#Motion Control Software In Robotics Market Value

Explore tagged Tumblr posts

Text

#Motion Control Software In Robotics Market#Motion Control Software In Robotics Market Share#Motion Control Software In Robotics Market Trends#Motion Control Software In Robotics Market Value

0 notes

Text

The Evolution of Warehousing: Navigating the World of Smart Warehouses

In the digitally-charged world of today, we're accustomed to the term "smart" permeating every aspect of our lives - smartphones, smart homes, smart cities. Now, it's time to familiarize ourselves with another addition to this repertoire - Smart Warehouses. So, what sets them apart in the vast realm of logistics?

The Blueprint of a Smart Warehouse:

Traditional warehouses store products. Smart Warehouses? They incorporate the magic of technology to reimagine the existing storage and distribution processes. We're talking about state-of-the-art robots working seamlessly alongside humans, intricate networks of sensors, the incredible capabilities of artificial intelligence, the omnipresent Internet of Things (IoT), and game-changing software systems.

Why Go Smart?

Automation: It’s the bedrock of any Smart Warehouse. Using SaaS tools and robots, business owners can now reduce human interventions and fast-track operations. No more manually picking, packing, or storing - robots have got your back!

Connectivity: Envision a unified platform where all your devices converge. With SaaS solutions, that vision becomes reality. Now, you can have real-time visibility and control over your networks, inventory, vehicles, and more.

Data Accessibility and Analytics: Being limited to on-site systems? A thing of the past. Advanced analytics not only facilitates strategic, data-driven decisions but also offers real-time insights, accessible from anywhere.

Security: We've progressed from simply employing guards to utilizing state-of-the-art security measures. Motion-tracking cameras, firewalls, biometrics – all these work in harmony to ensure both physical and digital security.

But, What’s in It for Me?

For those in the e-commerce realm, this isn't just about keeping up with the trends. It’s about survival and thriving. Here are the wins you can expect:

Cost Efficiency: The upfront costs may be daunting, but in the long run, the savings, from reducing manual labor and minimizing errors, can be substantial.

Bolstered Efficiency: Tasks that once took hours are now completed in mere minutes.

Pinpoint Accuracy: Say goodbye to inventory mismatches or out-of-stock scenarios.

Enhanced Customer Service: Faster processing, real-time tracking, and fewer errors translate to happier customers.

Safety First: No more fretting about accidents or cyber threats. Smart Warehouses are equipped to tackle both.

Tech to Look Out For:

From collaborative robots (hello, cobots!) to Automated Guided Vehicles and the widely celebrated Warehouse Management Systems (like ERP software), the tech tools available today are pushing the boundaries of what's possible in warehousing.

Parting Thoughts:

The verdict is clear. As we hurtle towards a future defined by technology, smart warehouses are not just an option; they're the inevitable next step. With a forecasted market value of a whopping $54.60 billion by 2030, it's a shift that promises rewards for those ready to embrace it. If you're an e-commerce business, the future beckons. Are you ready?

0 notes

Text

Global Linear Motion System Market Is Estimated To Witness High Growth Owing To Increasing Demand in Automation and Robotics

The global Linear Motion System Market is estimated to be valued at US$ 9.38 Bn in 2021 and is expected to exhibit a CAGR of 8.1% over the forecast period 2022-2030, as highlighted in a new report published by Coherent Market Insights. A) Market Overview: Linear motion systems are essential components used in various industries such as manufacturing, packaging, healthcare, automotive, and others. These systems provide smooth and accurate movement along a linear path, enabling efficient transportation of goods or components. The advantages of linear motion systems include high precision, improved productivity, reduced downtime, and increased efficiency. The growing demand for automation and robotics in industries is driving the market for linear motion systems. B) Market Key Trends: One key trend observed in the global linear motion system market is the increasing demand for miniaturized linear motion systems. Miniaturization is a significant trend observed across various industries, driven by the demand for compact and lightweight solutions. Miniaturized linear motion systems offer precise movement in restricted spaces and are widely used in applications such as medical devices, microelectronics, and laboratory automation. For example, THK Co. Ltd offers miniature linear motion systems that are compact, lightweight, and provide high rigidity and accuracy. C) PEST Analysis: - Political: The political stability of a country affects the growth of the linear motion system market. Government policies supporting industrial automation and technological advancements play a crucial role in the market growth. - Economic: The economic conditions of a country influence the demand for linear motion systems. Growing economies and rising disposable incomes drive the adoption of advanced automation solutions. - Social: The increasing need for improved efficiency, productivity, and safety in industries is driving the adoption of linear motion systems. The shift towards Industry 4.0 and the growing demand for smart manufacturing further contribute to the market growth. - Technological: Technological advancements such as the integration of sensors, controllers, and software with linear motion systems enhance their capabilities and enable precise control and monitoring of movement. D) Key Takeaways: 1: The global Linear Motion System Market Growth is expected to witness high growth, exhibiting a CAGR of 8.1% over the forecast period, due to increasing demand for automation and robotics in industries. With the growing focus on productivity and efficiency, the adoption of linear motion systems is expected to increase. 2: The Asia Pacific region is expected to be the fastest-growing and dominating region in the global linear motion system market. Factors such as rapid industrialization, increasing investments in the manufacturing sector, and the presence of key market players contribute to the market growth in this region. 3: Key players operating in the global linear motion system market include Hiwin Corporation, Bosch Rexroth AG, The Timken Company, Schneeberger Group, Rockwell Automation Inc., Ewellix AB, THK Co. Ltd, Thomson Industries Inc., Parker Hannifin Corporation, Nippon Bearing Co. Ltd, HepcoMotion Inc., Lintech Corporation, and NSK Ltd. These players focus on product innovation, partnerships, and strategic collaborations to stay competitive in the market.

#Information and Communication Technology#ICT Industry#Linear Motion System#Linear Motion System Market

0 notes

Text

Manufacturing Industrial Robots

Automate repetitive duties and take the ergonomic pressure off staff with an array of commercial robots from Raymond and Bastian Solutions. Talk to us about customizing an answer to help streamline your distinctive pallet assembly and disassembly purposes. Just because the name suggests, cylindrical robots have a cylindrical work area. They function a robotic arm that's connected to a base via a single joint, with one more linear joint connecting the arm’s links visit site.

A second type of singularity in wrist-partitioned vertically articulated six-axis robots occurs when the wrist middle lies on a cylinder that is centered about axis 1 and with radius equal to the gap between axes 1 and four. Some robot manufacturers also mention alignment singularities, the place axes 1 and 6 turn into coincident. When the robotic passes near a shoulder singularity, joint 1 spins very fast. Repeatability is usually crucial criterion for a robotic and is just like the concept of 'precision' in measurement—see accuracy and precision. ISO 9283 units out a method whereby both accuracy and repeatability can be measured.

Many of probably the most oppressive and routine workplace chores—those that are dirty, dull, or dangerous—are now entirely within the robot realm. But because of current technologic advances, robots are also handling more complex operations that require extreme precision. For example, robots with laser-vision techniques can match doorways exactly to automotive bodies. These improvements, combined with several financial forces, are prompting companies to contemplate industrial robots extra significantly. The Silver Arm was created by MIT's David Silver to perform exact meeting using contact and stress sensors and a microcomputer.

