#Motorcycle drivetrains

Explore tagged Tumblr posts

Text

Maintenance Tips: Keeping Your Drivetrain in Top Shape

https://gob.stayingalive.in/unleashing-the-thrills-of/maintenance-tips-keeping.html Maintaining your motorcycle’s drivetrain is crucial for optimal performance and longevity. Here are some practical tips to ensure your chain, belt, or shaft drive remains in excellent condition. Chain Drive Maintenance Lubrication: Regularly lubricate the chain to reduce friction and prevent rust. Tension…

View On WordPress

#automotive#Belt drive motorcycles#bike#cars#Chain drive motorcycles#Drivetrain technology#Electric motorcycles#Future motorcycle technology#Good Old Bandit#Gud Ol Bandit#Hybrid motorcycles#Lightweight materials#motorcycle#Motorcycle drivetrains#Motorcycle efficiency#Motorcycle maintenance#Motorcycle performance#News#Sanjay K Mohindroo#Sanjay Kumar Mohindroo#Sanjay Mohindroo#Shaft drive motorcycles#Smart drivetrains#Sustainable motorcycles#touring motorcycles

1 note

·

View note

Text

Motorcycle Drivetrain Market To Witness the Highest Growth Globally in Coming Years

The report begins with an overview of the Motorcycle Drivetrain Market 2025 Size and presents throughout its development. It provides a comprehensive analysis of all regional and key player segments providing closer insights into current market conditions and future market opportunities, along with drivers, trend segments, consumer behavior, price factors, and market performance and estimates. Forecast market information, SWOT analysis, Motorcycle Drivetrain Market scenario, and feasibility study are the important aspects analyzed in this report.

The Motorcycle Drivetrain Market is experiencing robust growth driven by the expanding globally. The Motorcycle Drivetrain Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Motorcycle Drivetrain Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing. Motorcycle Drivetrain Market Size, Share & Industry Analysis, By Fuel Type (Petrol, Electric, Others), By Propulsion Type (Chain Drive, Belt Drive, Shaft Drive), By Transmission Type (MT, AMT, AT) and Regional Forecast, 2022-2029

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/101893

Key Strategies

Key strategies in the Motorcycle Drivetrain Market revolve around optimizing production efficiency, quality, and flexibility. Integration of advanced robotics and machine vision technologies streamlines assembly processes, reducing cycle times and error rates. Customization options cater to diverse product requirements and manufacturing environments, ensuring solution scalability and adaptability. Collaboration with industry partners and automation experts fosters innovation and addresses evolving customer needs and market trends. Moreover, investment in employee training and skill development facilitates seamless integration and operation of Motorcycle Drivetrain Market. By prioritizing these strategies, manufacturers can enhance competitiveness, accelerate time-to-market, and drive sustainable growth in the Motorcycle Drivetrain Market.

Major Motorcycle Drivetrain Market Manufacturers covered in the market report include:

Some of the major companies that are present in the motorcycle drivetrain market include American Axle & Manufacturing Inc., ZF Friedrichshafen AG, GKN PLC, Borgwarner Inc., Showa Corporation, Schaeffler Group, Magna International Inc., Aisin Seki Co. Ltd., Dana Incorporated, and JTEKT Corporation among the other players.

Growing demand for lightweight drivetrains to improve fuel efficiency is also another factor which is anticipated to drive the motorcycle drivetrain market. Key manufacturers are hence, focusing on producing drivetrain, which is light in weight and enhances the performance of the vehicle.

Trends Analysis

The Motorcycle Drivetrain Market is experiencing rapid expansion fueled by the manufacturing industry's pursuit of efficiency and productivity gains. Key trends include the adoption of collaborative robotics and advanced automation technologies to streamline assembly processes and reduce labor costs. With the rise of Industry 4.0 initiatives, manufacturers are investing in flexible and scalable Motorcycle Drivetrain Market capable of handling diverse product portfolios. Moreover, advancements in machine vision and AI-driven quality control are enhancing production throughput and ensuring product consistency. The emphasis on sustainability and lean manufacturing principles is driving innovation in energy-efficient and eco-friendly Motorcycle Drivetrain Market Solutions.

Regions Included in this Motorcycle Drivetrain Market Report are as follows:

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Significant Features that are under offering and key highlights of the reports:

- Detailed overview of the Motorcycle Drivetrain Market.

- Changing the Motorcycle Drivetrain Market dynamics of the industry.

- In-depth market segmentation by Type, Application, etc.

- Historical, current, and projected Motorcycle Drivetrain Market size in terms of volume and value.

- Recent industry trends and developments.

- Competitive landscape of the Motorcycle Drivetrain Market.

- Strategies of key players and product offerings.

- Potential and niche segments/regions exhibiting promising growth.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2025 to 2032?

► What are the key market dynamics influencing growth in the Global Motorcycle Drivetrain Market?

► Who are the prominent players in the Global Motorcycle Drivetrain Market?

► What is the consumer perspective in the Global Motorcycle Drivetrain Market?

► What are the key demand-side and supply-side trends in the Global Motorcycle Drivetrain Market?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global Motorcycle Drivetrain Market?

Table Of Contents:

1 Market Overview

1.1 Motorcycle Drivetrain Market Introduction

1.2 Market Analysis by Type

1.3 Market Analysis by Applications

1.4 Market Analysis by Regions

1.4.1 North America (United States, Canada and Mexico)

1.4.1.1 United States Market States and Outlook

1.4.1.2 Canada Market States and Outlook

1.4.1.3 Mexico Market States and Outlook

1.4.2 Europe (Germany, France, UK, Russia and Italy)

1.4.2.1 Germany Market States and Outlook

1.4.2.2 France Market States and Outlook

1.4.2.3 UK Market States and Outlook

1.4.2.4 Russia Market States and Outlook

1.4.2.5 Italy Market States and Outlook

1.4.3 Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

1.4.3.1 China Market States and Outlook

1.4.3.2 Japan Market States and Outlook

1.4.3.3 Korea Market States and Outlook

1.4.3.4 India Market States and Outlook

1.4.3.5 Southeast Asia Market States and Outlook

1.4.4 South America, Middle East and Africa

1.4.4.1 Brazil Market States and Outlook

1.4.4.2 Egypt Market States and Outlook

1.4.4.3 Saudi Arabia Market States and Outlook

1.4.4.4 South Africa Market States and Outlook

1.5 Market Dynamics

1.5.1 Market Opportunities

1.5.2 Market Risk

1.5.3 Market Driving Force

2 Manufacturers Profiles

Continued…

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

US:+18339092966

UK: +448085020280

APAC: +91 744 740 1245

#Motorcycle Drivetrain Market#Motorcycle Drivetrain Market Share#Motorcycle Drivetrain Market Size#Motorcycle Drivetrain Market Trends#Motorcycle Drivetrain Market Growth#Motorcycle Drivetrain Market Insights

0 notes

Text

Including link:

"Max.torque:27N.M/6500/rpm.

