. These increased input costs make it difficult for Indian manufacturers to maintain competitive pricing for Nilotinib API, especially when margins are already tight due to intense market competition.

Quality Assurance: Ensuring the quality and purity of imported raw materials is critical. If the KSMs or intermediates are not up to standard, it can result in subpar batches of Nilotinib API, leading to potential regulatory issues or product recalls.

To mitigate these risks, some Indian manufacturers are exploring the possibility of localizing their raw material supply chains by developing domestic production capabilities for KSMs and intermediates. However, this transition is complex and requires significant investment in R&D and infrastructure.

3. Market Competition: Pressure on Pricing and Innovation

The Indian pharmaceutical industry is known for its highly competitive nature, and Nilotinib API manufacturing is no exception. With several players vying for a share of the global API market, manufacturers are under constant pressure to offer competitive pricing while maintaining high product quality.

Key challenges in market competition include:

Price Wars: The global market for APIs, including Nilotinib, is highly price-sensitive. Indian manufacturers often find themselves competing with counterparts from countries like China, which may have lower production costs due to economies of scale or government subsidies. This intense competition can drive down prices, reducing profit margins and making it difficult for smaller players to sustain their operations.

Pressure to Innovate: In addition to pricing pressures, manufacturers are expected to invest in innovation to stay ahead of the competition. This includes developing more efficient manufacturing processes, improving the purity and yield of Nilotinib API, and exploring new delivery mechanisms or formulations. However, innovation requires substantial investment in R&D, which can be a financial strain for companies already facing slim margins.

Maintaining Quality at Scale: Scaling up production to meet growing demand while maintaining consistent quality is another significant challenge. As production volumes increase, so do the complexities involved in ensuring uniformity and compliance with stringent regulatory standards.

Conclusion

Manufacturing Nilotinib API in India is a lucrative yet challenging endeavor. From navigating complex regulatory requirements to securing reliable raw material supplies and staying competitive in a crowded market, Indian API manufacturers face a series of obstacles that require careful management and strategic planning.

To thrive in this environment, manufacturers must invest in quality control, explore ways to localize raw material sourcing, and adopt innovative technologies to streamline production processes. By addressing these challenges head-on, Indian Nilotinib API manufacturers can continue to play a pivotal role in the global pharmaceutical supply chain while maintaining their competitive edge.

0 notes

Text

0 notes

Text

Quality Control and Regulatory Compliance in Nilotinib API Manufacturing

In the pharmaceutical industry, ensuring the highest standards of quality control and regulatory compliance is critical, particularly when manufacturing Active Pharmaceutical Ingredients (APIs) like Nilotinib. Nilotinib is used in the treatment of chronic myeloid leukemia, and any compromise in its quality can have serious implications for patient health. Therefore, manufacturers must adhere to stringent quality control processes and meet rigorous regulatory standards to ensure the safety and efficacy of their products.

The Importance of Quality Control

Quality control (QC) in the manufacturing of Nilotinib API is paramount. This process involves rigorous testing and monitoring to ensure that the API meets all specified criteria for identity, purity, potency, and safety. Effective quality control processes help to detect and eliminate any defects or inconsistencies that may arise during production.

A robust QC system includes a variety of testing methodologies, such as:

Raw Material Testing: Ensuring that all raw materials used in the production of Nilotinib meet predefined quality standards before they enter the manufacturing process.

In-Process Testing: Continuous monitoring of the manufacturing process to ensure that each step meets quality requirements. This can include checks for pH levels, temperature controls, and intermediate product specifications.

Finished Product Testing: Comprehensive testing of the final API product to confirm its compliance with predefined quality attributes, including assay, impurity levels, and dissolution properties.

Regulatory Compliance Standards

Pharmaceutical manufacturers must comply with various regulatory standards set by health authorities such as the U.S. Food and Drug Administration (FDA), European Medicines Agency (EMA), and other international regulatory bodies. These regulations are designed to ensure that APIs, including Nilotinib, are produced consistently and are safe for use.

Key regulatory requirements include:

Current Good Manufacturing Practices (cGMP): These are guidelines provided by regulatory agencies that outline the standards for manufacturing, testing, and quality assurance. Adhering to cGMP ensures that products are consistently produced and controlled to the quality standards appropriate for their intended use.

ICH Guidelines: The International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH) provides guidelines that harmonize the regulation of pharmaceuticals across Europe, Japan, and the United States. These guidelines cover aspects such as quality, safety, efficacy, and multidisciplinary topics.

