#Mostly printed CNC

Explore tagged Tumblr posts

Text

making a keyboard, pt. 3

at this point i should mention my ultimate goal is to make a case that's as rugged as the switchplate i designed earlier. however, i'm still waiting on some much-needed training for both the plasma cutter CNC and the bridgeport at my local makerspace. once i feel comfy enough on both i'll be experimenting with some proper metal chassis designs. for now, however, i'm sticking to acrylic. it's cheap, easy to cut, and has a fun look.

i stacked these translucent 3mm plates to be the perfect height to sink some heat-threaded inserts into, which mostly worked. the bottom ends of the inserts poke out slightly (curse you Chinese parts for not being exactly the listed dimensions), but not so much that they cause problems. i covered these plates with a thin dress plate made of white acrylic that i found laying in the scrap bin, hiding the inserts from view when oriented correctly for typing.

the switchplate-PCB assembly is then sandwiched between these plates and some male-to-female standoffs...

and lastly, another dress plate for the bottom. i still need to 3D-print some feet to add angle and grip, but at this point it's ready for the final touches!

3 notes

·

View notes

Text

i went to a con this past weekend. didn't go to any panels or anything, just wanted to browse the vendors and artist alley. which i did, with two primary goals:

the first was to find some comics and books by little indie outfits i have never heard of. and there were several of those, and i picked up a couple of books from local (or quasi-local. two states over counts as "nearby" when it's Montana) authors, but i guess i was hoping to see more? there weren't as many comics as i was expecting at The Comic Con. like, it's been a good number of years since i've been to one of these, but much more than the last time i went, it felt like the crowd consisted of (and the vendors catered to) people whose engagement with geek culture is mostly Star Wars and D&D by way of Stranger Things. like a very big presence hinged on big corporate-owned media, compared to indie and creator-controlled stuff. merchwise, there were far fewer handmade tchotchkes than there were kinda samey looking things made with 3D printers and CNC routers. i'm not trying to be snooty about it, but there was something alienating about the whole thing that i'm trying to figure out.

the artist alley was at least closer to what i was expecting, though i didn't find much that i actually wanted to spend money on. this was the other thing i was looking out for: FFXIV-related art. and there were like, two artists (of like 50 or so booths, plus however many more scattered throughout the vendor hall) that had anything FFXIV-themed at all, as far as i could tell. one artist had a bunch of prints of rather lovely watercolor-esque portraits of major characters (plus a landscape of the Crystal Tower, which I bought a print of), and someone else had acrylic charms of the standard set of fan-favorite characters in a cuter anime style that had different appearances on either side. but overall, the FFXIViness levels were disappointing, both in quantity and in selection.

overall the experience was very... whelming. i was kinda underwhelmed, but not so much i am officially disappointed. i would summarize my trip as "an unusual way to spend a saturday afternoon." it was a thing that happened.

the local anime con is happening in a month or two and i was kinda thinking of going to that. being in a nerd crowd, at least, was nice, and i kinda want more of that. but if i'm out of touch with nerd culture, i'm double plus out of touch with Anime culture. i'd probably be saving some trouble if i didn't go. like if i wanna see a buncha Genshin Impact art that i don't care about i can already go to twitter, right now, and do exactly that. don't even need to buy a ticket or anything

admittedly the whole experience was colored by attending the con with someone who was in a shitty mood, didn't like the crowd and was constantly trying to avoid it. maybe i woulda had more fun if i wasn't spending 40% of my mental energy worrying about that, or feeling like i had to keep offering excuses and apologies every time i wanted to stop and look at something, or trying not to get caught showing an untoward amount of interest in something that's too cute or feminine or pink. performative gender clown act BS. nah yeah now that i think about it, that was really biting into how much fun i was having

anyway, regardless, it still sucks that in today's economy you can reliably get pictures of one of ffxiv's numerous government-issued boyfriends but not a single wee doodle of Ysayle....

4 notes

·

View notes

Text

Lucy Miller Headcanons (Grown Up Addition!)

Alright, so I've been really thinking about Lucy as a character, and how I personally want to head canon her for her to be fun for ME to write personally. @kscribs already has a FANTASTIC version but I've been wanting to throw my hat into the ring. And considering that I've already made other head canons for her teenage self, I figured I might as well.

Rambles about her under the cut LETS GO!

If her teenage self was mostly a Mable Pines vibe, her 30s and 40s are the next evolution of just straight up Ms. Frizzle.

She dresses like a middle school art teacher got dowsed in a rainbow, and she likes it that way. Bright colors, graphic prints and quirky earrings are EVERYWHERE

And she lives to help people, she gets her master's in psychology and opens up two offices for both humans and folklore, doing both one-on-one and relationship counseling.

(She wrote a very compelling capstone thesis paper on the development and the nature vs nurture effects of narcissism (Jack is none the wiser this was about him))

Her magic is most suited for this line of work as she can see people's auras/core's

And her appearance is a bit misleading, and people usually doubt her professionalism, so no one is expecting her to absolutely CLOCK THEIR ASS with the most 100% accurate soul read of their issues. She's the best in the business, and a miracle worker and helping people through their traumas.

This also happens combat wise because no one is expecting this little rainbow of a lady to start whipping out GOD POWERS out nowhere.

And while she does try peaceful conflict resolution first, she is definitely not afraid to start blasting when she needs to, she is completely capable of putting someone into the ground if she has to.

She is a collector of Things and Knickknacks. Which kinds you may ask? All of them. Any item that she finds remotely interesting or beautiful is at risk to be bought and join her collection of stuff, magical or otherwise.

She probably has an impressive display cabinet of colorful glassware.

Also probably has a trunk somewhere of magical items that she's forgotten about and doesn't remember what any of them do.

She can do SO MANY sick staff tricks. She's spinning that shit around like its NOTHING. And Charlie has been calling her Donnie/Donatello because of it. TMNT looking ass up in here.

Meanwhile Cupid has been calling her Artie, for Artemis!

Try as Cupid will, she still uses the staff to smack people on the head and occasionally bludgeons enemies.

She calls its The Snow Shovel Move.

This staff in the images isn't even the staff she really ends up with at the end of CnC. This one is the one she ends up getting at the end if the series of epilogue stories I've been thinking about.

Not pictured, but she also has quite a few dangling pendants for her staff for reminders of her loved ones.