Displacement:350ml.

Start mode:electric.

Tranmission mode:shaft drive transission.

Min.ground clearance:120mm.

Max.speed: >120km/h.

Power source:12V,12AH.

Fuel tank capacity:10L."

It's under a hundred miles an hour it'll look 95 mph top speed and they say they're five grand on AliExpress that's an older one the newer ones maybe they can sell for seven Grand but they're not really selling that many. It's too slow it's underpowered and people say they want it and they'll modify it you just take a motorcycle apart down to the rear end and you attach it it's like an easy thing to do you run some solid rod from the front all the way to the back and there you go it's like going to swing arm on it already and people are saying this this like would be a cool mod and if you can't buy it from them but you probably can and you probably can get a kind of cheap on AliExpress if you bought a bunch you could put all sorts of motors in there we think at 7:50 and above is good the Kawasaki and ninja and things like that are pretty good but they don't have torque and you'd like to have the torque Harley Davidson is a prime motor and this will go very fast we think it has some form of cage and they do sell for a lot they're not really faster to sell that much but if you put a Harley Davidson in an 883 and they do make them and you can buy an aftermarket motor and just switch the motor out and you don't have to work the frame you don't have to with other motors either I need to put a 883 s&s which is really like a 881 or something and it has around 65 ftlb torque and 103 horsepower. And it goes pretty good we think top speed around 280 mph.

People are getting up now they have them and they think their dogs they suck they just change the motor and it's an easy change they're mostly change driven so they just have to change the motor and align it right and put in a chain it might be easier to put a smaller motor in a 750cc ninja motor has about 110 horsepower and 45 footlb torque and it will go $255 mph

So we're going to start doing that and really he says you could sell these without a motor because it would cost a lot less and you can sell it partially disassembled in other words you can buy it for a motorcycle to be put in and attached with a certain kit it would be like generic or universal and the price would go way down and the motor is not worth anything the drivetrain on the motorcycle will be correct the one on there is kind of beefy but not that beefy and the kit would be cheap like three grand and you could sell tons and tons and tons of them people come out of the woodwork because they're motorcycles are useless now and if it has like a small cage in it it'll be perfect but these will be a hit right away and you can have a four-wheel kit and they would be a massive hit and these guys started doing this and got discouraged but this is the idea and he says oh change the engine out and his will go fast and that's Daniel from Mexico

Thor Freya

I'm going to get a bunch of these these things are awesome and they don't have a cage but we can put a small one in you have to have it these days but this would be so fast and really it's safer with the cage then any of these compact cars and it'll be fast much faster the idea is speed he's going to be driving in something like this but it will look like a regular sports car I know what it looks like

Daniel

Olympus

0 notes

Text

Flatbed vs. Wheel-Lift Towing: Which Is Right for Your Vehicle?

hen your vehicle breaks down, gets into an accident, or simply refuses to start, the last thing you want to worry about is how to get it safely from point A to point B. That’s where professional towing services come in. But not all towing methods are created equal. The two most common techniques are flatbed towing and wheel-lift towing—and each comes with its own pros and cons.

So, which one is right for your vehicle? In this blog, we’ll break down both methods and help you decide. Plus, we’ll explain why hiring the best towing company in St. Petersburg, FL can make all the difference in protecting your vehicle and your peace of mind.

What Is Flatbed Towing?

Flatbed towing involves placing the entire vehicle onto a flat platform that is mounted on the back of a tow truck. This method requires the truck operator to either drive or winch the car up onto the bed before transporting it.

Advantages of Flatbed Towing:

Maximum Vehicle Protection: Since all four wheels are off the ground, there is minimal risk of wear and tear during transport.

Ideal for All-Wheel Drive & Luxury Vehicles: Flatbed towing is the safest choice for AWD systems, sports cars, and exotic vehicles.

Accident Recovery: If your car has suffered severe damage or is undrivable, a flatbed can safely transport it without worsening the condition.

No Additional Mileage: Unlike wheel-lift towing, your car’s tires don’t touch the road, which means no added mileage or tire wear.

What Is Wheel-Lift Towing?

Wheel-lift towing uses a metal yoke to lift either the front or rear wheels of the vehicle off the ground, while the other two wheels remain in contact with the road. It’s quicker to set up and often used for shorter-distance towing.

Advantages of Wheel-Lift Towing:

Cost-Effective: Generally more affordable than flatbed towing for short distances or lightweight vehicles.

Faster Setup Time: Ideal for tight urban areas or situations requiring quick removal.

Fits in Tight Spaces: Wheel-lift tow trucks are more maneuverable, making them suitable for narrow roads or crowded parking lots.

However, this method may not be suitable for AWD, luxury, or low-clearance vehicles, as it can potentially cause drivetrain or undercarriage damage.

Which Towing Method Is Right for Your Vehicle?

When your vehicle needs towing in St. Petersburg, choosing between flatbed and wheel-lift towing can impact its safety and condition. Understanding the differences helps you make the best decision.

Flatbed towing is the safest option, transporting your vehicle fully on a trailer. It’s ideal for luxury cars, AWD/4WD vehicles, motorcycles, and damaged cars since it prevents drivetrain stress and road debris damage. While slightly more expensive, flatbed towing ensures maximum protection, especially for long-distance moves.

Wheel-lift towing is more affordable and faster, lifting either the front or rear wheels while the others roll. It works well for standard front-wheel-drive cars needing short-distance tows. However, it’s not recommended for AWD, lowered, or classic cars, as it can strain transmissions and suspensions.

