#Multitek Technologies Delhi

Explore tagged Tumblr posts

Text

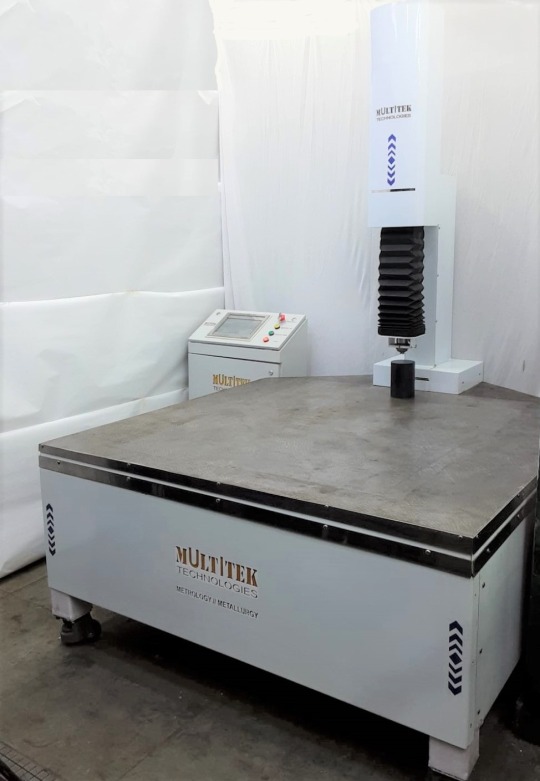

Exploring Multitek Technologies: Pioneers in Fully Automatic CNC Based Digital Rockwell Hardness Testing

The HR-600 Series challenges conventional thinking with its innovative design and versatile functionality, enabling a diverse range of measurements for hardness testing.

Exceed expectations and surpass limits. The top-tier CNC Rockwell Hardness Testing Machine offers a completely automated Rockwell hardness testing sequence.

The HR-600 Series consolidates the features of multiple preceding models.:

The new HR-600 Series revolutionizes hardness testing by supporting a wide range of methods, including Rockwell hardness testing, Brinell hardness testing, Brinell and Vickers depth measurement hardness testing, and even hardness testing of plastic materials—all within a single machine. This series expands the spectrum of available measurements.

Powered by Multitek's unique high-resolution scale load cell, the HR-600 Series offers precise test load feedback control. Its cutting-edge design not only enhances aesthetics but also ensures user-friendly operation. This innovative approach challenges traditional notions of hardness testing. Designed for both functionality and aesthetics, the HR-600 Series features a workpiece mounting table and a vertically mobile head, prioritizing ease of use. Every aspect of its design has been meticulously tailored for both functionality and visual appeal, embodying Multitek's pioneering spirit. Feel free to visit us at https://www.multitek.in drop an email at [email protected]

#metallurgy#metalography#rockwell hardness tester#multitek technologies#micro vicker#hardness tester#metrology#metal engineering#rockwell#Rockwell Hardness Tester#Digital Hardness Tester#Universal hardness Tester#Multitek Technologies Delhi#Metal Testing Machine

0 notes

Text

Multitek Technologies: Leading Provider of Microscope, Micro Vicker, Vicker, and Rockwell Hardness Tester Repair and Upgradation Services in Delhi

In the bustling city of Delhi, where technological advancements continue to reshape industries, Multitek Technologies has emerged as a trusted provider of repair and upgradation services for microscopes, Micro Vicker, Vicker, and Rockwell hardness testers. With their expertise and commitment to customer satisfaction, Multitek Technologies has established itself as a go-to destination for reliable and efficient solutions in the field of material testing equipment. In this article, we will explore the range of services offered by Multitek Technologies and highlight their contribution to enhancing the capabilities of scientific instruments.

Repair Services:

Multitek Technologies understands the critical role that microscopes and hardness testers play in various scientific and industrial applications. When these instruments malfunction or undergo wear and tear, it can hamper productivity and accuracy in testing processes. That's where Multitek Technologies steps in, providing comprehensive repair services to address any issues that arise.

Their team of skilled technicians possesses in-depth knowledge of various microscope models, Micro Vicker, Vicker, and Rockwell hardness testers. Equipped with state-of-the-art tools and diagnostic equipment, they diagnose problems with precision and efficiency. Whether it's repairing faulty components, resolving optical alignment issues, or addressing electronic malfunctions, Multitek Technologies ensures that the instruments are restored to their optimal working condition.