She has a plethora of hand braces to help manage her tremors.

In her even later years, she gets more into helping the council and maybe even eventually joins, probably at the point when Charlie has already taken over.

Works closely with Cupid/Sandman/Killian as an adult on the magic side of things.

Calls herself, Sandy and Kills "The Night Crew"

Probably gets a husky at some point because she keeps rather cold company and doesn't wanna worry about the dog freezing.

Possibly Asexual! I don't think she herself has ever put a label on it.

She gets her own realm that serves as her home/therapy office. It's probably somewhere in a field where the grass is lavender, and the moon is always visible.

#artists on tumblr#digital art#hc#headcanon#the santa clause#the santa clause 3#lucy miller#I just like her okay!#this is the first time in FORVER ive actually been able to sit down at my desk#I will get to answering that ask I PROMISE!#but its been a struggle to find the time for hobbies recently#but heres a Lucy post to hold yall over!

5 notes

·

View notes

Text

Bewop

Hello, masterlist pinned post hihi

Social / Other Places I Am

Twitter

Twitch

Commissions

Prints

Stickers n stuff

Fandom Specific Blogs (you’ll see specific art on these)

@randbitb (JRWI / MCYT)

@royalbilliards (PERSONA 5 ROYAL)

F.A.Q

What program do you use to draw?

Clip Studio Paint Pro (Version 1.0)

What Drawing Tablet do you use?

Wacom Cintiq 16’ Screen Tablet

What are your Brushes???

Lines are mostly done using Calish Ink, and I sketch with the same brush too

I want a print of something but it’s not on either of your stores?

LMK which one you’d like! I’m more than happy to up the resolution on pieces and upload them to Inprnt and Redbubble, though it may take a while for them to appear on the Redbubble store.

Did you go to school for art?

Yes and no. I studied Fine art for 2 years at GCSE and 2 years College level, and then went to university for half a year for BA Illustration, but ended up dropping out. I’m going back to university hopefully this year to get my degree. So, kinda. Most skills however were self taught when I was a teenage and honed into what you see now

What’s (Where Clovers Grow / Coffee And Cannibals)?

OC Universes / Comic projects I work on, both on and off, current project is CnC, as WCG has been semi abandoned.

5 notes

·

View notes

Note

ouughh cnc machines my beloved!! i've not even touched one in years bc i went down the coding path, not the engineering path, but man do i miss them sometimes. i wish i could have one but honestly what would i even make with it

truth! my biggest weakness is that im an artist and not an engineer sooo. that does complicate things. but im good as fuck at toolpathing/general troubleshooting so i mostly help other people with projects. when i do design for the cnc i do a lot of text engraving (not dissimilar to signmaking) and some flatpack furniture type stuff. ive also been experimenting with making triptychs with cnc cut bases. we also have a 3d printed pen holder for our big shopbot LOL so i want to try toolpathing it to write stuff for me sometime soon. because why not

#answers#m#not to flex but we also have a cnc plasma cutter that ive messed w here and there#but the software for that thing is really annoying so i still suck at running it but oh well#since i work with mostly found/scavenged stock its hard to find decent sheet steel so cnc router it is

1 note

·

View note

Text

Rapid Prototyping in Prototype

Rapid prototyping refers to one or several prototypes made first according to the product appearance drawings or structure drawings for checking the appearance or structure reasonableness without opening the mould. With the development of technology, the definition and use of the handpiece has expanded, and it is now more often used to test and validate products, optimize product design, and even used directly as a finished product.

Historical Background and Definition Rapid prototyping technology originated in the 1980s, initially to solve the problems in traditional manufacturing methods, such as high cost and long cycle time. With the development of technology, rapid prototyping has gradually matured and has been widely used in various fields. It is not only suitable for product development, but also has a wide range of applications in software applications, architectural design and other fields.

Process Rapid prototyping processes include a variety of technologies such as Stereolithography (SLA), Fusion Deposition Modeling (FDM) and others. SLA technology initiates the polymerisation of photosensitive resins by means of a light source of a specific wavelength to form polymers, while FDM technology involves the extrusion of melted material in layers. In addition, traditional moulding methods such as vacuum infusion, low pressure casting and CNC machining are also widely used in the production of handmade boards. 1.3D printing: Prototypes are created using a 3D printer by adding material layer by layer. This method allows for fast, low-cost prototyping of products with complex structures. 2.CNC machining: Cutting and engraving of materials by means of computer numerically controlled machines, suitable for prototypes requiring high precision and complex shapes. 3.Vacuum casting: Liquid material is injected into the mould using a mould and then cured into shape, suitable for validation prior to mass production. 4.Rapid tooling: Creation of moulds by means of rapid tooling technology, followed by series production. 5.Injection molding: Mass reproduction using injection moulding machines for situations where mass production is required.

Material There is also a wide selection of materials for rapid prototyping, with common ones such as photosensitive resin and nylon. For small batch production, vacuum casting process can be used, using materials such as ABS and PMMA for replication, followed by subsequent processing such as sanding and spraying with oil. For metal parts, the machining services are mostly used.

Advantages 1.Rapid outputs: Compared to traditional manufacturing methods, rapid prototyping can complete prototyping in a short period of time, greatly reducing product development cycles which suitable for low volume manufacturing. 2.Low cost: 3D printing technology, in particular, allows for the low-cost production of complex structural prototypes and small batches. 3.High flexibility: Can be prototyped using a wide range of materials and techniques, adapting to different design needs. 4.High precision: The ability to accurately replicate the structure, detail and texture of a prototype provides a surface quality. 5.Variety of materials: Polyurethane materials with different properties such as rigid, elastic, transparent or various coloured materials can be selected according to requirements.

Applications 1.Manufacturing and Industrial Applications Rapid prototyping technology enables the rapid production of complex and accurate prototypes, helping designers and engineers to validate design concepts, perform functional testing and evaluate appearance. For parts that need to be produced in small quantities, it offers a cost-effective and flexible solution. 2.Automobile industry Automakers use rapid prototyping technology to rapidly develop prototype automotive parts for performance testing and validation.In addition, it enables the manufacture of personalised automotive parts, such as dashboard panels and door handles, and is used for production tooling. 3.Medical field Rapid prototyping technology enables personalized medical devices, implants and prosthetics to be tailored to a patient's body structure, providing better fit and comfort.In the field of bioprinting, it is used for research in tissue engineering and organ transplantation. 4.Others Rapid prototyping also plays an important role in a number of industries, including aerospace, consumer electronics, and artwork creation, and its applications will become more widespread as technology advances and costs are reduced.