Regulatory Inspections: Regular inspections by regulatory authorities ensure compliance with cGMP and other regulations. These inspections can include reviews of manufacturing processes, quality control systems, and documentation practices.

Best Practices for Ensuring High-Quality and Compliant API Manufacturing

To maintain high standards of quality control and regulatory compliance, Nilotinib API manufacturers can adopt several best practices:

Implementing a Comprehensive Quality Management System (QMS): A QMS integrates all quality-related processes and procedures, ensuring that quality control and compliance are maintained throughout the manufacturing lifecycle. This includes document control, training, corrective and preventive actions (CAPA), and regular internal audits.

Training and Development: Continuous training and development programs for employees ensure that they are knowledgeable about the latest quality control techniques and regulatory requirements. This helps in maintaining a culture of quality and compliance within the organization.

Supplier Quality Management: Establishing robust relationships with suppliers and conducting regular audits ensures that raw materials meet the necessary quality standards. This reduces the risk of contamination or variability in the final product.

Utilizing Advanced Analytical Techniques: Employing state-of-the-art analytical techniques, such as high-performance liquid chromatography (HPLC) and mass spectrometry, enhances the accuracy and reliability of quality testing. These techniques help in the precise identification and quantification of impurities and active components.

Continuous Improvement: Implementing a culture of continuous improvement, where feedback from quality control processes and regulatory inspections is used to enhance manufacturing practices. This can involve process optimization, technological upgrades, and adopting industry best practices.

Conclusion

Quality control and regulatory compliance are critical components of Nilotinib API manufacturing. By implementing robust quality management systems, adhering to regulatory guidelines, and adopting best practices, manufacturers can ensure that their products meet the highest standards of safety and efficacy. This not only protects patient health but also enhances the manufacturer's reputation and trustworthiness in the pharmaceutical industry.

0 notes

Text

𝐀𝐛𝐬𝐭𝐫𝐚𝐜𝐭: Nilotinib is a highly selective second-generation Bcr-Abl tyrosine kinaseInhibitor (#tki s), which is effective in #patients with #philadelphia chromosome–positive #ChronicMyeloidLeukemia (#CML). #tyrosine kinase inhibitors have broadly similar types of non-hematological adverse #sideeffects (AES), but some of the AES are specific to one drug compared to the others.

View more here @ https://symbiosisonlinepublishing.com/hematology/hematology20.php

#symbiosisonlinepublishing #hematology #hematologia #hematologist #skinrash #leukemia #chronicillness #chronicillnessawareness #journalwithme #journals #journal #pubmed #peerreviewed #peerreview #OpenAccess

0 notes

Text

Acoustic Neuroma Market Growth Anticipated | Oticon Medical, Novartis, Med-El Corporation, Elekta, Natus Medical, Amgen, AstraZeneca, Siemens Healthcare

To strategically aid Acoustic Neuroma companies developing drugs for Acoustic Neuroma, DelveInsight launched a report titled as “Acoustic Neuroma Market Insight Epidemiology and Market Forecast, 2032”. This comprehensive report delves into epidemiology based market analysis, providing a roadmap for success in the dynamic landscape of Acoustic Neuroma market.

Get a free sample of “Acoustic Neuroma Market Report”

Acoustic Neuroma Market Report’s Key Highlights:

Acoustic Neuroma market is expected to grow during the study period in 7MM.

Key Acoustic Neuroma Companies: Oticon Medical, Novartis Pharmaceuticals, Med-El Corporation, Elekta, Natus Medical Incorporated, Amgen, AstraZeneca, Siemens Healthcare, and others.

Acoustic Neuroma is estimated to affect 1 in 100,000 people in the general population

Acoustic Neuroma is responsible for 6 in 100 cases of brain tumors

The prevalence of Acoustic Neuroma is more common in middle-aged adults and rare in children

Acoustic Neuroma tends to affect the people aged 30 to 6 and usually has no obvious cases, neither there are any symptoms of cancer in the early stages.

The Acoustic Neuromamarket is expected to surge due to the disease’s increasing prevalence and awareness during the forecast period. Furthermore, launching various multiple-stage Acoustic Neuroma pipeline products will significantly revolutionize the Acoustic Neuroma market dynamics

Acoustic Neuroma Country based Treatment Analysis:

The Acoustic Neuroma treatment market report provides treatment regimen across the 7MM. It will help companies to analyse the practices followed across 7MM, patient journey and advances in Acoustic Neuroma Therapies that have the potential to transform treatment paradigms and improve patient outcomes.