Collaborative and traditional industrial robots © IFR International Federation of Robotics For more data, please refer to the IFR Positioning Paper on Demystifying Collaborative Robots and case studies. FANUC’s new SCARA robots are ideal for high-speed, precision applications corresponding to meeting, pick and place, testing/inspection, dispensing and packaging processes. It may be that when informed to go to a sure X-Y-Z place that it gets solely to inside 1 mm of that place. But if that position is taught into controller reminiscence and each time it is despatched there it returns to inside zero.1mm of the taught place then the repeatability will be inside zero.1mm. The cylindrical coordinate robots are characterised by their rotary joint at the base and a minimal of one prismatic joint connecting its hyperlinks.

How the robot interacts with other machines within the cell should be programmed, each with regard to their positions in the cell and synchronizing with them. Power source – some robots use electric motors, others use hydraulic actuators. Nowadays, it is extremely unlikely to see any hydraulic robots available in the market.

The automotive manufacturing industry has long been one of many quickest and largest adopters of commercial robotic expertise, and that continues to today. Robots are used in nearly each part of automotive manufacturing in one way or another, and it stays as one of the most highly automated supply chains on the planet. The report was produced as part of the MIT Work of the Future initiative. Worker resistance has not seemed to play an enormous role in slowing adoption of business robots, according to MIT.

This company developed a robot to complete a spray painting utility and finally turned ABB. This is only one example of when giant companies began to develop their own industrial robots. The first prototype, Unimate, was produced in 1961 and put in in GM's factory for die casting dealing with and spot welding.

The most deployed kind of robots within the manufacturing sector include gantry robots, which move alongside a single axis, and SCARA robots, which are able to shifting alongside three axes. Among the most recent types of robots, both exoskeletons and collaborative robots are designed to work in close proximity to people. Infineon’s components and system options are properly suited for industrial robots as a whole. Power digital elements, similar to IGBTs and CoolSIC™ MOSFETs, including becoming EiceDRIVER™ gate driver options throughout varied energy ranges, help a extensive range of robotic payloads. CoolMOS™ and CoolSIC™ MOSFETs, and auxiliary power supply solutions corresponding to CoolSET™ allow energy management.

However, they'd zero external sensing and were used for easy tasks such as pick and place. Spot welding joins two contacting metal surfaces by directing a big present via the spot, which melts the steel and forms the weld delivered to the spot in a really quick time . How sensible, connected robots are reworking manufacturing © IFRFor extra info, please check with the IFR Information Paper on How Connected Robots are Transforming Manufacturing.

This means they can produce high-quality products with little variation and greater consistency than their human counterparts. Here is a brief overview of how robotics in manufacturing are being used to vary the industry panorama by increasing productivity and precision while defending staff from unsafe working environments. With greater than 250 software features for enhanced intelligence, motion, safety and productiveness and a wide variety of FANUC high quality accessories, we now have an answer for almost every conceivable utility. The area of commercial robotics may be extra virtually outlined as the study, design and use of robotic techniques for manufacturing (a top-level definition counting on the prior definition of robot).

FANUC robots are easy to function and supply full flexibility due to a variety of application-specific choices, easy integration, payloads up to 2,300kg and most reaches as much as 4.7m. Fully autonomous robots in manufacturing are generally needed for high-volume, repetitive processes — where the speed, accuracy and sturdiness of a robot provides unparalleled advantages. Other manufacturing automation solutions include robots used to assist folks with extra intricate tasks. The robot executes elements of the method corresponding to lifting, holding and shifting heavy items. As extra companies are seeing the worth of robotics, the variety of industrial robots installed worldwide is estimated to extend to 2.6 million units by 2019.

When it involves purchase concerns, component price is mostly not a high concern when firms are shopping for finish effectors. This is very true for automotive OEMs that will incur high interruption prices if their production strains are down. Since grippers and EOATs account for around three % of the total value of automation, the choice of a high-priced provider will have relatively little influence on a company’s production-line prices.

Automation in manufacturing is extremely cost-effective for corporations of all sizes. Rather than outsourcing jobs abroad, smaller corporations can use robots to perform chosen tasks at a decrease price and with greater quality results than with outsourced workers. This may be stunning, since smaller manufacturing companies may assume that buying robotics is an costly funding. While the preliminary price could also be steep, the advantages can save manufacturers hundreds of dollars in reduced costs and improved productiveness.

Automation was achieved using punched paper tape to energise solenoids, which would facilitate the movement of the crane's control levers. The variety of motor revolutions required for every desired motion was first plotted on graph paper. This info was then transferred to the paper tape, which was also driven by the robotic's single motor. They are one of many first robots to have been used in industrial functions. They are commonly used for machine tending in die-casting, plastic injection and extrusion, and for welding. While there are many robotic functions to select from inside the industry, there are 6 that stand out as the most common and most precious purposes available on the market.

Accuracy may be improved with exterior sensing for example a vision system or Infra-Red. Accuracy can vary with velocity and position within the working envelope and with payload . This could additionally be outlined when it comes to the angular or linear velocity of every axis or as a compound pace i.e. the velocity of the tip of the arm when all axes are shifting. Delta robots are particularly helpful for direct control tasks and high maneuvering operations (such as quick pick-and-place tasks).

Concurrently, the robotic retains inventory on missing, mispriced or misplaced stock. But sooner or later, autonomous robots will work in all aspects of retail, from the warehouse to supply. These robotic arms can have a mess of sensors and imaginative and prescient systems able to viewing photographs to help with their computer-based control. That sensor and imaginative and prescient feedback can be utilized with with synthetic intelligence to make choices about the conduct of the robotic arm.

Alex Owen-Hill is a contract author and public speaker who blogs about a massive range of topics, together with science, presentation expertise at CreateClarifyArticulate.com, storytelling and robotics. He completed a PhD in Telerobotics from Universidad Politecnica de Madrid as part of the PURESAFE project, in collaboration with CERN. As a recovering academic, he maintains a firm foot in the robotics world by running a blog about industrial robotics. This is necessary because it allows producers to maintain their operations in the U.S and still compete within the world market. In reality, automation is changing into increasingly necessary for firms who wish to create more jobs in the U.S and stay competitive.

They may make the most of various sensors to help the robotic system in finding, handling, and positioning products. Industrial robotics took off quite rapidly in Europe, with each ABB Robotics and KUKA Robotics bringing robots to the market in 1973. ABB Robotics introduced IRB 6, among the many world's first commercially available all electric micro-processor managed robotic. The first two IRB 6 robots have been bought to Magnusson in Sweden for grinding and sprucing pipe bends and were installed in production in January 1974. Also in 1973 KUKA Robotics constructed its first robotic, known as FAMULUS, additionally one of the first articulated robots to have six electromechanically pushed axes.

Typically a robotic is shipped to a taught place numerous occasions and the error is measured at every return to the position after visiting 4 other positions. Repeatability is then quantified using the usual deviation of these samples in all three dimensions. A typical robotic can, after all make a positional error exceeding that and that might be a problem for the method. Moreover, the repeatability is completely different in different elements of the working envelope and likewise changes with velocity and payload. ISO 9283 specifies that accuracy and repeatability should be measured at most pace and at maximum payload. But this results in pessimistic values whereas the robotic could probably be rather more correct and repeatable at light hundreds and speeds.

youtube

1 note

·

View note

Text

Industrial Robots

Robot sales to automotive producers increased by 22 p.c to a brand new peak of almost a hundred twenty five,seven hundred models. Carmakers remained the biggest prospects for industrial robots last year – just – with a one-third share of the total supply. Innovators have created robots that mimic the movements of dogs, cats, insects, and people with eerie precision. In industrial settings, these advances are letting firms transfer a few of the most tough, harmful, and time-consuming duties from workers to robots. As this trend accelerates, each traders and robotic-component manufacturers are in strong positions to entry profit swimming pools.