Rapid Prototyping is the process of creating a simple model of a product or project in the early stages of development so that it can be used to validate and test design concepts, features and interfaces. It is a method of rapidly building physical prototypes and iterating on a design with few changes to improve the design.

#design#business#prototyping#autos#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#3d printing services#3d printing#metal 3d printing#3d printed#cnc machining service#vacuum casting#rapid tooling#rapid prototype

1 note

·

View note

Text

3D Rapid Prototyping Compared to Traditional Methods

Cost Efficiency of 3D Rapid Prototyping Compared to Traditional Methods

With the continuous improvement of 3D rapid prototyping technologies and techniques, push brand including RMT more to the industry, the product development is no longer strenuous. Various firms now stand to cut on time and resources eliminating the use the traditional and inefficient methods during the prototyping phase. This articles focuses on the cost advantage of using the newer technologies over the older or the basic ones while establishing how innovations at RMT are raising the cost efficiency and performance bar. Get more news about 3D rapid prototyping,you can vist our website!

Reduced Initial Investment and Setup Costs

One of the most beneficial aspects when compared to other forms of prototyping and hence the more appealing one, 3D rapid prototyping is mostly cost effective. Traditional prototyping methods, such as injection molding or CNC machining, require expensive molds, tooling, and equipment setup. In contrast, RMT's 3D printing solutions eliminate the need for complex tooling and setup, enabling companies to create prototypes directly from digital designs. For small or medium sized enterprises, this means low upfront operational costs, especially.

Production time ensures quick time to market

The traditional prototyping phase can take a number of weeks and sometimes months for the creation of custom molded parts or tooling. The flip side of this is that with traditional tooling and machining processes, the overall time taken for rapid prototyping is only a few days. Advanced 3d printers by RMT make it possible to produce functional prototypes fast, allowing companies to make changes quickly on future designs and perform more tests before going for actual production. These efficiencies result in reduced labor expenses and a faster time to market for product launches.

Reduction inefficiencies in the use of materials and wastage of materials in production process

With positions like these, one can expect long lead times, material wastage as when processes like CNC machining take place to merely remove material to achieve the end goal. 3D printing, on the other hand, has a completely different working principle- it is an additive process, and thus material is placed only where required in order to limit wastage. Using the latest 3d prototyping technologies at RMT, manufacturers will be able to control their wastage and cut their overall material costs particularly in instances when such expensive materials as metals or specialized polymers are needed.

Prototyping with More Complicated Geometries

Creating intricate and more complex geometries by conventional methods sometimes becomes impossible without incurring unreasonable costs. With 3D rapid prototyping however, it is possible to produce precise and detailed components with complex form features that would have been either impossible or too costly to produce through traditional methodologies. 3D printers available with RMT can construct complex designs of prototypes internally rather than assembling multiple pieces which would raise costs in normal processes. This extends the possibility of developing more sophisticated designs in the products without a significant rise in the costs.

Failure Risk Reduction and More Iterations are Possible

One of the problems with conventional prototyping is that it makes it very costly to have so many iterations. Each new prototype may force the use of a new mold or tooling setup which adds more costs. On the contrary, 3D rapid prototyping is not overly time-consuming, meaning several iterations can be made in a matter of hours allowing companies to quickly validate a design before the whole production plant is constructed. The flexible prototyping systems developed by RMT allow the designers to make changes in the design of the parts and try out different material options which minimizes the losses incurred from errors that may occur in the latter stages of production.

Economics for Low Volume Production – Good Value

Traditional techniques seem to be reasonably efficient for mass production but it is a costly option for lower volume runs. The expenses to create molds, the tools and setup for small quantity prototypes or small volume production runs too often seem to have more downsides. RMT’s 3D rapid prototyping technology is particularly effective for low volume production runs as it is easy to set up and cost of manufacture is very low, making it ideal for industries such as aerospace, automotive and consumer electronics.

Starting from a smaller upfront cost, speed of production, cost of materials, and up to the capability of producing intricate designs, there are sinning benefits with 3D printing. Particularly with companies like RMT on the forefront of innovation, the industries can only look forward to more affordable and better solutions in the prototyping and production scenarios.

0 notes

Text

Why Stoneglass Surfaces Stand Out: A Closer Look

Engineered materials are reshaping the interior design industry with their exceptional durability and pristine looks. After quartz and porcelain, stoneglass became popular due to its unique combination of natural stone strength and the beauty of glass.

Stoneglass is composed primarily of glass, silicon, and calcium. The raw materials undergo intense processes of melting, forming sheets, cutting, heating, cooling, printing, finishing, and packaging.

What is 3D Stoneglass?

3D stoneglass is the new variety. Until now, stoneglass surfaces were available in mostly solid colors with only CNC or laser etchings. However, 3D stoneglass is an absolute game changer. Designs like subtle veins give the stone a marble-like appearance. The designs on the surfaces are achieved through 3D printing or inkjet printing. 3D stoneglass surfaces look elegant and captivating.

What are the amazing properties of stone glass?

Translucency: As we have mentioned earlier, stoneglass is a unique material. It offers a crystalline luster or brilliance like other glass surfaces. Light can filter through the material, enhancing the effects of its engravings or designs.

Hardness: Normal glass is brittle and prone to heavy impact. In contrast, 3D stoneglass is a hard material, ranking 7 on Moh’s scale of mineral hardness. It is not easily breakable, which renders it a suitable surfacing material for high-traffic areas in both residential and commercial spaces.

Porosity: Stoneglass is a non-porous material. Therefore, it does not absorb any liquid, making it immune to stains from coffee, wine, or any other spills. Having stoneglass in the kitchen countertop and backsplashes can rid one of the cleaning fuss.

Heat Resistance: Unlike quartz surfaces, stoneglass exhibits excellent resistance against heat. It can bear high temperatures without getting aesthetically or structurally compromised. You can keep your hot pans and pots directly on the surface without worrying about damage. This is why stoneglass can be used in cooking areas.

Acid Resistance: Since stoneglass is a chemically stable material, it does not react with domestic acidic substances such as coffee, wine, vinegar, and lemon juice. Natural stones react with acidic substances, developing dull spots on the surface. However, stone glass beats natural stones by offering outstanding acid resistance.