Acoustic Neuroma is a slowly growing non-cancerous tumor that forms along the branches of the eighth cranial nerve. These nerves start from the brain to the inner ear and to other divisions of the body that plays an important role in healing and balancing the body.

If Acoustic Neuroma is diagnosed in the early stages then the tumor can be stopped from further growing, but in case the tumor has already gone bigger than it can cause a life-threatening build-up of fluid in the brain.

Acoustic Neuroma Symptoms:

The symptoms of Acoustic Neuroma includes a gradual loss in hearing, ringing in the affected ear, dizziness, difficulty in balancing, facial numbness and weakness

Download the report to understand which factors are driving Acoustic Neuroma epidemiology trends @ Acoustic Neuroma Epidemiology Forecast

Acoustic Neuroma Epidemiology Insights:

The report proffers historical and forecasted epidemiology insights that helps to understand the target patient population for Acoustic Neuroma. The analysis is from 2019-2032, providing insights how the patient trends are going to shape the market dynamics. Further, the epidemiology is segmented to provide in-depth analysis of patient pools allowing companies to understand their target patient’s pools. The epidemiology in report is segmented as:

Acoustic Neuroma Epidemiology Segmentation:

Total Prevalence of Acoustic Neuroma

Prevalent Cases of Acoustic Neuroma by severity

Gender-specific Prevalence of Acoustic Neuroma

Diagnosed Cases of Episodic and Chronic Acoustic Neuroma

“Assessments as per DelveInsight’s analysts shows that the prevalence of Acoustic Neuroma is more common in middle-aged adults and rare in children”

Acoustic Neuroma Pipeline Therapies:

Nilotinib

Aspirin

Bevacizumab

Gentamicin

Axitinib

Emerging Acoustic Neuroma drugs Uptake:

In June 2023: A clinical trial is expected to initiate with 36 participants to evaluate the efficacy of microsurgical resection of vestibular schwannoma and stereotactic radiosurgery. The trial is sponsored by the Medical College of Wisconsin, United States.

In May 2022: The Brain Foundation, Australia, funded a project led by researchers at the University of Newcastle to develop an innovative target therapy for treating acoustic neuroma.

To know more about Acoustic Neuroma companies working in the treatment market, visit @ https://www.delveinsight.com/sample-request/acoustic-neuroma-market

Acoustic Neuroma Market Forecast:

The research includes a thorough analysis of the past and projected markets for Acoustic Neuroma, which includes pharmacological outreach in the 7MM nations.

The dynamics of the Acoustic Neuroma market are anticipated to change in the coming years owing to the expected launch of emerging therapies such as Bevacizumab, Axitinib, and others during the forecasted period 2019-2032.

Rising prevalence, increasing prevalence, less competition for upcoming therapies and Companies shifting their focus to this area, despite low awareness of the disease are fuelling the Acoustic Neuroma Market.

Discover more about therapies set to grab major Acoustic Neuroma market share @ https://www.delveinsight.com/sample-request/acoustic-neuroma-market

DelveInsight’s report offers comprehensive insights, market analysis, and forecasts aiding leading companies in strategic decision-making for the Acoustic Neuroma market landscape.

Gain Competitive Edge in Indication Market: Understand the current landscape of the Acoustic Neuroma market, including the competitive environment, key companies developing drugs for Acoustic Neuroma, and their strategies. By analyzing Acoustic Neuroma market dynamics, treatment approaches, and emerging therapies, stakeholders can identify opportunities to position themselves effectively, gaining a competitive edge over others.

Identify Market Gaps and indication market opportunities: Analysing Acoustic Neuroma epidemiological trends, country wise patient journeys and existing treatment practices can helps in identifying gaps and opportunities within the Acoustic Neuroma market. This involves recognizing areas where current Acoustic Neuroma treatments may be insufficient or where there is an unmet need. The Acoustic Neuroma market report is curated by taking account of various KOLs dealing with Acoustic Neuroma. Identifying these gaps allows stakeholders to explore new therapeutic avenues, potentially leading to the development of novel treatments that address specific Acoustic Neuroma market needs and price their emerging products strategically to gain a competitive edge.

Strategic decision making : Armed with insights from epidemiological and market forecasts, stakeholders can make informed and strategic decisions. This may involve deciding on research and development investments, portfolio expansion, pricing – reimbursement strategies, partnerships, or other strategic moves. Understanding the Acoustic Neuroma market dynamics enables stakeholders to align their goals with the prevailing trends and future projections.