Collaborative industrial robots are designed to carry out duties in collaboration with employees in industrial sectors. The International Federation of Robotics defines two forms of industrial robots designed for collaborative use. The different group covers robots designed for collaborative use that do not satisfy the requirements of ISO.

Since grippers and EOATs account for around 3 p.c of the total price of automation, the selection of a high-priced supplier could have relatively little impact on a company’s manufacturing-line prices. As China builds its robotic installed base, it's going to see a 25 % annual increase in demand for end effectors from 2018 by way of 2023. That determine represents about 45 % of the whole market growth expected over those years, and it’s greater than the mixed contribution of Europe and North America. Of the $5.1 billion in market worth for grippers and EOATs in 2023, greater than $1 billion will come from China. If your business isn’t listed on this listing, it doesn’t imply that you can’t use robots in your business. In reality, lots of the hottest robotic functions are applicable to almost any business.

Increased use of robots can be enabling firms in high value nations to ‘re-shore’ or bring again to their home base components of the supply chain that they have beforehand outsourced to sources of cheaper labor. This implies that even small-quantity productions can effectively be automated in areas similar to components welding and slicing, versatile assembly and packaging and palletizing. Robot investments have gotten more and more worthwhile and hence turn out to be increasingly widespread within business. The robotic’s actions are directed by a mixture of programming software and controls. Their automated performance allows them to function around the clock and on weekends—in addition to with hazardous supplies and in difficult environments—releasing personnel to carry out other duties.

The International Federation of Robotics has predicted a worldwide enhance in adoption of industrial robots and so they estimated 1.7 million new robot installations in factories worldwide by 2020 . Using knowledge from the Bureau of Labor Statistics, NIOSH and its state companions have investigated four robot-associated fatalities beneath the Fatality Assessment and Control Evaluation Program. In addition the Occupational Safety and Health Administration has investigated dozens of robot-associated deaths and accidents, which could be reviewed at OSHA Accident Search page. Injuries and fatalities could increase over time because of the rising number of collaborative and co-existing robots, powered exoskeletons, and autonomous automobiles into the work environment.

ISO 9283 specifies that accuracy and repeatability should be measured at most velocity and at maximum payload. But this ends in pessimistic values whereas the robot could be rather more accurate and repeatable at gentle loads and speeds. Repeatability in an industrial process is also topic to the accuracy of the end effector, for instance a gripper, and even to the design of the 'fingers' that match the gripper to the item being grasped. For instance, if a robot picks a screw by its head, the screw might be at a random angle. A subsequent try and insert the screw into a gap could simply fail.

In the year 2020, an estimated 1.64 million industrial robots have been in operation worldwide according to International Federation of Robotics . Industrial robots are automated, programmable and capable of motion on three or more axes. The most commonly used robot configurations for industrial automation, include articulated robots, SCARA robots and gantry robots. The IFR forecasts continued annual industrial robot growth of 5 percent in Germany over the subsequent three years. IFR forecast US industrial robot development of 5 percent this year, rising to 10 percent between 2019 and 2021.

The enthusiasm and funding weren't at all times matched with understanding. General Motors Corporation spent greater than $40 billion on new technology in the 1980's, but a lack of know-how led to expensive robotic fiascos. In 1988, robots at the Hamtramck Michigan plant wreaked havoc - smashing home windows andpaintingone one other. Unfortunately, the premature introduction of robotics began to create monetary instability. The Silver Arm was created by MIT's David Silver to perform exact meeting using touch and pressure sensors and a microcomputer.

The International Federation of Robotics has published its annual report on the state of the commercial robotics market worldwide. Companies usually buy finish effectors once they automate a brand new manufacturing line or when they determine to transform or overhaul their existing production tools, together with robotic arms. Likewise, corporations may purchase grippers and EOATs after they must retool their manufacturing strains to support the introduction of new or updated products or once they introduce a variant, similar to a hybrid version of a automotive. Although companies additionally buy robotic elements because of general wear and tear, this isn’t a substantial source of revenue for suppliers of end effectors, since most parts are covered beneath lengthy warranties. End effectors also tend to final for much longer than the expected lifetime outlined in their specs. Despite the rising demand for grippers and EOATs, little analysis is available on this crucial market phase.

However a computer is commonly used to 'supervise' the robotic and any peripherals, or to offer further storage for entry to quite a few complicated paths and routines. A robotic and a set of machines or peripherals is known as a workcell, or cell. A typical cell might contain a elements feeder, a molding machine and a robotic. The varied machines are 'integrated' and managed by a single pc or PLC.

ABB Robotics is a pioneer in robotics, machine automation and digital companies, providing progressive solutions for a diverse range of industries, from automotive to electronics to logistics. As one of many world’s leading robotics and machine automation suppliers, ABB Robotics employs greater than 11,000 folks in fifty three international locations and has shipped greater than 500,000 robotic options. Sensors and vision systems allow robots to reply to their exterior setting in real-time, increasing the range of duties the robotic can perform - such as choosing and putting unsorted parts - and expanding robotic mobility. Mobile robots are key to enabling versatile manufacturing, in which production is split into discrete processes and manufacturing cells working in parallel. Collaborative and conventional industrial robots © IFR International Federation of Robotics For more info, please check with the IFR Positioning Paper on Demystifying Collaborative Robots. In 2019, about 4.eight% industrial robots installed, had been cobots, an increase of 11% over 2018.

In 1969 Victor Scheinman at Stanford University invented the Stanford arm, an all-electrical, 6-axis articulated robotic designed to allow an arm resolution. This allowed it accurately to comply with arbitrary paths in space and widened the potential use of the robotic to more sophisticated purposes similar to meeting and welding. Other robots are far more versatile as to the orientation of the object on which they are operating or even the task that has to be performed on the object itself, which the robotic may even have to determine.

Often known as ‘cobots’, these robots are designed with quite a lot of technical options that ensure they do not cause harm when a employee comes into direct contact, either deliberately or accidentally. In the context of common robotics, most types of industrial robots would fall into the class of robot arms. Elsewhere in Europe, robot investments increased by 19 percent to a new record of 7,seven hundred units last 12 months in Italy.

Many of probably the most oppressive and routine office chores—these which are soiled, dull, or dangerous—are actually totally within the robotic realm. But thanks to current technologic advances, robots are also handling extra complex operations that require excessive precision. For example, robots with laser-vision systems can fit doorways exactly to car bodies. These improvements, combined with several economic forces, are prompting corporations to contemplate industrial robots more critically.

With 18 sequence of fashions, FANUC offers the widest range of industrial robots on the planet. Covering a various vary of functions and industries, FANUC machines are simple to operate and supply complete flexibility. With greater than one hundred models, FANUC provides the widest vary of commercial robots in the world. FANUC offers the widest collection vary of commercial robots in the world.

For examples of how this may look in well-liked robot languages see industrial robotic programming. The most important robot peripheral is the top effector, or end-of-arm-tooling . End effectors are regularly highly advanced, made to match the handled product and often able to picking up an array of merchandise at one time. They might utilize numerous sensors to aid the robotic system in finding, dealing with, and positioning products. Manufacturing impartial robotic programming instruments are a relatively new however flexible method to program robot applications. Using a graphical consumer interface the programming is completed through drag and drop of predefined template/building blocks.

This consists of following a security-licensed growth course of for safety-crucial system components. An experienced companion with intensive information about robotics – from the system as a whole to every final drive and sensor – is crucial to a project’s success. A big selection of parts flows into an industrial robot design to create a seamlessly functioning system. Each robotic usually includes three main parts, a control box, a manipulator and a selected software, mounted on the highest of the robotic’s arm.