Discoloration: Stoneglass does not lose its brilliance with time. Its colors and patterns do not fade away as this material is not affected by external impacts such as UV rays, snow-thaw cycles, and rain, making it a suitable choice for outdoor environments.

Scratch Resistance: Stoneglass is resistant to scratches as well. It is so hard and dense that cooking knives and forks and even heavy footfall do not have any effect on it. Source link

0 notes

Text

How Automotive Metal Fabrication is Driving Change in the Industry

Metal fabrication has been a vital part of the automotive industry for decades, with advancements in technology and materials continuously driving change. From creating prototypes to producing finished parts, metal fabrication plays a critical role in the design, development, and manufacturing of vehicles.

What is Metal Fabrication?

Metal fabrication is the process of cutting, shaping, and assembling metals into various structures. It involves using raw materials such as steel, aluminum, and other metals to create parts or components used in different industries, including automotive. Metal fabrication techniques include cutting, bending, welding, and machining to produce complex structures with high precision.

The Evolution of Automotive Metal Fabrication

Metal fabrication has come a long way since the first automobiles were built in the late 1800s. In the early days, cars were made mostly of wood and powered by steam engines. However, as technology advanced, so did the materials used in automotive manufacturing. The introduction of mass production techniques by Henry Ford in the early 1900s saw a shift towards using steel as it was stronger and more durable than wood.

Impact on Vehicle Design

The use of metal fabrication in automotive production has had a significant impact on vehicle design, making it possible to create complex and innovative shapes that were previously not achievable. With advancements in computer-aided design (CAD) and computer-aided manufacturing (CAM), designers can now create detailed 3D models of vehicles before they are even built, allowing for more precise design and reducing the time and cost of creating prototypes. Metal fabrication techniques also allow for the production of lighter, yet stronger components, improving fuel efficiency and overall vehicle performance.

Applications of Metal Fabrication in Automotive

Metal fabrication is a critical aspect of automotive production, with vehicles consisting of thousands of different parts and components made using various metalworking techniques. One of the most common applications of metal fabrication in this industry is in the body and frame construction. The use of steel, aluminum, and other metals allows for the creation of lightweight bodies that are still strong enough to protect passengers in the event of a crash. Metal fabrication is also used for various engine and transmission components, such as pistons, crankshafts, and gears. These parts need to be precisely machined to ensure proper performance.

Advancements in Metal Fabrication Techniques

With the constant evolution of technology, metal fabrication techniques have also advanced significantly over the years. The use of laser cutting, CNC machining, and waterjet cutting has made it possible to create intricate and precise parts with ease. These techniques also reduce material waste and increase production efficiency, making them highly beneficial for automotive manufacturers.

Customization and Personalization

Metal fabrication in the automotive industry not only allows for the mass production of vehicles but also enables customization and personalization for individual customers. With metal fabrication techniques, different types of metals can be molded, bent, and welded to create unique designs and styles for vehicles. This adds a level of personalization and exclusivity to cars that were previously only achievable through expensive hand-crafting methods.

The Future of Metal Fabrication in Automotive

As the automotive industry continues to advance towards electric and autonomous vehicles, metal fabrication will play a crucial role in their development. With the need for lighter and more efficient components, the use of advanced metal fabrication techniques will become even more critical. Additionally, with the rise of 3D printing technology, metal fabrication can be taken to new heights in terms of complexity and customization.

Conclusion

Metal fabrication automotive is a cornerstone of the modern automotive industry, enabling both mass production and individual customization. As we advance into the era of electric and autonomous vehicles, the relevance and importance of automotive metal fabrication is poised to increase. It will continue to evolve, embracing new technologies like 3D printing, and fostering innovation in vehicle design and efficiency. Indeed, the future of the automotive industry is inextricably linked with the future of metal fabrication.

0 notes

Photo

New Post has been published on https://www.vividracing.com/blog/top-7-best-wings-spoilers-for-the-toyota-gr86-subaru-brz/

Top 7 Best Wings/Spoilers for the Toyota GR86 & Subaru BRZ

We have recently shared the top 6 best canard kits that improve the aerodynamics performance of the Toyota GR-86 and Subaru BRZ, in the same breath we want to share another recommendation for these performance cars, this time it is wings and spoilers. Guaranteed to take your car’s aerodynamics performance to the next level imaginable, wings and spoilers are different car parts that are usually confused as one part. If you are one of the people who usually confuse the two, stay with us to the end to know the difference.

Wings and spoilers are aerodynamics performance upgrades, but once installed they serve different aerodynamic purposes on the vehicle. Wings are mostly used in racing cars to generate lift that enhances down force for better traction and stability, while spoilers disrupts airflow to reduce lift, enhancing the vehicle’s grip and stability on the road, particularly at high speeds.

This is a wing

Installing a wing is easy and you can do it yourself or with the help of a friend, the hard part maybe drilling holes in your trunk. But once installed wings can have several advantages including;

Increase down force

Enhance traction

Improve stability and handling.

Optimize overall aerodynamics performance

This is a spoiler

Installing a spoiler is more than just for aesthetics purposes, a spoiler can;

Reduce aerodynamic drag which can lead to improved fuel efficiency and top-end speed

Optimize overall aerodynamics

Reduce lift by disrupting airflow, which in turn increases the stability of the vehicle at higher speeds

If you would love to experience these benefits on your ride, check out these 7 recommendations that we have for your Toyota GR-86 and Subaru BRZ

1.) APR Performance Carbon Fiber GTC 200 Adjustable Wing Subaru BRZ | Toyota GR-86 2022+

There are some brands that are known for their outstanding products, and APR Performance is one of them, the list would be incomplete without a product from this company. Their wings come with stainless-steel machine screws, washers, and nuts, and they manufactured to deliver maximum down force in midsize and compact car applications.

2.) APR Performance Carbon Fiber GTC-300 61 Inch Adjustable Wing Subaru BRZ | Toyota GR-86 2022+

We love the APR Performance Carbon Fiber GTC 200 Adjustable Wing, we had to recommend another one from the brand. The APR Performance Carbon Fiber GTC-300 61 Inch Adjustable Wing has a span of 61 inches and a height of 13 inches, and it is also adjustable. The GTC-300 3D airfoil shape allows for optimal airflow that reduces drag yet supplies an effective amount of down force.