Which Should You Choose?

Flatbed: Best for high-value, specialty, or non-running vehicles.

Wheel-Lift: Suitable for quick, local tows of standard cars.

For reliable service, always hire the best towing company in St. Petersburg, FL—they’ll assess your vehicle’s needs and use the safest method. Whether you need a flatbed’s security or a wheel-lift’s efficiency, professional tow operators ensure your car arrives undamaged.

Why You Should Hire the Best Towing Company in St. Petersburg, FL

Choosing the right towing method is only part of the equation. Equally important is who you trust to handle your vehicle.

Here’s why hiring the best towing company in St. Petersburg, FL is a smart move:

1. Professional Expertise

Experienced towing professionals understand the nuances of different vehicle types and towing methods. Whether you drive a compact sedan or a high-end SUV, the best towing company in St. Petersburg, FL has the training and equipment to transport your vehicle safely and efficiently.

2. Right Equipment for Every Job

Top-rated companies maintain a full fleet of both flatbed and wheel-lift trucks to accommodate any towing need. That means no guesswork and no unnecessary risk to your vehicle.

3. 24/7 Emergency Service

Breakdowns don’t follow a 9-to-5 schedule. The best towing company in St. Petersburg, FL offers round-the-clock assistance, so you’re never left stranded—whether it’s 2 p.m. or 2 a.m.

4. Safe Handling and Damage Prevention

Hiring a cheap or inexperienced towing service can lead to damage that costs far more than the tow itself. A trusted provider uses proper tie-down techniques, high-quality gear, and proven procedures to keep your vehicle protected.

5. Transparent Pricing and Reliable ETA

With the best towing company in St. Petersburg, FL, you get clear pricing, no hidden fees, and accurate arrival times. That kind of reliability is invaluable during a stressful roadside situation.

Final Thoughts

Both flatbed and wheel-lift towing have their place, depending on your vehicle type and situation. The key is knowing which option offers the best protection and efficiency. When in doubt, turn to the professionals.

Hiring the best towing company in St. Petersburg, FL ensures not only the correct towing method is used but also that your vehicle is in safe, experienced hands. From emergency roadside help to long-distance transport, a reliable local towing company brings peace of mind and top-tier service.

0 notes

Text

Recreational Vehicles Powertrain Market Trend Analysis, Latest Revenue Figures, Growth Insights and Forecast to 2030

Recreational Vehicles Powertrain MarketReport 2024 by Delvens offers comprehensive market insights, empowering businesses with a competitive edge. It includes detailed estimates for numerous segments and sub-segments, providing valuable strategic guidance, the global Recreational Vehicles Powertrain Market size is projected to reach a CAGR of 8.45% and Forecast to 2030

Get Free Sample Report: https://www.delvens.com/get-free-sample/recreational-vehicles-powertrain-market

Recreational vehicles have often been powered by conventional internal combustion engines that run on either petrol or diesel. Because of their high torque output and durability, these engines are well-suited for difficult off-road terrains. ICE powertrains are still being improved by manufacturers for performance, fuel efficiency, and pollution reduction.

Specialized gearbox systems are frequently needed by recreational vehicles to enhance torque delivery and performance in difficult terrain. To improve the performance and efficiency of off-road vehicles, manufacturers are creating cutting-edge transmission technologies like continuously variable transmissions (CVT), automatic gearboxes, and dual-clutch transmissions.

All-wheel drive or four-wheel drive systems are frequently used in recreational vehicles to increase traction and off-road performance. Manufacturers are constantly enhancing these systems, adding elements like torque vectoring, electronic differential locking, and adaptive drivetrain controls to enhance power distribution to specific wheels and off-road performance.

The Prominent Players in Recreational Vehicles Powertrain Market

Vitesco Technologies

Zf Friedrichshafen

Valeo

Ford Motor Company

Magna Powertrain

Hitachi Automotive Systems Ltd

Bosch Mobility Solutions

Avl

Mitsubishi Electric Corporation

Cummins Inc

Gkn Plc

Schaeffler Ag

Magneti Marelli S.P.A.

Nidec Corporation and More

Key Findings

Based on vehicle type Recreational Vehicles Powertrain Market is segmented into Snowmobiles, All-Terrain Vehicles, Side by Sides, Rugged Terrain Vehicles (Rtvs), Golf Carts, Motorcycles, Personal Watercraft, And Others. The all-terrain vehicles segment holds the largest market share and is estimated to grow at a significant CAGR during the forecast period.

Based on fuel type Recreational Vehicles Powertrain Market is segmented into Gasoline, Diesel, and Electric. Currently, the market is dominated by gasoline-fuel-type Recreational Vehicles with the highest market share. However, the Electric Recreational Vehicles market is anticipated to grow at the highest CAGR, due to rising concerns of the environment and sustainable future.

Based on application Recreational Vehicles Powertrain Market is segmented into Sports, Entertainment, Agriculture, Military & Defense, and Other (Hunting & Forestry). The sports segment accounted for the largest market share. Professional racing championships and series are propelling the growth of the market. In the Grand National cross-country series, ATV National Motocross Championship, and championship Mud Racing ATVs and UTVs are Used. Hence racing clubs procure different types of racing vehicles to prepare for these kinds of events.

Access Full Report: https://www.delvens.com/report/recreational-vehicles-powertrain-market

In addition to the market data for Recreational Vehicles Powertrain Market, Delvens offers a client-centric report customized according to the company’s specific demand and requirement.

More Related Reports:

EHV AC and HVDC in XLPE Onshore Land Cables and Accessories Market

HVAC XLPE onshore Land cable Market

About Us:

Delvens is a strategic advisory and consulting company headquartered in New Delhi, India. The company holds expertise in providing syndicated research reports, customized research reports and consulting services. Delvens qualitative and quantitative data is highly utilized by each level from niche to major markets, serving more than 1K prominent companies by assuring to provide the information on country, regional and global business environment. We have a database for more than 45 industries in more than 115+ major countries globally.