Of course, major technologic advances might disrupt the robotic-part business, as they've carried out in other sectors, and shift demand in surprising directions. It’s hard to predict whether or not such disruptions will materialize—or anticipate the time-frame over which they might occur—however industry stakeholders might want to monitor all technologic developments closely. The robotic installed base will see robust global growth, however rising markets will account for the best enhance. China, in particular, will see automation surge, partly in response to the government’s Made in China 2025 plan. Introduced in 2015, the plan goals to transform the country into the world’s high manufacturing powerhouse by bettering product high quality via larger automation.

Including the cost of software, peripherals and techniques engineering, the annual turnover for robot systems is estimated to be US$48.zero billion in 2018. This is a wrist about which the three axes of the wrist, controlling yaw, pitch, and roll, all pass by way of a common point. An instance of a wrist singularity is when the path by way of which the robot is traveling causes the primary and third axes of the robotic's wrist (i.e. robotic's axes 4 and 6) to line up. The second wrist axis then attempts to spin 180° in zero time to keep up the orientation of the top effector. The result of a singularity may be fairly dramatic and may have antagonistic effects on the robot arm, the top effector, and the process. Some industrial robotic producers have tried to side-step the situation by slightly altering the robot's path to stop this situation.

With more than 250 software capabilities for enhanced intelligence, motion, security and productiveness and a wide variety of FANUC top quality equipment, we have a solution for nearly each conceivable application. Introducing the high rigidity robotic M-900iB/280 The M-900iB/280 is FANUC’s new specialist for purposes that demand maximum rigidity from the robotic. With more than 20,000 painting robots put in worldwide, ABB’s many years of expertise have culminated in PC software designed with the customer’s wants in thoughts. Get even more accurate search results via payload analyses with KUKA Compose.

The cylindrical coordinate robots are characterized by their rotary joint at the base and at least one prismatic joint connecting its hyperlinks. The compact effector design permits the robotic to succeed in tight workspaces without any lack of speed. Cartesian robots, additionally known as rectilinear, gantry robots, and x-y-z robots have three prismatic joints for the motion of the software and three rotary joints for its orientation in space. Receive the latest IoT news and analysis in your trade, straight to your inbox. Robot gross sales to the /electronics trade worldwide have been significantly up since 2013 and are now virtually at the same level because the automotive business. Compared to Germany and Japan , the gap is exceptional – particularly since Japan had the world’s highest robotic density in 2009.

While it’s definitely true that robots are becoming ever extra well-liked, some industries are extra affected than others. The invention of the Numerically Controlled machines, the recognition of the computer , and the built-in circuit all helped to make it possible to begin to develop the very first, but simple, industrial robot. Discover what your industrial robotic project can obtain when you partner with us. We sit up for listening to from you – and to studying extra about your design.

To have the ability to move and orient the effector organ in all directions, such a robotic wants 6 axes . In a 2-dimensional environment, three axes are enough, two for displacement and one for orientation.

It additionally presents robotic density, i.e. the number of robots per 10,000 staff, as a measure for the degree of automation. The setup or programming of motions and sequences for an industrial robotic is typically taught by linking the robotic controller to a laptop, desktop laptop or community. Power source – some robots use electrical motors, others use hydraulic actuators. Nowadays, it's extremely unlikely to see any hydraulic robots available in the market. Additional sealings, brushless electrical motors and spark-proof protection eased the development of units which might be in a position to work in the environment with an explosive environment.

There, robotic installations elevated considerably between 2012 and 2017, by 26 p.c a yr on average. That figure represents development of 31 p.c, but the IFR forecasts that UK gross sales will now develop at a modest three p.c a yr till 2021. Robot installations within the US increased to a brand new peak of 33,192 units in 2017 – the seventh successive 12 months of development, and 6 p.c larger than in 2016. Since 2010, the main driver of this development has been the need to strengthen US industries at house and abroad. But China is far from the leading country by way of robotic density – the number of robots per 10,000 employees, IFR’s most popular measurement for comparing the relative sizes of the market in different economies. Since 2013, China has been the world’s biggest robot market with “continued dynamic development” and a 36 percent share of the world’s complete supply in 2017.

Repeatability is then quantified utilizing the usual deviation of these samples in all three dimensions. A typical robotic can, of course make a positional error exceeding that and that could possibly be an issue for the process. Moreover, the repeatability is completely different in numerous parts of the working envelope and in addition modifications with speed and payload.

The capacity to preview the habits of a robotic system in a virtual world permits for a variety of mechanisms, gadgets, configurations and controllers to be tried and examined earlier than being applied to a "real world" system. Robotics simulators have the flexibility to provide actual-time computing of the simulated movement of an industrial robotic using both geometric modeling and kinematics modeling. Offline programming is where the complete cell, the robotic and all of the machines or devices in the workspace are mapped graphically. A robotics simulator is used to create embedded applications for a robotic, with out depending on the physical operation of the robotic arm and end effector. The benefits of robotics simulation is that it saves time in the design of robotics functions.

youtube

For instance, for more exact steering, robots usually include machine vision sub-techniques performing as their visual sensors, linked to powerful computers or controllers. Artificial intelligence, or what passes for it, is turning into an more and more necessary factor within the trendy industrial robotic. Serial architectures a.k.a Serial manipulators are the most common industrial robots and they are designed as a sequence of links related by motor-actuated joints that extend from a base to an finish-effector.

1 note

·

View note

Text

GLIMPSE ON INDIAN TECHNOLOGY REVOLUTION SINCE 1947 (IN THIS INDEPENDENCE DAY)

This Independence day we all will take time out to celebrate precisely. As how in recent times the advancement of specific technology and automation liberated various types of companies. The independence of India itself has been a turning point in its economic history. We are celebrating our 74th independence day on 15 August 2020 and the truth has happened to us that we are a long way. From being an underdeveloped nation ruled by the British to a prosperous economy in the developing world .

The country was hopelessly poor as a result of British deindustrialization. We have a huge market and an enormous pool of talent to fuel our growth. In the past 74 years it has achieved a lot. Science and technology are one of the areas where India has made great achievements and seen the technological transition. Computers have a profound influence on society. The revolution often called the "digital revolution" has almost four phases of technology.

Digital Revolution

The first generation wherein computers were invented and used vacuum pipes for their electrical logic. And liquid mercury safety, changing industry all over the world in the early 1960s. The business became a pioneer in this age of computers.

The second generation occurred in the 1980s when customers became clients for personal computers, and India would not have seen the first wave of IT entrepreneurship without that.

If the Internet had not spread, the third generation may not have flourished. This was the age of popular and micro computers, bigger organized machines and desktop-small enterprises.

The fourth started with the adoption of smart devices , data analytics and artificial intelligence. Further it went with the automation industry.

Fifth Generation: The future, this period will concentrate on collaboration between man and machine. When human intellect functions in conjunction with cognitive computation, employees may be able to have value-added employment in their industry by bringing humans back into industrial manufacturing with interactive robotics. More advanced work and the recognition of natural languages are features that users understand, but software that enhances their features through self learning will change everything in the future in the technical world.

On this independence day as we all are going to stay at home due to this pandemic let's change our home and know more about switches.Switches illuminate the house. You would say that lighting and bulbs do it, but the light control is the switch.So you have come to the right place if you want to get new lighting solutions for your home!! Here you find everything you need to choose the right switches, so you do not have to think about your home's lighting.