Plan RoadMap to Success : Through this report the leading Acoustic Neuroma companies can set short-term and long-term goals, define strategies for market penetration, and outline steps for product development or market expansion. A well-informed roadmap ensures that stakeholders navigate the complexities of the Acoustic Neuroma market with clarity and purpose.

Related Reports

Parkinson’s Disease Epidemiology Forecast

Parkinson’s Disease Epidemiology Forecast – 2032 report delivers an in-depth understanding of the disease, historical and forecasted epidemiology, and Parkinson’s disease epidemiology trends.

Parkinson’s Disease Pipeline

Parkinson’s Disease Pipeline Insight – 2023 report provides comprehensive insights about the pipeline landscape, pipeline drug profiles, including clinical and non-clinical stage products, and the key Parkinson’s disease companies, including Cerevel Therapeutics, Inhibikase Therapeutics, Neuraly, Peptron, Biogen, Roche, Brain Neurotherapy Bio, Inc., Modag, Annovis Bio Inc., BioVie Inc., United Neuroscience Ltd., Luye Pharma Group, AbbVie, UCB Biopharma SRL, InnoMedica Schweiz AG, Integrative Research Laboratories AB, H. Lundbeck A/S, Shanghai WD Pharmaceutical Co., Ltd., Cerevance Beta, Inc., Nobilis Therapeutics Inc., BlueRock Therapeutics, Taiwan Mitochondrion Applied Technology Co., Ltd., among others.

Psychosis in Parkinson’s and Alzheimer’s Disease Market

Psychosis in Parkinson’s and Alzheimer’s Disease Market Insights, Epidemiology, and Market Forecast – 2032 report delivers an in-depth understanding of the disease, historical and forecasted epidemiology, as well as the market trends, market drivers, market barriers, and key psychosis in Parkinson’s and Alzheimer’s disease companies, including Sunovion Pharmaceuticals, Karuna Therapeutics, Vanda Pharmaceuticals, Suven Life Sciences, Enterin, Intra-Cellular Therapies, Merck Sharp & Dohme, among others.

Parkinson’s Disease-Related Dementia Market

Parkinson’s Disease-Related Dementia Market Insights, Epidemiology, and Market Forecast – 2032 report delivers an in-depth understanding of the disease, historical and forecasted epidemiology, as well as the market trends, market drivers, market barriers, and key Parkinson’s disease-related dementia companies, including AbbVie, UCB Biopharma SRL, InnoMedica Schweiz AG, Integrative Research Laboratories AB, H. Lundbeck A/S, Shanghai WD Pharmaceutical Co., Ltd., Cerevance Beta, Inc., among others.

Other Trending Reports

Foot And Ankle Devices Market | Hepatitis B Virus Market | Image Guided Surgery Devices Market | Bone Anchored Hearing Systems Market | Alopecia Aerata Market | Pressure Ulcers Market Size | Alopecia Areata Market | Brain/cranial Implants Market | Global Electrophysiology Devices Market | Abetalipoproteinemia Market | Alopecia Market | Hearing Aid Devices Market | Hemodynamic Monitoring Systems Market | Neurovascular Devices Market | Parkinson’s Disease Market | Adult Growth Hormone Deficiency Market | Pulse Oximeters Market | Automated External Defibrillators Market | Energy Based Aesthetic Devices Market | Prefilled Syringes Market | Scleroderma Market | Human Papilomavirus Market | Capnography Device Market | Hyperuricemia Market | Atherectomy Devices Market | Xerostomia Market | Defibrillators Market | Blood Glucose Monitoring Systems Market | Acoustic Neuroma Market

Explore Our Success Story on Building an Interactive Competitive Intelligence Dashboard for HR+ HER2- Breast Cancer Market Landscape. Download our Oncology Competitive Intelligence Case study!

About DelveInsight

DelveInsight is a leading Healthcare Business Consultant, and Market Research firm focused exclusively on life sciences. It supports Pharma companies by providing comprehensive end-to-end solutions to improve their performance.

It also offers Healthcare Consulting Services, which benefits in market analysis to accelerate the business growth and overcome challenges with a practical approach.