Delvens database assists the clients by providing in-depth information in crucial business decisions. Delvens offers significant facts and figures across various industries namely Healthcare, IT & Telecom, Chemicals & Materials, Semiconductor & Electronics, Energy, Pharmaceutical, Consumer Goods & Services, Food & Beverages. Our company provides an exhaustive and comprehensive understanding of the business environment.

Contact us:

Unit No. 01, 3rd Floor, Plot No. 56, Block B

Sector 2 Noida, Near Noida Sector 15 Metro Station 201301, IN

+44 20 3290 6466

+0120- 4903958

0 notes

Text

Everything You Must Know About Flatbed Towing Services

El Cajon Towing Service professionals understand that vehicle breakdowns happen at the worst possible times. It leaves you stranded and stressed on the side of the road. You do not have a clear solution for getting your vehicle safely transported to a repair facility.

Flatbed towing represents the most secure method for moving vehicles. It is because you can load the entire car onto a flat platform instead of dragging dragged with wheels on the ground. It prevents additional damage to your transmission and undercarriage during transportation.

Why Choose Flatbed Towing

The primary advantage of flatbed towing service lies in its ability to completely remove your vehicle from the ground, eliminating any potential for road contact that might cause friction damage to tires or mechanical components.

Chula Vista Towing Service operators utilize powerful hydraulic systems that allow the entire platform to tilt downward, creating a ramp that makes loading disabled vehicles much easier than with traditional tow trucks that require complex hookup procedures.

Cars with front-wheel drive, all-wheel drive, or certain transmission types absolutely require this method of transport to prevent catastrophic mechanical failure during the towing process.

When Flatbed Towing Becomes Essential

Certain situations absolutely demand flatbed towing services rather than traditional hook-and-chain or wheel-lift methods. Chula Vista Towing Service experts recommend flatbed transport for vehicles involved in accidents with structural or suspension damage that might compromise steering control or stability during conventional towing operations.

Exotic cars, classic vehicles, and motorcycles benefit tremendously from the added security and protection that only flatbed transportation can provide against road hazards and potential mechanical stress. Electric vehicles with their battery configurations and specialized drivetrains typically require flatbed towing according to manufacturer specifications to prevent potential damage to sensitive components.

Finding Reliable Providers

Selecting the right towing provider requires research beyond simply calling the first company listed in search results. Chula Vista Towing Service providers with positive customer reviews and proper licensing demonstrate commitment to professional standards and reliable service delivery during your transportation emergency.

The response time, service area coverage, and available equipment should factor into your decision when selecting a towing company that can properly address your specific vehicle requirements. El Cajon Towing Service companies typically maintain fleets with various towing options, including flatbeds, precisely because vehicle transportation needs vary significantly depending on the situation.

Conclusion

Flatbed towing offers superior protection and safety for your vehicle during transport emergencies compared to traditional towing methods. Professional El Cajon Towing Service understands the technical requirements for properly securing different vehicle types on the platform. The investment in quality flatbed service ultimately saves money by preventing secondary damage that might occur with less appropriate towing techniques.

0 notes

Text

Why Is Flatbed Towing the Safest Option for Your Vehicle?

When your vehicle breaks down or needs to be transported, choosing the right towing method is essential. One of the best and safest options is flatbed towing. Whether you have a luxury car, an SUV, a motorcycle, or even a damaged vehicle, flatbed towing provides the highest level of protection during transportation. If you need reliable flatbed towing in Kansas City KS, understanding its benefits will help you make the right decision.

In this article, we will explore why flatbed towing is the safest option, how it works, and when you should choose it over other towing methods.

How Flatbed Towing Works

Flatbed towing uses a specialized tow truck with a long, flat platform that can be hydraulically inclined to ground level. Once the vehicle is driven or winched onto the platform, it is securely strapped down, preventing any movement during transport. Unlike other towing methods, flatbed towing ensures that all four wheels of the vehicle are off the ground, eliminating risks associated with dragging or rolling.

If you require flatbed towing in Kansas City KS, you can rest assured that this method will provide maximum safety and security for your vehicle.

Top Reasons Why Flatbed Towing Is the Safest Option

1. Prevents Wear and Tear on Your Vehicle

One major advantage of flatbed towing is that it prevents additional wear and tear on your vehicle. Traditional towing methods, such as wheel-lift towing, keep two wheels on the ground, which can cause unnecessary stress on the tires, suspension, and transmission. With flatbed towing, your vehicle is completely lifted off the road, ensuring it remains in perfect condition during transport.

2. Reduces Risk of Damage

Vehicles towed using hook and chain or wheel-lift methods are at a higher risk of damage. Dragging a vehicle on the road can result in scratches, dents, or undercarriage damage. Additionally, if the tow truck driver makes sharp turns or sudden stops, the towed vehicle could swing and collide with other objects. Flatbed towing eliminates these risks by keeping the vehicle securely fastened on a stable platform.

3. Ideal for Luxury and Exotic Vehicles

Luxury and exotic vehicles often have low ground clearance, making them more vulnerable to damage if towed using traditional methods. Flatbed towing ensures that these vehicles are not subjected to rough handling, maintaining their pristine condition. If you own a high-end car and require safe transportation, opting for flatbed towing in Kansas City KS is the best choice.

4. Best Option for All-Wheel and Four-Wheel Drive Vehicles

Many vehicles today come equipped with all-wheel drive (AWD) or four-wheel drive (4WD) systems, which require all four wheels to rotate together. Towing these vehicles using wheel-lift or dolly methods can cause serious transmission damage. Flatbed towing eliminates this risk by keeping all wheels off the ground and preventing unnecessary drivetrain strain.

5. Safe for Heavily Damaged or Inoperable Vehicles

If your vehicle has been involved in an accident or has significant mechanical issues, flatbed towing is the safest way to transport it. A damaged vehicle may have misaligned wheels, broken suspension components, or leaks that make traditional towing methods unsafe. With flatbed towing, your vehicle is carefully secured and transported without further damage.

6. Better Stability During Transport

Flatbed tow trucks provide superior stability compared to other towing methods. Since the vehicle remains stationary on the flatbed platform, there is no risk of swaying, bouncing, or shifting during transit. This stability is especially crucial when transporting vehicles over long distances or through rough terrain. For anyone seeking secure flatbed towing in Kansas City KS, this method ensures a smooth and damage-free ride.