3.) Street Hunter Carbon Fiber Rear Trunk Spoiler Subaru | Toyota 2022

Street Hunter Designs is also one of those brands with a good rep when it comes to the carbon fiber body kits, parts, and accessories that they make. They utilize state-of-the-art technologies and equipment such as 3D scanning, 3D printing, and precision CNC milling in their designing and manufacturing processes to ensure that they produce the highest quality parts and molds. This rear trunk spoiler is durable, of high quality and ready to deliver the highest performance.

4.) HKS Body Kit Type-S Rear Wing Toyota GR-86 | Subaru BRZ 2022+

When we said the top 7 best wings and spoilers in the title, we actually meant it. HKS is one of those brands that consistently delivers high quality aftermarket products, and their wing is designed to reduce aerodynamic drag, improve rear down force balance against the stock body, breaking stability, and drivability at high-speed corner.

5.) Artisan Spirits Rear Wing Black Label Carbon Fiber CFRP Toyota GR86 | Subaru BRZ 2022+

Artisan Spirits is a Japanese brand with more than two decades of experience in manufacturing aftermarket products. They have a lot of experience in manufacturing products using carbon-reinforced plastic, and that’s what they have used to make this wing which means it is incredibly strong and durable.

6.) Rexpeed V1 ABS Trunk Spoiler Toyota GR86 | Subaru BRZ 2022-2023

Rexpeed, is a brand based in Taiwan, which is known for manufacturing quality automotive components that both complement and improve the aesthetics and aerodynamics of your vehicle. This spoiler is made using high grade ABS plastic material, and the kit comes with necessary hardware for easy installation so you can take it as a challenge and DIY

7.) Versus Engineering UCW Rear Wing Kit with Carbon Endplates Toyota GR-86 2022+

The last wing upgrade recommendation we have for you is a Versus Engineering UCW Rear Wing Kit with Carbon Endplates which was manufactured using the state-of-the-art analysis software. This wing is a great addition to your Toyota GR86 as it will increase down force significantly in the rear, increase confidence on track, and reduce lap times. This is the perfect match for your ride as it is designed to work on the factory trunk and handle the down force well, click the blue button to grab it right now!

There are many who think wings/ spoiler upgrades are for aesthetics only but if you made it to the end then you have seen how crucial they are to your car’s aerodynamics performance, grab one today to see the difference in your car. If you would love to get more upgrade recommendations for your Toyota GR-86 and Subaru BRZ, please do not hesitate to contact us. You can reach us by phone at 1-480-966-3040 or via email at [email protected]

#Best spoiler upgrades for performance cars#Best spoiler upgrades for Toyota GR-86#Best wing upgrades for performance cars#Best wing upgrades for subaru BRZ#Best wing upgrades for Toyota GR-86#Spoiler uogrades for Subaru BRZ#Toyota

0 notes

Text

Liked on YouTube: Why this Walking Machine is Really Weird

Why this Walking Machine is Really Weird Ad: You and your company can try Onshape for Free at https://ift.tt/zoQD56n I’ve built quite a few omni-directional robots using various types of omni-directional wheels. Normal omni-wheels are a large wheel with smaller wheels around its circumference, allowing it to be driven in one axis, and slide passively in the other. Using three omni-wheels allows a vehicle to move in any direction, although I’ve also built machines with one omni wheel. Most of my omni-wheel vehicles worked ok on flat ground, but they weren’t great at climbing over obstacles. So in this video I’m going to build a omni-directional walking machine which should be better at stepping over things. CAD and Code: https://ift.tt/aHMIJuV You can support me on Patreon or buy my Merchandise: *************************** Patreon: https://ift.tt/tVZF1Ex Merchandise: https://ift.tt/UtTySjE *************************** Affiliate links - I will get some money of you use them to sign up or buy something: *************************** Matterhackers 3D printing supplies: https://ift.tt/So4fdDk Music for your YouTube videos: https://ift.tt/PeRQKCM *************************** Other socials: *************************** Instagram: https://ift.tt/SNpU1a3 Facebook: https://ift.tt/jf8kYSc Twitter: https://twitter.com/xrobotsuk *************************** CAD and Code for my projects: https://ift.tt/0wmbNCW Huge thanks to my Patrons, without whom my standard of living would drastically decline. Like, inside out-Farm Foods bag decline. Plus a very special shoutout to Lulzbot, Inc who keep me in LulzBot 3D printers and support me via Patreon. HARDWARE/SOFTWARE Below you can also find a lot of the typical tools, equipment and supplies used in my projects: Filament from: https://www.3dfuel.com/ Lulzbot 3D Printers: http://bit.ly/2Sj6nil Bearings from: https://ift.tt/FE4djzr Lincoln Electric Welder: https://bit.ly/2Rqhqos CNC Router: https://bit.ly/2QdsNjt Ryobi Tools: http://bit.ly/2RhArcD Axminster Micro Lathe: http://bit.ly/2Sj6eeN 3D Printer Filament: http://bit.ly/2PdcdUu Soldering Iron: http://bit.ly/2DrNWDR Vectric CNC Software: http://bit.ly/2zxpZqv Why not join my community, who are mostly made up of actual geniuses. There’s a Facebook group and everything: https://ift.tt/hvZcGmH XROBOTS Former toy designer, current YouTube maker and general robotics, electrical and mechanical engineer, I’m a fan of doing it yourself and innovation by trial and error. My channel is where I share some of my useful and not-so-useful inventions, designs and maker advice. Iron Man is my go-to cosplay, and 3D printing can solve most issues - broken bolts, missing parts, world hunger, you name it. XRobots is the community around my content where you can get in touch, share tips and advice, and more build FAQs, schematics and designs are also available. via YouTube https://www.youtube.com/watch?v=e1cMjbQnDwY

0 notes

Text

Why is CNC Machining Preferred in the Automotive Industry?

The automotive industry is continually advancing in its sector with the advancement in automation and robotic invention. In such a context, this industry is highly dependent on precise components for their daily operation. This is why they are moving towards CNC Machining for automotive parts to transform their industrial processes.

In this article, you will come to know why CNC machining is the top choice in the automotive sector.

Faster Production- CNC machining is a complete computer-controlled technique. This means there is very little human intervention in the method, making the production faster than the traditional machining process. In addition, it can be repeated as many times as required and so, it can be used to make large amounts of components at a very quick pace.