Media Contact

Company Name: DelveInsight Business Research LLP

Contact Person: Ankit Nigam

Assistant Manager Marketing

Email: [email protected]

Website: https://www.delveinsight.com/consulting

0 notes

Text

Upholding Quality Standards: Best Practices in Regulatory Compliance Among Nilotinib API Manufacturers

In the pharmaceutical industry, ensuring stringent quality assurance and adherence to regulatory standards are paramount, especially for manufacturers of active pharmaceutical ingredients (APIs) like Nilotinib. The production of Nilotinib API involves intricate processes that demand rigorous quality control measures and compliance with stringent regulations to ensure the safety and efficacy of the final product.

Nilotinib, a tyrosine kinase inhibitor used in the treatment of chronic myeloid leukemia, requires meticulous manufacturing practices to meet international quality standards set by regulatory bodies such as the United States Food and Drug Administration (FDA), the European Medicines Agency (EMA), and other global health authorities.

Good Manufacturing Practices (GMP): Adherence to Good Manufacturing Practices is the cornerstone of quality assurance in pharmaceutical manufacturing. Nilotinib API manufacturers strictly adhere to GMP guidelines outlined by regulatory authorities. These guidelines encompass stringent protocols for facility design, equipment maintenance, personnel training, documentation, and quality control measures throughout the manufacturing process.

Stringent Quality Control Protocols: Quality control is an integral part of Nilotinib API manufacturing. Robust quality control protocols ensure that raw materials, intermediates, and the final API meet predefined quality parameters. Advanced analytical techniques, including high-performance liquid chromatography (HPLC), mass spectrometry, and nuclear magnetic resonance (NMR), are employed to verify the identity, purity, and potency of Nilotinib.

Risk Assessment and Management: Manufacturers conduct comprehensive risk assessments at various stages of the manufacturing process. Identifying potential risks, implementing mitigation strategies, and establishing contingency plans ensure that the quality and safety of Nilotinib API remain uncompromised. Continuous monitoring and periodic reassessment of risks contribute to a proactive approach in maintaining quality standards.

Documentation and Traceability: Accurate and comprehensive documentation is crucial in demonstrating compliance with regulatory requirements. Manufacturers maintain detailed records of all manufacturing processes, including batch records, analytical data, validation reports, and stability studies. Complete traceability ensures transparency and accountability throughout the production chain.

Regulatory Compliance Audits and Inspections: Regular audits and inspections by regulatory agencies and internal quality assurance teams are essential components of quality assurance. Nilotinib API manufacturers undergo thorough audits to assess compliance with GMP regulations and other relevant standards. Adherence to these standards is crucial for obtaining and maintaining product approvals and certifications.

Continuous Improvement Initiatives: Embracing a culture of continuous improvement drives innovation and excellence in Nilotinib API manufacturing. Manufacturers implement lean principles, Six Sigma methodologies, and other quality improvement techniques to optimize processes, reduce variability, and enhance overall efficiency while maintaining high-quality standards.

Supplier and Vendor Qualification: Ensuring the quality and reliability of raw materials and components is critical in Nilotinib API manufacturing. Manufacturers establish stringent criteria for selecting and qualifying suppliers and vendors. Thorough evaluation, qualification, and monitoring processes guarantee the integrity and quality of sourced materials.

In conclusion, Nilotinib API manufacturers adhere to stringent quality assurance and regulatory compliance measures to produce pharmaceutical ingredients that meet the highest standards of safety, efficacy, and quality. The commitment to these best practices, along with a steadfast dedication to continuous improvement, underscores the pharmaceutical industry's unwavering commitment to delivering safe and effective medications to patients worldwide.

0 notes

Text

0 notes

Text

Knilonat 150mg is a chemotherapeutic drug used to treat chronic myeloid leukemia (CML). It contains the active salt nilotinib which successfully treats blood cancer by blocking certain proteins linked to uncontrolled white blood cell growth.

Enquire Now: https://snip.ly/vqnv6l

#Nilotinib#Nilotinib (150mg)#Nilotinib Capsules#Knilonat 150mg#Knilonat 150mg Capsules#Nilotinib 150 Mg Capsules#Pharmaceutical Exporter#Pharmaceutical Importer#Pharmaceutical Wholesaler

0 notes

Text

Aurobindo Pharma shares rise 3% after subsidiary signs license for generic version of Nilotinib Capsules

CMLHope.Com http://dlvr.it/SrZWRk

0 notes

Text

0 notes

Text

Aurobindo Pharma shares rise 3% after subsidiary signs license for generic version of Nilotinib Capsules

CMLHope.Com http://dlvr.it/SrZJ7x

0 notes