7. Ensures Safety on the Road

Not only is flatbed towing safe for your vehicle, but it is also safer for other drivers on the road. Traditional towing methods require the towed vehicle to follow behind the tow truck, which can create hazards such as swerving, unexpected stops, or tire blowouts. With flatbed towing, the vehicle remains stationary and does not pose any additional risks to traffic.

8. Works for a Wide Range of Vehicles

Flatbed towing is versatile and can be used for various types of vehicles, including:

Sedans and compact cars

SUVs and pickup trucks

Classic and luxury cars

Motorcycles

Heavy-duty and commercial vehicles

Exotic and sports cars

Regardless of the type of vehicle you own, flatbed towing in Kansas City KS provides a secure solution for your towing needs.

When Should You Choose Flatbed Towing?

While traditional towing methods may be suitable for short-distance transport or minor roadside issues, flatbed towing is recommended in the following situations:

Your vehicle has suffered severe damage in an accident.

You drive a luxury, exotic, or classic car that requires extra care.

Your vehicle has all-wheel or four-wheel drive and cannot be towed with wheels on the ground.

You need long-distance transportation for your vehicle.

Your car has a low ground clearance that makes traditional towing risky.

Your vehicle is inoperable due to mechanical failures.

In these cases, choosing flatbed towing ensures that your vehicle is transported in the safest and most secure manner.

How to Choose a Reliable Flatbed Towing Service

If you need flatbed towing in Kansas City KS, selecting a trustworthy towing service is essential. Here are a few tips to help you find the best provider:

1. Check Their Experience and Expertise

Look for a towing company with experience in flatbed towing. A professional team will know how to secure your vehicle properly and transport it without any risks.

2. Verify Licensing and Insurance

Always choose a towing company that is fully licensed and insured. This protects you from liability in case of any accidents or damages during transport.

3. Read Customer Reviews

Customer reviews can provide valuable insights into the quality of service offered by a towing company. Look for a company with positive feedback and a track record of reliable service.

4. Ensure 24/7 Availability

Breakdowns and accidents can happen at any time. Choose a towing service that operates 24/7 to ensure you can get assistance whenever you need it.

5. Get a Price Estimate

Before hiring a towing service, ask for a price estimate to avoid hidden charges. A reputable company will provide transparent pricing based on distance and vehicle type.

Conclusion

Flatbed towing is the safest and most reliable way to transport your vehicle, whether it’s a standard car, motorcycle, or luxury vehicle. It prevents unnecessary wear and tear, reduces the risk of damage, and ensures stability during transit. If you ever need towing assistance, choosing flatbed towing in Kansas City KS guarantees the best protection for your vehicle.

By selecting a professional and experienced towing service, you can have peace of mind knowing your vehicle will be transported safely and efficiently. Whether you need emergency roadside assistance or long-distance towing, flatbed towing remains the top choice for vehicle safety.

0 notes

Text

Flatbed Towing in Airdrie

Why Flatbed Towing?

If your car breaks down or needs transport, flatbed towing is the safest and most reliable option. Unlike traditional towing methods, flatbed towing keeps all four wheels off the ground, preventing damage to tires, suspension, and drivetrain. Whether you drive a luxury car, motorcycle, or AWD vehicle, this method ensures a smooth, damage-free transport.

When Do You Need Flatbed Towing?

Breakdowns: Mechanical failures or engine issues? A flatbed tow keeps your car secure. Accident Recovery: If your vehicle is damaged, flatbed towing prevents further harm. Luxury & Exotic Cars: Avoid scratches, dents, and unnecessary wear. Long-Distance Transport: Keeps mileage low and protects your vehicle. Motorcycles & Specialty Vehicles: Offers a stable and safe towing solution.

How Much Does Flatbed Towing Cost in Airdrie?

The cost of flatbed towing depends on several factors, including distance, vehicle type, and time of service. Here’s a rough breakdown: Local Tow (5-10 km): $100 - $150 Medium Distance (20-50 km): $150 - $200 Long Distance (50+ km): $200+ Emergency and after-hours towing may come at a higher rate. To get an exact quote, reach out to Trigger Towing and Recovery LTD.

Why Choose Trigger Towing and Recovery LTD?

24/7 Availability – Emergency towing anytime, anywhere in Airdrie. Fast Response Times – Quick, efficient service to get you back on track. Transparent Pricing – No hidden fees, just honest rates. Professional & Insured – Your vehicle is in safe hands. Locally Trusted Trucks – Serving Airdrie with reliable towing services.

Need a Tow? Call Us Now!

Flatbed towing is the best way to ensure your vehicle arrives safely and securely at its destination. If you need towing in Airdrie, Trigger Towing and Recovery LTD is ready to help.

1 note

·

View note

Text

Towing Myths: What You Need to Know in Littleton

Towing services are a crucial part of road safety and vehicle maintenance. However, misconceptions about towing often lead to confusion and unnecessary stress for vehicle owners. If you find yourself in need of towing services in Littleton, CO, it's important to separate fact from fiction. In this article, we’ll debunk some of the most common towing myths and provide essential information to help you make informed decisions.

Myth 1: Towing Always Damages Your Vehicle

Many people believe that towing causes significant damage to their vehicles. While improper towing can lead to issues, professional towing services in Littleton, CO, use modern equipment and techniques to ensure your vehicle is safely transported. Flatbed tow trucks, for instance, lift the entire vehicle off the ground, preventing wear and tear on the tires and suspension. To find out more about how towing professionals ensure vehicle safety, always choose a reputable service provider.

Myth 2: Any Vehicle Can Tow Another Vehicle

Some drivers assume that they can use their personal vehicle to tow another car without any issues. However, towing requires specialized equipment, proper weight distribution, and knowledge of towing capacities. Attempting to tow a vehicle without the right setup can result in damage to both vehicles and create dangerous driving conditions. Instead of taking unnecessary risks, check over here for professional towing services in Littleton, CO, that have the right tools for the job.