Highly Precise- When any components especially related to the automotive sector are developed by human force, chances of error are much on the higher side. CNC machining, on the other hand, can create any tough component with high precision while eliminating the chances of any mistakes.

Reduced Costs- Another big reason why CNC is mostly preferred in the automotive sector is because of its reduced costs. Manufacturers no need to make any infrastructure or hire extra staff as the whole method is computer-controlled. Thus, it reduces the extra costs associated with hiring staff or infrastructure and streamlining the entire process.

Conclusion

Createproto Rapid System Limited is a trusted manufacturer of top-notch CNC machining for automotive industries. Their team of highly qualified engineers go through several important steps like developing, examining and testing the prototype to give the best quality products to their customers. In addition, the company also specialises in prototyping, additive manufacturing and 3D printing technology to produce high-precision parts at an affordable price.

Want to get a free estimate? Log in to their website now!

0 notes

Text

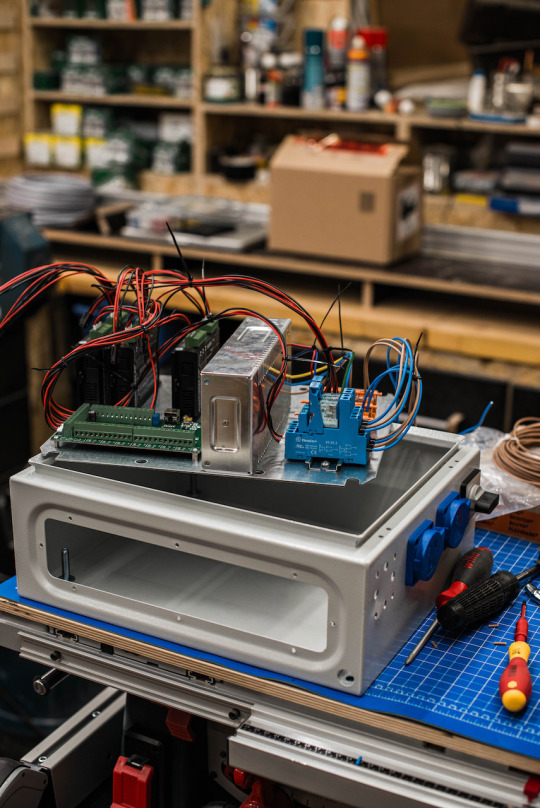

MPCNC Steuerung nach ESTLCAM-Vorbild inklusive Schaltplan

MPCNC Steuerung nach ESTLCAM-Vorbild inklusive Schaltplan

In diesem Beitrag zeige ich, wie ich meine Steuerung für die MPCNC nach dem Vorbild von der Estlcam-Homepage zusammengebaut habe. Dabei habe ich ein Gehäuse von Rital verwendet und für die Motorsteuerung das Estlcam Klemmen Adapter Board. Als Motortreiber kommen die DMS542T zum Einsatz. Warum habe ich mich jetzt für Das Board von ESTLCAM entschieden? Ich habe mich dazu entschlossen, das…

View On WordPress

#CNC Fräse#CNC Steuerung#ESTLCAM#Finder#Fräse#Fräsensteuerung#heimwerken#Heimwerker#Hobbykeller#Ilmenau#Klemmen Adapter#Mostly printed CNC#MPCNC#MPCNC Steuerung#Nema 17#Nikon#Rital#Schaltschrank#Schrittmotorsteuerung#Stepperonline#Steuerung#Thüringen#Wago#Wago Klemme#Weidmüller#Werkzeug

0 notes

Text

Strangers on a Train (Geto Suguru x Reader)

Contains: cnc, groping, 'strangers', public sex, fingering, forced flashing, 'cheating', cum eating, size difference, reader being manhandled.

I'm not quite sure what made me write this other than my attempt at writing consensual non consent. The idea of someone (specifically Geto) wanting to go along with reader's fantasy of groping in public is just so hot to me. Wrote most of this in one sitting, the end was a bit of a mess though, hopefully its enjoyable! Hopefully the end is obvious enough that you can tell it was Geto the whole time. As always, reblog/comment if you enjoy! I love you all!

For a Saturday morning, the metro was a lot busier than you had anticipated. You weren't expecting too much of a crowd, but as you stepped into your usual car you were almost overwhelmed by the amount of people.

You hoped the ride would have had some bench space, as you weren't dressed for standing in a crowd. Today's plans involved a beach date with your loving boyfriend, Suguru Geto. Unfortunately you had to take a 30 minute train ride to get to the beach you were meeting him at. Your clothes little more than a cover up for the swimsuit you wore instead of underwear, and the main cover you wore being the fishnet stockings covering your legs.

Moving against the crowd a bit you planted yourself near the back exit of the train car. There weren't any seats available so you found yourself standing. Not quite against the wall, as a large man with a hat, glasses, and a bored look on his face leaned against the wall looking at the phone in his hands.

You payed the stranger no mind. There was only one stop between you and your fun beach date, maybe a seat would clear up by then.

As the train lurched forward you reached a hand up to grab the rail above your head for balance. You felt your phone vibrate against your skin. Pulling it out of the waistband of your short skirt you saw a new message from your boyfriend.

Waiting for you ♡ it read. You smiled to yourself, he was always thinking of you. Lowering your hand from the bar to text back, you weren't ready when the train jostled a little. Nothing to be alarmed about, but enough to push you into the tall man in front of you.

Your face crushing into his chest, arms reaching for support and grasping his biceps.

"I'm so sorry," you whispered, not wanting to draw any attention to yourself. You felt your face flush with embarrassment.

Before you could straighten yourself, you felt a large hand on your hip steadying you. The grip was tight, unexpected. You were too nervous to look up at him so you brought a hand to rest on top of his before pushing it away. The fingers drug down your leg across the fishnet material before returning to his own side.

Nervously you placed your phone back into the waistband and smoothed out your short skirt. His large hand had made you more anxious about your clothing choice. You weren't small in any sense of the word, but the way his hand had engulfed your hip made you blush from more than just embarrassment.

As you stood, you tried to pay more attention to your surroundings and less to the body in front of you. Glancing around you noted that the car was full mostly of people that looked like they were on their way to work. A sea of mostly men in suits.