Upgradation Services:

To keep pace with advancing technology and meet the evolving needs of clients, Multitek Technologies offers upgradation services for microscopes, Micro Vicker, Vicker, and Rockwell hardness testers. Upgrading these instruments not only enhances their performance but also extends their lifespan, allowing users to benefit from the latest features and functionalities available in the market.

The skilled technicians at Multitek Technologies carefully assess the existing equipment and propose suitable upgradation solutions tailored to the specific requirements of each client. They provide recommendations on upgrading components such as lenses, illumination systems, stage controls, and measurement capabilities to improve accuracy, speed, and overall functionality. By collaborating with renowned manufacturers and suppliers, Multitek Technologies ensures that the upgraded instruments meet the highest standards of quality.

Quality Assurance and Timely Service:

Multitek Technologies prioritizes customer satisfaction and strives to deliver superior service at every step. Their commitment to quality is evident in their attention to detail and rigorous testing procedures. After repairing or upgrading an instrument, Multitek Technologies conducts comprehensive performance tests to verify its functionality and accuracy. This ensures that the instruments meet or exceed the original manufacturer's specifications, giving customers confidence in their reliability.

Additionally, Multitek Technologies understands the importance of timely service. They recognize that the downtime caused by a malfunctioning instrument can be costly and disruptive. Therefore, they endeavor to provide prompt turnaround times without compromising on the quality of their work. This commitment to efficiency has earned them a reputation for delivering reliable solutions within agreed-upon timelines.

Conclusion:

Multitek Technologies has become a trusted name in Delhi's scientific community, offering exceptional repair and upgradation services for microscopes, Micro Vicker, Vicker, and Rockwell hardness testers. With their skilled technicians, cutting-edge equipment, and dedication to customer satisfaction, Multitek Technologies ensures that scientific instruments are restored to their optimal performance or upgraded to meet the demands of modern research and industry. By choosing Multitek Technologies, customers can expect reliable, efficient, and timely service that enhances their equipment's capabilities and maximizes their productivity.

0 notes

Text

#Multitek#Multitek Technologies#MultitekTechnologies Reviews#Multitek Delhi#Metallurgy and Metrology

0 notes

Text

Rockwell Hardness Tester: A Comprehensive Guide by Multitek Technologies

What is Hardness Testing in Material Science and Engineering?

We at Multitek Technologies excited to share the knowledgebase on Rockwell Hardness Tester. In the world of material science and engineering, understanding the mechanical properties of materials is crucial for ensuring their quality and reliability in various applications. One of the key properties that engineers and manufacturers often need to measure is hardness. Hardness is defined as the resistance of a material to deformation, indentation, or scratching, and it plays a significant role in determining a material's suitability for specific uses.

Hardness testing is a widely used method for quantifying the hardness of materials. It involves applying a controlled force or pressure to the surface of a material and measuring the resulting indentation or penetration. There are several methods of hardness testing available, each with its own advantages and limitations. One of the most popular and widely used methods is the Rockwell hardness test.

Why Rockwell Hardness Tester?

The Rockwell hardness test is a non-destructive testing method used to measure the hardness of metallic materials. It is based on the depth of penetration of an indenter into the material under a specific load. The test is named after its inventor, Stanley P. Rockwell, who developed the method in the early 20th century.

The Rockwell hardness test is known for its simplicity, speed, and accuracy, making it suitable for a wide range of applications across various industries. It is particularly well-suited for quality control and materials testing in manufacturing environments.

What are the Principles of the Rockwell Hardness Tester?

The Rockwell hardness test works on the principle of measuring the depth of penetration of an indenter into the material under two loads: a minor load to establish a reference position (preliminary load), and a major load to complete the test (additional load). The difference in indentation depths between the two loads is used to calculate the Rockwell hardness number.

The Rockwell hardness scale is defined by a combination of the indenter type (diamond or ball) and the applied load. There are several Rockwell scales designated by letters, such as HRA, HRB, HRC, etc., each suitable for different types of materials and hardness ranges.

Components of a Rockwell Hardness Tester

A typical Rockwell hardness tester consists of several key components:

Indenter: The indenter is the tool that is pressed into the material to create the indentation. In Rockwell testing, the indenter can be either a diamond cone or a hardened steel ball, depending on the hardness scale being used.

Anvil: The anvil provides a stable surface against which the material being tested is placed. It ensures that the material is properly supported and prevents any deflection during the test.

Load Application System: The load application system applies the predetermined loads to the indenter. It typically consists of a mechanical or hydraulic mechanism that controls the application of the minor and major loads. Feel Free to Navigate about Multitek’s Other Products/Machines

Depth Measurement System: The depth measurement system accurately measures the depth of penetration of the indenter into the material under the applied loads. This measurement is crucial for calculating the Rockwell hardness number.