Myth 3: Towing Services Are Only for Breakdowns

Many people associate towing services solely with vehicle breakdowns, but towing companies offer a wide range of services beyond roadside assistance. Towing professionals can help with vehicle relocations, long-distance towing, accident recovery, and transporting specialty vehicles like motorcycles and classic cars. If you ever need assistance beyond an emergency breakdown, go right here to explore the various towing solutions available in Littleton, CO.

Myth 4: You Can’t Be Towed if You Have All-Wheel Drive

There’s a common belief that all-wheel-drive (AWD) vehicles cannot be towed. While AWD systems require special handling, towing professionals have the expertise to transport these vehicles safely. Flatbed tow trucks are often used to keep all four wheels off the ground, ensuring no damage to the drivetrain. To find out more about how AWD vehicles can be safely towed, consult a trusted towing company in Littleton.

Myth 5: Towing Is Too Expensive

Many drivers avoid calling a tow truck because they believe it will be too costly. While towing services do come with a fee, the cost is often reasonable and varies based on factors such as distance, vehicle type, and service complexity. In many cases, roadside assistance memberships or insurance policies may cover towing expenses, making it a more affordable option than expected. If you’re concerned about costs, check over here for transparent pricing from local towing companies.

Myth 6: Towing Companies Take Too Long to Arrive

Another misconception is that towing services take hours to arrive. While wait times may vary depending on traffic and demand, professional towing companies in Littleton prioritize quick response times to assist stranded drivers efficiently. Many companies offer real-time tracking and estimated arrival times, so you can have peace of mind while waiting for assistance. If you ever need fast and reliable towing services, go right here to connect with professionals who prioritize customer satisfaction.

Myth 7: Only Large Vehicles Require Towing

Some people think that towing services are only needed for large vehicles, such as trucks and RVs. In reality, towing companies assist all types of vehicles, from motorcycles and sedans to SUVs and vans. Regardless of the vehicle’s size, towing professionals have the expertise to ensure safe transport. If you drive a compact car and experience a breakdown, don’t hesitate to seek professional assistance.

Conclusion

Towing myths can create unnecessary fear and confusion, but understanding the facts can help you make better decisions when you need assistance. Whether you require emergency roadside help, vehicle relocation, or specialty towing, professional towing services in Littleton, CO, are equipped to handle your needs safely and efficiently. To learn more about the best towing solutions in your area, check here for reputable providers. Don’t let myths prevent you from getting the help you need—rely on experts to keep you and your vehicle safe.

Original Link: https://mphtowing.blogspot.com/2025/03/towing-myths-what-you-need-to-know-in.html

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] From the brand Allextreme- King of the Road Shop for High Quality Protective Gears, Car & Bike Accessories at the most affordable prices. Visit our Brand Store Page. Shop all Allextreme Products Universal Car Bed Mattress Anti-Theft Lock for Car & Bike Dustproof Car Body Cover Fog Lamp for Bikes & Cars Parking Bulb for Bikes & Cars EASY TO USE: The cleaning brush clips directly to the chain without the need to remove the chain from the bicycle or motorcycle. Its ergonomic and easy to grasp design makes chain cleaning a quick task. FULL COVERAGE: This chain cleaner tool comes with 3-sided bristles that helps you to clean all 4 sides of your motorcycle, bike chain and the long bristle side lets you clean other parts of your bike like sprockets and wheels. DURABLE NYLON BRISTLES: The offered chain brush cleaning tool is made of high-quality material, which offers durability in terms of life and shape. Nylon bristles are tough enough to provide thorough cleaning towards grime and soft enough to preserve flexibility. VERSATILE USE: This versatile brush cleaner can be used to clean numerous types of chains including mountain bikes, road bikes, cruisers, and different kinds of bikes and motorcycles. It also helps to clean sprockets, derailleurs, cranksets, brakes, and pedals. PROVIDES PROTECTION: This chain cleaner tool helps prevent premature wear of your drivetrain and helps maintain smooth operation when riding the motorcycle and bike. It’s appropriate hardness is not only powerful but also durable. [ad_2]

0 notes

Text

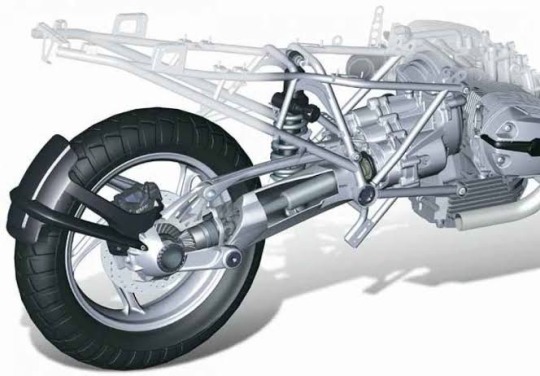

Motorcycle Drivetrains: Understanding the Three Types and Their Unique Benefits

https://gob.stayingalive.in/unleashing-the-thrills-of/motorcycle-drivetrains.html Discover the world of motorcycle drivetrains! Learn about chain, belt, and shaft drive systems, their efficiency, advantages, and which one reigns supreme. #MotorcycleLife #RidingExperience The Heart of Motorcycle Performance Motorcycle drivetrains are the unsung heroes of the riding experience. These systems…

View On WordPress

#automotive#Belt drive motorcycles#cars#Chain drive motorcycles#Drivetrain technology#Electric motorcycles#Future motorcycle technology#Good Old Bandit#Gud Ol Bandit#Hybrid motorcycles#Lightweight materials#motorcycle#Motorcycle drivetrains#Motorcycle efficiency#Motorcycle maintenance#Motorcycle performance#News#Sanjay K Mohindroo#Sanjay Kumar Mohindroo#Sanjay Mohindroo#Shaft drive motorcycles#Smart drivetrains#Sustainable motorcycles#technology#touring motorcycles

0 notes

Text

Motorcycle Drivetrain Market To Witness the Highest Growth Globally in Coming Years

The report begins with an overview of the Motorcycle Drivetrain Market and presents throughout its development. It provides a comprehensive analysis of all regional and key player segments providing closer insights into current market conditions and future market opportunities, along with drivers, trend segments, consumer behavior, price factors, and market performance and estimates. Forecast market information, SWOT analysis, Motorcycle Drivetrain Market scenario, and feasibility study are the important aspects analyzed in this report.