You suddenly felt another brush against your thigh, making you almost jump out of your skin. Quickly looking down you saw the man's knee bent and gently pressing in between your plush thighs. You pressed your thighs closer together, but as you did he removed his knee. He continued to stand there as if nothing had happened.

You noted his clothing, the board shorts and tropical print shirt a contrast to those around you. Not unlike yourself. However upon looking up to note his facial features, you noticed a black face mask. The rest of his face was mostly obscured by a hat, his long black hair pulled up under it.

It was probably an accident anyway, you were both just standing on a moving train. Still the feeling of his skin rubbing against your partly clothed thighs gave you a feeling in your guts you didn't want to label.

You moved to step back a little, to create some more space between the two of you. Unfortunately you happened to step on the back of someones foot.

"Watch it!" a voice harshly whispered before elbowing you in the back. The jab you weren't expecting causing you to once again fall into the large stranger's chest.

This time, both of his hands came to rest on your hips, pressing your body tightly against his own.

Trying to keep your sound of shock in, you bit your lip as you wiggled against his grip.

He held you tighter against his noticeably sturdy body. You could feel his musculature through the thin shirt he wore.

Suddenly you felt him lifting you off of the ground and switching your spots. He sat you down as swiftly as he'd lifted you. The strength it must have taken to move you so quickly and gently had you too stunned to speak.

"Now that you're against something solid maybe you'll be less clumsy," the man's quiet voice whispered in your ear. His hands gripped your hips tighter before falling away. One coming up to the rail above your head, he leaned slightly into your space as he stood.

You looked down and leaned back, pressing into the wall trying to disappear. This whole situation was embarrassing! It was also very shameful for you, as the feeling of being manhandled in such a way lit a fire in your guts that was reserved for you darling Suguru.

Crossing your arms across your stomach in an attempt to hide yourself further, you silently willed the train to travel faster.

After a few moments of nothing strange happening you relaxed a bit. Checking your phone again you saw that you only had about twenty minutes left on this ride.

While you were looking at your phone, you didn't notice the arm above you coming to rest against the wall above your shoulder. What you did notice, however, was his other hand. It pressed lightly into your hip and slowly slid up to rest against the side of your breast.

You froze, looking up and noticing how caged in you were. You met his eyes for the first time and the heat in them made your blood run cold.

Without breaking eye contact, the stranger's hand squeezed your breast through your shirt. The thin material of your button up and swimsuit top leaving little in the way of protection against his hands kneading your soft flesh.

Leaning into you more, the hand undid a few more of the buttons on your shirt before slipping inside and cupping the skin directly. You gasped, shaking your head at the stranger.

"Please don't do this," you whispered, begging to keep your decency.

The hand inside your shirt yanked at the swimsuit top, exposing your breasts to him. He was so close to you that you doubted anyone else could see, but the thought still made your guts burn with a hot mix of shame and desire.

"Shhh," is the only response he gives you before twisting one of your nipples between his fingertips. The sensitive nub hardening at the attention.

You bit down on your lip trying hard to keep quiet and not draw attention to yourself. It felt so good and you hated it, one hand coming up to hold the arm near your face and the other coming to your lips.

His knee again nudged your legs open, this time you let him. Your plush legs parting without resistance. The sensation of his knee sliding up your thighs made you squirm. Not too much though, as you were exposed and the only thing keeping you from flashing the train was his large frame.

The hand fondling you breast squeezed harder before moving to play with the neglected nipple. A moan threatened to escape your lips but you swallowed it down like a bitter pill. Like the realization that you were enjoying being groped by a stranger.

The knee in between your thighs finally pressed against your pussy, and you knew it was unlikely he wouldn't notice how wet you were. The thrill of being caught and being forced into this situation was uncomfortably arousing.

The train lurched again, slowing to a stop. The man stepped even closer to you, shielding you even more from potential view and preventing you from escaping even if you wanted to.

Only one more stop til you met with your sweet boyfriend.

You buried your face into the chest now directly in front of you, shamefully hiding your exposed form. As you felt the train fully stop and heard the doors open, you felt the knee against your pussy grind up into you. You forced a cough from your throat in an attempt to cover up the moan escaping your lips.

The pressure the man was putting on your pussy had you clenching around nothing, barely daring to grind your hips down. The hand on your chest squeezed again before moving away, leaving you to feel you nipples rub up against his shirt. Your over sensitive body shivering at the contact.

His large hand lifted to pat your head, pressing your face into his pecks. The gentleness unexpected. You heard a muffled voice but couldn't quite make it out.

"Oh she's okay, trains make her feel ill. I'm just trying to comfort her," the smooth voice of the man trapping you against the wall said. You nodded against his chest, an affirmation to anyone watching. You knew you didn't want to meet anyone's eyes right now.

You'd assumed the person inquiring about you had left or turned away because the hand on your head slid down to your ass. Despite wearing a skirt, fishnets, and swimsuit bottoms, the grip his hand had on your ass was definitely enough to bruise. He forced you down on his knee. You could feel the bottoms you wore wetting his skin.

You pushed at the man's chest weakly, not strong enough to remove him, but more like an attempt at showing him you didn't want this.

The hand on your ass moved, making you think for a moment that this was all over as his knee also slid out from between your legs. You sighed, attempting to move back but you were just pushed more into the wall.

Instead of looking up to meat the eyes of the man groping you, you glanced around again. No one was looking in your direction, but plenty of people were around you.

Your moment of reprieve was short lived as his hands switched places. The hand by your shoulder dropping to your hip while the other moved up next to your head against the wall. The angle and position change, though slight, now cornered you even more.

The hand on your hip slid down, rubbing circles into your fishnet-clad thighs. His fingers traced the hem of your skirt before slipping up under the thin material and moving toward your soaked pussy.

Your hand again shot up to cover your mouth as the thick fingers slipped your bottoms to the side and slid in through the holes in your fishnets to caress your folds gently. His finger circling your clit gently before pinching at the sensitive bud.

Choking on a moan, you again coughed, burying you head in his chest and clutching the bicep near your head. You were glad you'd braced yourself as you felt his finger slip down and stroke at your tight hole. Swirling around your juices a little before it began pressing into you, it was an easy fit considering how wet you were.