EVOLUTION OF LIGHT SWITCHES

Just Like Anything Switches too have their history. Let us find out how the switches developed over time with technological advancement

QUICK BREAK SWITCH

A quick break switch established in 1888 by Henry Holmes. The main problem that it solved the switches contact did not create an electrical arching whenever the circuit opened or closed. This increased switch life.

THUMB SWITCH

The thumb switch light works on a single lever system, unlike the more common push-button switch. The switch is pressed, then turned down to close the circuit and return the electrical outlet's power

TOGGLE SWITCH

This is the most common switch presently as the simple circuit life of the switch extended. This is flammable, reducing fire chances by a circuit break. The switches are 1.00,000 clicks long.

SMART TOUCH SWITCH

Not only does a smart touch switch turn light on or off, it also adjusts the light intensity. This helps you to change the color of the light according to your mood! The switch has variable resistors to change the intensity of the switch.

CONCLUSION

Switches were invented earlier in the early 80s. They used for on-off purposes only before. The new switches that are currently available are not only possible to turn on and off for various purposes. Some of the purposes are to adjust the lamp's luminosity, to regulate fan speed and to adjust the comfortable room 's temperature. Most of the time, switches type still mounted wall and give a mechanical sound. But technology developments have also made it possible to use sensitive touch or motion switches!

#independenceday#74th independence day#independeceday#happyindependenceday#independenceindia#independenceday2020#technology#smartindia#digitalindia#technology revolution#whitelion#smart home#smart house#smart device

1 note

·

View note

Link

Asia Pacific Motion Sensor Market is expected to reach USD XX Billion by 2024 from USD XX Billion in 2016 at a CAGR of XX% (Detailed analysis of the market CAGR is provided in the report).

Asia Pacific Motion Sensor MarketA motion sensor is a device which is capable of detecting physical movement on a designated device or monitors movement within an environment. These devices have the ability to detect as well as capture physical movements in real time basis. The motion sensors are also known as motion detectors. Depending on the capacity of the motion sensor, it detects motions within devices in which it is integrated also comprising of the surrounding environment. The motion sensors are usually connected with a system or a software that processes the overall motion into a definitive action or information.

Asia Pacific Motion Sensor Market is classified based on technology, embedded sensor type, by application, and by geography. By technology, the market is segmented into ultrasonic, tomographic, infrared motion, microwave, and dual technology. Based on sensor type, the market is divided into MEMS gyroscope, MEMS accelerometer, MEMS magnetometer, and sensor combos. Aerospace & defense, consumer electronics, automotive, healthcare, and industrial application.

Asia Pacific (APAC) is known for manufacturers that make advanced sensors for global level industry applications. The sophisticated and innovative hardware being developed and assembled in APAC from all over the world is remarkable. The APAC region has undergone huge changes in terms of technological development and the usage of sensors. Some of the latest trends found in APAC comprises of the Robotic Kitchen. It has the capability to learn the activities and actions of real chefs and also replays their actions in the desired accurate motion for creating the same dishes. The recipe database present will store various cooking motions of global chefs that the users will be able to access and can be controlled using their smartphones. Motion sensors help in addressing and understanding the key movements by chefs which will eventually be copied for future reference.

APAC has been one of the largest automotive manufacturing regions globally. Presence of a large number of manufacturers along with the higher application of motion sensor across various industry verticals has boosted the overall demand for motion sensors. Large automotive manufacturers are using motion-enabled sensors that are embedded inconspicuously within the interior of the car. These sensors enable users to open the sunroof, or unfold and fold the attached rear-view mirrors further adjusting navigation or the entertainment systems using motioning intuitive gestures.

Availability of these sensors in automotive sector helps in keeping the driver’s eyes only on the road and also providing him with a more entertaining, efficient, and enriching driving experience. Application of these sensors by the automotive manufacturers in the APAC region signifies the rising trend of using motion-sensing technology across various consumer products. Tech giants like Intel have also shown the advanced application of motion-sensing technology in consumer electronic products at the inaugural ceremony of CES Asia which is a trade fair organized by the Consumer Technology Association.

China, India, Japan, South Korea, and Australia are some of the key countries that were the major contributors to the rise in demand for motion sensor market in Asia Pacific region. Higher application of motion sensors in the automotive sector which has seen immense growth along with the development of smart cities has further fuelled the market demand for motion sensor in APAC region.

Key Highlights:

• Asia Pacific Motion Sensor market size analysis and forecast.

• Comprehensive study and analysis of market drivers, restraints, and opportunities influencing the growth of the Asia Pacific Motion Sensor market.

• Asia Pacific Motion Sensor Market segmentation on the basis of technology, embedded sensor type, application, and geography.

• Asia Pacific Motion Sensor Market strategic analysis with respect to individual growth trends, future prospects along with the contribution of various sub-market stakeholders have been considered under the scope of the study

• Asia Pacific Motion Sensor Market analysis and forecast for major countries has been provided.

• Profiling of key industry players, their strategic perspective, market Motioning and analysis of core competencies

• Competitive landscape of the key players operating in the Asia Pacific Motion Sensor Market including competitive developments, investments, and strategic expansion

Years that have been considered for the study are as follows:

• Base Year – 2016

• Estimated Year – 2017

• Forecast Period – 2017 to 2024

For company profiles, 2016 has been considered as the base year. In cases, wherein information was unavailable for the base year, the years prior to it have been considered.

Research Methodology:

The market is estimated by triangulation of data points obtained from various sources and feeding them into a simulation model created individually for each market. The data points are obtained from paid and unpaid sources along with paid primary interviews with key opinion leaders (KOLs) in the market. KOLs from both, demand and supply side were considered while conducting interviews to get an unbiased idea of the market. This exercise was done at a country level to get fair idea of the market in countries considered for this study. Later this country-specific data was accumulated to come up with regional numbers and then arrive at the market value for Asia Pacific Motion Sensor Market

For more information visit:

https://www.maximizemarketresearch.com/market-report/asia-pacific-motion-sensor-market/4593/

Some of the key players of the Asia Pacific Motion Sensor market include:

• Sensinova

• China WLCSP Co., LTD.

• Murata Manufacturing Co. Ltd.

• Omron Electronics

• SICK

• Optex

• mCube

• Arcsoft

• Swann

• Panasonic Corporation

• STMicroelectronics N.V.

Key Target Audience:

• Semiconductor product designers and fabricators

• Motion sensors manufacturers

• Component suppliers

• End-users/enterprise-users

• Research institutes and organizations

• Government bodies, venture capitalists, and private equity firms

• Market research and consulting firms

• Enterprise data center professionals

The Scope of the Asia Pacific Motion Sensor Market:

The research report segments Asia Pacific Motion Sensor market based on methodology, industry, and application.

Asia Pacific Motion Sensor Market, By Technology:

• Ultrasonic Sensor

• Tomographic Sensor

• Infrared Motion Sensor

• Microwave Sensor

• Dual Technology Sensor

Asia Pacific Motion Sensor Market, By Embedded Sensor Type:

• MEMS Gyroscope

• MEMS Accelerometer

• MEMS Magnetometer

• Sensor Combos

Asia Pacific Motion Sensor Market, By Application:

• Aerospace & Defense

• Consumer Electronics

• Automotive Application

• Healthcare

• Industrial Application

Asia Pacific Motion Sensor Market, By Geography:

• Asia Pacific

o China

o Japan

o India

o South Korea

o Australia

o Others

Geographic Analysis:

• Breakdown of China Motion Sensor market

• Breakdown of Japan Motion Sensor market

• Breakdown of India Motion Sensor market

• Breakdown of South Korea Motion Sensor market

• Breakdown of Australia Motion Sensor market

• Breakdown of Others Motion Sensor market

Available Customization:

Maximize Market Research offers customization of reports according to the specific requirement of our clients.