Display and Readout: The display and readout system provides the results of the hardness test in the form of Rockwell hardness numbers. It may include analog or digital indicators, depending on the model of the hardness tester.

Procedure for Performing a Rockwell Hardness Test

Performing a Rockwell hardness test involves the following steps:

Prepare the Specimen: Ensure that the surface of the specimen is clean, flat, and free from any contaminants or irregularities. Visit us to learn more about Multitek’s Calibration Services

Select the Indenter and Scale: Choose the appropriate type of indenter (diamond or ball) and the Rockwell scale based on the material being tested and the expected hardness range.

Apply the Preliminary Load: Apply the minor load to the indenter, which establishes a reference position on the specimen surface.

Apply the Additional Load: Apply the major load to the indenter, which creates the indentation on the specimen surface.

Release the Load: Release the major load while maintaining the minor load, allowing the indenter to partially retract from the specimen surface.

Measure the Depth of Penetration: Use the depth measurement system to accurately measure the depth of penetration of the indenter into the material.

Calculate the Rockwell Hardness Number: Calculate the Rockwell hardness number using the formula specified for the selected Rockwell scale.

Record the Results: Record the Rockwell hardness number along with relevant details such as the test conditions, specimen identification, and any observations.

Other Hardness Testing Machines available at Multitek Lab:

Micro Vickers or Universal Hardness Tester

Brinell hardness Testing (BHN & LCB)

Rockwell Hardness Testing (RMT-AL & RHT-LC1500-1A)

Rubber Hardness Testing Machines

Advantages of the Rockwell Hardness Test

The Rockwell hardness test offers several advantages over other hardness testing methods:

Versatility: The Rockwell hardness test can be used to measure the hardness of a wide range of metallic materials, including ferrous and non-ferrous metals.

Speed: The test is relatively quick to perform, allowing for high throughput in quality control and production environments.

Accuracy: The Rockwell hardness test provides accurate and repeatable results, making it suitable for precise materials testing and characterization.

Non-Destructive: Unlike some other hardness testing methods, such as the Brinell test, the Rockwell test is non-destructive, meaning it does not significantly alter the specimen's properties.

Ease of Use: The test is relatively simple to perform and requires minimal training, making it accessible to operators with varying levels of expertise. Reach out to us for Microscope and Hardness Testing Machine Repair and Up gradation Services!

Applications of the Rockwell Hardness Test

The Rockwell hardness test has widespread applications across various industries, including:

Manufacturing: The test is commonly used for quality control and materials testing in manufacturing processes, such as automotive, aerospace, and machinery production.

Metalworking: The test is used to assess the hardness of metal components, including forgings, castings, and heat-treated parts.

Engineering: The test helps engineers and designers select materials with suitable hardness properties for specific applications, such as tooling, dies, and machine components.

Construction: The test is used to evaluate the hardness of construction materials, such as steel beams, structural components, and concrete.

Research and Development: The test is employed in research and development activities to characterize the mechanical properties of new materials and alloys.

Visit us to know more about our Customized Rockwell Hardness Test Machines

According to Multitek Technologies the Rockwell hardness test is a versatile, accurate, and widely used method for measuring the hardness of metallic materials. Its simplicity, speed, and non-destructive nature make it an invaluable tool for quality control, materials testing, and engineering applications across various industries.

By understanding the principles, procedures, and applications of the Rockwell hardness test, engineers and manufacturers can ensure the quality, reliability, and performance of their products and components. Feel Free to Contact Us, if you have any question related to Rockwell Hardness Tester!

#rockwell hardness tester#rockwell tester#metallurgy#metrology#metalography#Metal Hardness Tester#Automotive Services#Multitek#Technologies#Delhi#India#engineering#mechanical#equipment#industrial#Machinary#Machine

0 notes

Text

#Micro Scope calibration Services#Rockbell Hardness Tester#Brinell Hardness Tester#Multitek Technologies#Delhi#Universal hardness Tester

0 notes

Text

Micro Vicker ans Hardness Testers Calibration Services By NABL Certified Lab in Delhi - Multitek Technologies

Micro Vicker and hardness testers are used to measure the hardness of materials. Calibration is necessary to ensure that the measurements are accurate and reliable. Calibration services are provided by NABL certified labs, which are accredited by the National Accreditation Board for Testing and Calibration Laboratories (NABL) in India. Multitek Technologies is a company that provides calibration services for micro Vicker and hardness testers in Delhi, India. They claim to be a NABL certified lab, which means that they have met the requirements for accreditation by NABL. Their services may include:

Calibration of micro Vicker and hardness testers

Verification of measurement accuracy

Adjustment of equipment as needed

Issuance of calibration certificates

It is important to have your micro Vicker and hardness testers calibrated regularly to ensure that they are providing accurate measurements. This can help to prevent errors in testing and ensure that your results are reliable. Feel Free to visit Us! https://www.multitek.in/calibration-services

#MicroVicker #HardnessTester #IndustrialEquipment #MechenicalEngineering #Automotive #Engineering #Metrology #Metallurgy #Metalography #Rockwell #Vicker #Brinell #Multitek #NABL #Calibration

0 notes

Text

youtube

Auto Focus Micro Vicker Hardness Tester Machine Manufactured by Multitek Technologies Delhi

1 note

·

View note

Text

Microscope Calibration Services from NABL Certified Lab in Delhi NCR Area.

If you are looking for microscope calibration services then you can contact to Multitek team, they have NABL certified lab and serving in calibration services for microscopes, hardness tester, profile projector and vision inpection machine at very competitive cost.

#calibration #engineering #instrumentation #iso #metrology #automation #flowmeter #technology #tuning #engineer #sensors #environmentalmonitoring #inspection #processcontrol #testequipment #controlsystem #testing #repair #fieldinstruments #datalogging #toolsofthetrade #fieldwork #protools #remotemonitoring #electrical #technicianlife #sparkylife #toolporn #cleanenvironment #laboratory

0 notes

Text

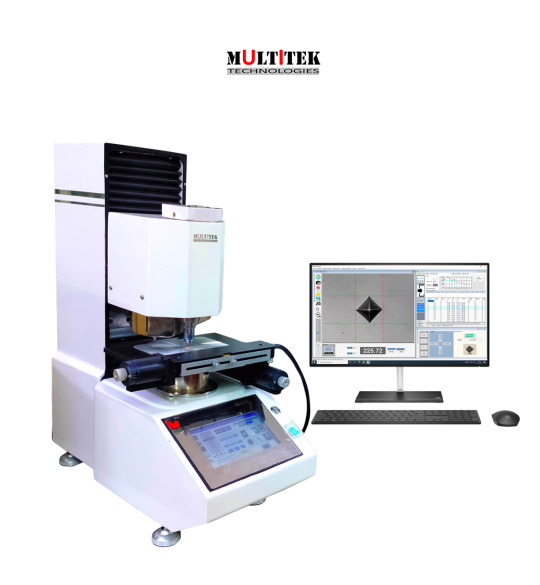

Multitek Technologies: The Leading Manufacturer of Micro Vicker Hardness Testers in New Delhi, India

Multitek Technologies is a leading manufacturer and supplier of Micro Vicker hardness testers in New Delhi, India. The company has been in the business of manufacturing and supplying high-quality testing equipment for more than a decade. They have a team of highly skilled professionals who are dedicated to providing their customers with the best quality products and services.

A Micro Vicker hardness tester is a device used to measure the hardness of materials. It is used in various industries such as automotive, aerospace, and manufacturing. The tester works by indenting a small diamond or tungsten carbide tip into the material and measuring the depth of the indentation. This measurement is then converted into a hardness value using a formula.

Multitek Technologies offers a wide range of Micro Vicker Hardness Testers to meet the needs of their customers. Their testers are designed to be accurate, reliable, and easy to use. They offer both manual and automatic testers, depending on the customer's requirements.

The manual testers are designed for basic hardness testing and are easy to operate. They come with a built-in microscope for easy viewing of the indentation. The testers are compact and can be easily transported from one location to another.

The automatic testers, on the other hand, are designed for high-volume testing and are more sophisticated. They come with advanced features such as automatic loading and unloading of samples, automatic depth measurement, and automatic calculation of hardness values. The testers are equipped with a computer interface for data transfer and analysis.

Multitek Technologies also offers customization options for their micro vicker hardness testers. They can customize the testers to meet the specific needs of their customers. They can modify the testers to test different types of materials, change the range of hardness values, and add additional features.

In addition to manufacturing and supplying micro vicker hardness testers, Multitek Technologies also provides calibration and repair services for their products. They have a team of trained technicians who can calibrate and repair the testers to ensure that they are functioning properly.

Multitek Technologies is committed to providing their customers with the best quality products and services. They have a strong reputation in the industry for their reliability, accuracy, and customer service. If you are looking for a micro vicker hardness tester manufacturer and supplier in New Delhi, India, Multitek Technologies is an excellent choice.

0 notes

Link

0 notes