The Motorcycle Drivetrain Market is experiencing robust growth driven by the expanding globally. The Motorcycle Drivetrain Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Motorcycle Drivetrain Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing. Motorcycle Drivetrain Market Size, Share & Industry Analysis, By Fuel Type (Petrol, Electric, Others), By Propulsion Type (Chain Drive, Belt Drive, Shaft Drive), By Transmission Type (MT, AMT, AT) and Regional Forecast, 2022-2029

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/101893

Key Strategies

Key strategies in the Motorcycle Drivetrain Market revolve around optimizing production efficiency, quality, and flexibility. Integration of advanced robotics and machine vision technologies streamlines assembly processes, reducing cycle times and error rates. Customization options cater to diverse product requirements and manufacturing environments, ensuring solution scalability and adaptability. Collaboration with industry partners and automation experts fosters innovation and addresses evolving customer needs and market trends. Moreover, investment in employee training and skill development facilitates seamless integration and operation of Motorcycle Drivetrain Market. By prioritizing these strategies, manufacturers can enhance competitiveness, accelerate time-to-market, and drive sustainable growth in the Motorcycle Drivetrain Market.

Major Motorcycle Drivetrain Market Manufacturers covered in the market report include:

Some of the major companies that are present in the motorcycle drivetrain market include American Axle & Manufacturing Inc., ZF Friedrichshafen AG, GKN PLC, Borgwarner Inc., Showa Corporation, Schaeffler Group, Magna International Inc., Aisin Seki Co. Ltd., Dana Incorporated, and JTEKT Corporation among the other players.

Growing demand for lightweight drivetrains to improve fuel efficiency is also another factor which is anticipated to drive the motorcycle drivetrain market. Key manufacturers are hence, focusing on producing drivetrain, which is light in weight and enhances the performance of the vehicle.

Trends Analysis

The Motorcycle Drivetrain Market is experiencing rapid expansion fueled by the manufacturing industry's pursuit of efficiency and productivity gains. Key trends include the adoption of collaborative robotics and advanced automation technologies to streamline assembly processes and reduce labor costs. With the rise of Industry 4.0 initiatives, manufacturers are investing in flexible and scalable Motorcycle Drivetrain Market capable of handling diverse product portfolios. Moreover, advancements in machine vision and AI-driven quality control are enhancing production throughput and ensuring product consistency. The emphasis on sustainability and lean manufacturing principles is driving innovation in energy-efficient and eco-friendly Motorcycle Drivetrain Market Solutions.

Regions Included in this Motorcycle Drivetrain Market Report are as follows:

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Significant Features that are under offering and key highlights of the reports:

- Detailed overview of the Motorcycle Drivetrain Market.

- Changing the Motorcycle Drivetrain Market dynamics of the industry.

- In-depth market segmentation by Type, Application, etc.

- Historical, current, and projected Motorcycle Drivetrain Market size in terms of volume and value.

- Recent industry trends and developments.

- Competitive landscape of the Motorcycle Drivetrain Market.

- Strategies of key players and product offerings.

- Potential and niche segments/regions exhibiting promising growth.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2024 to 2030?

► What are the key market dynamics influencing growth in the Global Motorcycle Drivetrain Market?

► Who are the prominent players in the Global Motorcycle Drivetrain Market?

► What is the consumer perspective in the Global Motorcycle Drivetrain Market?

► What are the key demand-side and supply-side trends in the Global Motorcycle Drivetrain Market?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global Motorcycle Drivetrain Market?

Table Of Contents:

1 Market Overview

1.1 Motorcycle Drivetrain Market Introduction

1.2 Market Analysis by Type

1.3 Market Analysis by Applications

1.4 Market Analysis by Regions

1.4.1 North America (United States, Canada and Mexico)

1.4.1.1 United States Market States and Outlook

1.4.1.2 Canada Market States and Outlook

1.4.1.3 Mexico Market States and Outlook

1.4.2 Europe (Germany, France, UK, Russia and Italy)

1.4.2.1 Germany Market States and Outlook

1.4.2.2 France Market States and Outlook

1.4.2.3 UK Market States and Outlook

1.4.2.4 Russia Market States and Outlook

1.4.2.5 Italy Market States and Outlook

1.4.3 Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

1.4.3.1 China Market States and Outlook

1.4.3.2 Japan Market States and Outlook

1.4.3.3 Korea Market States and Outlook

1.4.3.4 India Market States and Outlook

1.4.3.5 Southeast Asia Market States and Outlook

1.4.4 South America, Middle East and Africa

1.4.4.1 Brazil Market States and Outlook

1.4.4.2 Egypt Market States and Outlook

1.4.4.3 Saudi Arabia Market States and Outlook

1.4.4.4 South Africa Market States and Outlook

1.5 Market Dynamics

1.5.1 Market Opportunities

1.5.2 Market Risk

1.5.3 Market Driving Force

2 Manufacturers Profiles

Continued…

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

308, Supreme Headquarters,

Survey No. 36, Baner,

Pune-Bangalore Highway,

Pune - 411045, Maharashtra, India.

Phone:

US:+1 424 253 0390

UK: +44 2071 939123

APAC: +91 744 740 1245

0 notes

Text

This is the idea and the gas tanks are similar to what he was saying you put the gas tank from the motorcycle there and you buy another one and you can do it that way cuz it looks kind of cool but you can see that that's the motorcycle itself and we think that they use the motorcycle to do this. It's just not very powerful. This is what he said last and it's recreating his idea that he had with his wife but he is saying to make it with a kit and Dave stager is a phony baloney and he doesn't get it. And he gets possessed or something thinks he's powerful and he's a loser it happens to retarded people quite easily. But BG says you have to control them and we don't and it's true you're toasting yourself as a threat so what you're an idiot and Joel watts is always been an idiot. So imagine a Harley-Davidson like a breakout motor and they're high performance on this vehicle now people will buy these and they'll switch out the motor and they have plenty of times these things are not much money they're like 3 Grand and they can handle a different motor because the drivetrain is from the bike itself you have to reinforce the frame where it connects the point this thing will move out he's going to look it up but I know that they're pretty fast already