This Report Is Submitted By Maximize Market Research

Customization of the report:

Maximize Market Research provides free personalized of reports as per your demand. This report can be personalized to meet your requirements. Get in touch with us and our sales team will guarantee provide you to get a report that suits your necessities.

About Maximize Market Research:

Maximize Market Research provides B2B and B2C research on 20,000 high growth emerging opportunities & technologies as well as threats to the companies across the Healthcare, Pharmaceuticals, Electronics & Communications, Internet of Things, Food and Beverages, Aerospace and Defense and other manufacturing sectors.

Contact info:

Name: Lumawant Godage

Organization: MAXIMIZE MARKET RESEARCH PVT. LTD.

Email: [email protected]

Address: Maharashtra 411051, India.

Contact:+919607365656

1 note

·

View note

Text

Automotive Embedded System Market Estimated to Expand at a Robust CAGR By 2032

The Global Automotive Embedded System Market was valued at US$ 4.5 Bn in 2021 and is expected to reach US$ 8.2 Bn by 2032, finds Future Market Insights (FMI) in a recent market survey. As per the findings of the report, a key driver of the Automotive Embedded System Market's expected growth is the necessity to expand target functionality and customize core software for a wide range of automobiles.

It is projected that revenue through the software segment in the automotive embedded system will grow at 5.2% CAGR during the forecast period. The increase in the number of software developers is predicted to reach over 250 thousand by 2030, reflecting the increased overall development effort in the coming decade. This represents an enormous market potential for the software segment in the automotive embedded system market.

The United States to Remain the Largest User of Automotive Embedded Systems Throughout the Analysis Period

From 2022 to 2032, the Automobile Embedded System Market is estimated to grow at a CAGR of 4.8% in the United States. In the United States, the suppliers cannot be regarded as truly independent from the carmakers. The United States has a leading market share in the embedded systems market due to stronger integration of the embedded systems market amongst research institutes, suppliers, and automobile manufacturers. North America accounts for 41.4% of the global automotive embedded system industry and would generate US$ 3.3 Bn by 2032, according to the forecast.

“A cooperative development process is preferred to design innovative in-vehicle embedded systems, in order to expand the system's flexibility. It will be a revenue multiplier for OEMs and suppliers by reducing the cost of the product.” comments an analyst at Future Market Insights.

Automotive Electric Connectors Market: Competition Insights

In October 2021, German technology group Robert Bosch has earmarked more than US$ 400 Mn for investments in microchip production to ease a global shortage.

In June 2022, Real-time Robotics, announced that it has collaborated with Mitsubishi Electric Automation, Inc., to further the programming and control of industrial robots with innovative motion control and collision avoidance software used in automotive.

In June 2021, Zhuhai ENPOWER Electric Co., Ltd announced that it is the first to integrate the latest 750 V automotive-grade IGBTs from Infineon Technologies AG. The discrete IGBT EDT2 devices enable performance boosts and system cost savings in main inverter applications and DC link discharge switches of electric vehicles are also useful in achieving system integration targets.

In January 2022,Johnson Electric launched an all-in-one e-axle solutions pack for energy vehicles. From safety parking to four-wheel drive mode switching to electric drive position detection, the pack covers all of the bases.

More Insights Available

Future Market Insights, in its new offering, presents an unbiased analysis of the Automotive Embedded Systems Market, presenting historical market data (2017-2021) and forecast statistics for the period of 2022-2032.

The study reveals extensive growth in Automotive Embedded Systems Market in terms of Type (Software and Hardware), By Component (Memory Devices, Microcontrollers, and Sensor), By Application (Powertrain & Chassis Control, Body Electronics, and Multimedia and Integrated Systems/Services), across five regions (North America, Latin America, Europe, Asia Pacific and Middle East & Africa).

For More Info@ https://www.futuremarketinsights.com/reports/automotive-embedded-system-market

About Future Market Insights (FMI)

Future Market Insights, Inc. is an ESOMAR-certified business consulting & market research firm, a member of the Greater New York Chamber of Commerce and is headquartered in Delaware, USA. A recipient of Clutch Leaders Award 2022 on account of high client score (4.9/5), we have been collaborating with global enterprises in their business transformation journey and helping them deliver on their business ambitions. 80% of the largest Forbes 1000 enterprises are our clients. We serve global clients across all leading & niche market segments across all major industries.

0 notes

Text

Robotic Surgery Systems Market: Introduction

Robotic-assisted surgery is the practise of performing operational procedures with the aid of robotic technology. The majority of telemanipulators that use robotic-assisted systems use a surgeon's movements to control the "effector" on the other side. For minimally invasive, remotely controlled operations, a robotic system provides precision. The current systems consist of electromechanical components that are computer-controlled and react to controls that surgeons adjust. This robotic-assisted device can be used for a variety of procedures, including minimally invasive cardiac, gynaecological, thoracic, urological, colorectal, and head and neck surgery. Market segments include application, system, consumable and accessory, software, and services.

Overview

The market for surgical robots was valued at $ 56,294.9 million in 2017 and is projected to grow to $ 98,737.0 million by 2024 at a CAGR of 8.5 percent. Laparoscopic or minimally invasive surgery (MIS) is becoming more and more popular due to its advantages for both patients and surgeons, including improved screening, increased precision, shorter hospital stays, decreased pain and discomfort, decreased risk of infection, and decreased blood flow and transfusion. Additionally, the market for surgical robots is expanding as a result of the rise in gynaecological, neurological, and urological conditions. In addition, the development of novel, advanced robots will satisfy the expanding demands of end users.However, as the number of these instances rises, so too does the demand for robotic-assisted surgical systems because of the many benefits they offer, including the facilitation of precise, tremor-free surgery and the advantages of minimally invasive techniques.

The market is expanding as a result of rising technology breakthroughs, new market entrants, the burden of chronic diseases is increasing, and minimally invasive procedures are becoming more popular. The most common diseases worldwide and the main causes of death are cardiovascular disorders. According to World Health Organization updates for 2020, ischemic heart disease is to blame for close to 16% of all fatalities worldwide. The number of cardiopulmonary procedures is rising along with the prevalence of cardiovascular disorders.

For More Insights, Download a Free Sample Copy of Robotic Surgery Systems Market@ https://healthcaremarketreports.com/sample-request/robotic-surgery-systems-market/11216/

Segmentation Analysis of Global Robotic Surgery Systems Market

Based on type

Non-invasive Surgery Robots

Based on application

Orthopedic

Laparoscopy

Neurology

Competitive Landscape

Intuitive Surgical,Inc.

Computer Motion,Inc.

Integrated Surgical

Stryker

Accuray

Medrobotics

Titan Medicals

Stereotaxis

Major questions answered in this report

• What is the driving factor for the growth of the Robotic Surgery Systems market?

• How will the COVID-19 pandemic impact the demand and consumption of the Robotic Surgery Systems market?

• What is the major application area of the Robotic Surgery Systems market?

• Who are the Robotic Surgery Systems manufacturers across the globe?

• Which geographical location is dominant in the Robotic Surgery Systems market?

• Which are the top industry players in the Robotic Surgery Systems market?