With how easy the first on slid in, he quickly added another alongside it and you felt yourself stretch on the thick digits. He wasn't thrusting much, but crooking his fingers to rub against the spongy spot inside of you. You felt your legs quiver, the pleasure too much. You bit hard into the meat of your palm to keep the noises inside.

"Such a slut, going to squirt on a stranger's hand are you?" he whispered into your ear before resting his chin on top of your head. The height difference and his ability to fully engulf you while still having his fingers buried inside of you turned you on even more than his words.

The train hit another bump, forcing his fingers deeper into your pussy. You felt tears prick your eyes at the overwhelming feeling. Being stretched open in front of a crowd by a sexy stranger. And he was right, you were close to climax already. It's as if he knew exactly where to touch you.

You felt his thumb swirl around your clit as the two other fingers sharply thrust up into your pussy. The added pleasure made your legs almost give out, you were thankful for his large frame hiding your trembling body.

You could feel your pussy clenching around his fingers. So close to climax.

The thought of your sweet Suguru waiting for you entered your mind, at the same time his thumb pressed harshly into your clit as his fingers sped up.

Turning your head, you bit into the stranger's arm to keep quiet. You felt more than heard him groan. You were too distracted by the cum gushing into his hand as you finally finished to care. The hot wet feeling of orgasm flooding your whole body as you squeezed his hand between your legs.

He rubbed a few more circles around your sensitive clit before his hand slid out from your bottoms. He was careful not to get any on your skirt, and you were thankful for that. Bringing his hand up between the two of you he pressed his soaked fingers against your lips. You opened your mouth without much resistance and quickly sucked your own release from his fingers.

You felt dizzy, but took your hands off of him to button your shirt back up. He didn't interrupt you at all. Now fully covered, you leaned away from him and against the wall, sighing as you noticed the train slowing again.

That was simultaneously the longest and fastest thirty minutes of your life.

Adjusting your skirt and making sure you were no longer exposed you stepped away from the stranger as the train fully stopped. You felt him turn behind you, following. But you paid him no mind.

Stepping outside the train car and walking a few steps away you stood, waiting.

An arm wrapped itself around your shoulder, before you could look up you felt a kiss pressed into the crown of your head followed by a hat being placed on you.

Turning to look you saw your sweet boyfriend, Suguru Geto, reading glasses perched on his nose and a black face mask dangling from his ear. You leaned into his large, sturdy frame. Face rubbing against the thin material of his tropical print shirt.

"Hopefully the ride was to your liking, sweetheart. We have a long day at the beach ahead of us!" he winked at you before whisking you off the platform and out into the sun.

#geto suguru x reader#geto suguru#jjk x reader#jjk smut#geto smut#getou suguru x reader#getou suguru#getou smut#jjk geto#jjk thirst#jjk getou

611 notes

·

View notes

Text

Process selection for prototype production

Process selection for prototype production

Product development involves getting a concept into a form that could be manufactured. This process requires various decisions to be made regarding the manufacturing method that can affect the outcome significantly. The right process is equivalent to constructing a strong foundation of a high rise building; doing so guarantees firmness and sets pace for what is ahead.Get more news about Custom Keyboard,you can vist our website!

(1)Understanding Prototype Production

Before proceeding with process selection, it is vital to understand what prototype production entails. Prototyping connects an idea with its expression in reality, enabling refinement and design validation. Irrespective of whether it’s a physical product or software application, prototypes help stakeholders visualize, test, and iterate.

(2)Factors Influencing Process Selection

Several factors come into play in selecting the right manufacturing process:

1.Material Compatibility: Different materials need specific technologies of production application. For instance, the chosen method must support different properties of metal, plastic or composite.

2.Cost Considerations: The budget determines which technique should be used. While some may work well in terms of precision and speed, they might cost more. Striking the right balance between quality and affordability is crucial.

3.Time-to-Market: In today’s fast-paced business environment, time is money. Fast prototyping approaches like 3D printing have quick turnaround times making them ideal for meeting deadlines.

4.Complexity of Design: Complicated designs may afford sophisticated techniques like CNC machining or injection molding while simple ones would require less complex means.

5.Volume Requirements: The selected process will depend on how much goods are expected to be produced. Injection molding falls within such scaleable technologies mostly used in mass production as additive manufacturing caters for low volume needs only.

(3)Common Manufacturing Processes

1.Rapid Prototyping (3D Printing): 3D printing creates three-dimensional solid objects by depositing layers of material iteratively as opposed to conventional machining methods where part is created by removal of material from solid block which are then built up layer by layer. This method is flexible, cheap for small amounts and allows for more design freedom.

2.CNC Machining: CNC machining basically means removing material from solid blocks using computer aided control systems to get the intended shape. It’s precise, versatile, as well as permits complex geometry.

3.Injection Molding: Injection molding which involves injecting molten material into a mold cavity is commonly used in mass production. It’s efficient, provides high repeatability and ensures consistency across large volumes.

4.Vacuum Casting: By making use of silicone molds and resin casting, this technique can replicate parts. This technology suits low to medium volume production runs because of its outstanding surface finish and ability to reproduce minute details accurately.

0 notes

Note

Send more audios recommendations 😳 sorry I’m a whore

Oh lord, so. I'm relatively new to the nsfw audio space but I've got some recommendations I can pass along.

The ones with a 🔥 are dark and have dubcon/noncon CNC content. 💙 are my favs.

❥ Don't Try To Run, Will Ya? 🔥💙 (this reminds me of Nick Fowler)

❥ Let Me Train You, Will Ya? 🔥 (also reminds me of Nick Fowler)

❥ Fit to Print 🔥 (makes me think of dark!Bucky or dark!Steve)

❥ Plants aren't the only things we breed in this shop (reminds me of @navybrat817's florist!Bucky)

❥ ~BuckyXListener NSFW:Interim~

❥ I Got a Question 💙 (makes me think of an age gap Bucky)

❥ What is this catnip stuff and why do I want to breed you now? (can't lie, my brain went to @thanatosfic's werepanther!Bucky)

❥ Cosytrapping my dearest blanket burrito (reminds me of @jobean12-blog's fic Beefy Burrito)

❥ Puppy 💙

❥ Naughty Bunny (made me think of Red Sun)

❥ Kidnapped by your favourite GWA Voice Actor 🔥

Basically Aasimar_Audio has the best dark ones omg. He's got non-dark ones too.

To search around I mostly use r/gonewildaudio.

438 notes

·

View notes