Thor Freya

Olympus

He has no gas money and I want to keep it that way so he says okay now I'm at Target good I'll kick him out and they'll go to another apartment and take my money

Stan

We're now going to Target him and to take his stuff and money and get it to our son he's an easy Mark and we're just sitting here and he's torturing him and we're going to torture the f***** too and we're taking a lot of other stuff of course

Olympus

0 notes

Text

Global High Performance Electric Vehicles Market — Forecast(2025–2031)

𝐓𝐡𝐞 𝐅𝐮𝐭𝐮𝐫𝐞 𝐢𝐬 𝐄𝐥𝐞𝐜𝐭𝐫𝐢𝐜: 𝐇𝐢𝐠𝐡-𝐏𝐞𝐫𝐟𝐨𝐫𝐦𝐚𝐧𝐜𝐞 𝐄𝐕𝐬 𝐓𝐚𝐤𝐢𝐧𝐠 𝐎𝐯𝐞𝐫!” 🔋🚀 IndustryARC™

The global electric vehicle market size was estimated at USD 1,328.08 billion in 2024 and is projected to grow at a CAGR of 32.5% from 2025 to 2030.

👉𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐒𝐚𝐦𝐩𝐥𝐞 𝐏𝐃𝐅 :

The Global High-Performance #Electric_Vehicles (#EVs) Market refers to the segment of electric vehicles designed for superior #speed, #acceleration, handling, and overall driving performance. These EVs combine cutting-edge technology with sustainability, catering to #automotive enthusiasts and consumers seeking high-speed, luxury, and eco-friendly transportation.

The expansion of the transportation and logistics sectors significantly drives the rising demand for EVs. As global trade and e-commerce continue to surge, there is an increased need for efficient and sustainable transportation solutions. Electric vehicles offer a promising alternative to traditional internal combustion engines, as they produce lower emissions and reduce operational costs.

𝐊𝐞𝐲 𝐂𝐡𝐚𝐫𝐚𝐜𝐭𝐞𝐫𝐢𝐬𝐭𝐢𝐜𝐬 𝐨𝐟 𝐇𝐢𝐠𝐡-𝐏𝐞𝐫𝐟𝐨𝐫𝐦𝐚𝐧𝐜𝐞 𝐄𝐕𝐬:

✅ Powerful Electric Drivetrains — Delivering high torque and rapid acceleration

✅ Advanced Battery Technology — Enabling extended range and fast charging

✅ Lightweight & Aerodynamic Designs — Enhancing efficiency and speed

✅ Smart Connectivity & AI Integration — Offering enhanced driver experience

𝐌𝐚𝐫𝐤𝐞𝐭 𝐆𝐫𝐨𝐰𝐭𝐡 & 𝐓𝐫𝐞𝐧𝐝𝐬:

📈 Increasing Demand for Performance & Sustainability — Consumers want speed without compromising on environmental impact 🌱

🏭 Major Automakers Investing Heavily — Companies like Tesla, Porsche, Rimac, Lucid Motors, Ferrari, and legacy brands like BMW & Mercedes-Benz are entering the space 🏎️

🔋 Battery Innovations — Solid-state and high-capacity lithium-ion batteries are enhancing range & efficiency 🔥

📊 𝐆𝐞𝐭 𝐭𝐡𝐞 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭 :

𝐌𝐚𝐫𝐤𝐞𝐭 𝐎𝐮𝐭𝐥𝐨𝐨𝐤:

With advancements in EV infrastructure, battery tech, and government incentives, the high-performance EV market is expected to grow exponentially, redefining the future of high-speed, zero-emission mobility.

Get this Report on discount of $1000 on purchase of Credit Card

✅ 𝗞𝗲𝘆 𝗖𝗼𝗺𝗽𝗮𝗻𝗶𝗲𝘀 𝗣𝗿𝗼𝗳𝗶𝗹𝗲𝘀 𝗚𝗶𝘃𝗲𝗻 𝗶𝗻 𝘁𝗵𝗶𝘀 𝗠𝗮𝗿𝗸𝗲𝘁 𝗥𝗲𝗽𝗼𝗿𝘁: Volvo Finland Ab | Byd Company Limited | BYD Electronic (International) Company Limited | Ford Motor Company | General Motors | American Honda Motor Company, Inc. | Honda Motor Europe Ltd | Kawasaki Motors Corp., U.S.A. | Mercedes-Benz Group AG | Mitsubishi Motors Corporation | Nissan Motor Corporation | Renault Group | Tesla | Toyota Motor Corporation | Volkswagen Group | Zero Motorcycles Inc. | Zero Motorcycles Australia |

#EVRevolution#HighPerformanceEVs#ElectricSupercars#SustainableMobility#FutureOfDriving#ZeroEmissions#EVInnovation#AutomotiveTech#GreenEnergy#FastAndElectric#BatteryTechnology#SmartMobility#EVPerformance

0 notes

Text

The NUEN N1-S: A production-ready electric motorcycle from Vietnam

In the world of electric motorcycles, the upstart is king. A small company with big ideas can grab an off-the-shelf electric drivetrain, rapidly prototype its concept, and massage it into a working motorcycle. And they can do it quicker than what it takes a major marque to get buy-in from the myriad internal departments that hold the reins. NUEN Moto only burst onto the scene a couple of years…

0 notes

Text

Aluminun Die Casting Motorcycle Transmission Case

Our aluminum die-casting motorcycle transmission case represents a pinnacle in modern engineering, embodying precision, durability, and efficiency. This component serves as the protective enclosure for the intricate transmission system within a motorcycle, playing a crucial role in ensuring smooth and reliable power transfer. Crafted through the meticulous process of aluminum die-casting, this transmission case exemplifies strength and lightweight characteristics. The die-casting method involves injecting molten aluminum into a precision-machined mold, creating a seamless and precisely shaped case. This not only enhances the overall structural integrity of the transmission housing but also contributes to the reduction of the motorcycle's weight, ultimately optimizing fuel efficiency and performance. The design of the aluminum die-casting motorcycle transmission case is engineered to withstand the rigorous demands of diverse riding conditions. Its robust construction provides protection for the transmission components against external elements, ensuring longevity and reliability for the entire drivetrain system.

0 notes