For More Details, Visit Our Robotic Surgery Systems Market Report Page

Key takeaways from the report

The market for surgical robots was valued at $ 56,294.9 million in 2017 and is projected to grow to $ 98,737.0 million by 2024 at a CAGR of 8.5 percent

The effect of COVID-19

As a result of the advent of cutting-edge medical treatments and rising internet usage, healthcare companies are currently operating in a dynamic environment that is undergoing seismic shifts. This has smart patients being more cautious, along with unmatched online access to astonishing amounts of knowledge. As a result, there is a growing need for intelligent, reasonably priced, and customised healthcare services. The COVID-19 epidemic has also increased demand for healthcare and related goods and services, boosting the performance of the healthcare sector as a whole.

We provide information in our personalised reports that is catered to the particular requirements of all the significant stakeholders. Our reports included market analyses that gave our clients relevant information on the market's size, present competition, and other elements. Additionally, reports evaluate the impact of common

Our specialized reports offer information that is tailored to the unique needs of all the important stakeholders. Our reports provided with market evaluations that provide our clients with useful insights into market size, current competition, and other factors. Reports also estimate the burden of common and unusual disease disorders based on prevalence and cost of care. Reports also include executive-level market blueprint and valuable ideas to help and establish effective expansion plans. Healthcare reports also provide in-depth examination of a market's research and development landscape. These data pointers and analysis provide in-depth research of pipeline product distribution by on clinical trial stage, therapeutic region, indication, and other factors.

About Us:

The healthcare industry is surely facing disruptions with global economies giving high importance to individual health. In this scenario, we expect our clients to get deep insights to power their innovations in the right direction. We have been keeping a close watch on the changes and modifications happening in the healthcare domain. As per our understanding, these alterations are active and unexampled

0 notes

Text

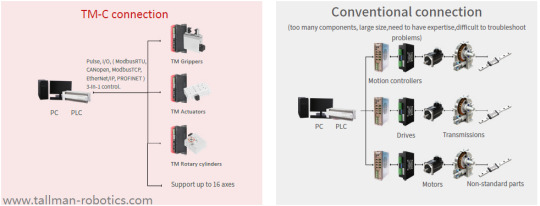

Motion Controller

Motion Controller: Tallman Robotics Limited provides one-stop solution for intelligent, reliable and affordable Motion Controller for servo electric cylinders in China. With strong independent R&D capabilities, the Company independently develops and manufactures servo grippers, servo pushers, servo slides, servo rotary cylinders and integrated drive and control controllers, and offers servo electric cylinders with reliable quality, high precision, low cost, ease of use and less maintenance, etc. by integrating its self developed servo control algorithms, electronic circuits, software design and high-precision force control technology, which promotes the widespread application of servo electric cylinders in China.

1. What are the features of Tallman Robotics Limited’s motion controller? Independent research and innovation, Mast core technology! Powerful and easy to use! Support multiple programming language control! Multilingual control TM provides complete programming, teaching, parameter modification and other API interfaces. It supports and is not limited to Lab view, C #, C ++, Python and other programming language controls. Three-in-one communication control Modbus control I / O mode control (maximum 16 bits, 256 points) Pulse control (perfectly compatible with all pulse mode controllers on the market)

Hybrid control of force and position Control modes can be selected for a variety of flexible combinations. Position, travel, speed control; clamping force, pushing pressure control; measurement control. Simple torque mode control Controlled by the TM software platform, it is more convenient to coordinate equipment. Quick adjustment through the external knob of TM-C controller. No additional sensors Without additional sensors, it can realize the functions of built-in area signal, return to mechanical origin, software limit and so on. Communication and IO isolation Block interference introduced by communication and improve system stability. Vibration suppression Reduce waiting time, reduce production costs, effectively improve accuracy and production efficiency. Self-adjusting and finishing function Reduce debugging difficulty, improve power utilization, and use it out of the box! Get started quickly No code is required, and the visual programming can complete the point programming, saving a lot of man-hours. 2. Multiple Operating Modes from TM Motion Controllers: Positioning action Area output function Based on the origin, set the target position to move to, and set the speed, acceleration, and deceleration zone. Set a "regional signal output range", and trigger the running event when moving to this region. Push action Relative displacement Set an output force value. When the target module moves to contact with the work piece, it stops moving and maintains a force value. Based on the current position, move a relative distance to the next position. 3. Simple connection, Apply out of the box: 4. Why choose Sango Automation? 5. Related knowledge: Motion Controller Motion control usually refers to the conversion of predetermined control schemes and planning instructions into desired mechanical motions under complex conditions to achieve precise position control, speed control, acceleration control, torque or force control of mechanical motions. The motion controller is a special controller that controls the operation mode of the motor: for example, the motor is controlled by the travel switch to control the AC contactor and the motor drags the object up to the specified position and then runs down, or the time relay is used to control the motor to reverse Or stop for a while and then stop for a while. The application of motion control in the field of robots and CNC machine tools is more complicated than in special machines, because the latter form of motion is simpler and is commonly referred to as general motion control (GMC). Motion controller defines a dedicated controller that controls the operation of the motor is widely used in the packaging, printing, textile and assembly industries Basic introduction: Motion control (Motion Control) usually refers to the conversion of predetermined control schemes and planning instructions into the desired mechanical motion under complex conditions to achieve precise position control, speed control, acceleration control, torque or force control of mechanical motion. According to the different power sources used, motion control can be divided into electric motion control with motor as power source, gas-liquid control with gas and fluid as power source and thermal engine motion control with fuel (coal, oil, etc.) as power source Wait. According to statistics, more than 90% of all power sources come from electric motors. The motor plays a very important role in modern production and life, so in these kinds of motion control, electrical motion control is the most widely used. Electric motion control is developed by motor dragging. Electric dragging or electric drive is a general term for a control system targeted by an electric motor. There are many kinds of motion control systems, but from the basic structure, the hardware of a typical modern motion control system is mainly composed of a host computer, a motion controller, a power drive device, a motor, an actuator, and a sensor feedback detection device. The motion controller refers to a control device that takes the central logic control unit as the core, the sensor as the signal sensitive element, and the motor or power device and the execution unit as the control objects. The motion controller is a special controller that controls the operation mode of the motor: for example, the motor is controlled by the travel switch to control the AC contactor and the motor drags the object up to the specified position and then runs down, or the time relay is used to control the motor to reverse Or stop for a while and then stop for a while. The application of motion control in the field of robots and CNC machine tools is more complicated than in special machines, because the latter form of motion is simpler and is commonly referred to as general motion control (GMC). The motion controller is the main device that determines the performance of the automatic control system. For the Mitsubishi series, the motion CPU is the motion controller. For a simple motion control system, a motion controller designed with a single-chip microcomputer can meet the requirements and has a high cost performance. Domestic products At present, the products provided by domestic motion controller manufacturers can be roughly divided into three categories: Take SCM or PC processor as the core The motion controller with a single-chip computer or a microcomputer processor as the core. This type of motion controller has a slow speed, low accuracy, and relatively low cost. It is used in some contour motion control applications that only require low-speed point motion control and low trajectory requirements. Use a dedicated chip as the core processor The motion controller with a dedicated chip as the core processor has a relatively simple structure, but this type of motion controller can only output pulse signals and work in an open-loop control mode. This type of controller basically meets the requirements for single-axis point control occasions, but for devices that require multi-axis coordinated motion and high-speed trajectory interpolation control, such motion devices cannot meet the requirements. Because this type of controller can not provide continuous interpolation function and no forward-looking function, especially for the occasion of continuous movement of a large number of small line segments, this type of controller cannot be used. In addition, due to the limitation of hardware resources, the circular interpolation algorithm of this type of controller usually uses the point-by-point comparison method, so that the accuracy of circular interpolation is not high. Using DSP and FPGA as core processors based on PC bus An open motion controller based on the PC bus with DSP and FPGA as the core processor. This type of motion controller uses the DSP chip as the core processor of the motion controller, the PC as the information processing platform, and the motion controller with a card The form is embedded in the PC, that is, the "PC + motion controller" mode. In this way, the information processing capability and open characteristics of the PC are combined with the motion trajectory control capability of the motion controller, which has the characteristics of strong information processing capability, high degree of openness, accurate motion trajectory control, and good versatility. This type of controller makes full use of the high-speed data processing capability of DSP and the super logic processing capability of FPGA, which is convenient for designing a motion controller with perfect functions and superior performance. This kind of motion controller can usually provide on-board multi-axis coordinated motion control and complex motion trajectory planning, real-time interpolation calculation, error compensation, and servo filter algorithm, which can achieve closed-loop control. Because FPGA technology is used for hardware design, it is convenient for motion controller suppliers to personalize customization according to customers' special process requirements and technical requirements to form unique products. The main function: Exercise planning function It is actually the reference quantity that forms the speed and position of the movement. Appropriate reference quantity can not only improve the accuracy of the trajectory, but also reduce the requirements on the rotating system and mechanical transmission elements. General motion controllers usually provide motion planning methods based on the limits of impact, acceleration and speed, which can affect the accuracy of dynamic trajectory. Users can directly call the corresponding functions. A motion plan that limits acceleration produces a trapezoidal velocity curve; a motion plan that limits impact produces an S-shaped velocity curve. Generally speaking, for CNC machine tools, the use of motion planning methods limited by the reference amount of acceleration and speed has already obtained an excellent dynamic characteristic. For the fast positioning system with high acceleration and small stroke movement, the positioning time and overshoot have strict requirements, and often require continuous motion planning methods with higher order derivatives. Multi-axis interpolation, continuous interpolation function The multi-axis interpolation function provided by the universal motion controller is widely used in the CNC machinery industry. In recent years, due to the rapid development of the engraving market, especially the mold engraving machine market, the continuous interpolation function of the motion controller has been promoted. There are a large number of short and short line processing in the mold engraving, which requires that the processing speed fluctuation between the sections should be as small as possible, and the inflection point of the speed change should be smoothly transitioned. This requires the motion controller to have the functions of speed preview and continuous interpolation. The continuous interpolation type motion controller specially developed by Googol Technology for small line processing technology has been well applied in the fields of mold engraving, laser engraving and plane cutting. Electronic gear and electronic cam function Electronic gears and electronic cams can greatly simplify the mechanical design, and can achieve many functions difficult to achieve by mechanical gears and cams. The electronic gear can realize the simultaneous movement of multiple motion shafts according to the set gear ratio, which makes the motion controller have a good application in fixed-length cutting and register printing without shaft rotation. In addition, the electronic gear function can also achieve a motion axis to follow a function with a set gear ratio, and this function is determined by the movement of several other motion axes; one axis can also follow the other two axes at a set ratio Synthesis speed. The electronic cam function can change the shape of the cam through programming without grinding the mechanical cam, which greatly simplifies the processing process. This function makes the motion controller have good applications in the fields of quenching of mechanical cams, cutting of special-shaped glass and all-motor driven springs. Comparison output function It means that during the movement process, when the position reaches the set coordinate point, the motion controller outputs one or more switching values, but the movement process is not affected. For example, in AOI flight detection, the comparison output function of the motion controller enables the system to run to the set position, that is, to start the CCD quick camera, and the motion is not affected, which greatly improves efficiency and improves image quality. In addition, in the application of laser engraving, this function of Googol's universal motion device has also been well applied. Probe signal latch function It can latch the moment when the probe signal is generated, the position of each motion axis, its accuracy is only related to the hardware circuit, and is not affected by the inertia of software and system operation. It has good applications in the CCM measurement industry. In addition, more and more OEM manufacturers hope that their own rich industry application experience will be integrated into the motion control system, and the functions of the motion controller will be personalized for different applications and control objects. Googol has developed a universal motion controller application development platform, which makes the general motion controller have a truly object-oriented open control structure and system reconfiguration capabilities. Users can load their own designed control algorithms into the memory of the motion controller In this way, a special motion controller for a special purpose can be reconstructed without changing the structural design of the control system. Architecture composition A motion controller is used to generate a trajectory point (expected output) and a closed position feedback loop. Many controllers can also close a speed loop internally. A driver or amplifier is used to convert the motion controller's control signals (usually speed or torque signals) into higher power current or voltage signals. More advanced intelligent drive can close the position loop and speed loop by itself to obtain more precise control. An actuator such as a hydraulic pump, cylinder, linear actuator or motor is used to output motion. A feedback sensor, such as a photoelectric encoder, resolver, or Hall effect device, is used to feed back the position of the actuator to the position controller to close the position control loop. Many mechanical components are used to convert the movement form of the actuator into the desired movement form. It includes gearboxes, shafts, ball screws, toothed belts, couplings, and linear and rotary bearings. Generally, the functions of a motion control system include: speed control and point control (point-to-point). There are many ways to calculate a motion trajectory, they are usually based on the speed curve of a movement such as triangular speed curve, trapezoidal speed curve or S-shaped speed curve. Such as electronic gear (or electronic cam). That is, the position of the driven axis mechanically follows the position change of a master axis. A simple example is that a system contains two turntables, which rotate according to a given relative angle relationship. The electronic cam is more complicated than the electronic gear. It makes the following relationship curve between the driving shaft and the driven shaft a function. This curve can be non-linear, but it must be a functional relationship. Advantages Advantages of motion controller: (1) The hardware composition is simple, insert the motion controller into the PC bus, and connect the signal line to form a system; (2) You can use the rich software that the PC already has for development; (3) The code versatility and portability of the motion control software are good; (4) There are many engineering personnel who can carry out development work, and development can be carried out without much training. Disadvantages Disadvantages of motion controllers: (1) The motion controller adopting the card structure is connected with gold fingers and fixed on one side. It is not suitable for long-term work in most industrial sites with poor environment (severe vibration, dust and oil pollution). (2) PC resources are wasted. Due to the bundled sales of PCs, users actually only use a small part of PC resources. Unused PC resources not only cause idleness and waste, but also cause maintenance trouble. (3) The overall reliability is difficult to guarantee, because the PC selection can be an industrial control machine or a commercial machine. After the system is integrated, the reliability varies greatly and is not guaranteed by the motion controller. (4) It is difficult to highlight industry characteristics. development trend Due to the strong demand for motion controllers from downstream machinery equipment manufacturers, China's general motion controller (GMC) market capacity is expected to reach US$1.065 billion in 2014, while the market size of CNC motion controllers will reach US$1.239 billion. Experts believe that the machine tool, textile machinery, rubber and plastic machinery, printing machinery and packaging machinery industries account for more than 80% of China's motion control market sales, and will be the main market for motion controllers now and in the future. The demand for motion controllers in the food and beverage machinery, tobacco machinery, medical equipment and scientific research equipment industries is closely related to people's lives. These terminal consumptions have been steadily increasing, so the demand for motion controllers in this type of machinery industry is stable Growing. Although the electronics and semiconductor machinery equipment industry suffered some shocks at the end of 2008, the application of motion controllers in electronics and semiconductor machinery has been growing. Read the full article

#ElectricLinearSlides#LargeStrokeMiniGripers#MicroRotaryServoGrippers#MiniServoRotaryTables#MotionControlSystem#MotionController#PrecisionSoftForceControl#ServoElectricCylinders#SmartMicroGrippers#SmartMiniServoGripper#SmartServoCylinders

0 notes

Text

Customized Automated Palletizer